Cleveland

™

Maintenance Procedures

& Parts Lists

Gas Floor Model Kettles

For units built after April 2010

KGL-40, KGL-60, KGL-80, KGL-100

KGL-40-T, KGL-60-T, KGL-80-T

KGL-40-SH, KGL-60-SH,

KGL-40-TSH

KGL-40-T

For your future reference.

Model # ______________________________________

Serial # _______________________________________

KGL-40

KGL-40SH

1333 East 179th St., Cleveland, Ohio, U.S.A. 44110

Ph: 216.481.4900 Fx: 216.481.3782

www.clevelandrange.com

This manual is to be used in conjunction with the

“Operators Manual”. See “Operators Manual” for

safety warnings, correct operation, installation

and preventative maintenance.

SE95003-1 PRTS Rev. 8

February 2012

STATEMENT OF RESPONSIBILITIES /

DÉCLARATION DES RESPONSABILITÉS /

DECLARACIÓN DE RESPONSABILIDADES

This document is for use by experienced

and trained Qualified Cleveland Range,

LLC Authorized Service Representatives

who are familiar with both the safety

procedures, and equipment they

service. Cleveland Range, LLC assumes

no liability for any death, injury,

equipment damage, or property damage

resulting from use of, improper use of,

or failure to use the information

contained in this document. Cleveland

Range, LLC has made every effort to

provide accurate information in this

document, but cannot guarantee that

this document does not contain

unintentional errors and omissions.

The information in this document may

be subject to technical and technological

changes, revisions, or updates.

Cleveland Range, LLC assumes no

liability or responsibility regarding errata,

changes, revisions, or updates.

Qualified Cleveland Range, LLC

Authorized Service Representatives are

obligated to follow industry standard

safety procedures, including, but not

limited to, OSHA regulations, and

disconnect / lock out / tag out

procedures for all utilities including

steam, and disconnect / lock out / tag

out procedures for gas, electric, and

steam powered equipment and / or

appliances.

All utilities (gas, electric, water and

steam) should be turned OFF to the

equipment and locked out of operation

according to OSHA approved practices

during any servicing of Cleveland Range

equipment

Qualified Cleveland Range, LLC

Authorized Service Representatives are

obligated to maintain up-to-date

knowledge, skills, materials and

equipment.

Ce document est destiné à l’usage des

Représentants de Service qualifiés et

autorisés de Cleveland Range, LLC qui

possèdent l’expérience et la formation

ainsi que la bonne connaissance des

mesures de sécurité et du matériel qu’ils

entretiennent.

Cleveland Range, LLC décline toute

responsabilité pour tout cas de décès,

blessure, dommage matériel ou

dommage aux biens résultant de

l'utilisation, de la mauvaise utilisation ou

du manquement d’utilisation des

renseignements contenus dans ce

document.

Cleveland Range, LLC s’est efforcé à

fournir des renseignements précis dans

ce document mais ne peut garantir que

ce document soit exempt d’erreurs et

d’omissions non intentionnelles.

Les renseignements contenus dans ce

document peuvent être assujettis à des

changements techniques et

technologiques, des révisions ou des

mises à jour.

Cleveland Range, LLC décline toute

obligation ou responsabilité concernant

les errata, modifications, révisions ou

mises à jour.

Les Représentants de Service qualifiés

et autorisés de Cleveland Range, LLC

sont tenus de se conformer aux

mesures de sécurité normalisées de

l’industrie, y compris, mais sans s'y

limiter, les réglementations de l'OSHA,

les procédures de débranchement /

verrouillage / étiquetage relatives à tous

les services publics, dont

l’approvisionnement en vapeur, et les

procédures de débranchement /

verrouillage / étiquetage relatives aux

équipements et/ou appareils

fonctionnant au gaz, à l’électricité et à la

vapeur.

Au cours de tout entretien d’un appareil

Cleveland Range, tous les services

publics (gaz, électricité, eau et vapeur)

doivent être FERMÉS au niveau de

l’appareil et le dispositif de

fonctionnement doit être verrouillé

suivant les pratiques approuvées de

l’OSHA.

Les Représentants de Service qualifiés

et autorisés de Cleveland Range, LLC

sont tenus d’actualiser en permanence

leurs connaissances, compétences,

matériel et équipement.

Este documento está destinado para el

uso de los Representantes de Servicio

calificados y autorizados de Cleveland

Range, LLC quienes cuentan con la

experiencia y la capacitación así como el

buen conocimiento de las medidas de

seguridad y de los equipos que

mantienen.

Cleveland Range, LLC, declina toda

responsabilidad en caso de cualquier

fallecimiento, lesiones, daños al equipo o

daños a la propiedad resultantes de la

utilización, del uso indebido o de la falta

de utilización de la información provista

en este documento.

Cleveland Range, LLC se ha esforzado

en suministrar información precisa en

este documento, pero no puede

garantizar que este documento esté

exento de errores y de omisiones no

intencionales.

La información contenida en este

documento podría estar sujeta a cambios

técnicos o tecnológicos, revisiones o

actualizaciones. Cleveland Range, LLC

declina toda obligación o responsabilidad

con respecto a erratas, modificaciones,

revisiones o actualizaciones.

Los Representantes de Servicio

calificados y autorizados de Cleveland

Range, LLC tienen la obligación de seguir

los procedimientos estándar de seguridad

de la industria; los cuales incluyen pero

no se limitan a los reglamentos de la

OSHA (La Administración de la Seguridad

y Salud Ocupacionales), los

procedimientos de desconexión, cierre y

etiquetado relativos a todos los servicios

públicos incluyendo el suministro de vapor

y los procedimientos de desconexión,

cierre y etiquetado para los equipos y/o

aparatos que funcionan a base de gas,

electricidad o vapor.

Cuando se esté dando servicio o

mantenimiento a un aparato de Cleveland

Range, todos los servicios públicos (gas,

electricidad, agua y vapor) deben estar

APAGADOS para el equipo en cuestión y

se debe seguir el procedimiento de cierre

de operaciones de acuerdo con las

prácticas aprobadas por la OSHA.

Los Representantes de Servicio

calificados y autorizados de Cleveland

Range, LLC tienen la obligación de

actualizar constantemente sus

conocimientos, destrezas, materiales y

equipamiento.

TROUBLESHOOTING AND

0

!

0

!

MAINTENANCE PROCEDURES

The following trouble shooting guide and maintenance procedures

are meant to be used by Qualified Service Technician

ANY REPAIRS TO THE PRESSURE VESSEL MUST BE DONE BY A CERTIFIED PRESSURE

VESSEL REPAIR SHOP AND ALL REPAIR METHODS AND MATERIALS MUST BE

APPROVED BY THE MANUFACTURER.

For periodic maintenance recommendations see “Operators Manual”.

TROUBLESHOOTING GUIDES

GENERAL

1. To turn the unit on, turn the switch to the on

position.

■ Power is sent to primary side of the

120vac/16vac transformer.

■ Power is sent to the normally closed high limit.

■ From the high limit power is sent to the normally

open contacts of the 12VDC relay and the L1 and

L2 terminals of the ignition module.

2. From the secondary of the transformer 16VAC is

sent to the controller.

■ Power is sent to the red LED (low water indicator

light) from terminal 4 of the controller.

■ If the water probe is grounded through water the

LED will go off.

■ If the water probe is not grounded the LED will

remain on and the unit will not heat.

■ If the resistance of the thermistor is higher than

the setting of the potentiometer( the unit is calling

for heat) then 16VDC is sent to the coil of the relay

and the green LED (heat indicator light)

■ The 12VDC relay will close until the unit reaches

temperature

3. With the contacts of the relay closed, 120VAC is

sent to the blower and primary coil of the

120VAC/24VAC transformer.

■ From the secondary of the 24VAC transformer

power is sent to the normally open contacts of the

air switch.

■ When the air from the blower closes the air

switch, 24VAC is sent to the Th terminal of the

ignition module.

4. With both 120VAC (at L1 and L2) and 24VAC (at

Gnd and Th) to the ignition module then 120VAC

will be sent to the surface igniter.

5. After the ignition module has been energized for 24

seconds the module will send 24VAC to the gas

valve.

■ The gas will touch the hot igniter and ignite.

■ The kettle will build pressure until the controller is

satisfied by the thermistor at the setting of the

potentiometer.

■ The controller will then turn off the heat circuit

until the temperature of the kettle is below the

setting

TROUBLESHOOTING GUIDES (continued)

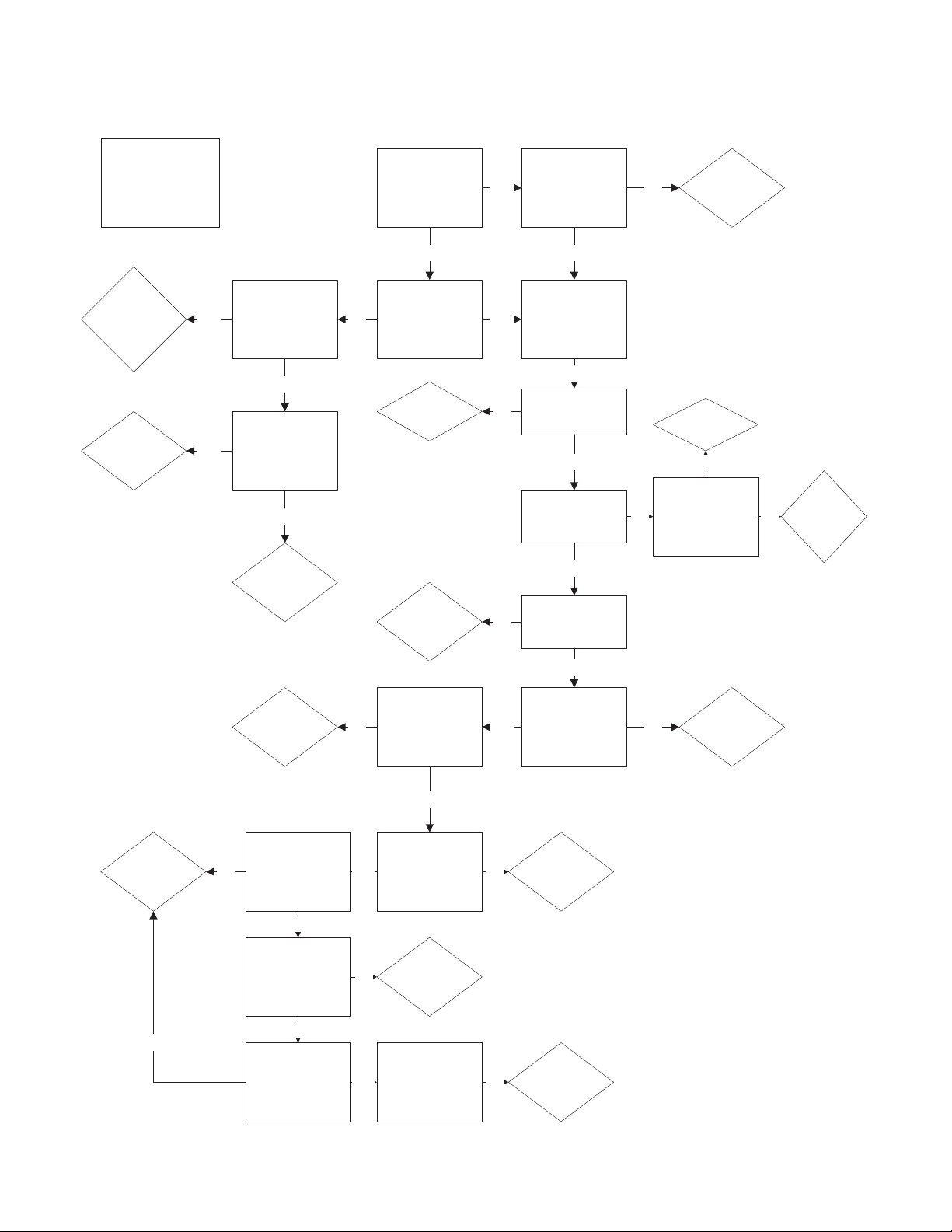

PROBLEM:

KGL

Kettle Won't

Heat

Does red light

come on when unit

is first turned on?

Does red light go

off shortly after

unit is turned on?

Yes

Add water to

jacket of Kettle.

With the

potentiometer set

at 10, is 12 VDC at

the coil of the

relay?

No

Yes

Is 16 VAC

measured across

Pins 9 and 10 on

the controller?

No

Yes

Is 16 VAC at the

secondary side of

the transformer?

No

Replace

the on/off

switch (toggle

or rotary).

Yes

Is there Power to

the primary of the

transformer?

No

Replace the

transformer.

Yes

Supply power

to the kettle.

No

Does the relay pull

in?

Yes

Replace the

relay.

No

Is there power to

the blower?

Yes

With the high limit

temporarily

bypassed, is

power at the

blower?

No

Replace the

high limit.

Yes

Replace

the wire to

the blower.

No

Is there power to

the ignition

transformer?

Is there 24 VAC at

the secondary of

the ignition

transformer?

Is there 24 VAC to

the igniton

module?

Yes

Does the blower

turn?

Replace

blower.

No

Yes

Yes

Replace the

DC relay.

Replace the

ignition

transformer

Replace the air

switch.

No

Is there 120 VAC

to the igniter?

Yes

Replace

ignition

module.

No

Does the ignitor

glow?

Yes

Replace the

ignitor.

No

No

Does the gas

valve get 24 VAC

20 sec. after the

ignitor is

energized?

Yes

No

Does the gas

valve open?

Yes

Replace gas

valve

No

Yes No

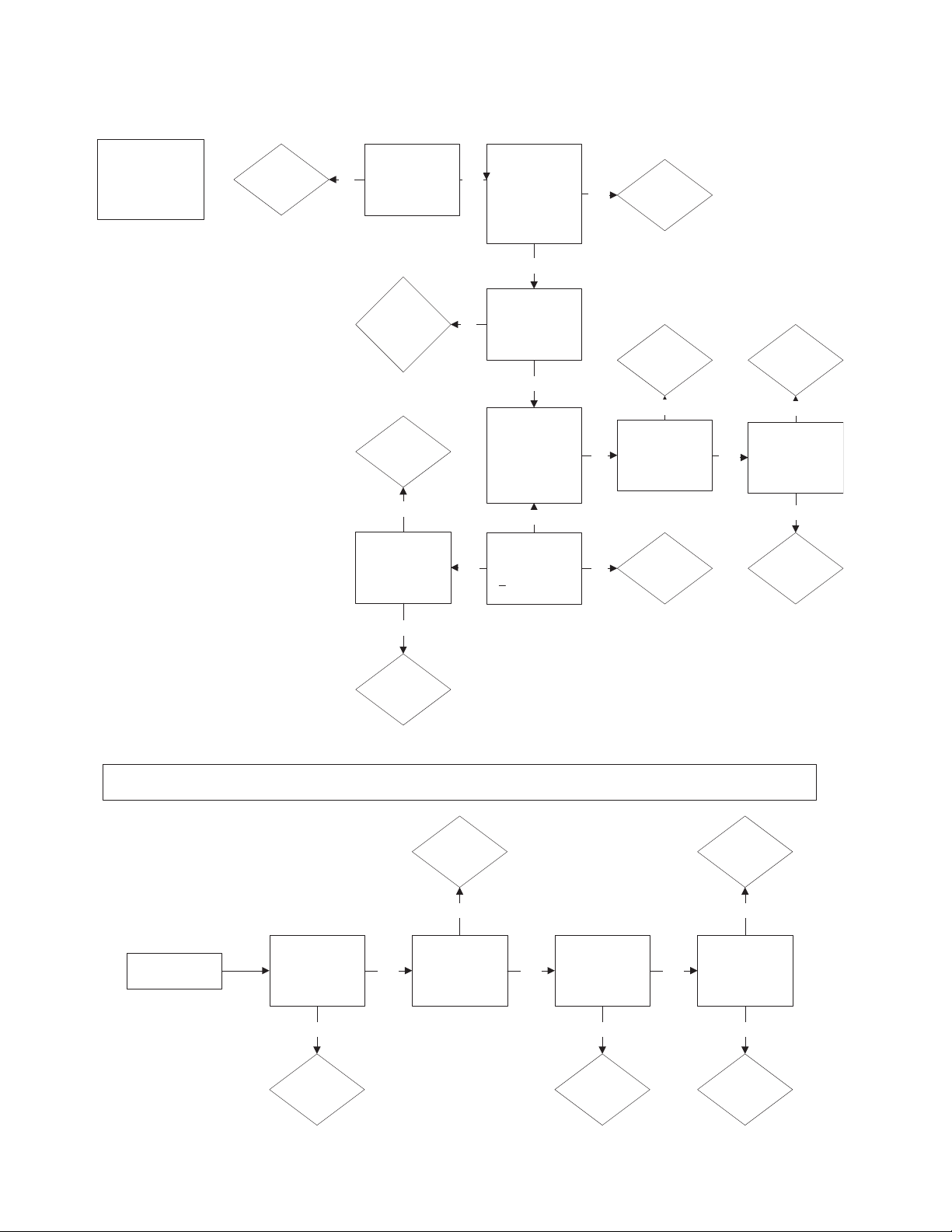

TROUBLESHOOTING GUIDES (continued)

PROBLEM:

KGL

Kettle Not

Hot Enough

W

ith kettle pot

empty and

temperature knob

s

et at 10, is the

t

emperature of the

surface of the pot

260 degrees?

U

nit is

operating

properly

Yes

W

hen unit is cold

(room temp) is the

p

ressure gauge in

the green?

N

o

V

ent

the kettle per

i

nstructions in

the manual.

N

o

When the unit is

calling for heat

(the green light is

on), is there flame

at the burner?

Y

es

I

s the resistance of

the thermister

100,000 ohms

+10% at room

temperature?

Yes

Replace the

thermister.

No

Is the

potentiometer

resistance 50,000

ohms at low and 0

ohms at high?

Yes

R

eplace

c

ontroller.

Yes

Replace the

potentiometer.

No

Does the kettle

h

eat at all?

Yes

See Problem:

K

ettle won't

h

eat.

No

Is the blower

turning?

Replace the

h

igh limit?

I

s there voltage to

the blower?

No

Y

es

N

o

Replace the

b

lower

No

Replace the air

switch

Y

es

PROBLEM: KGL Kettle Has Delayed Ignition

Delayed Igniton

Is the gas

pressure to the

burner 3.5" W.C.?

Adjust or

replace the gas

Valve.

Does the ignior

glow evenly

Replace ignitor.

No

Yes

No

Does the gas

valve get 24 VAC

20 seconds after

the ignitor is

energized?

Replace the

ignition

module.

Is the blower

turning?

Replace blower

and air switch.

Replace burner

Yes

No

Yes

No

Yes

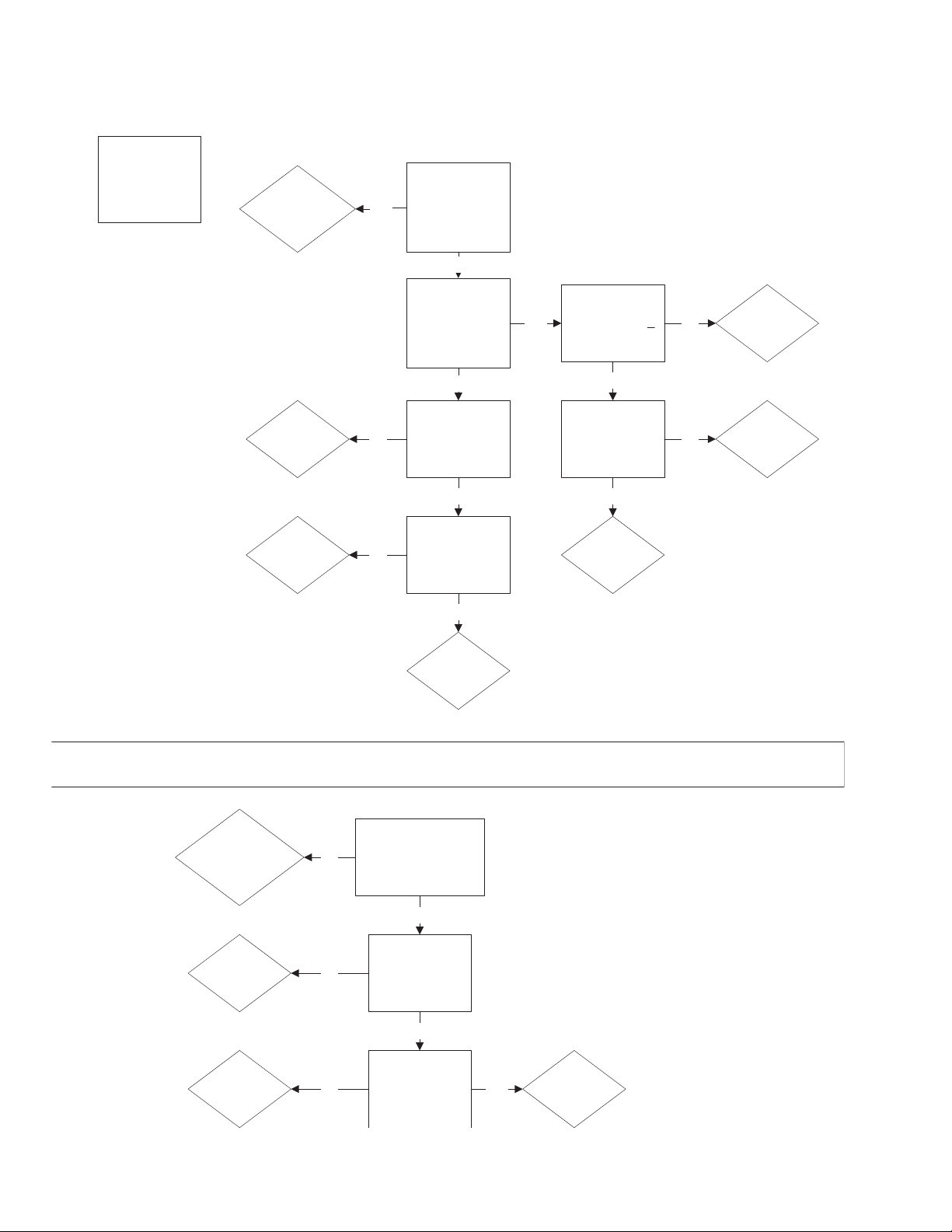

TROUBLESHOOTING GUIDES (continued)

PROBLEM:

KGL Kettle

Gets Too

Hot

With the kettle

empty and the

temperature set at

10, is the surface

temp 260-265

degrees?

The

kettle is working

properly.

Yes

Does the kettle

continue to call for

heat (green light

stays on) when

the kettle reaches

260-265 degrees?

No

Is there supply

voltage to the coil

of the gas valve?

No

Replace the

gas valve.

No

Is there any DC

voltage to the coil

of the relay?

Replace the

Relay

Yes

Replace the

controller

Yes

No

Is the resistance of

;the thermister

1

00,000 ohms +

10% at room

temperature?

Yes

Replace the

thermister.

No

Is the resistance of

the potentiometer

50,000 ohms at

the low setting and

0 ohms at high?

Yes

Replace the

controller

Replace the

potentiometer

No

Yes

PROBLEM: Red Add Water LED Stays On

Does Red LED stay on

after adding the proper

amount of distilled

water and rust inhibitor?

Add the proper

amount of distilled

water and rust

inhibitor.

No

Is the red LED on

with probe

grounded?

Yes

Clean or

replace water

probe.

No

Does the red LED

stay on with a

jumper between

pins 5 and 7 on

the controller?

Yes

Replace the

wire harness in

the trunion.

No

Replace the

controller.

Yes

KETTLE SAFETY INSPECTION AND TESTING

260º - 270º

MAXIMUM

KETTLE

TEMPERATURE

265º

✔

2

3

5

6

7

8

9

1

4

10

OFF

!

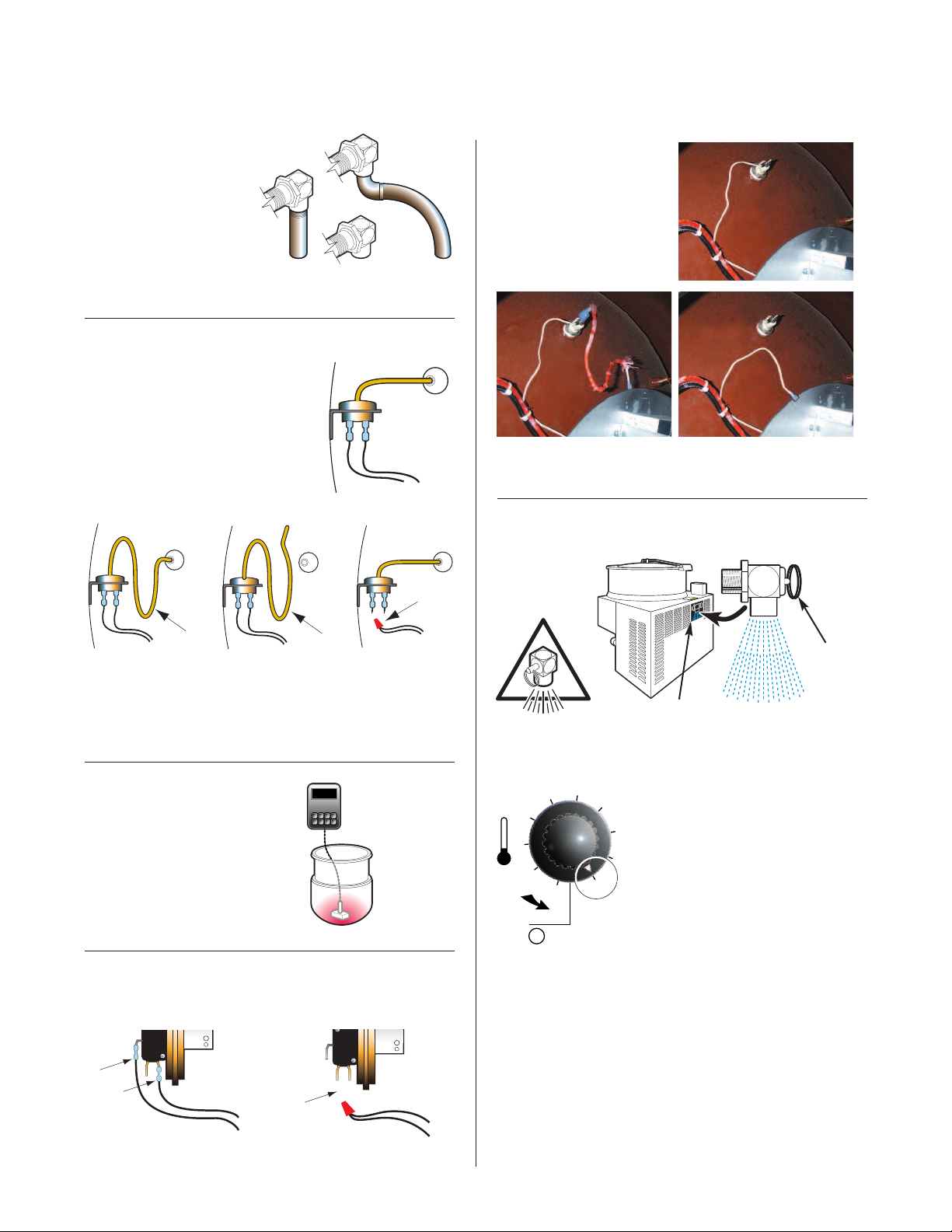

SAFETY VALVE

INSTALLATION:

The above illustrations show

the three variations of factory

installed Safety Valves.

Modifications are unacceptable.

SAFETY THERMOSTAT:

Correct

Installation

Incorrect

Installations

1.

2.

P

robe

fully

inserted

i

n tube

Wiring is properly

connected

3.

LOW WATER

LEVEL PROBE:

Probe

p

Probe bypassed by

running (A) an

✘

additional wire

roperly

attached

✔

Probe bypassed by

(B) grounding the

✘

connecting wire

PRESSURE RELIEF VALVE TESTING

Probe removed

partially

1.

Safety thermostat probe is not completely inserted into tubing.

2. Safety thermostat probe is removed from tubing.

3. Safety thermostat electrical connection is bypassed.

Probe removed

completely

OPERATING

THERMOSTAT:

If maximum temperature is not

in this range (on empty kettle),

refer to the “Calibrating

Procedure”.

GAS KETTLE AIR SWITCH:

Correct Incorrect

Wiring is properly connected Switch electrically bypassed

Thermostat

electrically bypassed

260° - 270° F

MAXIMUM

KETTLE

TEMPERATURE

Access

Panel

WARNING:

personal injury.

Pull Pressure Relief Valve Ring open for a maximum of

4.

one second. Repeat test three to four times. Each time

the mechanism should move freely and be

accompanied by a rapid escape of steam.

5.

Replace access panel.

IMPORTANT:

If valve appears to be sticking replace pressure relief

valve.

If foreign material is discharged then drain kettle and

replace pressure relief valve.

Use of gloves and eye protection to prevent

1. With the kettle empty, set On-

Off Switch/Temperature Control

to "10" (Max.). Allow the kettle

to heat until the unit cycles off.

Switch On-Off Switch/Temperature

2.

Control to

main power at fused disconnect

switch.

3. Remove Access Panel at back

of main kettle console.

"0"

(Off) and disconnect

Pressure

Relief

Valve

Ring

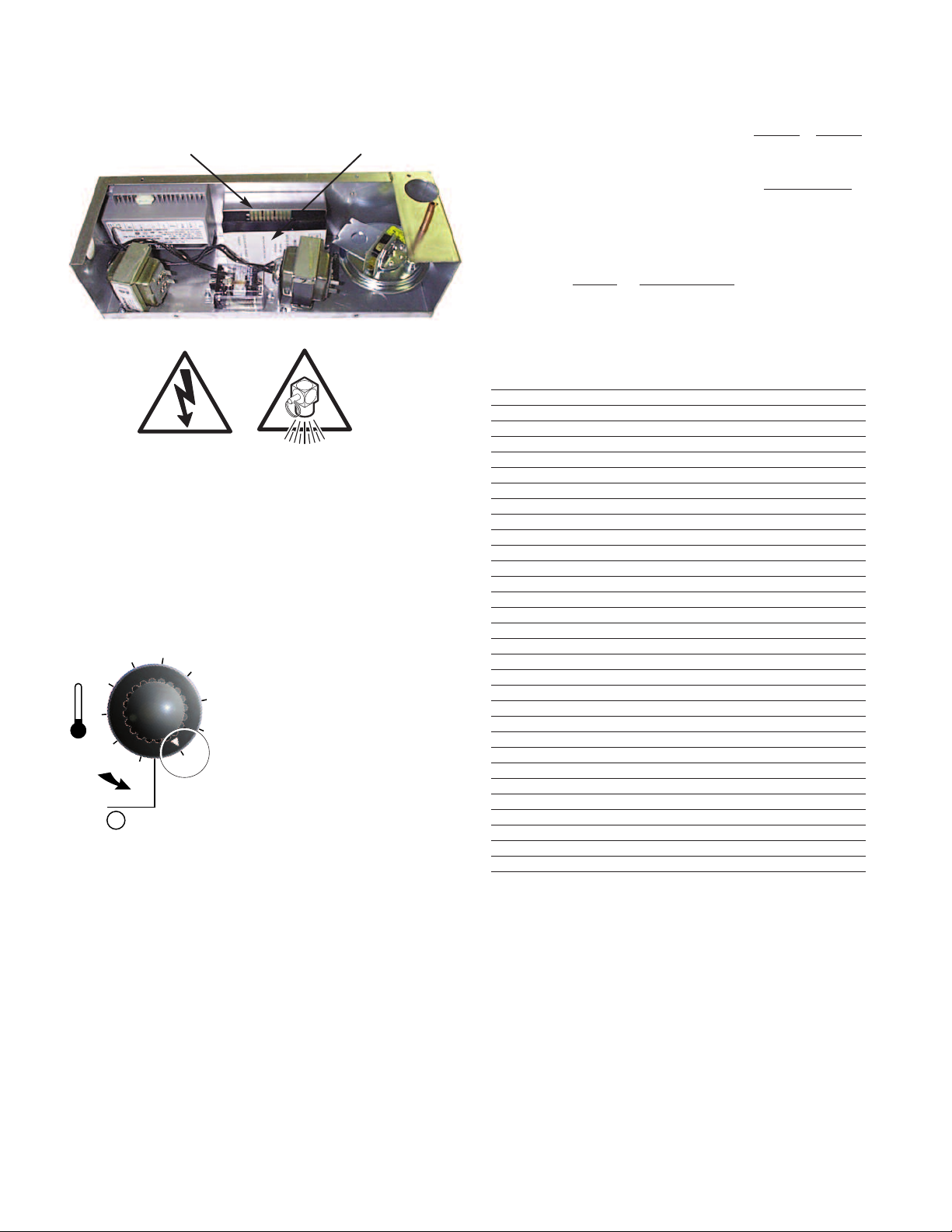

CALIBRATING PROCEDURE FREE AIR CALCULATION

2

3

5

6

7

8

9

1

4

10

OFF

0

!

!

Insert drager pump tube 4" down the center

olid State Temperature

S

ontrol Box

C

djustment

A

ot

P

of the flue and take one sample each of

Carbon Dioxide (CO2) and Carbon

Monoxide (CO) and record results.

With results obtained for CO2 use chart to

determine dilution factor for gas type used.

Enter these numbers in the following formula

to determine the concentration of carbon

monoxide in an air free sample of flue gas.

_____________

_

CO

%

PPM)

(

__________________________

_

ilution Factor

D

______________

CO2

%

1. Insure the unit has a vacuum before you begin

calibrating procedures. If unit requires venting refer to

KETTLE VENTING INSTRUCTIONS.

Set On-Off Switch/Temperature Control to "10"(Max.).

2.

3. Allow the unit to cycle twice.

4. Check temperature of the inner kettle surface with a

digital surface thermometer.

5. Temperature should be between 260°F and 265°F.

6. Using a screw driver

adjust temperature by

turning the potentiometer

on the Solid State

Temperature Control Box.

Turn very little. Turn

clockwise to INCREASES

and counter-clockwise to

DECREASE temperature.

7. Allow the unit to cycle

twice.

8. Check temperature of the

inner kettle surface with a

digital surface

thermometer.

9. Repeat steps 4. through 8. until unit is calibrated.

Dilution Factor X CO (PPM) =

0,000

1

_____________________________

% Carbon Monoxide

Result must not exceed 0.08% carbon monoxide.

CARBON DIOXIDE IN FACTOR FACTOR

SAMPLE (PERCENT) PROPANE GAS NATURAL GAS

4.0 3.50 3.05

4.2 3.33 2.90

4.4 3.18 2.77

4.6 3.04 2.65

4.8 2.92 2.54

5.0 2.80 2.44

5.2 2.69 2.34

5.4 2.59 2.26

5.6 2.50 2.18

5.8 2.41 2.10

6.0 2.33 2.03

6.2 2.26 1.97

6.4 2.19 1.91

6.6 2.12 1.85

6.8 2.06 1.80

7.0 2.00 1.74

7.2 1.94 1.70

7.4 1.89 1.65

7.6 1.84 1.61

7.8 1.79 1.56

8.0 1.75 1.53

8.2 1.71 1.49

8.4 1.67 1.45

8.6 1.63 1.42

8.8 1.59 1.39

9.0 1.56 1.36

9.2 1.52 1.33

9.4 1.49 1.30

9.6 1.46 1.27

9.8 1.43 1.24

10.0 1.40 1.22

Loading...

Loading...