Page 1

Cleveland

™

Maintenance Procedures

!

& Parts Lists

Electric Table Top Kettles

For units built after April 2010

KET-3-T

KET-6-T

KET-12-T

KET-20-T

TKET-3-T

TKET-6-T

TKET-12-T

For your future reference.

Model # ______________________________________

Serial # _______________________________________

Model # & Serial #.

1333 East 179th St., Cleveland, Ohio, U.S.A. 44110

Ph: 216.481.4900 Fx: 216.481.3782

www.clevelandrange.com

This manual is to be used in conjunction with the

“Operators Manual”. See “Operators Manual” for

safety warnings, correct operation, installation

and preventative maintenance.

Read the manual thoroughly.

Improper installation, operation or

maintenance can cause property

damage, injury or death.

SE95004 Rev. 9

August 2012

Page 2

STATEMENT OF RESPONSIBILITIES /

DÉCLARATION DES RESPONSABILITÉS /

DECLARACIÓN DE RESPONSABILIDADES

This document is for use by experienced

and trained Qualified Cleveland Range,

LLC Authorized Service Representatives

who are familiar with both the safety

procedures, and equipment they

service. Cleveland Range, LLC assumes

no liability for any death, injury,

equipment damage, or property damage

resulting from use of, improper use of,

or failure to use the information

contained in this document. Cleveland

Range, LLC has made every effort to

provide accurate information in this

document, but cannot guarantee that

this document does not contain

unintentional errors and omissions.

The information in this document may

be subject to technical and technological

changes, revisions, or updates.

Cleveland Range, LLC assumes no

liability or responsibility regarding errata,

changes, revisions, or updates.

Qualified Cleveland Range, LLC

Authorized Service Representatives are

obligated to follow industry standard

safety procedures, including, but not

limited to, OSHA regulations, and

disconnect / lock out / tag out

procedures for all utilities including

steam, and disconnect / lock out / tag

out procedures for gas, electric, and

steam powered equipment and / or

appliances.

All utilities (gas, electric, water and

steam) should be turned OFF to the

equipment and locked out of operation

according to OSHA approved practices

during any servicing of Cleveland Range

equipment

Qualified Cleveland Range, LLC

Authorized Service Representatives are

obligated to maintain up-to-date

knowledge, skills, materials and

equipment.

Ce document est destiné à l’usage des

Représentants de Service qualifiés et

autorisés de Cleveland Range, LLC qui

possèdent l’expérience et la formation ainsi

que la bonne connaissance des mesures

de sécurité et du matériel qu’ils

entretiennent.

Cleveland Range, LLC décline toute

responsabilité pour tout cas de décès,

blessure, dommage matériel ou dommage

aux biens résultant de l'utilisation, de la

mauvaise utilisation ou du manquement

d’utilisation des renseignements contenus

dans ce document.

Cleveland Range, LLC s’est efforcé à

fournir des renseignements précis dans ce

document mais ne peut garantir que ce

document soit exempt d’erreurs et

d’omissions non intentionnelles.

Les renseignements contenus dans ce

document peuvent être assujettis à des

changements techniques et technologiques,

des révisions ou des mises à jour.

Cleveland Range, LLC décline toute

obligation ou responsabilité concernant les

errata, modifications, révisions ou mises à

jour.

Les Représentants de Service qualifiés et

autorisés de Cleveland Range, LLC sont

tenus de se conformer aux mesures de

sécurité normalisées de l’industrie, y

compris, mais sans s'y limiter, les

réglementations de l'OSHA, les procédures

de débranchement / verrouillage /

étiquetage relatives à tous les services

publics, dont l’approvisionnement en

vapeur, et les procédures de

débranchement / verrouillage / étiquetage

relatives aux équipements et/ou appareils

fonctionnant au gaz, à l’électricité et à la

vapeur.

Au cours de tout entretien d’un appareil

Cleveland Range, tous les services publics

(gaz, électricité, eau et vapeur) doivent être

FERMÉS au niveau de l’appareil et le

dispositif de fonctionnement doit être

verrouillé suivant les pratiques approuvées

de l’OSHA.

Les Représentants de Service qualifiés et

autorisés de Cleveland Range, LLC sont

tenus d’actualiser en permanence leurs

connaissances, compétences, matériel et

équipement.

Este documento está destinado para el uso

de los Representantes de Servicio

calificados y autorizados de Cleveland

Range, LLC quienes cuentan con la

experiencia y la capacitación así como el

buen conocimiento de las medidas de

seguridad y de los equipos que mantienen.

Cleveland Range, LLC, declina toda

responsabilidad en caso de cualquier

fallecimiento, lesiones, daños al equipo o

daños a la propiedad resultantes de la

utilización, del uso indebido o de la falta de

utilización de la información provista en este

documento.

Cleveland Range, LLC se ha esforzado en

suministrar información precisa en este

documento, pero no puede garantizar que

este documento esté exento de errores y de

omisiones no intencionales.

La información contenida en este

documento podría estar sujeta a cambios

técnicos o tecnológicos, revisiones o

actualizaciones. Cleveland Range, LLC

declina toda obligación o responsabilidad

con respecto a erratas, modificaciones,

revisiones o actualizaciones.

Los Representantes de Servicio calificados y

autorizados de Cleveland Range, LLC tienen

la obligación de seguir los procedimientos

estándar de seguridad de la industria; los

cuales incluyen pero no se limitan a los

reglamentos de la OSHA (La Administración

de la Seguridad y Salud Ocupacionales), los

procedimientos de desconexión, cierre y

etiquetado relativos a todos los servicios

públicos incluyendo el suministro de vapor y

los procedimientos de desconexión, cierre y

etiquetado para los equipos y/o aparatos

que funcionan a base de gas, electricidad o

vapor.

Cuando se esté dando servicio o

mantenimiento a un aparato de Cleveland

Range, todos los servicios públicos (gas,

electricidad, agua y vapor) deben estar

APAGADOS para el equipo en cuestión y se

debe seguir el procedimiento de cierre de

operaciones de acuerdo con las prácticas

aprobadas por la OSHA.

Los Representantes de Servicio calificados y

autorizados de Cleveland Range, LLC tienen

la obligación de actualizar constantemente

sus conocimientos, destrezas, materiales y

equipamiento.

Page 3

TROUBLESHOOTING AND

0

0

!

0

!

MAINTENANCE PROCEDURES

The following trouble shooting guide and maintenance

procedures are meant to be used by Qualified Service Technician

ANY REPAIRS TO THE PRESSURE VESSEL MUST BE DONE BY A CERTIFIED PRESSURE VESSEL REPAIR

SHOP AND ALL REPAIR METHODS AND MATERIALS MUST BE APPROVED BY THE MANUFACTURER.

For periodic maintenance recommendations see “Operators Manual”.

Extreme caution must be taken if unit is electrically energized for testing.

Remove power from the unit while servicing.

DIAGNOSTIC GUIDE

This section contains servicing information intended for use by Authorized Service Personnel.

NOTE 1: If Fault Isolation Procedure is required, be sure to start at step #1.

NOTE 2: On table type kettles the entire control mounting panel may be removed from kettle control housing for easier

troubleshooting and parts replacement.

A/ Problem: Kettle is not heating at all. (Kettle must be on and temperature

control set.)

PPoossssiibbllee CCaauusseess

1. No incoming power.

2. Kettle is tilted.

3. Low water condition.

4. Defective ON/OFF switch.

5. Defective 12 VDC relay.

Fault Isolation Procedure

SStteepp TTeesstt

1. Is there proper incoming voltage at terminal block?

Yes - Go to step #2.

No - Correct external power supply problem.

2. Is the red LED illuminated?

Yes - Follow Reservoir Fill Procedure. If this does not correct the problem, go to Problem D.

No - Go to step #3.

3. Is the green LED illuminated?

Yes - Go to step #4.

No - Go to step #7.

4. Do both contactors energize?

Yes - Check contactor contacts for pitting. Voltage across contactor terminals while in a closed position indicates a poor contact.

Replace contactor/s as necessary. Check elements for short at ground or an open circuit. If element/s are defective contact the

factory. Elements are not field replaceable.

No - Go to step #5.

5. Measure continuity across safety thermostat. Is it an open circuit?

Yes - Replace defective safety thermostat.

No - Go to step #6.

6. Defective safety thermostat.

7. Defective contactor/s.

8. Defective potentiometer

9. Defective low water level

(temperature control).

probe.

10. Defective thermistor.

11. Defective 240/16 VAC

transformer.

12. Defective control box.

13. Defective elements.

Page 4

6. Is there 120 VAC present across the coils of the contactors?

Yes - Replace defective contactor/s.

No - Go to step #7.

7. Remove wire from low water level probe and ground it to the body of the kettle. Do the contactors now energize?

Yes - Clean or replace defective low water level probe. Replace defective red LED.

No - Go to step #8.

8. Is there 16 VAC present at output of 16 VAC transformer?

Yes - Go to step #9.

No - Replace defective 240/16 VAC transformer.

9. Measure continuity of ON/OFF switch/ temperature control. Is it operating properly?

Yes - Go to step #10.

No - Replace defective ON/OFF switch/temperature control.

10. Unplug control box and measure the resistance across potentiometer. Is it approximately 0 ohms at maximum setting and

50,000 ohms at minimum?

Yes - Go to step #11.

No - Replace defective potentiometer (ON/OFF switch/temperature control)

11. Remove edge connector from control box. While kettle is cold or thermistor is removed and allowed to cool, measure the

resistance between edge connector’s pins #2 and #7. Is it approximately 100,00 ohms?

Yes - Spray contact cleaner on control box terminals and edge connector. Try box again, if the problem still exists, replace

defective control box.

No - Replace defective thermistor.

B/ Problem: Kettle heats too slowly or not hot enough. (Note: normal max.

operating pressure with an empty kettle is 30-35 psi.)

PPoossssiibbllee CCaauusseess

1. Air in jacket requires venting.

2. Defective safety thermostat.

3. Defective potentiometer (temperature control).

4. Defective thermistor.

Fault Isolation Procedure

SStteepp TTeesstt

1. In a cold state, does the pressure gauge read in the green zone?

Yes - Go to step #2.

No - There is air present in the jacket of the kettle. Follow Kettle Venting Procedure. If constant venting is required, there is

a leak that should be corrected.

2. Do the contactors shut off too early? (before reaching normal maximum operating pressure.)

Yes - Go to step #3.

No - Check contactor contacts for pitting. Voltage across terminal of contactor while energized signifies a poor contact.

Replace contactor/s as necessary. Check elements for short to ground or open circuit. If elements are defective, contact

the factory. Elements are not field replaceable.

3. Does the green LED remain illuminated after the contactors shut off?

Yes - Replace defective safety thermostat.

No - Go to step #4.

4. Unplug control box and measure the resistance across potentiometer (temperature control). Is it approximately 0 ohms at

maximum and 50,000 ohms at minimum setting?

Yes - Go to step #5.

No - Replace defective thermistor.

5. Remove kettle thermistor and allow to cool. Remove edge connector from control box. Test resistance across edge

connector's pins #2 and #7. Is it approximately 100,000 ohms?

Yes - Go to step #6.

No - Replace defective thermistor

6. Turn the potentiometer on the control box clockwise to increase the maximum operating temperature. Does the kettle now

achieve maximum operating pressure of 30-35 psi in an empty kettle?

Yes - Kettle is operating correctly.

No - Spray contact cleaner on control terminals and edge connector. Try box again. If problem still exists, replace

defective control box.

5. Defective contactor/s.

6. Defective control box.

7. Defective elements/s.

Page 5

C/ Problem: Kettle is overheating.

PPoossssiibbllee CCaauusseess

1. Defective thermistor

2. Defective potentiometer (temperature control).

Fault Isolation Procedure

SStteepp TTeesstt

1. Does the green LED turn off even though the contactors remain energized?

Yes - Replace defective 12 VDC relay.

No - Go to step #2.

2. Unplug the control box and measure the resistance across the potentiometer (temperature control), Is the resistance

approximately 0 ohms at maximum and 50,000 ohms at minimum setting?

Yes - Go to step #3.

No - Replace defective thermistor.

3. Remove kettle thermistor and allow to cool Remove edge connector from control box. Test resistance across edge

connector’s pins #2 and #7. Is it approximately 100,000 ohms?

Yes - Go to step #4.

No - Replace defective thermistor.

4. Turn the potentiometer (temperature control) on the control box counter-clockwise to decrease the maximum operating

temperature. does the kettle continue to overheat?

Yes - Spray contact cleaner on control box terminal and edge connector. Try box again. If problem still exists, replace

defective control box.

No - Kettle is operating correctly.

3. Defective 12 VDC relay.

4. Defective control box.

D/ Problem: Red LED remains illuminated even though water has been

added.

PPoossssiibbllee CCaauusseess

1. Defective low water level probe

2. Defective control box.

Fault Isolation Procedure

SStteepp TTeesstt

1. Remove wire from low water level probe and ground the wire to the body of the kettle. Does the red LED turn off?

Yes - Replace or clean defective low water level probe.

No - Spray contact cleaner on control box terminals and edge connector. Try box again. If problem still exist, replace

defective control box.

Page 6

SAFETY INSPECTION CHECKLIST

Adjusting

Screw

Worm

Screw and

Tilt

Gear

Cross

Bar

Locking

Nuts

0

!

!

NOTE: The following instructions are intended

for use by qualified service personnel.

Regular inspection and maintenance of units is essential to obtain trouble free and safe operation of

equipment. The following steps should be completed IN SEQUENCE every year or more frequently, if unit

is in a high volume facility.

A/ KETTLE PREPARATION

1. Disconnect main power at fused disconnect switch.

2. Kettle should be cold. If necessary add water to kettle pot to cool unit.

3. The pressure gauge should now show a vacuum and have no indication of leakage.

If gauge gauge looks damaged replace gauge.

4. Gauge must be showing a vacuum prior to proceeding. If not check for leaks, and repair

kettle prior to proceeding. Refer to REFERENCE SECTION (KETTLE VENTING INSTRUCTIONS).

hoto of Pressure Gauge in Vacuum.

P

B/ MECHANICAL CHECKS

1. Inspect controls, replace damaged seals, switches, LED's etc..

2. Remove the console cover and check that the seal is not cracked or split.

Replace seal, screws, missing or worn nylon anchor nuts. Leave cover off.

3. Remove the kettle bottom cover and check that the seal is not cracked or split.

Leave cover off.

4A. FOR UNITS WITH TILT HANDLE -

A. Check handle for tightness. If loose apply lock tight and reinstall. Check handle

knob is on end of handle and firmly tightened. If missing replace, if loose apply

lock tight and reinstall.

B. Check that kettle tilts smoothly and there is no excessive wear in the trunnion bearings.

Add grease to nipples as required or for older units without grease nipples refer to

REFERENCE SECTION

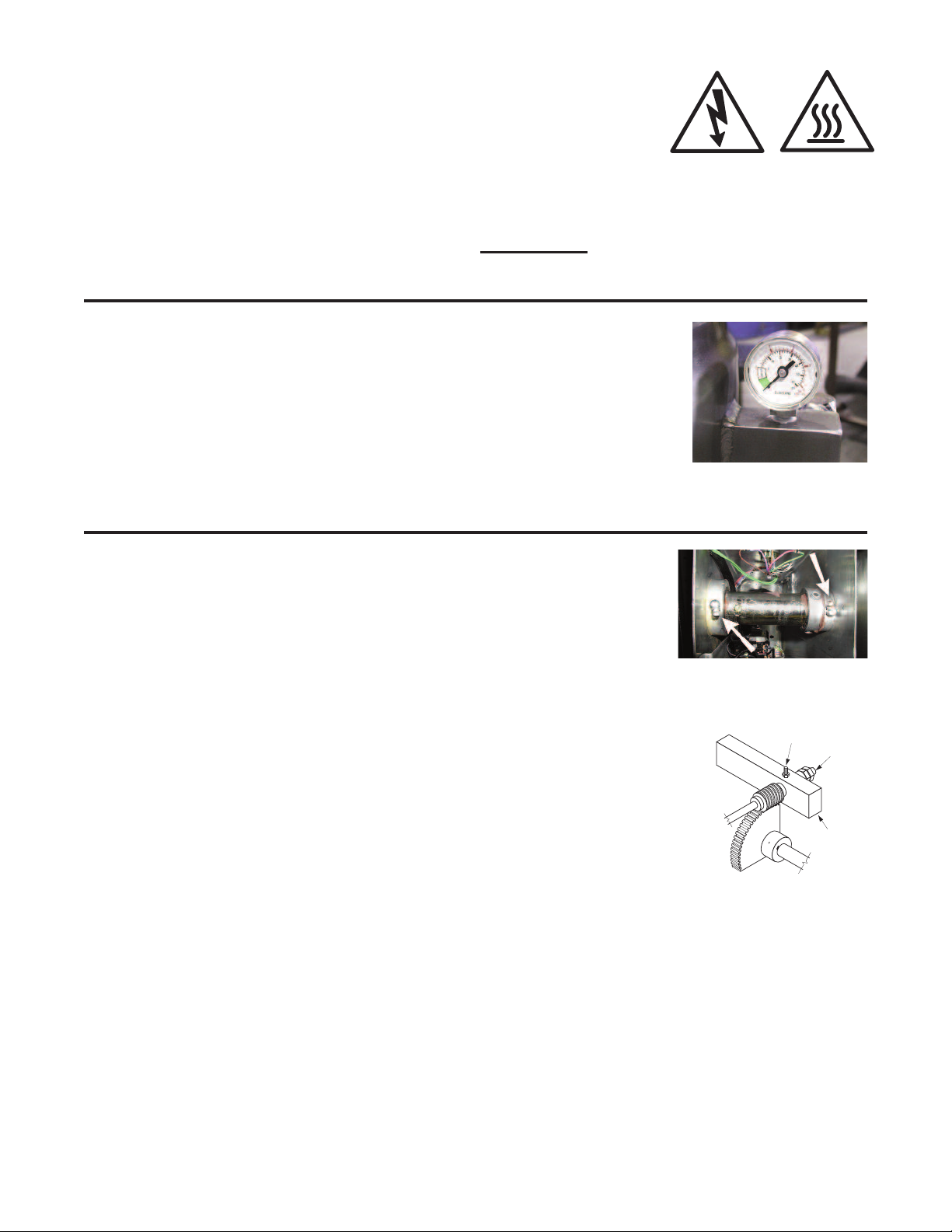

4B. FOR UNITS WITH TILT CRANK -

A. Check that the kettle tilts smoothly. If there is excess play adjust the worm to gear

clearance with Locking Nuts or Adjusting Screw as required.

B. Check that there is no excessive wear in the trunnion bearings.

C. Apply grease to gear teeth.

(BEARING LUBRICATION PROCEDURE)

.

Photo of Grease Nipples.

Illustration inverted for clarity.

KE55450 Rev. 2

Page 7

C/ MARINE LOCK TEST

1. Check that lock mechanism is not bent or damaged.

2. Check that lock clears stop pin on side box without

rubbing when kettle is tilted (Figure A).

3. Check side to side play. Lock should remain fully

over stop pin when pushed to it's maximum side to

side play (Figure B).

4. Check that the kettle when pushed fully upright

forces the lock to a closed position. To check this:

A/ Hold the latch firmly in the unlocked

while tilting the kettle back to an upright position.

B/ The kettle sidebox will force the lock into a new position.

C/ Hold the lock in this position and try to tilt the kettle forward.

The latch should prevent the kettle from tilting.

5. Check shoulder bolt is firmly seated against console body.

6. Check on inside of console box that shoulder bolt locknut is secure.

position

D/ CONTACTOR TEST

1. Remove power to unit.

2. Remove nut holding component mounting plate to console.

Pull plate out and place on top of console. (Depending on how the

3.

installer wired the kettle you may have to remove the supply wire and

reconnect).

4. Physically push in on contacts of each contactor to check for free

movement. Replace contactor(s) if required.

Stop Pin on

Sidebox

hen re-assembling,

W

carefully apply locktight

to the final two threads.

S

ide Box

Shoulder Bolt

Figure A

(Side View)

Figure B

(Top View)

Marine Lock

(Latch)

S

ide to Side Play

Lockwasher

Locknut

Console

E/ LOW WATER LEVEL PROBE:

Installation Check:

(A)

(B)

Probe properly

attached

✔

Functional Test:

1. Turn main power on at fused disconnect switch.

2. Turn kettle on and set temperature to maximum.

3. Green light will come on and contactors close.

4. Tilt kettle over. After approximately a five-second delay the red light will come on, green light go off and the contactors

will disengage.

5. Turn kettle upright. Green light will come back on and contactors reengage.

6. Turn kettle off

7. If unit does not function as above, make required repairs.

8. Disconnect main power at fused disconnect switch.

Probe bypassed by

running (A) an

✘

additional wire

Probe bypassed by

(B) grounding the

✘

connecting wire

Page 8

✘

Plug

✘

Tube

diameter

reduced

✘

Plumbed to

drain or

water line

1

2

3

✔

✔

F/ SAFETY THERMOSTAT INSTALLATION CHECK:

✘

Probe

removed

partially

✘

Probe

removed

completely

✘

Thermostat

electrically

bypassed

✔

Probe

fully

inserted

in tube

Wiring is properly

connected

1

2

3

G/ SAFETY VALVE INSTALLATION CHECK:

Incorrect

Installations

Safety thermostat

1

probe is not

completely inserted

into tubing (except

KET-3-T that has a

small loop).

Safety thermostat

2

probe is removed

from tubing.

Safety thermostat

3

electrical connection

is bypassed

.

✔

Incorrect Installations

1

2

3

Physical Checks

1. Check that the PSI rating on the valve matches MAWP (maximum allowable

working pressure) on the plate welded to the kettle.

2. Check that the Safety Valve has a "UV" stamp.

3. Check that the valve is not damaged in any way.

If any of the above criteria is not met, replace valve.

4"

maximum

length

The above illustrations show the variations

of factory installed Safety Valves.

Any modifications are unacceptable.

Safety valve has plug threaded into the discharge opening preventing any

steam from escaping.

Safety valve’s tube diameter has been reduced.

Safety valve is plumbed to a drain or water line creating back pressure

and reducing flow.

Page 9

BEARING LUBRICATING

PROCEDURE

1. Remove console cover.

2. Loosen two Allen screws on locking ring.

3. Pull locking ring to center of trunnion.

4. Pull kettle two

inches away

from console

and rest on

support block.

5. Clean newly exposed sections of trunnion.

6. Grease trunnion between kettle and console.

7. Repack outer needle bearing.

8. Push kettle back in place.

10. Reinstall trunnion and lock collar.

11. Replace console cover.

Page 10

CALIBRATING PROCEDURE

P

ressure

Gauge

P

ressure

Relief

V

alve

0

Pressure Gauge

Pressure Relief Valve

1. Kettle must be empty when this procedure is executed.

2. Insure the unit has a vacuum before you begin

calibrating procedures. If unit requires venting refer to

KETTLE VENTING INSTRUCTIONS.

Set On-Off Switch/Temperature Control to "10"(Max.).

3.

4. Allow the unit to cycle twice.

5. Check temperature of the inner kettle surface with a

digital surface thermometer.

6. Temperature should be between 260° F and 265° F.

7. Using a screw driver adjust temperature by turning the

potentiometer on the black box. Turn very little. Turn

clockwise to INCREASES and counter-clockwise to

DECREASE temperature.

8. Allow the unit to cycle twice.

9. Check temperature of the inner kettle surface with a

digital surface thermometer.

10.

Repeat steps 5. through 9. until unit is calibrated.).

PRESSURE RELIEF VALVE

PERIODIC TESTING PROCEDURE

1. With the kettle empty, set On-Off Switch/Temperature

Control to "10" (Max.). Allow the kettle to heat until

the unit cycles off.

Switch On-Off Switch/Temperature Control to "0"(Off) and

2.

disconnect main power at fused disconnect switch.

3. Stand to the side of the pressure relief valve

discharge tube and pull valve open for a maximum

of one second. Repeat test three to four times. Each

time the mechanism should move freely and be

accompanied by a rapid escape of steam.

If valve appears to be sticking replace pressure relief

valve.

If foreign material is discharged then drain kettle and

replace pressure relief valve.

Page 11

2

3

5

6

7

8

9

1

4

10

OFF

50

0

100

150

200

250

300

350

400

40

50

60

0

10

20

30

psi

kPa

V

E

N

T

A

I

R

50

0

100

150

200

250

300

350

400

40

50

60

0

10

20

30

psi

kPa

V

E

N

T

A

I

R

50

0

100

150

200

250

300

350

400

40

50

60

0

10

20

3

0

psi

kPa

V

E

N

T

A

I

R

50

0

100

150

200

250

300

350

400

40

50

6

0

0

10

20

3

0

psi

k

Pa

V

E

N

T

A

I

R

50

0

100

1

50

200

250

300

3

50

4

00

40

50

6

0

0

10

2

0

30

psi

kPa

V

E

N

T

A

I

R

50

0

100

150

200

2

50

300

350

400

40

50

60

0

10

2

0

3

0

psi

kPa

V

E

N

T

A

I

R

5

0

0

1

00

150

2

00

250

3

00

350

4

00

40

50

6

0

0

10

20

30

psi

k

Pa

V

E

N

T

A

I

R

50

0

1

00

1

50

2

00

250

300

350

400

40

5

0

60

0

10

20

3

0

p

si

kPa

V

E

N

T

A

I

R

A.*

Remove

Pressure

Relief

Valve

B.

Attach Street

Elbow

C. Fill unit via Street Elbow

Pressure

Gauge

Pressure

R

elief

Valve

KETTLE JACKET CLEANOUT AND PASSIVATION PROCEDURES

0

!

!

The following procedure should be preformed at least once every three years to prevent possible corrosion and

ensure the optimum life of the kettle.

RUST INHIBITOR

Use a “radiator rust inhibitor” that can be purchased at

your local automotive centre. It should not contain any

anti-freeze and preferably no lubricant.

To ensure satisfactory

mixing follow the

manufacturer’s instructions.

DISPOSAL - Follow all

Federal, State and local

codes when disposing of

product.

SSPPRRIINNGG WWAATTEERR

RREEQQUUIIRREEMMEENNTTSS

Kettle Light” comes on,

Capacity add Spring Water

3 gallon 50 ounces

6 gallon 70 ounces

12 gallon 120 ounces

20 gallon 1 gallon

When Red “Low Water

1. Ensure kettle is at room

temperature and pressure

gauge showing zero or

less pressure.

2. Shut off power to the kettle

at the fused disconnect

switch.

DANGER:

Rust inhibitor can be

dangerous. read label and

follow safety instructions.

KETTLE VENTING INSTRUCTIONS

The following venting procedure

Vacuum/Pressure Gauge needle

NOTE: Check for and eliminate leaks prior to venting

(See REPAIRING LEAKS IN STEAM JACKETED KETTLE

FITTINGS).

WARINING:

Improper refilling of kettle

jacket will result in

irreversible damage to unit.

Pressure Gauge

Pressure Relief

should be followed when the

is in the "VENT AIR" zone:

1.

Set On-Off Switch/Temperature

Control to "10" (Max.). Heat

the empty kettle until unit

cycles off.

Valve

C. Fill Unit via Street Elbow

3. Pull Pressure Relief Valve (A) open to insure vessel is

not pressurized.

4. Remove Pressure Relief Valve (A).

5.

Replace Pressure Relief Valve (A) with Street Elbow (B).

6. Add Spring Water (C) through the Street Elbow (B),

using a funnel if necessary. Refer to Spring Water

Requirements chart for the proper amount required.

7. Apply a thread sealant (i.e. Teflon tape) to the

Pressure Relief Valve's (A) thread and replace.

8.

Restore power to unit at the fused disconnect switch.

9.

The kettle must now be vented. (Refer to the Kettle

Venting Instructions).

Attach Street

Elbow

B.

*Important - Pull ring on

Pressure Relief Valve prior

to removal to insure vessel

is not pressurized.

A.*

Remove

Pressure Relief

Valve

2. Vent kettle by pulling safety

valve ring 8-10 times in short

2-3 second blasts with a 5

second interval between

pulls.

NOTE: If unit cycles ON, stop

venting and wait for kettle to

cycle OFF before continuing.

3. Turn kettle OFF. Add cold

water to kettle until its surface

temperature is below 100°F.

The pressure gauge needle

should be in the green zone,

indicating a vacuum in the

kettle’s jacket.

Page 12

VACUUM LEAKS

THIS CONTROL BOX MUST BE

CALIBRATED WHEN REPLACED

(see back for test and

calibration instructions)

SSK Solid State Control (part number KE00458-1)

DIAGNOSTIC

LED

SWITCH

CPU

SWITCH - Push for 5 seconds to enter TEST #1

Press again for TEST #2 and again for TEST #3

CPU - Rapid ashing during normal operation

TEST #1 = 1 ash/sec Water level test

TEST #2 = 2 ash/sec Thermistor test

TEST #3 = 3 ash/sec Heater Ouput test

TEST #1 GREEN Probe senses water

RED No water sensed

TEST #2 GREEN Thermistor is sensed

ORANGE Thermistor is shorted

RED Thermistor is open circuit

POTENTIOMETER

LOW WATER

HEATER OUTPUT

TEST #3 GREEN voltage output

to relay for 20 seconds.

Normal operation LED matches

Front heater (greeen) LED

If unit will not hold a vacuum the most likely cause is a

leak at one of the fittings.

Often, the easiest way to eliminate a leak is reseal the

suspect areas.

1. Water Level Probe

Remove, clean threads, apply teflon thread sealant

and reinstall.

2 Pressure Relief Valve

A/ Inspect for signs of leaks. Replace if required.

B/ Remove, clean threads, apply teflon thread

sealant and reinstall.

3. Pressure Gauge

A/ Inspect face of gauge. If it contains moisture on

the inside of face replace.

B/ Remove, clean threads, apply teflon thread

sealant and reinstall.

I leak persists replace all three components at same

time.

SSK SOLID STATE CONTROL

TEST INSTRUCTIONS

1. If required remove board from holding bracket for

better access.

2. Turn unit on and set to 10 (maximum).

3. Push and hold the SWITCH button for approximately

5 seconds until the CPU starts to flash 1

flash/second. You are now in TEST #1. Output to

12v relay is disabled. With kettle upright the

DIAGNOSTIC LED should be green, with kettle tilted

it should be red.

4. Push SWITCH button. The CPU starts to flash 2

flash/second. You are now in TEST #2. Check the

DIAGNOSTIC LED for indication of the temperature

probe status.

5. Push SWITCH button. The CPU starts to flash 3

flash/second. You are now in TEST #3. The HEATER

OUTPUT LED should light for 20 seconds and

power to the relay should energize the 12v relay for

the heat source.

After 20 seconds test mode is exited and unit reverts to

normal operation.

Page 13

SERVICE PARTS

1

9

11

10

13

1314

12

6

5

7

8

6

5

7

8

2

3

4

(for Standard & Remote Faucets)

WARRANTY

Our Company supports a worldwide network of Maintenance and Repair Centers. Contact your nearest

Maintenance and Repair Centre for replacement parts, service, or information regarding the proper

maintenance and repair of your cooking equipment

In order to preserve the various agency safety certification (UL, NSF, ASME/Ntl. Bd., etc.), only factorysupplied replacement parts should be used. The use of other than factory supplied replacement parts will

void warranty.

FAUCET ASSEMBLY

ITEM # PART # DESCRIPTION QTY.

SPK2 SINGLE PANTRY FAUCET for KET20T & MKET12/20T (includes items 1-10)

DPK2 DOUBLE PANTRY FAUCET for KET20T

SPK9 SINGLE PANTRY FAUCET for KET3/6/12T

DPK9 DOUBLE PANTRY FAUCET for KET3/6/12T

1. KE50825-2 3/4" SPOUT for - SPK2

KE50825-9 3/4" SPOUT for - SPK9 & DPK9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. FA95007-10 RETAINING RING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3. FA05002-19 "O" RING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. KE51736 LONG FAUCET NUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5. KE54159 FAUCET MOUNTING BRACKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

6. FA11258 HEX CAP SCREW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

7. FA31029 LOCK WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

8. FA210028 HEX NUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

9. KE51401 SINGLE PANTRY BODY (c/w item 13) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

10. KE50335 ADAPTER WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

11. KE51403 DOUBLE PANTRY BODY (c/w item 13 & 14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

12. SE50447 REPLACEMENT HORSESHOE WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

13. SE50021 REPLACEMENT STEM ASSEMBLY, COLD WATER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

14. SE50020 REPLACEMENT STEM ASSEMBLY, HOT WATER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE02071-1 PRISON FAUCET MOUNTING BRACKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

& DPK2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

& MKET12/20T (includes items 1-8 & 11)

(includes items 1-10)

(includes items 1-8 & 11)

Page 14

KETTLE BOTTOM & SIDE

6

7

1 8

9

4

Element

Terminals

3

11

5

2

10

ITEM NO. PART NO. DESCRIPTION QTY.

1. KE50556-1 Probe, Low Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. KE54941-6 Safety Valve, 50 PSI, 1/2" (North America) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE54941-31 Safety Valve, 50 PSI, 1/2", (Europe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3. KE55425-1 Bottom Cover Gasket, 3 gallon kettle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE55425-2 Bottom Cover Gasket, 6 gallon kettle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. KE00515 Thermistor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5. KE55069-5 Safety Thermostat (140º C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

6. FA11145 Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

7. FA21007 Nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

8. KE50151-E Knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

9. KE54670-1 Handle, 3 & 6 gallon kettle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

10. KE50429-5 Pressure Guage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

11. KE52041 Bottom Cover, 3 gallon kettle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE55425-3 Bottom Cover Gasket, 12 gallon kettle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE55425-4 Bottom Cover Gasket, 20 gallon kettle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE54670-2 Handle, 12 gallon kettle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE54670-3 Handle, 20 gallon kettle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE603864-1 Bottom Cover, 6 gallon kettle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE603864-2 Bottom Cover, 12 gallon kettle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE603864-3 Bottom Cover, 20 gallon kettle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE54811 Bottom Cover, 12 gallon kettle, 380-480V . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Page 15

CONSOLE

12

11

10

13

14

15

28

29

23

27

16

17

18

19

20

21

24

25

KE95555-1D

PUSH UPRIGHT TO LOCK

POUSSER EN POSITION

VERTICALE POUR VERROUILLER

ZUM SPERREN GERADE

NACH OBEN DRÜCKEN

EMPUJAR DERECHO HACIA

ARRIBA PARA BLOQUEAR

PREMERE IN ALTO PER

LA CHIUSURA

10

9

8

7

6

5

4

3

2

1

OFF

2

3

22

5

6

7

4

1

COMPONENTS

& MARINE

LOCK

ITEM NO. PART NO. DESCRIPTION QTY.

1. SE00114 Potentiometer with ON/OFF Switch, c/w Item #2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/ 2

2. KE51005 Rubber Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/ 2

3. KE50569-1 Knob, Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/ 2

4. KE55486-2 Indicator Light, Red . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/ 2

5. KE55486-3 Indicator Light, Green . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/ 2

6. KE603634 Bracket, Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 / 4

7. FA21006 #10-24, Hex Nut, S.S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4/ 8

10. FA05002-20 "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/ 2

11. FA19184 Allen Screw, #10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2/ 4

12. SK50047-2 Collar, Trunnion Lock, KET, TKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/ 2

SK50047-3 Collar, Trunnion Lock, TGB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/ 2

13. FA21024 Hex Nut, 5/16-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/ 2

14. FA32027 Lockwasher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/ 2

15. KE01833 Bearing, KET-3-T, KET-20-T, TGB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/ 2

KE01834 Bearing, KET-6-T, KET-12-T, TGB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/ 2

16. FA95031 Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

17. FA95074 Nylon Anchor Nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

18. FA15019-1 Hex Socket Shoulder Bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/ 2

19. FA31029 Split Lockwasher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/ 2

20. KE02078-1 Latch, Left Hand, KET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

KE02078-2 Latch, Right Hand, TKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

KE95555-12 Label (KET-6-TGB, KET-12-TGB, KET-20-TGB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

21. FA21008 Hex Nut, 1/4-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/ 2

22. KE95555-1 Label (KET-3-T, KET-6-T, KET-12-T, KET-20-T) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE95555-3 Label (TKET-3-T) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

23. KE53838-11 Transformer, 380 to 415v . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

24. KE54846-1 Cover Gasket, KET- 3/6/12/20-T, TKET-3-T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

25. KE003688-1 Console Cover, (KET-3-T, KET-6-T, KET-12-T, KET-20-T) . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE95555-4 Label (TKET-6-T, TKET-12-T) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE53838-12 Transformer, 440 to 480v . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE54846-2 Cover Gasket, TKET-6/12-T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE003688-2 Console Cover, (TKET-6-T, TKET-12-T) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

28. FA95073 Carriage Bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

29. KE50473 Ground Lug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/ 2

Single/Twin

Page 16

TRUNNION

SHOWN

FOR CLARITY

F

6 & 12 GALLON20 GALLON

4

7

6

8

9

10

11

33

34

5

6

9

8

14

30

15

29

13

12

35A

2

APPLY

RTV

SEALANT

32

19B

19A

31

35B

3

21

28

TILTING GEARBOX

ASSEMBLY

(6, 12 & 20 gallon kettles)

ITEM NO. PART NO. DESCRIPTION QTY.

2. KE54738-3 WASHER S.S. (SHAFT HOLE COVER) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3. KE51738 BEARING SLEEVE FOR GEAR BOX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. KE50315 WORM GEAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5. FA95005 TENSION PIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

6. KE51891 WASHER 1 1/2" O.D. X 13/16" I.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

7. KE52193-1 THRUST BEARING SPACER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

8. KE52192 THRUST WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

9. KE52191 THRUST BEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

10. FA30088 TILT SHAFT WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

11. FA95008 LOCK NUT 3/4-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

12. FA19177 SET SCREW 5/16-24 X 1" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

13. FA20047 JAM HEX NUT 5/16-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

14. KE54927 SUPPLY WIRE PROTECTION GUARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

15 . KE00151-2 SEGMENT GEAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

19A. KE50306-2 TILT SHAFT (3, 6 & 12 GALLON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

19B. KE50375 TILT SHAFT (20 GALLON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

21. KE02057-1 TILT SHAFT BEARING ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

28. KE50245 BEARING FOR GEARBOXES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

29. FA95083 WOODRUFF KEY #808 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

30. FA19500-4 SET SCREW, 1/4-28 X 3/4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

31. KE00508 HANDWEEL ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

32 FA19505 SET SCREW 3/8-24 X 3/8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

33. KE55431 NUT, SLOTTED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

34. KE55432 COTTER PIN, 3/32 X 1 3/4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

35A. KE55433-1 SPACER, SAFETY (6 & 12 GALLON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

35B. KE55433-2 SPACER, SAFETY (20 GALLON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE02062

Page 17

380-400V (HIGH VOLTAGE)

3 KE52548 ELECTRONIC BOX BRACKET (NOT SHOWN) 1

380-600V (HIGH VOLTAGE)

(HIGH VOLTAGE)

ELECTRICAL PANEL ASSEMBLIES KE00224 KET-20-T, T-KET-6/12-T

KE00224-1 KET-3, 208-240V

KE00224-2 KET-12-TGB

KE00224-3 T-KET-3, 380-600V

KE00224-4 K-ET-6/12/20, 208-240V

KE00224-5 K-ET-6/12/20, 380-600V

KE00224-6 T-KET-6/12, 208-240V

KE00224-7 T-KET-6/12, 380-600V

KE00224-8 T-KET-12, 208-24V

14

13

12

11

7

8

17

18

1

2

3

5

10

15

9

16

10

5

23*

22*

2

14

5

10

13

11

12

10

5

15

9

1

19

16

20

17

18

7

8

1

0

5

* HIGH VOLTAGE ( 380-600 V) OPTION PARTS

FOR GEARBOX MODELS ONLY

FOR GEARBOX

MODELS ONLY

20

21*

NOTE:

Component configuration may vary according to model

but part numbers remain the same.

ELECTRICAL PANELS

KE00224 rev. F

Page 18

WIRING DIAGRAM

3 Gallon Kettles

200-240v

Single Phase Only

380-480v

Single Phase Only

Page 19

WIRING DIAGRAM

6-20 Gallon

200-240v

380-600v

Loading...

Loading...