Cleveland KEL Service Manual

CLEVELAND

INSTALLATION, OPERATION AND REPAIR MANUAL

CLEVELAND RANGE INC.

1333 East 179th St.

Cleveland. Ohio

U.S.A. 44110

(216)481-4900

9209 REV:1 213-01CC

KET-06

CLEVELAND

INSTALLATION, OPERATION AND MAINTENANCE

INSTRUCTIONS FOR

ELECTRIC SELF-CONTAINED KETTLES

FLOOR MODELS

KEL-25

KEL-40

KEL-60

KEL-80

KEL-100

KEL-25-T

KEL-40-T

KEL-60-T

KEL-80-T

KEL-100-T

SSE -25-L

SSE -40-L

SSE -60-L

SSE -80-L

SSE -100-L

SSE -25-T

SSE -40-T

SSE -60-T

SSE -80-T

SSE -100-T

RETAIN THIS MANUAL FOR YOUR REFERENCE

INSTALLATION INSTRUCTIONS

WARNING:

Installation of this kettle must be accompanied

by qualified electrical installation personnel

working to all applicable local and national

codes. Improper installation of this product could

cause injury or damage.

This equipment is built to comply with applicable

standards of manufacturers. Included among

these approval agencies are UL,

NSF,ASME/Ntl. Bd., CSA,ETL,and others.

Many local codes exist, and it is the

responsibility of the owner and installer to

comply with these codes.

INSPECTION

Before unpacking visually inspect the unit for

evidence of damage during shipping. If damage is

noticed, do not unpack the unit, follow shipping

damage instructions.

4. Fill out all carrier claims forms and have

the examining carrier sign and date each

form.

INSTALLATION

The first installation step is to refer to the

specification sheet for the clearance

requirements, in order to determine the location of

the kettle. Next, carefully cut open the shipping

carton for easy removal of the kettle.

SHIPPING DAMAGE INSTRUCTIONS

If shipping damage to the unit is discovered or

suspected, observe the following guidelines in

preparing a shipping damage claim.

1. Write down a description of the damage

or the reason for suspecting damage as

soon as it is discovered. This will help in

filling out the claim for ms later.

2. As soon as damage is discovered or

suspected, notify the carrier that

delivered the shipment.

3. Arrange for the carrier's representative

to examine the damage.

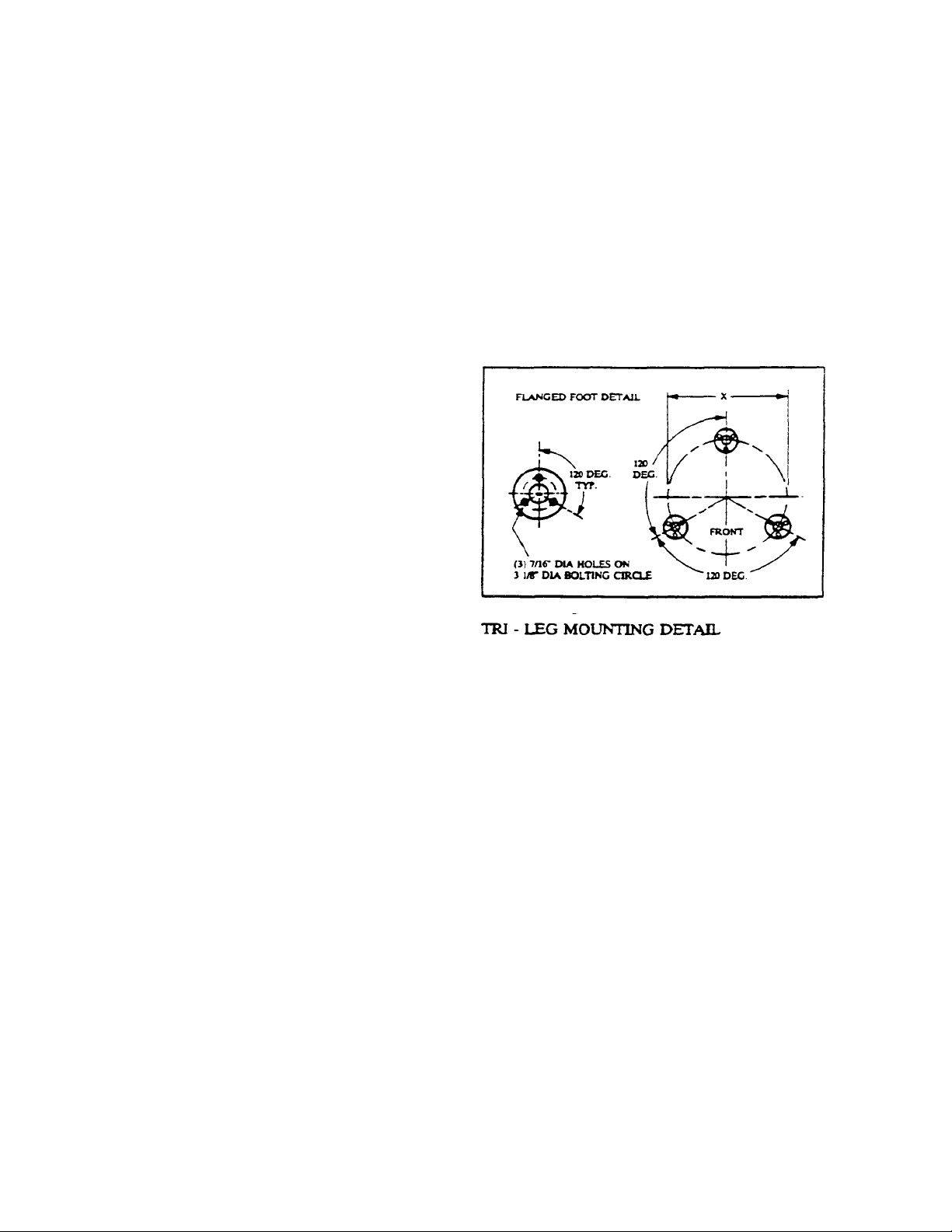

ASSEMBLY

Position the kettle in its' permanent location, and

level the kettle by turning the adjustable flanged

feet. Once positioned and leveled, permanently

secure the kettle's flanged feet to the floor using

5/16 inch lag bolts and floor anchors (supplied by

the installer). There are three bolts required to

secure each of the flanged feet.

1

ELECTRIC SERVICE CONNECTION

TILTING MODELS

Install in accordance with local codes and/or the

National Electric Code ANSI/NFPA No. 70-1990

(USA) or the Canadian Electric Code CSA

Standard C22.1 (Canada). A separate fused

disconnect switch must be supplied and installed.

The kettle must be electrically grounded by the

installer.

The electric supply must match the power

requirements specified on the kettle's rating plate.

The copper wiring must be adequate to carry the

required current at the rated voltage. Refer to

specifi cation sheet for all electrical specifications.

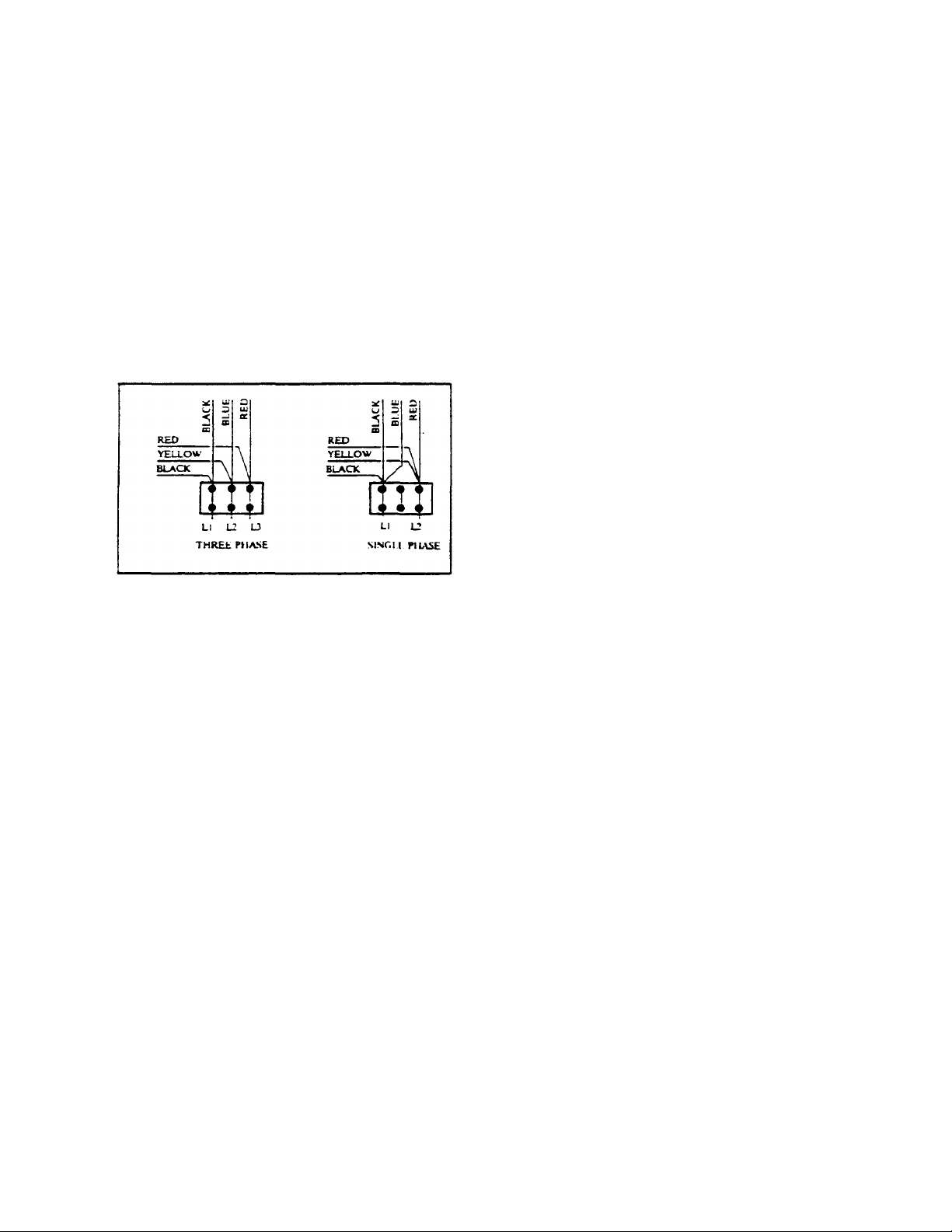

The kettle is wired for 3-phase operation at the

factory. For single phase operation, rewire the

terminal block to that shown in the accompanying

diagram.

Remove the screw at the rear of the console

cover and remove the cover. A wiring diagram is

affixed to the underside of the console cover.

Feed permanent copper wiring through the cutout in the bottom of the console, and fasten to the

three-connection terminal block. Be sure to

connect the ground wire to the separate ground

terminal connector (ground lug). Replace the

console cover and secure it with the screw.

INSTALLATION CHECK

Although the kettle has been thoroughly tested

before leaving the factory, the installer is

responsible for ensuring the proper operation of

the kettle once installed.

1. Supply power to the kettle by placing the

fused disconnect switch to the "on"

position.

2. Read the vacuum/pressure gauge to

ensure that the needle rests in the green

zone(at room temperature). If the needle

is in the "vent air" zone, refer to the

"Kettle Venting Instructions".

3. Place the kettle's power on/off switch to

the "on" position.

ELECTRICAL CONNECTION

STATIONARY MODELS

Remove the screws securing the dome -shaped

service cover underneath the kettle and remove

the cover. A wiring diagram is affixed to the

inside of cover. Fasten permanent copper wiring

to the three-connection terminal block. Be sure to

connect ground wire to the separate ground

terminal connector (ground lug). Slide the cover's

slot over the wiring and secure the cover to kettle

with the screws.

4. Turn the temperature control knob to

"min". The green LED light should

remain lit, indicating the heater elements

are energized, until the set temperature

(124°F/50°C) is reached. Then the green

light will cycle on and off with the

thermistor (solid state control).

2

5. If the kettle is a tilting model, tilt the

kettle forward. The red "low water" light

should be lit when the kettle is in a tilted

position. This light indicates that the

heater elements are not submerged in

water, and they have automatically been

shut off by the kettle's safety circuit. This

is a normal conditon when kettle is in a

tilted position.

6 Lower the kettle to the upright position.

The red "low water" light should go out

when the kettle is upright. If the red light

remains lit in the upright position, it

indicates a low water condition, and water

must be added to reservoir before the

kettle can be operated. Refer to the

"Reservoir Fill Procedures", on the kettle's

label, for details.

7. Turn the temperature control knob to

"max." and allow the kettle to preheat.

The green light should remain on until the

set temperature is reached (260°F/127°

C), then cycle on and off with the

thermistor. Fill the kettle with cold water

to the steam jacket's welded seam. Refer

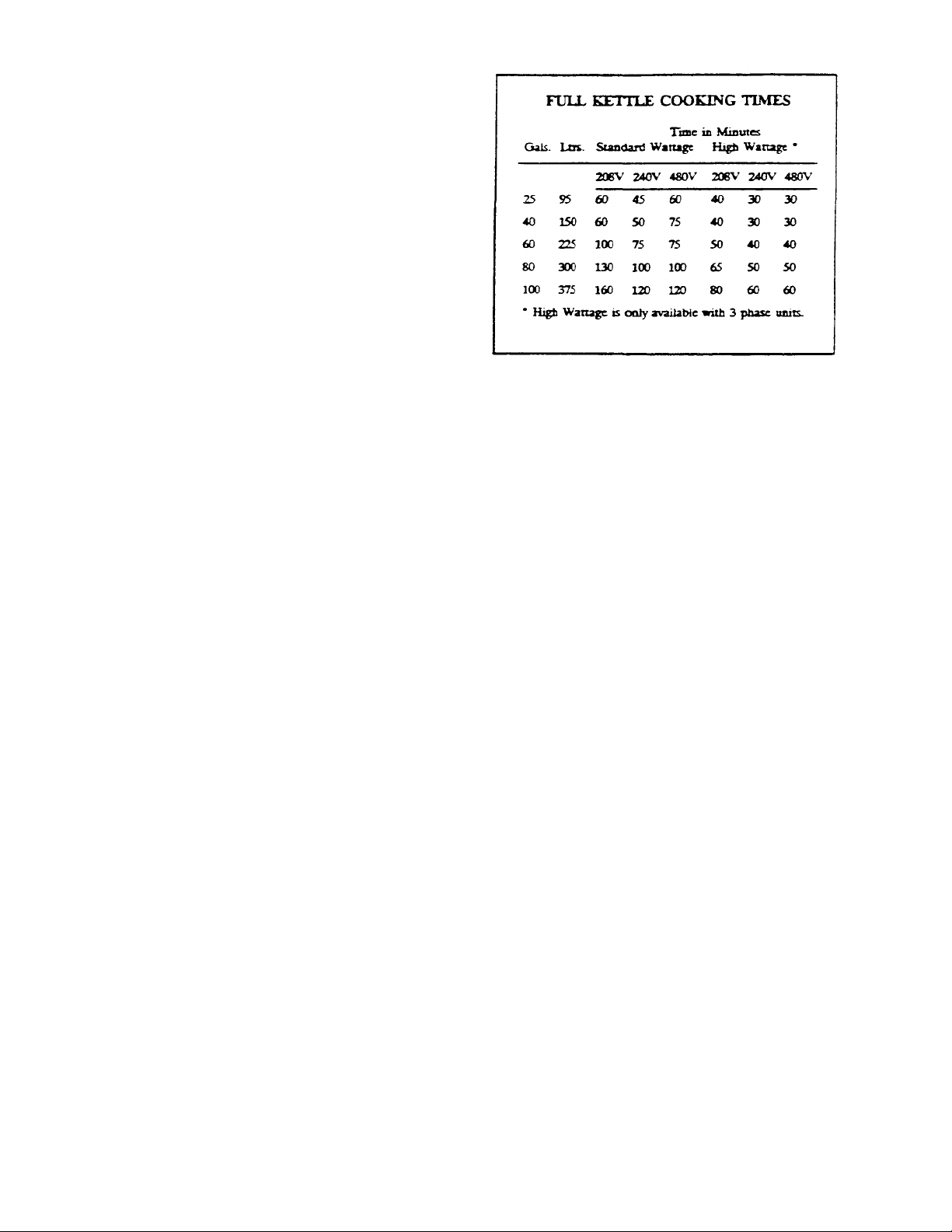

to the chart below for the time required to

bring the water to a boil.

8. When all testing is complete, empty the

kettle and place the power on/off switch

in the "off" position.

The accompanying chart shows

approximate times required for electric

kettles of various capacities to boil water.

Temperature control knob must be set at

"Max." throughout the heatup period.

Water will boil about 1/3 faster if the

kettle is filled only to the outer steam

jacket's welded seam, resulting in a kettle

filled to 2/3 capacity.

KETTLE VE NTING INSTRUCTIONS

If the vacuum/pressure gauge reading is in the

"vent air" zone, it means that the air has entered

the steam/water jacket, resulting in little or no

vacuum. Air inside the jacket will act as an

insulator therefore reducing kettle efficiency. To

remedy this situation, the following venting

procedures should be followed:

1. With the temperature control knob set at

number 6 or 7, heat the empty kettle

until the vacuum/pressure gauge

indicates 5-10 psi.

2. Release steam and air from the

steam/water jacket by loosening, one -half

turn, the 7/16 inch chrome-plated brass

venting valve nut (located at the rear of

the kettle) for 10-15 seconds.

3. Tighten the vent valve nut, being careful

not to overtighten.

The kettle's steam/water jacket should now be

free of air. At room temperature, the pressure

gauge needle should rest in the green zone,

indicating a vacuum in the kettle's jacket.

3

To check the gauge for proper vacuum after

venting, the temperature can be quickly reduced

by filling the kettle with cold water.

If the kettle will not hold a vacuum, have a

qualified service technician test for leaks at the

vent valve, the safety valve, the probe, and the

vacuum/pressure gauge fittings. We suggest

mixing a 50/50 solution of liquid detergent and

water while heating the kettle to at least 5 psi

pressure. Then, shut off power to the kettle at the

fused disconnect switch.

The soapy solution should be applied to the

suspected area while the gauge shows at least 5

psi pressure. Any bubbles which appear will

indicate a leak.

WARNING: The fused disconnect

switch must be off before removing the

kettle's bottom cover, which exposes

dangerous high voltage.

RESERVOIR FILL PROCEDURES

The reservoir's water level must be maintained at

the proper level to submerge the heater elements.

Under normal operating conditions, the sealed

water reservoir should never require the addition

of water. If the red "low water" light comes on

during use (while the kettle is in an upright

position), the water level has reached a critically

low level. The low water protection control has

automatically shut off the heater elements. The

following procedure must be completed before

further use:

NOTE: Have a qualified service

technician locate and repair the

leakage problem before adding

water to the unit. Ensure that the

red "low water" light is on when

the kettle is upright.

On tilting kettles, it is normal for the red light to

come on when the kettle is in a tilted position, as

the elements are not submerged in water at this

point.

1. Ensure kettle is at room temperature.

2. Shut off power to the kettle at the fused

disconnect switch.

3- Remove the bottom cover (tilting kettles

can be tilted forward for easier access to

the cover). Tilt the kettle back to the

upright position once the cover has been

removed.

4. Unscrew and remove the chrome -plated

brass venting valve nut located on the

back of the ke ttle.

5. Hold the safety valve open while adding

distilled water through the vent hole,

using a funnel. Refer to chart below for

the proper amount required.

6. Place the chrome -plated brass venting

valve nut into the water fill bole and

carefully tighten. Do not overtighten.

Replace bottom cover.

7. Restore power to the kettle at the fused

disconnect switch.

8. The kettle must now be vented. Refer to

the "Kettle Venting Instructions".

CAUTION: Only distilled water

should be used when

adding water to a

partially filled water

reservoir. Local tap water

conditions may cause

kettle damage which is

not covered under

warranty.

4

DISTILLED WATER REQUIREMENTS

When Red

When the

Reservoir is

Completely Empty,

"Low Water Light''

Kettle

Capacity

30gaL 1.80 gal 4.25 gal

40 gal

60 gal 2.10 gal 5.50 gal

80 gal 2.60 gal 6.25 gal

100 gal 2.80 gal 7.00 gal

Comes on, Add

Distilled Water

2.00 gal.

Add Distilled Water

4.50 gal

OPERATING INSTRUCTIONS

1. Before turning the kettle on, read the

vacuum/pressure gauge. The gauges needle

should be in the green zone. If the needle

is in the "vent air" zone, refer to the "Kettle

Venting Instructions". Any air that may be

present will increase cooking times. Once

heated, the kettle's normal maximum

operating pressure is approximately 10-12

psi, while cooking a water base product

2. Ensure that the electrical service to the

kettle is turned on at the fused disconnect

switch.

3. Place the kettle's power on/off switch to

the "on" position.

NOTE: When cooking egg and

milk products, the kettle

should not be preheated,

as products of this

nature adhere to hot

cooking surfaces, These

types of food should be

placed in the kettle

before heating is begun.

5. Place the food product into the kettle.

6. Turn the temperature control knob to the

required temperature setting between

"Min." (120° F/49° C) and "Max." (260°

F/127° C). The green light will cycle on

and off with the solid state control,

indicating the heaters are cycling on and

off to maintain the set temperature.

7. The red "low water" light should not be

lit during kettle operation. This light

indicates that the heater elements are not

submerged in water, and they have been

automatically shut off by the kettle's

safely circuit. On tilting kettles, it is

normal for the red light to come on when

the kettle is in a tilted position. However,

the kettle cannot be operated when the

red light remains lit while the kettle is in

the upright position. This indicates a low

water condition, and water must be added

to the reservoir. Refer to the "Reservoir

Fill Procedures " for details.

4. Preheat the kettle by turning the

temperature control knob to the desired

temperature setting (see temperature range

chart). The green light will remain lit,

indicating the heater elements are

energized, until the temperature setting is

reached. When the green light goes off, the

heaters are off, and preheating is complete.

8. When cooking is completed, place the

power on/off switch to the “off” position.

5

9. Pour the contents of the kettle into an

appropriate container by opening the

draw-off valve or tilting the kettle

forward. Care should be taken to pour

slowly enough to avoid splashing off the

product.

NOTE: As with cleaning food soil from

any cookware, an important pan of kettle

cleaning is to prevent food from drying

on. For this reason, cleaning should be

completed immediately after cooked

foods are removed. Refer to the "Care

and Cleaning Instructions" for detailed

kettle washing procedures.

WARNING: Do not use chloride base

detergents.

1. Prepare a warm water and mild detergent

solution in the kettle.

2. Remove food soil inside the kettle using

a nylon brush. Do not use a metal bristle

brush, as this may permanently damage

the kettle's stainless steel surface.

3. Loosen food which is stuck to the kettle

by allowing it to soak at a low setting.

4. If the kettle is equipped with a draw-off

valve, it should be cleaned as follows:

TEMPERATURE RANGE CHART

Temperature

Control

Setting

Minimum 120 49

1 130 54

2 145 63

3 160 71

4 170 77

5 185 85

6 195 91

7 210 99

8 230 110

9 245 118

Maximum 260 127

* Approx. Product

Temperature

°F °C

* Certain combinations of ingredients will result in

temperature variations.

a. Remove the drain screen from the

bottom of the kettle. Thoroughly

wash and rinse the screen either

in a sink or a dishwasher, then

replace it into the kettle.

b. Disassemble the draw-off valve

first by turning the valve knob

counter-clockwise, then turning

the large hex nut counterclockwise until the valv e stem is

free of the valve body.

c. In a sink, wash and rinse the

valve stem, hex nut and knob.

Wash and rinse the inside of the

valve body using a nylon brush.

d. Reassemble the draw-off valve by

reversing the procedure for

disassemble. The valve 's hex nut

should be hand tight only.

CARE AND CLEANING

Your kettle must be cleaned regularly to

maintain its fast, efficient cooking

performance, and to ensure its continued safe,

reliable operation.

6

5. Rinse kettle interior thoroughly, then

dram the rinse water.

ELECTRIC KETTLE

CALIBRATING PROCEDURE

6. Leave the cover off when the kettle is

not in use.

7. Using mild soapy water and a damp

sponge, wash the exterior of the kettle,

rinse, and dry. Avoid soaking the electric

control panel. Always turn off

equipment power before using water to

wash equipment.

NOTE: For more difficult cleaning

applications one of the following can be

used: alcohol, baking soda, vinegar, or a

solution of ammonia in water. Avoid the

use of chloride cleansers, which may

damage the kettle's stainless steel surface.

WARNING: Steel wool should never be

used for cleaning the cooking chamber of

kettle. Particles of steel wool become

embedded in the cooking surface and

rust, which may corrode the stainless

steel.

WARNING: Never hose down the kettle.

Water seeps into the underside of the

kettle, shorting and burning out the

elements.

1. Insure the unit has a vacuum before you

begin calibrating procedures. If unit

requires venting refer to "KETTLE

VENTING INSTRUCTIONS'' in this

manual.

2. Turn kettle on and set temperature dial to

maximum (10).

3. Allow the unit to cycle twice.

4. Check temperature of the inner kettle

surface with a digital thermometer.

5. Temperature should be 265°F.

6. Using a screw driver adjust temperature

by turning the potentiometer on the black

box. Turn very little. Turn clockwise to

INCREASE, and counter-clockwise to

DECREASE temperature.

7. Allow the unit to cycle twice.

8. Check temperature of the inner kettle

surface with a digital thermometer.

9. Repeat steps 4 through 8 until unit is

calibrated.

MAINTENANCE

This equipment requires very little preventive

maintenance other than daily cleaning. Some

kettles are equipped with handwheel tilting

mechanisms which require periodic preventive

maintenance to assure continued trouble-free

operation. Inspect the worm screw, tilting gears

and bearings occasionally (at least once a year).

Lubricate as required using a high temperature

grease. Remove bottom cover, heat kettle and

test pressure relief valve twice a year.

7

OPERATING CONTROLS AND INDICATORS

ITEM NO. DESCRIPTION FUNCTION

16 On-Off Toggle Switch

( Pg. 213-09DR )

20 Solid State Temperature Control Knob

( Pg. 213-09DR )

17 Heat Indicator Light (Green)

( Pg. 213-09DR )

21 Low Water Indicator Light (Red)

( Pg. 213-09DR )

15 Vacuum/Pressure Gauge

( Pg. 213-09DR )

5 Pressure Relief Valve

( Pg. 213-09DR )

Controls electrical power to kettle.

This control knob allows the operator to select

kettle heat increments from Min. to Max.(see

temperature setting chart in the operating

instructions section of this manual).

When lit, indicates that the kettle heating

elements are on. Cycles On-Off with solid state

contols.

When lit, indicates that the kettle heating

elements have cut out and the unit requires more

water. (See Reservoir Fill Procedure).

Indicates steam pressure in PSI inside the steam

jacket as well as vacuum in inches of mercury.

In the unlikely event that there is an excess steam

build-up in the jacket, this valve opens

automatically to relieve this pressure.

1 Chrome Plated Brass Vent

( Pg. 213-09DR )

NS Service Cover

( Not Shown )

1-7 Daw-Off Valve

( Pg. 600-04TD )

11 Hand Wheel

( Pg. 213-10DR )

16 Power Tilt Control Switch

( Pg. 213-12DR )

This valve is used to vent the kettle if there is

insufficient vacuum as well as for refilling the

kettle with water. (See Venting Instructions and

Reservoir Fill Procedures).

Located underneath the kettle. Remove this cover

for easy access to contactor, kettle control box,

etc.

This valve is used to empty the kettle of either

food products or wash water. It is supplied as

standard equipment on stationary models and is

optional on tilting kettles.

Turn to tilt kettle for pouring.

This switch allows the operator to tilt the kettle

up or down.

8

PARTS LIST - KETTLE BOTTOM

ITEM NO. PART NO. DESCRIPTION QTY.

1. F105025 Bleed vent elbow 1

2. KE50570 Bleed vent nut 1

3. F105022 Connector 1

4. KE50556 Probe, low water 1

5. KE51723 Safety valve, 50 PSI, 1/2" 1

6. KE50997

7. KE51226 Wire connector terminal 10

8. KF51225 Edge connector 1

9. KE00458 Solid state control box 1

10. KE50753 Relay, 12 VDC 1

11. KE51322 Contactor, 208/240V, 40 Amp. 2

KE50750 Contactor, 208/240V, 50 Amp. 2

KE50751 Contactor, 208/240V, 60 Amp. 2

12. KE50377 Terminal block section 3

SK50055 Terminal block section 3

13. KE50376 Terminal block end section 1

SK50054 Terminal block end section 1

14. KE50752 Transformer 1

15. KE50429 Pressure gauge 1

16. KE50504 Switch, toggle, SPST 1

17. KE50568

18. SK50062 Rubber boot 1

19. KE50988 Potentiometer 1

20. KE50569 Knob, potentiometer 1

21. KE50567 L.E.D. red 1

22 KE50558 Safety Thermostat (140° C) 1

23. KE00515 Thermistor 1

24. KE51005 Rotary seal 1

Blow down tube

(Standard kettles)

(Special high wattage kettles-6 elements)

(Special high wattage kettles-6 elements)

(Large, white)

(Small, black)

(Large, white)

(Small, black)

L. E. D green

1

1

9

Loading...

Loading...