Page 1

Cleveland

™

P

roject ________________________________

I

tem __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

Date __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

ELECTRIC KETTLES

TRI-LEG, ELECTRIC KETTLES

STATIONARY, “

2⁄3 STEAM JACKETED

(100, 150, 225, 300, or 375 LITERS)

Cleveland Standard Features

n

Self-contained, easily installed - needs only an electrical hook-up

n Steam jacket filled with treated water

not required

n Accurate, consistant solid state temperature controls (mechani-

cal thermostate not as accurate) - less than ±1°C variance

(ideal for simmering). Operating temperature range from 145° 260°F (63°C - 127°C)

Control panel includes:

• LED indicator for heat cycle • LED indicator for low water

• Power ON/OFF switch • Adjustable temperature control dial

n Water resistant controls, splash-proof construction

n Re-inforced rolled rim design prevents damage to kettle rim,

eliminates "bar rim designs"

n Welded-in heating elements, (holds vacuum better

or loose water)

n Easily cleaned: kettle and all exterior surfaces are of type 304

stainless steel with an #4 finish

n Rear mounted easy access pressure gauge and pressure relief

valve to prevent tampering. Color coded easy to read pressure

gauge with "green" and "vent air zone"

n 50 psi steam jacket rating for higher cooking temperatures

n 50 psi safety valve

n

Solid state water level control (no sight glass gauge to break or leak)

n Splash proof element cover with a double gasket seal

n Faucet mounting bracket

n 2˝ diameter tangent draw-off valve with drain strainer

n

1 5/8˝ O.D. tri-leg supports with level adjustable feet for floor bolting

n Spring-assisted, hinged, rotatable, domed stainless steel cover

n Standard voltage is 208-240 volts, 60 Hz, 3-phase, 3-wire

ypical approvals include UL., CSA, CE, NSF and ASME

n T

Options & Accessories

SPLASH PROOF SERIES”

,

25, 40, 60, 80 or 100 GALLONS

, venting and/or refilling is

, SELF-CONTAINED

, won't leak

MODELS: c KEL-25 c KEL-60

c KEL-30 c KEL-80

c KEL-40 c KEL-100

t Form Specifications

Shor

Shall be CLEVELAND, Electric Kettle, T

tained, stationary, Model KEL - _____ gallons, 2⁄3 Steam Jacketed.

Type 304 Stainless Steel Kettle and Supports. Rated 50 psi with

Safety Valve; Permanently filled Steam Jacket. Spring-assisted

Domed Cover. (Provide 1.50˝ Freeboard above batches of rated

size.) Splash Proof Solid State Temperature

Control System in plug-in Module including L.E.D. indicators. Base

Mounted for Floor Bolting with thr

angent Draw-of

T

f V

alve.

ri-leg mounted, self-con-

(±1° C) and Safety

ee (3), tri-bolt flanges. 2˝ diameter

p Hot and Cold W

ype 316 Stainless Steel Kettle Liner for high acid food

p T

products (316)

p Cooking Baskets and

p Kettle

p Automatic W

p W

p Lift-of

p Drain Strainers (DS-)

p Measuring Strip

Accessory Kit (KAK) includes:

p Clean-up Brush (CB) p 36˝ Kettle Paddle (KP)

p 36˝ Kettle Whip (KW) p 36˝ Kettle Brush (KB)

p Draw-of

ater Meter Stand (SWM)

f Covers (CL)

ater Faucet with Swing Spout (DPK)

ri-Basket Supports (BS and

T

f Brush (DB)

ater Meter (GMF or LMF)

(MS)

p 24 oz. Ladle (KL)

p Kettle Markings (KM)

TBS)

p Hot and cold or cold only Kettle Filler with 60˝ Hose

(DKF-K or SKF-K)

p Swing Funnels for drain (SF)

p Alternate Mounting Systems

p High Wattages and Special Voltages

p 3" diameter Tangent Draw-Off Valve w/Strainer (TD3)

p Heat Deflector Shield (HS001)

p Correctional Packages

p Insulated Outer Jacket (IOJ)

SECT. VIII PAGE 13

0707

Page 2

RECOMMENDED

F

LOOR SLOPE

1

" (26 mm) per 4' (1220 mm)

PIPE DRAIN RECOMMENDED

m

in. valve size plus 1" (26 mm)

4" (102 mm)

R

ECOMMENDED

9

/16"

14

mm

1

20º

TYP

1

" (25

m

m)

MAX. ADJUSTMENT

1 5/8" (42 mm)

Ø

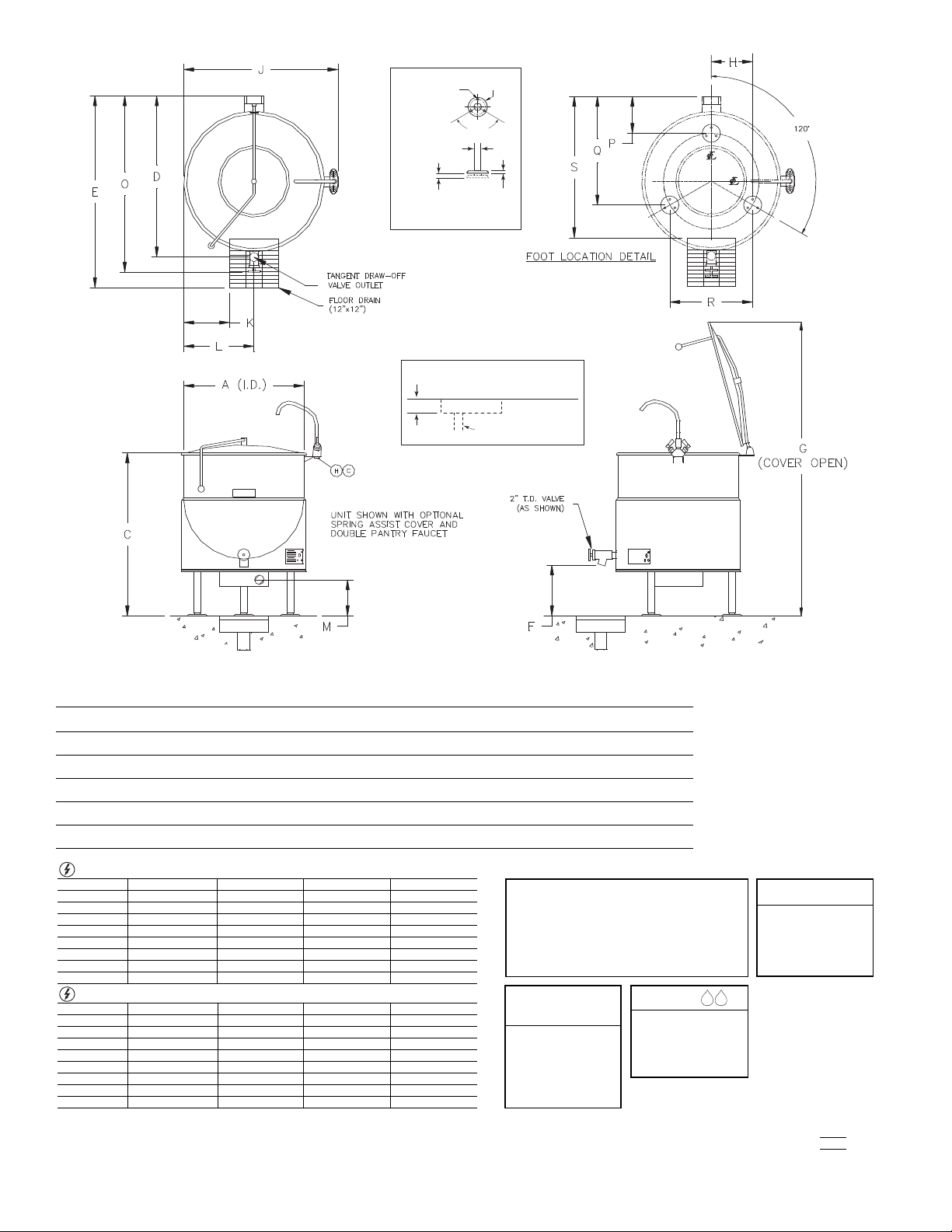

F

LANGED FOOT DETAIL

7/16" (11 mm)

Ø

3 HOLES ON

3 1/8" (80

mm)

Ø

B.C.D.

4 7/8"

124

Ø

mm

H

C

DIMENSIONS

GALS./

LITERS A C D E F G HJKLMNOPQRS

25/ IN 21 36 3/4 21 7/8 34 13 7/8 60 3/4 17 7/8 29 7/8 5 1/4 11 1/4 9 3/4 7 1/2 26 3/4 4 5/8 20 15 1/2 22 3/8

100 mm 534 934 556 864 353 1544 455 759 134 286 248 191 680 118 508 394 569

30/ IN 24 38 24 7/8 37 15 5/8 65 1/4 20 7/8 28 3/4 6 3/4 12 3/4 11 1/2 9 1/4 29 3/4 4 5/8 20 1/4 18 1/8 25 3/8

115 mm 610 966 632 940 397 1658 531 731 172 324 299 293 756 118 515 461 645

40/ IN 26 40 29 1/8 40 15 1/8 69 1/2 22 7/8 30 3/4 7 3/4 13 3/4 11 8 3/4 34 4 5/8 21 3/4 19 7/8 28 5/8

150 mm 661 1016 740 1016 385 1766 582 782 197 350 280 223 864 118 553 505 728

IN

60/

225 mm 750 1093 839 1118 372 1925 670 870 242 394 267 210 963 131 699 582 826

80/ IN 33 43 1/2 36 5/8 47 13 79 1/2 29 7/8 37 3/4 11 1/4 17 1/4 9 6 3/4 41 1/2 5 1/8 29 3/8 25 7/8 35 7/8

mm

300

100/ IN 35 1/2 45 39 1/4 50 12 1/2 83 3/8 32 3/8 40 1/4 12 1/2 18 1/2 8 1/2 6 1/4 44 1/8 5 1/8 5 1/8 28 38 3/8

375 mm 902 1144 997 1270 318 2118 823 1023 318 470 216 159 1121 131 131 712 975

43 33 44 14 5/8 75 3/4 26 3/8 34 1/4 9 1/2 15 1/2 10 1/2 8 1/4 37 7/8 5 1/8 27 1/2 22 7/8 32 1/2

29 1/2

105 931 1194 331 2020 759 959 286 439 229 172 1055 131 747 658 912

1

839

STANDARD WATTAGE

208V 240V 416V 480V

GALS. LITERS KW 1PH 3PH KW 1PH 3PH KW 1PH 3PH KW 1 PH 3PH

100

25

15

1

30

40 150 14.7 70.8 40.9 19.6 81.7 47.1 18.1 43.5 25.1 19.6 40.8 23.6

225

60

300

80

100 375 14.7 70.8 40.9 19.6 81.7 47.1 18.1 43.5 25.1 19.6 40.8 23.6

HIGH WATTAGE

LITERS

GALS.

25 100 14.7 70.8 40.9 19.6 81.7 47.1 18.1 43.5 25.1 19.6 40.8 23.6

30 115 19.6 NA 54.5 26.1 NA 62.9 24.1 58.0 33.5 26.1 54.4 31.4

40 150 24.5 NA 68.1 32.7 NA 78.6 30.1 72.5 41.8 32.7 68.1 39.3

60 225 29.4 NA 81.7 39.2 NA 94.3 36.2 87.0 50.2 39.2 81.7 47.1

80 300 29.4 NA 81.7 39.2 NA 94.3 36.2 87.0 50.2 39.2 81.7 47.1

100 375 29.4 NA 81.7 39.2 NA 94.3 36.2 87.0 50.2 39.2 81.7 47.1

AMPS AMPS AMPS AMPS AMPS AMPS AMPS AMPS

47.2 27.2 13.1 54.4 31.4 12.1 29.0 16.7 13.1 27.2 15.7

9.8

12.3

14.7

14.7

KW 1PH 3PH KW 1PH 3PH KW 1PH 3PH KW 1 PH 3PH

34.1

59.0

70.8 40.9 19.6 81.7 47.1 18.1 43.5 25.1 19.6 40.8 23.6

40.9

70.8

208V 240V 416V 480V

AMPS AMPS AMPS AMPS AMPS AMPS AMPS AMPS

68.1 39.3 15.1 36.2 20.9 16.3 34.0 19.6

16.3

19.6

47.1 18.1 43.5 25.1 19.6 40.8 23.6

81.7

Consult factory for other voltages.

TES

NO

:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Cleveland Range equipment is built to comply with applicable standards for manufacturers. Included among those approval agencies are U.L., NSF, CGA, CSA, ETL and others.

CAPACITIES:

•

(in 8 oz. servings, other sizes may be calculated)

25 Gallon / 100 liters.............400 servings

30 Gallon / 110 liters.............480 servings

40 Gallon / 150 liters.............640 servings

60 Gallon / 225 liters.............960 servings

80 Gallon / 300 liters...........1280 servings

100 Gallon / 375 liters

SHIPPING

WEIGHT (LBS.)

KEL-25 = 230

KEL-30 = 264

KEL-40 = 289

KEL-60

KEL-80 = 400

KEL-100 = 430

361

=

..............1600 servings

WATER

3

⁄8˝ O.D. copper tube or

1

⁄2˝ N.P.T. pipe.

When ordered with

optional faucet.

CLEARANCE

RIGHT = 0

LEFT = 0

REAR = 0

Allow 12" minimum on

right side for servicing.

T

(NOT

.

SECT

VIII P

Litho in U.S.A.

O SCALE)

AGE

14

0707

Loading...

Loading...