Page 1

Cleveland

™

P

roject ________________________________

I

tem __________________________________

Quantity _______________________________

FCSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

DIRECT STEAM KETTLES

QUAD-LEG, DIRECT STEAM

TILTING, 2⁄3 STEAM JACKETED

80 or 100 GALLONS (300 or 375 LITERS)

Cleveland Standard Features

n Kettle legs of 1

adjustable feet, with three-bolt flanges for floor bolting

ype 304 Stainless Steel construction, with #4 finish

n T

on kettle and supports

n Tilting Mechanism with permanently lubricated, self-locking,

Worm Drive of space saving design

n 50 psi Steam Jacket Rating on 80 - 100 gal. models,

35 psi Steam Jacket Rating on 125 - 150 gal. models

n 50 psi chrome plated Safety Valve on 80 - 100 gal. models,

35 psi chrome plated Safety Valve on 125 - 150 gal. models

n High Capacity Pouring Lip

n Condensate Drain Valve with insulated handle

n Steam Control Valve mounted on console

n Typical approvals include NSF and ASME

Options & Accessories

p Type 316 Stainless Steel Kettle Liner for high acid food

products (316)

p Lift-off Covers (CL)

p Steam Control Kit includes: Steam Trap, Condensate Strainer,

Check Valve, nipples and fittings, factory assembled and mounted on kettle (SCK2)

p Spring-assisted, hinged, rotatable, domed Stainless Steel Cover

(CHS-)

p Hot and Cold Water Faucet, comes with Swing Spout (DPK)

p

2˝ or 3" diameter

aise height of kettle by 5-5/8" (143mm)

r

p 3" diameter Butterfly Valve (BV3)

p 100 psi Pressure Option (PO) (for 125 gallons and larger)

p Cooking Baskets and Tri-Basket Supports (BS and TBS)

p Pan Carrier (PCK)

p Measur

p Gallon Markings (KM)

ettle Accessor

p K

p Clean-up Brush (CB) p 36˝ Kettle Paddle (KP)

p 36˝ Kettle Whip (KW) p 36˝ Kettle Brush (KB)

p Draw-off Brush (DB) p 24 oz. Ladle (KL)

p Swing Funnels f

p Faucet Mounting Bracket (FBKT)

p Pressure Reducing

steam pressure of over 45 psi (PRV-K)

5

⁄8˝ OD, type 304 Stainless Steel, with 3 level

e (TD2 or TD3*), *TD3 will

alv

V

w-Off

angent Dr

T

ips (MS)

ing Str

y Kit (KAK) includes:

or dr

a

ain (SF)

or regulating incoming

e f

alv

V

MODELS: c KDL-80-T c KDL-125-T

c KDL-100-T c KDL-150-T

Shown with optional Spring-Assisted Cover, 2" Tangent Draw-Off Valve

Short Form Specifications

Shall be CLEVELAND, Direct Steam Kettle, Quad-leg mounted,

Model KDL - _____ - T, _____ gallons, Tilting (hand or power) 23

Steam Jacketed. Type 304 Stainless Steel kettle and support

50 psi Steam Jacket Rating on 80 - 100 gallon, 35 psi on125 gallon and

Steam Control Valve; heavy re-enforced Rolled Rim. To oper-

larger;

ate, connect directly to a steam source supplying 10 to 45 psi

steam.

p Hot and cold, or cold only, Kettle Filler with 60˝

Hose (DKF-K or SKF-K)

p

Automatic Water Cooling (AWC-1), requires Console Mounting

Option

p Alternate Mounting Systems - Console Mounting

p Automatic Water Meter (GMF or LMF)

p Water Meter Stand (SWM)

p Food Strainer (FS)

erter (FD)

w Div

p Flo

p Drain Strainers (DS-)

y Head and Hose (PRSK)

p Pre-Rinse Spr

p Heat Deflector Shield (HS001)

p Correctional Packages

a

SECT. X PAGE 11

legs.

0707

Page 2

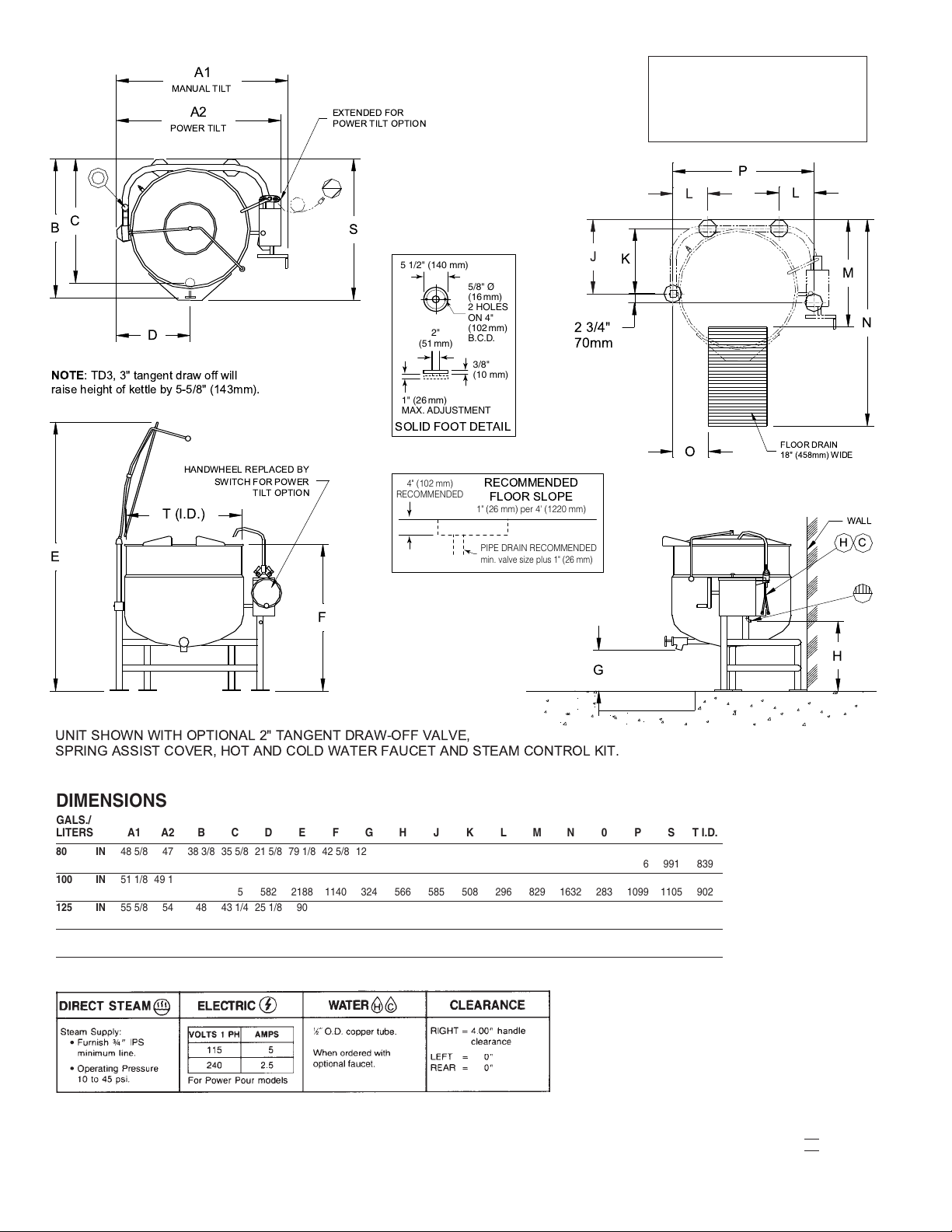

UNIT SHOWN WITH OPTIONAL 2" TANGENT DRAW-OFF VALVE,

SPRING ASSIST COVER, HOT AND COLD WATER FAUCET AND STEAM CONTROL KIT.

J

L

P

O

G

B

C

S

D

A

1

MANUAL TILT

E

T (I.D.)

F

HANDWHEEL REPLACED BY

SWITCH FOR POWER

TILT OPTION

2

3/4"

70mm

A2

POWER TILT

E

XTENDED FOR

POWER TILT OPTION

K

N

M

H

WALL

C

H

FLOOR DRAIN

18" (458mm) WIDE

L

SOLID FOOT DETAIL

5 1/2" (140 mm)

3/8"

(

10 mm)

2

"

(51

mm)

1" (26 mm)

MAX. ADJUSTMENT

5/8"

Ø

(

16

mm)

2 HOLES

ON 4"

(

102

m

m)

B.C.D.

RECOMMENDED

FLOOR SLOPE

1" (26 mm) per 4' (1220 mm)

PIPE DRAIN RECOMMENDED

min. valve size plus 1" (26 mm)

4" (102 mm)

RECOMMENDED

NOTE

: TD3, 3" tangent draw off will

raise height of kettle by 5-5/8" (143mm).

C

APACITIES: (in 8 oz. servings,

o

ther sizes may be calculated.)

80 Gallon / 300 liters . . . 1280 servings

100 Gallon / 375 liters . . . 1600 servings

125 Gallon / 475 liters . . . 2000 servings

150 Gallon / 575 liters . . . 2400 servings

DIMENSIONS

GALS./

LITERS

80 IN 48 5/8 47 38 3/8 35 5/8 21 5/8 79 1/8 42 5/8 12 1/2 21 1/4 20 1/2 17 1/2 11 3/8 29 5/8 60 10 1/8 40 3/4 39 33

300

100 IN 51 1/8 49 1/2 43 38 3/8 22 7/8 86 1/8 44 7/8 12 3/4 22 1/4 23 20 11 5/8 32 5/8 64 1/4 11 1/8 43 1/4 43 1/2 35 1/2

375

125 IN 55 5/8 54 48 43 1/4 25 1/8 90 46 3/8 13 3/4 24 1/2 27 24 11 7/8 38 1/4 72 13 3/8 47 3/4 50 40

475

150 IN 55 5/8 54 48 43 1/4 25 1/8 94 50 3/4 13 1/2 25 1/4 27 24 11 7/8 38 1/4 72 13 3/8 47 3/4 50 40

575

IN

mm

mm

mm

A1

1236

1299

1413

1413

B

A2

1194 975 905 550 2010 1083 318 540 521 445 289 753 1524 258 1036 991 839

1258 1093 975 582 2188 1140 324 566 585 508 296 829 1632 283 1099 1105 902

1372 1220 1099 639 2286 1178 350 623 686 610 302 972 1829 340 1213 1270 1016

1372 1220 1099 639 2388 1290 342 642 686 610 302 972 1829 340 1213 1270 1016

DEFGHJKLMN0PST I.D.

C

NOTES:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Installation of backflow preventers, vacuum breakers and other specific coder requirements is the responsibility of the owner and installer.

Cleveland Range equipment is built to comply with applicable standards for manufacturers. Included among those approval agencies are U.L., A.G.A., NSF, ASME/N.Bd., CSA, CGA, ETL and others.

SECT

(NO

.

O SCALE)

T

T

GE

A

X P

12

0707

Litho in U.S.A.

Loading...

Loading...