Cleveland C4ED-10.10GB Owner’s Manual

Combi Steamer

Convotherm 4

Installation Manual UL, USA - Original, ENG

Your meal. Our mission.

FOR THE INSTALLER, OPERATOR, RESPONSIBLE OWNER

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the

vicinity of this or any other unit.

WARNING

Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury and death. Read the installation, operating

and maintenance instructions thoroughly before installing or servicing this

equipment.

WARNING

Disconnect power at the main external power switch before servicing or

repairing a combi steamer.

WARNING

To reduce the risk of electric shock, do not remove or open cover.

No user serviceable parts inside. Refer servicing to qualified personnel.

Disconnect power supply before servicing.

IMPORTANT

IT IS COMPULSORY TO POST INSTRUCTIONS WHICH ARE TO BE FOLLOWED IN THE EVENT

THE USER SMELLS GAS. THESE INSTRUCTIONS MUST BE LOCATED IN A PROMINENT LOCA‐

TION, AND BE FULLY UNDERSTOOD BY ALL USERS OF THIS EQUIPMENT. THIS INFORMA‐

TION NEED TO BE OBTAINED FROM YOUR LOCAL GAS SUPPLIER.

ALL SERVICE MUST BE PERFORMED BY A QUALIFIED CONVOTHERM AUTHORIZED TECHNI‐

CIAN.

KEEP AREA FREE AND CLEAR OF COMBUSTIBLES.

Installation

■

Installation of this unit must be done by a licensed professional when installed in the Commonwealth

of Massachusetts.

■

The wiring diagram is located on the inner part of the side panel.

Customer documentation

■

The customer documentation is part of the combi steamer.

■

Keep the customer documentation manuals handy at all times so that you can look up any required

information.

■

Keep the customer documentation manuals for the entire life of the unit.

■

Carefully read the installation manual, the operating manual, and the operating instructions before

using, handling, and working on this unit.

■

If you transfer the combi steamer to a new owner, make sure to give the new owner the customer

documentation manuals as well.

Table of Contents

Table of Contents

1 General 8

1.1 Environmental Protection 8

1.2 Identifying Your Combi Steamer 9

1.3 Customer Documentation Structure 10

1.4 Safety Information That Must Be Read without Exception 11

1.5 About This Installation Manual 12

2 Configuration and Functions 14

2.1 The Combi Steamer's Configuration and Functions 14

2.2 Operating Panel Layout and Functions 20

3 For Your Safety 21

3.1 Basic Safety Instructions 21

3.2 Your Combi Steamer's Intended Use 23

3.3 Warning labels on combi steamer table-top models 25

3.4 Warning labels on combi steamer floor-standing models 28

3.5 Hazards and Safety Measures When Moving the Unit 31

3.6 Hazards and Safety Measures During Setup 32

3.7 Hazards and Safety Measures During Installation 33

3.8 Hazards and Safety Measures When Putting the Unit into Operation 35

3.9 Hazards and Safety Measures When Removing the Unit from Service 38

3.10 Safety Devices 41

3.11 Staff and Work Area Requirements 45

3.12 Personal Protective Equipment 47

4 Transportation 48

4.1 Safely Using the Unit 48

4.2 Transporting the unit to the installation location 49

5 Setup 50

5.1 Working Safely During Setup 50

5.2 Adjacent Systems 51

5.3 Installation location requirements 52

5.4 Unpacking 57

5.5 Removing the unit from the pallet 61

5.6 Setting Up Table-Top Models on a Work Table (Standard Equipment) 63

5.7 Setting Up Table-Top Models on an Equipment Stand (Standard Equipment) 65

5.8 Setting up the table-top model on a stand with casters 67

5.9 Setting Up Floor-Standing Models on the Floor (Standard Equipment) 70

6 Installation 71

6.1 Electrical installation 71

6.1.1 Working Safely When Installing the Electrical Installation 71

6.1.2 Planning the Electrical Installation 72

6.1.3 Performing the Electrical Installation 74

6.1.4 Connecting an Energy Optimization System (for Electrical Units Only) 75

6.1.5 Connecting the Signal Tower 77

6.1.6 Connecting the Water Treatment Filter Monitoring System 79

6.2 Gas Installation 81

6.2.1 Working Safely When Installing the Gas System 81

Installation Manual 5

Table of Contents

6.2.2 Planning the Gas Installation 83

6.2.3 Forced Air Burner and Gas Main Valve Locations 85

6.2.4 Performing the Gas Installation 87

6.2.5 Measuring the Supply Flow Pressure 88

6.2.6 Measuring the Exhaust Gas Values 89

6.3 Water connections 90

6.3.1 Working Safely When Setting Up the Water Connection and Drain Connection 90

6.3.2 Water supply 91

6.3.3 Checking the water quality 95

6.3.4 Drain Connection 96

6.4 Installing the fully automatic oven cleaning system 98

6.4.1 Working Safely During Installation 98

6.4.2 Components of Fully Automatic Oven Cleaning System 99

6.4.3 Connecting the Fully Automatic Cleaning System 101

6.5 Installing the Grease Collection Canister (ConvoGrill Only) 103

6.5.1 Working Safely During Installation 103

6.5.2 Connecting the Grease Collection Canister 104

7 Placing into operation 105

7.1 Working Safely When Putting the Unit Into Operation 105

7.2 Procedure for Placing the Unit into Operation 108

7.3 Measuring unit gaps 110

8 Removal from Service and Disposal 111

8.1 Working Safely When Removing the Unit from Service 111

8.2 Removal from Service and Disposal 113

9 Technical data 114

9.1 Dimensions and weights 115

9.2 Maximum permissible loading weight 117

9.3 Electrical supply 118

9.4 Gas Characteristic Values for Natural Gas (USA), Propane (USA) 122

9.5 Exhaust gas volume 122

9.6 Heat output 123

9.7 Water connections 123

9.8 Water quality 124

9.9 Boiler 124

9.10 Water consumption during cooking 125

9.11 Water consumption during cooking and cleaning 125

10 Connection drawings 126

10.1 Dimensions and Connection Points for Electrical Units 127

10.1.1 Convotherm 4 6.10 Electrical units 128

10.1.2 Convotherm 4 6.20 Electrical units 130

10.1.3 Convotherm 4 10.10 Electrical units 132

10.1.4 Convotherm 4 10.20 Electrical units 134

10.1.5 Convotherm 4 12.20 Electrical units 136

10.1.6 Convotherm 4 20.10 Electrical units 138

10.1.7 Convotherm 4 20.20 Electrical units 140

10.2 Dimensions and Connection Points for Gas Units 142

10.2.1 Convotherm 4 6.10 Gas Unit with Boiler 143

10.2.2 Convotherm 4 6.10 Gas Unit with Sprayer 145

10.2.3 Convotherm 4 6.20 Gas Unit with Boiler 147

10.2.4 Convotherm 4 6.20 Gas Unit with Sprayer 149

Installation Manual 6

Table of Contents

10.2.5 Convotherm 4 10.10 Gas Unit with Boiler 151

10.2.6 Convotherm 4 10.10 Gas Unit with Sprayer 153

10.2.7 Convotherm 4 10.20 Gas Unit with Boiler 155

10.2.8 Convotherm 4 10.20 Gas Unit with Sprayer 157

10.2.9 Convotherm 4 12.20 Gas Unit with Boiler 159

10.2.10 Convotherm 4 12.20 Gas Unit with Sprayer 161

10.2.11 Convotherm 4 20.10 Gas Unit with Boiler 163

10.2.12 Convotherm 4 20.10 Gas Unit with Sprayer 165

10.2.13 Convotherm 4 20.20 Gas Unit with Boiler 167

10.2.14 Convotherm 4 20.20 Gas Unit with Sprayer 169

11 Checklists and Completing the Installation 171

11.1 Checklist: Transportation, Setup, and Installation 171

11.2 Checklist: Safety guards, safety devices, and warning labels 173

11.3 Checklist: Customer briefing 174

11.4 Completing the Installation 175

Installation Manual 7

1 General

1 General

Purpose of this section

This section provides information on how to identify your combi steamer and how to use this manual.

1.1 Environmental Protection

Policy statement

Our customers' expectations, the legal regulations and standards we have to follow, and our compa‐

ny's reputation are what drives the quality and service behind all our products.

Our environmental management policy is not only designed to ensure that we are always in full com‐

pliance with all environmental laws and regulations, but also reflects our commitment to the environ‐

ment and to continuously improving our performance in this field.

In order to ensure that we meet all of our environmental goals while maintaining the high quality of our

products, and that things stay this way, we have developed a quality and environmental management

system.

This system meets the requirements set forth in ISO 9001:2008 and ISO 14001:2004.

Environmental protection measures

The following measures apply to this product:

■

Uses fully compostable packing products

■

Uses RoHS-compliant products

■

Complies with the REACH regulation

■

Recommends and uses biodegradable cleaning agents

■

E-waste recycling

■

Environmentally friendly disposal of old units through the manufacturer

Join us in our commitment to protecting the environment!

Installation Manual 8

1 General

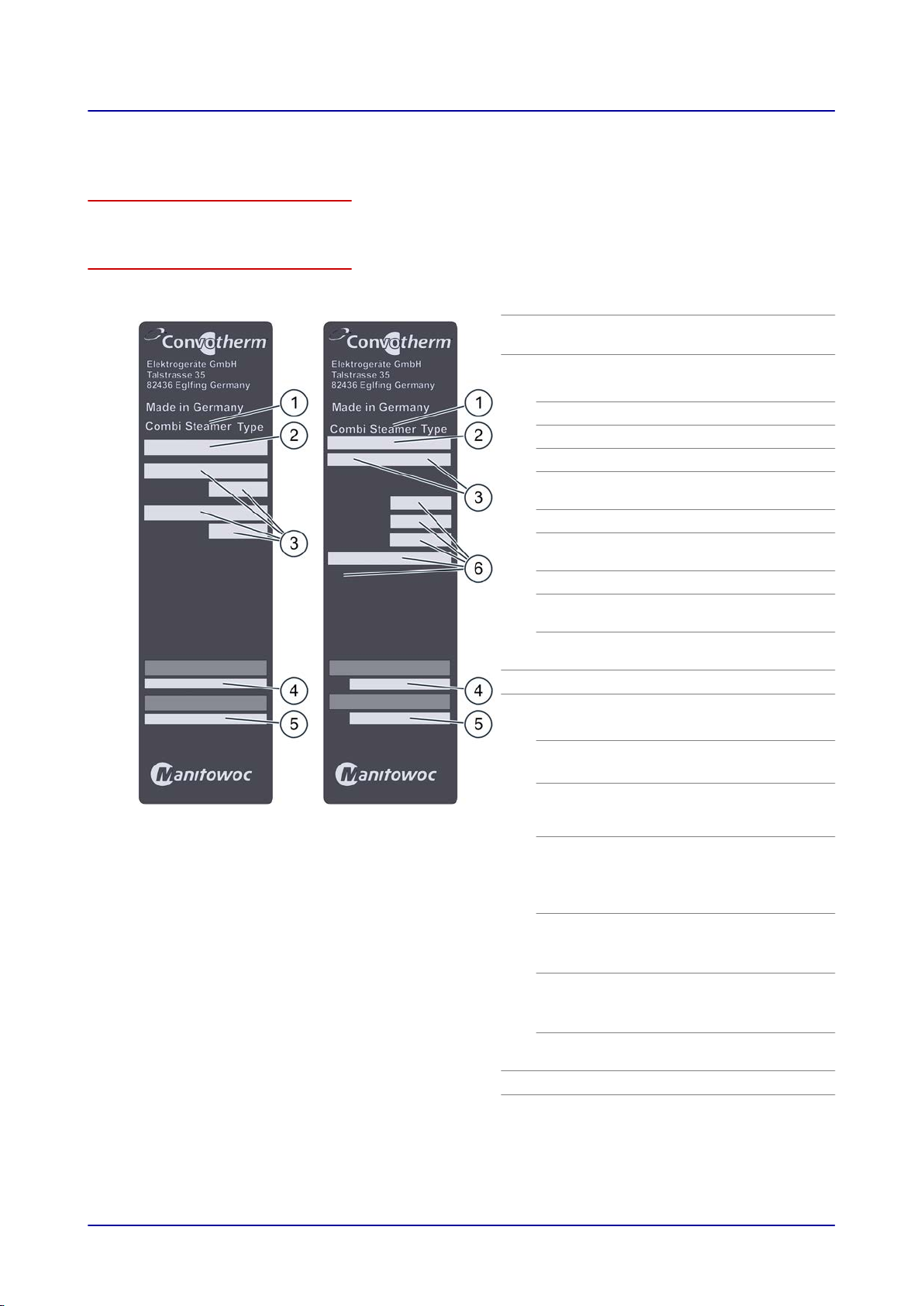

1.2 Identifying Your Combi Steamer

Nameplate location

The nameplate is found on the left side of the combi steamer.

Nameplate layout and structure

Electrical units Gas unit

Designation

Unit name

1

Combi Steamer

Trade name

2

Letters Meaning

C4 Convotherm 4 line of units

eT easyTouch controls

eD easyDial controls

xx.yy num‐

Unit size

bers

EB Electrical units with boiler

ES Electrical units with water

injection

GB Gas unit with boiler

GS Gas unit with water injec‐

tion

-N On units with NSF certifica‐

tion

Electrical specifications

3

Serial number

4

Letters Meaning

Heating

method

Steam gen‐

eration

■

Electrical units (X, V)

■

Gas unit (Y, W)

■

Sprayer (S)

■

Boiler (B)

method

Unit size

Year of

manufac‐

ture

Month of

manufac‐

ture

Consecutive

■

6.10 (1)

■

6.20 (2)

■

10.10 (3)

■

10.20 (4)

■

2014 (14)

■

2015 (15)

■

...

■

January (01)

■

February (02)

■

...

4-digit

■

■

■

number

Item number

5

Gas specifications

6

12.20 (5)

20.10 (6)

20.20 (7)

Installation Manual 9

1 General

1.3 Customer Documentation Structure

Customer documentation parts

The customer documentation for the combi steamer is made up of the following:

■

Installation manual (this manual)

■

Operating manual

■

easyTouch operating instructions (extract from the on-screen help pages)

■

On-screen help integrated into easyTouch (complete instructions for using the software)

■

easyDial Operating Instructions

Installation manual topics

The installation manual is intended for trained qualified personnel; see 'Staff Requirements' on page

45 in the installation manual.

It covers the following topics:

■

Configuration and functions: Describes the parts that are relevant when installing the combi steam‐

er

■

Safety: Goes over all the hazards involved in the various installation activities and how to prevent

and/or counter them

■

Transportation: Contains important information on transporting the combi steamer

■

Setup: Lists and describes the various setup options for the combi steamer

■

Installation: Goes over all the necessary utility and hose connections

■

Placing into operation: Explains how to put the combi steamer into operation for the first time

■

Removal from service: Goes over the activities that need to be carried out at the end of the combi

steamer's lifecycle

■

Technical data, connection diagrams: Contain all the required technical information concerning the

combi steamer

■

Checklists: Includes checklists for the combi steamer's installation and warranty

Operating manual topics

The operating manual is intended for briefed staff and trained qualified staff; see 'Staff Requirements'

in the operating manual.

It covers the following topics:

■

Configuration and functions: Describes the parts that are relevant when using the combi steamer

■

Safety: Goes over all the hazards involved in using the combi steamer and how to prevent and/or

counter them

■

Cooking: Goes over the various rules, workflows, operating steps, and actions required for cooking

■

Cleaning: Lists and describes the cleaning methods, cleaning agents, workflows, operating steps,

and actions required for cleaning

■

Maintenance: Contains warranty information; the maintenance schedule; information on faults, er‐

rors, and emergency mode; and the workflows, operating steps, and actions required for mainte‐

nance

Operating instructions and on-screen help (easyTouch only) topics

The operating instructions and the on-screen help (easyTouch only) are intended for briefed staff and

trained qualified staff; see 'Staff Requirements' in the operating manual. For units with easyTouch, the

operating instructions will be an extract from the on-screen help pages.

The operating instructions and the on-screen help (easyTouch only) cover the following topics:

■

User interface layout: Goes over the combi steamer's user interface

■

Using the software: Contains instructions on how to enter and access cooking profiles, access

cleaning profiles, and start cooking and cleaning sequences; describes the various settings and

goes over how to import and export data

■

Select cooking profiles: Lists tried-and-true cooking profiles

Installation Manual 10

1 General

1.4 Safety Information That Must Be Read without Exception

Safety information found in the documentation for the customer

Only the installation manual and operating manual provide safety information for the combi steamer.

The installation manual provides safety information for the transportation, setup, installation, placinginto-operation, and removal-from-service tasks it describes.

The operating manual provides safety information for the cooking, cleaning, and maintenance tasks it

describes.

When using the operating instructions, the operating manual or installation manual should always be

consulted in order to obtain the relevant safety information. When performing activities that go beyond

simply using the software, the safety information in the operating manual and installation manual must

always be observed.

Parts of this document that must be read without exception

Failure to take the information in this document into account may result in death, injury, or property

damage.

In order to ensure their safety and the safety of others, everyone working with/on the combi steamer

must read and understand the following parts of this document before starting any work:

■

The 'For Your Safety' on page

■

The sections describing the work that will be carried out

21 section

Danger symbol

Danger symbol Meaning

Used to warn of potential injury. Observe all the precautionary state‐

ments following this symbol in order to avoid injury or death.

Precautionary statements

The precautionary statements in this manual are categorized using the following hazard levels:

Hazard level Consequences Likelihood

Death / severe injury (irreversible) Imminent

Death / severe injury (irreversible) Potential

Minor injury (reversible) Potential

NOTICE

Property damage Potential

Installation Manual 11

1 General

1.5 About This Installation Manual

Purpose

The purpose of this installation manual is to provide everyone working with/on the combi steamer with

the information they will need to transport, set up, install, and place the unit into operation safely and

correctly.

Target groups for this installation manual

Name of target group Tasks

Person placing the unit

into operation

(service technician)

Combi steamer owner

or

the owner's employee

who is responsible for

the unit

Mover Transporting the unit within the facilities

Service technician

Electrician

Water and wastewater

installer

Gas technician Installing and uninstalling gas connections

■

Responsible overall for placing the combi steamer into operation

■

Briefing the user

■

Briefed on all of the combi steamer's safety-relevant functions, mecha‐

nisms, and devices by the person placing the unit into operation

■

Shown how the unit is operated by the person placing the unit into oper‐

ation

■

If necessary, helping out as directed with transportation within the facili‐

ties and with setting up the unit

■

Setting up the unit

■

Installing the fully automatic oven cleaning system

ConvoClean / ConvoClean+ (optional)

■

Placing the unit into operation and removing it from service

■

Connecting the unit to the electrical connection at the facilities

■

Uninstalling electrical connections

■

Connecting the unit to the water connection at the facilities

■

Uninstalling water connections

■

Connecting the unit to the drain connection at the facilities

■

Uninstalling the drain connection

Installation manual outline

Section / sub-section Purpose

General

Configuration and Func‐

tions

For Your Safety Describes all the risks and hazards posed by the unit, as well as appro‐

Transportation

Setup

■

Helps identify your unit

■

Explains how to use this installation manual

■

Describes the unit's intended use

■

Explains the unit's functions and describes where its components are

located

priate instructions on how to prevent and/or counter them

Read this section carefully!

■

Provides basic unit dimensions

■

Explains how to transport the unit to its installation location

■

Provides information on adjacent systems used for exhaust and ex‐

traction purposes

■

Provides information on the requirements concerning the installation

location

■

Explains how to unpack the unit and goes over the included equip‐

ment and parts

■

Explains how to set up the unit

Installation Manual 12

1 General

Section / sub-section Purpose

Installation Explains how to install:

Placing into operation Explains how to put the unit into operation

Removal from service and

Disposal

Technical data Contains technical specifications

Connection drawings Contains drawings with dimensions and connection points

Checklists and Completing

the Installation

Decimal mark used

■

Electrical specifications

■

Gas

■

The water and wastewater systems

■

Exhaust gas and exhaust air systems

■

The ConvoClean+ / ConvoClean fully automatic cleaning system

■

Explains how to remove the unit from service

■

Provides disposal information

■

Contains the checklists for

■

Installation

■

Safety guards, safety devices, and warning labels

■

Customer briefing

■

Provides warranty information and goes over how to use the check‐

lists at the end

In order to ensure that all numbers can be properly understood internationally, a decimal point is al‐

ways used.

Installation Manual 13

2 Configuration and Functions

2 Configuration and Functions

Purpose of this section

This section describes the combi steamer's configuration and explains its functions.

2.1 The Combi Steamer's Configuration and Functions

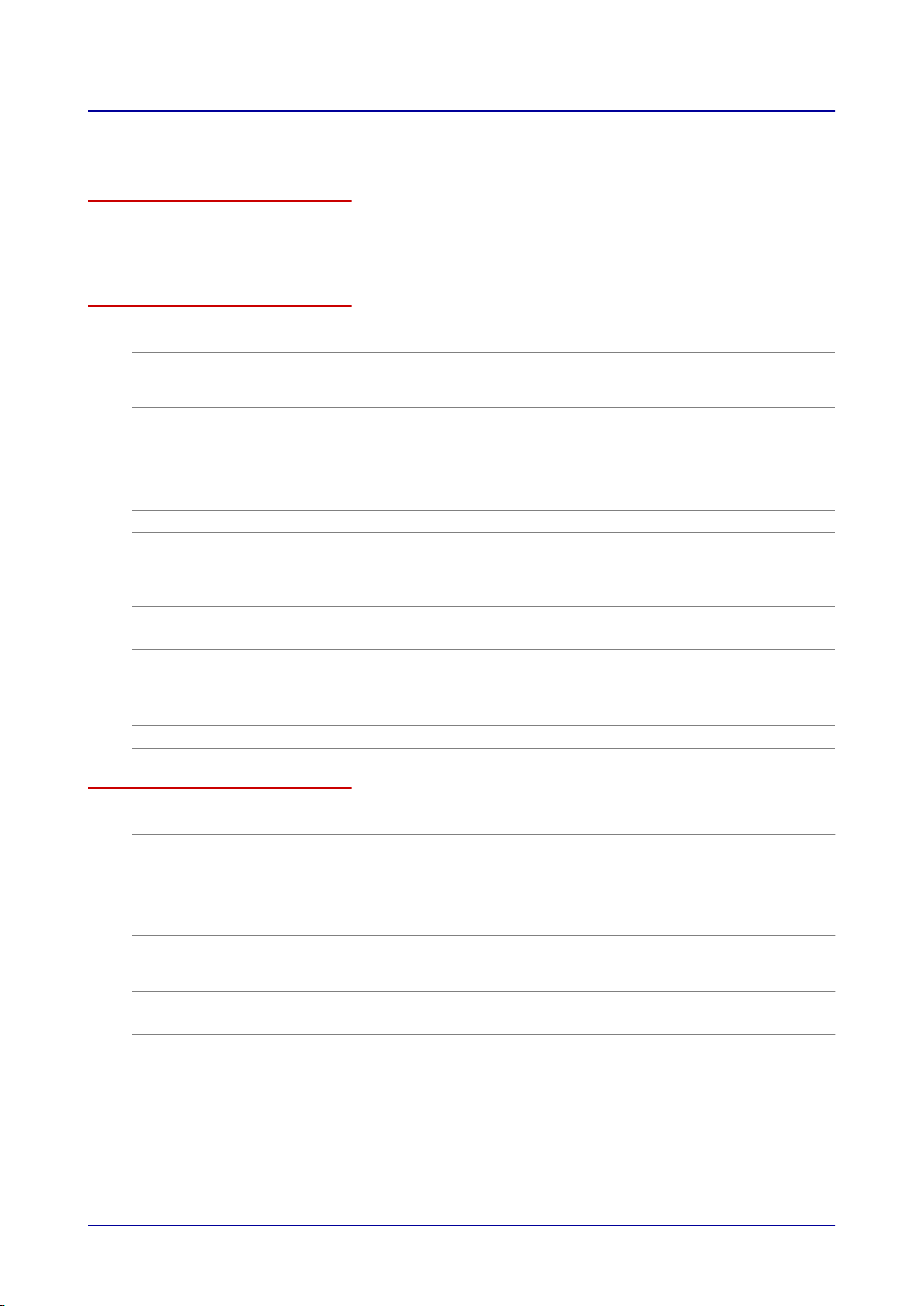

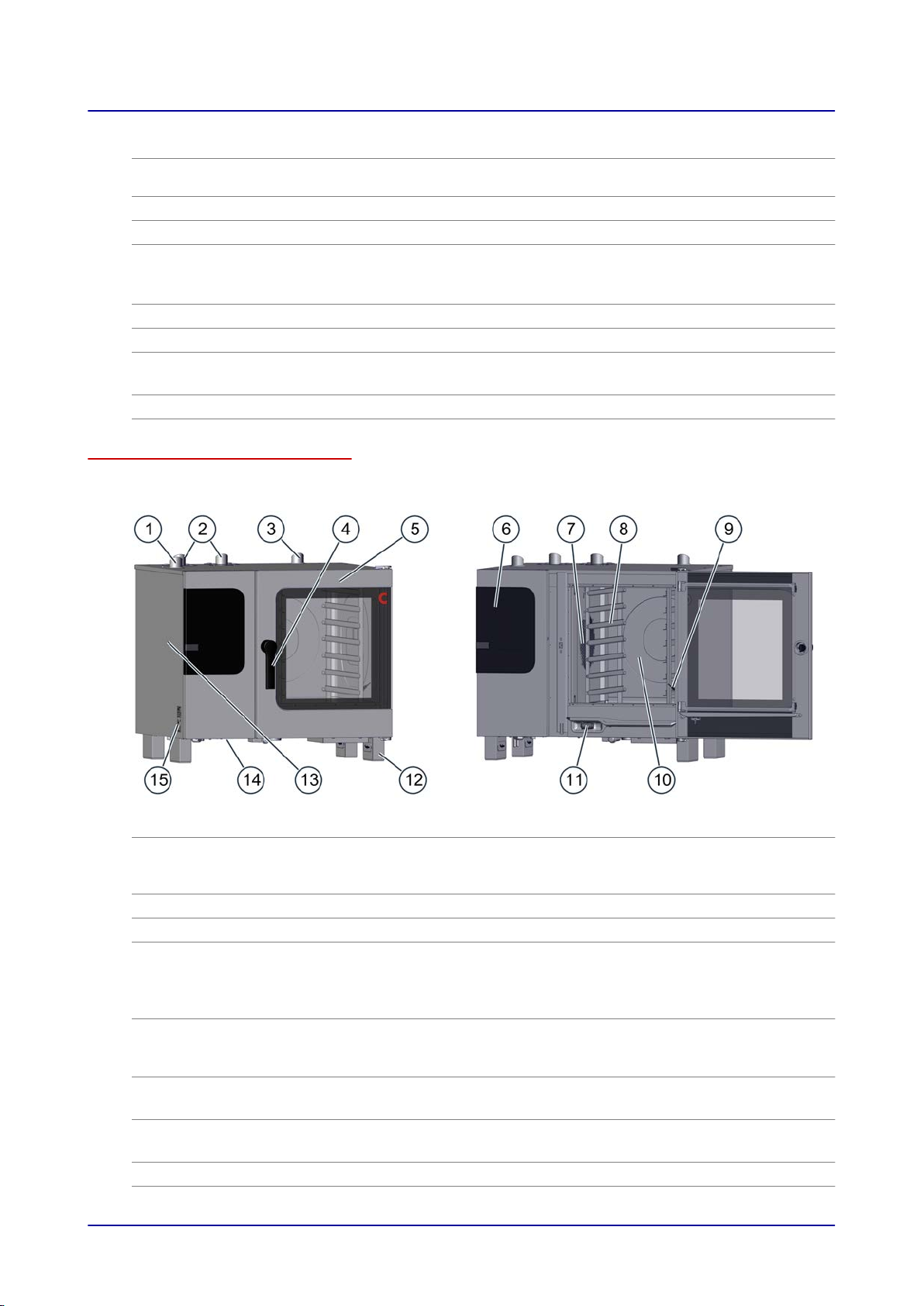

Parts and functions (electrical table-top models)

The figure below shows a size 6.10 combi steamer used as an example representing all electrical ta‐

ble-top models:

No. Designation Function

Ventilation port

1

■

Draws in ambient air in order to remove moisture from the oven

cavity

■

Compensates for pressure fluctuations inside the oven cavity

Air vent Lets hot steam escape

2

3

4

Door handle

Unit door

■

Used to open and close the unit door

■

Cracked-open position for safely opening the unit ('safety lock')

■

Closing-shut function

■

Antibacterial material with silver ions ("HygienicCare")

■

Seals the oven cavity

■

When opened, it can be slid backwards along the unit's side in

order to save space ('disappearing door') (optional)

Operating panel

5

Suction panel

6

Rack Used to hold standard-size bakeware

7

Core temperature probe,

8

sous vide probe (optional)

■

Used to operate the unit

■

Antibacterial ("HygienicCare")

■

Used to distribute heat uniformly within the oven cavity

■

Separates the fan compartment from the oven cavity

■

Used to measure the food's internal temperature

■

Available as an internal version that is permanently connected

inside the oven and/or as an external version that can be tem‐

porarily connected

Oven cavity Is where food is placed while it is being cooked

9

Recoil hand shower

10

(not included in certain

units)

Unit feet Are height-adjustable so as to make it possible to level the unit

11

■

Meant exclusively for rinsing the oven cavity with water

■

Is retracted automatically into its holder after being used

■

Antibacterial ("HygienicCare")

Installation Manual 14

2 Configuration and Functions

No. Designation Function

Side panel Covers the unit's wiring compartment

12

Vents at the bottom of the

13

unit

Nameplate Used to identify the unit

14

■

Used to ventilate the unit

■

Must not be blocked

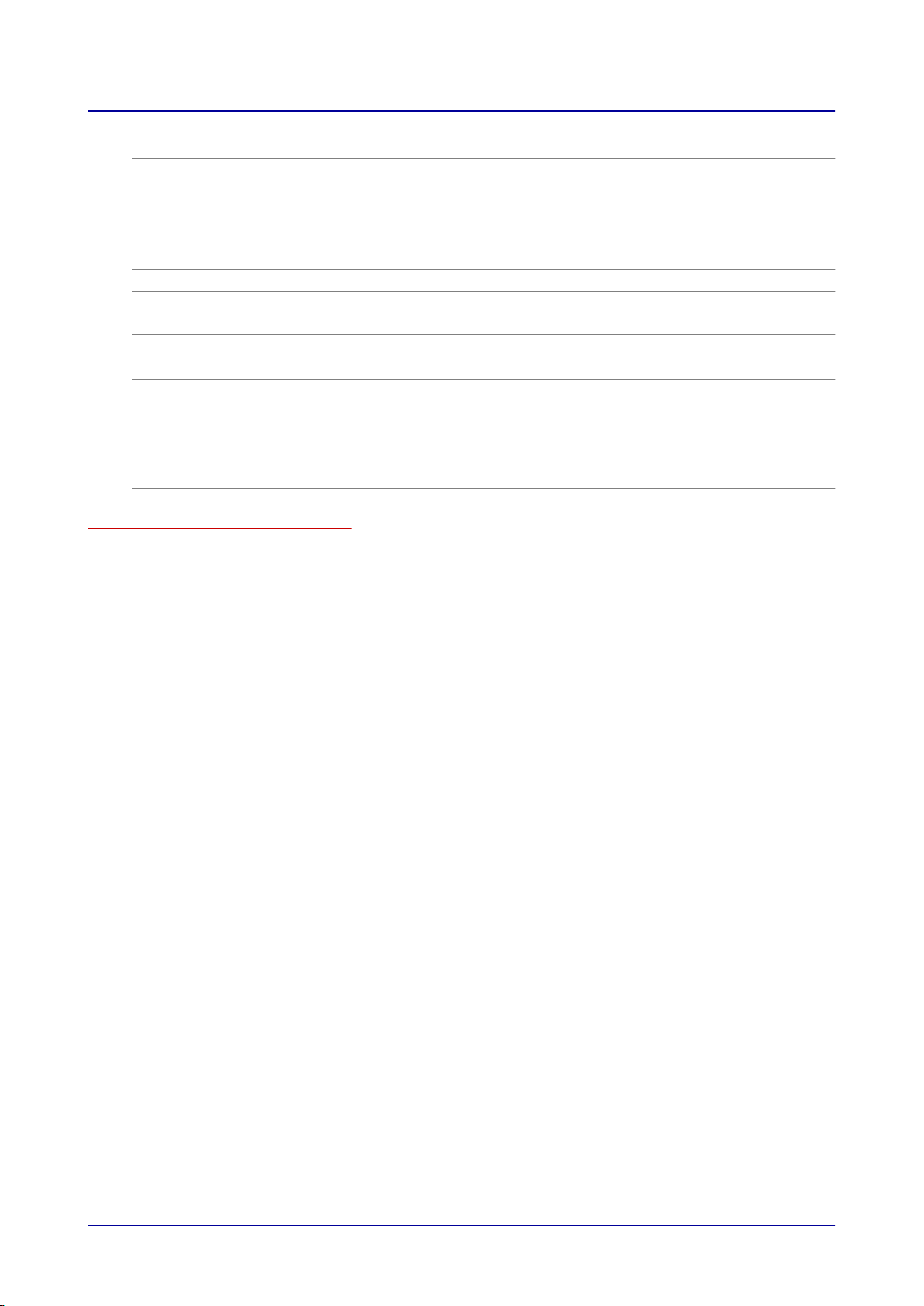

Parts and functions (electrical floor-standing models)

The figure below shows a size 20.20 combi steamer used as an example representing all electrical

floor-standing models:

No. Designation Function

Ventilation port

1

■

Draws in ambient air in order to remove moisture from the oven

cavity

■

Compensates for pressure fluctuations inside the oven cavity

Air vent Lets hot steam escape

2

3

4

Door handle

Unit door

■

Used to open and close the unit door

■

Cracked-open position for safely opening the unit

■

Antibacterial material with silver ions ("HygienicCare")

■

Seals the oven cavity

■

When opened, it can be slid backwards along the unit's side in

order to save space ('disappearing door') (optional)

Operating panel

5

Suction panel

6

Core temperature probe,

7

sous vide probe (optional)

■

Used to operate the unit

■

Antibacterial ("HygienicCare")

■

Used to distribute heat uniformly within the oven cavity

■

Separates the fan compartment from the oven cavity

■

Used to measure the food's internal temperature

■

Available as an internal version that is permanently connected

inside the oven and/or as an external version that can be tem‐

porarily connected

Installation Manual 15

2 Configuration and Functions

No. Designation Function

Integrated preheat bridge

8

in unit door

Loading trolley Used to hold standard-size bakeware

9

Oven cavity Is where food is placed while it is being cooked

10

Recoil hand shower

11

(not included in certain

units)

Side panel Covers the unit's wiring compartment

12

Unit feet Are height-adjustable so as to make it possible to level the unit

13

Vents at the bottom of the

14

unit

Nameplate Used to identify the unit

15

Works as a safety element during pre-heating and reduces ener‐

gy losses

■

Meant exclusively for rinsing the oven cavity with water

■

Is retracted automatically into its holder after being used

■

Antibacterial ("HygienicCare")

■

Used to ventilate the unit

■

Must not be blocked

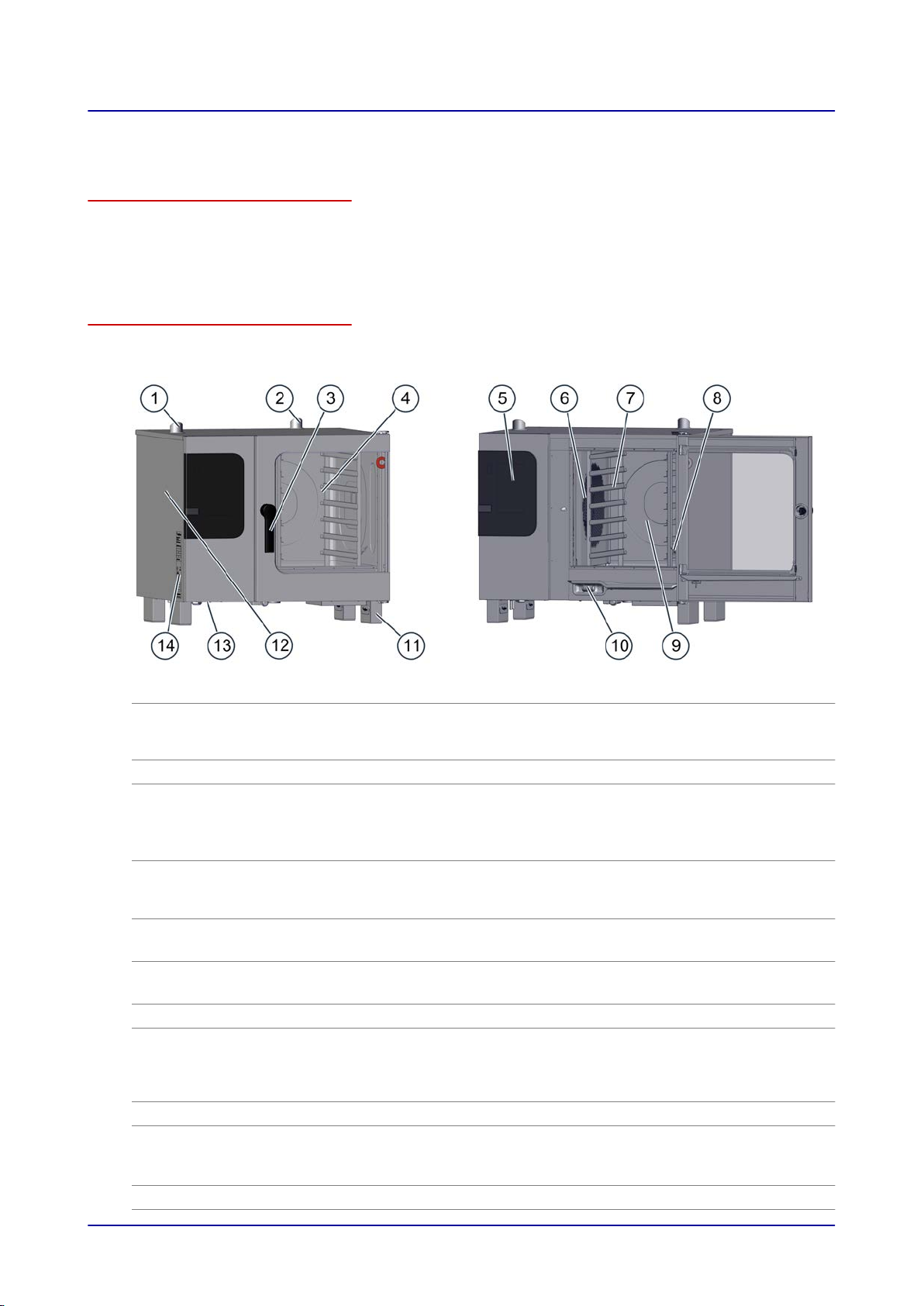

Parts and functions (gas table-top models)

The figure below shows a size 6.10 combi steamer used as an example representing all gas table-top

models:

No. Designation Function

Ventilation port

1

■

Draws in ambient air in order to remove moisture from the oven

cavity

■

Compensates for pressure fluctuations inside the oven cavity

Exhaust outlet Discharges hot exhaust gases

2

Air vent Lets hot steam escape

3

4

5

Door handle

Unit door

■

Used to open and close the unit door

■

Cracked-open position for safely opening the unit ('safety lock')

■

Closing-shut function

■

Antibacterial material with silver ions ("HygienicCare")

■

Seals the oven cavity

■

When opened, it can be slid backwards along the unit's side in

order to save space ('disappearing door') (optional)

Operating panel

6

Suction panel

7

Rack Used to hold standard-size bakeware

8

■

Used to operate the unit

■

Antibacterial ("HygienicCare")

■

Used to distribute heat uniformly within the oven cavity

■

Separates the fan compartment from the oven cavity

Installation Manual 16

2 Configuration and Functions

No. Designation Function

Core temperature probe,

9

sous vide probe (optional)

■

Used to measure the food's internal temperature

■

Available as an internal version that is permanently connected

inside the oven and/or as an external version that can be tem‐

porarily connected

Oven cavity Is where food is placed while it is being cooked

10

Recoil hand shower

11

(not included in certain

units)

Unit feet Are height-adjustable so as to make it possible to level the unit

12

Side panel Covers the unit's wiring compartment

13

Vents at the bottom of the

14

unit

Nameplate Used to identify the unit

15

■

Meant exclusively for rinsing the oven cavity with water

■

Is retracted automatically into its holder after being used

■

Antibacterial ("HygienicCare")

■

Used to ventilate the unit

■

Must not be blocked

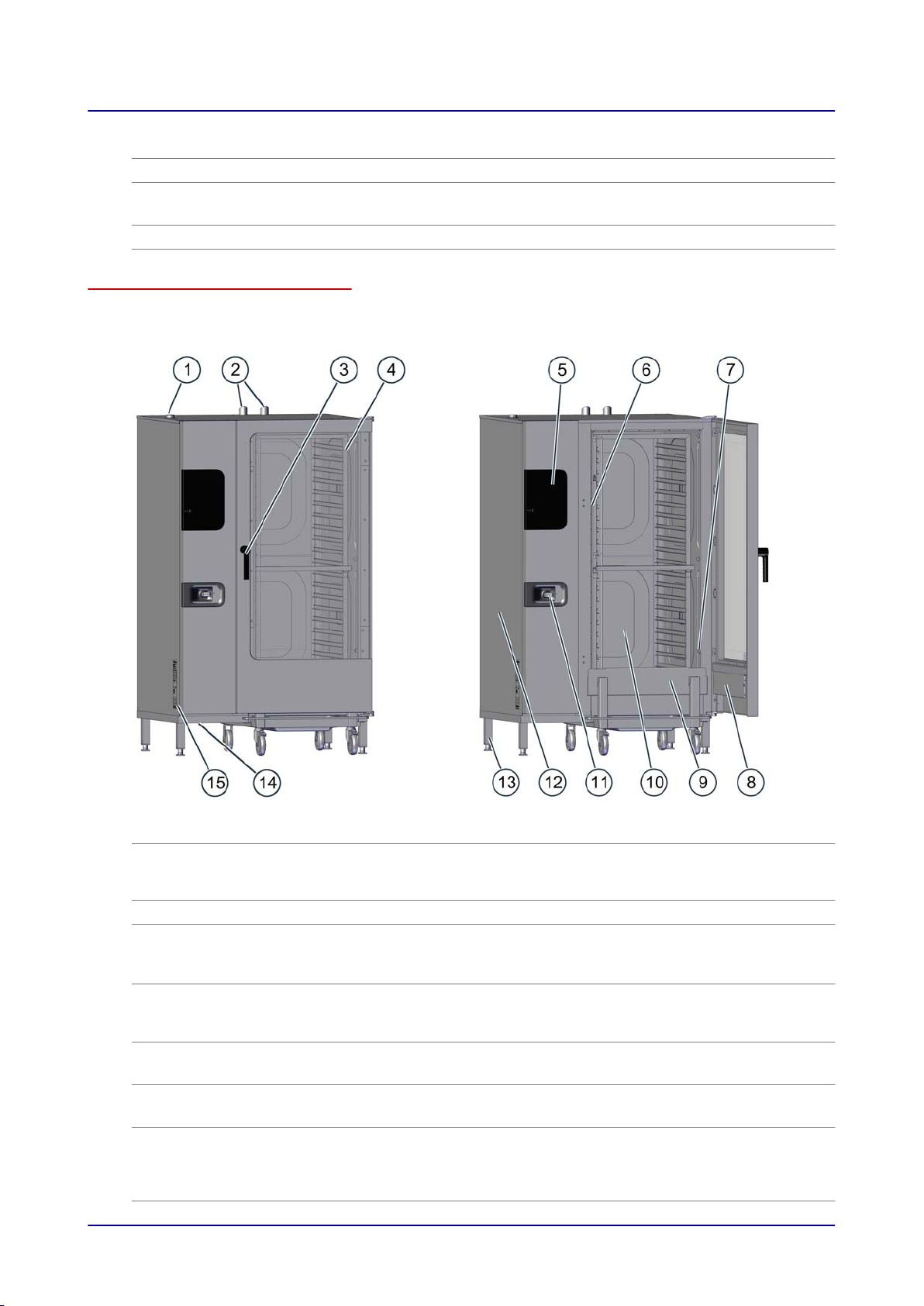

Parts and functions (gas floor-standing models)

The figure below shows a size 20.20 combi steamer used as an example representing all gas floorstanding models:

No. Designation Function

Ventilation port

1

■

Draws in ambient air in order to remove moisture from the oven

cavity

■

Compensates for pressure fluctuations inside the oven cavity

Exhaust outlet Discharges hot exhaust gases

2

Air vent Lets hot steam escape

3

4

Door handle

■

Used to open and close the unit door

■

Cracked-open position for safely opening the unit

■

Antibacterial material with silver ions ("HygienicCare")

Installation Manual 17

2 Configuration and Functions

No. Designation Function

Unit door

5

Operating panel

6

Suction panel

7

Core temperature probe,

8

sous vide probe (optional)

Integrated preheat bridge

9

in unit door

Loading trolley Used to hold standard-size bakeware

10

Oven cavity Is where food is placed while it is being cooked

11

Recoil hand shower

12

(not included in certain

units)

Side panel Covers the unit's wiring compartment

13

Unit feet Are height-adjustable so as to make it possible to level the unit

14

Vents at the bottom of the

15

unit

Nameplate Used to identify the unit

16

■

Seals the oven cavity

■

When opened, it can be slid backwards along the unit's side in

order to save space ('disappearing door') (optional)

■

Used to operate the unit

■

Antibacterial ("HygienicCare")

■

Used to distribute heat uniformly within the oven cavity

■

Separates the fan compartment from the oven cavity

■

Used to measure the food's internal temperature

■

Available as an internal version that is permanently connected

inside the oven and/or as an external version that can be tem‐

porarily connected

Works as a safety element during pre-heating and reduces ener‐

gy losses

■

Meant exclusively for rinsing the oven cavity with water

■

Is retracted automatically into its holder after being used

■

Antibacterial ("HygienicCare")

■

Used to ventilate the unit

■

Must not be blocked

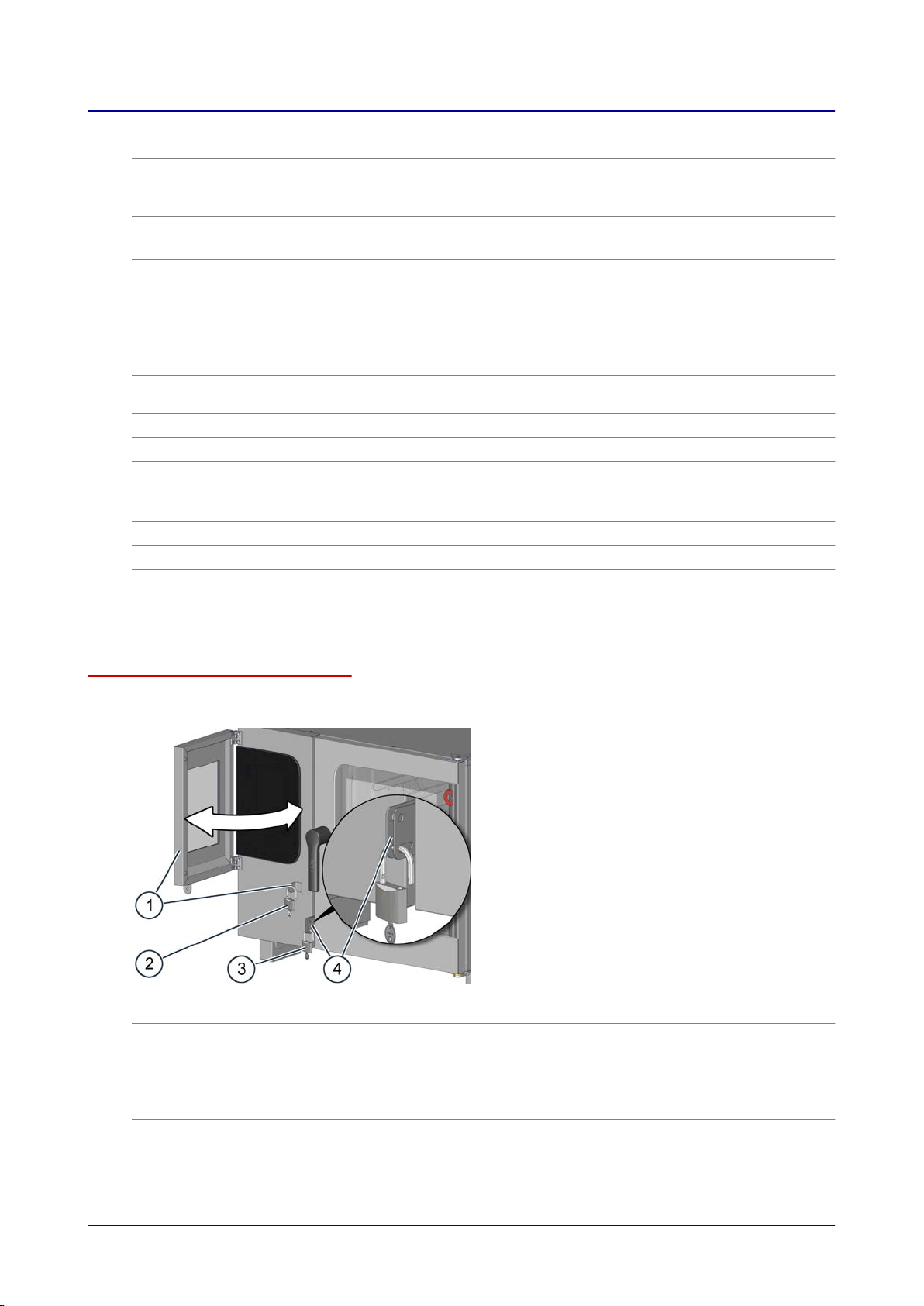

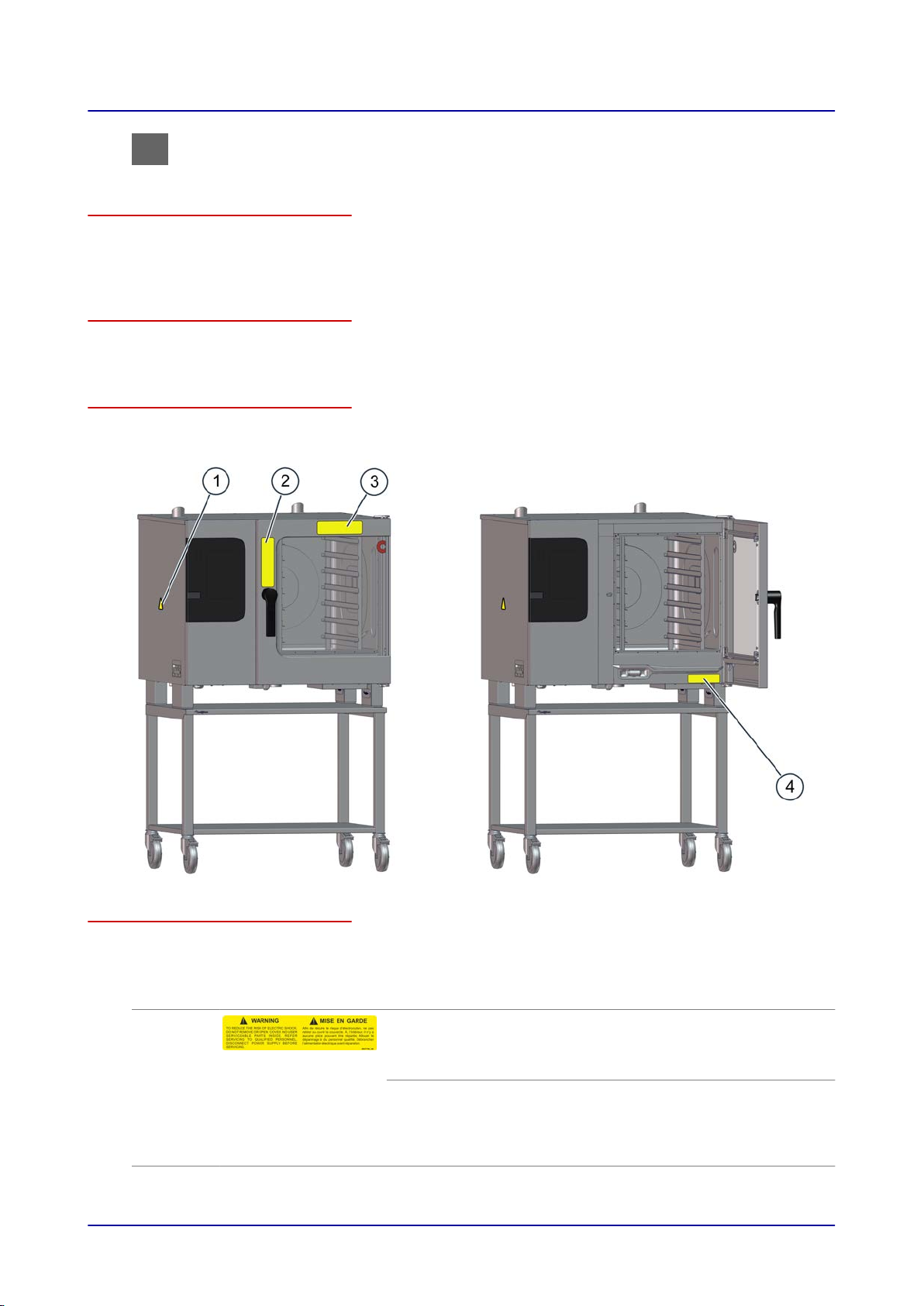

Parts and functions for special locking feature (security model only)

The figure below shows a special locking feature for enhanced security on a size 6.10 combi steamer

used as an example representing all unit sizes:

No. Designation Function

Lockable operating panel

1

cover

The cover can be swung in and secured onto the unit case so

that it covers the operating panel, preventing unauthorized users

from operating the combi steamer.

Padlock

2

■

Used to secure the operating panel cover onto the unit case

■

Not included

Installation Manual 18

2 Configuration and Functions

No. Designation Function

Padlock

3

Unit door hasp Features two different slots that can be used to lock the unit door

4

■

Used to secure the unit door onto the unit case

■

Not included

in order to prevent unauthorized users from opening and closing

it

Unit door action:

■

If the unit door is locked using the upper slot, the door will al‐

ways be fully closed.

■

If the unit door is locked using the lower slot, it will be possible

to open the door all the way to the cracked-open position.

Material

The unit's inner and outer parts are made of stainless steel.

Installation Manual 19

2 Configuration and Functions

2.2 Operating Panel Layout and Functions

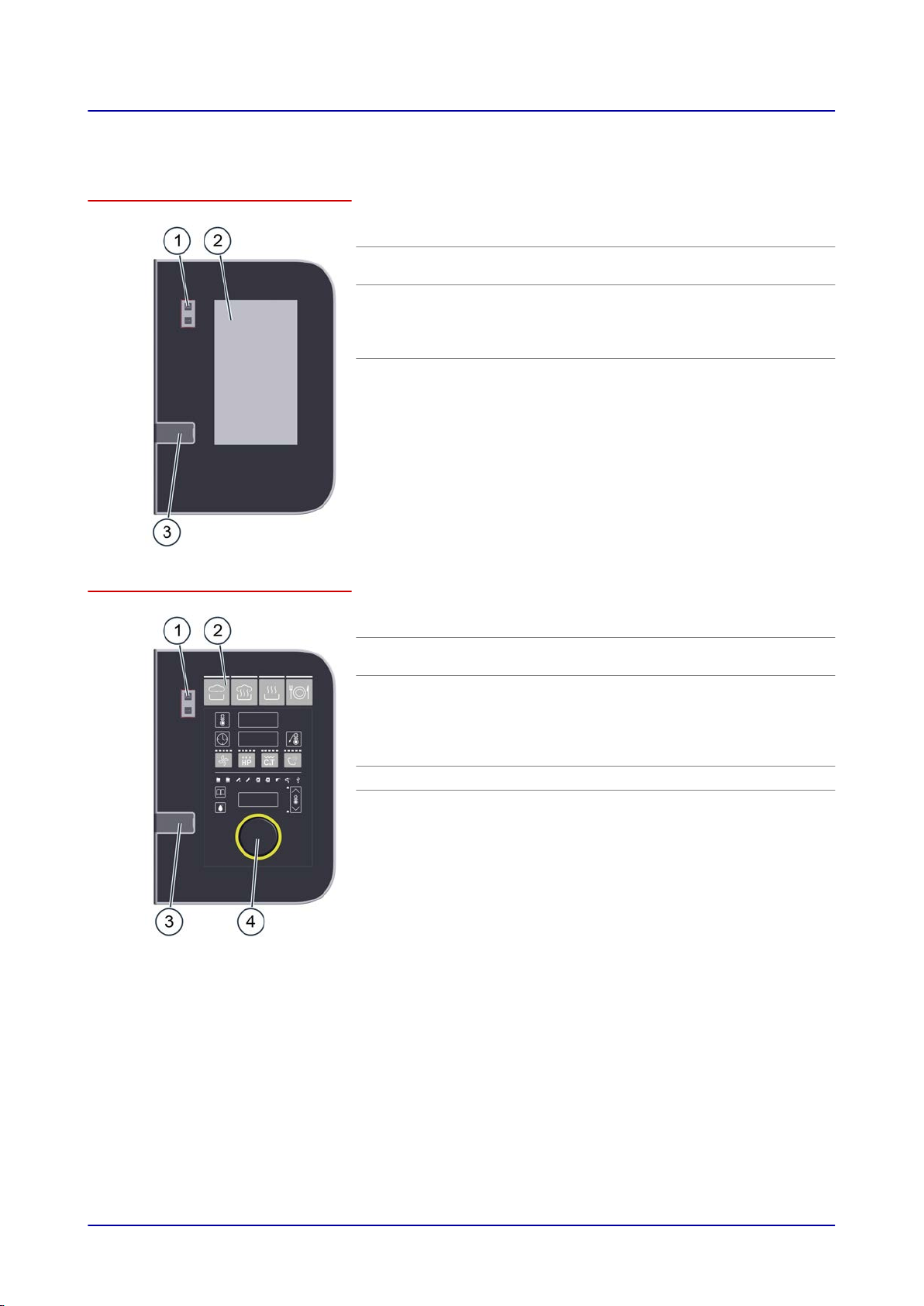

Operating panel layout and parts in easyTouch

No. Designation Function

1

2

3

Unit

ON/OFF switch

Full-touch dis‐

play

USB port Used to plug in a USB stick

Used to turn the combi steamer on and

off

The unit's central control interface

■

Used by touching the icons on the fulltouch display

■

Status indicators

Operating panel layout and parts in easyDial

No. Designation Function

1

2

3

4

Unit

ON/OFF switch

Used to turn the combi steamer on and

off

Control panel The unit's central control interface

■

Buttons used to enter cooking programs

■

Displays used to indicate configured

values

■

Prompt indicators for the operator

USB port Used to plug in a USB stick

C-Dial Used to set cooking parameters by turn‐

ing and pressing the encoder.

Installation Manual 20

3 For Your Safety

3 For Your Safety

Purpose of this section

The purpose of this section is to provide you with all the information you will need in order to safely

work with/on the combi steamer without putting yourself and others at risk.

Read this section very carefully!

3.1 Basic Safety Instructions

Purpose of these instructions

The purpose of these instructions is to ensure that everyone working with and on the combi steamer

will be fully aware of all the risks, hazards, and safety requirements involved and will observe the

warnings in the operating manual and on the combi steamer. Failure to follow these instructions may

result in death, injury, or property damage.

Customer documentation manuals

Follow the instructions below:

■

Fully read the 'For Your Safety' section, as well as the section that applies to the way you will be

interacting with the combi steamer.

■

Keep the customer documentation manuals handy at all times so that you can look up any required

information.

■

If you transfer the combi steamer to a new owner, make sure to give the new owner the customer

documentation manuals as well.

Basic rules for installation

The unit must be installed in compliance with all national and state laws and regulations, with all appli‐

cable local requirements and regulations set forth by the relevant local utility companies and authori‐

ties, and with all other relevant regulations and standards.

These include, but are not limited to:

■

The National Electrical Code, ANSI/NFPA 70 (current edition)

■

The Canadian Electrical Code, CSA C22.2

■

National Fuel Gas Code, ANSI Z223.1 /NFPA 54 (latest version)

■

Natural Gas and Propane Installation Code, CSA B149.1

■

The Food Code and Food Service Sanitation Manual published by the Food and Drug Administra‐

tion (FDA) (current editions)

■

Latest edition of the International Plumbing Code published by the International Code Council (ICC)

or the Uniform Plumbing Code published by the International Association of Plumbing and Mechan‐

ical Officials (IAPMO)

■

The standards published by the National Sanitation Foundation (NSF)

■

All local fire protection and occupational health and safety regulations

Working with/on the combi steamer

Follow the instructions below:

■

Only people who meet all the requirements specified in this operating manual should be allowed to

use and otherwise work with/on the combi steamer.

■

Only use the combi steamer for its intended use as described in this manual. Never, under any cir‐

cumstance, use the combi steamer for other purposes, even if they seem obvious.

■

Observe all the safety measures specified in this operating manual and on the combi steamer. This

applies especially to wearing the required personal protective equipment.

■

Make sure to always stay in the specified work areas when working with/on the combi steamer.

■

Do not make any alterations to the combi steamer. This includes removing components and add‐

ing components that have not been expressly approved.

Above all, however, make sure not to

disable any safety devices or guards.

Installation Manual 21

3 For Your Safety

For more information...

Related subjects

Your Combi Steamer's Intended Use 23

Warning labels on combi steamer table-top models 25

Warning labels on combi steamer floor-standing models 28

Hazards and Safety Measures When Moving the Unit 31

Hazards and Safety Measures During Setup 32

Hazards and Safety Measures During Installation 33

Hazards and Safety Measures When Putting the Unit into Operation 35

Hazards and Safety Measures When Removing the Unit from Service 38

Safety Devices 41

Staff and Work Area Requirements 45

Personal Protective Equipment 47

Installation Manual 22

3 For Your Safety

3.2 Your Combi Steamer's Intended Use

The combi steamer's intended use

■

The combi steamer has been designed and built exclusively for cooking a variety of food in stand‐

ard-size bakeware (steam table pans, sheet pans, etc.). Steam, convection, and combi-steam

(steam superheated without pressure) are used for this purpose.

■

The bakeware can be made of stainless steel, ceramic, plastic, aluminum, enameled steel, or

glass. Glass bakeware must not be damaged.

■

The combi steamer is intended exclusively for professional commercial use.

Limitations on use

The combi steamer should not be used to heat up the following materials:

■

Dry powders or granular products

■

Readily flammable substances or objects with a flashpoint lower than 518 °F, such as readily flam‐

mable oils, fats, and plastics

■

Food in sealed cans

Staff requirements

■

The combi steamer must be run and installed exclusively by staff meeting the specified require‐

ments. For the corresponding training and qualifications requirements, please refer to 'Staff and

Work Area Requirements on page

■

All staff must be familiar with the risks, hazards, and rules involved in handling heavy loads.

45.'

Requirements concerning the combi steamer's functional capability

■

Do not operate the combi steamer unless it has been properly transported, set up, installed, and

placed into operation as indicated in the installation manual and the person responsible for placing

it into operation has confirmed this.

■

The combi steamer should only be used if all safety devices and guards are present, working prop‐

erly, and correctly locked in place.

■

All manufacturer specifications concerning how to run and service the combi steamer must be ob‐

served.

■

The load placed inside the combi steamer must never exceed the maximum permissible loading

weight; please refer to 'Technical Data' on page

114.

Requirements concerning the combi steamer's surroundings

Required combi steamer surroundings

■

Ambient temperature between 40 °F and 95 °F

■

No toxic or potentially explosive atmospheres

■

Do not use or store gasoline or other flammable vapors, gases, or liquids in the vicinity of a combi

steamer

■

Dry kitchen floor in order to reduce the risk of accidents occurring

Required installation location characteristics

■

NO fire alarms or sprinkler system directly above the unit

■

NO flammable materials, gases, or liquids above, on, under, or close to the unit

Limitations on use

■

When used outdoors, the unit must be protected from rain and wind

■

Do NOT shift or move the unit during operation

Installation Manual 23

3 For Your Safety

Prerequisites for cleaning

■

Only use the cleaning agents approved by the manufacturer.

■

Do NOT use a pressure washer to clean the unit.

■

Do NOT use a water jet to clean the outside of the unit. Do not use the recoil hand shower for any‐

thing other than cleaning the oven cavity.

■

Do NOT use bases or acids to clean the combi steamer and make sure it is not exposed to acid

fumes. The only exception is when the oven cavity and the boiler are descaled by an authorized

service company following the manufacturer's instructions.

Installation Manual 24

3 For Your Safety

3.3 Warning labels on combi steamer table-top models

Stationary base

The term 'stationary base' refers to a stationary work table or stand for the combi steamer. These

bases are not intended to move and accordingly do not feature any components that would enable

them to do so.

Moving base

The term 'moving base' refers, for example, to a work table or stand on casters or to a stacking kit with

casters for the combi steamer.

Warning label locations on the unit

The figure below shows a size 6.10 electrical combi steamer with a moving base used as an example

representing all table-top models:

Required warning labels on the unit

The following warning labels must always be clearly visible on the combi steamer at the locations

shown in the previous figure.

Location Warning label Description

1 and 4

Installation Manual 25

WARNING

To reduce the risk of electric shock, do not remove or open

cover. No user serviceable parts inside. Refer servicing to

qualified personnel. Disconnect power supply before servicing.

AVERTISSEMENT

Afin de réduire le risque d'électrocution, ne pas retirer ou ouvrir

le capot. Aucune pièce réparable ne se trouve à l'intérieur.

Confier le dépannage à du personnel qualifié. Débrancher l'ali‐

mentation électrique avant réparation.

3 For Your Safety

Location Warning label Description

2

Hot steam warning

There is a risk of scalding posed by the hot steam coming out

when the unit door is opened.

2

2

2

3

3

Hot food, hot bakeware, and hot liquid warning

Hot food and hot bakeware can pose a burn hazard if bakeware

topples over and out of the shelf levels or if food slides off from

bakeware being held in an inclined position. The risk of this oc‐

curring is particularly high in the case of shelf levels located

above the operator's field of view.

Risk of scalding when liquid food is spilled. This hazard exists

when liquids, or food that becomes liquefied during cooking,

are placed on the upper shelf levels. Do not use shelf levels lo‐

cated above your field of view to hold liquids or food that will

become liquefied.

Combi steamer tip-over hazard warning for when the combi

steamer is placed on a base with casters

There is a risk of the combi steamer toppling over when being

moved. Exercise extreme caution when moving the combi

steamer. When moving the combi steamer, look out for obsta‐

cles and uneven surfaces.

Unit connection damage and disconnection warning for when

the combi steamer is placed on a base with casters

There is a risk of the unit's hookups being damaged or discon‐

nected when the combi steamer is moved. Exercise extreme

caution when moving the combi steamer and take the connec‐

tions' length into account. Every time after moving it, secure the

combi steamer so that it cannot roll away by accident.

CAUTION

Do not open combi door during smoking. Outside air entering

the combi may cause wood bisquettes to ignite.

WARNING

The use of improper materials for smoke mode may result in

equipment damage or hazards or may shorten the life of the

combi. Only use materials listed for smoke mode in the opera‐

tor's manual.

CAUTION

Door(s) and handle(s) may be hot.

ATTENTION

Porte(s) et poignée(s) chaudes

Required warning labels on the optional transport trolley (does not apply to ConvoSmoke)

The following warning labels must always be clearly visible on the transport trolley at the location

shown in the figure below.

Installation Manual 26

3 For Your Safety

Location 5 Warning label Description

Hot food, hot bakeware, and hot liquid warning

Hot food and hot bakeware can pose a burn hazard

if bakeware topples over and out of the shelf levels

or if food slides off from bakeware being held in an

inclined position. The risk of this occurring is partic‐

ularly high in the case of shelf levels located above

the operator's field of view.

Risk of scalding when liquid food is spilled. This

hazard exists when liquids, or food that becomes

liquefied during cooking, are placed on the upper

shelf levels. Do not use shelf levels located above

your field of view to hold liquids or food that will be‐

come liquefied.

Transport trolley tip-over hazard warning

There is a risk of the transport trolley toppling over

when being moved. Exercise extreme caution when

moving the transport trolley. When moving the

transport trolley, look out for obstacles and uneven

surfaces.

Installation Manual 27

3 For Your Safety

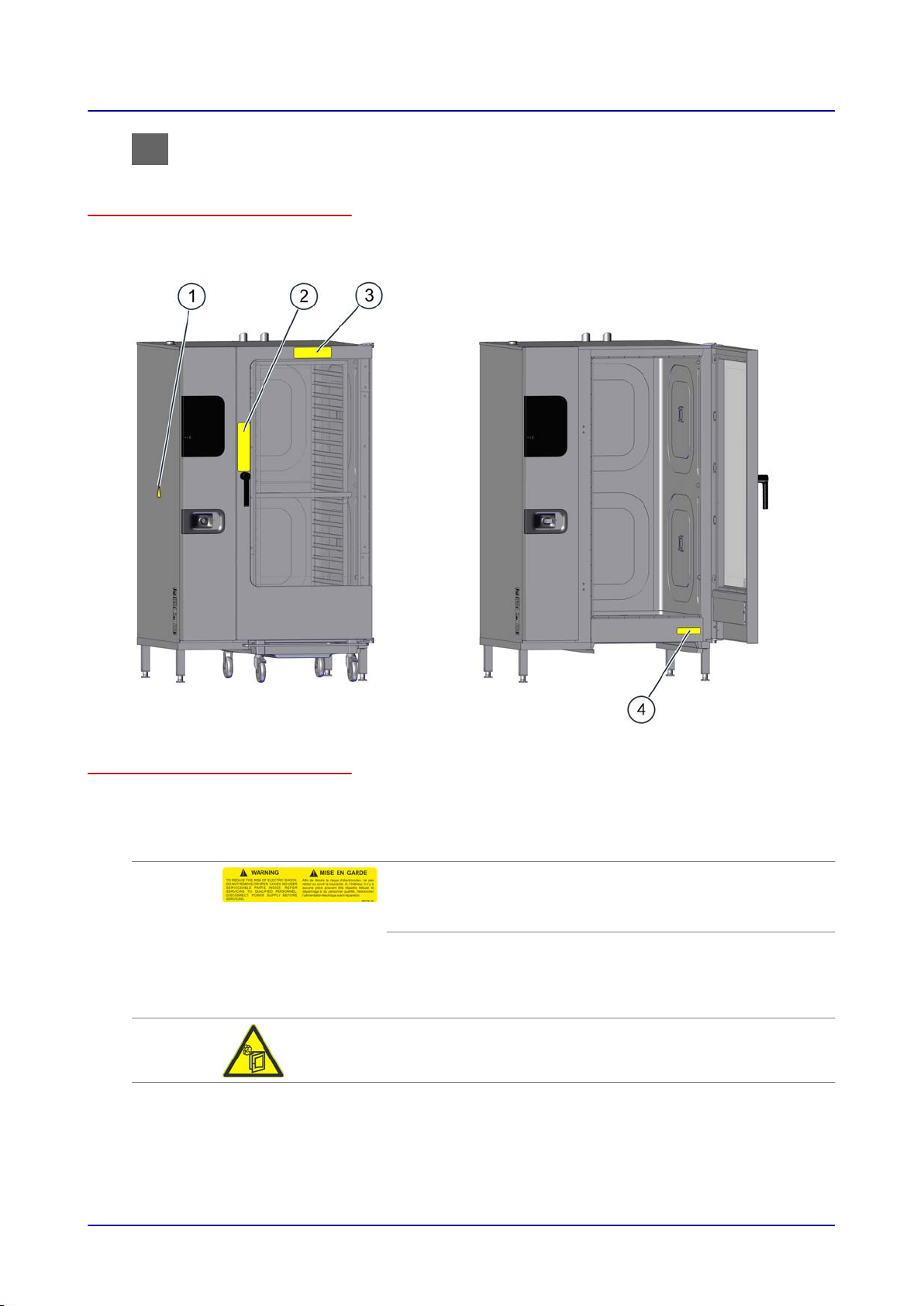

3.4 Warning labels on combi steamer floor-standing models

Warning label locations on the unit

The figure below shows a size 20.20 electrical combi steamer used as an example representing all

floor-standing models:

Required warning labels on the unit

The following warning labels must always be clearly visible on the combi steamer at the locations

shown in the previous figure.

Location Warning label Description

1 and 4

2

WARNING

To reduce the risk of electric shock, do not remove or open

cover. No user serviceable parts inside. Refer servicing to

qualified personnel. Disconnect power supply before servicing.

AVERTISSEMENT

Afin de réduire le risque d'électrocution, ne pas retirer ou ouvrir

le capot. Aucune pièce réparable ne se trouve à l'intérieur.

Confier le dépannage à du personnel qualifié. Débrancher l'ali‐

mentation électrique avant réparation.

Hot steam warning

There is a risk of scalding posed by the hot steam coming out

when the unit door is opened.

Installation Manual 28

3 For Your Safety

2

3

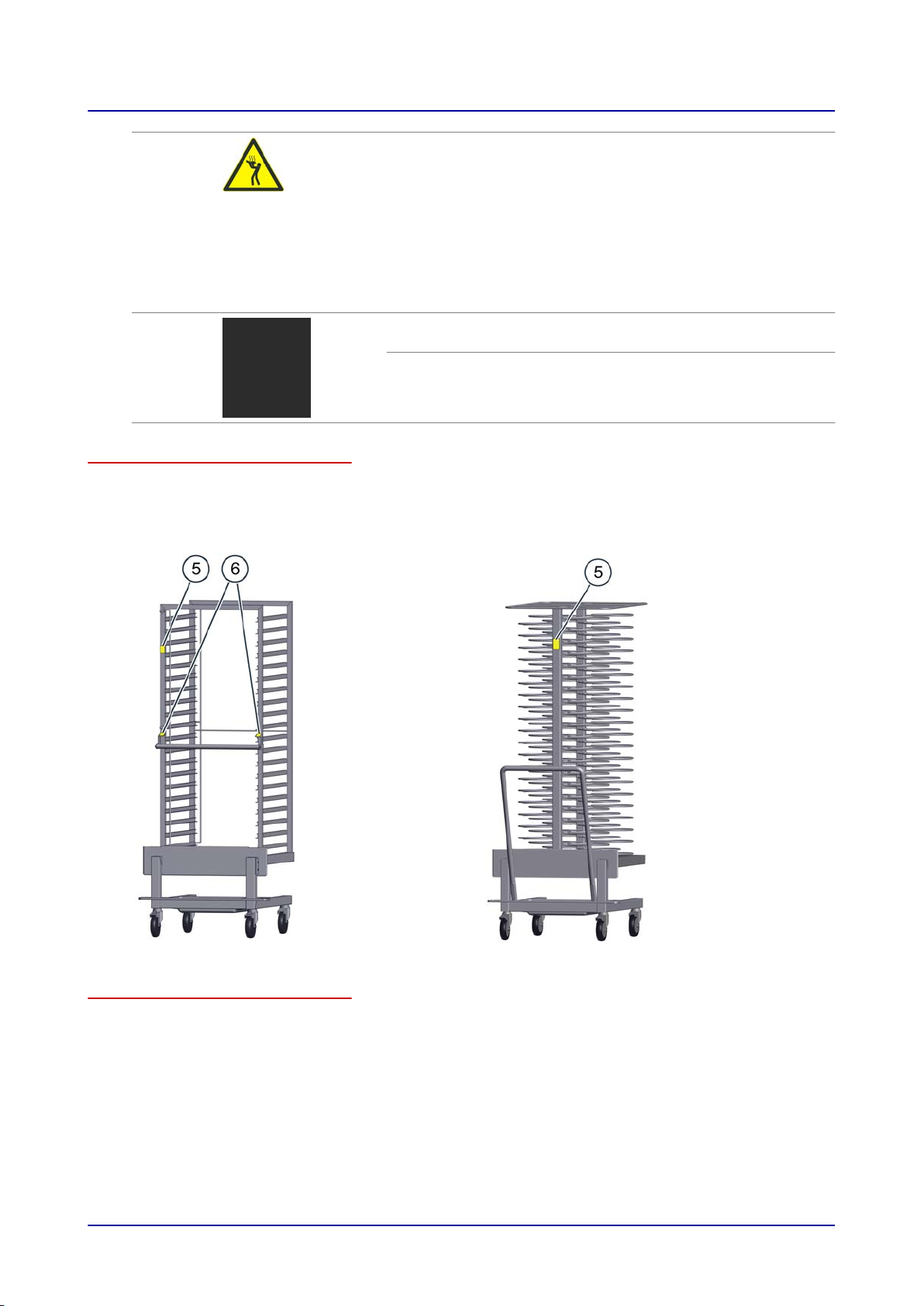

Warning label locations on the loading trolley

The figure below shows a loading trolley and a plate loading trolley for a size 20.20 combi steamer

used as examples representing all unit sizes:

Loading trolley Plate loading trolley (optional)

Hot food, hot bakeware, and hot liquid warning

Hot food and hot bakeware can pose a burn hazard if bakeware

topples over and out of the shelf levels or if food slides off from

bakeware being held in an inclined position. The risk of this oc‐

curring is particularly high in the case of shelf levels located

above the operator's field of view.

Risk of scalding when liquid food is spilled. This hazard exists

when liquids, or food that becomes liquefied during cooking,

are placed on the upper shelf levels. Do not use shelf levels lo‐

cated above your field of view to hold liquids or food that will

become liquefied.

CAUTION

Door(s) and handle(s) may be hot.

ATTENTION

Porte(s) et poignée(s) chaudes

Required warning labels on the loading trolley

The following warning labels must always be clearly visible on the loading trolley and (if applicable) on

the plate loading trolley at the locations shown in the previous figures.

Installation Manual 29

3 For Your Safety

Location Warning label Description

5

5

6

Security

models on‐

ly

Hot food, hot bakeware, and hot liquid warning

Hot food and hot bakeware can pose a burn hazard if bakeware top‐

ples over and out of the shelf levels or if food slides off from bakeware

being held in an inclined position. The risk of this occurring is particu‐

larly high in the case of shelf levels located above the operator's field

of view.

Risk of scalding when liquid food is spilled. This hazard exists when

liquids, or food that becomes liquefied during cooking, are placed on

the upper shelf levels. Do not use shelf levels located above your field

of view to hold liquids or food that will become liquefied.

Loading trolley and plate loading trolley tip-over hazard warning

There is a risk of the loading trolley or plate loading trolley toppling

over when being moved. Exercise extreme caution when moving the

loading trolley or plate loading trolley. When moving the loading trolley

or plate loading trolley, look out for obstacles and uneven surfaces.

Hot surface warning

Hot surfaces on the loading trolley's handle pose a burn hazard.

Installation Manual 30

Loading...

Loading...