Cleveland OES-6.08 Installation Manual

Operator’s Manual

Use and Care Instructions

The MINI

Model Number: OES-6.08

1333 East 179th Street

Cleveland, Ohio 44110

Phone: (216) 481- 4900

Fax: (216) 481 - 3782

www.clevelandrange.com

Part No. OES6.08-OPM Rev. A, 9/07

equipment damage, and property damage.

FOR YOUR SAFETY

Do not store or use gasoline or

other flammable vapors or liquids

in the vicinity of this or any other

appliance.

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death.

Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

Disconnect power at the main external power switch before servicing or repairing a Combi.

Failure to disconnect power can result in death, injury, and property damage.

ALL SERVICE MUST BE PERFORMED BY A QUALIFIED

CLEVELAND RANGE AUTHORIZED TECHNICIAN.

Do not connect the Combi Oven-Steamer drain connection to any drain

material that cannot sustain 140o Fahrenheit.

Using drain material that cannot withstand 140o Fahrenheit can result in injury,

This Operation Manual is a part of your new MINI. You must keep and maintain it for

the entire life span of your MINI and pass it on to the next owner of the MINI.

This manual may be subject to new technical developments, modifications, and unforeseen errors.

KEEP THIS MANUAL FOR REFERENCE

The MINI Convotherm by Cleveland Combi/Oven-Steamers are intended for other than household use.

For caster equipped MINIs: If the Restraining Device must be disconnected,

it must be reconnected after the MINI has been returned to its originally

installed position BEFORE restarting the MINI.

Cleveland STATEMENT OF POLICIES

L I M I T E D W A R R A N T Y

CLEVELAND RANGE products are warranted to the original purchaser to be free from defects in materials and workmanship under

normal use and service for the standard warranty period of one year from date of installation or 18 months from date of shipment,

which ever comes first.

CLEVELAND RANGE agrees to repair or replace, at its option, f.o.b. factory, any part which proves to be defective due to defects

in material or workmanship during the warranty period, providing the equipment has been unaltered, and has been PROPERLY

INSTALLED, MAINTAINED, AND OPERATED IN ACCORDANCE WITH THE CLEVELAND RANGE OWNER’S MANUAL.

CLEVELAND RANGE agrees to pay any FACTORY AUTHORIZED EQUIPMENT SERVICE AGENCY (within the continental

United States, and Hawaii) for reasonable labor required to repair or replace, at our option, f.o.b. factory, any part which proves to be

defective due to defects in material or workmanship, during the labor warranty period. This warranty includes travel time not to

exceed two hours and mileage not to exceed 50 miles (100 miles round-trip), BUT DOES NOT INCLUDE POST START-UP,

TIGHTENING LOOSE FITTINGS, MINOR ADJUSTMENTS, MAINTENANCE, CLEANING OR DESCALING.

The standard labor warranty allows factory payment of reasonable labor required to repair or replace such defective parts.

Cleveland Range will not reimburse the expense of labor required for the repair or replacement of parts after the standard warranty

period, unless an Extended Labor Warranty Contract has been purchased to cover the equipment for the balance of the warranty

period from the date of equipment installation, start-up, or demonstration.

PROPER INSTALLATION IS THE RESPONSIBILITY OF THE DEALER, THE OWNER-USER, OR INSTALLING CONTRACTOR,

AND IS NOT COVERED BY THIS WARRANTY. Many local codes exist, and it is the responsibility of the owner and installer to

comply with these codes. Cleveland Range equipment is built to comply with applicable standards for manufacturers, including UL,

ANSI, NSF, ASME/Ntl. Bd., CSA, and others.

BOILER (Steam Generator) MAINTENANCE IS THE RESPONSIBILITY OF THE OWNER-USER AND IS NOT COVERED BY

THIS WARRANTY. The use of good quality feed water is the responsibility of the Owner-User (see Water Quality Recommendations

below). THE USE OF POOR QUALITY FEED WATER WILL VOID EQUIPMENT WARRANTIES. Boiler maintenance supplies,

including boiler hand hole gaskets, are not warranted beyond the first 90 days after the date the equipment is placed into service.

Preventive maintenance records must be available showing descaling per applicable Cleveland Operator Manual for Boiler Proration

Program considerations.

WATER QUALITY RECOMMENDATIONS

TOTAL DISSOLVED SOLIDS less than 60 parts per million

TOTAL ALKALINITY less than 20 parts per million

SILICA less than 13 parts per million

CHLORIDE less than 30 parts per million

pH FACTOR greater than 7.5

The foregoing shall constitute the sole and exclusive remedy of original purchaser and the full liability of Cleveland Range for any

breach of warranty. THE FOREGOING IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER WRITTEN,

ORAL, OR IMPLIED, INCLUDING ANY WARRANTY OF PERFORMANCE, MERCHANTABILITY, OR FITNESS FOR PURPOSE,

AND SUPERSEDES AND EXCLUDES ANY ORAL WARRANTIES OR REPRESENTATIONS, OR WRITTEN WARRANTIES OR

REPRESENTATIONS, NOT EXPRESSLY DESIGNATED IN WRITING AS A “WARRANTY” OR “GUARANTEE” OF CLEVELAND

RANGE MADE OR IMPLIED IN ANY MANUAL, LITERATURE, ADVERTISING BROCHURE OR OTHER MATERIALS.

CLEVELAND RANGE’S liability on any claim of any kind, including negligence, with respect to the goods or services covered

hereunder, shall in no case exceed the price of the goods or services, or part thereof, which gives rise to the claim. IN NO EVENT

SHALL CLEVELAND RANGE BE LIABLE FOR SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, OR ANY DAMAGES

IN THE NATURE OF PENALTIES.

Free Start-Up Program

Get the most from your MINI with Cleveland Range’s “Free

Start-Up.”

Performance Check-Out: Contact your Cleveland Range maintenance and repair

center for your Performance Check-Out before starting your new MINI

Convotherm by Cleveland Combi/Oven-Steamer. The Performance Check-Out

includes: inspection of installation, review of cleaning and maintenance

instructions, and start of warranty protection.

Equipment Demonstration: After your Performance Check-Out, contact your

Cleveland Range sales representative for your free demonstration of proper

operation, optimal use, and correct care of your new equipment.

Consult your Customer Service Directory or call Cleveland Range at 216-4814900 to begin your free Start-Up Program.

Your MINI in Action

You can cook a variety of foods in your MINI Convotherm by Cleveland

Combi/Oven-Steamer using hot air, steam, and MINI hot air and steam.

Your MINI is extremely versatile and can cook sous-vide as well as steam, blanch,

poach, stew, boil, roast, braise, bake, grill, “fry,” rethermalize and defrost.

Just place food in containers or on wire racks, select the cooking mode, and time, or

core temperature and start cooking with your MINI.

NOTICE: MINIs are intended for commercial use only.

NOTICE: The ambient temperature for operating your new MINI must be between

40°F and 95°F.

OPERATOR’S MANUAL

The MINI

Table of Contents

Page

CHAPTER 1 INTRODUCTION _______________________________________________ 1

A. OPERATIONAL SAFETY __________________________________________________ 1

B. CLEANING AND MAINTENANCE ____________________________________________ 2

C. NEVER! ________________________________________________________________ 2

D. SERVICE AND SERVICE RECORDS _________________________________________ 2

E. OPERATOR TRAINING ____________________________________________________ 2

CHAPTER 2 GENERAL OPERATION __________________________________________ 3

A. MAIN EXTERNAL POWER SWITCH __________________________________________ 3

B. DOOR HANDLE and DOOR SWITCH _________________________________________ 3

C. START-UP AND SHUTDOWN INSTRUCTIONS _________________________________ 4

D. INSPECTING THE MINI BEFORE SWITCHING ON _______________________________ 4

E. INSPECTING THE COOKING COMPARTMENT _________________________________ 5

F. PRE-HEATING THE MINI ____________________________________________________ 5

G. CORE TEMPERATURE SENSOR 6

H. ERROR MESSAGES FUNCTION _____________________________________________ 6

CHAPTER 3 PRODUCT VIEWS AND OPERATION________________________________ 7

A. EXTERIOR VIEWS ________________________________________________________ 7

B. QUICK START GUIDE _____________________________________________________ 8

C. CONTROL PANEL DETAIL VIEW _____________________________________________ 9

CHAPTER 4 COOKING WITH THE MINI ______________________________________ 10

A. STEAM MODE ____________________________________________________________ 11

B. COMBI MODE ____________________________________________________________ 12

C. HOT AIR MODE ___________________________________________________________ 13

D. RETHERM MODE _________________________________________________________ 14

E. MEASURING THE CORE TEMPERATURE _____________________________________ 16

F. DELTA-T COOKING ________________________________________________________ 18

G. COOK & HOLD ____________________________________________________________ 19

H. LT COOKING _____________________________________________________________ 20

CHAPTER 5 ADVANCED FUNCTIONS _________________________________________ 21

A. CRISP & TASTY ___________________________________________________________ 21

B. TRAY TIMER _____________________________________________________________ 22

C. PRE-HEAT ___ ____________________________________________________________ 23

D. VAPOR REDUCTION _______________________________________________________ 23

E. KEY LOCK _______________________________________________________________ 23

F. ADD MOISTURE MANUALLY ________________________________________________ 24

G. OVERNIGHT COOKING ____________________________________________________ 25

H. COOL DOWN ____________________________________________________________ 25

CHAPTER 6 USING MULTI-STEP RECIPIES _____________________________________ 26

A. CREATING A MULTI-STEP RECIPE __________________________________________ 26

B. RECORDING A RECIPE IN REAL-TIME ________________________________________ 26

CHAPTER 7 USING THE COOKBOOK _________________________________________ 28

A. ENTERING A NEW RECIPE IN THE COOKBOOK ________________________________ 28

B. EXECUTING A RECIPE FROM THE COOKBOOK ________________________________ 28

C. INTEGRATING PRE-HEATING INTO A RECIPE _________________________________ 29

D. COPYING A RECIPE _______________________________________________________ 29

E. DELETING A RECIPE ______________________________________________________ 29

F. CHANGING A STEP OF A RECIPE ___________________________________________ 29

G. INSERTING A STEP INTO A RECIPE _________________________________________ 30

H. ADDING A STEP TO A RECIPE ______________________________________________ 30

I. DELETING A STEP FROM A RECIPE _________________________________________ 30

J. SAVE RECIPES TO MEMORY _______________________________________________ 31

K. LOAD RECIPES FROM MEMORY ____________________________________________ 31

L. ADDING AN “ACTION” PROMPT TO A RECIPE _________________________________ 32

CHAPTER 8 USING PRESS & GO ____________________________________________ 33

A. ASSIGN A RECIPE OR SEMI-AUTOMATIC CLEANING TO A PRESS & GO KEY ______ 33

B. TO OVERWRITE A PRESS & GO KEY ________________________________________ 33

C. EXECUTING A COOKING RECIPE WITH PRESS & GO __________________________ 33

CHAPTER 9 AT THE END OF THE DAY OR SHIFT _______________________________ 34

A. CLEANING THE OVEN CHAMBER ____________________________________________ 34

B. SEMI-AUTOMATIC CLEANING OF THE OVEN CHAMBER _________________________ 36

CHAPTER 10 MINI SETUP __________________________________________________ 38

TO USE THE SETUP MENU ____________________________________________________ 38

A. SIGNAL TONE ____________________________________________________________ 38

B. VOLUME ________________________________________________________________ 38

C. TIME ____________________________________________________________________ 38

D. DATE ___________________________________________________________________ 39

E. ORDER OF COOKBOOK RECIPES ___________________________________________ 39

F. DEFAULT AND MEMORY SETTINGS _________________________________________ 39

G. TEMPERATURE DISPLAY __________________________________________________ 40

H. NETWORK ADDRESS ______________________________________________________ 40

I. LANGUAGE ______________________________________________________________ 40

CHAPTER 11 TROUBLESHOOTING ____________________________________________ 41

A. ERROR DIAGNOSIS SYSTEM _______________________________________________ 41

B. ERROR MESSAGES AND REMEDIES (TABLE) __________________________________ 42

C. OPERATING IRREGULARITIES NOT HAVING ERROR MESSAGES (TABLE) _________ 42

CHAPTER 12 EMERGENCY OPERATION _______________________________________ 44

A. INSTRUCTIONS FOR EMERGENCY OPERATION _______________________________ 44

B. EMERGENCY OPERATION METHODS ________________________________________ 45

CHAPTER 1 INTRODUCTION

For safe use of MINIs, each operator must read, understand, and follow the instructions, and heed and

obey the warnings of the Installation Manual and Operators Manual, and the labels on the MINI,

accessories, and supporting products.

The owner(s) and operator(s) of this equipment must keep these instructions in an easily accessible

location for reference and training.

The owner(s) and operators(s) of this equipment must be aware that steam can cause serious injuries

and equipment damage. Pay particular attention to the Operational Safety section of this chapter and the

various NOTICES, CAUTIONS, WARNINGS, and DANGERS displayed in this manual and on the

equipment.

A. OPERATIONAL SAFETY

The safe and effective operation of one or more MINIs depends upon proper installation, use,

maintenance, and repair. Operational Safety must encompass all of these factors. This section outlines

the minimum safety policies that must be considered when using one or more MINIs. Any Operational

Safety Program must be tailored to the specific site and use of the equipment. To help avoid injuries,

accidents and damage to the MINI Oven-Steamer, the owner / operator must instruct and train employees

on a regular basis.

Burn hazards are present in any professional food service operation. When using the MINI, observe the

following precautions to help reduce the risk of burns and other injuries.

NOTE: Cooking is interrupted whenever the MINI door is opened.

1. AIR SUPPLY Use the MINI Oven-Steamer in a draft-free and well vented environment. Proper air

supply for ventilation is REQUIRED for and CRITICAL to safe, efficient operation of a MINI.

2. STEAM –Remember at all times that steam can cause severe burns.

3. HEAT – The MINI, cooking containers, shelves, and inner door and anything else inside the cooking

compartment are HOT, as are many of the component parts. Wear DRY heatproof gloves or mitts.

4. HEAT – During operation the temperature of the glass panel in the door and the outer door casing

can rise above 140°F.

5. Never breathe steam, condensate, or hot air.

6. SCALDS – Do not place containers with liquid contents or contents that become liquid on oven racks

higher than you can see into the containers.

7. SCALDS – Cover containers (individual or on trolleys) containing hot or hot liquid items to help

prevent spills during transport.

8. EXHAUST VENTS – The top of the MINI, and the steam exhaust vents are very hot during operation

and remain hot for some time.

a. Never breathe gas or steam from the exhaust vents.

b. Use extreme caution when working on or near the exhaust vents, surrounding area and component parts.

9. HAND SHOWER: GREASE SPATTER – Hot grease will spatter and cause burns if sprayed with

water. Locate fryers and similar appliances outside the range of the optional MINI hand shower.

10. HAND SHOWER: ELECTRIC SHOCK – Use the optional hand shower only on the inside of the oven.

Use of the hand shower, hoses, power cleaners, or pressure washers on the outside of the MINI can

cause electric shock and / or damage electrical and electronic components.

11. Optional HAND SHOWER – Do NOT spray water in a hot cooking compartment.

12. Wear BOOTS appropriate to the work area to help protect feet, and to help prevent slips and falls.

13. Use non-slip, draining, anti-fatigue FLOOR MATS (not included) rated for use in wet, greasy, and dry

work areas to help prevent slipping and / or falling injuries.

• Obtain the best mats for your needs from your local supplier.

1

B. CLEANING AND MAINTENANCE

1. CLEANING AND DAILY MAINTENANCE – Wait for the MINI to cool before cleaning and performing

daily maintenance.

2. CLEANING AND DAILY MAINTENANCE – Do NOT use hoses, power cleaners or pressure washers,

or harsh or abrasive cleaning agents inside OR outside the cooking compartment.

3. CLEANING AGENTS – Use only genuine Convotherm by Cleveland and Cleveland Range cleaning

and descaling products.

4. CLEANING AGENTS – Follow the instructions and heed and obey the warnings on the labels.

5. CLEANING AGENTS – Products other than genuine Convotherm by Cleveland and Cleveland Range

cleaning and descaling products can damage the MINI, cause injury, or present heath hazards.

6. DRAIN – Inspect and clean the drain cover and drain before each use. Injury, equipment damage,

and/or reduced cooking performance can result from a blocked drain cover and drain at the bottom of

the cooking compartment.

7. GENERAL INSPECTION – Before each use of the MINI, Inspect the door glass, door gasket

assembly, shelves, racks, drain and accessories for proper installation and cleanliness.

C. NEVER!

1. MINI must NEVER be started or operated at a temperature lower than 40°F, including after transport,

or storage outside, or in an unheated area.

2. The MINI must never be operated outside.

3. MINIs must never be used to cook foodstuffs in sealed containers other than those designed for this

purpose. (MINIs are excellent for “purpose built” containers such as sous-vide packages.)

4. MINIs must never be used to heat flammable items such as oils, fats, cloths, or similar items.

5. MINIs must never be used to heat non-food items (except suitable appliance accessories).

6. Never operate a MINI without the fan guard latched in place.

7. Never reach behind the fan guard during operation.

8. Never manually stop the fan.

9. Never operate a MINI without the drain cover in place.

10. Never use anything but hands to operate the keys, switches, and controls on the MINI.

11. Never push food, debris, or scale into the drain.

D. SERVICE AND SERVICE RECORDS

1. Allow only qualified Cleveland Range authorized service representatives to service the MINI.

2. Use only Cleveland Range factory authorized repair parts.

3. Maintain written records of maintenance, service, and repairs. Each record should include at least:

• The date and time of maintenance, service, or repair

• A description of the maintenance, service, or repair. Include part numbers if applicable.

• Copies of purchase orders and invoices for parts and labor.

• The name and signature of the person performing the maintenance, service, or repair.

E. OPERATOR TRAINING

Any Operational Safety Program must be tailored to the specific site and use of the equipment.

Operator training should include:

1. Operation of the MINI and accessories.

2. Start-up procedures.

3. Normal and emergency shut-down procedures.

4. Interior and exterior cleaning procedures

5. How to recognize and report problems so that corrective action can be taken by trained personnel.

2

MINI

DR AI N LI NE

CO L D W ATE R SU PPL Y L IN E S

MAIN E X TE R NA L

PO W E R S WITC H

CHAPTER 2 GENERAL OPERATION

A. MAIN EXTERNAL POWER SWITCH

NOTE: To help protect electrical and electronic

components: Turn OFF the Control Power Service

Disconnect Switch BEFORE turning on the Main External

Power Switch.

The Main External Power Switch is usually left ON. If the

switch is off, turn it ON as follows:

1. Turn ON the water supply valve(s).

2. Turn ON the Main External Power Switch.

3. Turn ON the MINI with the ON/OFF key (see Chapter

3).

NOTE: Depending on the time the Main External Power Switch has been off, the date and time may need

to be reset (see Chapter 10).

B. DOOR HANDLE and DOOR SWITCH

See Chapter 3, “Product Views.” The door handle combines the door latch with a safety vent position and

a wear-free door switch. The MINI cannot start unless the door is closed and latched. Cooking functions

stop if the door handle is moved to the open position. The MINI Oven-Steamer can only work with a

functioning door switch. If a malfunction occurs, immediately contact your qualified Cleveland Range

authorized service representative.

The door handle operates as follows:

Handle Positions

• Vertical: closed. (The wear-free door switch is engaged and the MINI can operate.)

• Horizontal: “airing” (partway open).

• Up past Horizontal: unlatched to open.

• The handle springs back to Horizontal when let go.

To open the closed MINI door:

1. Stand to the hinge side and back from the door.

2. Turn the handle to the horizontal (airing) position and wait for steam, condensate and heat to

dissipate. (The MINI cannot operate with the handle in the airing position.)

3. Lift the handle slightly past horizontal to unlatch it.

4. Open the door.

3

C. START-UP AND SHUTDOWN INSTRUCTIONS

Do NOT attempt to operate a MINI during a power failure!

Death, injury, and equipment damage can result.

In the event of a power failure:

1. Turn OFF the Main External Power Switch.

2. Turn OFF Control Power Service Disconnect Switch.

3. If the power failure is prolonged: turn OFF the water supply.

4. When power is restored: restart a MINI with the Startup Procedure.

Start-up Instructions

1. Turn on the MINI by pressing the ON/OFF key.

2. Press the key for operating mode desired; steam or hot air:

a. Select time and temperature.

b. Start the MINI by pressing the Start/Stop Key.

3. To cook in other modes or use features: see the Operator’s Manual.

Shutdown Instructions

1. Press the ON/OFF key to turn off the MINI.

D. INSPECTING THE MINI BEFORE SWITCHING ON

Inspect the MINI before switching ON.

1. Check for assembly, operation, and cleanliness as follows:

a. Check regularly to ensure that the screws and hinges of the door are firmly in place and operating

properly.

b. Inspect the glass door panels. If the glass door panels are nicked, scratched, or cracked: remove the

MINI from service and replace the glass immediately. Damaged glass panels may shatter during

operation.

c. Make sure the glass door panels are clean and latched into place.

d. Do not place or store anything on top of the MINI. The exhaust vent area and the top of the MINI

are hot.

e. Do not place or store anything underneath the MINI.

f. KEEP THE APPLIANCE AREA FREE OF AND CLEAR FROM COMBUSTIBLES.

g. Do not store or leave combustibles near the MINI.

h. Do not block or obstruct the area beneath the gas MINI with objects of any kind.

i. Make sure the air vents of the MINI are not blocked.

j. Check for water line leaks.

k. Check for clogged or slow cooking compartment drain, drainpipe, and floor drain.

l. Check for control malfunctions.

m. Check the door gasket for proper assembly, damage, wear, and seal leaks.

4

E. INSPECTING THE COOKING COMPARTMENT

Inspect the cooking compartment before starting a cooking operation with a MINI for proper assembly and

cleanliness as follows:

1. Inspect the Drain

The drain in the bottom of the cooking compartment has a removable cover. The cover prevents large

food particles, debris and scale from entering and blocking the drain line. Any blockage of the drain

line or drain cover can reduce reduced cooking performance, equipment damage, and injury.

A blocked or slow drain may cause:

•

Hot water to collect in the compartment and spill out when the compartment door opens.

•

Steam leaks around the door gasket.

•

Reduced cooking performance.

CAUTION

Injury, equipment damage, and/or reduced cooking performance can result from a

blocked drain cover and drain at the bottom of the cooking compartment.

2. Inspect for proper latching and assembly of the cooking compartment.

The following features should be checked before every operation of the MINI for proper assembly.

a. Check that the fan guard is in position and secure.

b. Check that the hanging shelf racks are secured into their operating positions at both the top and

bottom.

c. Make sure that the inner door glass is properly latched into position. When properly latched, the

inner door is tight with the outer door and does not move by itself or rattle.

d. Open and close the door. All movements should be smooth.

NOTES:

• DO NOT USE the MINI if water stands in the drain opening. Immediately clean the drain. See

Chapter 9, “At the End of the Day or Shift” for instructions.

• Remove any food, debris, or scale blocking the drain or screen.

• Never push food, debris, or scale into the drain.

• Be sure the drain cover is properly installed into the bottom of the cooking compartment. The

drain cover prevents large pieces of food from entering and blocking the drain.

Inspect and clean the drain cover and drain before each use.

F. PRE-HEATING THE MINI

1. The pre-heating function heats the oven to the desired temperature before loading food and helps

ensure consistency and quality. Use pre-heating at the start of a shift, after long pauses in cooking,

and between multiple cooking or rethermalizing batches.

NOTICE: Before pre-heating: inspect and clean the Oven Compartment. After pre-heating the Oven

Compartment is too hot to inspect and clean safely.

a. To pre-heat a MINI: Close the door and start the MINI in the desired mode (Steam, Hot Air, or

MINI).

• Pre-heat temperatures should be 10-20% higher than cooking temperatures.

• Typical-pre-heat times are 10 to 15 minutes.

• See Chapter 3, for basic operating instructions.

5

• Repeat the preheat process as needed to maintain constant oven temperature and high food

quality.

b. To use pre-heating in a recipe: Pre-heating is also a programmable function. See “Pre-Heating”

in Chapter 5, “Advanced Functions” for, details.

c. To Pre-Heat or reheat between batches for Rethermalization: See “Retherm Mode” in

Chapter 4 for times and temperatures for specific applications.

Do not place containers with liquid contents or contents that become liquid on oven

racks higher than you can see into the containers.

Hot liquid can spill or splash causing death, injury, or equipment damage

G. CORE TEMPERATURE SENSOR

• See “Measuring the Core Temperature” in Chapter 4 for details regarding use and care.

• The Core Temperature Sensor is REQUIRED for PC-HACCP, Delta-T cooking, and Cook & Hold.

1. The Core Temperature Sensor may be HOT! Wear dry, heatproof gloves or mitts to handle it.

2. The Core Temperature Sensor is a precision measuring device. Handle with care.

3. Hang the Core Temperature Sensor correctly in its rack when not in use.

4. Do not allow the Core Temperature Sensor to hang out of the oven.

5. Do not prick yourself or others with the Core Temperature Sensor tip(s).

6. Remove the Core Temperature Sensor from the food before removing dishes from the oven.

H. ERROR MESSAGES FUNCTION

NOTES:

• MINIs have a fully automatic error diagnosis system.

• Most errors are indicated in the Multifunction Display by an error code and description.

• See Chapter 11 “Troubleshooting” for a list of error codes and remedies.

.

6

CAUTION

HOT!

CHAPTER 3 PRODUCT VIEWS AND OPERATION

A. EXTERIOR VIEWS

1.

Control Panel

2. Oven Light

3. Door with Double Glass Panel

4.

Door Handle

1

5. Door Drip Tray

6. Appliance Drip Tray

7. Legs (Required)

8. Rating Plate

2

3

4

8

Notes:

1. Magnetic Door Switch

• If the oven door is opened during operation, the magnetic door switch automatically interrupts the

recipe. The timer stops.

• After the door is closed, the MINI automatically continues the recipe.

• If the oven door is opened when the buzzer sounds at the end of a recipe, it automatically

switches the buzzer off.

2. Operate controls with hands only!

7

6

5

7

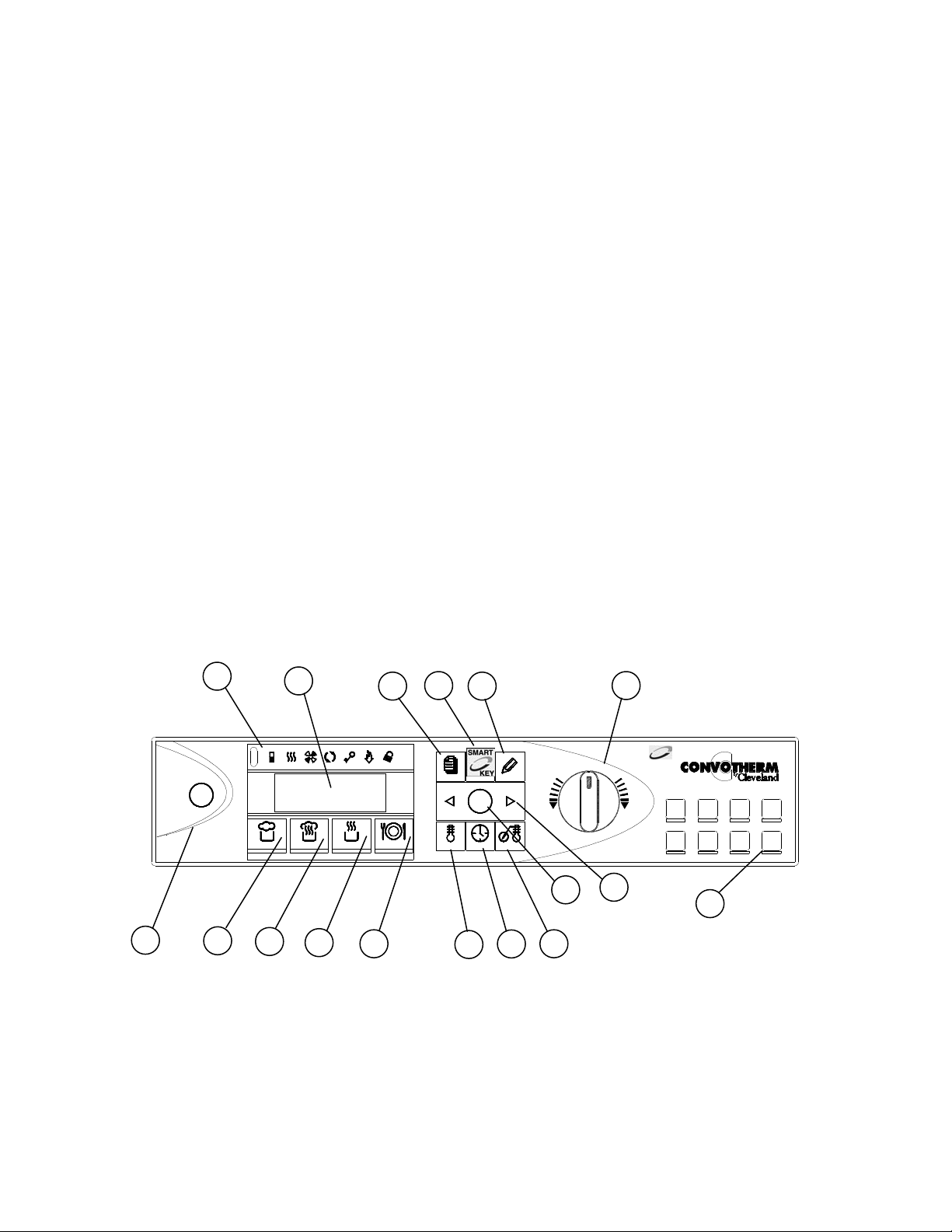

B. QUICK START GUIDE CONTROL PANEL BASIC OPERATION

Operate Controls with HANDS Only!

ALWAYS PRE-HEAT!

1. Switch on with key (1).

2. Select cooking mode with keys (2-5).

3. Press key (10) to start.

OR

1. Press key (7) and rotate Selector Dial

(15) to set oven temperature.

2. Press key (8) and rotate Selector Dial

(15) to set cooking time.

OR

Press key (9) and rotate Selector Dial (15)

to set core temperature.

ALL

1. Press key (10) to start the MINI.

17

6

13

2. To change the settings while cooking:

press keys (7) OR (8) OR (9) and adjust

the settings with the Selector Dial (15).

3. When the buzzer sounds press key (11)

or open the door.

NOTE: See “CONTROL PANEL” in Chapter

4, Section B for detailed descriptions of

control panel functions.

14 12

15

ON

OFF

STEAM COMBI RETHERMHOT AIR

COOKBOOK EDIT

START

STOP

TEMP PROBETIME

1 2 3 4

5 6 7 8

1

2

3

4

5

7

8

Figure 4-1

Control Panel

10

9

11

16

8

C. CONTROL PANEL DETAIL VIEW

Item numbers correspond to numbers on the control panels in Figure 4-1

Operate controls with hands only!

1. ON/OFF

When the MINI is turned ON:

• Self-diagnosis is performed.

• Oven light turns on.

• Steam generator fills and heats (OEB and

OGB models).

2. Steam

• Oven temperature is continuously

variable between 86°F and 248°F.

3. Combi Hot Air and Steam

• Oven temperature is continuously

variable between 212°F and 482°F.

4. Hot Air

• Oven temperature is continuously

variable between 86°F and 482°F.

5. Retherm

• Oven temperature is continuously

variable between 248°F and 320°F.

6. Display

Display in normal mode:

• Date.

• Time.

• Oven Temperature.

• Cooking Time

• Core Probe Temperature.

Display in programming mode:

• Clear text.

• Memory.

• Symbols.

7. Oven Temperature

• Set the nominal oven temperature.

• View the actual or nominal oven

temperature.

• See elapsed cooking time when using

Core Temperature mode.

8. Cooking Time

• Set the cooking time from 1 minute to 9

hours, 59 minutes using the Selector Dial.

• Set Continuous Mode

1. At 9:59 or 0:01, release the Selector

Dial.

2. Turn the Selector Dial again to the left

or right.

• See the actual or nominal cooking time.

• See elapsed cooking time when using

Core Temperature mode.

9. Core Temperature

• Set the nominal core temperature.

• See the actual or nominal core

temperature.

• See the actual core temperature during

cooking time mode.

• See elapsed cooking time when using

Core Temperature mode.

10. Start/Stop

• Start cooking modes and recipes.

• Stop the cooking activity.

• Escape or Exit Smart Key functions

11. Scroll Left and Scroll Right

• Page / Scroll one step forward or back

in programming mode.

12. Cookbook

• Call up, exit cookbook.

• View a list of stored recipes in the

display.

13. Smart Key

• Set Extra Functions.

• Set-Up the MINI.

• Enter Sub-Menus.

14. Edit

• Create, change, copy, and delete

recipes.

15. Selector Dial

• Set: Oven temperature, cooking time,

core temperature, recipe name, recipe

number.

• Select Smart Key functions, editing

functions and recipes in the cookbook.

16. Press & Go Keys

• Start saved recipes with one key.

• LED below key lights up when

corresponding recipe is started.

17. Function Indicators (left to right)

• Light up when function or activity is

engaged:

Reduced Power

Burner or Electric Heating ON

Reduced Fan Speed

Cooking Mode Engaged

Button Lock

Crisp & Tasty Engaged

Program Protection

9

drips juices. Dripping juices can cause burns and clog the drain.

CHAPTER 4 COOKING WITH THE MINI

CAUTION

Some foods drip juices. Use a solid catch pan under perforated pans when cooking food that

Do NOT use hanging shelf racks that are bent or otherwise

damaged in any way.

Pans and accessories placed in damaged racks can tip and

spill, causing burns, injuries and/or equipment damage

DO NOT BREATHE STEAM, HOT AIR OR CONDENSATE

DEATH OR INJURY WILL RESULT.

CAUTION

Hot Air, Steam, and Condensate will cause burns and scalds.

To help prevent burns and scalds when opening the MINI door: always stand to the hinge side and

back from the MINI door, and then open the MINI door to the “airing” position, and wait for the

steam and heat to dissipate before carefully opening the door.

Maximum Combined Weight of Food and Containers or Accessories

Model Number Maximum Per Shelf

6.08 Max. 33 lbs per shelf

Table 5-1

10

Loading...

Loading...