Cleveland HA-MKGL-100 Owner’s Manual

Operators Manual

Cleveland

™

Installation & Operation

HORIZONTAL AGITATOR

MODEL: HA-MKGL-60 HA-MKGL-60-T

HA-MKGL-80 HA-MKGL-80-T

HA-MKGL-100 HA-MKGL-100-T

HA-MKGL-60-CC HA-MKGL-60-CC-T

HA-MKGL-80-CC HA-MKGL-80-CC-T

HA-MKGL-100-CC HA-MKGL-100-CC-T

GAS MIXING KETTLES

For a complete Service Manual

refer to www.clevelandrange.com

Enodis

1333 East 179th St., Cleveland, Ohio, U.S.A. 44110

Phone: (216) 481-4900 Fax: (216) 481-3782

Visit our web site at www.clevelandrange.com

SE95022 Rev. 6

FOR THE USER

IMPORTANT!

ENSURE KETTLE IS AT ROOM TEMPERATURE AND

PRESSURE GAUGE IS SHOWING ZERO OR LESS PRESSURE

PRIOR TO REMOVING ANY FITTINGS.

FOR YOUR SAFETY

WARNING: Improper installation,

adjustment, alteration, service or

DO NOT STORE OR USE GASOLINE

OR ANY OTHER

FLAMMABLE LIQUIDS AND

VAPOURS IN THE VICINITY

OF THIS OR ANY OTHER

APPLIANCE.

.

maintenance can cause property

damage, injury or death. Read the

installation and operating

instructions thoroughly before

installing or servicing this

equipment.

IMPORTANT

The following points are to insure the safe installation and operation of this equipment:

• Insure all gas and electrical supplies match rating plate and electrical stickers.

• Observe all clearance requirements.

• Disconnect the electrical power supply to the appliance before cleaning or servicing unit.

• All service must be performed by a qualified Cleveland Range Technician.

• Do not obstruct the flow of combustion and ventilation air.

The installation and connection must comply with current local codes, or in the absence of local codes, with

CAN/CGA-B149.1 and .2 installation code or with the national fuel gas code, ANSI Z223.1-L988.

Post in a prominent location, instructions to be followed in the event the user smells gas. This information shall

be obtained by consulting your local gas supplier.

The appliance and its individual shut off valve must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in excess of 1/2 psig. (3.45 kpa).

The appliance must be isolated from the gas supply piping system by closing its individual manual shut off

valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2

psig. (3.45 kpa).

RETAIN THIS MANUAL FOR YOUR REFERENCE.

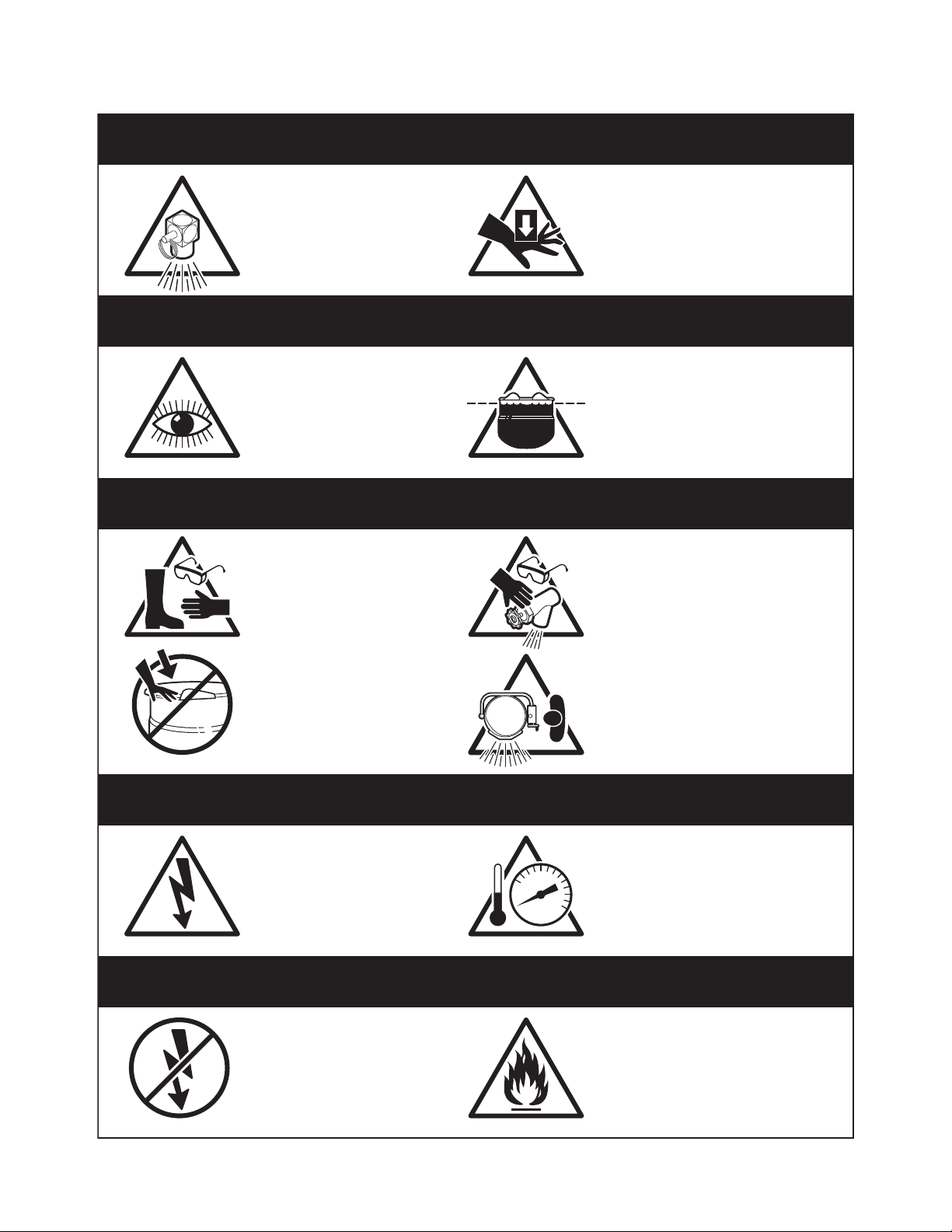

Shut off power at main

fuse disconnect prior

to servicing.

Ensure kettle is at room

temperature and pressure

gauge is showing zero or less

prior to removing any fittings.

Inspect unit daily for

proper operation.

0

Do not fill kettle above

recommended level

marked on outside of kettle.

Surfaces may be

extremely hot! Use

protective equipment.

Keep appliance and area free

and clear of combustibles.

Stand clear of product

discharge path when

discharging hot product.

Wear protective equipment

when discharging hot product.

Do not lean on or place

objects on kettle lip.

Do not attempt to operate

this appliance during a

power failure.

Keep clear of pressure

relief discharge.

Keep hands away from

moving parts and pinch points.

SERVICING

IMPORTANT

CAUTION

DANGER

GAS APPLIANCES

For your safety

INSTALLATION

GENERAL

Installation of the kettle must be accomplished by

qualified installation personnel working to all applicable

local and national codes. Improper installation of

product could cause injury or damage.

This equipment is built to comply with applicable standards

for manufacturers. Included among those approval agencies

are: UL, A.G.A., NSF, ASME/N.Bd., CSA, CGA, ETL, and

others. Many local codes exist, and it is the responsibility of

the owner/installer to comply with these codes.

Observe all clearance requirements to provide proper makeup air flow as well as sufficient clearance for servicing.

Dimensions and clearance specifications are shown on the

specification sheet and in the Clearance Requirements

section. Do not install kick plates or otherwise obstruct the

flow of combustion and ventilation air.

Check rating plate to ensure that kettle has been equipped

to operate with the type of gas available at the installation.

VENTILATION

Gas fired kettles are only to be installed under a

ventilation hood in a room which has provisions for

adequate make up air. Further information can be

obtained by referring to the U.S.A. National Fire

Protection Associations NFPA96 regulations. These

standards have also been adopted by the National

Building Code in Canada.

INSPECTION

Before unpacking visually inspect the unit for evidence

of damage during shipping. If damage is noticed, do

not unpack the unit, follow shipping damage

instructions.

SHIPPING DAMAGE

INSTRUCTIONS

If shipping damage to the unit is discovered or

suspected, observe the following guidelines in

preparing a shipping damage claim.

1. Write down a description of the damage or the

reason for suspecting damage as soon as it is

discovered. This will help in filling out the claim

forms later.

2. As soon as damage is discovered or suspected,

notify the carrier that delivered the shipment.

3. Arrange for the carrier's representative to examine

the damage.

4. Fill out all carrier claims forms and have the

examining carrier sign and date each form.

CLEARANCE REQUIREMENTS

This unit must be installed in accordance with the

clearances shown on the rating label which is adhered

to the unit.

FOR YOUR SAFETY. Keep the appliance area free and

clear of combustible materials.

KETTLE

1. When removing the kettle from the platform, handle

with care to prevent scratching or any other

damage. It is imperative that the kettle be level

before bolting to the floor. This will prevent any

twist or out of roundness to the kettle and will stop

deflection of the agitator. Make sure the kettle is

securely bolted to the floor and follow the

procedure listed below:

⇒ Raise the flange on the leg under the motor so

that it sets freely (stationary kettles only).

⇒ Position the kettle in its permanent location,

check clearances and level the kettle by turning

the adjustable feet.

⇒ Lower the flange or flanges under the motor

channel. Over adjustment, whether up or down,

could cause misalignment and cause damage to

the agitator drive shaft and hub (stationary kettles

only).

2. Next you must check the alignment of the drive

shaft for a uniform clearance between the hub and

the shaft. In order to check for clearance you must

remove the seal cover plate and pull the seal back.

You can check the distance for clearance by using

a wire feeler gauge.

3. If adjustment is required for side direction, loosen

the motor bolts, center the shaft and retighten.

If vertical alignment is needed, loosen the motor

bolts and add a shim to raise or remove a shim to

lower. Retighten bolts. When this is complete,

check to see if the agitator shaft coupling slides

freely for easy removal of the agitator.

4. Once positioned and leveled, permanently secure

the kettle’s flanged feet to the floor using 1/2 x 2 I/2

inch lag bolts and floor anchors (supplied by the

installer). Two bolts per leg are required to secure

each of the flanged feet.

CONTROL PANEL

Refer to Wiring Diagram supplied with Control Panel for

installation instructions.

GAS

It is recommended that a sediment trap (drip leg) be

installed in the gas supply line. If the gas pressure

exceeds 14” water column, a pressure regulator must

be installed, to provide a maximum of 14” water column

gas pressure to the gas control valve.

Connect the gas supply piping to the input side of the

gas control valve. Location and pressure data are

shown on the specification sheet.

Installation must be in accordance with local codes

and/or the National Fuel Gas Code ANSI Z223.1-1988

(USA) or the Installation Codes for Gas Burning

Appliances and Equipment CANI B149.1 and B149.2

(Canada). Use a gas pipe joint compound which is

resistant to L.P. gas. Test all pipe joints for leaks with

soap and water solution. Ensure that the gas pressure

regulator is set for the manifold pressure indicated on

the gas rating plate.

The appliance and its individual shut-off valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psi (3.45 kPa). The appliance must be

isolated from the gas supply piping system by closing

its individual manual shut-off valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.45 kPa).

WATER

The sealed jacket of the gas-fired kettle is precharged

with the correct amount of a water-based formula, and

therefore, no water connection is required to the kettle

jacket.

CLEANING

After installation the kettle must be thoroughly cleaned

and sanitized prior to cooking.

WARRANTY

Our Company supports a worldwide network of

Maintenance and Repair Centres. Contact your nearest

Maintenance and Repair Centre for replacement parts,

service, or information regarding the proper

maintenance and repair of your cooking equipment

In order to preserve the various agency safety

certification (UL, A.G.A., NSF, ASME/Ntl. Bd., etc.), only

factory-supplied replacement parts should be used. The

use of other than factory supplied replacement parts will

void warranty.

ELECTRICAL

Electrical installation must be in accordance with local

codes and/or the National Electric Code ANSI/NFPA 701990 (USA) or the Canadian Electrical Code CSA

Standard C22.1 (Canada). The kettle must be

electrically grounded by the installer.

A separate fused disconnect switch must be supplied

and installed in the high voltage electrical supply line.

The wire gauge size and electric supply must match the

power requirements specified on the kettle’s rating

plate. The waterproof conduit enclosed permanent

copper wiring must be adequate to carry the required

current at the rated voltage. Refer to the

SPECIFICATION SHEET or RATING LABEL for electrical

specifications and location of electrical connections.

Remove the screws securing the component cover

(located to the left rear side of kettle), and remove the

cover. A wiring diagram is affixed to the inside of the

cover. Feed conduit enclosed permanent copper wiring

through the cut-out in the bottom of the console and

fasten to the terminal block. Fasten the ground wire to

the ground lugs connected to the frame, beside the

terminal block. Replace the console cover and secure it

with the screws.

OPERATING INSTRUCTIONS

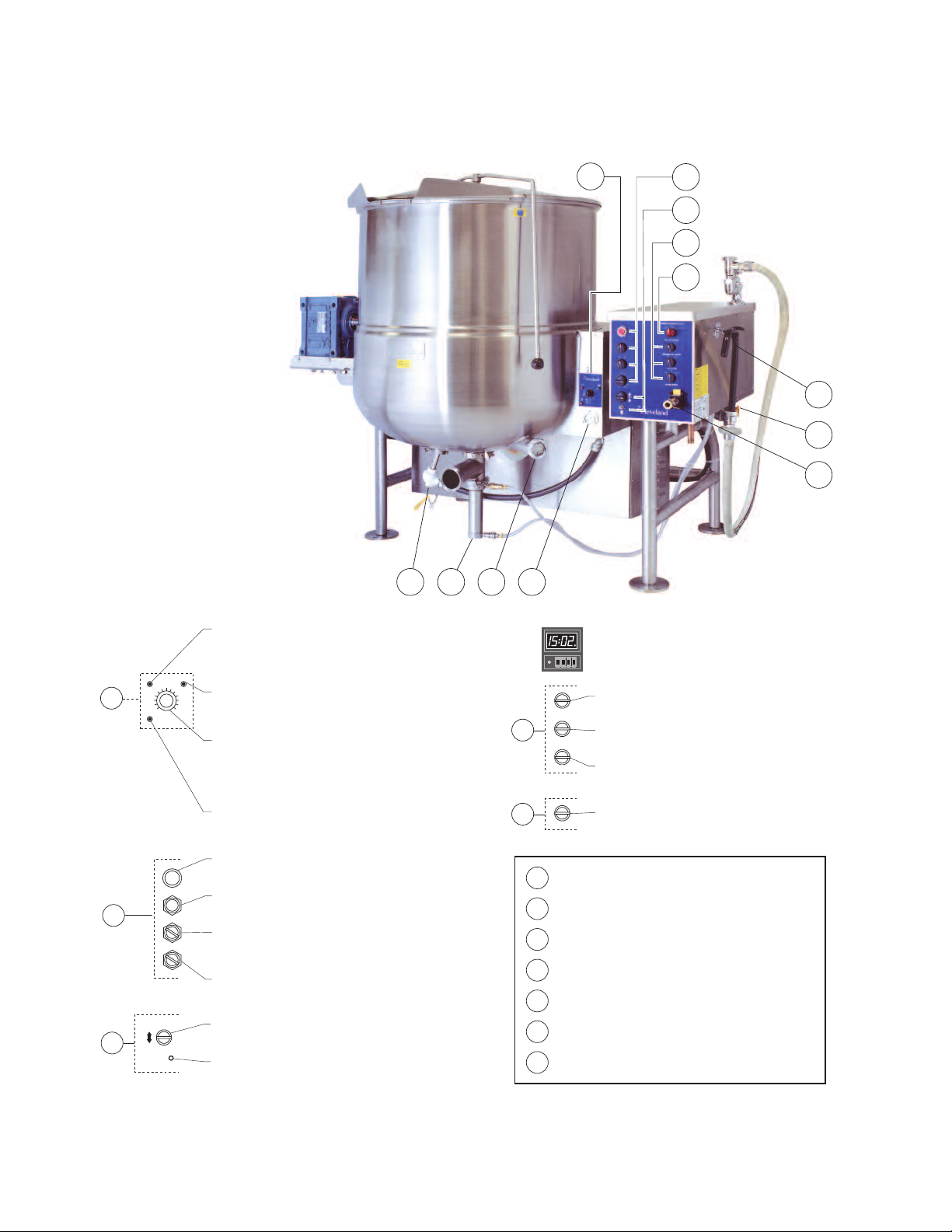

Temperature Sensor

Senses temperature of product

Automatic Dump Valve

Empties kettle of either food product or wash water

Sight Glass

For checking water level of kettle jacket

Vacuum /Pressure Gauge

Indicates steam pressure inside steam jacket in PSI, as

well as vacuum in inches of mercury

Gas Shut-Off Valve

Air Quick Connect

Push yellow tab down to release air pressure before

disconnecting air hose

Kettle Filler Nozzle

A

Red Low Water Indicator Light

When lit, in the upright position, indicates kettle gas

burner has cut out and unit requires more water.

Occasional pulsing of this light is normal.

Green Heat Indicator Light

When lit, indicates gas burner is on; cycles on-off with

solid state controls.

Solid State Temperature Control Knob /

On-Off Toggle Switch

Controls electrical power to kettle. and allows operator to

select kettle heat increments from minimum, 1-10.

A setting of 7 or higher will boil water

Amber Ignition Failure Indicator Light

Indicates failure of heating system to ignite

(Used prior to July 2004)

B

Agitator Stop Button

Stops agitator in case of emergency

Agitator Start Switch

Starts agitator. Agitator power control switch must be ON

Agitator Power Switch

Allows power to agitator. When not in use, turn control

power OFF

Agitator Speed Control Switch

Turn clockwise until desired speed is reached

1

2

3

4

5

6

7

21 3

5

7

6

B

C

D

A

E

4

CCC

Power tilt control switch

Tilts kettle for pouring; some kettles have manual hand tilt

Reset circuit breaker

Protects power tilt system from overload. Push to reset

EEE

DDD

Fill Interrupt Switch

Interrupts water fill cycle

Potable Fill Water Switch

Selects hot or cold water

Fill Cycle Switch

Start/continue cycle switch

Product Discharge Valve Switch

Toggle momentary switch to desired valve opening

Water Meter Digital Counter (not shown)

Location may vary dependant on customer's specific

options

0 123

NOTE:

Location of

switches may

vary dependant

on customers

specific options

Parts Description Kettle

General

WARNING: Do not attempt to operate this appliance

during a power failure. Keep appliance and area free and

clear of combustibles.

Before turning kettle on, ensure that following

conditions exist:

• If you are cooking an egg or milk product, do not

pre-heat kettle.

• The vacuum/pressure gauge needle is in green

zone; if it is not and is in "vent air" zone, call your

service agent to repair leak.

• The electrical service to kettle is turned on

NOTE: The kettle should be sanitized prior to the daily

production run - see CLEANING INSTRUCTIONS .

Mixing ("AGITATOR ")

WARNING:

Never add product to kettle while agitator is running.

•

•

Do not put hands in kettle.

•

Watch for loose clothing near agitator.

1. Turn "SPEED CONTROL" to "0".

2. Switch agitator to "ON".

3. Push agitator "START" to initiate mixing.

4. Turn "SPEED CONTROL" to desired mixing speed.

5. To stop mixing action, push agitator stop button.

NOTE: Mixing speed depends on the product

consistency. The faster the mixing speed the more

damage may be done to fragile product.

Heating (General Notes)

• The green light cycles on and off, indicating that

burners are cycling to maintain set temperature.

• The red "low water" light should not be lit during

operation. This light indicates that water level is

critically low and that gas burners have

automatically shut off. Before further use, refer to

RESERVOIR FILL INSTRUCTIONS for adding

distilled water.

• Occasional flashing of the red "low water" light is ok

while kettle is heating.

Manual Heating

1. Switch "POWER" to "ON".

2. Turn temperature control knob to desired setting.

3. Switch "CONTROLLER" to "BYPASS".

4. After closing discharge valve, place product in kettle.

Automatic Heating

1. Switch "CONTROLLER" to "ACTIVE".

2. Turn temperature control knob to "10".

3. Continually push function key " " until "OFF" is

displayed.

4. Push and hold key " " or " " until desired

temperature is set.

5. To Start:

" " until "CtrL" is displayed.

6. Push down key " ".

7. To Stop:

" " until "OFF" is displayed.

8. Push down key " ".

9. After closing discharge valve, place product in kettle.

push function key

push function key

Emptying the Kettle

1. To open automatic dump valve:

• Turn PRODUCT DISCHARGE VALVE switch

clockwise to JOG TO OPEN. Release switch to the

HOLD position when desired valve opening is

achieved.

• To close valve, turn switch counterclockwise to

CLOSED position.

2. To avoid splashing, slowly empty kettle contents into

an appropriate container by partially opening dump

valve.

NOTE: When pumping with a Metering Filling Station the

speed of the agitator arm must be sufficient to suspend

the heavier items in the mix in order to achieve an even

distribution in your packaged items.

3.

Immediately clean kettle as outlined in CLEANING

INSTRUCTIONS on page.

Water Meter

1. Switch "POTABLE FILL WATER" to "HOT" or "COLD".

2. Set required volume by first pushing the " " key

until the digit you want to change is flashing in the

lower display. Then use the " " key to change the

value of the selected digit.

When all digits are set, press the "ENT" key.

3. Locate delivery spout over kettle.

4. Turn switch to "RESET". Delivery will start at "0" and

stop at preset volume.

5. To stop delivery at any time, turn "FILL INTERRUPT"

switch to " ● ".

6. To complete delivery after interrupting, turn switch

"FILL CYCLE" to "CONTINUE".

Stagnant

Water

High Pressure

Spray Hose

Chloride Cleaners

Steel Pads

Wire Brush &

CLEANING INSTRUCTIONS

CLEANING INSTRUCTIONS

CAUTION

SURFACES MAY

BE EXTREMELY HOT!

1. Turn unit off.

2. Remove drain screen (if applicable). Thoroughly

wash and rinse the screen either in a sink or a

dishwasher.

CARE AND CLEANING

Cooking equipment must be cleaned regularly to

maintain its fast, efficient cooking performance and

to ensure its continued safe, reliable operation. The

best time to clean is shortly after each use (allow

unit to cool to a safe temperature).

WARNINGS

➩ Do not use detergents or

cleansers that are chloride

based or contain quaternary

salt.

➩ Do not use a metal bristle

brush or scraper.

➩ Steel wool should never be

used for cleaning the stainless

steel.

➩ Unit should never be cleaned

with a high pressure spray

hose.

3. Prepare a warm water and mild detergent solution in

the unit.

4. Remove food soil using a nylon brush.

5. Loosen food which is stuck by allowing it to soak at

a low temperature setting.

6. Drain unit.

7. Rinse interior thoroughly.

T

8. If the unit is equipped with a

VVaallvve

e

a) Disassemble the draw-off valve first by turning

the valve knob counter-clockwise, then turning

the large hex nut counter-clockwise until the

valve stem is free of the valve body.

b) In a sink, wash and rinse the inside of the valve

body using a nylon brush.

Use a nylon brush to clean tangent draw-off tube.

c)

d) Rinse with fresh water.

e) Reassemble the draw-off valve by reversing the

procedure for disassembly. The valve's hex nut

should be hand tight only.

9. If the unit is equipped with a

s follows:

a

a) Place valve in open position.

b) Wash using a warm water and mild detergent

solution.

c) Remove food deposits using a nylon brush.

d) Rinse with fresh water.

e) Leave valve open when unit is not in use.

10. Using mild soapy water and a damp sponge, wash

the exterior, rinse, and dry.

, clean

as follows:

Taannggeenntt DDrraaww--OOffff

BBuutttteerrffllyy VVaallvve

e

, clean

➩

Do not leave water sitting in unit

when not in use.

NOTES

➩ For more difficult cleaning applications one of the

following can be used: alcohol, baking soda, vinegar,

or a solution of ammonia in water.

➩ Leave the cover off when the kettle is not in use.

➩ For more detailed instructions refer to the Nafem

Stainless Steel Equipment Care and Cleaning manual

(supplied with unit).

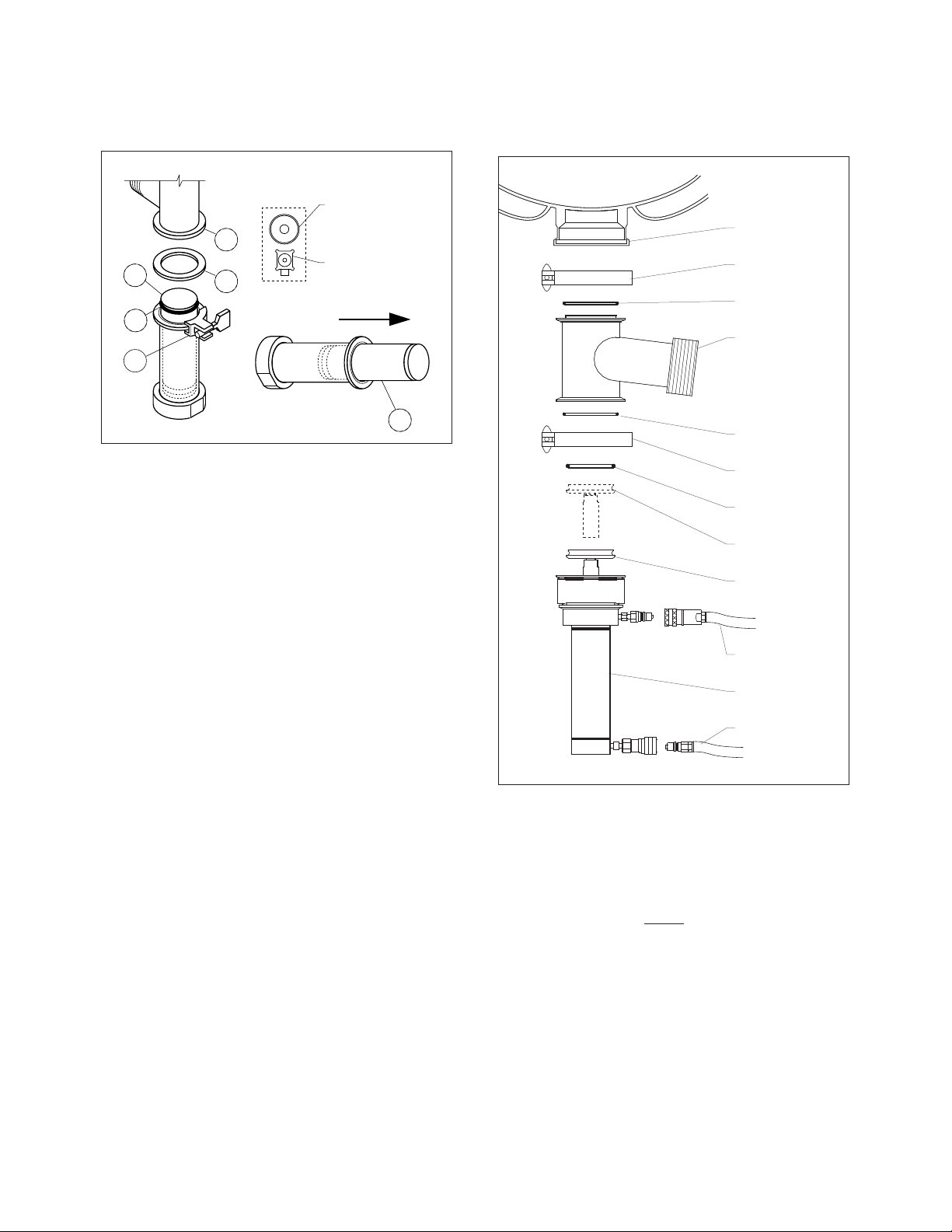

FLUSH PISTON VALVE

5

2

3

4

1

Air regulator

Controls air flow to

automatic dump valve,

turn clockwise to open and

counterclockwise to close

(extend plunger)

Air quick connect

Push yellow tab down to

release air pressure before

disconnecting air hose

4

AIR VALVE

ASSEMBLY

FPVA-3

AIR HOSE

AIR

CYLINDER

AIR HOSE

OPEN

POSITION

CLOSED

POSTITION

0-RING

CLAMP

0-RING

VALVE

TEE

0-RING

CLAMP

KETTLE

OUTLET

KETTLE

(Used prior to 2003.)

Daily - clean valve as follows:

To remove valve from kettle:

1. Place valve in open position.

2. Holding bottom of valve, loosen and remove sani-

clamp (1).

3. Lower valve, and remove from body.

4. Remove sani-clamp seal (2) and "O" ring (3).

5. With valve on its side, turn air dial

counterclockwise to extend plunger.

6. Disconnect air supply at valve.

7. Being careful not to submerge entire valve in water,

wash cylinder body (4), inside valve body (5), "O"

ring and seal.

⇒ Wash in a sink, using a warm water and mild

detergent solution.

⇒ Rinse with fresh water and then sanitize using a

properly diluted sanitizing solution.

⇒ Allow to air dry thoroughly on a flat, clean

surface.

To install valve on kettle:

1. Replace "O" ring and seal if worn.

2. Coat cylinder body and "O" ring with cooking oil or

food safe grease.

3.

Coat kettle cylinder with cooking oil.

4.

Reconnect air supply.

5.

With valve on its side, place valve in open position

by turning air regulator clockwise.

6.

Put valve in place, and secure with sani-clamp.

(Used after 2003.)

Daily - clean valve as follows:

1.

Open product valve.

2.

Disconnect air hoses.

3.

Remove air cylinder.

4.

Remove valve tee.

5.

Remove all O-rings.

6.

Clean air cylinder, do not submerge in water. Wipe

clean and sanitize.

7.

Clean and sanitize tee and O-rings.

8.

Grease and reinstall O-rings.

9.

Reinstall tee to kettle outlet.

10.

Reinstall air cylinder to bottom of tee.

11.

Reconnect air hoses.

12.

Close valve and check for alignment.

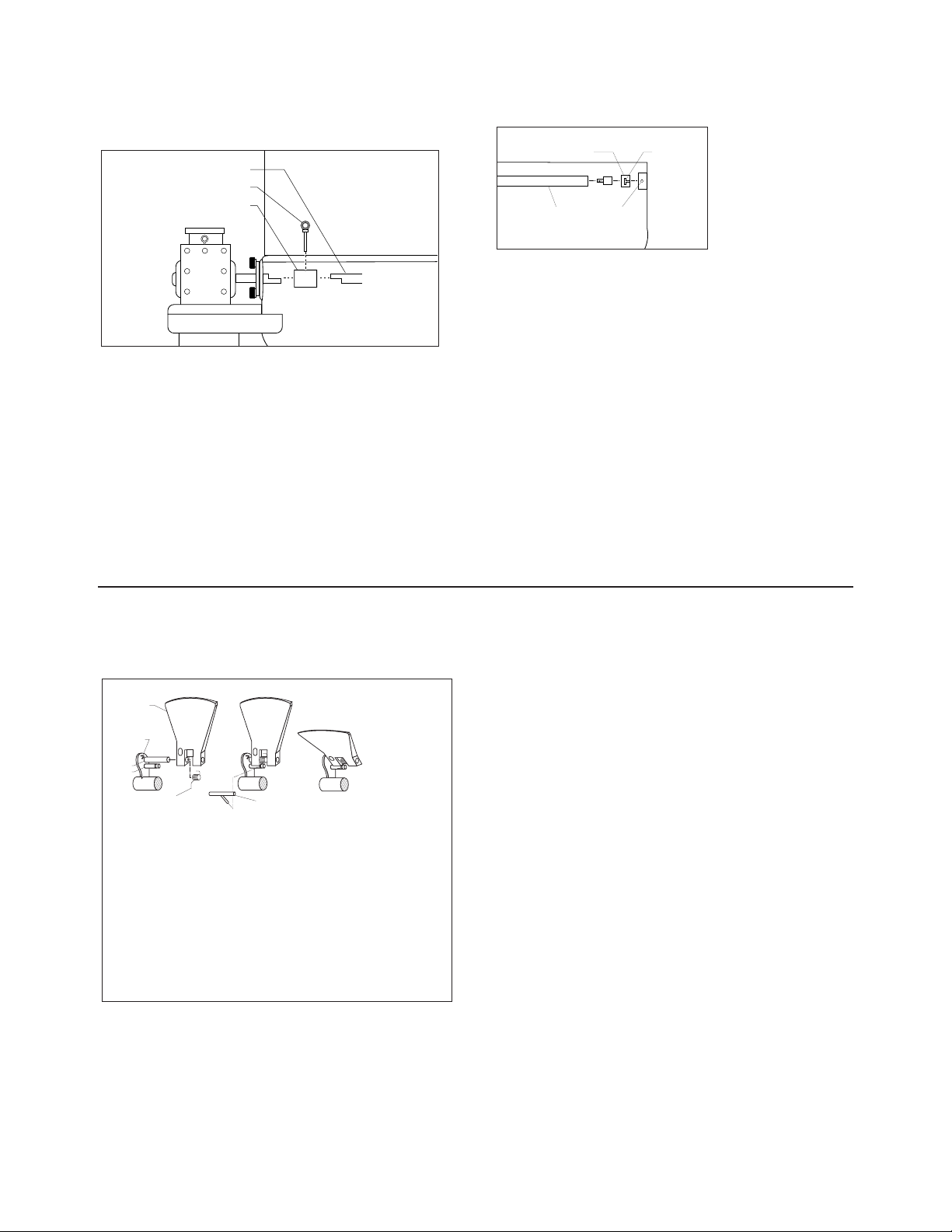

AGITATOR

Agitator shaft

Pin

Coupling

Fig. 2 Fig. 3Fig. 1

Scraper

blade

Back stop

Pin A

Pin B

Tool

Spring

To Install Scraper Blade

1. Slide scraper blade and spring onto Pin A as shown in Fig. 1.

2. Hook spring arm and pull up.

3. Using tool, engage spring arm into groove on Pin B.

Scraper blade is now in place.

To Remove Scraper Blade

1. Insert tool that is provided as shown in Fig. 2.

2. Pull up on spring arm until arm clears groove in Pin B.

3. Spring is now disengaged, gently release spring to remove

scraper blade.

Slot

Bushing

Retaining

pin

Agitator

Shaft

To remove and clean agitator (two-person

job):

1. Remove scraper blades.

2. Rotate agitator until pull pin is on top side.

3. Turn power OFF.

4. Pull pin out.

5. Slide coupling toward kettle wall, and carefully lift

agitator pulling back to lift out.

6. Clean in a sink, using a warm water and mild

detergent solution.

7. Rinse with fresh water.

AGITATOR BUSHING

With agitator out, remove bushing by:

1. Remove bushing by turning 1/4 turn and pulling

away from the kettle wall.

2. Clean, rinse and sanitize bushing and bushing

mounting area.

3. Lubricate metal surfaces with food safe grease.

4. Install bushing by locating retaining pin and sliding

bushing on.

5. Rotate to lock into position.

SCRAPER BLADES

To remove and clean scraper blades:

1. Remove scraper blades using the tool to release the

spring from the retaining pin and sliding the blade off

the shaft.

2. Place parts in a pan of warm water to soak.

3. Clean in a sink, using a warm water and mild

detergent solution.

4. Rinse with fresh water.

5. Allow to dry thoroughly on a flat, clean surface.

Loading...

Loading...