Page 1

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

COOK CHILL SYSTEMS

Cook/Chill Systems

COOK/CHILL

HORIZONTAL AGITATOR

TILTING MIXER KETTLES

Cleveland Standard Features

I Full 60, 100, 150, 200 or 300 gallon working capacity

I Electrically driven, Tilting, Horizontal Agitator Mixer Arm

I Hydraulic kettle tilt mechanism with kettle mounted power-pack

I Variable mixer speed control

I Spring loaded blades scrape entire heated surface area

I Internal mixing fins for most efficient, uniform mixing, heating

and cooling

I Flush mounted, easily removable temperature sensor

I Simmer control for cooking delicate products

I 3” diameter air operated, flush mounted piston draw-off valve

(requires air compressor)

I Spiral flights for even water cooling

I Easily removable agitator without the use of tools

I Spring assist, one piece cover (bifold cover with

counterweight for 300 gallon model)

I Heavy duty rim bar

I 100 psi steam jacket rating and safety valve

I Type 316 stainless steel for all food contact surfaces

I Water fill faucet with swing spout

I Kettle mounted valve box for single point utility connections

I NSF approved

I Accepted for use in USDA inspected facilities

Note: This COOK/CHILL mixer kettle requires a control panel for opera-

tion which must be specified separately.

Standard Features for Kettle Control Center:

I Solid state temperature control with digital read-out

I Time/Temperature Chart Recorder to provide permanent record

of Batch Processing

I Automatic and manual steam control

I Automatic and manual water cooling

I Simmer control for delicate products

I Automatic water meter with accumulative “add on” button and

digital readout

I U.L. listed

Options & Accessories

Ë Clean in place (CIP) agitator idler bearing with hot water/steam

connector

Ë Water meter for hot and cold kettle fill

Ë Single or dual remote control center

MODELS:

HA-MKDL-60-CC-T HA-MKDL-200-CC-T

HA-MKDL-100-CC-T HA-MKDL-300-CC-T

HA-MKDL-150-CC-T

Short Form Specifications

Shall be CLEVELAND Model HA-MKDL-___-CC-T; COOK/CHILL

HORIZONTAL TILTING MIXER KETTLE, ___ gallons; leg mounted;

2/3 jacketed, direct steam;100 psi Steam Jacket Pressure Rating;

316 Stainless Steel Liner; electrically driven Horizontal Agitator;

Variable Mixer Speed Control; Hydraulic Tilt Mechanism with kettle

mounted power-pack; 3" diameter air operated, flush mounted

Piston Draw-Off Valve; spring loaded Scraper Blades; flush

mounted Temperature Probe; Automatic Water Meter; Water Fill

Faucet with swing spout; Time/Temperature Chart Recorder

(located in Control Center); Spring Assist, one piece Cover

(bifold cover with counterweight for 300 gallon model).

Ë Stainless steel bifold hinged cover

Ë Dolly for horizontal agitator

Ë 3", 90° Elbow

Ë Food Strainer

Ë Flow Diverter

Ë 3” flush mounted ball valve

Ë Loading bucket and dolly

Ë Electric chain hoist for lifting

the product load

SECT. XIV PAGE 9

0609

Page 2

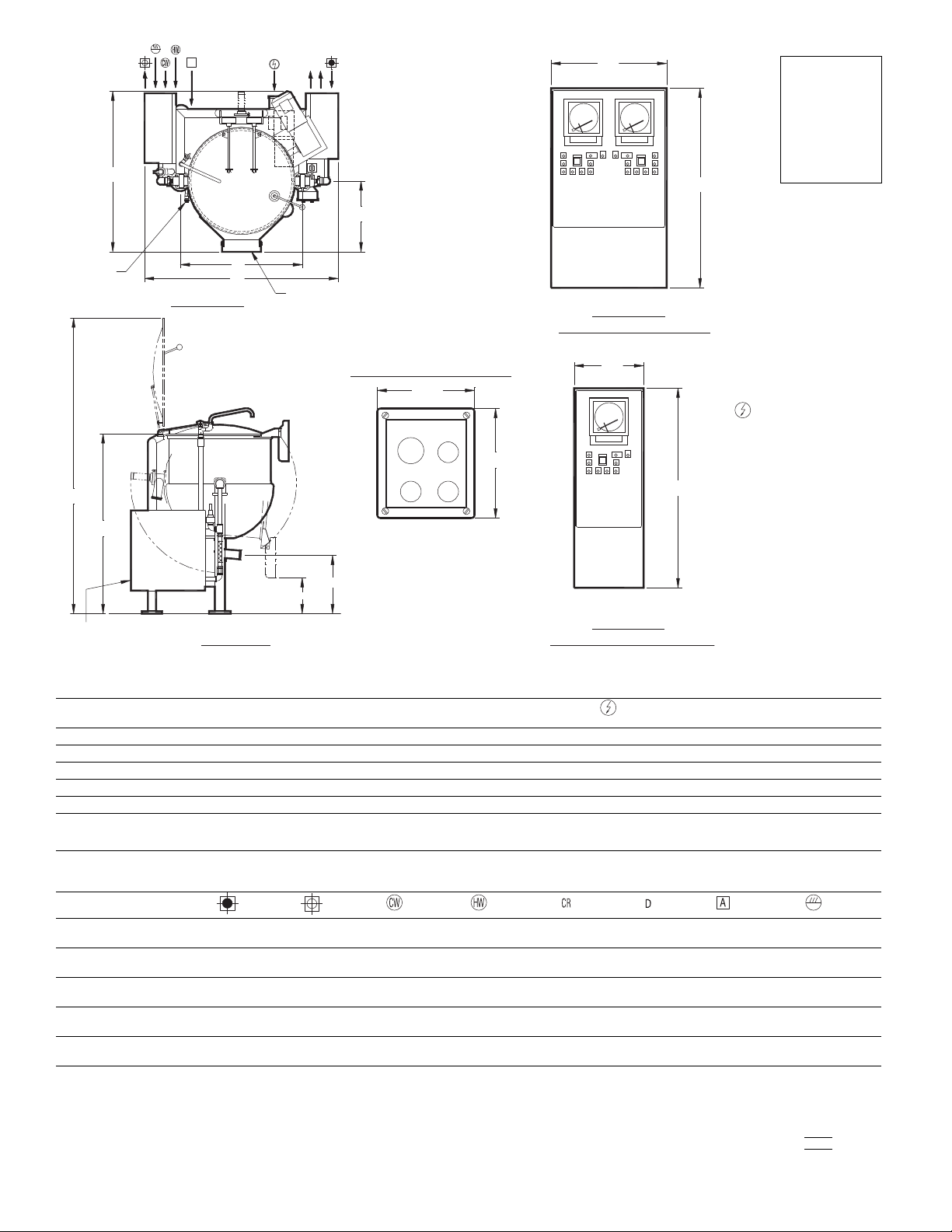

69"

6

9"

24"

40"

QUICK DISCONNECT

FOR FOOD PUMP

G

1

2 1/2"

F

E

A

B

C

D

PLUMBING BOX

WITH REMOVABLE

ACCESS PANEL

POURING LIP AND

POURING DEFLECTOR

PLAN VIEW

SIDE VIEW

SINGLE CONTROL PANEL

HA-SE-CC2

DUAL CONTROL PANEL

HA-DE-CC2

DEPTH 18 3/4"

C

ONTROL PANEL

7 1/4"

7

1/4"

KETTLE MOUNTED CONTROLS

N

OTE:

AGITATOR

STOP

O

UTLET VALVE

TILT

CONTROL

POUR

TILT

C

ONTROL

RETURN

HOLD

C

LOSED

JOG TO

OPEN

A

DCR

MINIMUM

CLEARANCE

FOR

KETTLES

FRONT 36"

IDE 12"

S

REAR 12"

LECTRICAL POWER

E

O AND FROM

T

CONTROL PANEL

CONTRACTOR

•

UST CUT ENTRY

M

OLE

H

• TOP OR BOTTOM

POWER ENTRY

RECOMMENDED

MUST USE PROPER

•

ONNECTIONS TO

C

MAINTAIN U.L.

LISTING

DIMENSIONS

MODEL ABCDEFGELECTRICAL PER KETTLE - R.P.M.

HA-MKDL-60-CC-T 59" 36 3/4" 22" 50" 83" 46" 5" 15 AMPS 3-22

HA-MKDL-100-CC-T 72" 42" 25" 57" 95" 52" 5" 18 AMPS 3-20

HA-MKDL-150-CC-T 75" 47 1/2" 29" 65" 105" 57" 5" 18 AMPS 3-18

HA-MKDL-200-CC-T 80 1/2" 52" 32" 70 1/4" 115" 62" 5" 25 AMPS 3-18

HA-MKDL-300-CC-T 92" 65 1/2" 34" 82" 106" 67" 5" 25 AMPS 3-16

UTILITY CONNECTIONS

MODEL INLET RETURN WATER WATER RETURN DRAIN INLET STEAM

CHILLED CHILLED COLD

WATER WATER POTABLE HOT CONDENSATE AIR

**

HA-MKDL-60-CC-T 3/4" 3/4" 3/4" 3/4" 1/2" 3/4" 1/2" 3/4"

15 GPM 15 GPM 15 GPM 1 CFM 320 lbs/hr

HA-MKDL-100-CC-T 1" 1" 3/4" 3/4" 3/4" 1" 1/2" 1"

20 GPM 20 GPM 20 GPM 1 CFM 525 lbs/hr

HA-MKDL-150-CC-T 1 1/4" 1 1/4" 3/4" 3/4" 1" 1 1/4" 1/2" 1 1/4"

20 GPM 20 GPM 20 GPM 1 CFM 780 lbs/hr

HA-MKDL-200-CC-T 1 1/4" 1 1/4" 3/4" 3/4" 1" 1 1/4" 1/2" 1 1/4"

25 GPM 20 GPM 20 GPM 1 CFM 1050 lbs/hr

HA-MKDL-300-CC-T 1 1/2" 1 1/2" 3/4" 3/4" 1" 1 1/2" 1/2" 1 1/2"

30 GPM 20 GPM 20 GPM 1 CFM 1575 lbs/hr

** HOT FILL WATER IS OPTIONAL

65 PSI STEAM OPERATING PRESSURE IS RECOMMENDED

NOTES: The pressure drop is 12 to 15 PSI for steam and chilled water passing through the kettle.

Air must be dry, clean and free of oil.

Cleveland Range reserves right of design improvement or modification, as warranted.

208V/ 3PH/60Hz

(NOT TO SCALE)

SECT. XIV PAGE 10

Litho in USA

0609

Loading...

Loading...