Page 1

Cleveland

™

P

roject ________________________________

I

tem __________________________________

Quantity _______________________________

FCSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

GAS KETTLES

LEG TYPE, GAS-FIRED KETTLES

STATIONARY, 2⁄3 STEAM JACKETED

“SPLASH PROOF SERIES”

40, 60, 80 or 100 GALLONS (150, 225, 300 or 337 LITERS)

Cleveland Standard Features

n H

igh efficiency Power Burner Heating System

(62% to 65% efficiency)

n Fast Heat-up and Recovery Time, 140M BTU’s on 40 gallon

models, 190M BTU’s on 60 gallon and larger

n Insulated Heat Exchanger

n Automatic Ignition System

n Steam jacket permanently filled with treated, distilled water.

Venting and/or refilling not required

n Solid State Controls, for Temperature and Low Water Safety,

in a plug-in Control Module

n Control Panel includes:

n

Precise, consistent temperature control: less than

n

± 1°C variance (ideal for simmering).

n

L.E.D. Indicators for Heat Cycle and Low Water

n

Warning.

n

Power

n Front mounted combination Pressure/Vacuum Gauge

n Type 304 Stainless Steel with #4 finish on kettle and

supports

n 2˝ diameter Tangent Draw-Off Valve with Drain Strainer

n Support Legs with level adjustable feet, flanged for floor

bolting

n Spring-assisted, hinged, rotatable, domed Stainless

Steel Cover

n 50 PSI Steam Jacket Rating and Safety valve

n Standard voltage is 1

with cord and plug

n Standard for natural gas operation

n Faucet Mounting Bracket (FBK)

ypical approvals include

n T

Options & Accessories

ype 316 Stainless Steel Kettle Liner for high acid food

p T

products (316)

p Hot and Cold Water Faucet with Swing Spout (DPK)

p Cooking Baskets and Tri-Basket Supports (BS and TBS)

p Drain Strainers (DS-)

p 3" diameter Tangent Draw-off Valve with Drain Strainer (TD3)

“on/of

f” Switch

15 volts, 60 Hz, single-phase, supplied

AGA, CSA, CE, NSF and ASME

MODELS: c KGL-40 c KGL-80

c KGL-60 c KGL-100

t Form Specifications

Shor

Shall be CLEVELAND, Gas-fired Stationary Kettle, Model

KGL-_____ ; _____ gallons. 2⁄3 Steam Jacketed, Power Burner Heating

System, Insulated Heat Exchanger, 50 psi Steam Jacket Rating.

Infinite Variable Temperature Control, L.E.D. indicators for Heat Cycle

and Low W

Valve with Drain Strainer, Automatic Ignition System.

p Kettle Accessory Kit (KAK) includes:

p Clean-up Brush(CB) p 36” Kettle Paddle (KP)

p 36” Kettle Whip(KW) p 36” Kettle Brush (KB)

p Draw-off Brush (DB) p 24 oz. Ladle (KL)

p Automatic Water Meter (GMF or LMF)

p Measuring Strip (MS)

p Option for Propane Gas operation

p Correctional Package

p Heat Deflector Shield (HS001)

arning, spring-assisted Cover, 2˝ Tangent Draw-off

ater W

SECT. IX PAGE 9

0707

Page 2

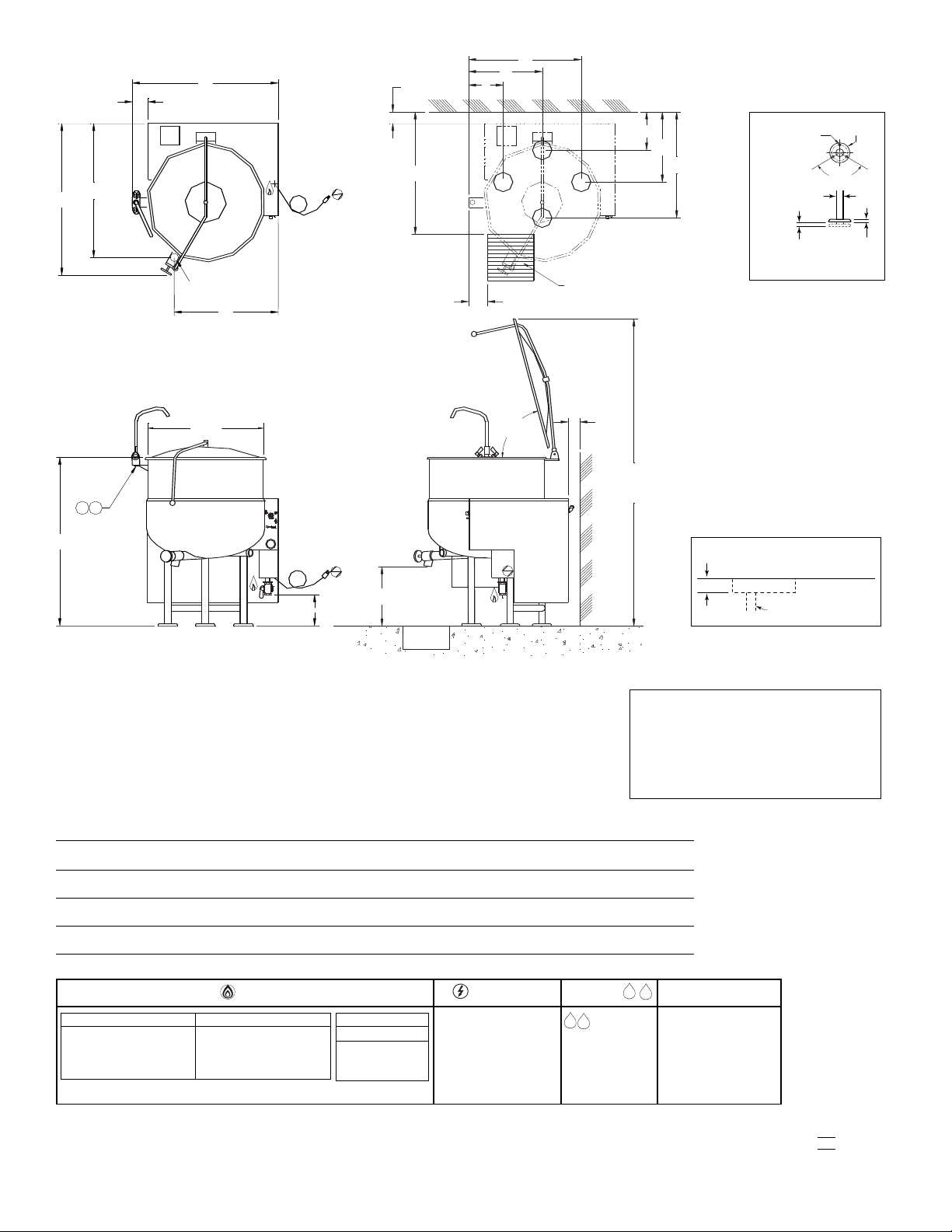

H

C

H

C

G

(

COVER

OPEN)

3

" (77

m

m)

MINIMUM

C

LEARANCE

F

3

(77

m

m)

L

M

N

O

P

H

J

K

F

LOOR DRAIN

1

2" (305

m

m) WIDE x

12" (305

mm) LONG

UNIT SHOWN WITH OPTIONAL 2" TANGENT DRAW-OFF VALVE,

SPRING ASSIST COVER AND HOT & COLD WATER FAUCET.

7

5º

H

C

E

D

A

S

C

4

" (102

m

m)

B

T

(

I.D.)

RECOMMENDED

FLOOR SLOPE

1" (26 mm) per 4' (1220 mm)

PIPE DRAIN RECOMMENDED

min. valve size plus 1" (26 mm)

4" (102 mm)

R

ECOMMENDED

9/16"

1

4 mm

120º

TYP

1" (25

mm)

M

AX. ADJUSTMENT

1

5/8" (42

m

m)

Ø

FLANGED FOOT DETAIL

7/16" (11 mm)

Ø

3 HOLES ON

3

1/8" (80

m

m)

Ø

B.C.D.

4 7/8"

124

Ø

mm

VALVE

OPENING

DIMENSIONS

GALS./

LITERS A B C D E F G H J K L M N O P S T I.D.

40 IN 35 1/8 37 32 1/4 40 1/2 9 1/4 16 71 1/2 9 9/16 17 3/4

150 mm 893 940 820 1029 235 407 1817 243 451 659 264 474 683 724 118 648 661

60 IN 38 1/4 39 34 1/4 43 1/2 8 3/4 14 1/4 75 8 15/16 19 1/8 29 5/16 10 3/8 18 5/8 27 7/8 30 1/4 5 1/4 27 29 1/2

225 mm 972 991 870 1105 223 362 1905 228 486 745 264 474 709 769 134 686 750

80 IN 41 5/8 42 3/8 35 1/2 45 1/2 8 3/4 15 1/2 79 9 1/4 20 3/4 32 1/4 10 3/8 18 5/8 29 5/8 31 1/2 6 5/8 29 33

300 mm 1058 1077 902 1156 223 394 2007 235 528 820 264 474 753 801 169 737 839

100 IN 44 43 1/2 36 1/2 47 1/2 8 3/4 15 1/2 83 1/2 9 1/8 21 7/8 34 5/8 10 3/8 18 5/8 31 1/4 32 1/2 7 1/2 30 1/2 35 1/2

375 mm 1118 1105 928 1207 22.3 394 2121 232 556 880 264 474 794 826 191 775 902

GAS CLEARANCE

NATURAL PROPANE

3

N.P.T. Piping:

⁄4˝

Piping:

Supply pressure:

4.00˝ W.C. minimum 4.00˝ W.C. minimum

.C. maximum

14.00˝ W

Manufacturer must be notified if unit will be operated above 2,000 ft. altitude.

TES

NO

:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Installation of backflow preventers, vacuum breakers and other specific coder requirements is the responsibility of the owner and installer.

Cleveland Range equipment is built to comply with applicable standards for manufacturers. Included among those approval agencies are U.L., A.G.A., NSF, ASME/N.Bd., CSA, CGA, ETL and others.

3

N.P.T.

⁄4˝

Supply pressure:

14.00˝ W

.C. maximum

B.T.U. RATING

140,000

40 gal.

60 gal.

190,000

80 gal.

100 gal.

25 15/16

10 3/8 18 5/8 26 7/8 28 1/2 4 5/8 24 1/2 26

ELECTRIC

-1 Phase, 60 Hz, 10

120V

amps

W

TER

A

1

⁄2˝ dia. Soft

Copper

ubing (each)

T

When

ordered with

optional

faucet.

CAPACITIES: (in 8 oz. servings,

other sizes may be calculated)

40 Gallon / 150 liters . . . 640 servings

60 Gallon / 225 liters . . . 960 servings

80 Gallon / 300 liters . . . 1280 servings

100 Gallon / 375 liters . . . 1600 servings

˝

3

=

RIGHT

LEFT = 3˝

REAR = 3˝

Allow 6˝ space minimum

from rear and sides when

located near combustible

walls. 12" recommended on

right side for service

SECT

.

AGE

IX P

0707

Litho in U.S.A.

10

Loading...

Loading...