Page 1

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

COOK CHILL SYSTEMS

Cook/Chill Systems

AIR AGITATED

ICE BUILDER

Cleveland Standard Features

I Direct expansion ice builder, with externally equalizing

thermostatic expansion valves.

I For operation with R-22, 404A or R507 refrigerant

(please specify).

I Liquid and suction headers are provided with single point

connections to the condensing unit.

I Coils are factory pressure tested, dried using a deep

vacuum, and filled with dry nitrogen at atmospheric

pressure for shipping.

I For fast, even temperature distribution the water return is

located on the rear of the tank and the chilled water outlet on

the front.

I Tank is constructed of 1/4" steel plate with angle stiffeners,

and all seams are double welded.

I 2" thick insulation between double plated tank bottom.

I Tank sides and ends have a 3" polystyrene insulation

between the tank wall and the outer sheathing of stucco

embossed aluminum.

I Interior of the tank is coated with a zinc dust primer.

I Standard top 2" insulated covers are sectional, overlapping,

and self-draining.

I Air blower with removable air distribution pipes, located

between each vertical bank of ice coils, for even ice

build-up and melting.

I Automatic ice bank control with temperature and

conductivity sensors. Indicates low ice condition.

I Waterproof control box mounted to outside of tank.

I Automatic water level control furnished with 3/4" water

solenoid valve.

I Available in sizes for up to 100,000 lbs. capacity.

I Accepted for use in U.S.D.A. Inspected Facilities

Options & Accessories

Ë Ice water control panel for location in production area (model

IW-CP).

Ë Condensing units for indoor or outdoor installation, air or

water cooled (specify).

Ë Water circulating pumps (must be sized by mechanical engi-

neer).

Ë Pump package stand with premounted water circulation

pump and air blower, complete with motor starters.

Ë Stainless steel evaporator coils.

Ë All stainless steel ice builder.

MODELS: IBC-50 IBC-150 IBC-250 IBC-450

IBC-75 IBC-175 IBC-300 IBC-500

IBC-100 IBC-200 IBC-350 IBC-600

IBC-125 IBC-225 IBC-400 IBC-1000

Short Form Specifications

Shall be Cleveland Model IBC-____; ____,000 lbs., capacity

air agitated ICE BUILDER for direct expansion operation;

thermostatic expansion valves; liquid and suction headers

are provided with single point connections to condensing

unit. The coils are factory tested, dried using a deep vacuum. Unit includes: Automatic water level control, insulated

covers, ice bank control, liquid line solenoid and air agitation package. Tank is constructed of 1/4" steel plate with

angle stiffeners, 3" polystyrene insulation on sides and

ends, 2" thick insulation on bottom. The exterior is covered

by stucco embossed aluminum panels.

SECT. XIV PAGE 39

0609

Page 2

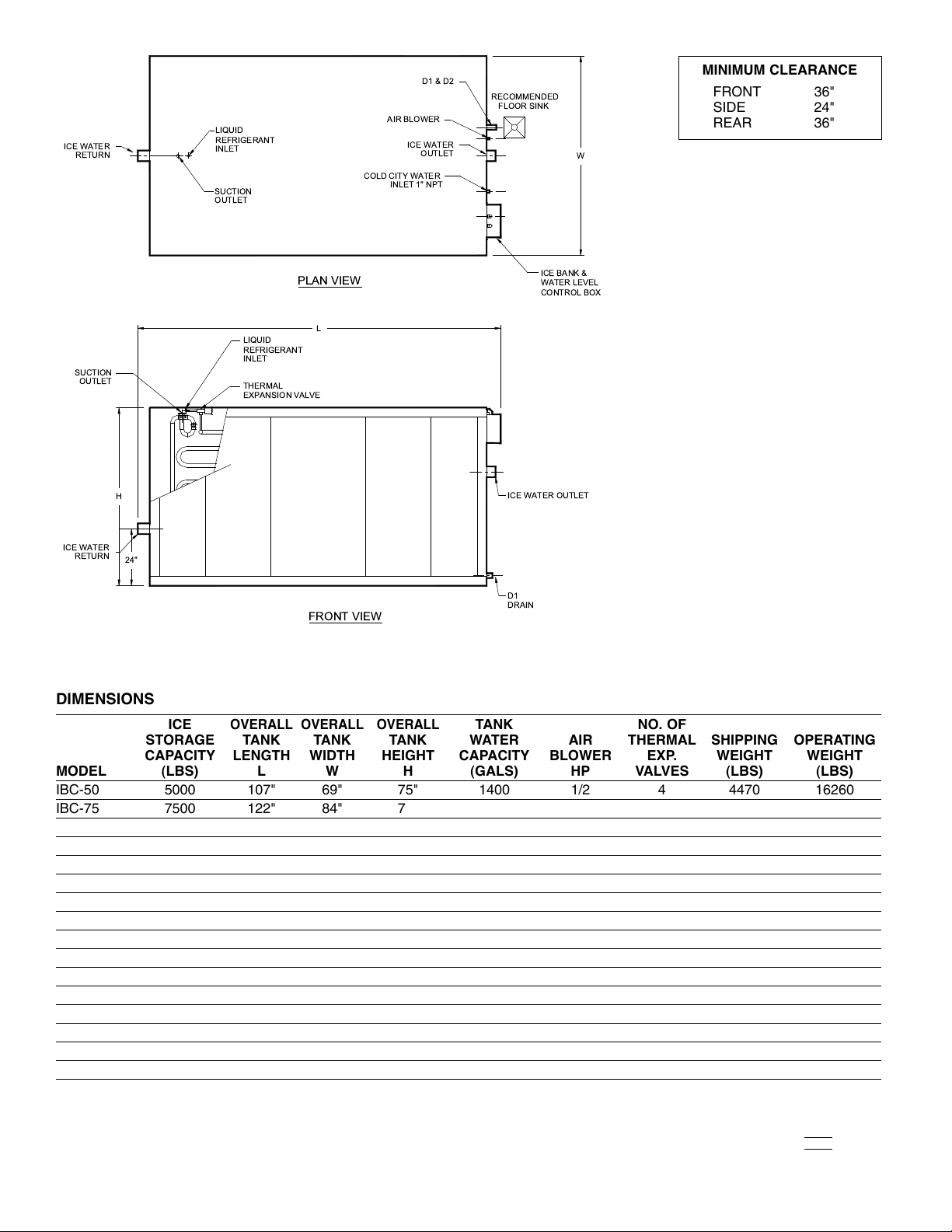

FRONT VIEW

PLAN VIEW

RECOMMENDED

FLOOR SINK

W

LIQUID

H

24"

OUTLET

SUCTION

EXPANSION VALVE

REFRIGERANT

THERMAL

INLET

LIQUID

SUCTION

O

UTLET

REFRIGERANT

INLET

ICE WATER OUTLET

D1

DRAIN

COLD CITY WATER

CONTROL BOX

WATER LEVEL

ICE BANK &

AIR BLOWER

L

INLET 1" NPT

D

1 & D2

ICE WATER

RETURN

ICE WATER

RETURN

ICE WATER

OUTLET

MINIMUM CLEARANCE

FRONT 36"

SIDE 24"

REAR 36"

ICE WATER CONNECTIONS

IBC-50 to IBC-100 3"

IBC-125 to IBC-250 4"

IBC-300 to IBC-500 5"

IBC-600 6"

IBC-1000 8"

LIQUID INLET

IBC-50 to IBC-100 7/8"

IBC-125 to IBC-250 1 1/8"

IBC-300 to IBC-400 1 3/8"

IBC-500 (2) 1 1/8"

IBC-600 to IBC-1000 (2) 1 3/8"

SUCTION OUTLET

IBC-50 to IBC-75 1 3/8"

IBC-100 to IBC-175 2 1/8"

IBC-200 to IBC-250 2 5/8"

IBC-300 to IBC-450 3 1/8"

IBC-500 (2) 2 5/8"

IBC-600 to IBC-1000 (2) 3 1/8"

AIR BLOWER INLET

IBC-50 to IBC-75 3/4"

IBC-100 to IBC-200 1"

IBC-225 to IBC-450 1 1/2"

IBC-500 to IBC-1000 2"

DIMENSIONS

ICE

OVERALL OVERALL OVERALL

TANK NO. OF

OVERFLOW

D2

IBC-50 to IBC-1000 2"

DRAIN

D1

IBC-50 to IBC-1000 3"

STORAGE TANK TANK TANK WATER AIR THERMAL SHIPPING OPERATING

CAPACITY LENGTH WIDTH HEIGHT CAPACITY BLOWER EXP. WEIGHT WEIGHT

MODEL (LBS) LW H(GALS) HP VALVES (LBS) (LBS)

IBC-50 5000 107" 69" 75" 1400 1/2 4 4470 16260

IBC-75 7500 122" 84" 75" 2150 1/2 5 5050 22900

IBC-100 10000 153" 84" 75" 2800 1 1/2 5 6500 29980

IBC-125 12500 153" 84" 90" 3150 1 1/2 5 9000 35150

IBC-150 15000 178" 84" 90" 3750 1 1/2 5 10500 42100

IBC-175 17500 173" 84" 105" 4350 3511500 47600

IBC-200 20000 194" 84" 105" 4950 3512750 54400

IBC-225 22500 184" 98" 105" 5550 3613250 59300

IBC-250 25000 201" 98" 105" 6100 3614750 66100

IBC-300 30000 236" 98" 105" 7250 3617250 78300

IBC-350 35000 236" 113" 105" 8450 3719500 90700

IBC-400 40000 206" 127" 120" 9550 3820250 100700

IBC-450 45000 228" 127" 120" 10700 3822500 112650

IBC-500 50000 381" 98" 105" 12100 5 12 28500 130400

IBC-600 60000 339" 113" 120" 14450 5 14 31000 152750

IBC-1000 100000 479" 127" 120" 23500 5 16 48500 246500

NOTES: LIQUID LINE SOLENOID VALVE, SIGHT GLASS AND AIR BLOWER SHIPPED LOOSE.

REGRIGERANT NOT SUPPLIED BY CLEVELAND RANGE.

Cleveland Range reserves right of design improvement or modification, as warranted.

(NOT TO SCALE)

SECT. XIV PAGE 40

0609

Litho in USA

Loading...

Loading...