Cleveland MKET-T Owner’s Manual

MODELS:

MKET-12-T, MKET-20-T

SE95015 Rev. 4

1333 East 179th St., Cleveland, Ohio, U.S.A. 44110

Phone: (216) 481-4900 Fax: (216) 481-3782

Visit our web site at www.clevelandrange.com

d

Enodis

For a complete Service Manual

refer to www.clevelandrange.com

Operators Manual

Installation & Operation

Electric Table Top Mixers

™

Clev elan

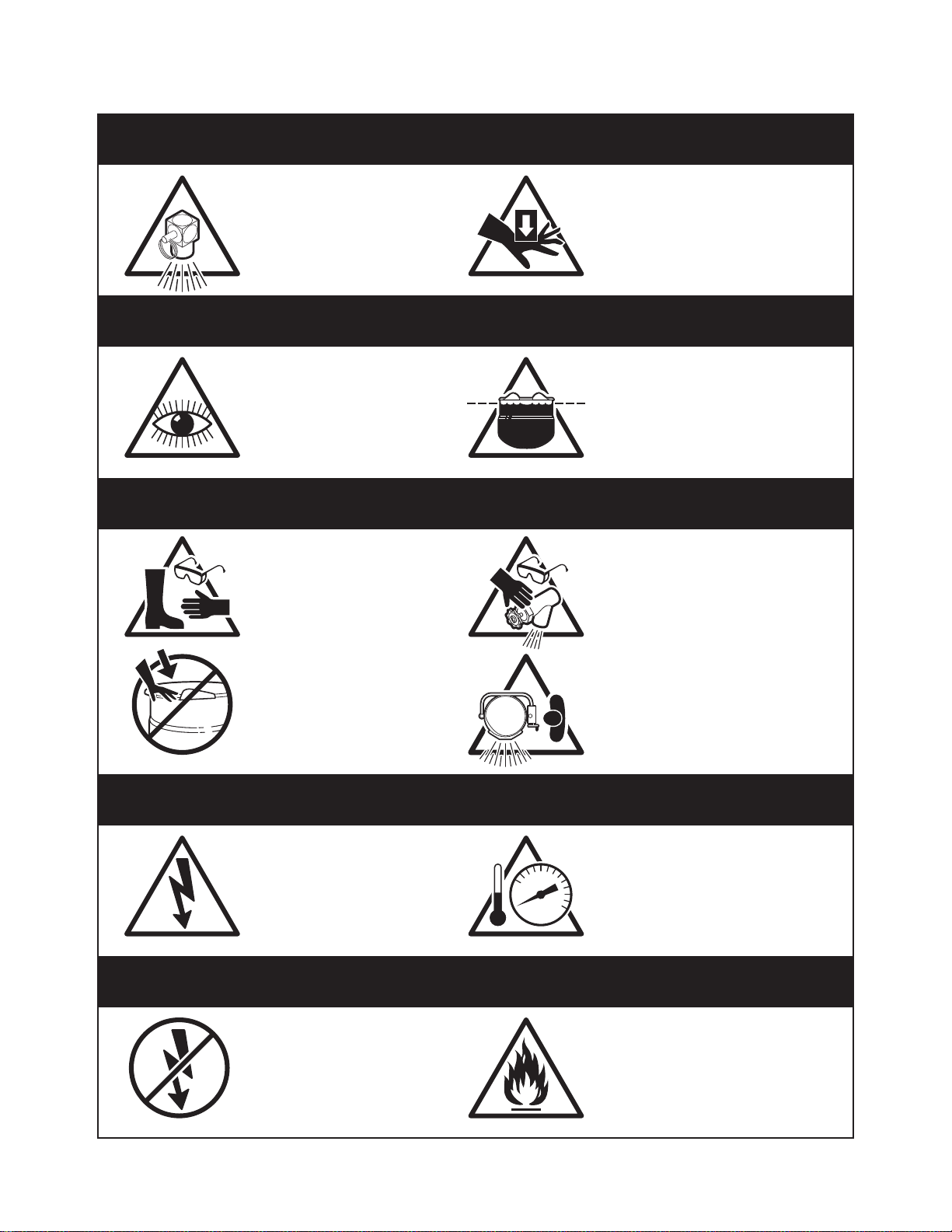

For your safety

DANGER

Keep clear of pressure

relief discharge.

IMPORTANT

Inspect unit daily for

proper operation.

CAUTION

Surfaces may be

extremely hot! Use

protective equipment.

Keep hands away from

moving parts and pinch points.

Do not fill kettle above

recommended level

marked on outside of kettle.

Wear protective equipment

when discharging hot product.

Do not lean on or place

objects on kettle lip.

SERVICING

Shut off power at main

fuse disconnect prior

to servicing.

GAS APPLIANCES

Do not attempt to operate

this appliance during a

power failure.

Stand clear of product

discharge path when

discharging hot product.

Ensure kettle is at room

0

temperature and pressure

gauge is showing zero or less

prior to removing any fittings.

Keep appliance and area free

and clear of combustibles.

GENERAL

Installation of the kettle must be accomplished by

qualified electrical installation personnel working

to all applicable local and national codes.

Improper installation of product could cause injury

or damage.

This equipment is built to comply with applicable

standards for manufacturers. Included among

those approval agencies are: UL, NSF, ASME/Ntl.

Bd., CSA, CGA, ETL, and others. Many local

codes exist, and it is the responsibility of the

owner/installer to comply with these codes.

Note: Maximum voltage for LVD (low volt

directive for Europe) to be 440 volts for CE

marked appliances.

INSPECTION

Before unpacking visually inspect the unit for

evidence of damage during shipping.

If damage is noticed, do not unpack the unit, follow

Shipping Damage Instructions shown below.

SHIPPING DAMAGE

INSTRUCTIONS

If shipping damage to the unit is discovered or

suspected, observe the following guidelines in

preparing a shipping damage claim.

1. Write down a description of the damage or the

reason for suspecting damage as soon as it is

discovered. This will help in filling out the claim

forms later.

2. As soon as damage is discovered or

suspected, notify the carrier that delivered the

shipment.

3. Arrange for the carrier's representative to

examine the damage.

4. Fill out all carrier claims forms and have the

examining carrier sign and date each form.

INSTALLATION

The first installation step is to refer to the

Specification Sheets or Specification Drawings for

detailed clearance requirements of the kettle.

Next, carefully cut open the shipping carton for

easy removal of the kettle.

ASSEMBLY

Table-top models (12 gallon) must be positioned on

a firm, level stand, or existing counter top, and

bolted in place. These models are supplied with four

threaded mounting bushings welded to the

underside of the base. An optional support stand

with level adjustable legs is available. Once the kettle

is secure, screw tilt handle into the threaded hole

provided at the right side of kettle.

Floor Type Leg Mount Models (20 gallon)

Position on a firm, level surface, and bolt flanged

feet in place. Once the kettle is secure, screw tilt

handle into the threaded hole provided at the right

of kettle.

ELECTRICAL

ENSURE THE ELECTRICAL SUPPLY MATCHES

THE KETTLE'S REQUIREMENTS AS STATED

ON THE RATING LABEL.

This kettle is built to comply with applicable

standards of manufacturers. Included among

these approval agencies are UL, NSF, ASME/Ntl.

Bd., CSA, ETL, and others. Many local codes

exist, and it is the responsibility of the owner and

installer to comply with these codes.

The electrical supply must match the power

requirements specified on the kettle’s rating plate.

The copper wiring must be adequate to carry the

required current at the rated voltage.

Note: Maximum voltage for LVD (low volt

directive for Europe) to be 440 volts for CE

marked appliances.

INSTALLATION

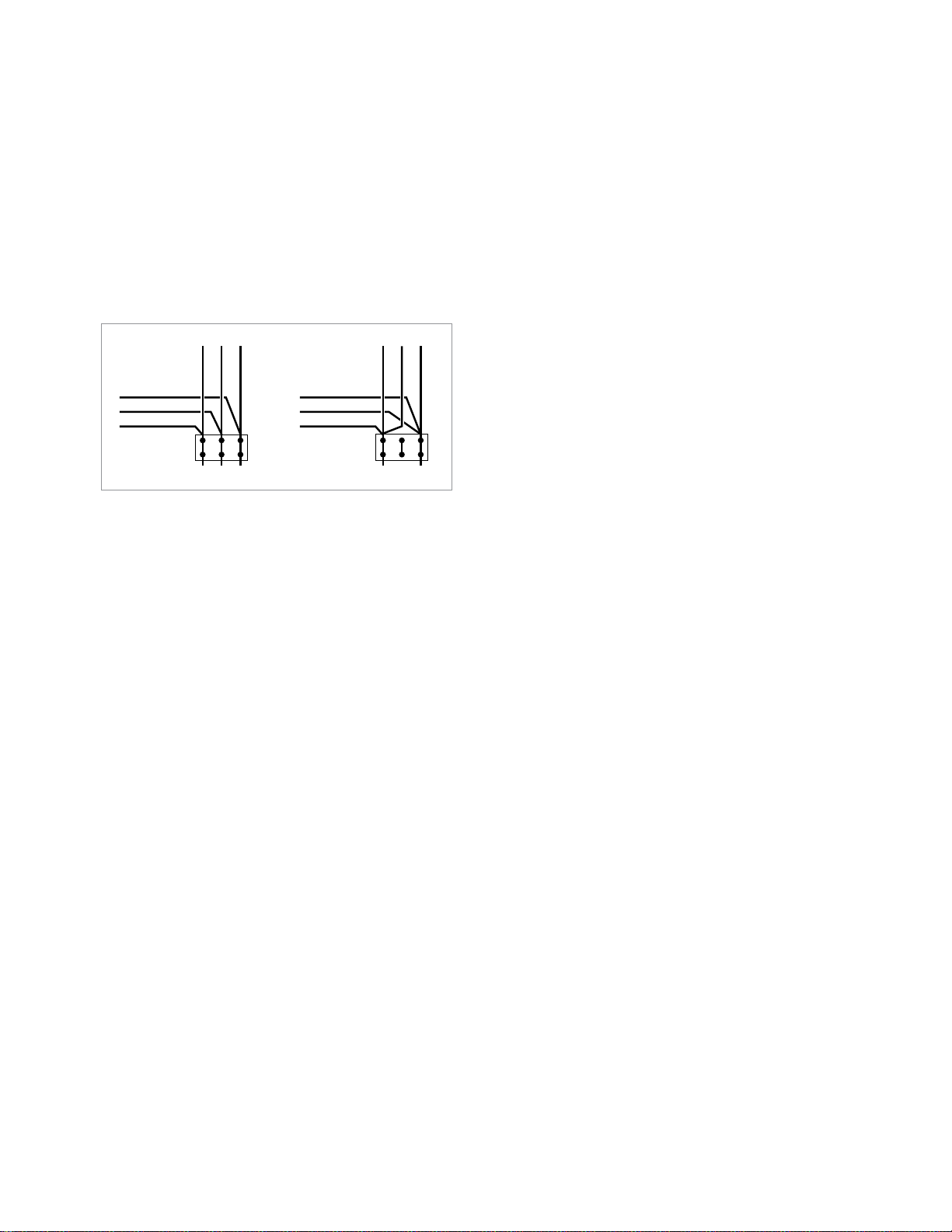

WIRE CONNECTION

If unit does not have cord and plug option, remove

the screw at the rear of the console cover and

remove the cover. A wiring diagram is affixed to

the underside of the cover. Feed permanent

copper wiring through the cut-out in the rear or

bottom of the console, and fasten to the three

connection terminal block, which is mounted on

the top of the console’s control panel. Be sure to

connect the ground wire to the separate ground

terminal connector (ground lug). Replace console

cover and secure it with the screw.

The kettle is wired for 3-phase operation at the

factory. For single phase operation, rewire the

terminal block to that shown in the above diagram.

WATER

The sealed jacket of the electric kettle is

precharged with the correct amount of a waterbased formula, and therefore, no water connection

is required to the kettle jacket. The kettle can be

equipped with optional hot and cold water taps,

the taps require 1/2" copper tubing as supply

lines.

INSTALLATION CHECKS

Although the kettle has been thoroughly tested

before leaving the factory, the installer is responsible

for ensuring the proper operation of kettle once

installed.

Performance Checks

1. Supply power to the kettle by placing the fused

disconnect switch to the "ON" position.

2. Before turning the kettle on, read the

vacuum/pressure gauge. The gauge's needle

should be in the green zone.

3. Place the kettle's power ON/OFF switch to the

"ON" position.

4. Turn the temperature control knob to "1" (Min.).

The green LED light should remain lit, indicating

the burner is lit, until the set temperature is

reached (124°F/50°C). Then the green light will

cycle on and off, indicating the element is

cycling on and off to maintain temperature.

5. Tilt the kettle forward. After a few seconds the

red "LOW WATER" light should be lit when the

kettle is in a tilted position. This light indicates

that the element has automatically been shut off

by the kettle's safety circuit. This is a normal

condition when the kettle is in a tilted position.

6. Raise the kettle to the upright position. The red

"low water" light should go out when the kettle is

upright.

7. Turn the temperature control knob to "10" (Max.)

and allow the kettle to preheat. The green light

should remain on until the set temperature

(260°F/127°C) is reached. Then the green light

will cycle ON and OFF, indicating the element is

cycling ON and OFF to maintain temperature. Fill

the kettle with cold water to the steam jacket’s

welded seam.

8. When all testing is complete, empty the kettle

and place the power ON/OFF switch in the

“OFF” position.

CLEANING

After installation the kettle must be thoroughly

cleaned and sanitized prior to cooking.

RED

YELLOW

BLACK

BLACK

BLUE

RED

L1 L2 L3

THREE

PHASE

RED

YELLOW

BLACK

BLACK

BLUE

RED

L1 L2

SINGLE

PHASE

Loading...

Loading...