Cleveland GFIR36C Installation Manual

INSTALLATION AND

OPERATION MANUAL

GARLAND GF SENTRY SERIES

INFRA-RED SALAMANDER BROILERS

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 19

Españo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Página 37

DO NOT OBSTRUCT THE FLOW OF COMBUSTION

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

AND VENTILATION AIR TO THIS APPLIANCE

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND MUST

BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER.

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting your

local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent using genuine

Garland replacement parts. Garland will have no obligation with respect to any product that has been improperly installed,

adjusted, operated or not maintained in accordance with national and local codes or installation instructions provided

with the product, or any product that has its serial number defaced, obliterated or removed, or which has been modified

or repaired using unauthorized parts or by unauthorized service agents. For a list of authorized service agents, please refer

to the Garland web site at http://www.garland-group.com. The information contained herein, (including design and parts

specifications), may be superseded and is subject to change without notice.

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario, CANADA L4W 1X4

905-624-0260 | fax 905-624-5669 | www.garland-group.com

phone

Part # 4526026 Rev. 03 (06/12/14) © 2008 Garland Commercial Ranges, Ltd

Part # 4526026 Rev. 03 (06/12/14) Page 1

USA Sales, Parts and Service 1-800-424-2411

Canadian Sales 1-888-442-7526

Canada or USA Parts/Service 1-800-427-6668

International Sales and Service www.ManitowocFoodservice.com

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the State of California to cause cancer and/or birth

defects or other reproductive harm. Installation and servicing of this product could expose you

to airborne particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/

ceramic fibers is known to the State of California to cause cancer. Operation of this product could

expose you to carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known

to the State ofCalifornia to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Part # 4526026 Rev. 03 (06/12/14)Page 2

TABLE OF CONTENTS

IMPORTANT INFORMATION. . . . . . . . . . . . . 2

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . 4

Product Application . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Uncrating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DIMENSIONS AND SPECIFICATIONS . . . . . 5

CE Gas Categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Gas Pressure And Ratings . . . . . . . . . . . . . . . . . . . . . 6

CE & General International Countries . . . . . . 6

Setting Pressure For “MIN” Tap Position. . . . 6

North America . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Australian Market . . . . . . . . . . . . . . . . . . . . . . . . 6

Gas Inlet Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

GENERAL INFORMATION . . . . . . . . . . . . . . . 7

Siting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Statutory Regulations . . . . . . . . . . . . . . . . . . . . . . . . 7

Australia Speci c Regulations . . . . . . . . . . . . . . . . . 7

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 7

National Code Requirements . . . . . . . . . . . . . . . . .7

Gas Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Optional Inter-Connect Kit . . . . . . . . . . . . . . . . . . . 9

Installation Of A Salamander To A Range . . . . . 11

Model GFIR36 – 36” Ranges . . . . . . . . . . . . . . 11

Model GFIR48 – 48” Ranges. . . . . . . . . . . . . . 12

Model GFIR60 – 60” Ranges . . . . . . . . . . . . . . 14

Wall Or Counter Mounted Salamanders . . . . . .15

Model GFIR36C. . . . . . . . . . . . . . . . . . . . . . . . . . 15

Ventilation and Air Supply . . . . . . . . . . . . . . . . . . . 16

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Burner Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . 16

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Safety concerns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Lighting The Salamander . . . . . . . . . . . . . . . . . . . . 17

Operating Suggestions . . . . . . . . . . . . . . . . . . . . . . 17

Operating Controls. . . . . . . . . . . . . . . . . . . . . . . . . . 17

MAINTENANCE AND CLEANING. . . . . . . . 18

Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Monthly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Part # 4526026 Rev. 03 (06/12/14) Page 3

INTRODUCTION

Units included in this manual are:

Salamander Models: GFIR36C, GFIR36, GFIR48, GFIR60

All units are shipped completely assembled with the pressure

regulator packed inside the unit drip tray if included. Units

are inspected at the factory prior to shipment.

The appliance should be given regular care and

maintenance. Periodic inspections by your dealer or a

quali ed service agency are recommended.

This product has been certi ed as commercial cooking

equipment and must be installed by professional personnel

as speci ed.

Product Application

The Garland infra-red salamander o ers broiling for a wide

variety of products such as steak, lobster, sh, onion soup,

casseroles, garlic bread and hamburgers. The over- re infrared design provides for quick preheat and e cient, uniform

production. The tilting rack feature allows for an easy view

broiling.

Uncrating

Check the crate for possible damage during transit. Carefully

remove the unit from the crate and again check for damage.

If damage has occurred, report it to the carrier immediately.

Shipping wire, or ties for retaining the packaging material

must be removed from the units, as well as any protective

material covering stainless steel.

DO NOT remove any permanently a xed label warnings or

the rating plate from the appliance, as this may invalidate the

manufacturer’s warranty.

The type of gas and supply pressure that the equipment was

set-up for at the factory are indicated on the rating plate and

packaging. The type of gas and pressure speci ed must be

supplied to the unit.

Rating Plate

The rating plate is a xed to the Salamander front panel and

is located underneath the removable drip tray.

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the pre x and su x

letters and numbers) and the warranty serial number. The

rating plate contains this information.

The rating plate also contains the gas type and supply

pressure, as well as listing the input rating of all burners.

In the event you have any questions concerning the

installation, use, care or service of the product, write or call

our Product Service Department.

Safety Information

Warning: Accessible parts may become hot during use.

Young children should be kept away.

This product is intended for professional use by quali ed

personnel. The appliance is not intended for use by persons

(including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

Part # 4526026 Rev. 03 (06/12/14)Page 4

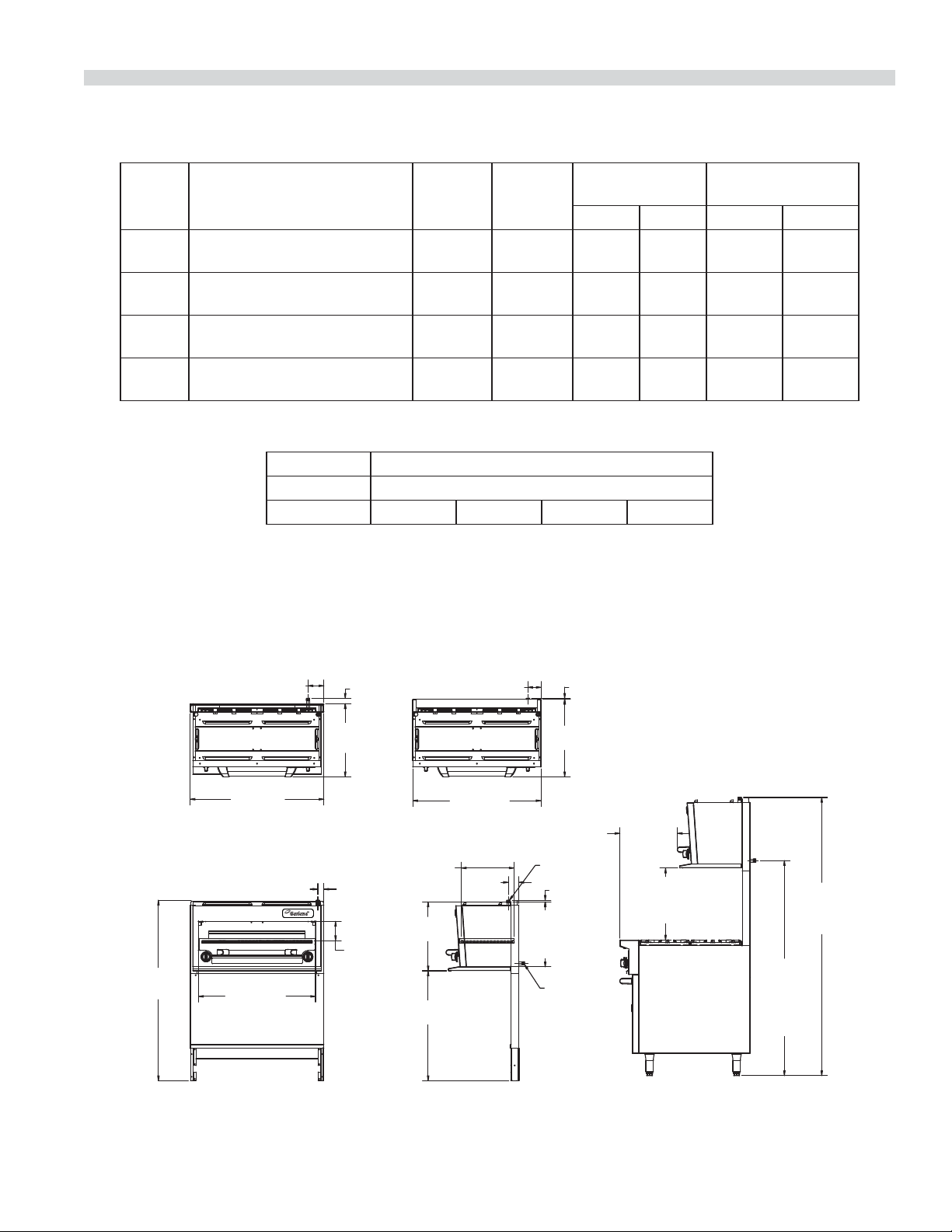

DIMENSIONS AND SPECIFICATIONS

Use With

Model Description Width

GF Series

Model

GFIR36C Counter/Wall Mount

GFIR36 Range Mount

GFIR48

*GFIR60

* Note: for range models, salamanders are standard on right but available on the left as an option.

For raised griddle/broiler models, salamanders are only available on left side of the range.

Center Mounted Broiler With

Extended Flue On Both Sides

Broiler With 24"(610 mm)

Flue Riser And Shelf

34"

(864mm)

35-1/2"

(900mm)

47-1/4"

(1200mm)

59-1/16"

(1500mm)

N/A 21 170/77

GF/GFE36

GF/GFE48

GF/GFE60

Shipping

Information

Entry Clearances

Cu Ft lbs/Kg Crated Uncrated

38.2

60.6

60.6

200/91

230/105

260/118

31"

(787mm)

31"

(787mm)

31"

(787mm)

31"

(787mm)

21"

(533mm)

21"

(533mm)

21"

(533mm)

21"

(533mm)

Model Combustible Clearances

Counter For use in non-combustible locations only

Range Mount Sides 6"(152mm) Back 6"(152mm)

Garland/U.S. Range products are not approved or authorized for home or residential use, but are intended for commercial

applications only. Garland / U.S. Range will not provide service, warranty, maintenance or support of any kind other than in

commercial applications.

Please specify gas type when ordering.

47-13/16"

[1215mm]

4-1/4"

[107mm]

RANGE MOUNT MODEL

35-7/16"

[900mm]

1-5/8"

[40mm]

31"

[787mm]

WIDTH OF OPENING

1-7/16"

[36mm]

19-3/8"

[492mm]

5"

[129mm]

HEIGHT OF

OPENING

FROM TOP

OF RACK

14"

[356mm]

COOKING

DEPTH

18-1/4"

[464mm]

29-1/8"

[704mm]

3-1/2"

[89mm]

COUNTER MODEL

34"

[864mm]

2-3/4"

[70mm]

1/4"

[6mm]

20-1/2"

[522mm]

1/2" NPT

STANDARD TOP

GAS CONNECTION

7/16"

[11mm]

17-3/16"

[437mm]

COUNTER

MODEL HEIGHT

1/2" NPT

OPTIONAL

REAR

GAS

CONNECTION

15-3/16"

[386mm]

19" [484mm]

CLEARANCE TO

COOKING SURFACE

73-11/16"

[1872mm]

OVERALL

HEIGHT

57"

[1447mm]

FLOOR TO

REAR

GAS

CONNECTION

Part # 4526026 Rev. 03 (06/12/14) Page 5

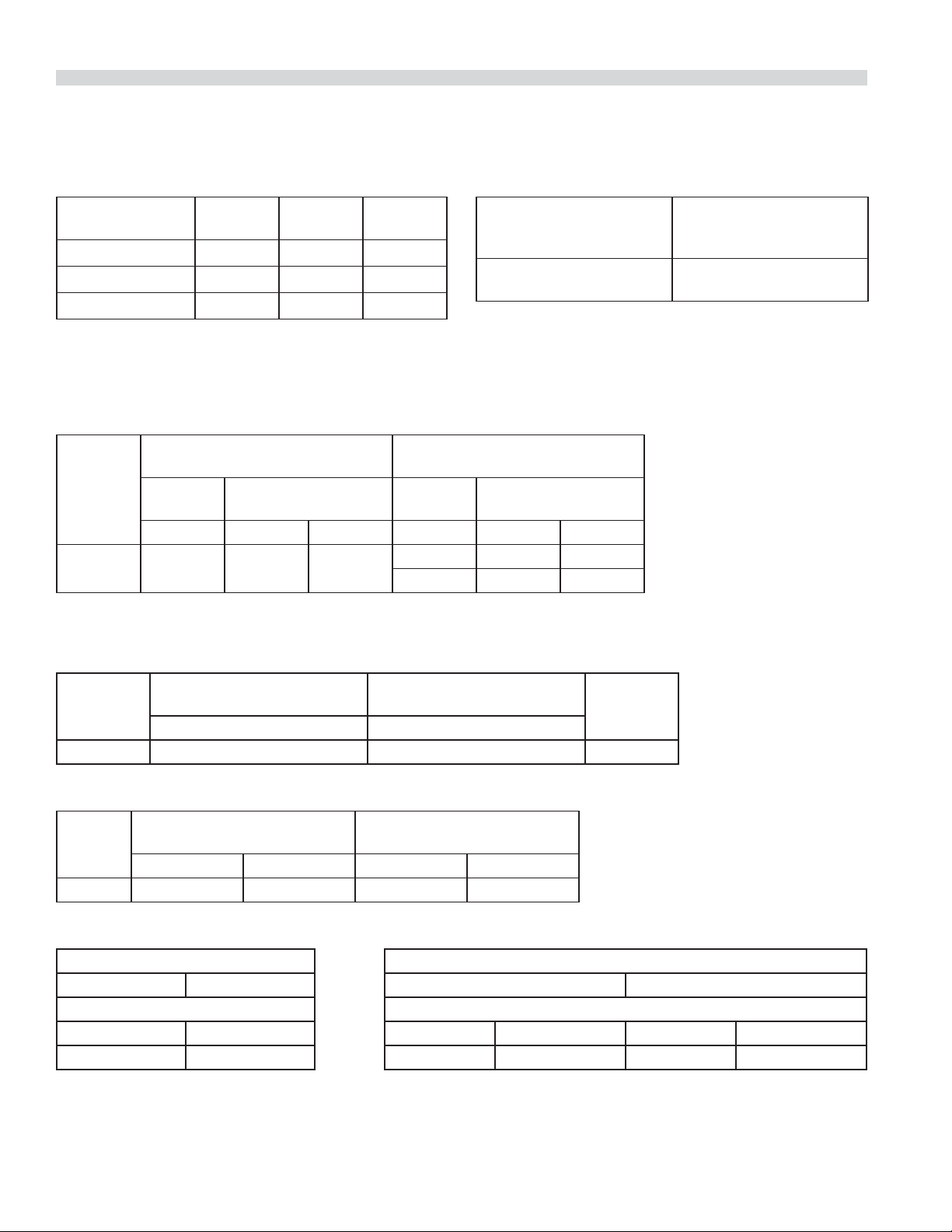

DIMENSIONS AND SPECIFICATIONS continued

CE Gas Categories

Country

GB, IE, ES, PT, GR

GB, IE, ES, PT, BE, FR

FR, NL, DE, ES

Gas

Category

I

2H

I

3P

I

3P

Gas Type

G20 20

G31 37

G31 50

Pressure

(mbar)

Gas Inlet Size

Connection

(North America &

Australia)

3/4” NPT Top Gas

Connection

Connection CE Models

(ISO7-1)

3/4” (19.1mm) BSPT

Gas Pressure And Ratings

CE & General International Countries

Pressure Setting / Injector Size

2nd Family, Group H

G20 @ 20 mbar inlet

MODELS

GFIR 20 1.6mm 1.6

* No appliance pressure regulator used, pressure measured at the test nipple on main manifold with all burners lit.

Setting

Pressure*

mbar DMS mm mbar DMS mm

Injector Size

Pressure*

3rd Family, Group P

G31 @ 37/50 mbar inlet

Setting

37 1.1mm 1.1

50 61 0.99

Injector Size

Heat Input (Gross)

2nd Family, Group H

MODELS

GFIR 4.2 4.2 2

(G20 @ 20 mbar) NAT

kW Per Burner kW Per Burner

3rd Family, Group P

(G31 @ 37/50 mbar) PROPANE

# Of

Burners

Setting Pressure For “MIN” Tap Position

2ND Family, Group H

MODELS

GFIR 10.5 4.2 23 9.4

(G20 @ 20 mbar) NAT. GAS

mbar “ W.C. mbar “ W.C.

North America

Operating Manifold Pressure

Natural 4.0” wc Propane 10.0” wc

Total Input

BTU/H BTU/H

28,000 26,000

Gas input ratings shown here are for installations up to 2,000 ft. (610m) above seal level. Specify altitudes over 2,000 ft.

3RD Family, Group 3P

(G31 @ 37/50 mbar) PROPANE

Australian Market

Operating Manifold Pressure

Natural 1 kPa (4.0” wc) LPG 2.49 kPa (10.0” wc)

Total Input

MJ/H Injector Dia. MJ/H Injector Dia.

21.0 2.4 mm 21.0 1.4mm

Part # 4526026 Rev. 03 (06/12/14)Page 6

GENERAL INFORMATION

The range-mounted, gas Infra-Red Salamander Broiler is

designed for a perfect match and t to the Garland GF series

Range.

Garland products are not approved or authorized for

home or residential use, but are intended for commercial

applications only. Garland will not provide service,

warranty, maintenance or support of any kind other than in

commercial applications.

Siting

The counter top unit should be installed on a rm, smooth

and level base capable of adequately supporting the

weight of the appliance and any ancillary equipment.

(Refer to Dimensions and Speci cations section for weight

speci cations). Any openings in the wall behind or beside

the appliance must be sealed. Once in position check that

the unit is level, both front to back and side to side. Adjust if

necessary using the leveling feet on the four corners of the

tted legs.

Statutory Regulations

The installation of this appliance must be carried out by

a competent person and in accordance with the relevant

regulations, standards, codes of practice and the related

publications of the Country of destination.

Australia Speci c Regulations

This appliance must be installed in accordance with the

manufacturers instructions, local gas tting regulations

and requirements of AS 5601 / AG 601 installation code.

All burner adjustments and settings should be made by a

quali ed gas technician.

INSTALLATION

This product has been certi ed as commercial cooking

equipment and must be installed by professional personnel

as speci ed. THIS APPLIANCE IS NOT RECOMMENDED FOR

RESIDENTIAL INSTALLATION.

We suggest installation, maintenance and repairs be

preformed by your local Garland/US Range authorized

service agency.

National Code Requirements

In European countries, installation must be carried out by

a competent person and in accordance with the relevant

regulations, codes of practice and the related publications of

the country of destination.

The importance of the proper installation of Commercial

Gas Cooking Equipment cannot be over stressed. Proper

performance of the equipment is dependent, in great part,

on the compliance of the installation with the manufacturer’s

speci cations. Installation must conform to local codes

or, in the absence of local codes, with the National Fuel

Gas Code, NFPA54 / ANSI Z223.1 or latest edition, Natural

Gas Installation Code, CAN/GCA-B149.1 or the Propane

Installation Code, CAN/CGA-B149.2 or latest editions, as

applicable.

Part # 4526026 Rev. 03 (06/12/14) Page 7

INSTALLATION Continued

Gas Connections

Danger

Turn O Gas

Supplies When

Installing or

Servicing Unit.

All xed (non mobile) appliances MUST be tted with a

manual gas cock upstream of the appliance to provide a

means of isolation for servicing or cleaning purposes. A

union or similar means of disconnection must be provided

between the gas cock and the appliance.

A manually operable valve must be tted to the gas supply

to the kitchen to enable it to be isolated in an emergency.

Whenever practical, this shall be located either outside the

kitchen of near an exit in a readily accessible position.

NOTE: When checking pressure, be sure that all other

equipment on the same gas line is on. If Garland supplied the

regulator with the unit, it has been preset to deliver the gas

pressure shown on the rating plate. If sourcing the regulator

adjust pressure as shown on the rating plate.

C. The appliance and its individual shut o (supplied by

others) must be disconnected from the gas supply piping

system during any pressure testing of that system at

pressures in excess of 1/2 psi (3.45 kPa).

D. The appliance must be isolated from the gas supply

piping system by closing its individual manual shut o

valve (supplied by others) during any pressure testing of

the gas supply piping system at test pressures equal to or

less than 1/2 psi (3.45 kPa).

E. The gas supply connection is made either at the top left

rear or lower rear right corner, depending on how the

unit was ordered. A readily accessible approved type of

hand valve should be installed on each supply line. Test

for leaks – DO NOT USE ANY OPEN FLAME.

Where it is not practical to do this, an automatic isolation

valve system shall be tted which can be operated from a

readily accessible position or near to the exit.

At locations where the manual isolation valve is tted or

the automatic system can be reset, a notice MUST be tted

stating:

“ALL DOWNSTREAM BURNER AND PILOT VALVES MUST

BE TURNED OFF PRIOR TO ATTEMPTING TO RESTORE THE

SUPPLY. AFTER EXTENDED SHUT OFF, PURGE BEFORE

RESTORING GAS.”

Before assembly and connection, check gas supply.

A. The type of gas for which the unit is equipped is stamped

on the rating plate located on the lower front panel

simply remove the drip tray for easy access. Connect a

unit stamped “NAT” only to natural gas; connect those

stamped “PRO” only to propane gas.

B. If it is additional equipment or a replacement have a

quali ed gas technician check the gas pressure to make

certain that existing gas facilities (meter piping, etc.)

will supply gas to the unit with no more than 1/2” water

column pressure drop.

F. A pressure tap plug is supplied with the units and it is

installed on the manifold. The drip tray must be removed

to use the pressure tap. The gas pressure must be

checked when the unit is installed, to insure that the unit

gas pressure is the same as speci ed on the rating plate.

If necessary, pressure adjustments must be made at the

supplied pressure regulator.

NOTE: the pressure regulator is located at the top left rear or

bottom right rear of the salamander. For European Countries,

the gas supply pressure is to be regulated according to the

information on the rating plate - regulator not included with

the appliance.

G. If it is a completely new installation, have a quali ed gas

technician check meter size and piping to ensure that

the unit is supplied with a su cient amount of gas at the

speci ed pressure for unit operation.

H. Make certain that the new piping, joints and connections

have been made in a clean manner and have been

purged, so that the piping compound, chips, etc, will not

clog pilots, valves and/or controls. Use pipe joint sealant

that is resistant to lique ed petroleum gas.

WARNING Check gas connections for leaks. Use a soap

solution or similar means. DO NOT USE AN OPEN FLAME!

Part # 4526026 Rev. 03 (06/12/14)Page 8

INSTALLATION Continued

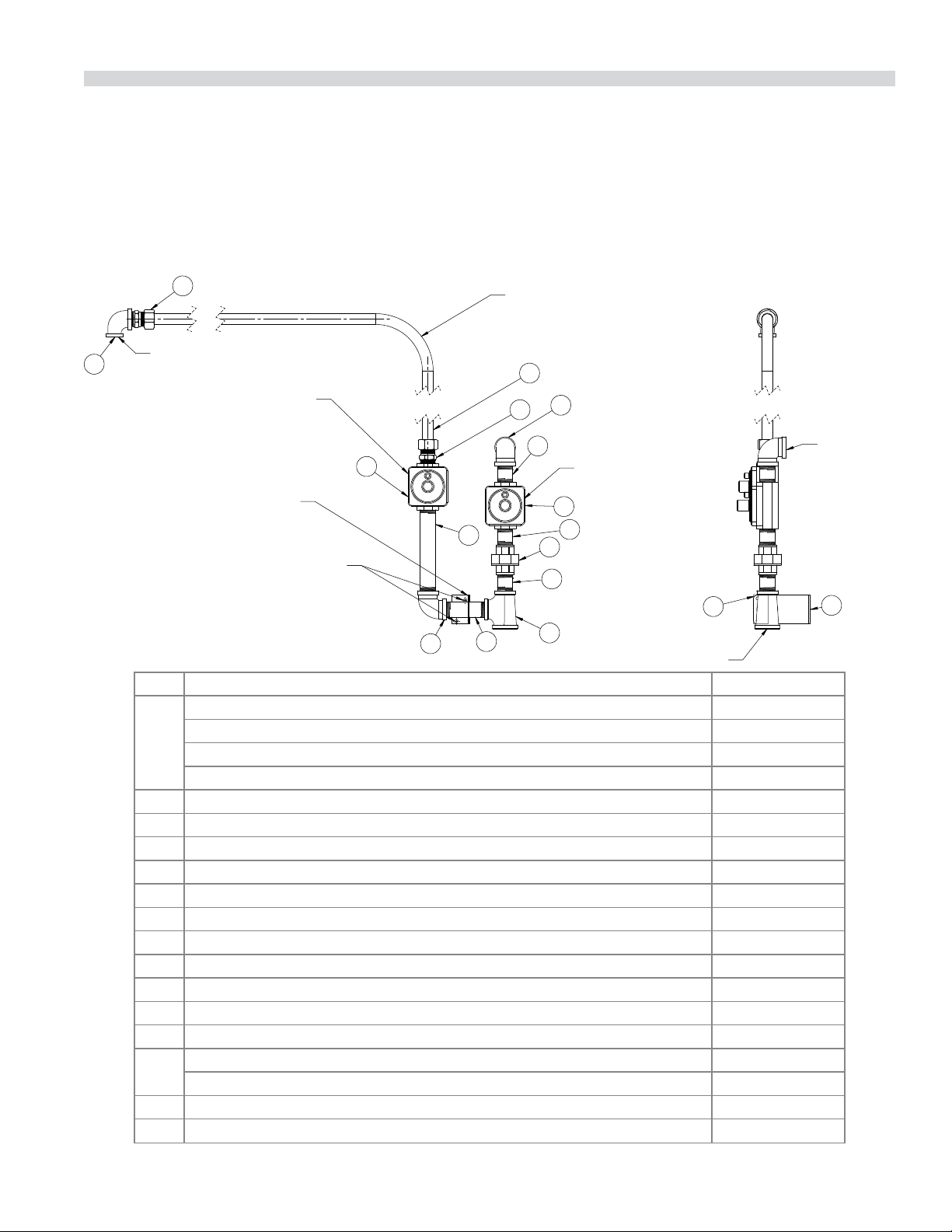

Optional Inter-Connect Kit

(Models GFIR36, GFIR48 & GFIR60)

The gas supply of the range mounted salamanders may be inter-connected with the supply of the range, so both units

are supplied from a single gas connection. The supply gas piping should be a minimum of 1” (25mm) diameter to ensure

enough gas capacity is available at the speci ed pressure to supply the total combined input rating of both appliances. The

components comprising the optional inter-connect kit are shown below.

Optional Interconnect Gas Kit #4531606 - Version 1, Connecting to a 36in Range

5

TO INLET OF SALAMANDER/

8

CHEESEMELTER MANIFOLD

REGULATOR - 6.0"w.c. NATURAL GAS

OR 10.0"w.c. PROPANE GAS

(SUPPLIED WITH SALAMANDER/

CHEESEMELTER)

CUT TUBING (ITEM 15 - 4531608) TO SIZE AS REQUIRED

TO SUIT SALAMANDER/CHEESEMELTER TOP OR REAR

MANIFOLD INLET CONNECTION

15

SUPPLIED WITH RANGE

3

5

SUPPLIED WITH RANGE

2

ATTACH SUPPORT CLAMP (ITEM 7 - 2640800)

TO SUPPORT BRACKET ( ITEM 6 - 2640700)

WITH (2)#10-24 SELF-TAPPING SCREWS (ITEM 12

F32 - NOT SHOWN) PROVIDED.

MARK HOLE LOCATIONS AND MOUNT

SUPPORT BRACKET (ITEM 6 - 2640700) TO RANGE

BACK WITH (2)#10-16 TEKS SELF-DRILL/TAP

SCREWS (ITEM 11 - F67 - NOT SHOWN) PROVIDED.

13

9

3

14

REGULATOR - 4.5" w.c. NATURAL GAS

OR 10.0" w.c. PROPANE GAS

(SUPPLIED WITH RANGE)

1

2

4

2

10

7

1" NPT GAS SUPPLY

CONNECTION

ITEM DESCRIPTION QUANTITY 36”

4.5” W.C 3/4”NPT, Regulator Natural Gas, supplied with Range 1

3/4” ISO 7-1, Regulator Natural Gas, supplied with Range 1

1

10” W.C 3/4”NPT, Regulator Propane Gas, supplied with Range 1

3/4” ISO 7-1, Regulator Propane Gas, supplied with Range 1

2 Nipple, 3/4” NPT x 1/2” (one supplied with range) 3

3 Elbow, 90deg, 3/4” NPT (one supplied with range) 2

4 Union, 3/4” NPT 2

5 3/4”CC x 3/4” NPT Straight Fitting 2

6 Bracket, Pipe Support 1

7 Clamp, Pipe Support Bracket 1

8 Reducing Elbow, 90deg, 3/4” NPT x 1/2” NPT 1

9 Nipple, 3/4” NPT x 6.5” 1

10 Reducing Tee, 3/4” NPT x 3/4” NPT x 1” 1

11 Screw, #10-16 x 1/2” Hex, Washer Head, Teks Self-Drill/Tap (not shown) 2

12 Screw, #10-24 x 1/2” Pan Head, Self-Tap, Type F (not shown) 2

6” W.C 3/4” NPT, Regulator Natural Gas, supplied with Salamander/Cheesemelter 1

13

10” W.C 3/4” NPT, Regulator Propane Gas, supplied with Salamander/Cheesemelter 1

14 Nipple, 3/4” NPT x 3.5” 1

15 Tubing 3/4” 1

TO INLET OF RANGE

MANIFOLD

6

Part # 4526026 Rev. 03 (06/12/14) Page 9

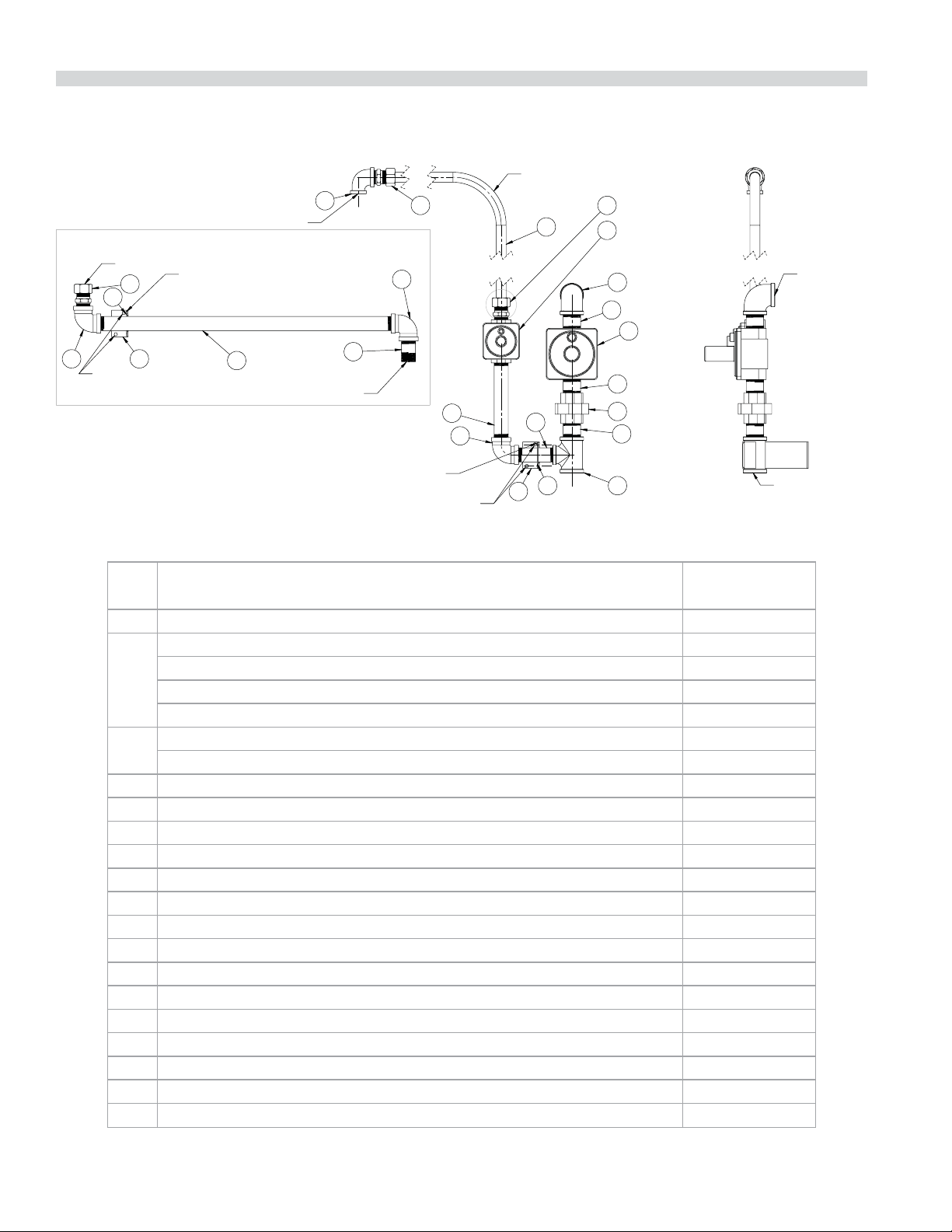

INSTALLATION Continued

Optional Interconnect Gas Kit #4531606 - Version 2, Connecting to a 48in or 60in Range

NOTE: CUT TUBING (ITEM 18 - 4531608) TO SIZE AS REQUIRED

TO SUIT SALAMANDER/CHEESEMELTER TOP OR REAR

MANIFOLD INLET CONNECTION

18

15

10

9

17

3

7

4

REGULATOR - 4.5"w.c.

NATURAL GAS OR 10.0"w.c.

PROPANE GAS (SUPPLIED

WITH RANGE)

4

8

4

11

TO INLET OF SALAMANDER/

CHEESEMELTER MANIFOLD

FOR LEFT-MOUNTED SALAMANDER/CHEESEMELTER

SUBSTITUTE COMPONENTS SHOWN FOR ITEM 17 CIRCLED IN ADJACENT VIEW

TO INTER-CONNECT TUBING ( ITEM 18 - 4531608)

17

10

6

MARK HOLE LOCATIONS AND MOUNT

SUPPORT BRACKET (ITEM 9 - 4531602 ) TO RANGE

BACK WITH (2) #10-16 TEKS SELF-DRILL/TAP

SCREWS (ITEM 14 - F67 - NOT SHOWN) PROVIDED.

ATTACH SUPPORT CLAMP (ITEM 10 - 2640800)

TO SUPPORT BRACKET (ITEM 9 - 4531602)

WITH (2) #10-24 SELF-TAPPING SCREWS (ITEM 1

F32 - NOT SHOWN) PROVIDED

9

12

TO OUTLET OF SALAMANDER/

CHEESEMELTER REGULATOR

16

13

ATTACH SUPPORT CLAMP (ITEM 10 - 2640800)

TO SUPPORT BRACKET (ITEM 9 - 4531602)

WITH (2) #10-24 SELF-TAPPING SCREWS (ITEM 1

F32 - NOT SHOWN) PROVIDED

MARK HOLE LOCATIONS AND MOUNT

SUPPORT BRACKET (ITEM 9 - 4531602) TO

BACK WITH (2) #10-16 TEKS SELF-DRILL/TAP

SCREWS (ITEM 14 - F67 - NOT SHOWN) PROVIDED.

17

6

5

6

REGULATOR - 6.0"w.c.

NATURAL GAS OR 10.0"w.c.

PROPANE GAS (SUPPLIED

WITH SALAMANDER/CHEESEMELTER)

SUPPLIED WITH

RANGE

SUPPLIED WITH

RANGE

2

TO INLET OF RANGE

MANIFOLD

1" NPT GAS SUPPLY

CONNECTION

ITEM DESCRIPTION

QUANTITY

48” / 60”

1 Screw, #10-24 x 1/2” Pan Head, Self-Tap, Type F (not shown) 4

4.5” W.C 1”NPT, Regulator Natural Gas, supplied with Range 1

1” ISO 7-1, Regulator Natural Gas, supplied with Range 1

2

10” W.C 1”NPT, Regulator Propane Gas, supplied with Range 1

1” ISO 7-1, Regulator Propane Gas, supplied with Range 1

6” W.C 3/4” NPT, Regulator Natural Gas, supplied with Salamander/Cheesemelter 1

3

10” W.C 3/4” NPT, Regulator Propane Gas, supplied with Salamander/Cheesemelter 1

4 Nipple, 1” NPT x 2” (one supplied with range) 3

5 Nipple, 3/4” NPT x 6.5” 1

6 Elbow, 90deg, 3/4” NPT 3

7 Elbow, 90deg, 1” NPT (supplied with range) 1

8 Union, 1” NPT 1

9 Bracket, Pipe Support 48/60 2

10 Clamp, Pipe Support Bracket 2

11 Reducing Tee, 1” NPT x 1” NPT x 3/4” 1

12 Nipple, 3/4” NPT x 22.75” 1

13 Nipple, 3/4” NPT x 2” 1

14 Screw, #10-16 x 1/2” Hex, Washer Head, Teks Self-Drill/Tap (not shown) 4

15 Nipple, 3/4” NPT x 3.5” 1

16 Reducing Elbow, 90deg, 3/4” NPT x 1/2” NPT 1

17 3/4”CC x 3/4” NPT Straight Fitting 2

18 Tubing 3/4” 1

Part # 4526026 Rev. 03 (06/12/14)Page 10

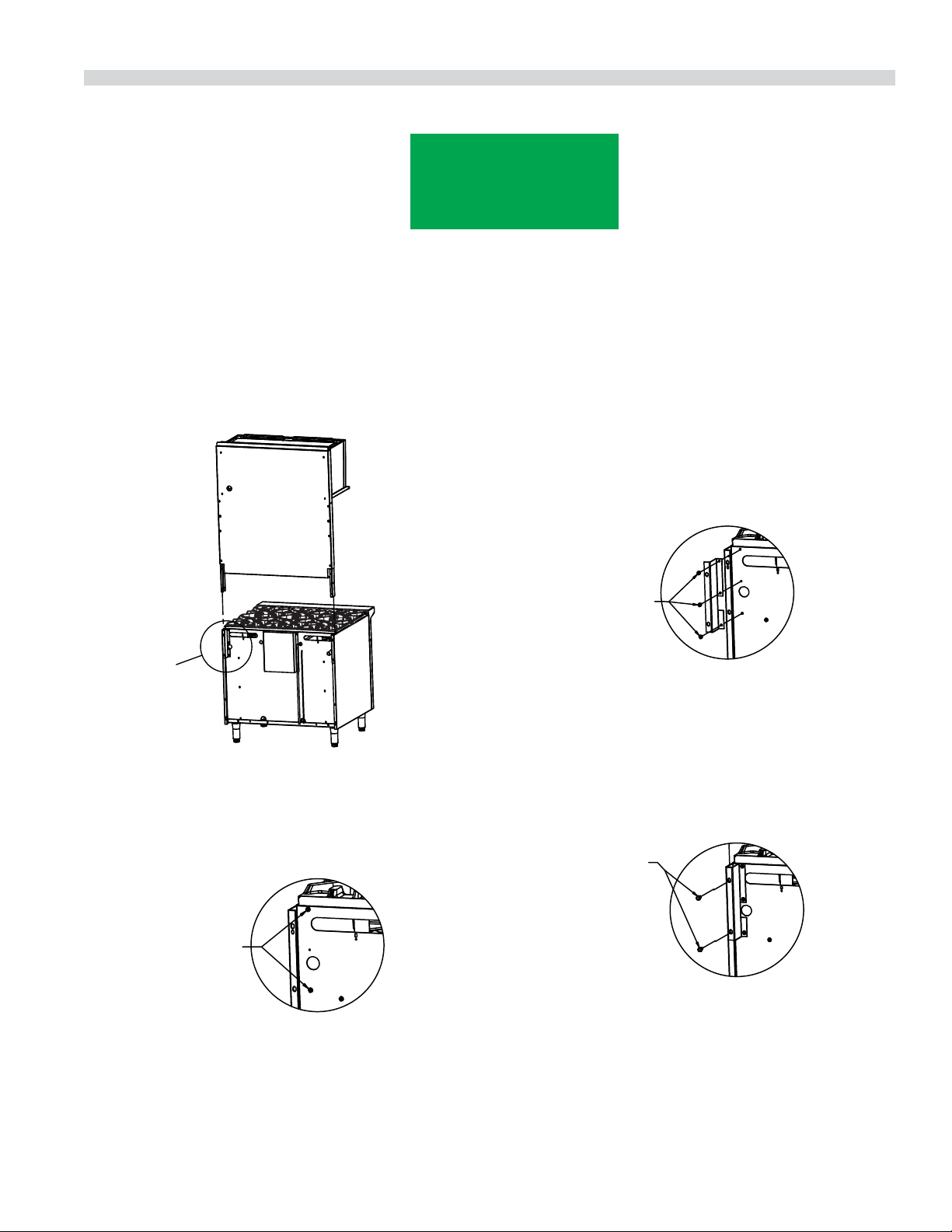

INSTALLATION Continued

Installation Of A Salamander To A Range

NOTE: The back of the range must be easily accessible.

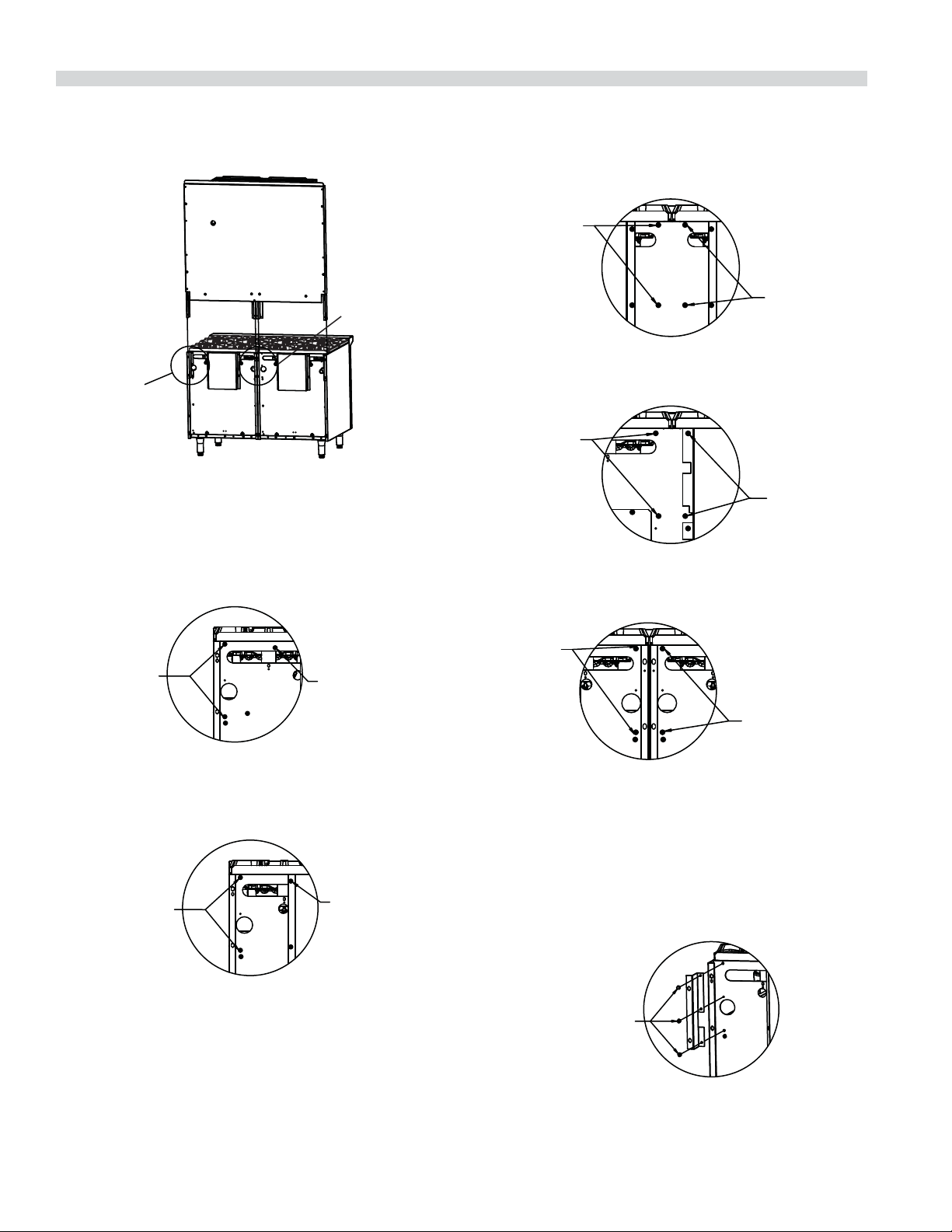

Model GFIR – ” Ranges

SAFETY

FIRST

USE PROPER

LIFTING TECHNIQUES

2. Install the left and right support brackets (part # 4523226

and 4523227) by re-inserting the 2 screws removed in

step 1 and one additional screw (on both sides of the

range).

DETAIL

I

36" RANGE

Figure 1 – With area detail de ned for 36 inch range.

1. Remove screws from back of oven (on both sides of

range) as shown:

REMOVE

2 SCREWS

(BOTH SIDES)

DETAIL I

INSERTED

SCREWS

DETAIL I

3. Slide the salamander down into the support brackets

installed in step 2, see gure 1.

4. Once the salamander is in place, fasten it to the unit on

both sides of the range with the provided #14B x 5/8 hex

washer head tapping screws.

PROVIDED

#14B x 5/8 HEX

WASHER HEAD

TAPPING SCREWS

DETAIL I

Part # 4526026 Rev. 03 (06/12/14) Page 11

INSTALLATION Continued

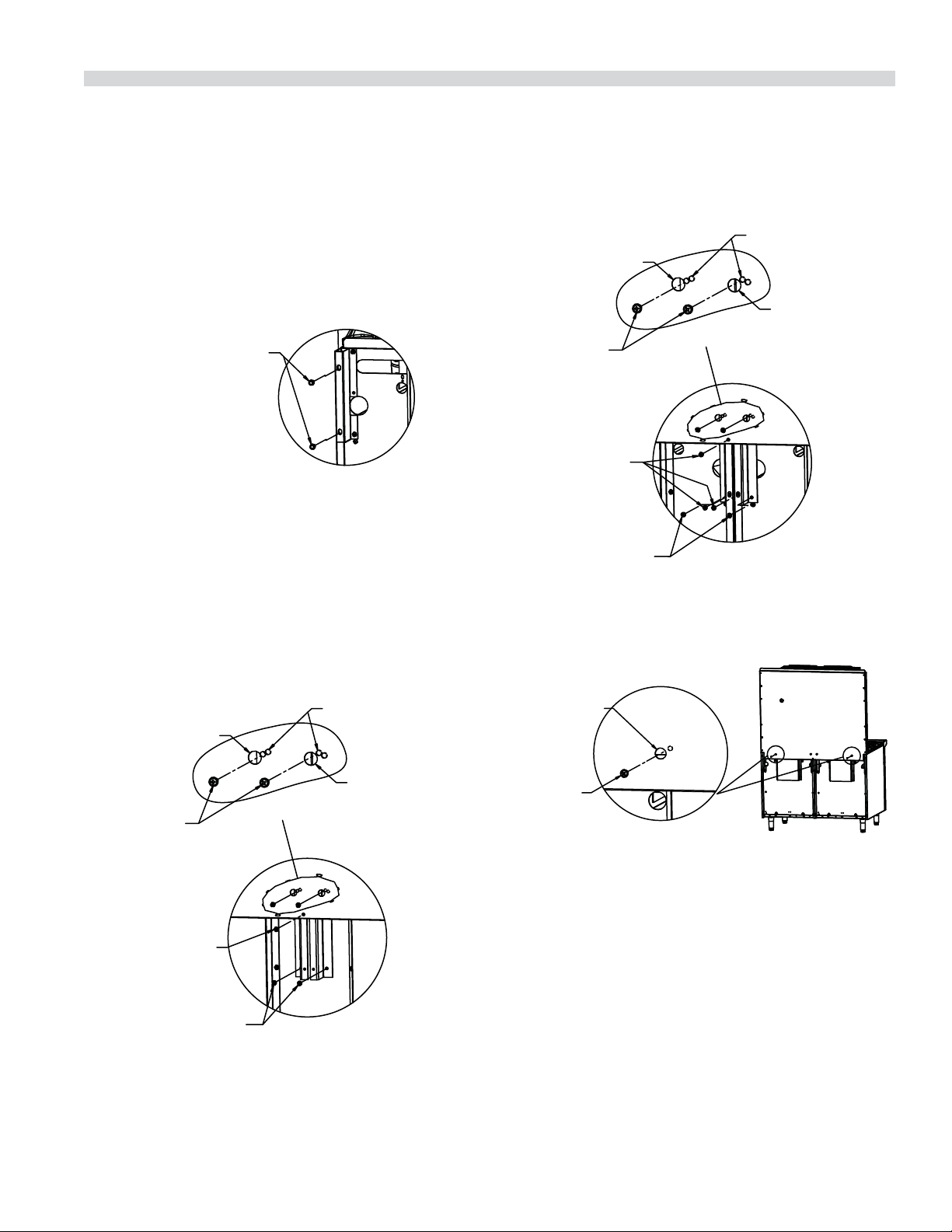

Model GFIR – ” Ranges

REMOVE

2 SCREWS

DETAIL

II

DETAIL

I

48" RANGE

Figure 2 – With area detail de ned for 48 inch ranges.

1. Remove screws (a total of 10) from back of oven on both

sides of the range (detail I) and center (detail II) as shown

for each range model:

REMOVE

2 SCREWS

BOTH SIDES

DETAIL I

48" RANGES WITH

STANDARD OR CONVECTION OVENS

AND STORAGE

REMOVE

1 SCREW

(BOTH SIDES)

REMOVE

2 SCREWS

DETAIL II 48" RANGES

WITH STANDARD OVEN AND STORAGE

REMOVE

2 SCREWS

(IF REQUIRED)

REMOVE

2 SCREWS

IF REQUIRED

DETAIL II 48" RANGES

WITH CONVECTION OVEN AND STORAGE

REMOVE

2 SCREWS

REMOVE

2 SCREWS

DETAIL II

FOR 48" RANGES

WITH 2 SPACE SAVER OVENS

REMOVE

2 SCREWS

(BOTH SIDES)

WITH 2 SPACE SAVER OVENS

DETAIL I

FOR 48" RANGES

REMOVE

1 SCREW

(BOTH SIDES)

2. For all 48” ranges install the left and right support

brackets (part # 4523226 and 4523227) by re-inserting

the 2 screws removed in step 1 and one additional screw

(on both sides of the range).

INSERTED

SCREWS

DETAIL I

ALL 48" RANGES

Part # 4526026 Rev. 03 (06/12/14)Page 12

INSTALLATION Continued

3. Slide the salamander down into the support brackets

installed in step 2, see gure 2. NOTE: On ranges with

space saver ovens, the center post must slide into the

center channels built into the back of the unit.

4. Once the salamander is in place, fasten it to the unit on

both sides of the range with the provided #14B x 5/8 hex

washer head tapping screws.

PROVIDED

#14B x 5/8 HEX

WASHER HEAD

TAPPING SCREWS

DETAIL I

ALL 48" RANGES

5. For center support, (detail II) re-insert screws removed in

step 1 or provided sheet metal screws as shown in detail

II and III, inserting screws for detail III through clearance

in back panel.

FOR 48" RANGES WITH

STANDARD OR CONVECTION OVENS

AND STORAGE

INNER

CLEARANCE

SCREWS

REMOVED

IN STEP 1

HOLE

DETAIL III

HOLES

CLEARANCE

HOLE

FOR 48" RANGES WITH

2 SPACE SAVER OVENS

INNER

CLEARANCE

HOLE

SCREWS

REMOVED

IN STEP 1

3 PROVIDED

SHEET METAL

SCREWS

2 SCREWS

REMOVED

IN STEP 1

6. Re-insert screws removed in step 1 though clearance hole

in back panel as shown:

CLEARANCE

HOLE

REMOVED

SCREW

DETAIL IV

ALL 48" RANGES

DETAIL III

HOLES

CLEARANCE

HOLE

DETAIL II

PROVIDED

SHEET METAL

SCREW

2 SCREWS

REMOVED

IN STEP 1

Part # 4526026 Rev. 03 (06/12/14) Page 13

DETAIL II

INSTALLATION Continued

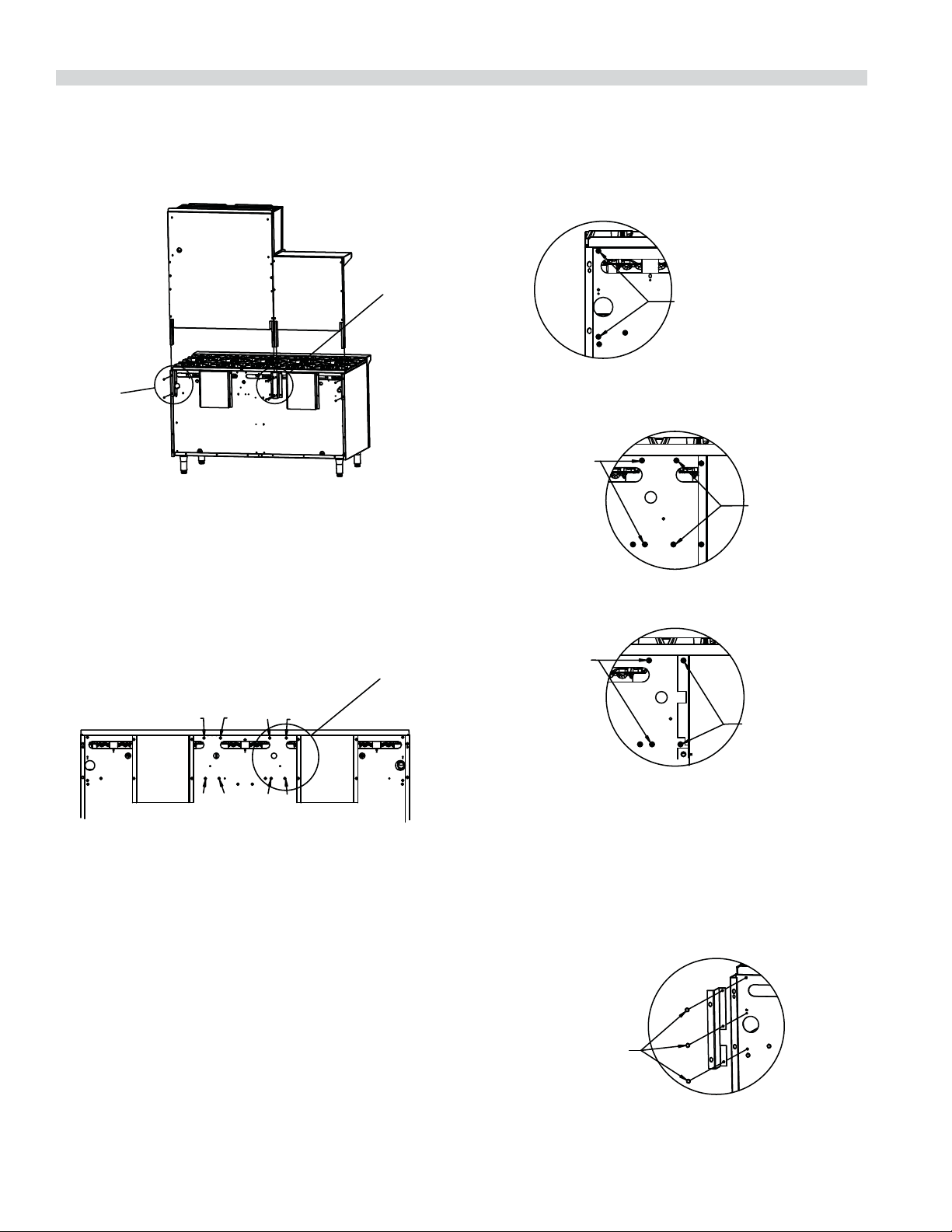

Model GFIR – ” Ranges

DETAIL

II

DETAIL

I

60" RANGE

Figure 3 – With area detail de ned for 60 inch range.

NOTE: Instructions are for mounting the salamander on the

right side, for mounting on the left side follow the same

directions except use references 1, 2, 3, & 4 (to the left of

detail II see below) in lieu of A, B, C, D for detail II in the

following steps.

DETAIL

II

12

AB

1. Remove screws from back of oven on both sides of the

range (detail I) and center (detail II) as shown:

REMOVE

2 SCREWS

FROM BOTH SIDES

DETAIL I

ALL 60" MODELS

REMOVE

2 SCREWS

IF REQUIRED

REMOVE

2 SCREWS

IF REQUIRED

A

CD

DETAIL II

FOR 60" RANGES

WITH STANDARD OVEN

ABB

C

D

REMOVE

2 SCREWS

IF REQUIRED

REMOVE

2 SCREWS

IF REQUIRED

34

CD

DETAIL II

FOR 60" RANGES

WITH CONVECTION OVEN

2. Install the left and right support brackets (part # 4523226

and 4523227) using the 2 screws removed in step 1

(detail I) and one additional screw on both sides of the

range, and center support bracket (part # 4523282) with

the four screws removed in step 1 (detail II).

INSERTED

SCREWS

DETAIL I

ALL 60" MODELS

Part # 4526026 Rev. 03 (06/12/14)Page 14

INSTALLATION Continued

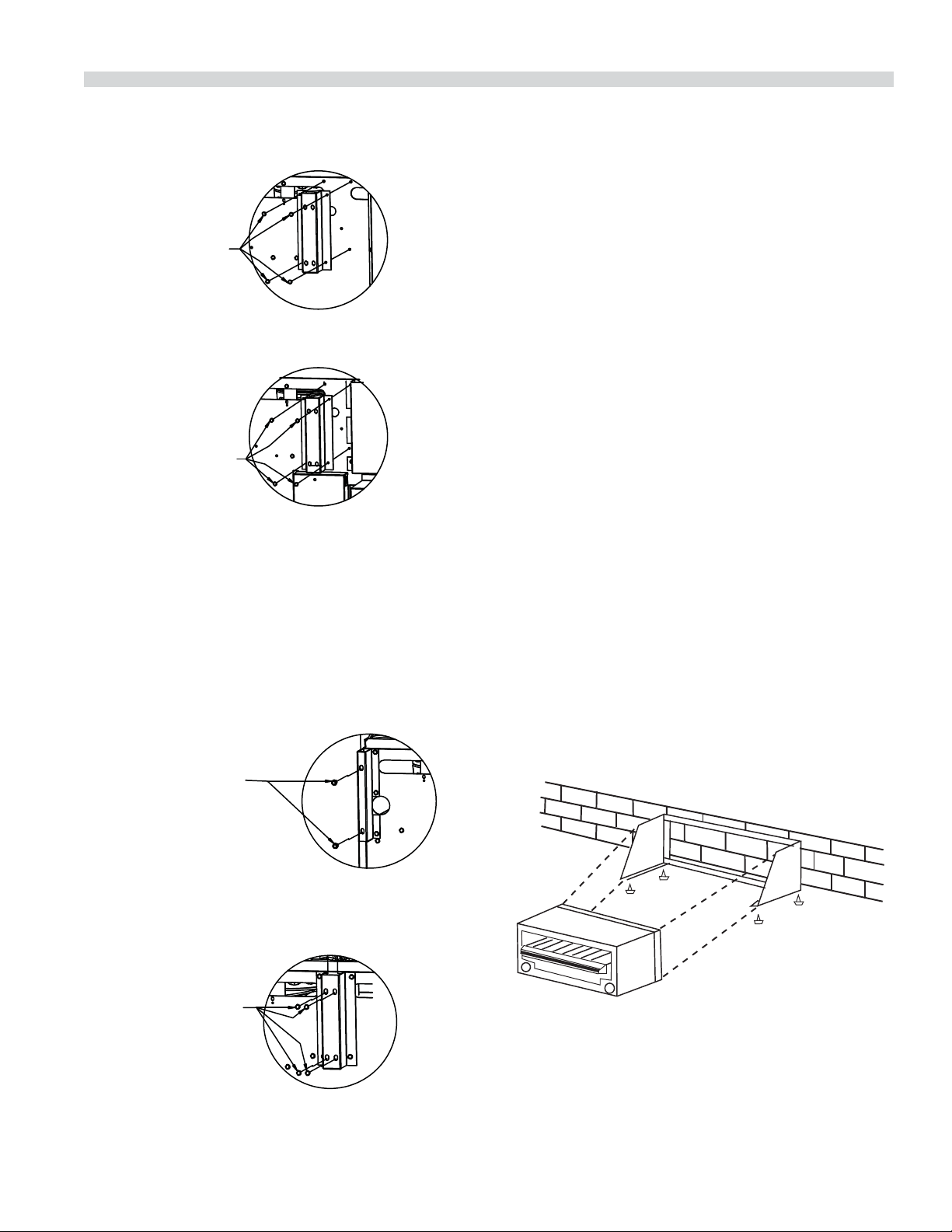

Wall Or Counter Mounted Salamanders

Model GFIRC

4 INSERTED

SCREWS

DETAIL II

FOR 60" RANGES

WITH STANDARD OVEN

4 INSERTED

SCREWS

DETAIL II

FOR 60" RANGES

WITH CONVECTION OVEN

3. Slide the salamander down into the support brackets

installed in step 2, see gure 3.

4. Once the salamander is in place, fasten it to the unit on

both sides of the range with the provided #14B x 5/8 hex

washer head tapping screws (detail I) and the center to the

support bracket using 4 of the provided screws (detail II).

1. The appliance shall be located with respect to building

construction and other equipment so as to permit access

to the appliance. Such access and clearance may be

necessary for service and cleaning.

2. Counter models are furnished with 4” (102mm) legs.

Level the unit with a carpenter’s level and make minor

adjustments with the threaded leg feet. Ensure that the

counter top can support the weight of the appliance

prior to installation and is comprised of non-combustible

material.

3. Provisions for gas connections, top or rear, should be

taken into consideration at time of installation.

4. If the unit is to be mounted on a non-combustible wall

contact the local authorities for local codes.

5. Position, level, and mark location of the assembled wall

mount kit.

6. Drill wall (locating studs if necessary) to accept suitable

fastening devices.

7. Drill the angle iron bars of the wall mounting kit to match

those drilled in the wall.

8. Install wall mounting kit to wall.

9. Install and secure broiler with bolts supplied.

PROVIDED

#14B x 5/8 HEX

WASHER HEAD

TAPPING SCREWS

DETAIL I

ALL 60" RANGES

4 PROVIDED

SCREWS

DETAIL II

ALL 60" RANGES

Part # 4526026 Rev. 03 (06/12/14) Page 15

INSTALLATION Continued

Ventilation and Air Supply

For detailed recommendations, refer to the applicable

code(s) in the country of destination. These appliances shall

be installed in a room with su cient ventilation to prevent

the occurrence of hazardous concentrations of combustion

by-products.

Proper ventilation is highly important for good operation.

The ideal method of ventilation for a Salamander Broiler is

the use of a properly designed canopy hood which should

extend six inches (6”, 152mm) beyond all sides of the

appliance and six (6) feet six (6) inches (1981mm)from the

oor.

A strong exhaust fan will create a vacuum in the room. For

an exhaust system to work properly, replacement air must

enter the room in which the vent is located. The amount

of air which is exhausted must equal the amount entering,

(make-up air).

All gas burners and pilots need su cient air to operate and

large objects should not be placed in front or on top of the

broiler which would obstruct the air ow through the front of

the broiler.

The following notes are intended to give general guidance.

For detailed recommendations, refer to the applicable

code(s) in the country of destination.

NOTE 1: The room containing the appliance is required to

have a permanent air vent. The minimum e ective area of

the vent is related to the maximum rated heat input of the

appliance and shall be 4.5 cm² per kW (2.04 X 10-4 in² per

BTU/H) in excess of 7 kW. (23,900 BTU/H).

NOTE 2: Air vents should be of such a size to compensate for

the e ects of any extract fan in the premises.

FOR YOUR SAFETY never place any type of object on top of

the salamander broiler. The top of the broiler will exceed

1000° F (538° C). It could cause severe burns and/or re

and also will obstruct ventilation.

Clearances

Clearance must be 6” (152mm) at the sides and rear from

combustible material. A clearance of 0.0” to noncombustible

construction at the sides & rear is acceptable, for the

Salamander.

This appliance is for use on non-combustible oors/counters

only.

Burner Adjustments

Minimum Flame Setting

1. Set the gas tap to the low “ ” position.

2. Connect a U-gauge manometer to the pressure test

nipple located downstream of the gas tap.

3. With a at screwdriver, turn the adjuster on the tap

body clockwise to reduce pressure or counter-clockwise

to increase pressure. Set the pressure to correspond

with Setting Pressure For “MIN” Tap Position” Table in

DIMENSIONS AND SPECIFICATIONS section.

Pilot

Adjuster

Low Flame

Adjuster

Test Point

When all the settings have been checked, remove the

U-gauge manometer, replace the pressure test point screw

and the front panel.

Hand these instructions to the user or purchaser for retention

and instruct them in the e cient and safe operation of the

appliance.

Tell the user of the location of the gas isolation cock for use in

an emergency.

Part # 4526026 Rev. 03 (06/12/14)Page 16

OPERATION

Safety concerns

It is the responsibility of the supervisor or equivalent

person to ensure that users of this equipment wear suitable

protective clothing and to draw attention to the fact that

some parts will by necessity become very hot and will cause

burns if touched accidentally.

Lighting The Salamander

NOTE: Ensure the gas supply to the appliance is turned “ON”.

During the initial ignition cycle, air must be purged from the

gas line and thus it may take one to two minutes for the pilot

burner to ignite.

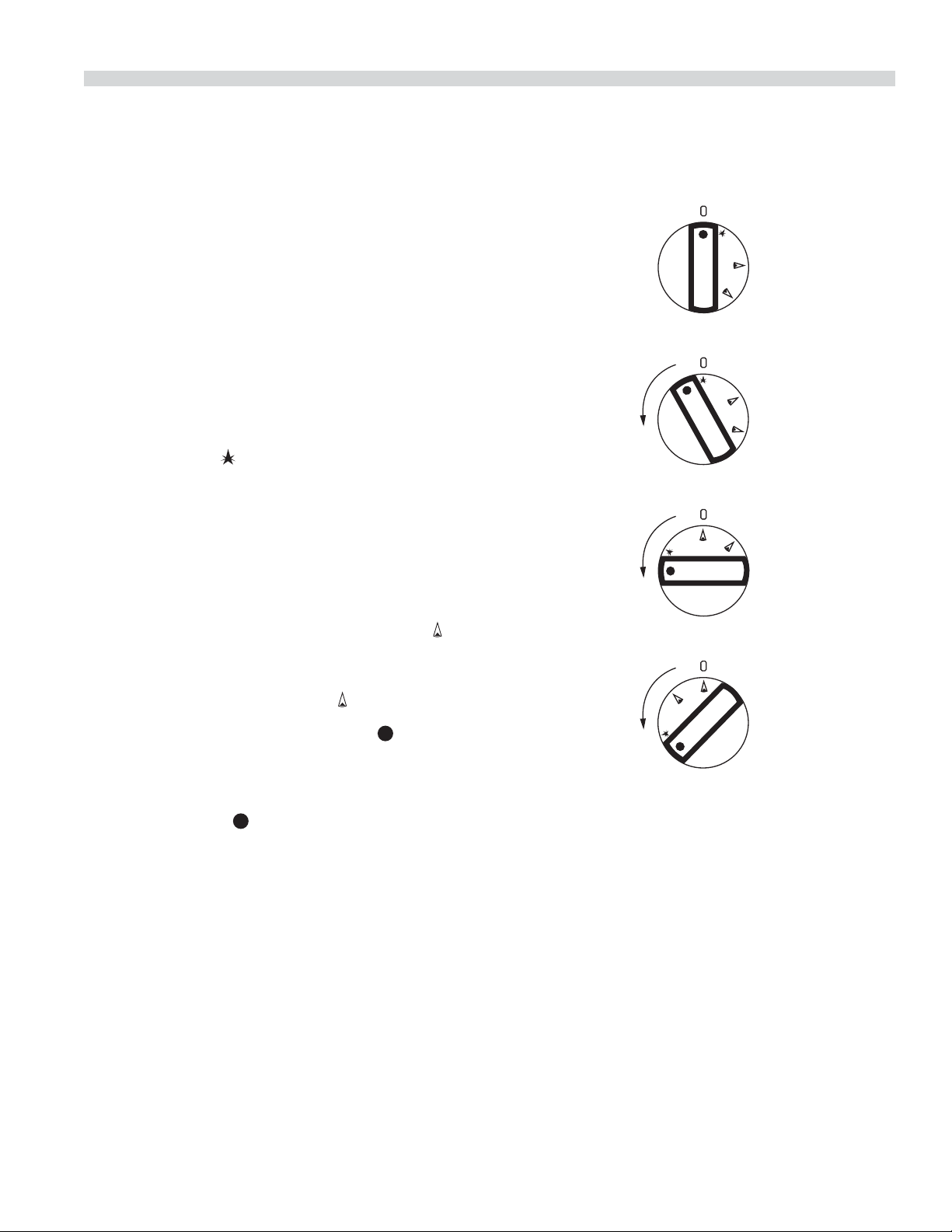

1. Push in the tap and turn it counter-clockwise to the

Ignition Position “ ”.

2. Holding the tap fully in, light the pilot with a match or

taper.

3. When the pilot is lit, continue to hold the tap fully in for

20 seconds, then release it. IF the pilot goes out, wait for

ve (5) minutes, and then repeat from step 1.

4. When the pilot is established, push the tap in again and

turn it counter-clockwise to the full ame position “ ”

thus lighting the main burner.

Operating Controls

OFF

IGNITION

MAX

5. For low ame or simmer, push the tap in and turn it

counter-clockwise to the low ame “ ” position.

6. To shut the burner o , turn the dial to the “ ” symbol and

the safety device will disengage within 60 seconds.

Operating Suggestions

1. Turn the tap to the “ ” position when the salamander is

not in use.

2. Clean the racks as soon as possible after cooking with

tomato or vinegar based products that have a high acid

content. These foods can cause pitting of the rack surface.

3. Allow the salamander to preheat before adding product.

4. Drain and clean the drip tray frequently. Excessive oil

drain o in the pan can cause spillover.

MIN

Part # 4526026 Rev. 03 (06/12/14) Page 17

Loading...

Loading...