Page 1

INSTALLATION, OPERATION AND SERVICE MANUAL

GAS TABLE TOP KETTLE -

MODEL: KGT-6-T

KGT-12-T

CLEVELAND RANGE INC.

1333 East 179th St.

Cleveland, Ohio

U.S.A. 44110

Toll Free 1-800-338-2204

SE95010 Rev.3

Page 2

FOR THE USER

IMPORTANT

POST IN A PROMINENT LOCATION, INSTRUCTIONS TO BE FOLLOWED IN THE EVENT

THE USER SMELLS GAS.THIS INFORMATION SHALL BE OBTAINED BY CONSULTING

YOUR LOCAL GAS SUPPLIER.

ALL SERVICE MUST BE PERFORMED BY A QUALIFIED CLEVELAND RANGE

TECHNICIAN.

RETAIN THIS MANUAL FOR YOUR REFERENCE.

WARNING: Improper installation,

adjustment, alteration, service or

maintenance can cause property

damage, injury or death. Read the

installation operating and

maintenance instructions

thoroughly before installing or

servicing this equipment.

FOR YOUR SAFETY

DO NOT STORE OR USE

GASOLINE OR ANY OTHER

FLAMMABLE LIQUIDS AND

VAPOURS IN THE VICINITY

OF THIS OR ANY OTHER

APPLIANCE.

Page 3

TABLE OF CONTENTS

Installation Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Shipping Damage Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Clearance Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operating Instructions General Parts Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operating the Kettle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Marine Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cleaning Instructions Care & Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Marine Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Service Parts Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Faucet Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Main Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Component Mounting Bracket Assembly. . . . . . . . . . . . . . . . . . . . 9

Piping Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Maintenance Inspection & Maintenance Check List . . . . . . . . . . . . . . . . . . . . 11

Calibrating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Vacuum Leak Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pressure Relief Valve Periodic Testing Procedure . . . . . . . . . . . . 12

Reservoir Fill Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Kettle Venting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Repairing Leaks in Steam Jacketed Kettle Fittings . . . . . . . . . . . 14

Kettle Jacket Filling & Draining Procedures . . . . . . . . . . . . . . . 15

Operating Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Field Conversion Instructions -

Natural Gas to Propane Gas . . . . . . . . . . . . . . . . . . . . . . . . . 17

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Page 4

1

INSPECTION

Before unpacking visually inspect the unit for evidence

of damage during shipping.

If damage is noticed, do not unpack the unit, follow

shipping damage instructions.

SHIPPING DAMAGE

INSTRUCTIONS

If shipping damage to the unit is discovered or

suspected, observe the following guidelines in

preparing a shipping damage claim.

1. Write down a description of the damage or the

reason for suspecting damage as soon as it is

discovered. This will help in filling out the claim

forms later.

2. As soon as damage is discovered or suspected,

notify the carrier that delivered the shipment.

3. Arrange for the carrier's representative to examine

the damage.

4. Fill out all carrier claims forms and have the

examining carrier sign and date each form.

GENERAL

Installation of the kettle must be accomplished by

qualified installation personnel working to all applicable

local and national codes. Improper installation of

product could cause injury or damage.

This equipment is built to comply with applicable

standards for manufacturers. Included among those

approval agencies are: UL, A.G.A., NSF, ASME/N.Bd.,

CSA, CGA, ETL, and others. Many local codes exist,

and it is the responsibility of the owner/installer to

comply with these codes.

Observe all clearance requirements to provide proper

make-up air flow. Do not obstruct the flow of combustion

and ventilation air. Check rating plate to ensure that

kettle has been equipped to operate with the type of

gas available at the installation.

Dimensions and clearance specifications are shown on

the specification sheet and in the Clearance

Requirements section.

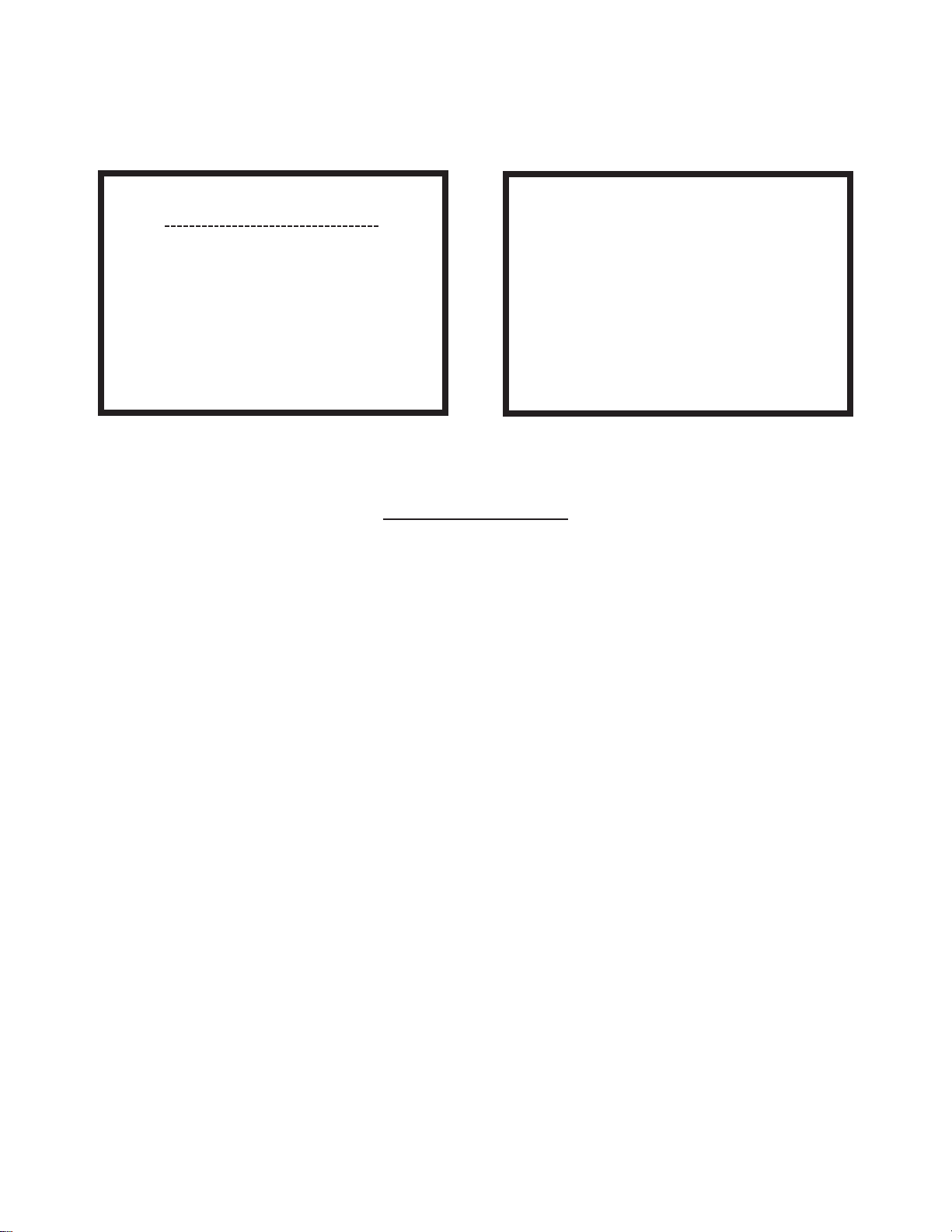

CLEARANCE REQUIREMENTS

CLEARANCE REQUIREMENTS TO COMBUSTIBLE

AND NONCOMBUSTIBLE SURFACES.

NOTE: To prevent removal of unit for servicing, allow

sufficient room on right hand side for servicing.

ASSEMBLY

Base Mounting Diagram

Table-top models must be positioned on a firm, level

stand, or existing counter top, and bolted in place. These

models are supplied with four threaded mounting

bushings welded to the underside of the base. An

optional support stand with level adjustable legs is

available. Once the kettle is secure, screw tilt handle into

the threaded hole provided at the right side of kettle.

GAS

ENSURE THE GAS SUPPLY MATCHES THE

KETTLE'S REQUIREMENTS AS STATED ON THE

RATING PLATE.

It is recommended that a sediment trap (drip leg) be

installed in the gas supply line. If the gas pressure

exceeds 14” water column, a pressure regulator must

be installed, to provide a maximum of 14” water column

gas pressure to the gas control valve.

Connect the gas line to the manual valve located at the

rear of the control box.

Model # Back Left Side Right Side

KGT-16-T 4” 0 0

KGT-12-T 4” 0 0

INSTALLATION

1 1/4"

10"

3 1/4"

14 1/2" 2 1/4"

14 1/2"

24" (6 gallon)

27" (12 gallon)

Page 5

2

Installation must be in accordance with local codes

and/or the National Fuel Gas Code ANSI Z223.1 Latest

Edition (USA) or the latest Installation Codes for Gas

Burning Appliances and Equipment CAN/ CGA B149.1

and CAN/ CGA B149.2 (Canada). Use a gas pipe joint

compound which is resistant to L.P. gas. Test all pipe

joints for leaks with soap and water solution. Ensure that

the gas pressure regulator is set for the manifold

pressure indicated on the gas rating plate.

The appliance and its individual shut-off valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psi (3.45 kPa). The appliance must be

isolated from the gas supply piping system by closing

its individual manual shut-off valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.45 kPa).

ELECTRICAL

ENSURE THE ELECTRICAL SUPPLY MATCHES THE

KETTLE'S REQUIREMENTS AS STATED ON THE

RATING LABEL.

A cord and plug are supplied with the unit. Simply plug

the unit into any grounded outlet rated for a minimum of

10 amps. The wiring diagram is located on the back of

the console access panel.

WARNING: Electrical Grounding Instructions.

This unit is equipped with a three-prong (grounding) plug

for your protection against shock hazard and should be

plugged directly into a properly grounded three-prong

receptacle. Do not cut or remove the grounding prong

from this plug. Standard supply voltage is 115 volts A.C.,

however, optional A.C. voltages can be supplied on

special order. A separate fused disconnect switch must

be supplied and installed in the high voltage electrical

supply line. The kettle when installed, must be electrically

installed and grounded in accordance with local codes,

or in the absence of local codes, with National Electrical

Code, ANSI/NFPA 7-1990 (USA) or the Canadian

Electrical Code, CSA C22.1, Part 1 (Canada).

VENTILATION

Gas fired kettles are only to be installed under a

ventilation hood in a room which has provisions for

adequate make up air. Further information can be

obtained by referring to the U.S.A. National Fire

Protection Associations NFPA96 regulations. These

standards have also been adopted by the National

Building Code in Canada.

WATER

The sealed jacket of the gas-fired kettle is precharged

with the correct amount of a water-based formula, and

therefore, no water connection is required to the kettle

jacket. The kettle can be equipped with optional hot and

cold water taps, the taps require 1/2" copper tubing as

supply lines.

INSTALLATION CHECKS

Although the kettle has been thoroughly tested before

leaving the factory, the installer is responsible for

ensuring the proper operation of kettle once installed.

DO NOT ATTEMPT TO OPERATE THIS APPLIANCE

DURING A POWER FAILURE.

KEEP APPLIANCE AND AREA FREE AND CLEAR OF

COMBUSTIBLES.

1. Supply power to the kettle by placing the fused

disconnect switch to the "ON" position.

2. Before turning the kettle on, read the

vacuum/pressure gauge. The gauge's needle

should be in the green zone. If the needle is in the

"VENT AIR" zone, follow air venting procedure.

3. Place the kettle's power on/off switch to the "ON"

position.

4. Turn the temperature control knob to "MIN .". The green

LED light should remain lit, indicating the burner is lit,

until the set temperature is reached. Then the green

light will cycle on and off, indicating the burner is

cycling on and off to maintain temperature.

5. Tilt the kettle forward. The red "LOW WATER" light

should be lit when the kettle is in a tilted position.

This light indicates that the burner has automatically

been shut off by the kettle's safety circuit. This is a

normal condition when the kettle is in a tilted

position.

6. Raise the kettle to the upright position. The red "low

water" light should go out when the kettle is upright.

If the red light remains lit in the upright position, it

indicates a low water condition, and water must be

added to the reservoir before the kettle can be

operated. Refer to the "Reservoir Fill Procedures", on

the kettle's label, for details.

7. Turn the temperature control knob to "MAX." and

allow the kettle to preheat. The green light should

remain on until the set temperature is reached. Then

the green light will cycle ON and OFF, indicating the

burner is cycling ON and OFF to maintain

temperature.

CLEANING

After installation the kettle must be thoroughly cleaned

and sanitized prior to cooking. See complete cleaning

instructions in this manual (page 5).

Page 6

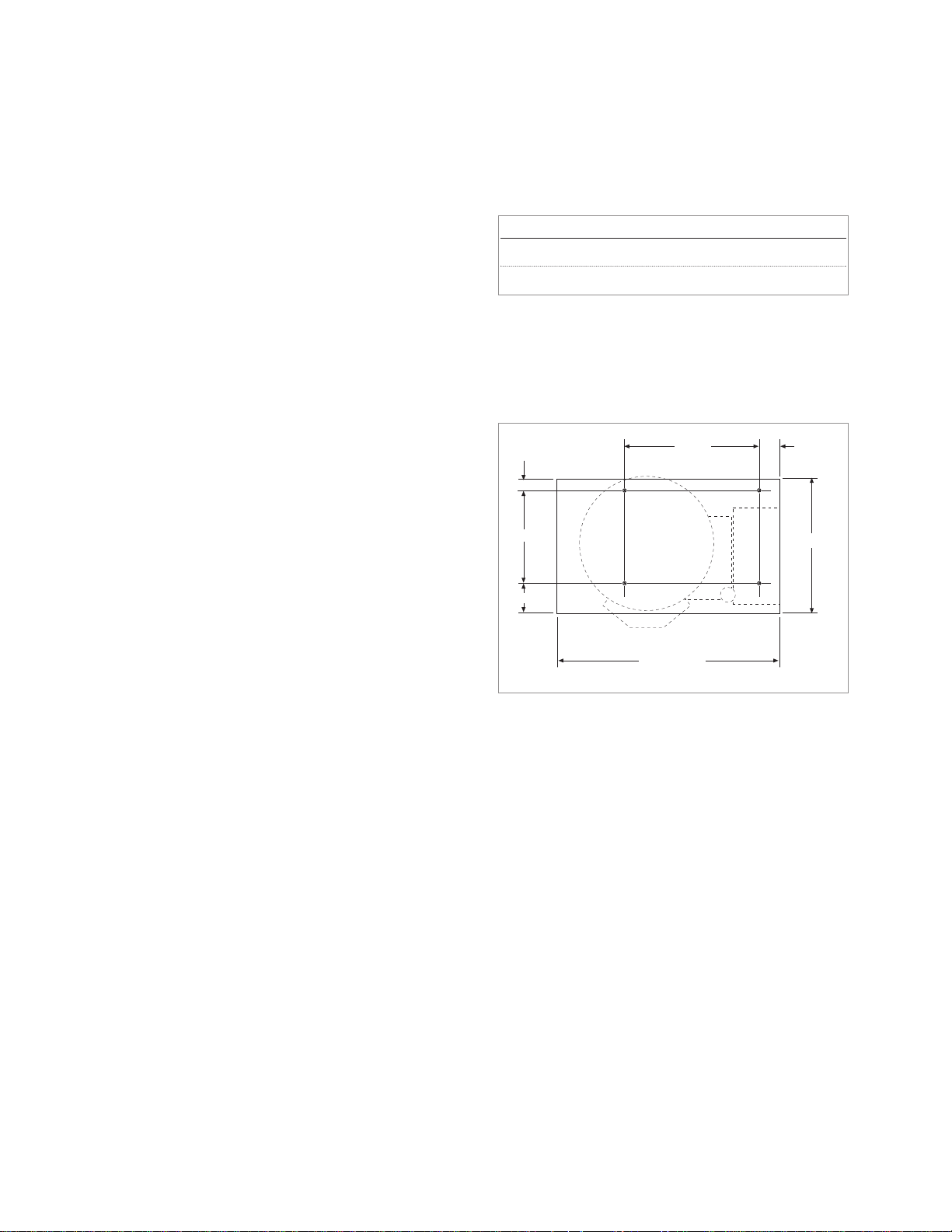

3

OPERATING INSTRUCTIONS

General Parts Drawing

ITEM # DESCRIPTION FUNCTION

1. On-Off Toggle Switch Controls electrical power to kettle.

2. Solid State Temperature This control allows the operator to adjust the kettle temperature in

Control Knob increments from MIN. to MAX. (see Temperature Range Chart on

page 4 of this manual.

3. Heat Indicator Light (Green) When lit, indicates that the kettle burner is on.

Cycles ON-OFF with burner.

4. Low Water Indicator Light (Red) When lit, indicates that the kettle is low on water and will not operate

in this condition (see Reservoir Fill Procedures on page 13 of this

manual).

5. Vacuum/Pressure Gauge Indicate steam pressure in PSI inside steam jacket as well as

vacuum in inches of mercury.

6. Pressure Relief Valve This valve is used to vent the kettle and in the unlikely event there is

an excess steam build-up in the jacket, this valve opens

automatically to relieve this pressure.

7. Plug Nut Plug nut is used for refilling the kettle with water (see "Kettle Venting

Instructions" and "Reservoir Fill Procedures" on pages 13 and 14 of

this manual).

8. Tilting Handle Used for tilting the kettle.

9. Marine Lock Prevents unit from accidental tilting.

10. Water Level Sight Glass Displays water level in steam jacket.

8

7

6

10

4

3

2

1

5

9

Page 7

4

OPERATING THE KETTLE

DO NOT ATTEMPT TO OPERATE THIS APPLIANCE

DURING A POWER FAILURE.

KEEP APPLIANCE AND AREA FREE AND CLEAR OF

COMBUSTIBLES.

DO NOT LEAN ON OR PLACE OBJECTS ON KETTLE

LIP. SERIOUS INJURY COULD RESULT IF KETTLE

TIPPED OVER, SPILLING HOT CONTENTS.

1. Before turning kettle on, read the

Vacuum/Pressure Gauge (5). The gauges

needle should be in the green zone. If the

needle is in the "VENT AIR" zone, refer to the

"Kettle Venting Instructions". Any air that may

be present will increase cooking times. Once

heated, the kettle's normal maximum

operating pressure is approximately 10-12

psi, while cooking a water base product.

2. Place the kettle's On-Off Toggle Switch (1) to

the "ON" position.

Temperature Range Chart

3. Preheat the kettle by turning the Solid State

Temperature Control Knob (2) to the desired

temperature setting (see Temperature Range

Chart on page 4). The Heat Indicator Light

(Green) (3) will remain lit, indicating the

burner is lit, until the temperature setting is

reached. When the green light goes off, the

heaters are off, and preheating is complete.

4. Place food product into the kettle. The green

light will cycle on and off indicating the burner

is cycling on and off to maintain the set

temperature.

NOTE: When cooking egg and milk products, the kettle

should not be preheated, as products of this nature

adhere to hot cooking surfaces. These types of food

should be placed in the kettle before heating is begun.

NOTE: The Low Water Indicator Light (Red) (4) should

not be lit during kettle operation. This light indicates that

the burner has been automatically shut off by the

kettle's safety circuit. It is normal for the red light to

come on when the kettle is in a tilted position. However,

the kettle cannot be operated when the red light

remains lit while the kettle is in the upright position. This

indicates a low water condition, and water must be

added to the reservoir. Refer to "Reservoir Fill

Procedures" in this manual for details.

5. When cooking is completed place On-Off

Toggle Switch (1) to the "OFF' position.

NOTE: A five minute complete shut-of period is

required before relighting.

6. Pour the contents of the kettle into an

appropriate container by tilting the kettle

forward. Care should be taken to pour slowly

enough to avoid splashing off the product.

NOTE: As with cleaning food soil from any cookware,

an important part of kettle cleaning is to prevent food

from drying on. For this reason, cleaning should be

completed immediately after cooked foods are

removed. Refer to the "Care and Cleaning Instructions"

for detailed kettle washing procedures.

MARINE LOCK

If your unit is equipped with a

marine lock to prevent

accidental tilting, the following

procedure should be used to tilt

the kettle.

1. Grasp the tilt handle with your right hand.

2. Push the marine lock button down with your

left hand to unlock tilting mechanism.

3. Pull the handle to tilt kettle.

4. When you return the kettle to its upright

position the marine lock will latch

automatically.

Temperature Approximate

Control Product Temperature

Setting °F °C

MIN. 120 49

1. 130 54

2. 145 63

3. 160 71

4. 170 77

5. 185 85

6. 195 91

7. 210 99

8. 230 110

9. 245 118

MAX.

265 130

NOTE: Certain combinations of ingredients will

result in temperature variations

Page 8

5

CARE AND CLEANING

Your kettle must be cleaned regularly to maintain its

fast, efficient cooking performance, and to ensure its

continued safe, reliable operation.

WARNING: Do not use chloride base detergents.

1. Place the kettle's On-Off Toggle Switch (1) to

the "OFF" position.

2. Prepare a warm water and mild detergent

solution in the kettle.

3. Remove food soil inside the kettle using a

nylon brush. Do not use a metal bristle brush,

as this may permanently damage the kettle's

stainless steel surface.

4. Loosen food which is stuck to the kettle by

allowing it to soak at a low temperature

setting.

5. Tilt kettle forward to drain wash water.

6. Rinse kettle interior thoroughly, then drain the

rinse water.

7. Using mild soapy water and a damp sponge,

wash the exterior of the kettle, rinse, and dry.

8. Leave the cover off when the kettle is not in

use.

NOTE: For more difficult cleaning applications one of

the following can be used: alcohol, baking soda,

vinegar, or a solution of ammonia in water. Avoid the use

of chloride cleansers, which may damage the kettle's

stainless steel surface.

WARNING: Steel wool should never be used for

cleaning the cooking chamber of the kettle. Particles of

steel wool become embedded in the cooking surface

and rust, which may corrode the stainless steel.

MARINE LOCK

Use a small nylon bristle brush to remove food and

debris from pivot point. If lock is sticking have

maintenance disassemble and clean pieces individually

and reassemble.

CLEANING INSTRUCTIONS

Page 9

6

SERVICE PARTS

WARRANTY

Our Company supports a worldwide network of Maintenance and Repair Centers. Contact your nearest Maintenance and

Repair Centre for replacement parts, service, or information regarding the proper maintenance and repair of your cooking

equipment

In order to preserve the various agency safety certification (UL, NSF, ASME/Ntl. Bd., etc.), only factory-supplied

replacement parts should be used. The use of other than factory supplied replacement parts will void warranty.

FAUCET ASSEMBLY

ITEM PART DESCRIPTION QTY.

NO. NO.

1. KE50825-2 3/4" Spout . . . . . . . . . . . . . . . . . . . . .1

2. FA95022 Retaining Ring . . . . . . . . . . . . . . . . . .1

3. FA05002-19 "O" Ring . . . . . . . . . . . . . . . . . . . . . . .1

4. KE51736 Long Faucet Nut . . . . . . . . . . . . . . . .1

5. SE50020 Hot Water Stem Assembly . . . . . . . . .1

(Double Pantry only)

6. SE50021 Cold Water Stem Assembly . . . . . . . .1

7. KE51401 Single Pantry Body . . . . . . . . . . . . . .1

(c/w Item No. 6)

8. KE50335 Adapter Washer . . . . . . . . . . . . . . . .1

(Single Pantry only)

9. KE51403 Double Pantry Body . . . . . . . . . . . . .1

(c/w Item No. 5&6)

10. KE54159 Faucet Mounting Bracket . . . . . . . . . .1

11. FA11258 Hex Cap Screw . . . . . . . . . . . . . . . . .2

12. FA30505 Washer . . . . . . . . . . . . . . . . . . . . . . .2

13. FA21008 Hex Nut . . . . . . . . . . . . . . . . . . . . . . .2

14. SE50447 Washer Horseshoe . . . . . . . . . . . . . .1

1

1

2

2

3

3

4

4

5

9

10

10

13

8

12

11

13

14

12

11

7

6

6

Page 10

7

MAIN COMPONENTS

ITEM NO. PART NO. DESCRIPTION QTY.

1. SK50403 Bronze Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. SK50434 Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3. KE00349 Bolt, Modified . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. KE54247 Hex Bolt, 14-20x3/4" lg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

5. KE02004-1 Trunnion Support Bar and Brace Assembly (6 gallon) . . . . . . . . . . . . . . . . . . .1

5. KE02004-2 Trunnion Support Bar and Brace Assembly (12 gallon) . . . . . . . . . . . . . . . . . .1

6. KE50474 Foot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

7. KE50429-2 Pressure Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

8. FA05002-21 "O" Ring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

9. FI05022 Compression Fitting, Brass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

10. KE50151-E Knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

11. KE54670-2 Handle, 6 gallon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE54670-3 Handle, 12 gallon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

12. FA05002-29 "O" Ring for Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

13. KE95457 Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

14. FA11258 Hex Capa Screw, 14-20x3/4" lg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

15. SA95116 Marine Lock Replacement Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

16. KE50997 Blow Down Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

17. KE51723-1 Safety Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

18. KE54676 Bolt c/w "O" Ring Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

20. SK50562 Cord Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

21. KE54721-2 Water Tight Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

22. KE54468 Water Level Sight Glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

23. KE52196-1 Plug Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

24. KE53316 Safety Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

25. KE50294-1 Mercury Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

26. KE00515 Thermistor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

27. KE50556-1 Water Level Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

11

22

33

4

5

6

7 8 9

10

11

12

SEE

FAUCET

DRAWING

14

15

16

17

18

20

21

22

23

24

25

26

27

13

Page 11

8

CONSOLE

ITEM NO. PART NO. DESCRIPTION QTY.

1. KE50504 Switch, Toggle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. SK50062 Rubber Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3. KE50988-2 Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. KE51005 Rubber Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5. KE50569-1 Knob, Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

6. KE50567-1 L.E.D., Red . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

7. FA05002-18 "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

8. KE50568-1 L.E.D., Green . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

9. KE53469-2 Ignition Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

10. KE54308 High Voltage Lead Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

11. KE54309 Low Voltage Lead Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

12. WH KGT Wiring Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

13. F01518-1 Gas Shut-Off Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

14. FA05002-25 "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

15. KE54434 Trunnion Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

16. FA95050 Retaining Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

TO MAIN GAS

SUPPLY

SEE COMPONENT MOUNTING

BRACKET ASSEMBLY DRAWING

SEE PIPING

ASSEMBLY

DRAWING

12

11

10

9

6

7

8

7

4

5

2

3

1

13

16

14

15

Page 12

9

COMPONENT MOUNTING BRACKET ASSEMBLY

ITEM NO. PART NO. DESCRIPTION QTY.

1-9 KE01928 Component Plate Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1. KE01927 Component Plate Weldment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. KE50753-7 Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. KE53838-20 Transformer, 120/24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE53838-18 Transformer, 220/24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5. KE53838-19 Transformer, 120/16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE53838-21 Transformer, 220/16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

6. KE00458 Solid State Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

7. KE50303 Box Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

8. FA11089 Screw, #8-32x1/4 lg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

9. FA11056 Screw, #6-32x1/2 lg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2

1

6

8

5

4

7

Page 13

10

PIPING ASSEMBLY

ITEM NO. PART NO. DESCRIPTION QTY.

1. KE54667 Gas Burner Tube, 12 gallon kettle . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE54667-1 Gas Burner Tube, 6 gallon kettle . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. KE02012 Compression Fitting and Nipple Assembly . . . . . . . . . . . . . . . . . . . . .1

3. KE01921 Reducing Elbow Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. FI05222-1 Swivel Elbow, Modified . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5. FI05163-1 Adapter, 1/2 NPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

6. KE53515-1 Gas Valve, Modified . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

7. FI00134 Street Elbow, 3/4" NPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

8. KE01929 Feed Pipe Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

9. KE01500-2 Gas Burner Assembly, 12 gallon kettle . . . . . . . . . . . . . . . . . . . . . . . .1

KE01500-3 Gas Burner Assembly, 6 gallon kettle . . . . . . . . . . . . . . . . . . . . . . . . .1

10. KE53406-11 Gas Orifice, Natural Gas, 12 gallon kettle . . . . . . . . . . . . . . . . . . . . . .1

KE53406-1 Gas Orifice, Natural Gas, 6 gallon kettle . . . . . . . . . . . . . . . . . . . . . . .1

KE53406-12 Gas Orifice, Propane Gas, 12 gallon kettle . . . . . . . . . . . . . . . . . . . . .1

KE53406-2 Gas Orifice, Propane Gas, 6 gallon kettle . . . . . . . . . . . . . . . . . . . . . .1

11. KE54666 Orifice Support Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

12. KE54700 Orifice Support Block, 6 gallon kettle only . . . . . . . . . . . . . . . . . . . . .1

13. FI05198-5 Compression Elbow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

14. KE53437-1 Ignitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3

1

2

4

5

6

7

8

9

10

11

12

13

14

Page 14

11

Cleveland Range equipment requires little preventative maintenance. We do however provide the following

chart as a guideline for inspection and maintenance to keep your unit functioning at 100%.

INSPECTION AND MAINTENANCE CHECK LIST

The following check should be completed every six months or more frequently if unit is in a high volume

facility.

WARNING: It is imperative that damaged seals be repaired immediately to prevent equipment failure

and/or damage.

ITEM CHECK

SIDE CONSOLE SEAL Insure there are six screws firmly holding down the cover. If not replace

screws and/or missing or worn nylon anchor nuts.

BOTTOM COVER GASKET Check to see it is in place and is not cracked or split.

TILT HANDLE Check handle for tightness. If loose apply lock tight and reinstall.

Check handle knob is on end of handle and firmly tightened. If loose

apply lock tight and reinstall.

PRESSURE GAUGE Check that the gauge does not have moisture on its inside face.

Replace if moisture is present.

Check that the gauge shows a vacuum (needle is well into the Green

zone) when cold and shows between 25-40 psi when unit is hot. If not

follow Vacuum Leak Test (page 12).

Check that the gauge is firmly held against the console. Tighten if

necessary.

PRESSURE RELIEF VALVE Check pressure relief valve as described in Pressure Relief Valve

Periodic Testing Procedure (page 12).

TEMPERATURE CHECK Following Calibrating Procedure (page 12) check the inner kettle

surface temperature with a digital surface thermometer and adjust if

required.

MAINTENANCE

ALL SERVICE MUST BE PERFORMED BY A QUALIFIED SERVICE TECHNICIAN.

Page 15

12

CALIBRATING PROCEDURE

1. Insure the unit has a vacuum before you begin

calibrating procedures. If unit requires venting refer

to " Kettle Venting Instructions" in this manual.

2. Turn kettle on and set temperature dial to maximum

(10).

3. Allow the unit to cycle twice.

4. Check temperature of the inner kettle surface with

a digital surface thermometer.

5. Temperature should be 265° F.

6. Using a screw driver adjust temperature by turning

the potentiometer on the black box. Turn very little.

Turn clockwise to INCREASES and counterclockwise to DECREASE temperature.

7. Allow the unit to cycle twice.

8. Check temperature of the inner kettle surface with

a digital surface thermometer.

9. Repeat steps 4 through 8 until unit is calibrated.

VACUUM LEAK TEST

If the kettle will not hold vacuum, test for leaks at the

water fill plug, sight gauge safety valve, probe, and

vacuum pressure gauge fittings. We suggest mixing a

50/50 solution of liquid detergent and water while

heating the kettle to at least 5 psi pressure. Then shut

off power to the kettle.

The soapy solution should be applied to the suspected

area while the gauge shows at least 5 psi pressure. Any

bubbles which appear will indicate a leak.

PRESSURE RELIEF VALVE

PERIODIC TESTING

PROCEDURE

Most insurance agencies require periodic testing of

pressure relief valves used on pressure vessels. This

procedure will allow you to safely and quickly test your

kettle's pressure relief valve. We recommend this test be

performed twice a year.

NOTE: The following instruction is intended for use by

qualified service personnel.

WARNING: Kettle surface will be hot and steam will be

released during testing. Take necessary precautions

including the use of gloves and eye protection to

prevent personal injury.

1. With the kettle empty, turn unit ON and set

temperature control knob to 10 (Max.). Allow the

kettle to heat until the unit cycles off.

2. Switch unit OFF and disconnect main power at

fused disconnect switch.

3. Stand to the side of the pressure relief valve

discharge tube and pull valve open for a maximum

of one second. Repeat test three to four times. Each

time the mechanism should move freely and be

accompanied by a rapid escape of steam.

If valve appears to be sticking replace pressure relief

valve.

If foreign material is discharged then drain kettle and

replace pressure relief valve.

See Reservoir Fill Procedure (page 13) for full

instructions on the correct method for refilling kettle

jacket.

WARNING: Improper refilling of kettle jacket will result

in irreversible damage to unit.

NOTE: Rust inhibitor is purchased locally. Read

directions and do not exceed manufacturer's

recommendation (excessive rust inhibitor can also

cause solidification).

DANGER: PRESSURE RELIEF

VALVE WILL EXHAUST HIGH

TEMPERATURE STEAM. CONTACT

WITH SKIN COULD RESULT IN

SERIOUS BURNS. KEEP FACE,

HANDS AND BODY CLEAR OF DISCHARGE.

DANGER: WORKING ON MACHINES

WITH POWER COULD RESULT IN

SEVERE ELECTRICAL SHOCK.

WARNING: IMPROPER REFILLING OF

KETTLE JACKET WILL RESULT IN

IRREVERSIBLE DAMAGE TO UNIT.

Page 16

RESERVOIR FILL

PROCEDURES

The kettle's water level must be maintained at the

proper level. Under normal operating conditions, the

sealed water reservoir should never require the addition

of water.

If the red "low water" light comes on during use (while

the kettle is in an upright position), the water level has

reached a critically low level. The low water protection

control has automatically shut off the gas burner. The

following procedure must be completed before further

use:

NOTE: Have a qualified service technician repair the

leakage problem and add water to the unit. Ensure that

the red "low water" light is on when the kettle is upright.

On tilting kettles, it is normal for the red light to come on

when the kettle is in a tilted position.

CAUTION: Only distilled water should be used when

adding water to a partially filled water reservoir (If unit is

completely empty see Kettle Jacket Filling & Draining

Procedures on page 15). Local tap water conditions

may cause kettle damage which is not covered under

warranty. Rust inhibitor is purchased locally. Read

directions and do not exceed manufacturer's

recommendation (excessive rust inhibitor can also

cause solidification).

DISTILLED WATER REQUIREMENTS

Kettle When Red “Low Water Light”

Capacity comes on, add Distilled Water

6 gallon 70 ounces

12 gallon 120 ounces

1. Ensure kettle is at room

temperature and pressure

gauge showing zero or

less pressure.

2. Shut off power to the kettle at the fused

disconnect switch.

3. Unscrew and remove plug

nut from top of pressure

gauge assembly.

4. With kettle in the upright position, add a

mixture of distilled water and rust inhibitor

through the plug nut hole with a funnel.

5. Fill the unit to the high

level mark on the sight

glass.

6. Replace plug nut and carefully tighten. Do not

over tighten.

7. Restore power to the kettle.

8. The kettle must now be vented. Refer to the

Kettle Venting Instructions (page 14).

DANGER: PRESSURE RELIEF

VALVE WILL EXHAUST HIGH

TEMPERATURE STEAM. CONTACT

WITH SKIN COULD RESULT IN

SERIOUS BURNS. KEEP FACE,

HANDS AND BODY CLEAR OF DISCHARGE.

DANGER: WORKING ON MACHINES

WITH POWER COULD RESULT IN

SEVERE ELECTRICAL SHOCK.

13

Plug Nut

Sight

Glass

WARNING: IMPROPER REFILLING OF

KETTLE JACKET WILL RESULT IN

IRREVERSIBLE DAMAGE TO UNIT.

50

0

100

150

200

250

300

350

400

40

50

60

0

10

20

30

psi

kPa

V

E

N

T

A

I

R

Page 17

14

KETTLE VENTING

INSTRUCTIONS

The following venting procedure

should be followed when the

Vacuum/Pressure Gauge needle

is in

the "VENT AIR" zone:

NOTE:

Check for and eliminate

leaks prior to venting (See

Repairing Leaks in Steam Jacketed

Kettle Fittings - page 14).

1. Turn kettle ON and set

Temperature Control Knob

to 10 (Max.), heat the

empty kettle until unit

cycles off.

3. Turn kettle OFF. Add cold

water to kettle until its

surface temperature is

below 100°F. The pressure

gauge needle should be

in the green zone,

indicating a vacuum in the

kettle’s jacket.

2. Stand to the side of the

pressure relief valve

discharge tube and pull

ring six to ten times,

holding valve open for

two seconds each time.

50

0

100

150

200

250

300

350

400

40

50

60

0

10

20

30

psi

kPa

V

E

N

T

A

I

R

NOTE: If unit cycles ON, stop venting and wait

for kettle to cycle OFF before continuing.

50

0

100

150

200

250

300

350

400

40

50

60

0

10

20

30

psi

kPa

V

E

N

T

A

I

R

DANGER: PRESSURE RELIEF

VALVE WILL EXHAUST HIGH

TEMPERATURE STEAM. CONTACT

WITH SKIN COULD RESULT IN

SERIOUS BURNS. KEEP FACE,

HANDS AND BODY CLEAR OF DISCHARGE.

DANGER: WORKING ON MACHINES

WITH POWER COULD RESULT IN

SEVERE ELECTRICAL SHOCK.

REPAIRING LEAKS IN STEAM JACKETED KETTLE FITTINGS

If unit will not hold a vacuum the most likely cause is a leak at one of the fittings.

Often, the easiest way to eliminate a leak is reseal the suspect areas.

1. Water Level Probe Remove, clean threads, apply teflon thread sealant and reinstall.

2. Pressure Relief Valve A/ Inspect for signs of leaks. Replace if required.

B/ Remove, clean threads, apply teflon thread sealant and reinstall.

3. Pressure Gauge A/ Inspect face of gauge. If it contains moisture on the inside of face

replace.

B/ Inspect compression nut and inspect for tightness. If it looks cracked

or damaged replace.

5

6

7

4

3

8

2

9

10

1

Page 18

Under normal circumstances the kettle does not require

the draining of all fluid. If the red “low water” light is on,

follow the Reservoir Fill Procedures (page 13) in this

manual.

If unit must be drained follow the procedures described

on the following pages.

Use only a mixture of water and rust inhibitor to refill

kettle jacket (see instructions below).

Contact your local water treatment company and

purchase rust inhibitor with the specifications described

below.

Recommended Corrosion

Inhibitors for Closed

Systems.

DESCRIPTION

Recommended for our units is a blend of SODIUM

NITRITE and BORAX for corrosion inhibition of ferrous

metals and axoles for copper and copper alloy

corrosion protection. Product should be formulated for

hot or cold closed recalculating water systems.

Source the chemicals stated above from your local

water treatment company. Mix only with water and

follow manufactures recommended mixing rate.

DISPOSAL OF INHIBITOR

Do not dispose of chemicals in any system which may

discharge into water supplies used for drinking or

washing or that could accidentally discharge into such

systems, or into stream accessible to animals.

Follow all Federal, State and local codes when

disposing of product.

Refill Quantities

(water and

corrosion inhibitor mixture)

Kettle Size U.S. Gallons Liters

6 gallon 1.5 5.70

12 gallon 2.19 8.3

WARNING: IMPROPER REFILLING OF

KETTLE JACKET WILL RESULT IN

IRREVERSIBLE DAMAGE TO UNIT.

15

KETTLE JACKET FILLING &

DRAINING PROCEDURES

DANGER: EXTREMELY

HOT SURFACES.

WORK ONLY ON COLD

KETTLE.

Draining Procedure

1. Shut off gas supply.

2. Disconnect gas line and electrical connection.

3. Remove bolts holding kettle to table.

4. Pull ring on pressure relief valve to insure there is

no pressure within the kettle jacket.

5. Remove filler plug (located next to the pressure

relief valve).

6. Remove sight glass.

7. Tilt kettle on its side (sight glass down) and allow

to drain.

8. Tilt kettle upright and refill with water. Tilt kettle

again on its side and allow to drain. Repeat until

water drains clear.

Refilling Unit (when empty)

1. Apply a thread sealant (i.e. Teflon tape) to the sight

glass threads and replace.

2. Fill unit with a mixture of corrosion inhibitor and

distilled water until the water reaches the “HI” line

on the sight glass.

3. Apply a thread sealant (i.e. Teflon tape) to the filler

plug threads and replace.

4. Turn kettle on and check for leaks at sight glass

and filler plug. See Vacuum Leak Test (page 12).

5. Vent kettle. See Kettle Venting Instructions (page

14) for proper procedure.

Pressure Relief Valve

Drain

Plug

Cap

Sight

Glass

Filler Plug

DANGER: PRESSURE RELIEF

VALVE WILL EXHAUST HIGH

TEMPERATURE STEAM. CONTACT

WITH SKIN COULD RESULT IN

SERIOUS BURNS. KEEP FACE,

HANDS AND BODY CLEAR OF DISCHARGE.

DANGER: WORKING ON MACHINES

WITH POWER COULD RESULT IN

SEVERE ELECTRICAL SHOCK.

Page 19

OPERATING SEQUENCES

1. Turn On-Off Switch "ON" * 16 volt relay is energized and powers solid state control system.

2. Temperature Control Knob * Temperature knob is turned up and control box calls for heat.

* Relay (RY-1) closes and powers 24 volt transformer.

* Ignition control box is powered.

3. Ignitor Sparks * Gas valve is energized

* Ignitor sparks and ignition occurs.

4. Temperature Reached * Solid state controls senses temperature reached.

* Relay (RY-1) opens and 24 volt transformer loses power.

* Ignition control box is turned off.

* Gas valve closes.

5. Maintaining Temperature * Solid state controls senses temperature drop.

* Relay (RY-1) closes and powers 24 volt transformer.

* Ignitor control box is powered.

* Steps three and four are repeated.

SOLID STATE CONTROL SEQUENCE

Our solid state controls consist of the following components.

On-Off Toggle Switch * Provides or interrupts electrical power to the control system.

Control Box * Analyzes inputs from water level probe, tilt switch, potentiometer, thermistor.

* Energizes control relay (RY-1)

Water Level Probe * Senses water in jacket.

Tilt Switch * When kettle is in upright position tilt switch is closed to complete circuit between

pin #8, the relay (RY-1) and green indicator light.

Potentiometer * Rotate to change resistance from 0 to 50,000 ohms. This resistance is

compared to the resistance on the thermistor using a voltage comparator circuit

inside the control box.

* If the resistance is lower than the thermistor resistance then the control box will

provide 16v dc to pin #8. The green indicator light illuminates and the control

relay (RY-1) is energized closed to provide power to the heating system.

Thermistor * The thermistor resistance decreases as temperature increases. When the,

thermistor resistance equals the potentiometer then 16v dc is removed from pin

#8. The control relay (RY-1) returns to the normally open position.

Green LED Light Indicates that the control box is calling for heat. pin #8 powered.

Red LED Light Indicates that the water level probe is not immersed in water. Not enough water

in the jacket or kettle tilted.

Relay (RY-1) When energized allows the heating circuit to function. Electric elements or gas

burner system.

NOTES:

* A ground loop circuit must be established between kettle body, water in jacket, water level probe and

control box. If this loop is present, it indicates that there is sufficient water in the kettle for safe operation.

* If there is not sufficient water in the jacket then the loop is broken and the control box will prevent 16v DC

from being supplied to pin #8. The control relay (RY-1 ) will remain (or return) to the normally open

position and the unit cannot heat. The red LED light will be illuminated.

16

Page 20

17

FIELD CONVERSION

INSTRUCTIONS

Natural Gas to

Propane Gas

NOTE: Use thread sealant compatible with

propane gas on all threaded piping connections.

1. Shut off main gas supply and disconnect

kettle from supply line.

2. Remove GAS SHUT-OFF VALVE from kettle

supply pipe and install REGULATOR (pre-set

to 10 " W.C. pressure) supplied in field

conversion kit.

3. Re-install SHUT-OFF VALVE using PIPE

NIPPLE supplied in kit.

4. Remove side cover from control console.

5. Remove PRESSURE REGULATOR UNIT from

GAS COMBINATION VALVE inside console,

and replace with blocked PRESSURE

REGULATOR UNIT from kit. Make sure

GASKET is correctly seated in recess in GAS

COMBINATION VALVE during installation.

6. Tilt kettle. Remove kettle side box cover.

Remove screw securing end of BURNER.

Remove BURNER. Support MAIN ORIFICE

FITTING and remove MAIN ORIFICE. Install

new orifice from kit.

7. Replace BURNER. Check ORIFICE/BURNER

alignment insuring ORIFICE points straight

into the center of the BURNER.

8. Reconnect to gas supply. Turn on propane

gas. Tilt kettle to upright position, turn on

power and check all gas connections for leaks.

9. Turn off power and main gas supply, and

replace all covers. Attach GAS

IDENTIFICATION STICKER to nameplate.

Field Conversion Kit

PART NO. DESCRIPTION

SE50438 Field Conversion Kit, 6 gallon

SE50438-1 Field Conversion Kit, 12 gallon

KE53406-2 Main Orifice, 6 gallon

KE53406-12 Main Orifice, 12 gallon

KE54618 Regulator

FI00607 Pipe Nipple

KE53515-2 Pressure Regulator Unit & Gasket

NOTE:

Place GAS IDENTIFICATION STICKER on

face of GAS COMBINATION VALVE.

GAS

SHUT-OFF

VALVE

REGULATOR

PIPE

NIPPLE

PRESSURE

REGULATOR

UNIT

GAS

COMBINATION

VALVE

GASKET

THIS CONTROL

HAS BEEN

CONVERTED

TO LP

GAS

IDENTIFICATION

STICKER

BURNER

MAIN

ORIFICE

MAIN

ORIFICE

FITTING

TO MAIN GAS

SUPPLY

SE90027 Rev. 0

Page 21

18

WIRING DIAGRAM

Loading...

Loading...