Page 1

1333 East 179th St., Cleveland, Ohio, U.S.A. 44110

Ph: 1-216-481-4900 Fx: 1-216-481-3782 Web Site: www.clevelandrange.com

Cleveland Range, LLC

SINCE 1922

INNOVATIVE STEAM COOKING SOLUTIONS

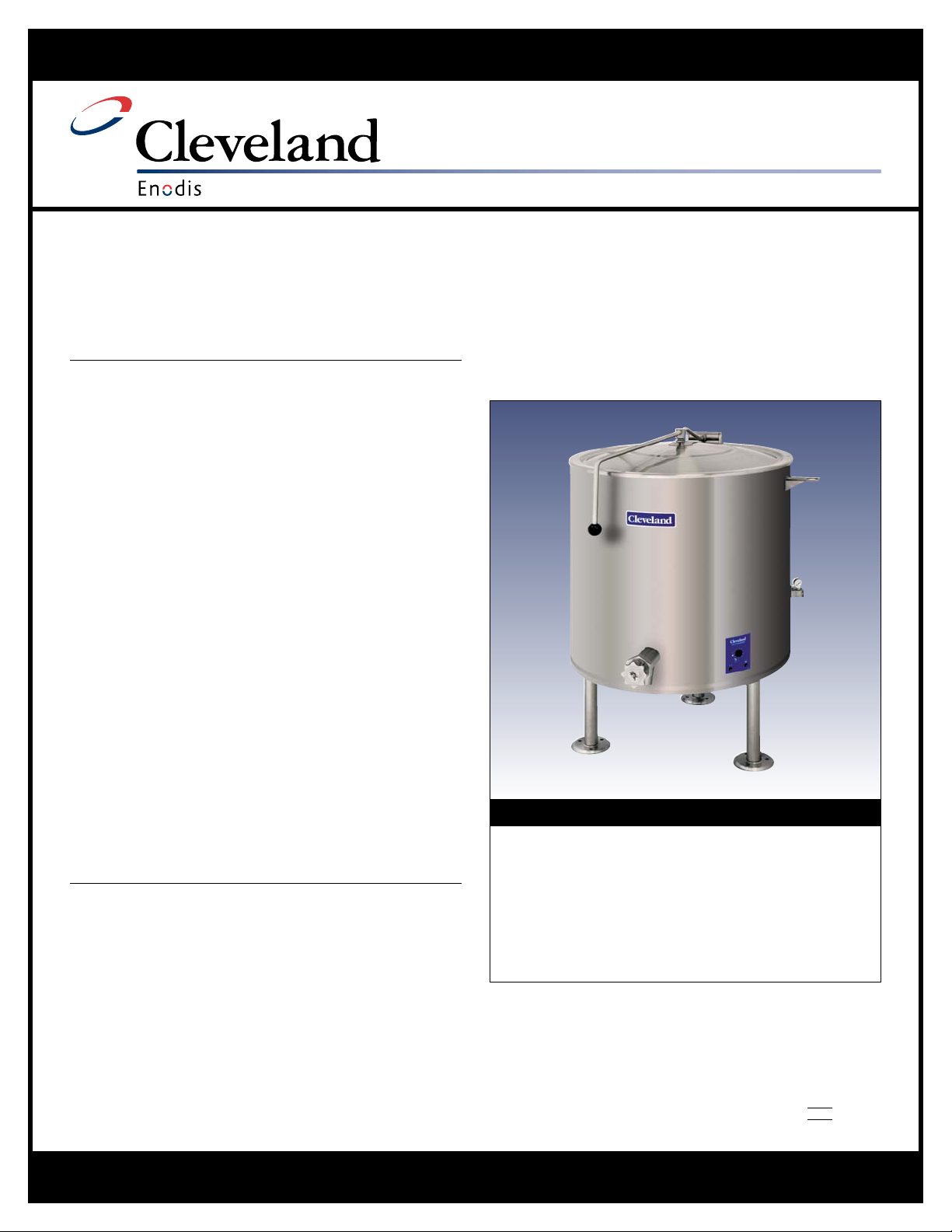

ELECTRIC KETTLES

ITEM NUMBER __________________________________________

JOB NAME / NUMBER __________________________________

Cleveland Standard Features

■ Insulated jacket keeps kitchen and the outside of kettle cool

■

Self-contained, easily installed - needs only an electrical hook-up

■ Steam jacket filled with treated water, venting and/or refilling is

not required

■ Accurate, consistant solid state temperature controls (mechanical thermostate not as accurate) - less than ±1°C variance

(ideal for simmering).Operating temperature range from 145° 260°F (63°C - 127°C)

Control panel includes:

• LED indicator for heat cycle • LED indicator for low water

• Power ON/OFF switch • Adjustable temperature control dial

■ Heavy Duty Reinforced Rim Bar:1/2’ x 1” stainless steel bar

continuously welded around the rim

■ Welded-in heating elements, (holds vacuum better, won't leak

or loose water).One extra element built in for field replacement

(standard wattage only)

■ Easily cleaned: kettle and all exterior surfaces are of type 304

stainless steel with an #4 finish

■ Rear mounted easy access pressure gauge and pressure relief

valve to prevent tampering. Color coded easy to read pressure

gauge with "green" and "vent air zone"

■ 50 psi steam jacket rating for higher cooking temperatures

■ 50 psi safety valve

■

Solid state water level control (no sight glass gauge to break or leak)

■ Faucet mounting bracket

■ 2˝ diameter tangent draw-off valve with drain strainer

■

1 5/8˝ O.D.tri-leg supports with level adjustable feet for floor bolting

■ Spring-assisted, hinged, rotatable, domed stainless steel cover

■ Standard voltage is 208-240 volts, 60 Hz, 3-phase, 3-wire

Options & Accessories

❐ Hot and Cold Water Faucet with Swing Spout (DPK)

❐ Type 316 Stainless Steel Kettle Liner for high acid food

products (316)

❐ Cooking Baskets and Tri-Basket Supports (BS and TBS)

❐ Kettle Accessor y Kit (KAK) includes:

❐ Clean-up Brush (CB) ❐ 36˝ Kettle Paddle (KP)

❐ 36˝ Kettle Whip (KW) ❐ 36˝ Kettle Brush (KB)

❐ Draw-off Brush (DB) ❐ 24 oz.Ladle (KL)

❐ Automatic Water Meter (GMF or LMF)

❐ Water Meter Stand (SWM)

❐ Lift-off Covers (CL)

❐ Drain Strainers (DS-)

❐ Measuring Strip (MS)

❐ Kettle Mar kings (KM)

Shall be CLEVELAND, Electric Kettle, Tri-leg mounted, self-contained, stationary, Model KEL - _____ gallons, 2⁄3 Steam Jacketed

with Insulated Kettle Jacket. Type 304 Stainless Steel Kettle and

Supports. Rated 50 psi with Safety Valve, Permanently filled Steam

Jacket. Spring-assisted Domed Cover. (Provide 1.50˝ Freeboard

above batches of rated size.) Splash Proof Solid State Temperature

(±1° C) and Safety Control System in plug-in Module including

L.E.D. indicators. Base Mounted for Floor Bolting with three (3), tribolt flanges. 2˝ diameter Tangent Draw-off Valve.

❐ Hot and cold or cold only Kettle Filler with 60˝ Hose

(DKF-K or SKF-K)

❐ Swing Funnels for drain (SF)

❐ Alternate Mounting Systems

❐ High Wattages and Special Voltages

❐ 3" diameter Tangent Draw-Off Valve

w/Strainer (TD3)

❐ Correctional Packages

Short Form Specifications

SECT. VIII PAGE 19

0604

TRI-LEG, ELECTRIC KETTLES

WITH INSULATED JACKET

STATIONARY, “SPLASH PROOF SERIES”, SELF-CONTAINED

2⁄3 STEAM JACKETED, 60, 80 or 100 GAL. (225, 300, or 375 LITERS)

MODELS: KEL-40-INS KEL-40-SHINS

KEL-60-INS KEL-60-SHINS

KEL-80-INS

KEL-100-INS

Page 2

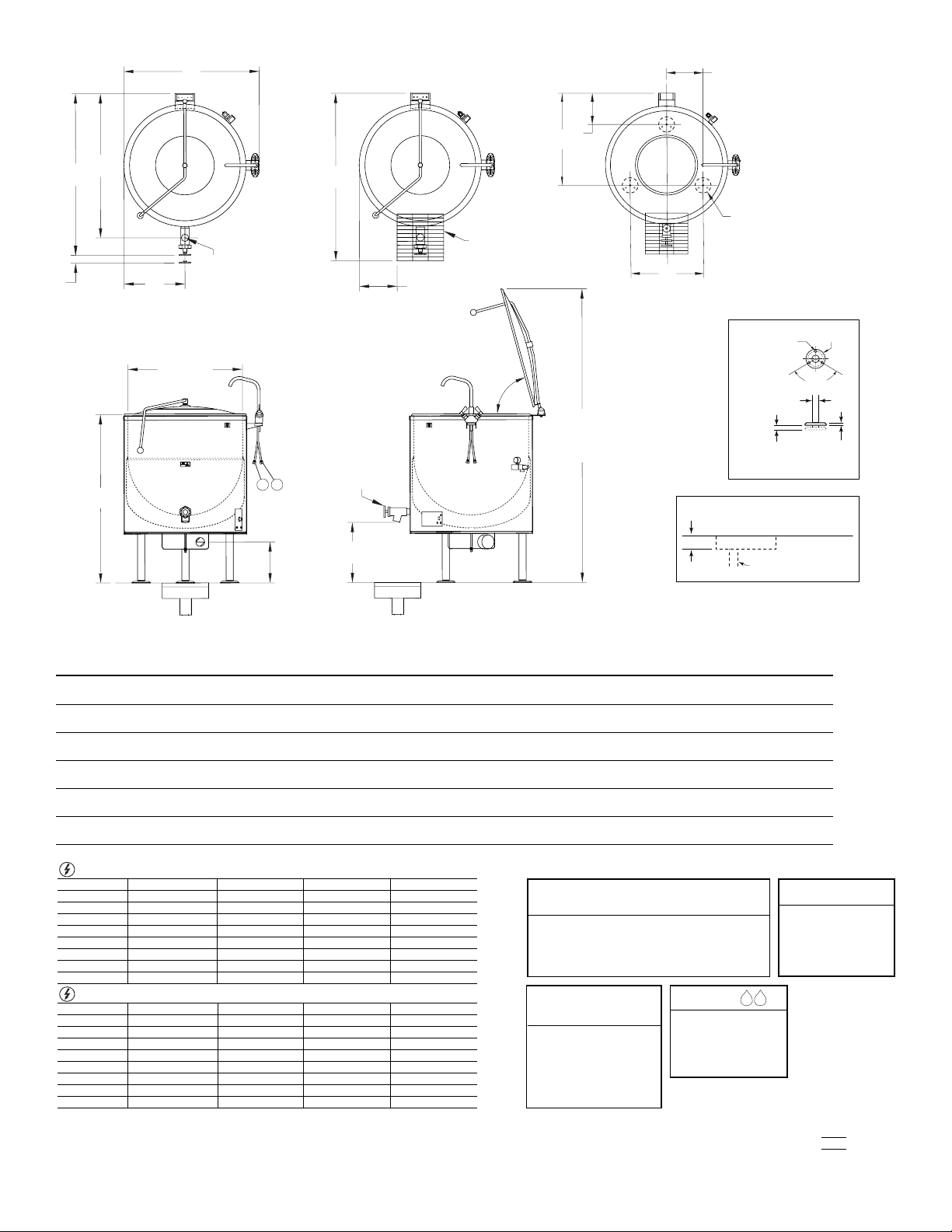

J

CAPACITIES

(in 8 oz. servings, other sizes may be calculated)

40 Gallon / 150 liters ............640 servings

60 Gallon / 225 liters ............960 servings

80 Gallon / 300 liters ..........1280 servings

100 Gallon / 375 liters..............1600 servings

ST ANDARD W A TT A GE

208V 240V 416V 480V

AMPS AMPS AMPS AMPS AMPS AMPS AMPS AMPS

MODEL KW 1PH 3PH KW 1PH 3PH KW 1PH 3PH KW 1 PH 3PH

25 100 9.8 47.2 27.2 13.1 54.4 31.4 12.1 29.0 16.7 13.1 27.2 15.7

30 115 12.3 59.0 34.1 16.3 68.1 39.3 15.1 36.2 20.9 16.3 34.0 19.6

40 150 14.7 70.8 40.9 19.6 81.7 47.1 18.1 43.5 25.1 19.6 40.8 23.6

60 225 14.7 70.8 40.9 19.6 81.7 47.1 18.1 43.5 25.1 19.6 40.8 23.6

80 300 14.7 70.8 40.9 19.6 81.7 47.1 18.1 43.5 25.1 19.6 40.8 23.6

100 375 14.7 70.8 40.9 19.6 81.7 47.1 18.1 43.5 25.1 19.6 40.8 23.6

HIGH WA TTAGE

208V 240V 416V 480V

AMPS AMPS AMPS AMPS AMPS AMPS AMPS AMPS

MODEL KW 1PH 3PH KW 1PH 3PH KW 1PH 3PH KW 1 PH 3PH

KEL-40-I

24.5 NA 68.1 32.7 NA 78.6 30.1 72.5 41.8 32.7 68.1 39.3

KEL-60-I

29.4 NA 81.7 39.2 NA 94.3 36.2 87.0 50.2 39.2 81.7 47.1

KEL-80-I

29.4 NA 81.7 39.2 NA 94.3 36.2 87.0 50.2 39.2 81.7 47.1

KEL-100-I

29.4 NA 81.7 39.2 NA 94.3 36.2 87.0 50.2 39.2 81.7 47.1

KEL-60-SHI

29.4 NA 81.7 39.2 NA 94.3 36.2 87.0 50.2 39.2 81.7 47.1

KEL-80-SHI

29.4 NA 81.7 39.2 NA 94.3 36.2 87.0 50.2 39.2 81.7 47.1

(NOT TO SCALE)

SECT. VIII PAGE 20

0604

Litho in U.S.A.

NOTES:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Cleveland Range equipment is built to comply with applicable standards for manufacturers. Included among those approval agencies are U.L., NSF, CGA, CSA, ETL and others.

Consult factory for other voltages.

CLEARANCE

WATER

3

⁄8˝ O.D.copper tube or

1

⁄2˝ N.P.T. pipe.

When ordered with

optional faucet.

H

C

RIGHT = 0

LEFT = 0

REAR = 0

Allow 12" minimum on

right side for servicing.

SHIPPING WEIGHT

(LBS./KGS)

KEL-40-I = 329/150

KEL-60-I = 401/183

KEL-80-I = 440/200

KEL-100-I = 470/214

KEL-40-SHI = 401/183

KEL-60-SHI = 440/200

DIMENSIONS

MODEL A C D E F G H J K L M O P Q R T

KEL-40-I IN

26 40 35 1/4 41 1/4 15 1/8 69 1/2 9 15/16 30 3/4 7 3/4 13 3/4 11 40 1/8 5 7/8 23 1/32 19 7/8 2

mm

660 1016 895 1048 384 1765 252 781 197 349 279 1019 149 585 505 51

KEL-60-I IN 29 1/2 43 38 3/4 44 3/4 14 5/8 75 3/4 11 7/16 34 1/4 9 1/2 15 1/2 10 1/2 43 5/8 5 7/8 25 21/32 22 7/8 2

mm

749 1092 984 1137 371 1924 291 870 241 394 267 1108 149 652 581 51

KEL-80-I IN 33 43 1/2 42 1/4 48 1/4 13 79 1/2 12 15/16 37 3/4 11 1/4 17 1/4 9 47 1/8 5 7/8 28 9/32 25 7/8 2

mm

838 1105 1073 1226 330 2019 329 959 286 438 229 1197 149 718 657 51

KEL-100-I IN 35 1/2 45 44 3/4 50 3/4 12 1/2 83 3/8 14 40 1/4 12 1/2 18 1/2 8 1/2 49 5/8 5 7/8 30 5/32 28 2

mm

902 1143 1137 1289 318 2118 356 1022 318 470 216 1260 149 765 711 51

KEL-40-SHI IN 29 1/2 35 38 3/4 44 3/4 13 67 3/8 11 7/16 34 1/4 9 1/2 15 1/2 9 1/8 43 5/8 5 7/8 25 21/32 22 7/8 2

mm

749 889 984 1137 330 1711 291 870 241 394 232 1108 149 652 581 51

KEL-60-SHI IN 33 34 7/8 42 1/4 48 1/4 9 1/2 71 12 15/16 37 3/4 11 1/4 17 1/4 5 3/4 47 1/8 5 7/8 28 9/32 25 7/8 2

mm

838 886 1073 1226 241 1803 329 959 286 438 146 1197 149 718 657 51

D

O

TANGENT

A

(I.D.)

DRAW-OFF

VALVE OUTLET

HC

T

UNIT SHOWN WITH OPTIONAL SPRING ASSIST COVER

AND DOUBLE PANTRY FAUCET

L

E

2" TANGENT

DRAW-OFF

C

M

RECOMMENDED FLOOR

DRAIN DETAIL

FLOOR DRAIN

GRATE (12"X 12")

SEE RECOMMENDED

FLOOR DRAIN DETAIL

K

F

75˚

P

Q

G

(COVER

FULLY OPEN)

R

FOOT

LOCATION

DETAIL

4" (102 mm)

RECOMMENDED

H

SEE

FLANGED

FOOT

DETAIL

7/16" (11 mm)

3 1/8" (80

1 5/8" (42 mm)

MAX. ADJUSTMENT

FLANGED FOOT DETAIL

Ø

3 HOLES ON

mm)

Ø

B.C.D.

Ø

1" (25

mm)

RECOMMENDED

FLOOR DRAIN

1" (26 mm) per 4' (1220 mm)

PIPE DRAIN RECOMMENDED

min. valve size plus 1" (26 mm)

124

120º

TYP

4 7/8"

Ø mm

9/16"

14

mm

Loading...

Loading...