Page 1

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

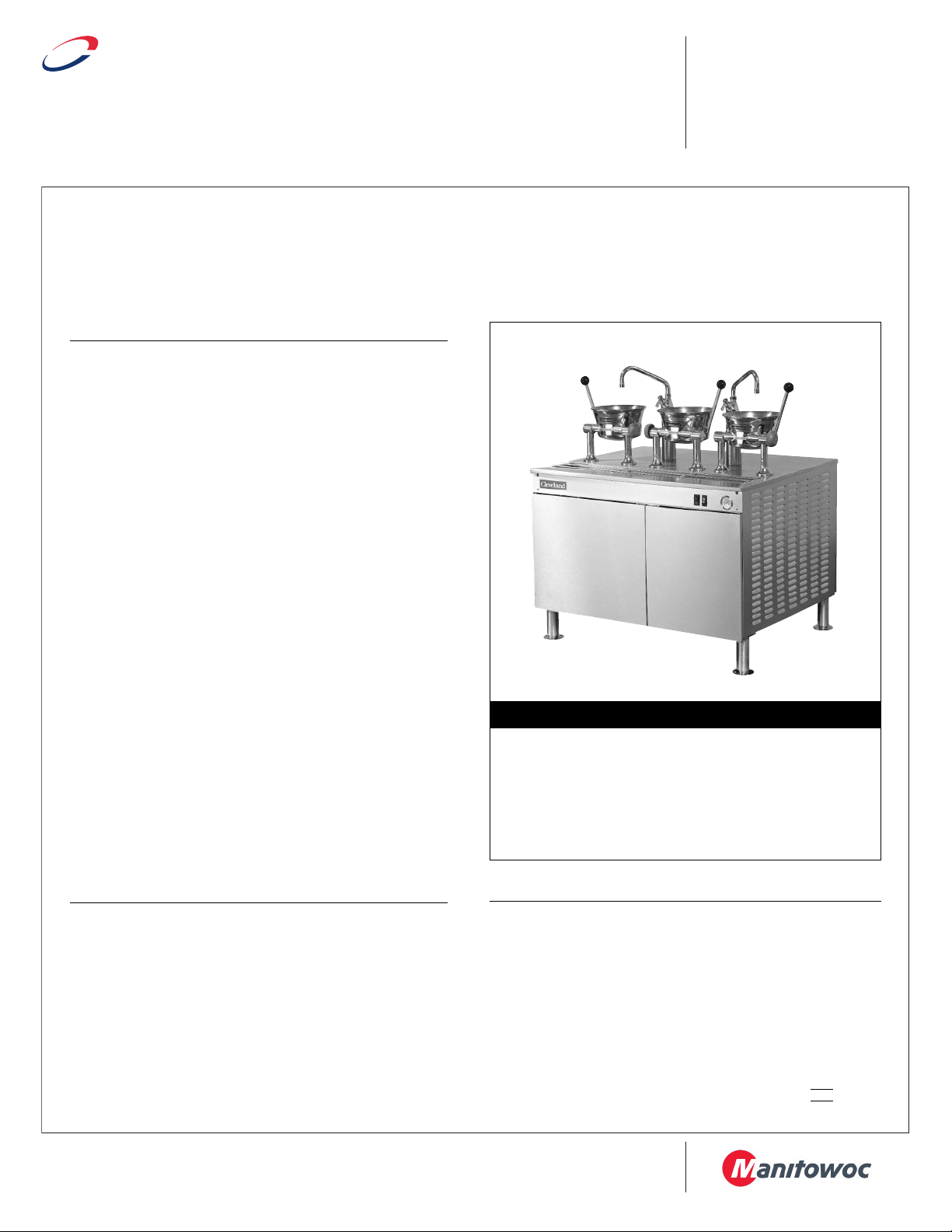

MODULAR BASES

2-3 OYSTER KETTLES

ELECTRIC STEAM GENERATOR 24KW

36" (900MM) or 42" (1050MM)

CABINET BASE

Cleveland Standard Features

II

24 KW Electric Steam Generator base with full width Drain

rough, Grate and a 11⁄2" drain.

T

II

Easy-Access Swing-Type Hinged Doors.

II

Automatic Generator Fill at start-up.

II

Automatic Generator Drain upon shutdown.

II

10 PSI operating pressure control.

II

Serviceable from the front.

II

80 oz. tilting Oyster Kettles with Lift-Off Covers.

II

50 PSI Steam Jacket Rating for kettles.

I

I

Factory installed Steam Control Kit

II

Mirror Finish on kettles

II

Cold Water Faucet with Swing Spout.

II

Cabinet Base Console includes a Pressure Gauge, Two

Rocker Type Power Switches: one, red color light for water

fill to generator; one, amber color light for power supply to

generator.

II

Solid State Water Level Control that includes a Low Water

Safety Shut-Off.

II

Generator Drain Cycle includes water cooling "Jet Rinsing"

drain cleaning feature.

II

Steam Generator includes a large Access Cover and Sight

Glass Gauge as required by ASME codes.

II

Secondary Low Water Cut-Off, factory installed (CAL-E)

Required for AZ, CA, CO, CT, FL, GA, IL, IA, MA, MN, NE,

NV, RI, SD, TN, WA, Houston, TX.)

II

NSF Approved 6" Stainless Steel Adjustable Legs: provides

one inch level adjustment.

II

Available in most voltages – 1 or 3 phase.

MODELS: 36-EM-K11-24

42-EM-K111-24

Short Form Specifications

Shall be CLEVELAND, Oyster Bar, Model

_____

volts,

_____

Hz,

_____

phase,

with drain trough, splashguard and cold water faucet(s). To

include, factory mounted, 80 oz. tilting oyster kettles with steam

control kit and lift-off covers. Electric steam generator with solid

state water level controls, pressure limit controls, sight glass and

15 psi safety valve. Automatic steam generator (boiler) blow-down

and refill on start-up.

_____

_____

- EM-K

KW, steam generator base

_____

- 24;

Applications

II

Quick, single-serving items for display cooking.

II

Pasta with sauces and other ingredients.

II

Classic Asian stir-fry.

II

Noodles featuring Asian, American or Italian styles.

II

Seafood items featuring oysters, shrimp and scampies.

II

Omelets and scrambled eggs.

II

Vegetable sautés.

Options & Accessories

Ë Voltages other than standard.

115 – 480/60/3 (VOS-2)

220 – 380/50/3 (VOS-3)

240 – 415/50/3 (VOS-4)

500 – 600/60/3 (VOS-5)

Ë 36 or 48 KW Generator Power Options.

Ë Type 316 Stainless Steel Liner, 6 gallon kettle (each, 316G).

Ë Stainless Steel Frame (FSS).

Ë Mineral Purge Cycle (MPC).

SECT. VII PAGE 37

0609

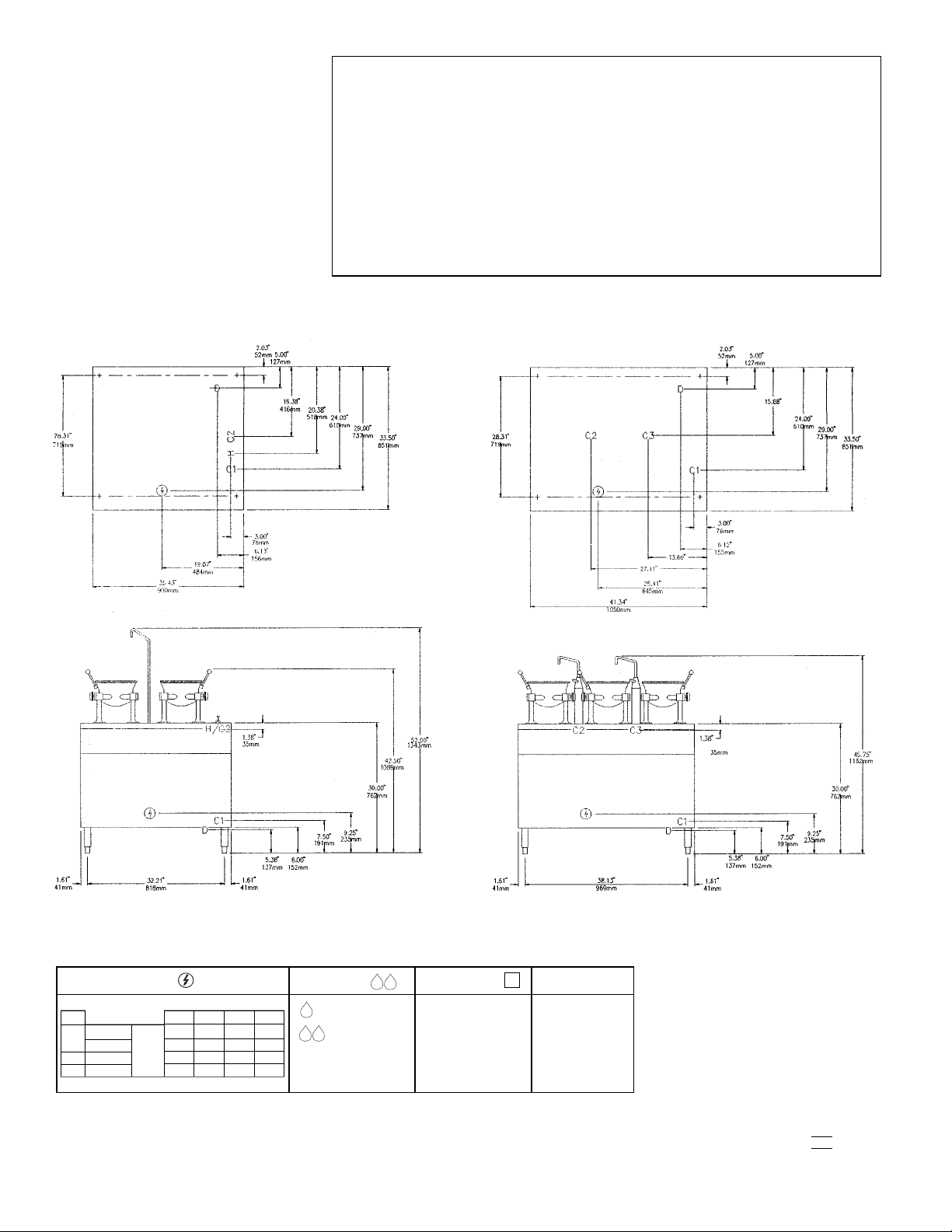

Page 2

C

HCC

H

WATER QUALITY REQUIREMENT

The recommended minimum water quality standards whether untreated or pre-treated,

based upon 10 hours of use per day, and a Daily Blowdown, are as follows:

TOTAL DISSOLVED SOLIDS less than 60 parts per million

TOTAL ALKALINITY less than 20 parts per million

SILICA less than 13 parts per million

pH FACTOR greater than 7.5

CHLORINE less than 30 parts per million

Consult a local water treatment specialist for an on site water analysis for recommendations

concerning steam generator feed water treatment (if required), in order to remove or

reduce harmful concentrations of minerals. The use of highly mineralized water will mean

that more frequent servicing of the steam generator will be necessary. The fact that a water

upply is potable is not proof that it will be suitable for the generator.

s

ELECTRIC WATER

1

KW 280V 220V 240V 480V

3 PHASE 57 63 52 26

24

36 3 PHASE 100 80 87 44

48 3 PHASE 119 127 107 53

NOTES:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Cleveland Range equipment is built to comply with applicable standards for manufacturers. Included among those approval agencies are ASME/N. Bd, UL, CSA and NSF.

AMPS

1 PHASE 99 N/A 89 45

PER

LINE

⁄4" NPT cold water inlet

3

⁄8" NPT hot and

cold water for kettles

35 psi minimum

60 psi maximum

DRAINAGE

1

1

⁄2" IPS common drain

The Floor Drain must be

located outside the

confines of the

equipment base.

Do not connect any

other units to this drain.

D

CLEARANCE

RIGHT = 4.00"

LEFT = 0.00"

REAR = 0.00"

Allow 6.00" minimum

from rear and sides

when located near

combustible walls.

(NOT TO SCALE)

SECT. VII PAGE 38

0609

Litho in U.S.A.

Loading...

Loading...