Page 1

Cleveland Range

36CSM16

REPAIR

MANUAL

Model No. 36CEM1648

36CGM16300

36CDM16

Cleveland Range, Inc.

UNITED STATES

1333 East 179th St.

Cleveland, Ohio 44110

Phone: (216) 481-4900 • Telex: 98-0546 • FAX: (216) 481-3782

CANADA

Garland Commercial Ranges • 1177 Kamato Rd.

Mississauga, Ontario CN L4W 1X4

Phone: (416) 624-0260 • FAX: (416) 624-0623

FSC-04

Page 2

Installation, Use and Care Instructions

INSTALLATION

Convection Pro XVI

INSTALLATION SAFETY

WARNING

Installation of this equipment must be accomplished by

qualified installation personnel, working to all applicable local

and national codes. Improper installation of this product could

cause injury or damage.

DO NOT store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

The flooring that will be directly under the boiler must also be

made of a noncombustible material.

Cleveland Range equipment is designed and built to comply

with applicable standards for manufacturers. Included among

those certification agencies which have approved the safely of

the equipment design and construction are: UL, A.G.A., NSF,

ASME, CSA, CGA, and others.

Cleveland Range equipment is designed and certified for safe

operation only when permanently installed in accordance with

local and/or national codes. Many local codes exist and it is the

responsibility of the owner and installer to comply with these

codes.

In no event shall Cleveland Range assume any liability for

consequential damage or injury resulting from installations

which are not in strict compliance with our installation instructions. Specifically, Cleveland Range will not assume any

liability for damage or injury resulting from improper instal lation of equipment, including, but not limited to, temporary or

mobile installations.

INSTALLATION INSTRUCTIONS

1. These instructions must be retained by the owner/user for

future reference. Gas-fired boilers are only to be installed in

noncombustible areas that have provisions for adequate air

supply. The term "boiler" will be used synonymously with

"steam generator".

2. Position: For proper operation and drainage, the equipment

must be level. It should be placed next to an open floor drain.

DO NOT POSITION THE UNIT DIRECTLY ABOVE THE

FLOOR DRAIN. Observe all clear ance requirements to

provide air supply for proper operation, as well as sufficient

clearance for servicing. The surrounding area must be free

and clear of combustibles. Dimensions and clearance

specifications are shown on the specification sheet.

3. Install in accordance with local codes and/or the National

Electric Code ANSI/NFPA No. 70-1987. Installation in

Canada must be in accordance with the Canadian Electrical

Code CSA Standard C22.1. Equipment that is con-

nected to electricity must be grounded by the installer. A wiring

diagram is provided inside the base cabinet.

WARNING

INJURY TO PERSONNEL AND EQUIPMENT DAMAGE may

result from an improper drain connection.

4. The drain line outlet discharges exhaust steam and hot

condensate. Connect 1-1/2-inch IPS piping (or larger) 10

extend the drain line to a nearby open floor drain. Up 10 two

elbows and six feet of 1-172-inch IPS (or larger) extension

pipe should be connected to the drain termination. Drain

piping extended six to twelve feet, or using three elbows,

should be increased to 2-inch IPS No more than two pieces of

Cleveland Range equipment should be connected to one

common drain line. The maximum length of extension from

the drain termination should not exceed six feet and use no

more than TWO elbows - The extension piping must have a

gravity flow and vent freely to the air. This drain outlet must be

free-vented to avoid the creation of back pressure in the

steamer cooking compartments. To ensure a vented drain

line, DO NOT, UNDER ANY CIRCUMSTANCES, CONNECT

THE DRAIN OUT LET DIRECTLY TO THE FLOOR DRAIN

OR SEWER LINE. Do not run the drain line discharge into

PVC drain piping or any other drain piping material not

capable of sustaining 180°F operation-

NOTE: Direct-steam connected pressure steamers do not require

a cold water connection, and therefore steps 5 and 6 do

not apply. Refer directly to step 7. A kettle fill faucet, if

so equipped, requires a hot and/or cold water

connection The data contained in step 5 for

cold water also applies to hot water.

5. Connect COLD water supply plumbing to the line strainer.

(Never connect hot water to the boiler water fill line strainer.)

Constant flow pressure must be maintained between 35 and

60 psi, and not experience a pressure drop below 35 psi when

other appliances are used. If the water pressure exceeds 60

psi, a pressure reducing valve must be installed in the water

supply plumbing to reduce the water pressure to less than 60

psi- Locations and pressure data are shown on the

specification sheet. 1/4 -inch IPS plumbing is sufficient for

water supply lines up to 20 feet in length, but water supply

lines longer than 20 feet should beat least 3/8 -inch IPS. Flush

water supply lines thoroughly before connecting them to the

unit. Use water which is low in total dissolved solids content

and low in gas content to prevent internal scaling, pitting and

corrosion of the steam generator, and carry-over of minerals

into the steam. Water which is fit to drink can still contain

highly detrimental impurities.

NOTE: If equipped with a kettle and kettle water fill swing

spout, 3/8 -inch (10mm) hot and/or cold water connections) will be required at the swing spout valve.

6. Turn on the cold water supply to the unit. Ensure that the

manual water valve, inside the base cabinet, is open.

Printed 6/90 Cleveland Range, Inc.

Page 3

Installation, Use and Care Instructions

Convection Pro XVI

Connect the primary fuel supply in accordance with the

following instructions. Location and other data are shown on

the specification sheet.

For Gas-Fired Steam Generators: Post in a prominent

location, instructions to be followed in the event the user

smells gas. This information shall be obtained by consulting

the local gas supplier. Install a sediment trap (drip leg) in the

gas supply line, then connect gas supply piping to the boiler

gas val ve piping. GAS-FIRED EQUIPMENT IS

DESIGNED FOR INSTALLATION ONLY IN NONCOMBUSTIBLE LOCATIONS. THIS INCLUDES THE

FLOORING THAT WILL BE DIRECTLY UNDER THE

EQUIPMENT. Location, plumbing size, and pressure data

are shown on the specification sheet. Boilers rated at less that

225,000 BTU require 3/4 -inch IPS gas supply piping, and

boilers rated at 225,000 BTU or more require 1-inch IPS gas

supply piping. Natural gas pressure must be between 4" -14"

water column, and L.P. gas supply pressure must be between

12" - 14" water column. NEVER EXCEED 14" WATER

COLUMN (1/2 psi) GAS PRESSURE. If the gas supply

pressure exceeds 14" water column, a pressure regulating

valve must be installed in the gas supply plumbing to reduce

the gas pressure 10 less that 14" water column. Installation

must be in accordance with local codes, or in the absence of

local codes, with the National Fuel Gas Code, ANSI 7.773.1-

1984. Installation in Canada must be in accordance with

Installation codes for Gas Burning Appliances and Equipment B149.1 and B149.2 Use a gas pipe joint compound

which is resistant to LP gas. Turn the gas valve control knob

to ON (the word "on" on the knob will be opposite the index

on the valve's body). Test all pipe joints for leaks with soap

and water solution. Never obstruct the flow of combustion

and ventilation air. Observe all clearance requirements to

provide adequate air openings into the combustion chamber.

The appliance and its individual shut-off valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

14" water column (1/2 psi or 3.45 kPa). The appliance must

be isolated from the gas supply piping system at test

pressures equal to or less than 14" water column (1/2 psi or

3.45 kPa). A permanent 115 volt electrical connection is

required at the junction box. The junction box location is

shown on the specification sheet. The unit must be

electrically grounded by the installer.

For Electric-Powered Steam Generators: Connect electric

power: location and data are shown on the specification

sheet. Provide connection as required by the unit; either

directly to the single contactor, or to the terminal block

(when equipped with multiple contactors). Electric supply

must match power requirements specified on the data plate

inside the base cabinet. The copper wiring must be adequate

to carry the required current at the rated voltage. A separate

fused disconnect switch must be supplied and installed. The

unit must be electrically grounded by the installer.

For Steam Coil Steam Generators: Conned steam supply

piping to the input side of the steam coil Location and pressure

data are shown on the specification sheet. Incoming steam

pressure must be regulated between 35 and 45 psi. A 3/4 -inch

strainer, equipped with a 20 mesh stainless steel screen, must

be supplied and installed at the incoming steam connection

point. Flush the steam line thoroughly before connecting it to

the boiler. To ensure an adequate volume of steam, the branch

steam supply line must be 3/4 -inch IPS minimum. Connect the

inverted bucket trap to the outlet end of the steam coil. Fill the

trap with water before installing it. A permanent 115 volt

electrical connection is required at the junction box. The

junction box location is shown on the specification sheet. The

unit must be electrically grounded by the installer.

For Direct -Steam Connected Steamers/Kettles: Connect

steam supply piping to the input side of the line strainer.

Location and pressure data are shown on the specification

sheet. Flush the steam line thoroughly before connecting it to

the steamer. To ensure an adequate volume of steam, the

branch steam supply line must be 3/4 -inch IPS minimum.

(Direct-steam-connected kettles require 1/2 -inch IPS pipe if

the kettle total capacity is 20 gallons or less, and 3/4 -inch IPS

pipe if the total capacity exceeds 20 gallons.) A permanent

115 volt electrical connection is required at the junction box.

The junction box location is shown on the specification sheet.

The unit must be electrically grounded by the installer.

Installation Checks

Proper operation of the Cleveland Convection Pro XVI steamer is

dependent upon proper installation. After the steamer has been

installed, a few quick checks could save unnecessary service

calls.

1. The unit must be level

2. The Convection Pro XVI steamer requires a cold water

connection for proper, efficient operation. DO NOT USE HOT

WATER. The cold water must be connected to the line strainer,

located at the front lower -right of the steamer base.

3. Check that the manual water supply valve is open.

4. Check all water supply lines and valves for leaks.

5. Check that the water supply pressure and water quality

meet the requirements of installation paragraph 5.

6. On electric units, verify that the supply voltage meets the

voltage requirements on the rating plate inside the base

cabinet, and the voltage shown on the packing slip. Verify

that the unit is protected with a separate fused disconnect, and

is properly grounded in accordance with the National Electric

Code.

7. On gas, steam coil, and direct-steam-connected units, verify

that there is a 115 Volt connection at the handi -box located on

the left side of the base at the bottom front.

Cleveland Range, Inc. Printed 6/90

Page 4

Installation, Use and Care Instructions

Convection Pro XVI

8. On steam coil units, the incoming steam pressure must be 35 to 50 psi

Less than 35 psi will not effectively operate the unit. Pressure in

excess of 50 psi must be reduced (with a pressure reducing valve) to

35 to 50 psi

WARNING

INJURY TO PERSONNEL AND EQUIPMENT DAMAGE may

result from an improper drain connection.

9. Check that the drain lines meet the installation requirements

specified in installation paragraph 4.

lO. After completing checks 1 through 9, and correcting any

deficiencies, refer to the Start-up and Preheat instructions in

the Operation section. Verify that the unit operates property,

and make checks 11 and 12.

11. Check to ensure that the water in the boiler sight gage glass

automatically stays about 1/3 full when the boiler is started

up and operated.

12. Check 10 ensure that the steam pressure gage registers 10

psi.

The steam pressure is factory-adjusted 10 provide the proper

pressure. In some cases, however, the factory setting may

shift due to shaking in transit, and resetting will be required

after installation. Proper adjustments and maintenance

procedures are detailed on separate data sheet entitled

"Steam Pressure Adjustments." Adjust ments should be made

only by qualified service personnel. The factory pressure

settings shown in the accompanying chart should never be

exceeded.

Gage Pressure Reading with No Steam Flow*

(Static Pressure)

Self-Contained Steam Generator, Gas or Electric

Operating Pressure Switch 10 psi

High Limi t Safety Pressure Switch 15

psi

Setf-Contained Steam Coil Generator

Operating Pressure Switch 10 psi

High Limit Safety Pressure Switch 15 psi

Steam Supply Pressure Range 35-45

psi

OPERATION

Operation of the Cleveland Range Convection Pro XVI steamer is very

easy. Each operator should read and understand the following

procedures to effectively start, operate, and shut down the steamer each

day. The owner(s) and operator(s) of this equipment should be aware

that live steam can cause serious injuries, and pay particular attention to

the WARNINGS in this text. These instructions are to be retained by

the owner(s) and operator(s) for future reference.

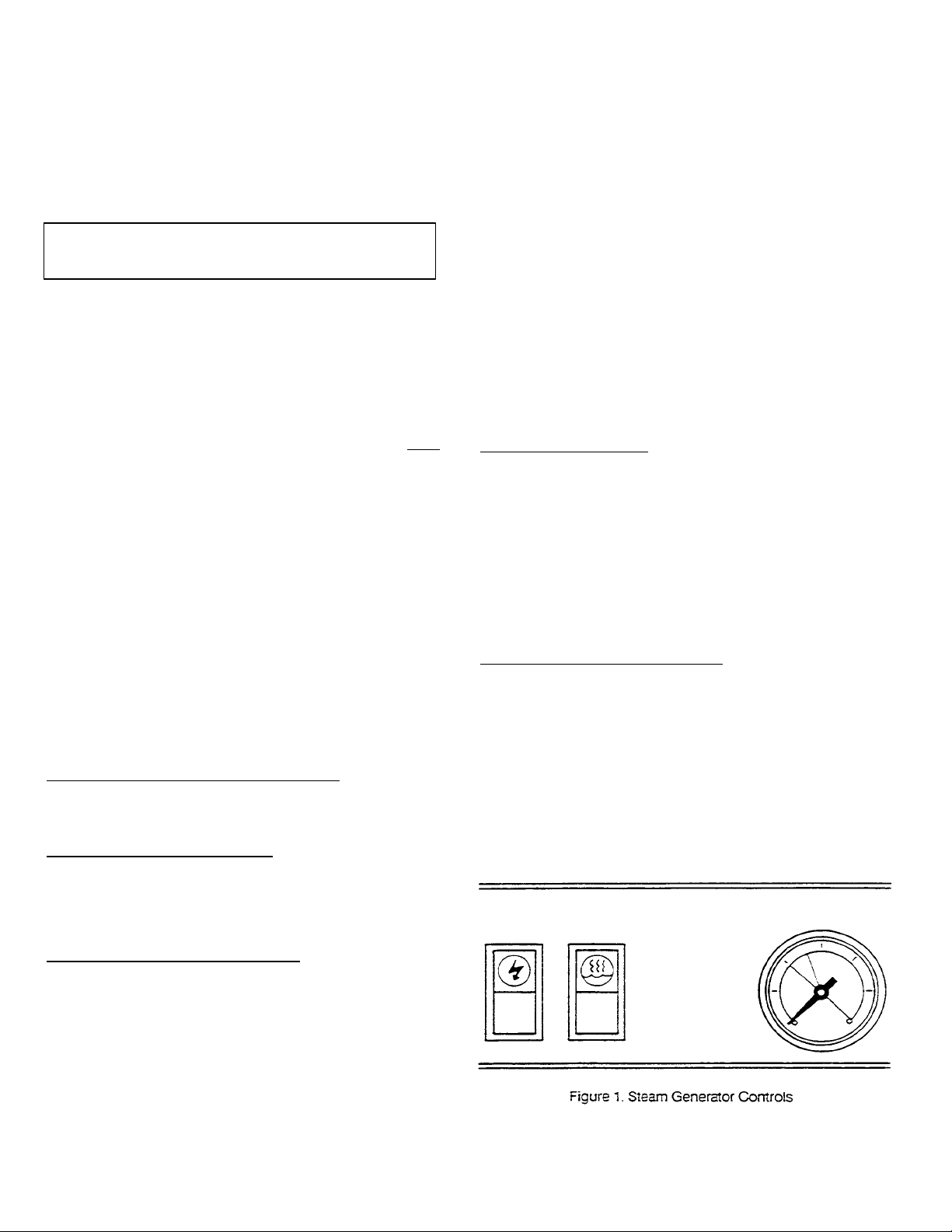

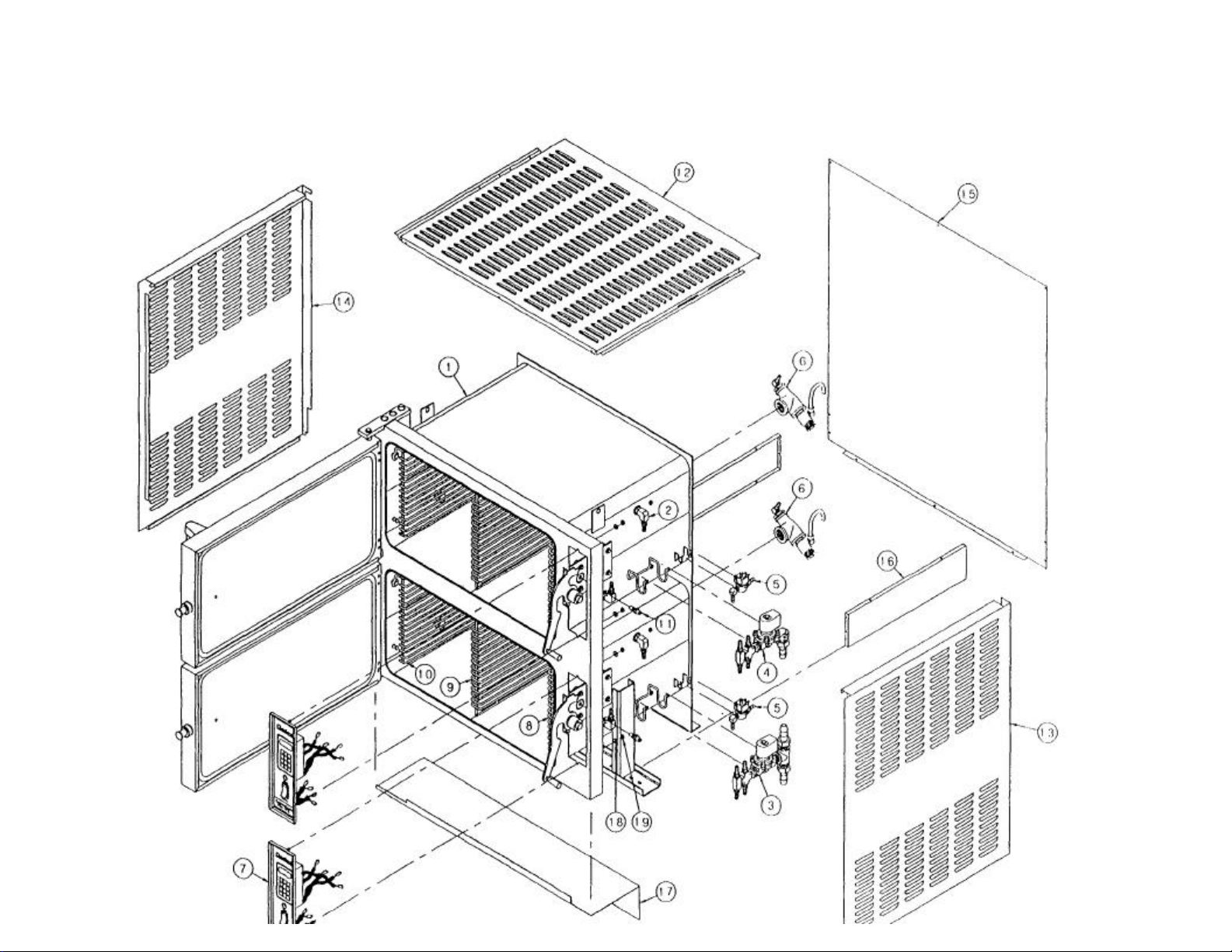

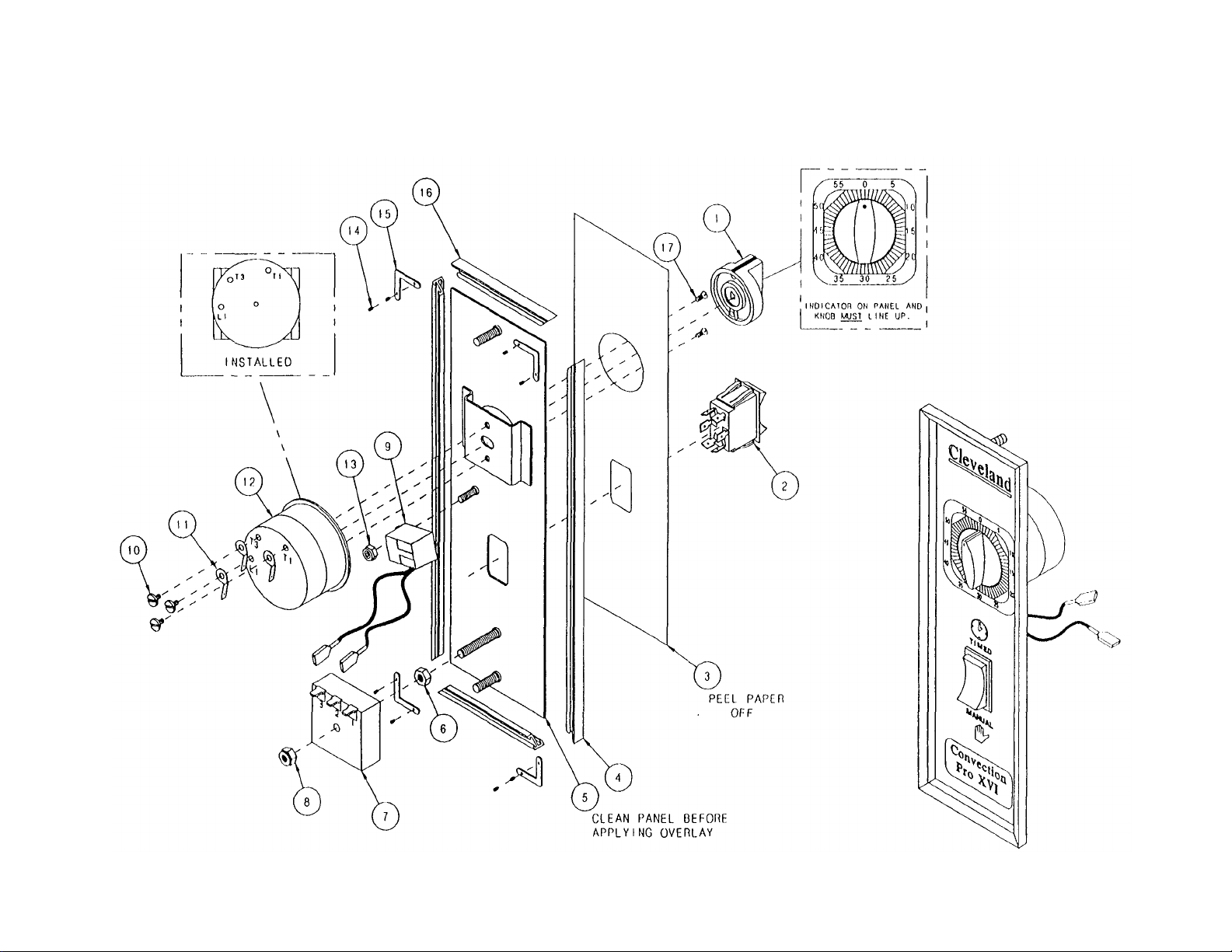

Controls and Control Panels

There are two steam generator control arrangements and two

steamer compartment control panels available for Cleveland

Range Convection Pro XVI steamers. The steam generator

controls are illustrated in Figure 1. The steamer compartment

control panels are illustrated in Figures 2 and 3. Compare these

figures with the equipment supplied, and identify which control

and panel combinations apply.

Steam Generator Controls

The steam generator controls are located on the front face of the

steamer base unit. The switches are to the left of the pressure

gage, as illustrated in Figure 1. Most Cleveland Range

Convection Pro XVI steamers have a steam generator built into

the base unit which supplies steam to the cooking compartments.

However, an external steam supply may also be used. Units with

a built-in boiler have both the POWER rocker switch and the

STEAM momentary switch next 10 the pressure gage. Units with

an external steam supply have the POWER rocker switch only.

They do not have the STEAM momentary switch.

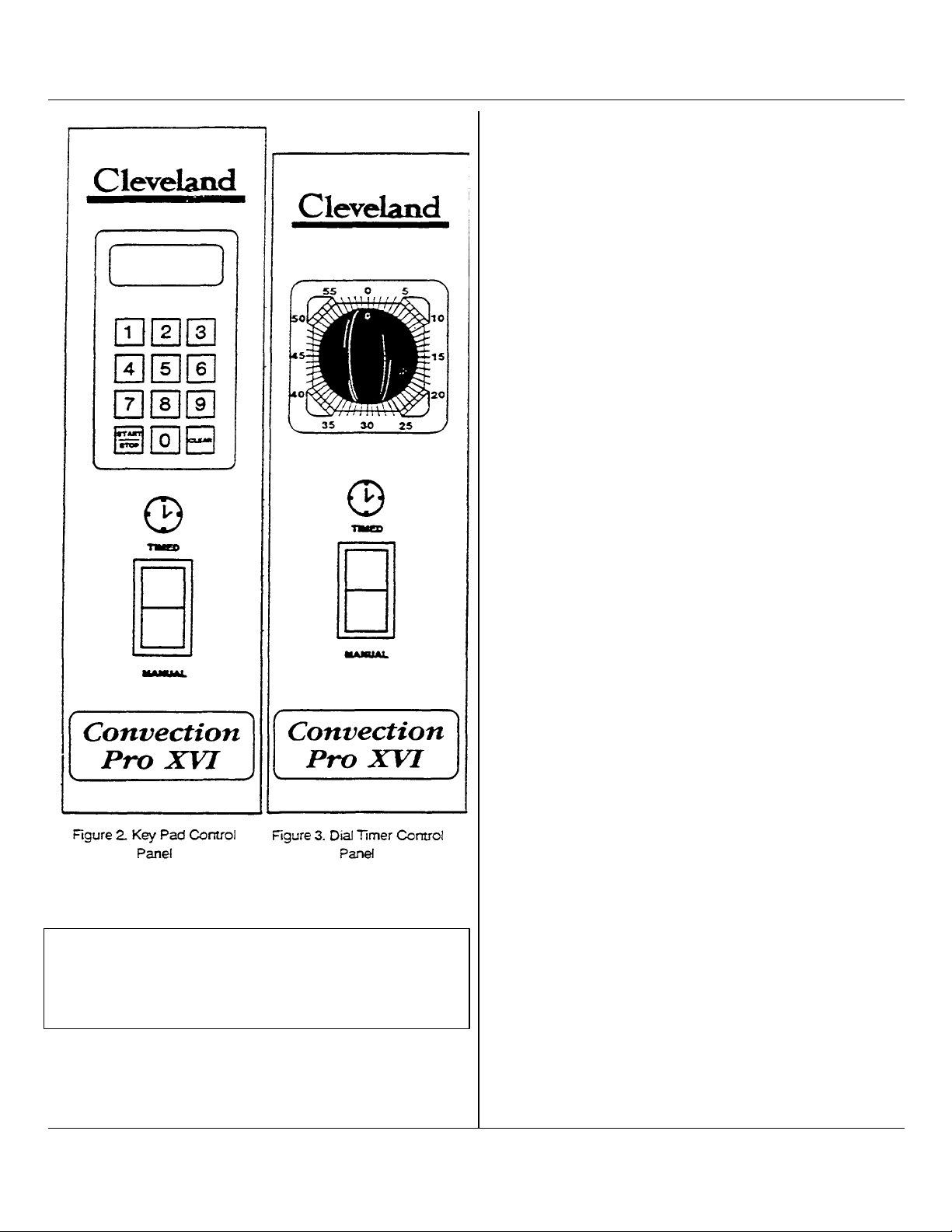

Steamer Compartment Control Panels

Figure 2 illustrates the standard electronic controls: the Key Pad

Control Panel. This panel has a rocker switch, a key pad, and a

digital timer. Figure 3 illustrates the optional electromechanical

controls: the Dial Timer Control Panel. This panel has a rocker

switch and dial timer. Steamer functions are the same for both

the standard and optional panel configurations. Operating details

are slightly different especially when setting the automatic

operating time. For clarity, two sets of instructions are provided

for cooking operations.

Direct-Connect (to House Steam Supply)

Steamer Pressure Reducing Valve 10 psi

Steam Supply Pressure Range 15-45 psi

*with or without kettle

Printed 6/90

Cleveland Range, Inc.

Page 5

Installation, Use and Care Instructions

Convection Pro XVI

2. Start the steam supply. The steam supply is either an integral

steam generator (boiler) built into the base unit, an external

steam supply.

• For units without a built -in boiler, refer to the start-up

procedures for the external steam supply and be sure it is

running properly - As soon as the pressure gage on the

Convection Pro XVI Steamer registers 10 psi, steamer

preheating may begin. Skip the remainder of step 2, and

begin step 3, preheat instructions.

• For units with a built -in boiler, fill the boiler with water and

start the steam generator as described in steps a.through

d. below.

a. Press the ON end of the POWER on-off rocker switch

located next to the steam pressure gage (Figure 1). The

red indicator light in the POWER rocker switch turns on

and the steam generator begins to fill with water. This

takes about 5 minutes.

b. When the water level in the steam generator reaches a safe

operating level, the amber light in the STEAM momentary

switch turns on. Whenever the amber light is on, the

heaters, steam supply, or burners are off, and no steam is

being generated. The energy source (electric, gas, etc.)

cannot be activated until the boiler contains sufficient

water, indicated by the amber light.

c. Press the STEAM momentary switch to produce steam in

the boiler. This activates the energy source (electric

heaters, gas burners, or steam solenoid valve) and the

amber light turns off.

The STEAM switch must be pressed to re-start the steamer

after it is shut off for any reason (including a brief power

interruption.). No attempt should be made 10 operate the

equipment during a power failure.

Start-up and Preheat

WARNING

Do not attempt to start or operate the Convection Pro

XVI steamer during a power failure. Critical safety circuits are not energized, and serious injury to pers onnel

or damage to equipment may result.

1. Inspect the steamer. Check the cooking compartments 10

ensure that the steam tubes and drain screens are in place and

secure. Check inside the steamer base cabinet to ensure that

the manual drain valve is closed and the manual water supply

valve is open.

NOTE: For steamers with built -in gas-fired boilers:

3. Preheat the Convection Pro XVI steamer cooking com-

a. Close the compartment door by gently swinging it shut.

If the burners fail to ignite in four seconds, a safety

circuit de-energizes the system. In this event, toggle the

POWER rocker switch to the OFF position and back to

the ON position. The amber light in the STEAM

momentary switch lights. Wait five minutes, then press

the STEAM momentary switch to start the burner ignition

cycle once again.

d. About 20 minutes after starting the boiler in step c, the

steam pressure gage on the unit base should register 10

PSI.

partments. For accurate, efficient cooking times, the cooking

compartments should be preheated during startup.

b. Refer to timer setting instructions under Automatic Operation

for the appropriate control panel. Set the timer for each

compartment 10 one minute, and start the cooking cycles.

Steaming begins in each compartment.

Cleveland Range, Inc. Printed 6/90

Page 6

Installation, Use and Care Instructions

Convection Pro XVI

NOTE: On Convection Pro XVI steamers equipped with the electronic

key pad control panels, the timer does not begin counting

down until the cooking compartment reaches operating

temperature. This may take 2 or 3 minutes if the steamer has

not been operating-

c. Steaming continues for the set one minute. When the preheating

is completed, the steam automatically shuts off and a 3-second

alarm sounds. The Convection Pro XVI steamer is ready for

cooking operations.

COOKING OPERATIONS

The control panels mounted on the cooking compartments

regulate cooking operations. Although cooking operations are

similar for all Convection Pro Steamers, regardless of control

panel configuration, separate instructions are provided for each

control panel type.

Cooking Operations for The Key

Pad Control Panel

The electronic key pad control panel is illustrated in Figure

2.

The Cleveland Range Convection Pro XVI steamer has two

cooking modes: Manual and Automatic. The Manual Mode

provides continuous steaming and is turned on and off by the

MANUAL/TIMED rocker switch- The Automatic Mode

monitors cooking time and compartment temperature to provide

accurate, efficient, uniform steam cooking.

NOTE: Whether using timed or manual cooking modes,

optimum steam heat transfer, and therefore a higher

quality food product, is achieved when shallow, per forated, uncovered pans are used.

WARNING

LIVE STEAM may cause severe bums. Use extreme caution

when opening the steamer door. Turn face away from the

steamer when first opening the door. Do not look into the

cooking compartment until steam has cleared. KEEP HANDS

OUT OF THE COOKING COMPARTMENT TO PREVENT

BURNS.

Manual Cooking Operation - Key Pad Controls

Use manual mode for a continuous supply of steam for long

periods, or if the required cooking time is unknown and

frequent inspection is required.

1. Place the pan(s) of food into the cooking companment-

2. To START the flow of steam, press the MANUAL end of the

MANUAL/TIMED rocker switch, located below the timer.

Steam immediately starts flowing into the cooking

compartment

3. If food inspection is required during steaming, refer to the

LIVE STEAM WARNING above. Use extreme caution

when opening the steamer door during steaming operations.

4. Although the timer can not rum the steam off in manual

mode, it can be used as a conventional cooking timer. Refer

to the timer setting instructions under Automatic Operation

and set the timer. The timer will count down the set period

and sound the buzzer, but IT WILL NOT TURN OFF THE

STEAM AFTER THE ALARM SOUNDS.

5. To STOP the flow of steam, press the TIMED end of the

MANUAL/TIMED rocker switch. Steam stops flowing into

the cooking compartment.

Automatic Cooking Operation - Key Pad Controls

Each Convection Pro XVI steamer cooking compartment is

equipped with an independent electronic digital timer, which has

a maximum setting of 99 minutes and 99 seconds. Each timer is

connected to a temperature sensing device in the cooking

compartment. THE SENSOR CIRCUIT ALLOWS THE TIMER

TO COUNT DOWN ONLY WHEN THE COOKING

COMPARTMENT IS AT THE PROPER COOKING

TEMPERATURE. This assures uniformity in the cooking times

as the timer automatically compensates for food product

defrosting and/or heat-up time.

1. Place the pan(s) of food into the cooking compartment

2. Clear and reset the timer. The timer can be set only when the

COOKING TIME display is clear. Press the CLEAR key on

the number pad to zero the timer.

3. Set the desired cooking time. The cooking time display

contains four digits. The left two digits are minutes, and the

right two digits are seconds. The display 1134 is set for 12

minutes and 34 seconds.

a. To set the cooking time, change the required cooking time

to minutes and seconds, press the number keys for the

minutes, and then press the number keys for the seconds.

If the cooking time is 99 seconds or less, only press the

number keys for seconds.

b. Example 1. To set the timer for 1 hour and 15 minutes:

Change 1 hour (60 min) and 15 minutes to 75 minutes.

Press the following number keys in sequence: 7500-The

display will read 75:00 when properly set for 1 hour and

15 minutes.

c. Example 2 To clear the time numbers set in example 1,

press the CLEAR key on the number pad The display

returns to 00:00.

d. Example 3. To set the timer for 1.5 minutes: Change the

time to 1 minute and 30 second Press the following

number keys in sequence: 130. The display will read

01:30, when set for 1.5 minutes.

All seconds method: Change the 1.5 minutes to 90

seconds and press 90. The display will read 00:90, when

set for 1.5 minutes.

4. Press the START/STOP key to start the timer. When the

START/STOP key is pressed. Steam enters the cooking

compartment

Printed 6/90 Cleveland Range, Inc.

Page 7

Installation, Use and Care Instructions

Convection Pro XVI

a. THE TIMER WILL BEGIN TO COUNT DOWN ONLY

AFTER THE COOKING COMPARTMENT

REACHES PROPER COOKING TEMPERATURE.

The timer automatically delays to compensate for

defrosting and/or food product heat-up time.

b. For example, a timer setting of 10 minutes may in fact

take 11 or 12 minutes for the timer to count down and

the alarm to sound. This is normal. Heating the compartment and food to cooking temperature uses the

additional time.

c. To stop or reset the timer, press and hold the

START/STOP key. The cooking time display returns to

the last time setting.

• To restart the same time, press the START/STOP key.

• To set a new time press the CLEAR key, and set the

new time.

5. When the timer counts down to zero, an alarm sounds

continuously. Press the START/STOP key to silence the

alarm. The cooking time display returns to the last time

setting. Either run this same setting again or clear and reset

the timer.

6. Example 4. To cook two 14 minutes cycles: Press the

CLEAR key to clear the timer. Press the following number

keys in sequence: 1400. The display shows 14:00. Press

the START/STOP key to start the timer. When the display

counts down to zero, the alarm sounds. Press the

START/STOP key, and the display returns to 14:00. Press

the START/STOP key to start the second 14 minute cycle.

Cooking Operations for

The Dial Timer Control Panel

The dial timer control panel is illustrated in Figure 3.

The Cleveland Convection Pro XVI steamer has two cooking

modes: Manual and Automatic. The Manual Mode provides

continuous steaming and is turned on and off by the

MANUAL/TIMED rocker switch. The Automatic Mode monitors

cooking time to provide accurate, efficient, steam cooking.

NOTE: Whether using timed or manual cooking modes,

optimum steam heat transfer, and therefore a higher

quality food product, is achieved when shallow, perforated, uncovered pans are used.

WARNING

LIVE STEAM may cause severe bums. Use extreme

caution when opening the steamer door. Turn face

away from the steamer when first opening the door. Do

not look into the cooking compartment until steam has

cleared. KEEP HANDS OUT OF THE COOKING COMPARTMENT TO PREVENT BURNS.

Manual Cooking Operation - Dial Timer Controls

Use manual mode for a continuous supply of steam for Iong

periods, or if the required cooking time is unknown and frequent

inspection is required

1. Place the pan(s) of food into the cooking compartment

2. To START the flow of steam, press the MANUAL end of the

MANUAL/TIMED rocker switch, located below the timer.

Steam immediately starts flowing into the cooking

compartment

3. If food inspection is required during steaming, refer 10 the LIVE

STEAM WARNING above. Use extreme caution when

opening the steamer door during steaming opera-tions.

4. Although the timer cannot turn the steam off in manual mode, it

can be used as a conventional cooking timer. Refer 10 the

timer setting instructions under Automatic Operation and set

the timer. The timer will count down the set period and sound

the buzzer, but IT WILL NOT TURN OFF THE STEAM

AFTER THE ALARM SOUNDS.

5. To STOP the flow of steam, press the TIMED end of the

MANUAL/TIMED rocker switch. Steam stops flowing into the

cooking compartment.

Automatic Cooking Operation Dial

Timer Controls

Each Convection Pro XVI steamer cooking compartment is

equipped with an independent dial timer. This timer controls the

cooking compartment steaming cycle. Use automatic mode when

an exact cooking time is required. Steam cooking begins when

the timer is set, and automatically stops when the timer counts

down to zero.

1. Check that the MANUAL/TIMED rocker switch is in the

TIMED position. If it is not, press the TIMED end of the

MANUAL/TIMED rocker switch

2. Place the pan(s) of food into the cooking compartment

3. Set the desired cooking time. Turn the dial until it points to the

desired cooking time. When the dial timer is set, steam enters

the cooking compartment

4. When the timer counts down to zero, an alarm sounds for three

seconds, and steam flow into the cooking compartment stops.

Boiler Shutdown

The red-lighted power switch must be shut off for 3 minutes a

minimum of once every 8 hours 10 automatically drain highly

mineralized water from the boiler, which reduces the forma tion of

scale. See step 1 in CARE A ND CLEANING instructions, which

follow.

Cleveland Range. Inc. Printed 6/90

Page 8

Installation, Use and Care Instructions

Convection Pro XVI

CARE AND CLEANING

The Cleveland Convection Pro XVI steamer must be cleaned

regularly to maintain its fast, efficient cooking performance,

and to ensure its continued safe, reliable operation.

1- The boiler must be drained (blowdown) after a maximum of

8 hours of use. If the boiler feedwater contains more than 60

pans per million of total dissolved solids, the boiler must

have a blowdown more often, the frequency depending upon

the mineral content of the feedwater. Blowdown means the

boiler must be drained under pressure.

THE BOILER BLOWDOWN IS PERFORMED BY

SIMPLY SHUTTING OFF THE STEAMER'S REDLIGHTED POWER SWITCH WHILE THE BOILER IS AT

NORMAL 10 PSI OPERATING PRESSURE-WHEN THE

BOTTOM OF THE POWER ROCKER SWITCH IS

PRESSED, ITS RED LIGHT GOES OUT, AND THE

DRAIN VALVE AUTOMATICALLY OPENS,

DRAINING THE BOILER. AN AUTOMAT ICALLYTIMED DRAIN WATER CONDENSER WILL FLUSH

THE DRAIN FOR 3 MINUTES, THEN SHUT OFF.

AFTER 3 MINUTES THE STEAMER IS READY TO BE

RESTARTED.

When steam is produced, the water in the boiler is being

distilled. Daring this process, the minerals that come into the

boiler with the water, remain in the boiler as the water boils

away as steam. When allowed to accumulate, the water

becomes hi ghly mineralized, which results in erratic

operation, lime build-up, corrosion, and premature electric

heater failures. In some cases, complete boiler replacement

becomes necessary, which is extremely expensive. By

draining the boiler under pressure, most sediment present will

be flushed down the drain.

2. The steamer is equipped with a drain in the back of the

cooking compartment. No compartment should be operated

without the drain screen in place. This screen prevents large

food panicles from entering and possibly plugging the drain

line. Any restriction of the drain line may cause a slight

build-up of back pressure in the compartment, resulting in

steam leaks around the door gasket. It also may adversely

affect the convection action of the steam in the

compartment, which is critical to optimum performance.

Pouring USDA approved drain cleaner through the

compartment drains once a week will help to ensure an open

drain- A manual (hand crank) drain auger, or "snake", may

be safely used to clear obstructions in the compartment

drains. Do not use a power auger, as damage to the plastic

drain system will result. With the steamer off, open the

cooking compartment doors and allow the steamer to cool

before cleaning the cooking compartments and their

components

3. At the end of each day's operation, wash the pan slides, steam

tubes, door gaskets, and compartment interiors with mild

detergent and warm water, either by hand or in a

dishwasher. Rinse thoroughly with clear water. Rinse water

should drain freely through the compartment drain

openings. If it does not, the dram must be cleaned before

using the steamer.

4. Once a week, remove the steam tubes and clean the orifices.

First, remove the pan slides by lifting upward and toward the

center of the compartment. Pressing backward on the steam

tube will allow its front eyelet to clear the compartment stud.

The tube is then angled toward the center of the compartment

just enough to clear the stud and be pulled forward, out of its

socket- The orifices can be cleaned easily with a paper clip.

Then, thoroughly wash and rinse all steam tubes- This can be

done in a dishwasher. Lubricate each rube's tapered end with

cooking oil before replacing in the steamers compartments.

Be sure all four steam tubes are securely in place before

activating the compartment. The tubes are interchangeable

and may be placed in any spot in either compartment.

5. To prolong door gasket life, always leave compartment door

ajar when not in use.

6. Exterior Care: Allow steamer to cool before washing. Use the

same cleaners and cleaning procedures as for other kitchen

surfaces of stainless steel and aluminum Mild soapy water,

with a clear water rinse, is recommended- Do not allow water

to run into electrical controls. Always turn off equipment

power before using water 10 wash equipment. Do not hose

down the steamer.

WARNING

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

MAINTENANCE

Periodically, a qualified serviceman should be summoned for

routine preventive maintenance.

1. The blowdown procedure will not completely remove the

mineral deposits that adhere to the top of the boiler - A

chemical descaling should be done by a boiler treatment

specialist. This should be done once a year in average water

conditions, but in poor water areas it may be needed two or

three times a year.

2. Periodic boiler inspection should be made by a qualified

serviceman.

3- Once every three months, the cold water line strainer should

be cleaned.

Cleveland Range supports a comprehensive network of Maintenance and Repair Centers (regional pans and service distributors) throughout the United States and Canada. Please

contact your nearest distributor for the name of an authorized

service agency in your area, or for replacement pans and

information regarding the proper maintenance and repair of

Cleveland Range equipment. In order to maintain the various

agency safety certifications, only factory-supplied replacement

pans should be used. The use of other than factory-sup-plied

replacement pans will void the warranty.

Primed 6/90 Cleveland Range, Inc.

Page 9

Page 10

Cleveland Convection Pro

Item

Part Number

Description

11 19972

Thermal Switch

15 66721

Panel, Rear Cover, PCL

19 14665

Nut, Hex, Elastic Lock,

1/4-20

Cleveland

92/03/28

Parts List Below Is For Drawing On Previous Page

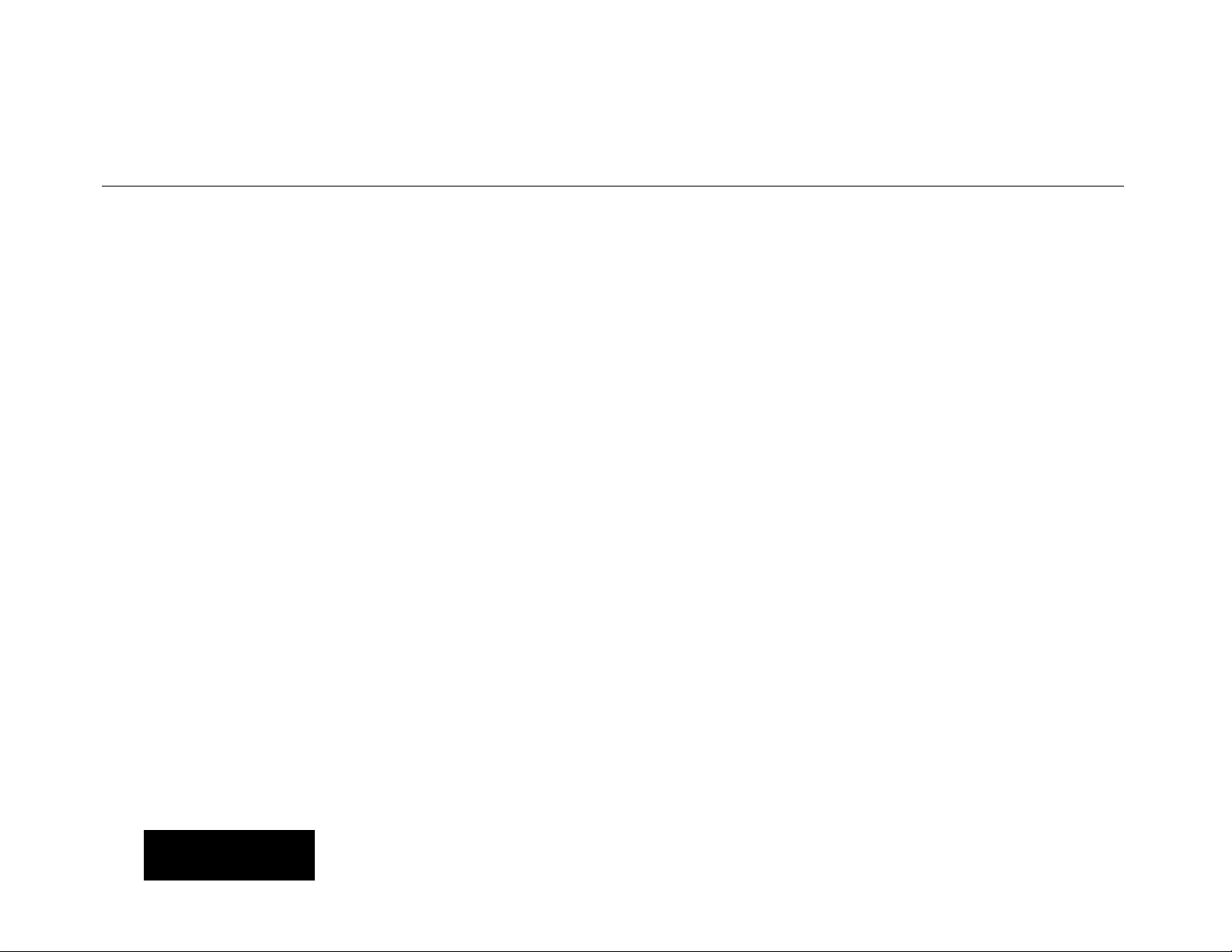

1 See Sheet 2 Upper Assembly, Intermediate, Convection Pro

2 106203 Spray Nozzle Assembly

3 See Sheet 7 Steam Inlet Assembly, Lower Compartment

4 See Sheet 7 Steam Inlet Assembly, Upper Compartment

5 104381 Fitting, Hose, 1/4 MPT x 1/4 H, Straight

22241 Valve, Solenoid, 1/4

105786 Fitting. Hose, 1/4 MPT x 1/4 H, 90°

6 See Sheet 8 Drain Assembly, Compartment, Back

7 See Sheet 5 Panel Assembly , Electronic

See Sheet 6 Panel Assembly, Mechanical

8 102420 Rack, Assembly, Right Side, PCL

9 102003 Rack, Assembly, Center Wire, PCL

10 102421 Rack, Assembly, Left Side, PCL

12 100697 Panel. Top, Weldment, PCL

13 100132 Panel, Right Side, Sheeting, PCL

14 100131 Panel, Left Side, Sheeting, PCL

16 101737 Panel, Pedestal, Side, Weldment

17 1044741 Pedestal Weldment

18 23116 Washer, Flat, 1/4 x 5/8 x .065

Steam Cooking Specialists

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 11

Page 12

Cleveland Convection Pro

Description

12 100004

Bar, Nut, Three 3/8

-

16 Holes

17 23120

Washer, Flat. 3/8x7/8x1/16

92/03/28

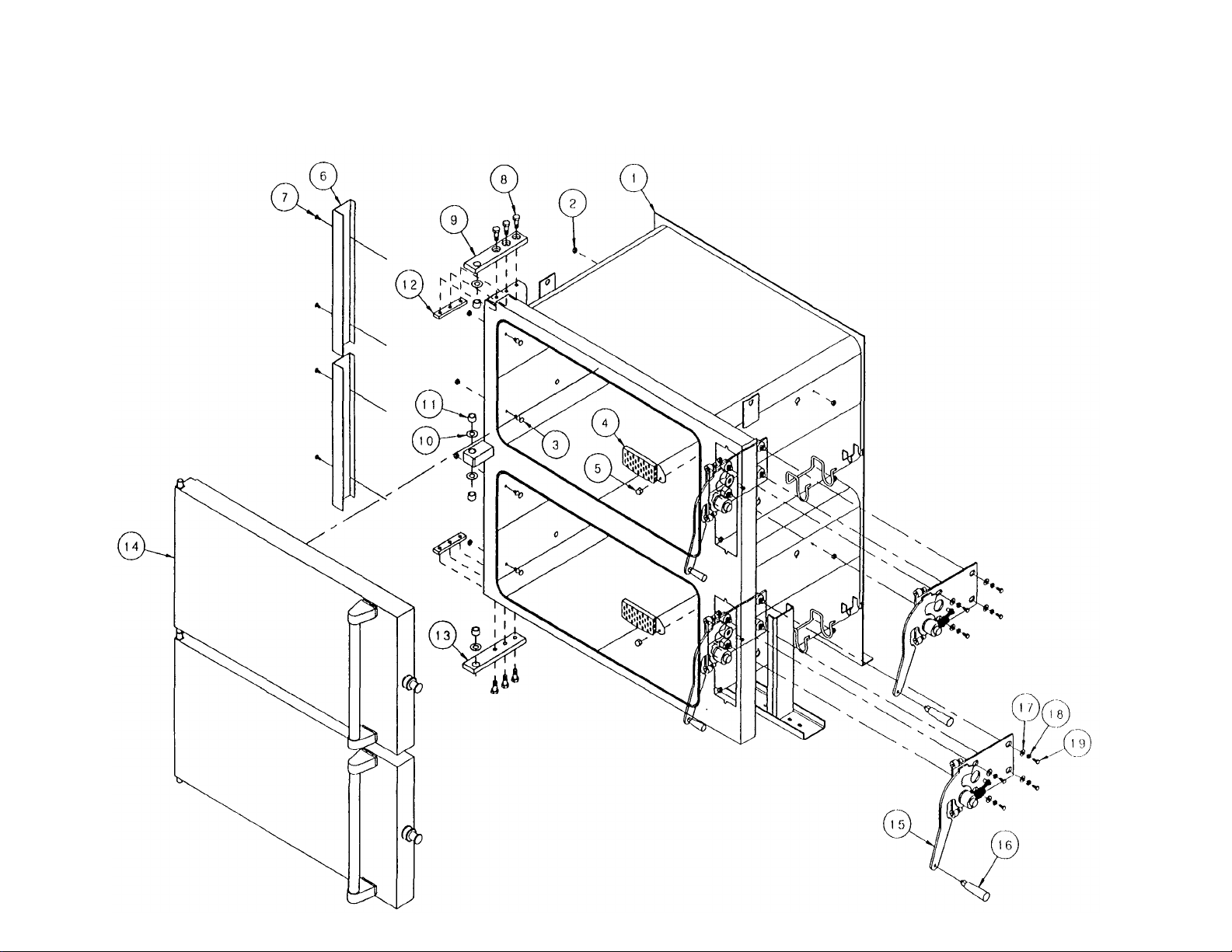

Item Part Number Parts List Below Is For Drawing On Previous Page

1 105836 Cavity, Weld Assembly, Convection Pro

2 14618 Nut, Hex, 1/4-20, S/S

3 101305 Pin, Rack

4 69298 Screen, Compartment Drain

5 146771 Nut, Acor n, 1/4-20

6 53124 Channel, Door End

7 101231 Screw, Truss Head, 10-24 x 1/2, S/S

8 191241 Screw, Hex Head, 3/8-16 x 1.00

9 101936 Bar, Hinge Top

10 100539 Washer, Door Hinge

11 02093 Bearing, .568 ID x .753 OD

13 101935 Bar, Hinge Bottom

14

15

See Sheet 3

See Sheet 4

Door Assembly, Convection Pro

Door Assembly, Convection Pro

16 106236 Handle Assembly, PCL/PCS Steamer

18 23108 Washer, Lock, Medium Pattern, 5/16, S/S

19 13129 Screw, Hex, 3/8-16 x 7/8, Alloy Steel

Cleveland

Steam Cooking

Specialists

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 13

Page 14

Cleveland Convection Pro

Description

4 54230

Cover, Door, Convection Pro

9 23105

Washer, Lock, 1/4, Katlink, S/S

14 68084

Roller, Door Latch

18 100557

Screw, Socket

Head, 1/4

-

28 x I". S/S

92/03/28

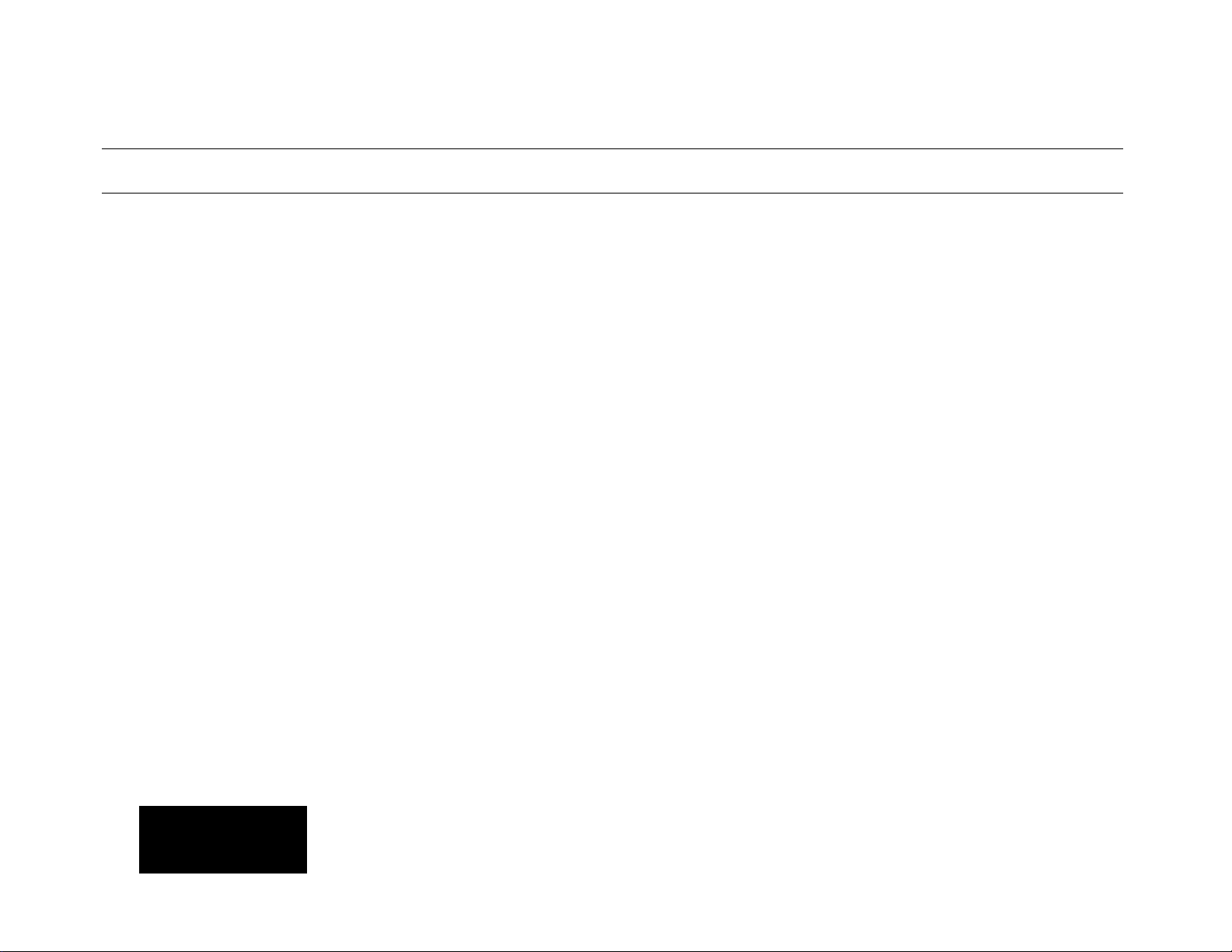

Item Part Number Parts List Below Is For Drawing On Previous Page

1 105825 Door, Weldment, Convection Pro

2 104292 Gasket, Door, Convection Pro

3 52061 Bar, Hinge, Pivot

5 100759 Bar, Door, Handle

6 1010441 Bracket, Door Handle

7 100990 Spring, Wave

8 101048 Pad, Insulator, Plastic

10 23116 Washer, Flat, 1/4 x 5/8 x .065, S/S

11 19176 Screw, Truss Head, Slotted, 1/4-20 x 1/2

12 23098 Washer, Flat, 3/4 x 1.187 x .05, S/S

13 02096 Bearing, .753 ID, Porous Bronze

15 52531 Pin, Roller

16 19136 Screw, Set, Cup Point, 1/4-20 x 1/2, S/S

17 19123 Screw, Socket Head, 1/4-28 x l 1/2, S/S

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 15

Page 16

Cleveland Convection Pro

Description

6 18307

Pin, Retainer

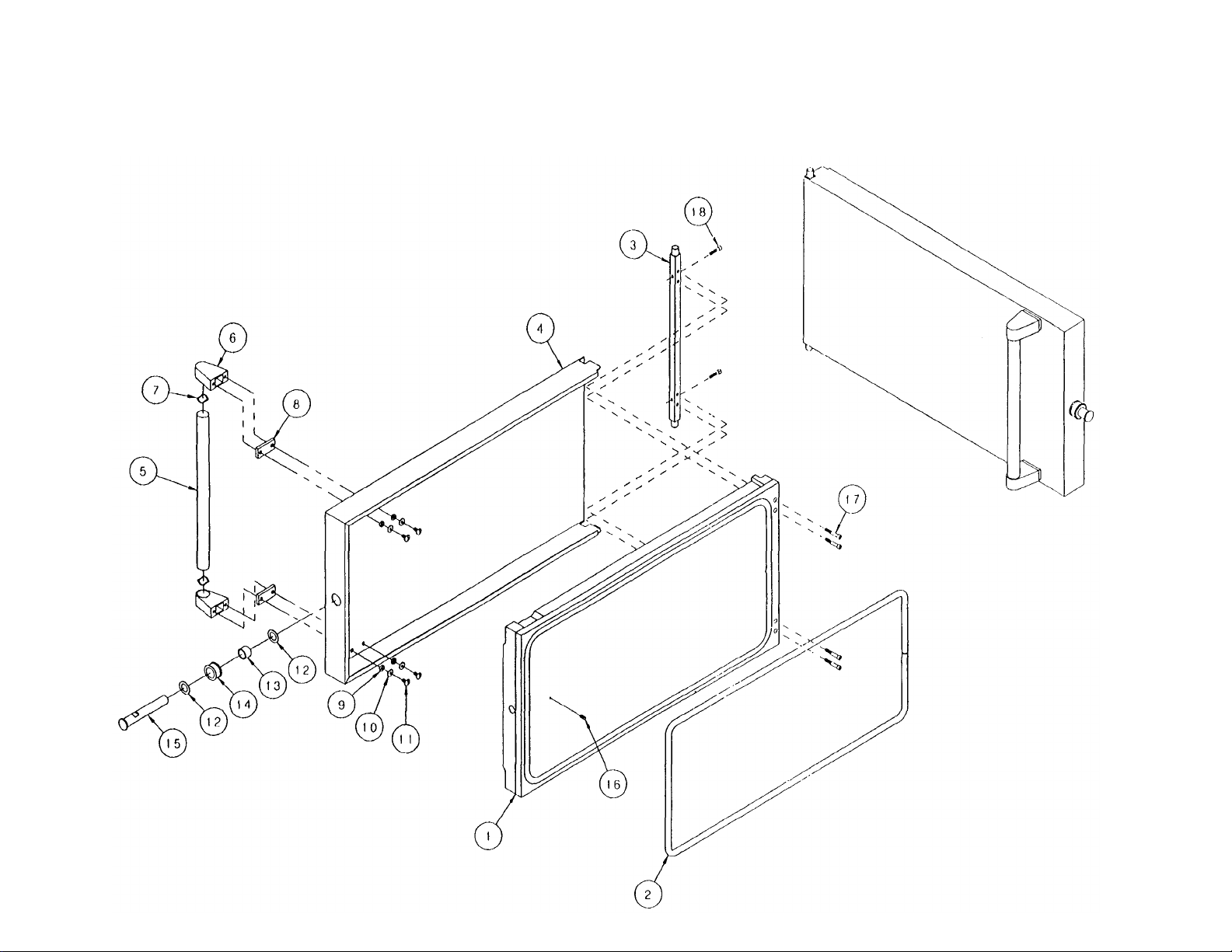

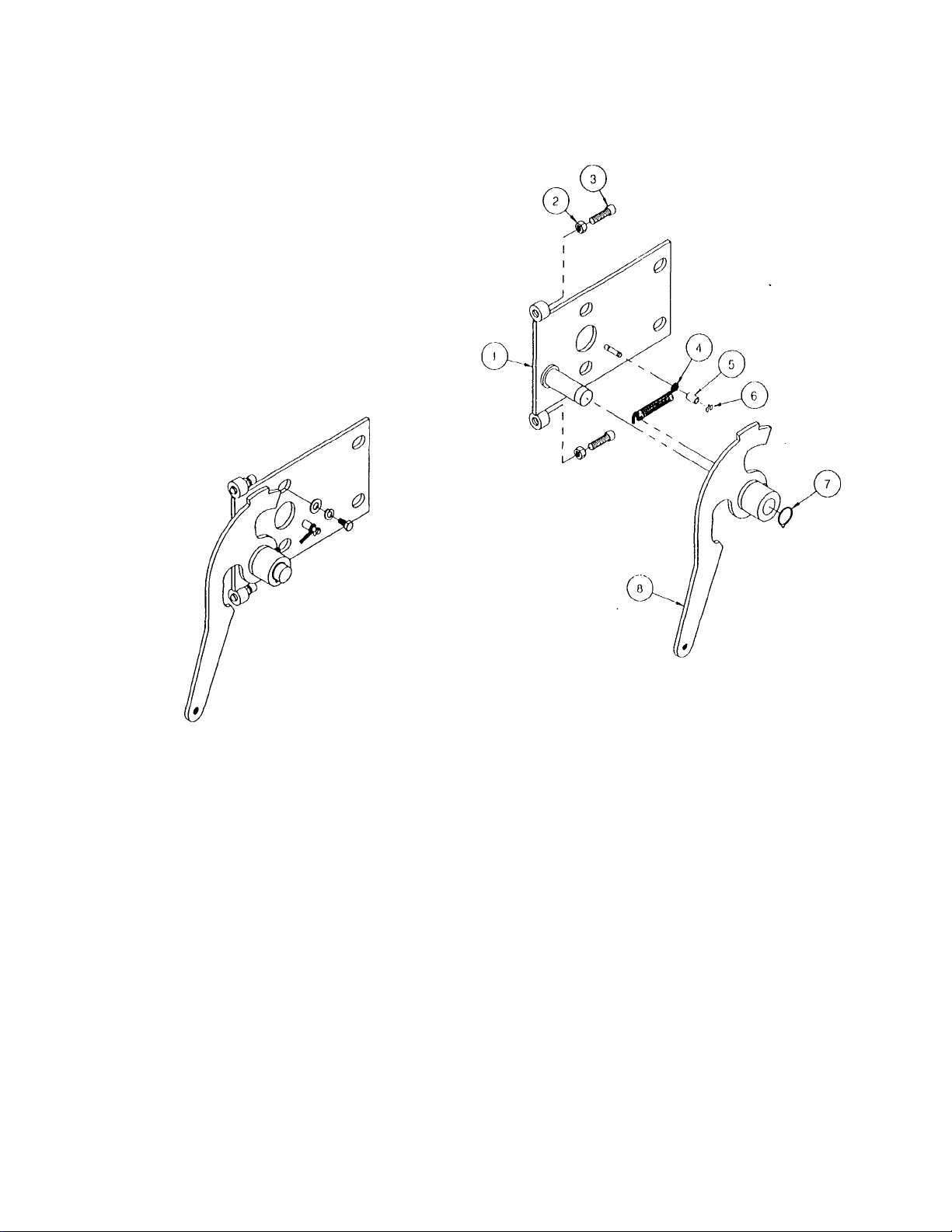

Item Part Number Parts List Below Is For Drawing On Previous Page

1 105917 Plate, Latch Mount, Weldment

2 14675 Nut, 3/8-16, S/S

3 100605 Screw, Socket Head, Cap, 3/8-16 x 1 1/4

4 100710 Spring, Latch

5 101408 Tubi ng, Latch Bumper

7 1044871 Handle Assembly

8 18306 Ring, Retaining

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 17

Page 18

Cleveland Convection Pro

Description

5 104224

Switch, Rocker, SPDT, Matte Finish

12 101655

Washer, Flat, #10, S/S

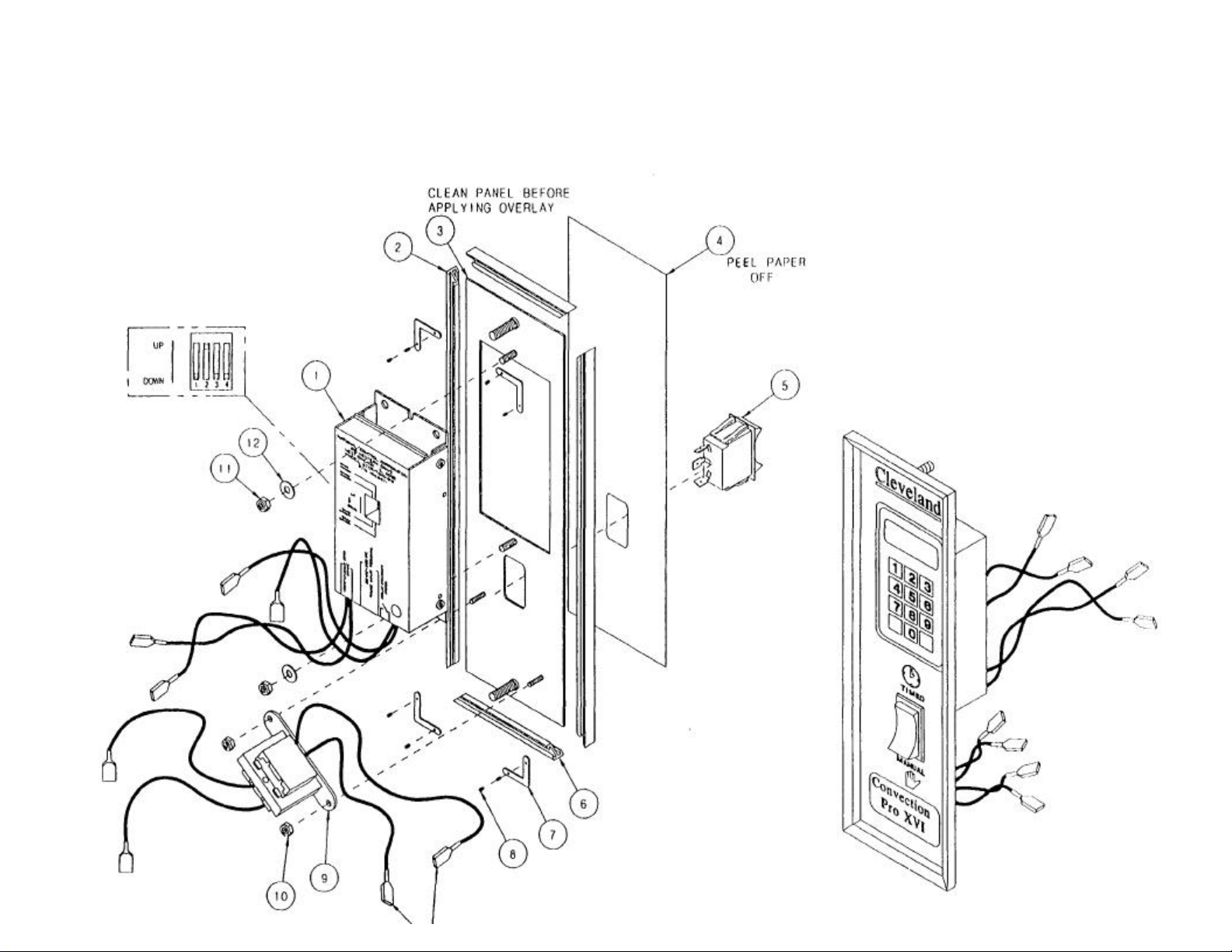

Item Part Number Parts List Below Is For Drawing On Previous Page

1 104389 Timer, Assembly - NCC

2 56237 Bar, Instrument Panel Frame, Side

3 103981 Panel, Weldment, Convection Pro, Electronic

4 106599 Label, Control Panel, Convection Pro

6 56235 Bar, Instrument Panel Frame, Top/Bottom

7 53264 Clip, Instrument Panel Frame, PCL

8 19151 Screw, Set, Cup Point, 3-48 x .125, S/S

9 104390 Transformer Assembly

10 104223 Nut, Hex, 6-32, Elastic Lock

11 14692 Nut, Hex, 10-24, Elastic Lock

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 19

Page 20

Cleveland Convection Pro

Description

10

Included With Item 10

17 19201

Screw, Pan Head, Slotted, 5

-

40 x .250, S/S

Item Part Number Parts List Below Is For Drawing On Previous Page

1 11307 Knob, Timer

2 19992 Switch, Rocker, Compartment Bypass

3 105822 Label, Control Panel, Convection Pro

4 56237 Bar, Instrument Panel Frame, Sid e

5 103974 Panel, Weldment, Convection Pro, Mechanical

6 14618 Nut, Hex, 1/4-20, S/S

7 20477 Timer, Solid State, 3 Second Delay

8 101873 Nut, 1/4-20, Elastic Lock

9 41350 Buzzer Assembly with Terminals

11 20323 Terminal, #10 Ring. .25 Male Tab

12 20476 Timer, 60 Minute, Mechanical Switching

13 14692 Nut, 10-24, Elastic Lock, Steel Plated

14 19151 Screw, Set, Cup Point, 3-48 x .125, S/S

15 53264 Clip, Instrument Panel Frame, PCL

16 56235 Bar, Instrument Panel Frame, Top/Bottom

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 21

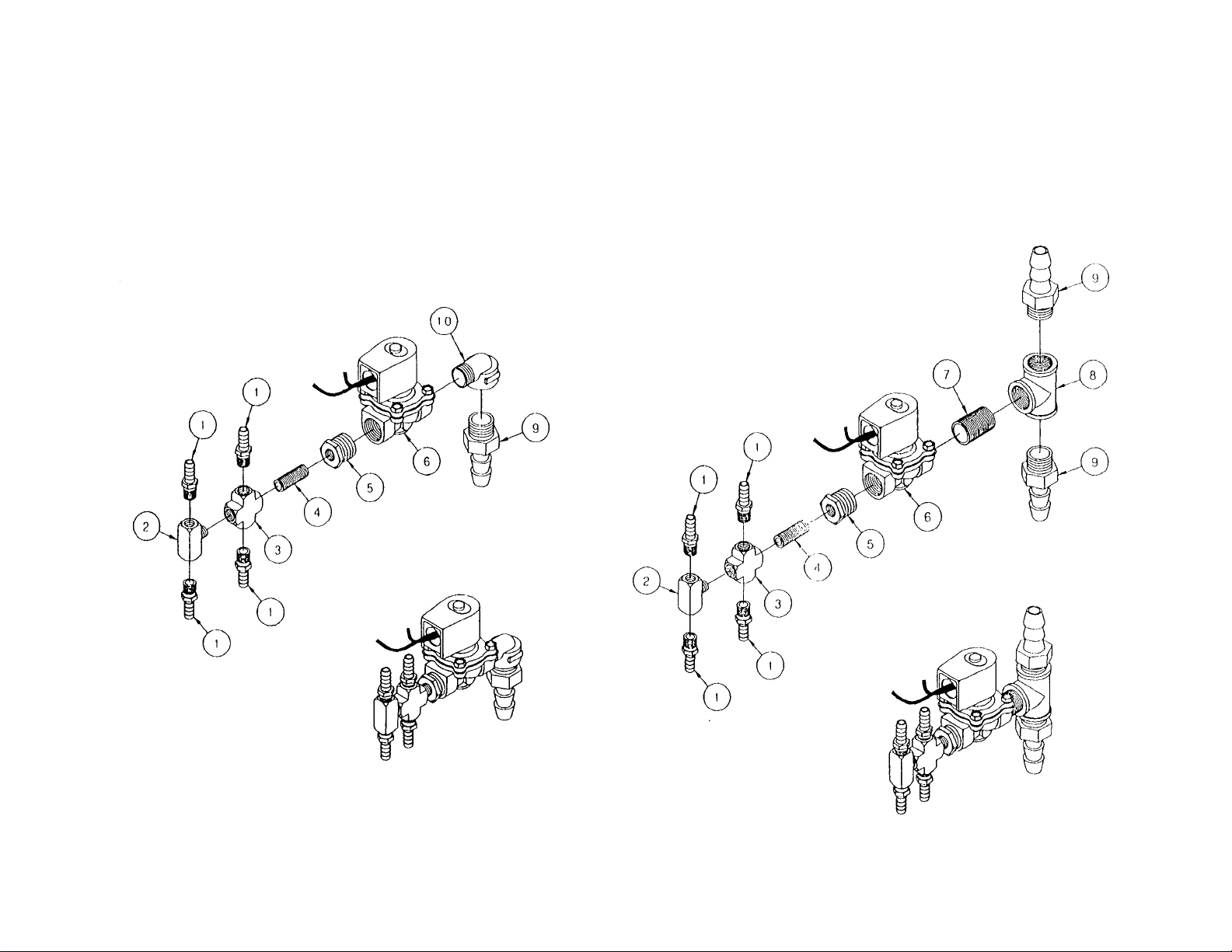

Page 22

Cleveland Convection Pro

Description

2 20245

Tee, Male Branch, 1/4, Brass

6 22193

Valve, Solenoid, 3/4 x 3/4, 120V, 60Hz

10 05231

Elbow, Street, 3/4 x 90°, Brass

Item Part Number Parts List Below Is For Drawing On Previous Page

1 105277 Fitting, Hose Barb, 3/8 H x 1/4 NPT

3 03729 Cross, 4-Way, 1/4, Brass

4 14304 Nipple, 1/4 x Close, Brass

5 02563 Bushing, Hex, 3/4 x 1/4, Brass

7 14342 Nipple, 3/4 x Close, Brass

8 20206 Tee. 3/4 x 3/4 x 3/4, Brass

9 06240 Fitting, Hose Barb. 3/4 H x 3/4 MPT

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 23

Page 24

Cleveland Convection Pro

Description

6 105783

Tee, 1" x 1" x 1 1/4, Black

Item Part Number Parts List Below Is For Drawing On Previous Page

1 105786 Fitting, Hose. 1/4 H x 1/4 MPT x 90°

2 06230 Fitting, Compartment Drain

3 14297 Nipple, 1/8 x 1 1/2, S/S

4 14555 Nozzle, Spray, 1/8, Full Jet

5 104838 Coupling, Full, 1/8, Brass

7 565191 Fitting, Hose, 1" with 1/8 Hole

8 06233 Fitting, Comp, 3/8 T x 1/8 MPT, 90°

9 70732 Tube, Air Vent, 3/8, Copper

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 25

Page 26

Cleveland Convection Pro

5 52192

Baffle, Rear. 250/300 KBTU

24 23137

Washer, Lock, 1/4, Internal T

ooth, S/S

25 19288

Screw, Hex Head, 1/4

-

20 x 3/4, S/S

30 14659

Nut, Hex, 10

-

24,

S/SPS

44 19206

Screw, Round Head, 6

-

32 x I", Zinc Plated

55 19218

Screw, Hex Head

, 1/4-20 x .375, S/S

56 52499

Bracket, Pressure Switch Retainer

Item Part Number Parts List Below Is For Drawing On Previous Page

Description

1 41120 Base, Weldment, 900mm, S/S

2

3 1009811 Collector Assembly, Top Flue, Large Gas

4 1011301 Flue Riser Assembly, Internal

6

7

8 105243 Connector, Greenfield, 3/8, Straight

9 52305 Box, Probe Cover, 2 Probes, A.C.S.

10 05259 Elbow. Street, 3/4, 90°, Black

11 22131 Valve, Safety, 3/4, 15 PSI, Bronze

12 14487 Nipple, T.O.E., 3/4 x 9, Black

13 44096 Box, Igniter Assembly

14 19287 Screw. Pan Head, 10-24 x .5, S/S

15 40842 Baffle, Front, 300 KBTU R/B

16 44169 Cable, Ignition Assembly

17

18

19 40922 Manifold Assembly, Reverse Bend, 300 KBTU

20 52602 Bracket, Alignment Manifold

21 15453 Orifice, Natural Gas, #29 Drill

22 14618 Nut, Hex, 1/4-20, S/S

23 23105 Washer, Lock, 1/4, Katlink Style

411201 Base, Weldment, 900mm, A.C.S.

See Sheet 10

See Sheet 11

See Sheet 12

See Sheet 13

See Sheet 14

See Sheet 14

Gas Generator Assembly, with Reference Parts

Steam Outlet Assembly

Blowdown Assembly, PCL, Gas

Box, Electric, Assembly for 2 Probe Gas

Valve Assembly, Natural Gas, 250/300 KBTU

Valve Assembly, Liquid Propane, Large Gas

15450 Orifice, Liquid Propane, #45 Drill

26 23116 Washer, Flat, 1/4 x 5/8 x .065

27 19148 Screw, Hex Washer Head, 10 x .5

28 19294 Screw, Round Head, 10-24 x .75 Long

29 23113 Washer, Split Lock ,10, Zinc Plated

31 02497 Burner Assembly, Gas

32 44157 Bracket, Support, Rear. 300, KBTU

33 63184 Bracket, Manifold, 900mm Base, S/S

1009351 Bracket, Manifold, 900mm Base, Aluminized Steel

34 14668 Nut, Hex, Jam, 3/4-10, Zinc Plated

35

See Sheet 15

Drain Assembly

36 06156 Leg, Bullet, 6"

37 1020663 Hinge, Lower Right

38

See Sheet 16

Water Feed Assembly, Reverse Bend Generator

39 412192 Bracket Assembly, Top Hinge, R.S.

40 53274 Clip, Magnetic Catch, S/S

41 14674 Nut, Hex, 6-32, Zinc Plated

42 18358 Rivet, 1/8 Diameter, Flush Break, S/S

43 03100 Catch, Magnetic

45 1020662 Hinge, Lower Left

46

See Sheet 17

Console Assembly, 900mm, 2 Switch

47 19329 Plug, Snap-In, 1/2" for 7/8" Hole

48 105246 Connector, Greenfield, 1/2, Straight

49 195552 Spacer

50 19555 Spacer

51 412182 Bracket Assembly, Top Hinge, S/S

52 14665 Nut, Hex. Lock, 1/4-20, S/S

53 19947 Switch Pressure Control

54 02599 Bushing, Insulating, 3/8 x 1/2, Heyco

57 526241 Bracket, Pressure Switch, Gas/Electric

58 105247 Connector, 1/2 x 90°, Snaptite

59 14688 Nut, Hex, Jam, 1/4-20, S/S

60 100883 Fitting, Comp Tee, 3/8 x 1/4 NPT x 3/8

61 06196 Fi tting, Comp, 3/8 x 1/4 MPT, 90°

Also Required For Liquid Propane

52615 Baffle, Side

52614 Baffle, Front Burner, Gas, Liquid Propane Only

Page 27

Page 28

Cleveland Convection Pro

Description

3 14263

Fastener, Pushnut, 1/4 Stud Diameter

10 14618

Nut, Hex, 1/4

-

20, S/S

12 23116

Washer, Flat, 1/4, S/S

15 07128

Gasket,

Heater

18 62453

Extension, Water Probe, 1/2 x 4.625

Item Part Number Parts List Below Is For Drawing On Previous Page

1 407431 Generator Assembly, Gas - Weldment

2 100980 Panel, Insulation Assembly, Rt/Lt. Natural Gas

4 105539 Disk, Hole Cover, Side Insulation Panel

5 19148 Screw. Hex Washer Head, 10x1/2

6 69967 Support, Generator Mounting Channel, 900/1050mm

7 07176 Gauge, Fittings, Water, 1/2

8 07302 Gauge, Water, 5/8 x 6, Glass

9 43895 Anode Assembly, Corrosion Prevention

11 23105 Washer. Split Lock, 1/4, S/S

13 16602 Plug, Square, 1/2 Pipe, Black

14 41943 Plate, Mounting

16 40421 Hand Hole Plate and Bar Assembly

17 06671 Probe, Warrik. 4.313 Long

19 62452 Extension, Water Probe, 1/2 x 3.125

20 23151 Washer, Internal Tooth Lock, 1/4

21 19218 Screw, Hex Head, 1/4-20 x 3/8, S/S

22 19288 Screw, Hex Head, 1/4-20 x 3/4, S/S

23 19995 Switch, Low Water Cutoff, California Code

24 02623 Bushing, Hex, 1/4 x 1/4, Brass (California Code Only)

25 05253 Elbow, Street, 1/2, 90°, Brass (California Code Only)

1009802 Panel, Insulation Assembly, Rt/Lt, Liquid Propane

Cleveland Range, Inc.

1333 East 179th St.

Cleveland. OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 29

Page 30

Cleveland Convection Pro

Description

Item Part Number Parts List Below Is For Drawing On Previous Page

1 100883 Fitting, Comp, Tee, 3/8 T x 3/8 MPT x 3/8 T

2 02563 Bushing, Reducing, 3/4 x 1/4, Brass

3 20206 Tee, 3/4, Brass

4 16607 Plug, Square Head, 3/4, Brass

5 14342 Nipple, 3/4 x Close, Brass

6 14431 Nipple, 3/4 x 2, Brass

7 06240 Fitting, Hose Barb, 3/4 H x 3/4 MPT, Brass

8 101207 Trap, Thermostatic, 1/4 x 1/4

9 14661 Nut, Compression, 1/4 T, Brass

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 31

Page 32

Cleveland Convection Pro

Description

Item Part Number Parts List Below Is For Drawing On Previous Page

1 06240 Fitting, Hose Barb, 3/4 H x 3/4 MPT

2 22244 Valve, Solenoid, 1/2. 15 PSI

3 105787 Fitting. Hose Barb, 1/4 H x 1/8 NPT, 90°

4 104381 Fitting, Hose Barb, 1/4 H x 1/4 NPT

5 05263 Elbow, Radiator, 3/4 x 90°

6 14431 Nipple, 3/4 x 2, Brass

7 05260 Elbow, 3/4 x 3/4, 90°

8 14495 Nipple, 3/4 NPT x 3, S/S

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 33

Page 34

Cleveland Convection Pro

Description

22 14614

Nut, Lock, 1/2, Elec

trical

Item Part Number Parts List Below Is For Drawing On Previous Page

1 44139 Box, Weldment, Electric for Gas, 2 Probe

2 03546 Control Module, Direct Spark Ignition

3 20258 Transformer - Spark Ignition Supply

4 20478 Ti mer, Solid State Interval, 3 Minute

5 44164 Terminal Block Assembly - 4 Pole, Gas Units

6 03525 Socket, Relay

7 03524 Relay, 120 V. 50/60 Hz, AC, DPDT

8 23198 Control, Water Level

9 19163 Screw, Round Head, Slotted, 6-32 x .75

10 19149 Screw, Round Head, Slotted, 6-32 x 1.75

11 19150 Screw, Round Head, Slotted, 6-32 x 1.25

12 19265 Screw, Round Head, 1/4-20 x 1.5. S/S

13 23116 Washer, Flat, 1/4 ID x .065 Thick

14 23111 Washer, Internal Tooth Lock, #6

15 101337 Washer. Internal Tooth Lock, #8

16 23105 Washer, Split Lock, 1/4, S/S

17 14674 Nut, Hex, 6-32, Zinc Plated

18 14598 Nut, Hex, 8-32, Zinc Plated

19 14618 Nut, Hex, 1/4-20, S/S, Full Finish

20 02361 Box, Handi-Box, Electrical

21 14334 Nipple, 1/2 x 4, Black

23 02368 Cover, Handi-Box

24 19329 Plug, Snap-In. 1/2" for 7/8" Hole

25 105243 Connector, Greenfield, 3/8, Snaptite

26 105246 Connector. Greenfield, 1/2, Snaptite

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 35

Page 36

Cleveland Convection Pro

Description

7 21305

Union, 3/4, Black

Item Part Number Parts List Below Is For Drawing On Previous Page

1 14347 Nipple, 3/4 x 3, Black

2 22230 Valve, Gas Control, Natural Gas

3 05259 Elbow, Street, 3/4, 90°, Black

4 14343 Nipple, 3/4 x Close, Black

5 05258 Elbow, 3/4, 90°, Black

6 14362 Nipple, 3/4 x 7.5, Black

22231 Valve, Gas Control, Liquid Propane

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 37

Page 38

Cleveland Convection Pro

Description

Item Part Number Parts List Below Is For Drawing On Previous Page

1 05238 Elbow, l 1/2 NPT x 90°, Black

2 05292 Elbow, Street, 1 1/2 NPT x 90°, Black

3 13252 Manifold, Drain, 1 1/2 NPT, Black

4 19917 Stud, Weld. 1/4-20 x .875, S/S

5 03616 Coupling, Reducing, 1 1/2 x 3/4, Black

6 06240 Fitting, Hose Barb, 3/4 H x 3/4 MPT

7 05259 Elbow, Street, 3/4 x 90°, Black

8 06192 Fitting, Comp, 1/4 T x 1/8 MPT, 90°

9 565191 Fitting, Hose Barb, Drain Manifold with 1/8 Hole

10 14481 Fitting, Hose Barb, 1" H x 1" MPT

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 39

Page 40

Cleveland Convection Pro

Description

6 22223

Valve, Solenoid,

1/4

NPT (GP200)

Item Part Number Parts List Below Is For Drawing On Previous Page

1 104381 Fitting, Hose, 1/4 H x 1/4 NPT

2 03276 Valve Ball, 1/4 NPT

3 05235 Elbow, Street, 1/4. 90°, Brass

4 22102 Valve, Check, 1/4 NPT

5 14304 Nipple, 1/4 x Close, Brass

7 20199 Tee, 1/4, Brass

8 106588 Tee, Hose Barb, 1/4, Brass

9 05236 Elbow, 1/4, 90°, Brass

10 100064 Clamp, Mounting

11 19870 Strainer, "V", 1/4, Brass

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 41

Page 42

Cleveland Convection Pro

Description

11 14692

Nut, Hex, Elastic Lock, 10

-

24, Zinc Plated

Item Part Number Parts List Below Is For Drawing On Previous Page

1 1041544 Console, Stud Assembly, 900mm, 2 Switch

2 07168 Gauge, Pressure, Back Mount, 10 PSI

3 19994 Switch, Rocker, SPST, 15 Amp

4 15019 Label, Pow er, Console Switch

5 19993 Switch, Rocker, DPDT, On-Off, 6 Amp

6 15018 Label, Power, Console Switch

7 105516 Box, Switch Protection

8 23116 Washer, Flat. 1/4 ID x 5/8 OD x .065

9 14665 Nut, Hex, Elastic Lock, 1/4-20. S/S

10 102535 Bracket, Magnet Mount

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 43

Page 44

Part Number Parts List Below Is For Drawing On Previous Page

Description

195552

Spacer

14674

Nut, Hex, 6

-

32, Zinc Plated

14688

Nut, Hex, Jam, 1/4

-

20, S/S

19947

Switch, Pressure Control

101692 Base, Weldment, 900mm, S/S

1016921 Base. Weldment, 900mm, A.C.S.

22131 Valve, Safety, 3/4, 15 PSI, Bronze

105245 Connector, Greenfield, 3/8, 90°

101112 Box, Probe Cover, Large Steam Coil

16602 Plug, Square Head, Cored, 1/2 NPT, Black

050073 Fitting, Comp, Tee, 3/8, Brass

101893 Bracket, Generator, Mounting, Large Steam Coil

105244 Connector, Greenfield, 3/8,45°

02361 Box, Handi-Box, Electrical

02368 Cover, Handi-Box

06156 Leg, Bullet, 6"

14618 Nut, Hex, 1/4-20, S/S

23105 Washer, Lock, 1/4, Katlink Style

23116 Washer, Flat, 1/4 x 5/8 x .065

19288 Screw, Hex Head, 1/4-20 x 3/4

19292 Screw, Round Head, Slotted, 1/4-20 x 1"

105243 Connector, Greenfield, 3/8, Straight

1020663 Hinge, Lower Right

See Sheet 19

See Sheet 20

See Sheet 21

See Sheet 22

See Sheet 23

See Sheet 24

See Sheet 25

See Sheet 26

Generator Assembly, Large Steam Coil With Reference Parts

Piping Assembly, Steam Outlet, PCL

Inlet, Steam Assembly, PCL Steam Coil

Piping, Steam Outlet, PCL Steam Coil

Blowdown Assembly, Auto, PCL Steam Coil

Box, Electric, Steam Coil with Components

Drain Manifold Assembly

Water Feed Assembly, Reverse Bend Generator, 3/8

528621 Hinge, Upper Right

1020662 Hinge, Lower Left

14668 Nut, Hex. Jam, 3/4-10, Zinc Plated

528611 Hinge, Upper Left

19555 Spacer

19206 Screw, Round Head, 6-32 x I", Zinc Plated

03100 Catch, Latch

53274 Clip, Magnet Catch, S/S

18358 Rivet, 1/8 DIA, Flush Break, S/S

19329 Plug, Snap-In, 1/2" for 7/8" Hole

105246 Connector, Greenfield, 1/2, Straight

23137 Washer, Lock, Internal Tooth, 1/4, S/S

100883 Fitting, Comp, Tee, 3/8 x 1/4 Npt x 3/8

06196 Fitting, Comp, 3/8 x 1/4 Mpt, 90°

02599 Bushing, Insulating, 3/8 x 1/2, Heyco

19218 Screw, Hex Head. 1/4-20 x .375, S/S

52499 Bracket, Pressure, Switch Retainer

19148 Screw, Hex Washer Head, Slotted

526241 Bracket, Pressure Switch, Gas/Electric

105247 Connector, 1/2, 90°, Snaptite

See Sheet 17

Console Assembly, 900mm, 2 Catch

Page 45

Page 46

Cleveland Convection Pro

Description

5 101912

Extension, Probe, Low Water, PCL

Item Part Number Parts List Below Is For Drawing On Previous Page

1 101927 Generator Assembly, 2 Probe, Large Steam Coil

2 07176 Gauge Fittings, Water, 1/2

3 101900 Gauge, Water, 5/8 x 4.625, Glass

4 16601 Plug, Square Head, 3/8 NPT, Black

6 101913 Extension, Probe, High Water, PCL

7 16671 Probe, Warrick, 4.313 Long

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 47

Page 48

Cleveland Convection Pro

Description

Item Part Number Parts List Below Is For Drawing On Previous Page

1 101708 Elbow, Street, I", 90°, Brass

2 14494 Nipple, l" x 4, Brass

3 70413 Tee, I", Brass - Modified (PCL Steam Coil)

4 101207 Trap, Thermostatic, 1/4 NPT

5 02570 Bushing, Hex, 1" x 3/4, Brass

6 05231 Elbow, Street, 3/4, 90°, Brass

7 06240 Fitting, Hose Barb, 3/4 H x 3/4 NPT

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 49

Page 50

Cleveland Convection Pro

Description

4 03277

Valve, Ball, 3/4, Br

ass

11 100075

Valve, Boiler Safety, 50 PSI

14 20209

Tee, 3/4 x 3/4 x 1/2, Black

Item Part Number Parts List Below Is For Drawing On Previous Page

1 05270 Elbow, Street, 1 1/4 x 3/4, 90°, Black

2 05259 Elbow, Street, 3/4, 90°, Black

3 14343 Nipple, 3/4 x Close, Black

5 101699 Valve, Steam Solenoid, 1" NPT

6 20205 Tee, 3/4, Black

7 02557 Bushing, 1/2 x 1/4, Black

8 16820 Pipe, Pigtail, 1/4

9 03665 Coupling, Full, 1/4, S/S

10 07169 Gauge, 0-100 PSI, 1/4 NPT

12 02598 Bushing, Hex, 1" x 3/4, Black

13 14344 Nipple, 3/4 x 2, Black

15 21305 Union, Pipe, 3/4, Black, No Warwicks

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, 011 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 51

Page 52

Cleveland Convection Pro

Description

5 19872

Strainer.

"Y",

3/4

Item Part Number Parts List Below Is For Drawing On Previous Page

1 05270 Elbow, 1 1/4 x 3/4, 90°, Black

2 14343 Nipple, 3/4 x Close, Black

3 21305 Union, 3/4, Black

4 14347 Nipple, 3/4 x 3, Black

6 16602 Plug, Square Head, 1/2, Cored

7 05259 Elbow, Street, 3/4, 90°, Black

8 20555 Trap, Bucket. 60#, 3/4, 80#

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 53

Page 54

Cleveland Convection Pro

Description

6 22223

Valve, Solenoid, 1/4 NPT

9 05244

Elbow, 3/8, 90°, Brass

15 20199

Tee, 1/4, Brass

Item Part Number Parts List Below Is For Drawing On Previous Page

1 104381 Fitting, Hose Barb, 1/4 H x 1/4 NPT

2 03276 Valve, Ball, 1/4 NPT

3 05235 Elbow, Street, 1/4,90°

4 22102 Valve, Swing Check, 1/4 NPT

5 14304 Nipple, 1/4 x Close, Brass

7 100527 Tee, 3/8 x 1/4 x 3/8, Brass

8 02594 Bushing, 3/8 x 1/4, Brass

10 100339 Strainer, "V", 3/8 NPT

11 100303 Clamp, Mounting

12 14427 Nipple, 3/8 x Clos e, Brass

13 05280 Elbow, Street, 3/8. 90°, Brass

14 105786 Fitting, Hose, 1/4 H x 1/4 MPT. 90°, Brass

16 22239 Valve, Pressure Reducing, Water, 3/8

17 07169 Gauge, Bottom Mount, 0-100 PSI

18 106588 Tee, Hose Barb, 1/4

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 55

Page 56

Cleveland Convection Pro

Description

Item Part Number Parts List Below Is For Drawing On Previous Page

1 05238 Elbow, I 1/2 NPT, 90°, Black

2 05292 Elbow, Street, 11/2, 90°, Black

3 13252 Manifold, Drain, 1 1/2,, Black

4 19917 Stud, Weld, 1/4-20 x 7/8, S/S

5 03616 Coupling, Reducer, 11/2 x 3/4, Black

6 05259 Elbow, Street, 3/4, 90°, Black

7 06240 Fitting, Hose Barb, 3/4 H x 3/4 MPT

8 14343 Nipple, 3/4 x Close, Black

9 05271 Elbow. 3/4 x 1/2,90°, Black

10 14323 Nipple, 1/2 x Close. Black

11 22149 Valve, Swing Check, 1/2, Brass

12 05252 Elbow, Street, 1/2,90°, Black

13 06241 Fitting, Hose Barb, 3/4 H x 1/2 MPT

14 565191 Fitting, Hose Barb, Drain Manifold with 1/8 Hole

15 14481 Fitting, Hose Barb. 1" H x 1" MPT

16 06192 Fitting, Comp, 1/4 T x 1/8 MPT, 90°

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 57

Page 58

Cleveland Convection Pro

Description

9 14618

Nut, Hex. 1/4

-

20, S/S, Full Finish

Item Part Number Parts List Below Is For Drawing On Previous Page

1 40939 Box, Weldment, Electrical, Steam Coil Generator

2 14674 Nut, Hex, 6-32, Zinc Plated

3 23111 Washer, Lock, Internal Tooth, #6, Zinc Plated

4 44164 Terminal Block Assembly - 4 Pole

5 19163 Screw, Round Head, Slotted, 6-32 x .75, Zinc Plated

6 03525 Socket, Relay

7 03524 Relay, 120V, 50/60 Hz, AC, DPDT

8 105044 Clip, Wire, Relay

10 23105 Washer, Loc k, Medium Pattern, 1/4, Katlink Style, S/S

11 23116 Washer, Flat, 1/4 ID x 5/8 OD x .065

12 20478 Timer, Solid State Interval, 3 Minute

13 23432 Clip, Mounting, Wire/Cable. 1.25 x 1.50

14 19265 Screw, Round Head, 1/4-20 x 1 1/2, S/S

15 105243 Connector, Greenfield, 3/8, Straight

16 19329 Plug, Snap-In, 1/2" for 7/8" Hole

17 23198 Control, Water Level

18 12330 Lug, Solderless Ground for 10-14 Gauge Wire

19 105244 Connector, Greenfield, 3/8 x 45°

20 105247 Connector, Greenfield, 1/2 x 90°

21 105245 Connector, Greenfield, 3/8 x 90°

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 59

Page 60

Cleveland Convection Pro

Description

6 21304

Union, 3/4, Red Brass

Item Part Number Parts List Below Is For Drawing On Previous Page

1 06240 Pitting, Hose Barb, 3/4 H x 3/4 MPT

2 22244 Valve, Solenoid, 3/4

3 105787 Fitting, Hose Barb, 1/4 H x 1/8 MPT, 90°

4 104381 Fitting, Hose Barb, 1/4 H x 1/4 MPT

5 14431 Nipple, 3/4 x 2, Brass

7 14342 Nipple, 3/4 x Close, Red Brass

8 05260 Elbow, 3/4, 90°, Brass

9 14490 Nipple, 3/4 x Close, S/S

Cleveland Range, Inc.

1333 East 179th St.

Cleveland, OH 44110

Ph: (216) 481-4900 Fax: (216) 481-3782

Page 61

ELECTRIC STEAM GENERATOR (BOILER) ASSEMBLY - 2 PROBE TYPE 18 KW, 27 KW, 36

1 43894 Electric Boiler Shell only. with legs. hand hole

08216 Heater.

12 KW. 440/480

volt. 1 phase

KW, & 48 KW (2, 3, & 4 HEATER ELEMENTS)

REFERENCE

NUMBER

flanged heater elements 10 07128 Healer Gasket

44149 Electric Boiler Shell (43894) above, also includ- 11 16546 3" Block-Off Plate

cover box. 22130 8 psi Safety Valve

2 40421 Hand Hole Plate Assembly including bar. nut. 13 19947 Pressure Switch

2a 43748 Hand Hole Plate only 03506 Contactor. 75 amp

3 07106 Hand Hole Gasket. 4- x 6" oval 15 23196 Control Board, water level and LWCO

4. 40462 Probe 16 03524 Relay

5 101466 Probe Extension Set (set of two) 17 03525 Relay Socket

6 52305 Probe Cover Box 18 44168 Terminal Block. 2 pole

7 40445 Water Gauge Set with Glass 19 03202 Circuit Breaker, 1 amp

07108 Fibre Washer (2 required) 20 20478 Interval Timer. 3 minute

23132 Gauge Glass Washer (2 required) 21 20535 Transformer. 150 VA

8 07302 Gauge Glass Only. 6" long 22 22102 Check Valve. V. •

9 08235 Heater. 9 KW. 208 volt. 3 phase 23 03276 1/4 "" Ball Valve, water supply shut-off

08236 Healer. 9 KW. 220/240 volt. 3 phase 24 22223 Solenoid Valve, water feed

08234 Heater. 9 KW. 600 volt. 3 phase 26 03277 3/4" Ball Valve, manual drain

08241 Heater. 9 KW. 208 volt. 1 phase 27 22221 Solenoid Valve, boiler drain

08243 Heater. 9 KW. 440/480 volt. 1 phase 29 45006 Low Water Cut-Off Assembly (California only)

08244 Heater. 9 KW. 600 volt. 1 phase 30 41943 LWCO Mounting Plate (California only)

08166 Heater. 12 KW. 230/240 volt. 3 phase 32 02623 Reducing Bushing. 1/2" - 1/4" (California only)

08167 Heater. 12 KW. 440/480 volt. 3 phase 33 19995 Float Switch. LWCO (California only)

08214 Heater. 12 KW. 208/220 vott. 1 phase 35 19994 SPST Momentary contact reset switch

08215 Heater. 12 KW. 230/240 volt. 1 phase 36 07167 Pressure gauge. 0-30 psi. 1 1/2"

PART

NUMBER

08237 Heater. 9 KW. 440/480 volt. 3 phase 25 19870 Line Strainer. 1/4"

08242 Healer. 9 KW. 220/240 volt. 1 phase 28 13252 Drain Manifold

08165 Healer. 12 KW. 208/220 volt. 3 phase 31 05253 Brass Street Elbow (California only)

08163 Heater. 12 KW. 600 volt. 3 phase 34 19993 DPDT Power switch

DESCRIPTION REFERENCE

plate assembly, mounting studs tor 3" square-

ing sight gauge, two probes and extensions with 12 22131 15 psi Safety Valve

and gasket. 14 03509 Contactor. 50 amp

NUMBER

PART

NUMBER

08217 Healer. 12 KW. 600 volt. 1 phase

DESCRIPTION

Manufacturer reserves right of design improvement or modification, as warranted

Page 62

PRE-INSTRUCTIONS FOR THE LIQUID DESCALING OF

BOILER BASE UNITS

PART NUMBER 106174

Enclosed is our latest instructions for the newest liquid chemical descaler.

Please note: THIS CHEMICAL IS DESIGNED TO BE USED WITHOUT ANY HEAT APPLIED. This

chemical can now be used for the two and three probe boiler base units. Because

the chemical is used without heat, there are some changes in the instructions.

They are as follows:

1. The bottle of our latest liquid descaler has a flip up spout in it like

a shampoo or liquid soap bottle.

2. The design of the bottle and the fact we can not pour the liquid into

the generator through the hand hole plate means you need to build a

special tool. We recommend you use about 24 inches of 1/4" O.D.

flexible tubing attached to a funnel. Remove the needle valve in the

upper sight gauge valve and insert this tube into the generator about

2" inches. Pull the funnel and tubing out front of and above the top

of the generator. Pour the liquid into the funnel.

3. On the right side of the two probe generator is a steam trap. The

bottom connection must be removed and capped so the liquid does not

flow through it.

4. Depending on the style of drain valve and if the unit has a TDS timer,

there are different wiring procedures.

5. The lower compartment steam solenoid valve must be open during the

filling of the generator to allow any air in the top of the generator

to escape.

6. Upon completion of the descale, check the top of the generator to make

sure the chemical has cleaned it.

If there are any questions or problems concerning these procedures, please let

us know right away at 1-800-338-2204.

Page 63

DESCALE PROCEDURE FOR TWO & THREE PROBE GENERATOR BASE STEAMERS

STEP BY STEP PROCEDURE

IMPORTANT WARNING: BEFORE REMOVING THE HAND HOLE PLATE TO DESCALE ANY STEAM GENERATOR, MAKE SURE

THERE IS NO WATER OR PRESSURE BUILT UP IN THE GENERATOR. CHECK THE OUTER SURFACE OF THE GENERATOR TO

MAKE SURE IT IS COLD. TURN THE YELLOW HANDLE ON THE MANUAL FILL VALVE 90 DEGREES TO THE BODY TO

PREVENT ANY WATER FROM ENTERING THE UNIT. THIS LIQUID DESCALER IS DESIGNED TO BE USED WITH NO HEAT

APPLIED TO THE GENERATOR.

STEP #1

Before opening the hand hole plate in the generator make sure the red power switch is in

the off position. Open the electric circuit box in front of the generator and look for two

black square solid state timers mounted on the side. If there are two solid state timers

in the box, this unit has a TDS blowdown. The timer mounted on top is a one second timer.

1. IF THE UNIT HAS AN ASCO DRAIN SOLENOID VALVE, remove the white wire from the

terminal marked number 3 on the TDS timer to prevent the purge from coming on.

2. IF THE UNIT HAS A PARKER DRAIN SOLENOID VALVE, remove the red/white wire from

the terminal marked number 2 on the TDS timer and attach it to L2 on the

terminal block.

To open the hand hole plate, loosen and remove the nut and bar across the generator

opening. Place the end of a two by four on the hand hole plate. Rap the end of the wood

with a hammer in various places until the plate and gasket fall inside the generator.

Remove any scale build-up that can be taken out by hand or with a small vacuum cleaner. IF

THE GENERATOR HAS PREVIOUSLY BEEN REPLACED WITH A NICKEL PLATED ONE, DO NOT SCRAPE OR

SCRATCH THE SURFACE. Assess the scale build-up above the water level on the tubes and the

top to determine the number of descalings that will be needed.

Use 2 quarts of liquid cleaner regardless of the size of the boiler. If there is a heavy

build-up of scale (1/4" or more) on the upper tubes (above the water level) and across the

top of the generator, it will have to be descaled twice.

After removing the scale and determining the number of descalings needed, replace the hand

hole plate with the old gasket still on the plate.

Page 64

Because the chemical is designed to work with no heat applied, the

steam trap on the right side of the new two probe boiler must be closed. Remove the bottom fitting and cap

the outlet side.

STEP #2

Remove the needle valve from the top of the sight gauge located on the front of the generator. This will be the

port of entry for the liquid descaling agent. REMEMBER TO MOVE THE YELLOW HANDLE ON THE WATER

FILL VALVE TO ALIGN WITH THE VALVE BODY. Before applying the descaler, turn on the power switch to

close the drain valve. This will also energize the fill valve.

STEP #3

Using the special funnel and tubing you assembled, squeeze the liquid into the generator through the port the

needle valve was removed from

STEP #4

After the descaling agent has been introduced into the generator, replace the needle valve.

1. Place the lower compartment timer switch in the manual position. As the generator is filling with water,

this will allow any air in the top to escape.

2. To completely fill the generator with water, bypass the water level probe:

a. Remove the black wire at the terminal marked HI on the

water level control board that connects to the water

level probe. b. When the water begins to enter the lower cooking

compartment, CAREFULLY replace the black wire on the

water level control. This will turn the water off.

3. Turn the lower compartment switch back to the timed setting. STEP #5

DO NOT PRESS THE AMBER STEAM SWITCH. THIS CHEMICAL WORKS BEST WHEN HEAT IS NOT APPLIED.

STEP #6

Wait one hour to allow for descaling of the generator. Drain the generator by turning off the red POWER

switch. The drain and fresh water solenoid valves will open for three minutes allowing the generator to flush

out. After draining, fill the generator with fresh water and repeat the flush process by turning off the power

switch.

Page 65

STEP #7

After the generator has been rinsed out, remove the hand hole plate and gasket as explained in STEP #1

Observe the edges and surfaces of the hand hole and the plate for excessive wear and corrosion. Replace the

used hand hole plate gasket with a new one and install new corrosion resistors.

For the corrosion resistors to work properly, the hanger must be firmly connected to the support rod. Make

sure no scale or debris is between the support and the hanger. It must be a metal to metal connection. There

are some two probe generators with no support rods. Lay the corrosion resistors on the floor of the generator.

If the generator is an electric and there are no support rods do not leave the resistors in it. They may come to

rest against the elements and ground them out.

Do not use a gasket sealing material on the hand hole plate gasket. When tightening the nut on the bar, make

sure that at least 1/16" of gasket material is showing on the hand hole plate around the inside of the hand hole.

Reinstall the wire removed from the purge timer in the electric box.

STEP #8

Bring the steamer up to pressure by pressing the red power switch to fill the generator and then the amber

switch when the light comes on. After twenty (20) minutes the generator should have steam in it. Check for

steam leaks around the hand hole. If any leaks are found repeat the process for replacing the gasket.

4

Page 66

WATER LEVEL CONTROL SYSTEM

TROUBLESHOOTING AND REPAIR

General Description of Operation:

The Cleveland Range water level control, P/N 23198, is designed to maintain operating

water level in Cleveland Range steam generators and to ensure that the heat source is

only operated when the generator water level is above a specified minimum level. The

sensing technique for the control relies on the fact that tap water is conductive to

electricity; if two metal electrodes are immersed in a bath of water, electric current

can flow between the electrodes using the water as a conductor. Water is not a good

conductor, like copper, but is conductive enough to be measured using appropriate

electronic circuitry.

The Cleveland Range control is a two probe system having two metallic probes (LOW and

HI) for sensing water in the generator; a COM terminal is placed on the tank. The LOW

probe is placed so that it will come in contact with the water when the water level is

just above the desired water level, enough to protect the heat source. If the water

is of sufficient level and the LOW probe is in the water, a small electrical current

provided by the level control electronics will flow between the probe and COM; this

flow will be sensed by the electronics which in turn will activate the "HEAT" relay to

apply AC power to the HEAT terminal on the control circuit board.

Similarly, the HI probe is located at the desired water level fill (above the LOW

probe level) so that when the water level has reached the desired fill level

electrical current will flow between the HI probe and COM. The action of this probe

is reversed from the previous situation so that when water reaches the HI probe, the

WATER fill relay is deactivated so that AC power to the WF is turned off. When the

water level drops below the HI probe, the WF terminal will be reenergized after a five

second delay. The time delay is to prevent bubbling or turbulence in the generator

from chattering to WATER fill relay or the water valve solenoid.

The control runs on 120 vac and is transformer isolated so that the probes and the

electronics are run at low voltage and are not common to the AC power line.

Note that in many Cleveland Range generators both sensing probes are inserted from the

front top of the unit down into the generator. In this case, the LOW probe will be

the longest and the HI probe will be the shortest.

Page 67

A) SYMPTOMS OF WATER LEVEL CONTROL RELATED PROBLEMS:

STEP

TEST

RESULT

REMEDY

1) Boiler overfills or floods

2) Boiler dry fires (system underfills or doesn't fill)

3) Boiler doesn't fill at all

4) Water fill solenoid chatter

5) Heater contactor chatter

6) Fills but cuts out on LOW WATER before filling again

7) Overfills but does not heat

8) Fills but does not heat

B) POSSIBLE CAUSES:

1) Inoperative water level control circuit board (P/N 23198)

2) Incorrect or damaged wiring to probes

3) Incorrect or damaged wiring from water level board to loads

4) Damaged probes

5) Probes shorted together

6) Scale build-up on probes

C) FAULT ISOLATION PROCEDURE:

Equipment Required: Volt/Ohmmeter (VOM) or Multimeter

1. Is power applied to the control circuit

board? Measure