Page 1

Cleveland

™

P

roject ________________________________

I

tem __________________________________

Quantity _______________________________

FCSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

DIRECT STEAM KETTLES

TRI-LEG / PEDESTAL, DIRECT STEAM

STATIONARY, 2⁄3 STEAM JACKETED

25, 40, 60, 80, 100, 125, 150, 200 OR 250 GALLONS

(100, 150, 225, 300, 375, 475, 575, 760 OR 950 LITERS

Cleveland Standard Features

n Spring-assisted Cover: domed, hinged, one-piece

rotatable (not available on KDL-250)

n Type 304 Stainless Steel construction, #4 finish on kettle and

supports

n 2˝ diameter Tangent Draw-off Valve with Drain Strainer

n 50 psi Steam Jacket Rating on 25 - 100 gal. models,

35 psi Steam J

n 50 psi chrome plated Safety Valve on 25 - 100 gal. models,

35 psi chrome plated Saf

n Condensate Drain Valve with insulated handle

n For Tri-leg Models: Tri-leg supports of 1.63˝ O.D., Type 304

Stainless Steel tubular construction, with level adjustable

Flanged Feet for Floor Bolting

n For Pedestal Models: Pedestal support of Type 304 Stainless

Steel with .75˝ thick floor plate, (level adjustable for sloping

floors), comes with Stainless Steel Collar for sealing

n Faucet Mounting Bracket

n Steam Control Inlet Valve

n Typical approvals include NSF and ASME

Options & Accessories

p Type 316 Stainless Steel Kettle Liner for high acid food

products (316-G)

p Lift-off Co

p Chrome plated Steam Control Kit includes:

Condensate Strainers, Check Valves, nipples and fittings,

f

actor

y assembled and mounted on kettle (SCK1)

p 100 psi Pressure Option (PO) (for 125 gallons and larger)

p Cooking Baskets and Tri-Basket Supports (BS and TBS)

p Measuring Strips (MS)

p Gallon Markings (KM)

p Kettle Accessory Kit (KAK) includes:

p Clean-up Brush (CB) p 36˝ Kettle Paddle (KP)

p 36˝ Kettle Whip (KW) p 36˝ Kettle Brush (KB)

p Draw-off Brush (DB) p 24 oz. Ladle (KL)

p Swing Funnels for drain (SF)

ket Rating on 125 - 250 gal. models

ac

ety Valve on 125 - 250 gal. models

ers (CL)

v

Steam

raps,

T

MODELS: c KDL-25 c KDL-80 c KDL-150 c KDP-40

c KDL-40 c KDL-100 c KDL-200 c KDP-60

c KDL-60 c KDL-125 c KDL-250 c KDP-80

c KDP-100

Shown with optional Steam Control Kit

m Specifications

t For

Shor

Shall be CLEVELAND, Direct Steam Kettle, Tri-leg or Pedestal stationary, Model KD __- _____ . 23 Steam Jacketed, Type 304 Stainless

Steel with

gallon and larger.

assisted, Domed Cover and 2 Tangent Draw-off Valve; heavy reenforced Rolled Rim. To operate, connect directly to a steam source

supplying from 5 to 45 psi steam.

p Pressure Reducing

steam pressure of over 45 psi (PRV-K)

p Hot and cold or cold only Kettle Filler with

60˝ Hose (DKF-K or SKF-K)

p Automatic Water Meter (GMF or LMF)

p Drain Strainers (DS-)

p Water Meter Stand (SWM)

p 3" diameter

p 3" diameter Butterfly

p Pre-Rinse Spr

p Correctional Packages

p Insulated Outer J

50 psi Steam Jacket Rating on 80 - 100 gallon, 35 psi on125

Supports to be Stainless Steel. Includes spring-

or regulating incoming

e f

alv

V

Tangent Draw-Off Valve w/Strainer (TD3)

e (BV3)

alv

V

y Head and Hose (PRSK)

a

et (IOJ)

k

ac

SECT. X PAGE 17

0707

Page 2

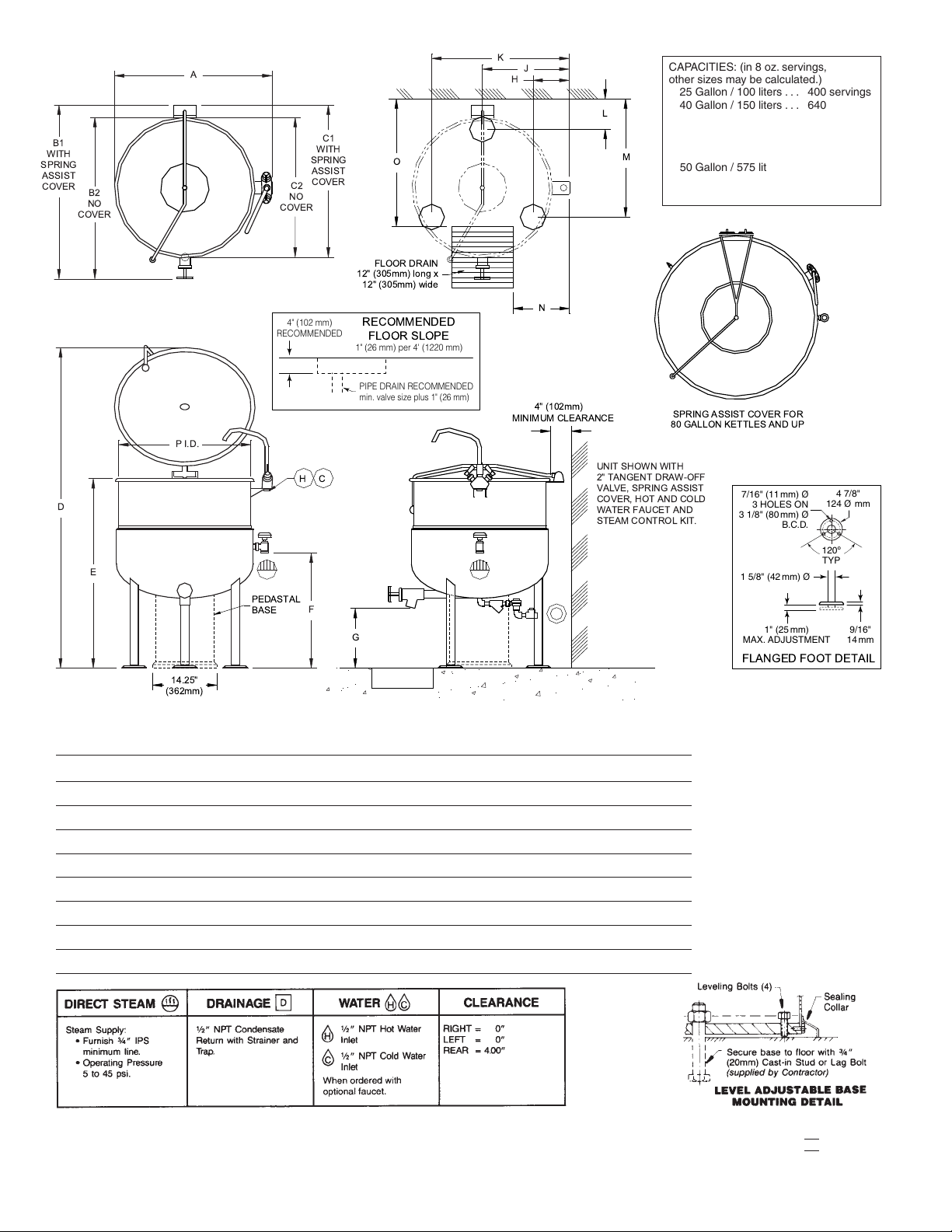

UNIT SHOWN WITH

2" TANGENT DRAW-OFF

VALVE, SPRING ASSIST

C

OVER, HOT AND COLD

WATER FAUCET AND

STEAM CONTROL KIT.

K

J

H

A

C1

W

ITH

SPRING

ASSIST

COVER

D

E

F

P I.D.

C2

NO

COVER

B1

WITH

SPRING

ASSIST

COVER

B2

NO

COVER

MINIMUM CLEARANCE

G

H

C

M

L

O

N

FLOOR DRAIN

12" (305mm) long x

12" (305mm) wide

4" (102mm)

8

0 GALLON KETTLES AND UP

SPRING ASSIST COVER FOR

14.25"

(362mm)

PEDASTAL

BASE

RECOMMENDED

F

LOOR SLOPE

1" (26 mm) per 4' (1220 mm)

PIPE DRAIN RECOMMENDED

min. valve size plus 1" (26 mm)

4" (102 mm)

RECOMMENDED

9/16"

14

mm

120º

TYP

1" (25

mm)

MAX. ADJUSTMENT

1 5/8" (42 mm)

Ø

FLANGED FOOT DETAIL

7/16" (11 mm)

Ø

3 HOLES ON

3

1/8" (80

m

m)

Ø

B.C.D.

4 7/8"

124

Ø mm

CAPACITIES: (in 8 oz. servings,

other sizes may be calculated.)

2

5 Gallon / 100 liters . . . 400 servings

4

0 Gallon / 150 liters . . . 640 servings

60 Gallon / 225 liters . . . 960 servings

80 Gallon / 300 liters . . . 1280 servings

100 Gallon / 375 liters . . . 1600 servings

125 Gallon / 475 liters . . . 2000 servings

1

50 Gallon / 575 liters . . . 2400 servings

200 Gallon / 760 liters . . . 3200 servings

250 Gallon / 950 liters . . . 4000 servings

DIMENSIONS

GALS./

LITERS A B1 B2 C1 C2 D E F G H J K L M N 0 P I.D.

25 IN 26 1/2 32 29 3/16 26 7/8 24 1/8 59 37 22 1/8 14 1/2 7 14 3/4 22 1/2 6 3/8 19 13/16 8 3/4 22 3/16 21

100 mm 674 813 742 683 613 1499 940 639 369 178 375 572 162 504 223 564 534

40 IN 31 1/8 35 7/8 33 1/16 31 3/16 28 7/16 62 1/8 36 7/8 22 1/2 12 1/2 7 11/32 17 1/4 27 5/32 6 13/32 23 9/16 11 1/4 26/7/16 26

150 mm 791 912 408 793 723 1578 937 572 318 187 362 690 163 599 286 672 661

60 IN 34 5/8 38 7/8 36 1/8 34 1/8 31 3/8 69 3/4 39 21 7/8 11 1/8 7 5/8 19 30 1/8 6 3/8 26 1/4 13 29 3/8 29 1/2

225 mm 879 988 918 867 797 1772 991 556 283 194 483 766 162 667 331 747 750

80 IN 38 1/8 41 1/4 38 1/2 36 1/2 33 3/4 74 7/8 40 7/8 23 11 7 3/4 20 3/4 33 3/4 6 3/8 28 3/4 14 3/4 31 3/4 33

300 IN 969 1048 978 928 858 1902 1039 585 280 197 528 858 162 731 375 807 839

100 IN 40 5/8 43 1/8 40 3/8 38 3/8 35 5/8 79 3/8 43 23 7/8 11 1/8 8 22 36 6 3/8 30 3/4 16 33 5/8 35 1/2

375 mm 1032 1096 1023 975 905 2017 1093 607 283 204 559 915 162 782 407 855 902

125 IN 45 1/8 46 5/8 43 1/2 41 7/8 38 3/4 83 1/4 43 24 7/8 10 7/8 8 1/4 24 1/4 40 1/4 6 3/8 34 18 1/4 36 3/4 40

475 mm 1147 1185 1105 1064 985 2115 1092 632 277 210 616 1023 162 864 464 934 1016

IN

150

mm

575

200 IN 50 1/8 46 5/8 43 3/8 41 7/8 38 3/4 94 49 1/4 29 3/8 10 5/8 7 7/8 26 3/4 45 5/8 7 1/4 34 3/8 20 3/4 36 3/4 45

760 mm 1274 1185 1102 1064 985 2388 1251 747 270 201 680 1159 185 874 528 934 1143

250 IN 53 1/8 48 7/8 45 5/8 44 1/8 39 1/4 104 1/4 54 32 3/4 10 1/4 8 1/8 28 1/4 48 3/8 7 1/4 36 7/8 22 1/4 37 1/4 48

mm

950

NOTES:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Installation of backflow preventers, vacuum breakers and other specific coder requirements is the responsibility of the owner and installer.

Cleveland Range equipment is built to comply with applicable standards for manufacturers. Included among those approval agencies are U.L., A.G.A., NSF, ASME/N.Bd., CSA, CGA, ETL and others.

45 1/8

1147

1350

46 5/8

1185

1242

43 1/2

1105

1159

41 7/8

1064

1121

88 3/8

38 3/4

2245

985

47 7/8 24 7/8 10 7/8 8 1/4 24 1/4 40 1/4 6 3/8 34 18 1/4 36 3/4 40

1217 632 277 210 616 1023 162 864 464 934 1016

997 2648 1372 82 261 207 718 1229 185 937 566 947 1220

SECT

T

T

(NO

.

X P

Litho in U.S.A.

O SCALE)

A

GE

18

0707

Loading...

Loading...