Page 1

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

GAS KETTLES

SHORT SERIES™ GAS-FIRED KETTLES

37.5˝ RIM HEIGHT, FULL STEAM JACKETED

STATIONARY, “

40 or 60 GALLONS (150 or 225 LITERS)

Cleveland Standard Features

I

I

igh Efficiency (65%) Forced Air Double Pass Heating

H

System

II

Fast Heat-up and Recovery Time, 190M BTU on

40 and 60 gallons

II

Automatic Hot-Surface Ignition System

I

I

50 psi Steam Jacket Rating and Safety Valve

Splash-Proof Solid-State control panel

I

I

II

Type 304 Stainless Steel with #4 finish on kettle and supports

II

Steam Jacket permanently filled with treated distilled water

II

Recessed, front-mounted Pressure/Vacuum Gauge

II

Solid-State, precise temperature controls with less than 1˚ C.

temperature difference

• Control Panel Includes:

• LED indicator for Heat Cycle

• LED Indicator for Low Water

• Power On/Off Switch

• Adjustable Temperature Control Dial

II

Spring-assisted, hinged, rotatable, domed Stainless Steel

Cover

II

2˝ Tangent Draw-Off Valve

II

Faucet Mounting Bracket (FBK)

II

Standard for natural gas operation

II

Standard voltage is 115 volt, 60 cycle, 1 phase, supplied with

cord and plug

II

Level adjustable flanged feet for floor bolting

II

Typical approvals include AGA, CSA, CE, NSF and ASME

Options & Accessories

SPLASH PROOF SERIES”

MODELS: KGL-40-SH

KGL-60-SH

Shown with optional Hot & Cold Water Faucet

Short Form Specifications

Cleveland Gas-Fired Stationary Kettle, Model KGL-( )SH, 37.5˝ rim

height, fully steam jacketed, 50 psi steam jacket rating, 190,000

BTU Double Pass Steam Generator, Power Burner System, SplashProof Solid-State Temperature Controls, Automatic Hot-Surface

Ignition System

Ë 316 Stainless Steel Interior Liner (316G)

Ë 3˝ Tangent Draw-off Valve (TD3)

Ë 3˝ Butterfly Valve (BV3)

Ë Hot & Cold Water Faucet (DPK)

Ë Kettle Accessory Kit (KAK)

Ë Tri-Basket Strainer Support Systems (TBS)

Ë Kettles Markings (KM)

Ë Measuring Strips (MS)

Ë Propane Gas (PG)

Ë Correctional Packages

Ë Heat Deflector Shield (HS001)

SECT. IX PAGE 13

0609

Page 2

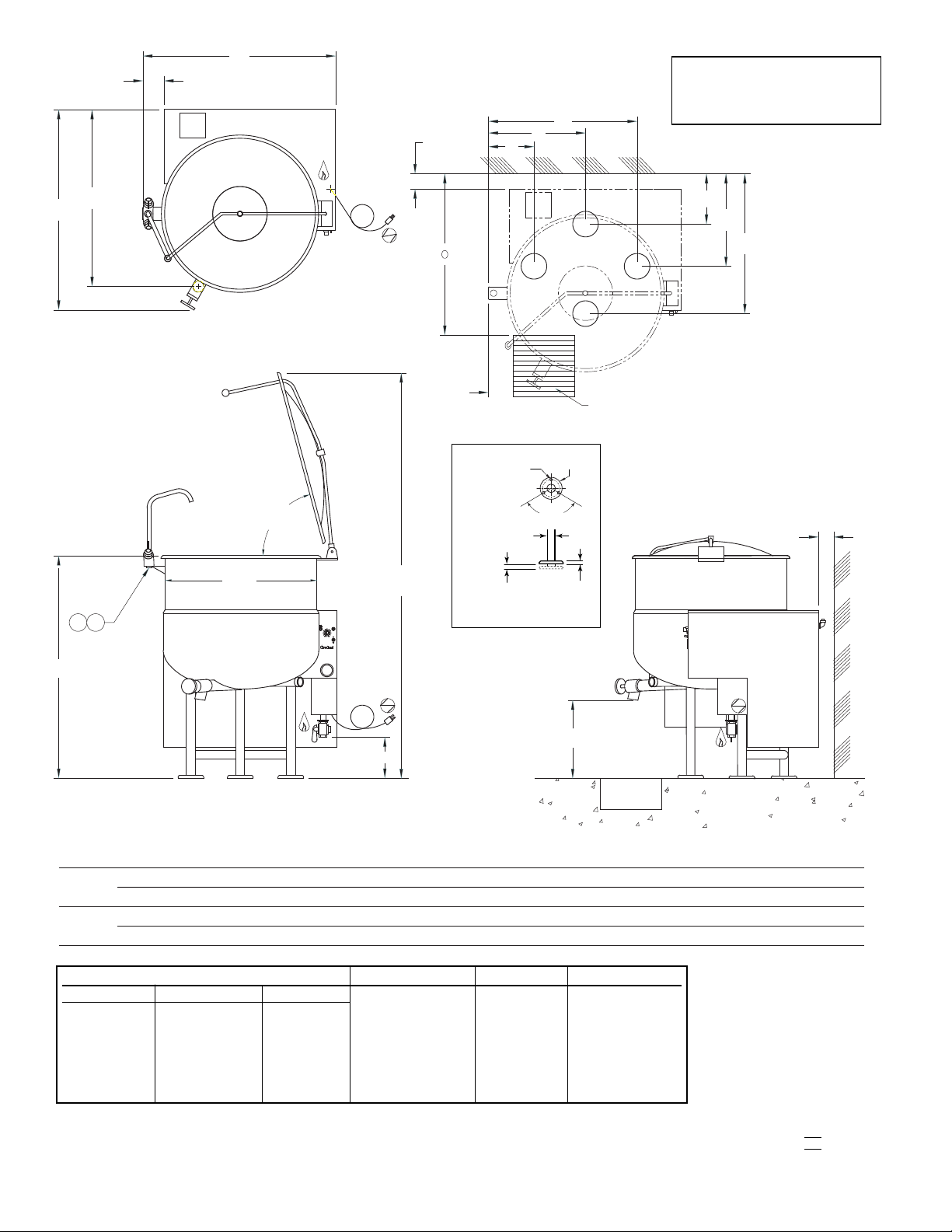

MODEL # A B C D E F G H J K L M N O P T (I.D.)

KGL-40-SH

41.63” 42.38 35.50” 37.00“ 8.75“ 15.50“ 71.00“ 9.25“ 20.75“ 32.25“ 10.38“ 18.63“ 29.63“ 31.50“ 6.38“ 33.00“

1057mm 1076mm 902mm 940mm 222mm 394mm 1803mm 235mm 527mm 819mm 264mm 473mm 753mm 800mm 162mm 838mm

KGL-60-SH

44.00” 43.50 36.50” 38.00“ 8.75“ 15.00“ 74.00“ 9.13“ 20.88“ 34.63“ 10.38“ 18.63“ 31.25“ 31.50“ 7.50“ 35.50“

1118mm 1105mm 927mm 965mm 222mm 381mm 1880mm 232mm 530mm 879mm 264mm 473mm 794mm 800mm 191mm 902mm

DIMENSIONS

UNIT SHOWN WITH 2” TANGENT DRAWOFF VALVE,

S

PRING ASSIST COVER AND OPTIONAL COLD WATER FAUCET

FRONT VIEW

D

H

C

G

(COVER OPEN)

T (I.D.)

E

75˚

SIDE VIEW

F

3

.00” (76mm)

MINIMUM

C

LEARANCE

B

C

A

TOP VIEW

4

.00” (102mm)

TOP VIEW

(SHOWING DRAIN &

FOOT LOCATIONS)

F

LOOR DRAIN

(12” (305mm) WIDE X

12”

(305mm) LONG)

H

J

K

L

P

M

N

O

3

.00”

(

76mm)

9/16"

14

mm

120º

T

YP

1" (25

mm)

MAX. ADJUSTMENT

1

5/8" (42

m

m) Ø

FLANGED FOOT DETAIL

7/16" (11 mm)

Ø

3 HOLES ON

3

1/8" (80

m

m)

Ø

B.C.D.

4 7/8"

124

Ø mm

CAPACITIES: (in 8 oz. servings,

other sizes may be calculated)

40 Gallon / 150 liters . . . 640 servings

60 Gallon / 225 liters . . . 960 servings

GAS ELECTRIC WATER CLEARANCE

NATURAL PROPANE BTU RATING 120V-1Phase, 60 Hz.1⁄2˝ diameter RIGHT = 3˝

3

Piping

⁄4˝ N.P.T. Piping 3⁄4˝ N.P.T. 190,000 10 amps Soft Copper LEFT = 3˝

Supply pressure Supply pressure Tubing each REAR=3˝

4.00˝ W.C. Min. 11.00˝ W.C. Min. When ordered Allow 6˝ space min.

14.00˝ W.C. Max. 14.00˝ W.C. Max. with optional from rear and sides

NOTES:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Installation of backflow preventers, vacuum breakers and other specific coder requirements is the responsibility of the owner and installer.

Cleveland Range equipment is built to comply with applicable standards for manufacturers. Included among those approval agencies are U.L., A.G.A., NSF, ASME/N.Bd., CSA, CGA, ETL and others.

faucet When located near

combustible walls

SECT. IX PAGE 14

Litho in U.S.A.

0609

Loading...

Loading...