Page 1

Statement of Responsibilities

This document is for use by experienced and trained Qualified Cleveland Range, LLC Authorized Service

Representatives who are familiar with both the safety procedures, and equipment they service.

Cleveland Range, LLC assumes no liability for any death, injury, equipment damage, or property damage

resulting from use of, improper use of, or failure to use the information contained in this document.

Cleveland Range, LLC has made every effort to provide accurate information in this document, but

cannot guarantee that this document does not contain unintentional errors and omissions.

The information in this document may be subject to technical and technological changes, revisions, or

updates.

Cleveland Range, LLC assumes no liability or responsibility regarding errata, changes, revisions, or

updates.

Qualified Cleveland Range, LLC Authorized Service Representatives are obligated to follow industry

standard safety procedures, including, but not limited to, OSHA regulations, and disconnect / lock out /

tag out procedures for all utilities including steam, and disconnect / lock out / tag out procedures for gas,

electric, and steam powered equipment and / or appliances

All utilities (gas, electric, water and steam) should be turned OFF to the equipment and locked out of

operation according to OSHA approved practices during any servicing of Cleveland Ran ge equipment

Qualified Cleveland Range, LLC Authorized Service Representatives are obligated to maintain up-to-date

knowledge, skills, materials and equipment.

Page 2

CLEVELAND RANGE

SEQUENCE OF OPERATIONS

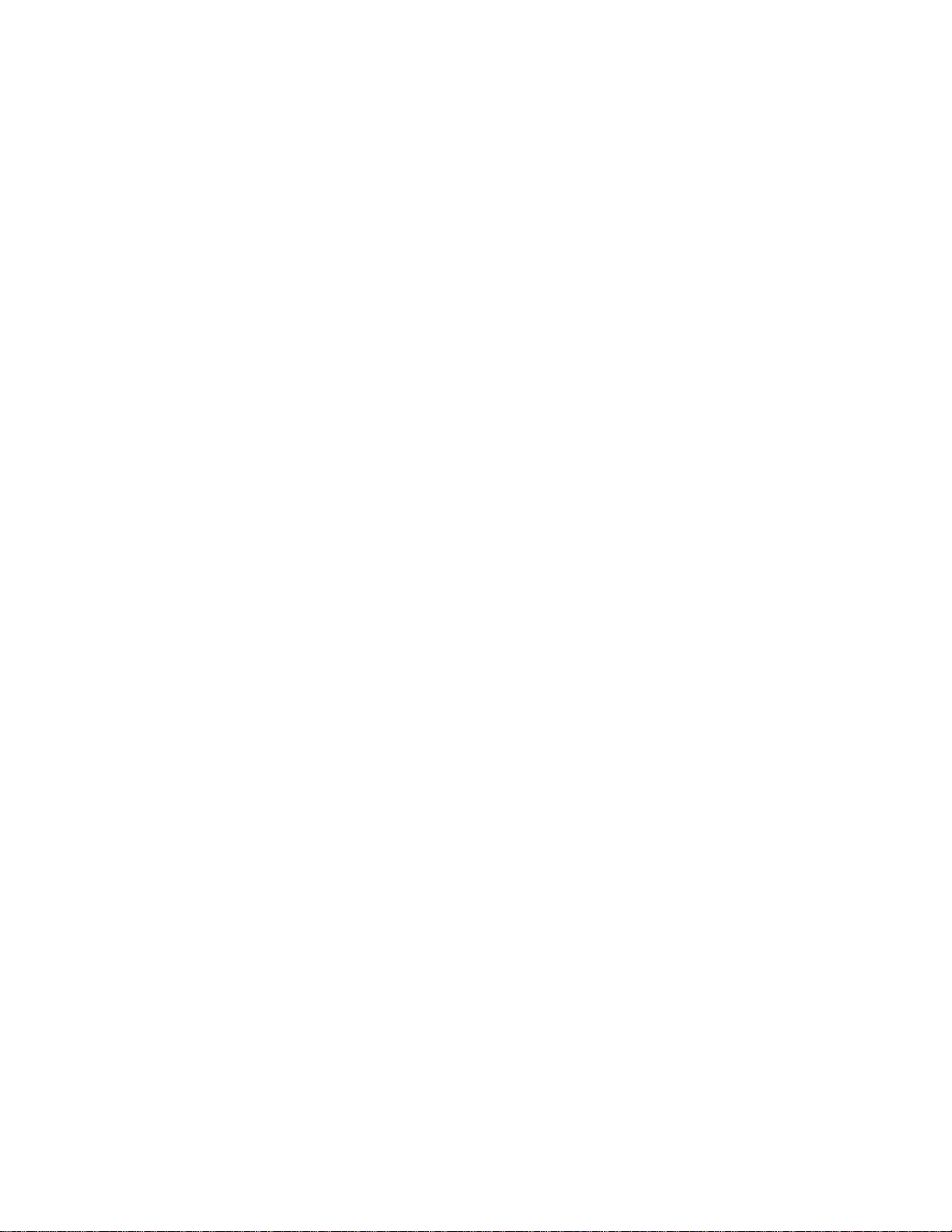

Convection Top

Electronic Timer

1. To turn the unit on, depress the red on/off rocker switch at the base.

• 115 VAC is sent to the red indicator light in the switch

• 115 VAC is sent to the 24 VAC timer transformer.

• 24 VAC is sent to the timer.

• 115 VAC is sent to the timed/manual switch.

2. With the timed/manual switch in the timed position (with time on the timer) or in the manual

position.

• The timer display alternates between “PAUS” and the set time.

• 115 VAC is sent through the optional door switch.

• 115 VAC is sent to the condensate solenoid and cold water is sent to the condensate

spray nozzle.

• 115 VAC is sent to the steam solenoid and steam is sent to the cooking cabinet. There

the steam is directed around the product and pulled down the drain by the condensate

spray.

• When the cooking compartment reaches 193 degrees internally the thermal switch closes

and the timer begins to count down.

3. When the timer counts down in the timed position:

• 115 VAC is removed from the condensate circuit.

• 115 VAC is removed from the steam solenoid.

4. The unit is turned off by depressing the red rocker switch.

Page 3

Page 4

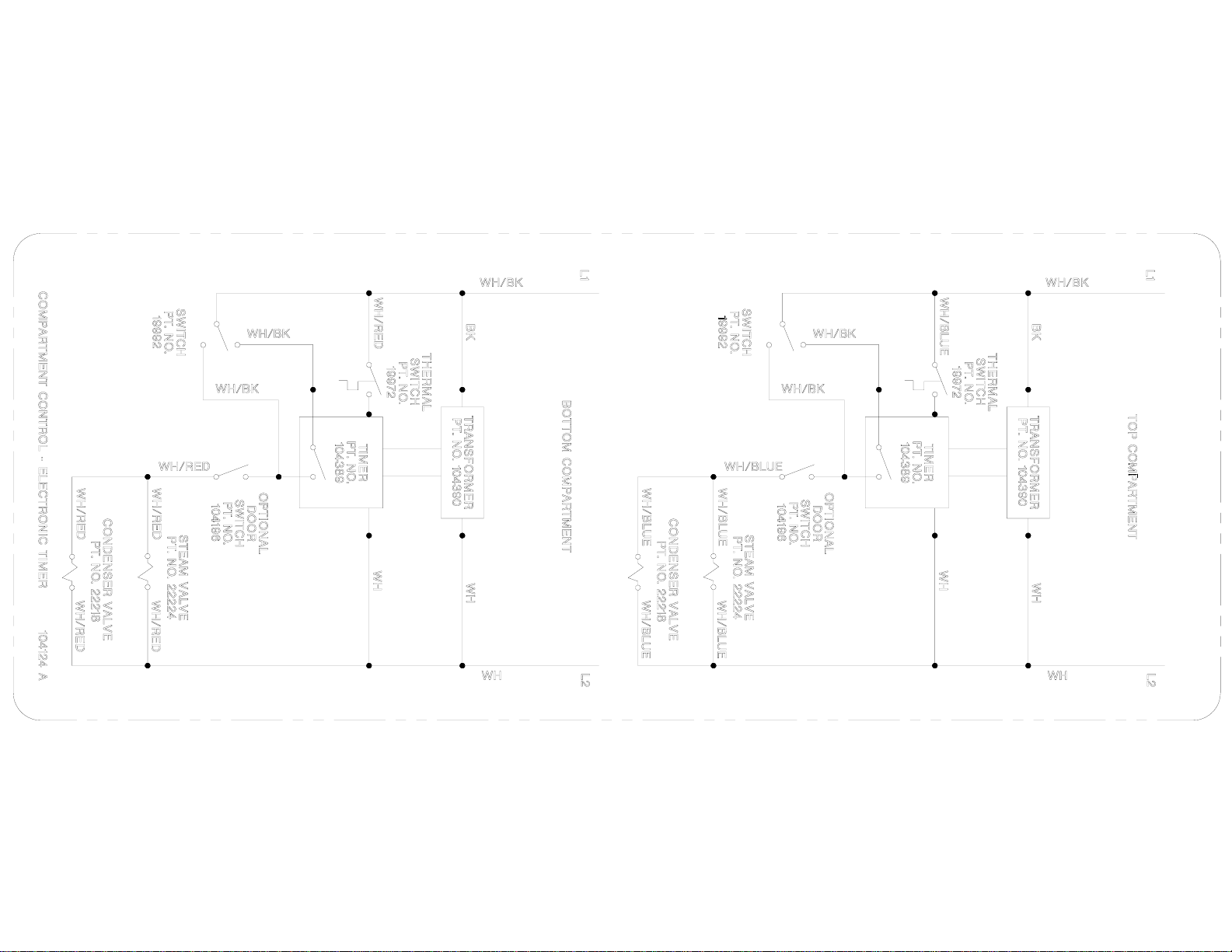

CLEVELAND RANGE

SEQUENCE OF OPERATIONS

Convection Top

Mechanical Timer

1. To turn the unit on, depress the red on/off rocker switch at the base.

• 115 VAC is sent to the red indicator light in the switch

• 115 VAC is sent to the timed/manual switch.

2. With the timed/manual switch in the timed position (with time on the timer) or in the manual

position.

• 115 VAC is sent through the optional door switch.

• 115 VAC is sent to the condensate solenoid and cold water is sent to the condensate

spray nozzle.

• 115 VAC is sent to the steam solenoid and steam is sent to the cooking cabinet. There

the steam is directed around the product and pulled down the drain by the condensate

spray.

3. When the timer counts down in the timed position:

• 115 VAC is removed from the condensate circuit.

• 115 VAC is removed from the steam solenoid.

• 115 VAC is sent to the 3-second timer

• 115 VAC is sent from the 3-second timer to the buzzer for 3 seconds.

4. The unit is turned off by depressing the red rocker switch.

Page 5

Page 6

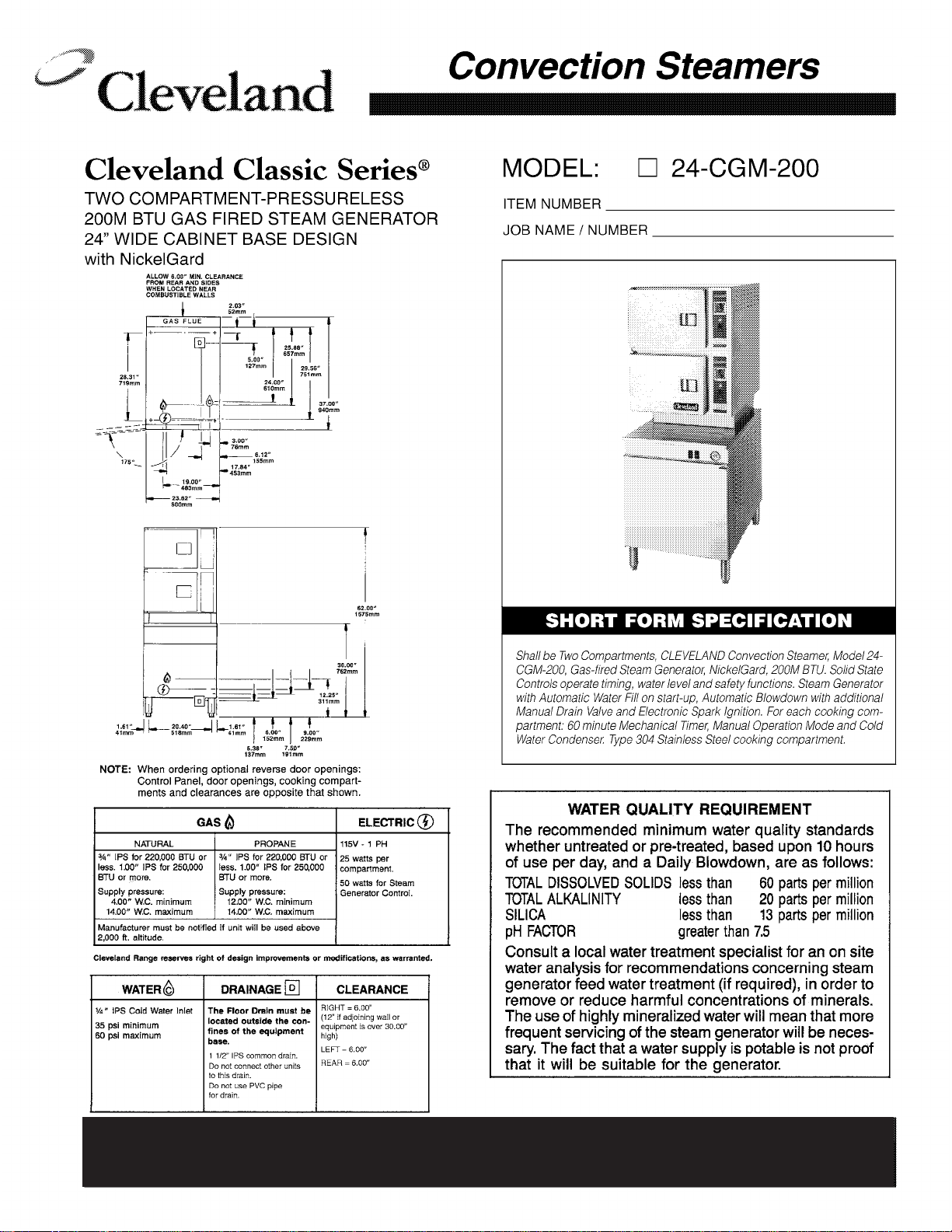

Cleveland Range, LLC

1333 East 179th St., Cleveland, Ohio, U.S.A. 44110

Ph: 1-216-481-4900 Fx: 1-216-481-3782 Visit our Web Site at www.clevelandrange.com

Page 7

CLEVELAND RANGE

SEQUENCE OF OPERATIONS

Gas Boiler Base

1. To turn the unit on, depress the red on/off rocker switch.

x 115 VAC is sent to the terminal block in control box.

x 115 VAC is sent to normally open blowdown valve closing it.

x 115 VAC is sent to L1 and L2 of the water level board.

2. With the water level board energized and no water in the boiler

x 115 VAC is sent from the IND terminal to the low water indicator light.

x 115 VAC is sent from the WF terminal to the fill solenoid.

x The fill solenoid opens and the boiler fills.

x The water fills to the low probe shorting it to ground

x 115 VAC is removed from the IND terminal and the low water indicator light is

de-energized.

x 115 VAC is sent from the HTR terminal through the normally closed contact of

the high-pressure switch to the amber reset switch,

x 115 VAC is sent through the normally closed R1B contact to energize the amber

light.

x If the low probe is not grounded for 20 seconds, 115 VAC is removed from

HTR and sent back to IND energizing the low water indicator light.

3. When the momentary amber switch is depressed 115 VAC is sent to the R1 relay closing it.

x The normally closed R1B contacts open de-energizing the amber light.

x The relay latches itself through contacts 3 and 5 with a jumper to the coil.

x If either the high-pressure switch opens or the low probe circuit on the water level

board opens, then the latch circuit opens.

x When the water level or pressure returns to a safe condition the amber light will

energize and the process may begin again.

x The R1B relay contacts close sending 115 VAC through the normally closed operating

pressure switch to the 24 VAC transformer.

x 24 VAC is sent to the ignition module.

4. With 24 VAC to the ignition module 24 VAC is sent to the gas valve.

x The gas valve is energized.

x The gas valve opens to the initial stage and sends gas to the burner.

x The initial stage for a 200,000 BTU boiler base natural gas is 1.25” W.C.

x The initial stage for a 300,000 BTU Boiler base natural gas is .75” W.C.

x The inital stage for L.P. boiler base is 2.5” W.C.

x A spark is generated at the igniter.

x The gas is ignited and the flame rectifies the AC current.

x The ignition module reads 1.5 micro amps DC current through the ground wire.

Page 8

x If the module does not read 1.5 micro amps DC in 4 seconds it will lock out.

x When the ignition module locks out 24 VAC is sent to the buzzer from the alarm

terminal on the module.

x The gas valve continues to open to 3.5” water column in 6-8 seconds for natural gas

boiler base and 10” W.C. for L.P.

5. The water in the boiler is heated to steam.

x As steam is generated and pressure builds the air is pushed out through the steamtrap.

x When steam goes through the steam trap and heats it to 192 degrees it closes.

6. Pressure builds in the boiler to the set point (8 PSI).

x The operating pressure switch opens and the heat circuit is de-energized.

x When the pressure drops below the set point the heat circuit is energized and the heat

process begins again.

7. Water continues to fill until the high probe is grounded.

x When the high probe is grounded the WF terminal on the water level board is de-

energized.

x The fill solenoid closes until the high probe is ungrounded for 5 seconds.

x If the water level drops below the high probe for more than 5 seconds the WF terminal

is energized and the water fill circuit begins again.

8. When the unit is turned off, by depressing the red rocker switch,

x 115 VAC is removed from the heat circuit.

x 115 VAC is removed from the drain circuit and the normally open drain valve opens

allowing the unit to drain.

x 115 VAC is sent to the 3-minute timer.

x The three-minute timer will energize the fill solenoid for 3 minutes while the steamer

drains.

Page 9

CLEVELAND RANGE

SEQUENCE OF OPERATIONS

Gas Boiler Base

With Secondary Low Water Cut Off Switch

1. To turn the unit on, depress the red on/off rocker switch.

x 115 VAC is sent to the terminal block in control box.

x 115 VAC is sent to normally open blowdown valve closing it.

x 115 VAC is sent to L1 and L2 of the water level board.

x 115 VAC is sent to the open contacts of the low water cut-off switch.

x 115 VAC is sent through the normally closed contacts of the R2 relay to the low water

indicator light.

2. With the water level board energized and no water in the boiler

x 115 VAC is sent from the IND terminal to the normally open contacts of R2A.

x 115 VAC is sent from the WF terminal to the fill solenoid.

x The fill solenoid opens and the boiler fills.

x The rising water raises the float on the low water cut-off switch closing it.

x R2 relay is energized.

x The normally closed contacts R2A open de-energizing the low water indicator

light.

x The normally open contacts of R2A close energizing the low water indicator light.

x The water fills to the low probe shorting it to ground

x 115 VAC is removed from the IND terminal and the low water indicator light is

de-energized.

x If the low water cut off float switch opens the low water indicator light re-

energizes.

x 115 VAC is sent from the HTR terminal to the normally open contacts of R2B.

x With water in the unit and the R2 relay energized, 115 VAC is sent through the

normally closed contact of the high-pressure switch to the amber reset switch,

x 115 VAC is sent through the normally closed R1B contact to energize the amber

light.

3. When the momentary amber switch is depressed 115 VAC is sent to the R1 relay closing it.

x The normally closed R1B contacts open de-energizing the amber light.

x The relay latches itself through contacts 3 and 5 with a jumper to the coil.

x If either the high-pressure switch opens, the secondary low water cut off switch

opens, or the low probe circuit on the water level board opens, then the latch

circuit opens.

x When the water level or pressure returns to a safe condition the amber light will

energize and the process may begin again.

x The R1B relay contacts close sending power through the normally closed operating

pressure switch to the 24 VAC transformer.

x 24 VAC is sent to the ignition module.

Page 10

4. With 24 VAC to the ignition module, 24 VAC is sent to the gas valve.

x The gas valve is energized.

x The gas valve opens to the initial stage sending gas to the burner.

x The initial stage Natural gas pressure for the 200 BTU boiler base is 1.2” W.C.

x The initial stage Natural gas pressure for the 300 BTU boiler base is .75”W.C.

x The initial stage LP gas pressure is 2.5” W.C. for both boiler bases.

x A spark is generated at the igniter.

x The gas is ignited and the flame rectifies the AC current.

x The ignition module reads 1.5 micro amps DC current through the ground wire.

x If the module does not read 1.5 micro amps DC in 4 seconds it will lock out.

x When the ignition module locks out 24 VAC is sent to the buzzer from the alarm

terminal on the module.

x The gas valve continues to open to the second stage in 6-8 seconds.

x The second stage natural gas pressure is 3.5” W.C.

x The second stage LP gas pressure is 11” W.C.

5. The water in the boiler is heated to steam.

x As steam is generated and pressure builds the air is pushed out through the steamtrap.

x When steam goes through the steam trap and heats it to 192 degrees it closes.

6. Pressure builds in the boiler to the set point.

x The operating pressure switch opens and the heat circuit is de-energized.

x When the pressure drops below the set point the heat circuit is energized and the heat

process begins again.

7. Water continues to fill until the high probe is grounded.

x When the high probe is grounded the WF terminal on the water level board is de-

energized.

x The fill solenoid closes until the high probe is ungrounded for 05 seconds.

x If the water level drops below the high probe for more than 05 seconds the WF

terminal is energized and the water fill circuit begins again.

8. When the unit is turned off, by depressing the red rocker switch, 115 VAC is sent to the 3-

minute timer.

x The three-minute timer will energize the fill solenoid for 3 minutes while the steamer

drains.

x 115 VAC is removed from all other circuits.

x The red light in the power switch is de-energized.

Page 11

Page 12

Page 13

Page 14

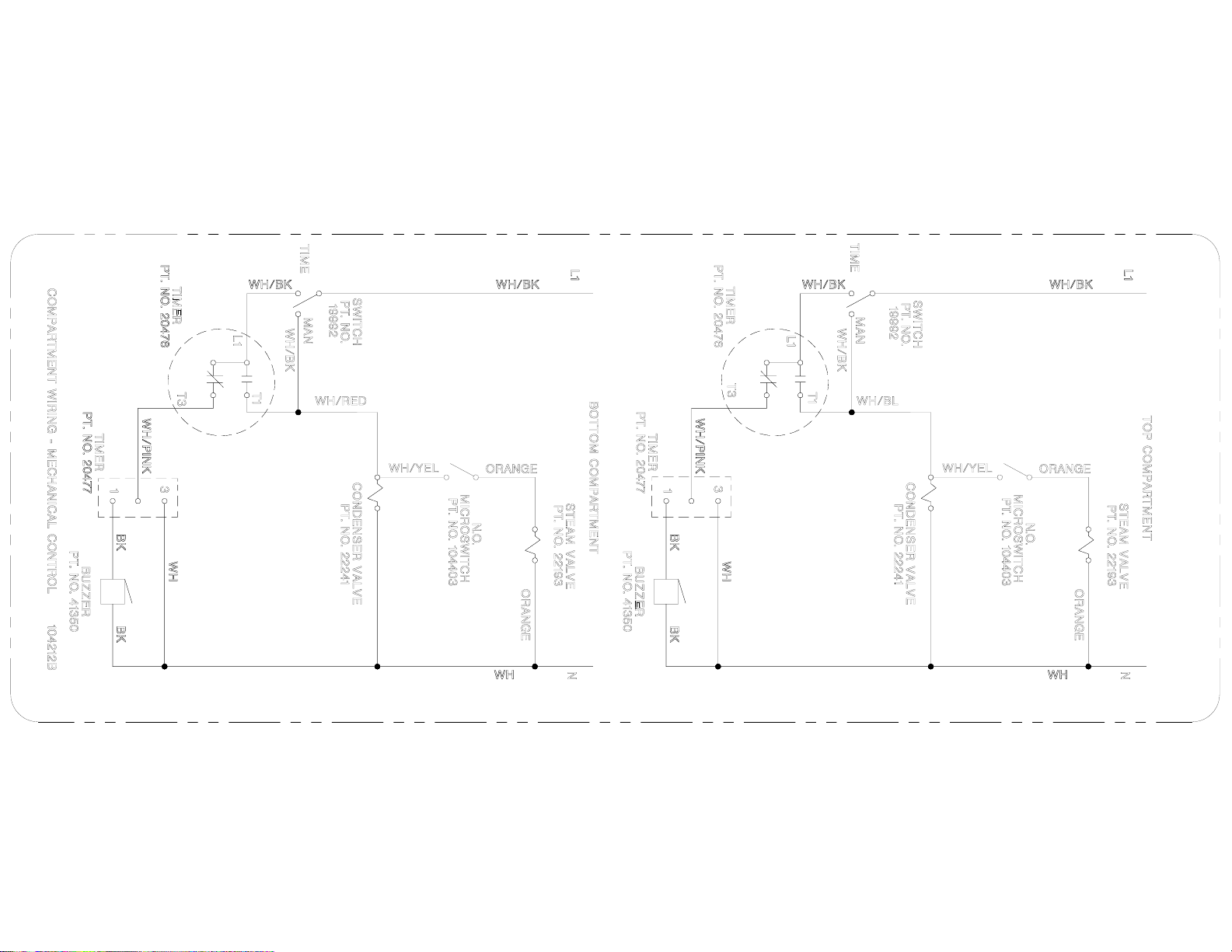

PROBLEM:

Gas Boiler won't

build pressure

Replac e the

water boar d .

Repair

or Replace the

probe circuit.

Yes

Yes

See

Steamer won' t

fill.

Is the red "LOW

Water" light on

with a jumper from

terminals LOW

and C on th e water

board?

No

Repair

or Replace the

probe circuit.

Replac e the

water boar d

No

Is there 120 VAC

between ter m i nals

L2 and HTR on t h e

water board wit h a

jumper b etween

LOW and C?

Replace the R1

relay

Boiler won't build

Is the red ligh t on

Is there water in

No

the sight glass?

Is the red "LOW

Yes

Water" light on ?

Is the Amber ligh t

on in the reset

Is there 120 VAC

terminals L2 and

No

HTR on the water

Is there 120 VAC

No

to terminal 2 on

the R1 relay?

pressure

in the power

switch?

Yes

Yes

No

switch?

No

between

board?

Yes

Yes

No

After depressing

the reset switch,

Yes

does th e A m ber

Is there 120 VAC

to the pri m ar y of

transformer?

Is there 24 VA C at

the secon d ary of

Is there p ow er to

the s t eam er?

Yes

Replac e the

on/off rocker

switch

Replace

the high limit

pressure

switch

light go off?

Yes

the 24 VAC

ignition

Yes

the ignition

module?

No

Yes

No

No

No

Connect power

to st eam er.

With the High

Limit pressu r e

switch

temporarily

bypassed , does

the Amber li g h t go

off when the reset

switch is

depressed?

No

Does this boiler

have the op t ional

Secondary Low

Water Cut Out?

Is there 120 VAC

to the pri m ar y of

the ignition

transformer wit h

the operating

pressure switch

temporarily

bypassed?

Replac e the

ignition

transformer

Yes

No

No

Yes

No

Replace

the operating

pressure

switch

Replac e the

relay.

Yes

With a jumper

from terminal 6 t o

4 on the R2 r elay,

does th e A m ber

light go out with

the reset switch

depressed?

No

With the SLWCO

switch

temporarily

bypassed , does

the Amber li g h t go

off with the reset

switch depressed?

Yes

Replac e the

SLWCO switch

Replace the R1

relay

Replac e the

Reset switch

Yes

Is there flam e at

the burner?

Yes

Is there allot of

steam comin g ou t

the drain?

Yes

Replac e the

steam t rap

No

See Boiler

won't ignite.

No

With

flame and water the

Boiler is making

steam. Check for

leaks.

Page 15

Boiler won't fill.

Yes

PROBLEM:

Gas boiler

won't fill

Is there p ow er to

the s t eam er?

Yes

Is there w at er to

the s t eam er?

Yes

Is there 120 VAC

between the L1

and L2 on the

water board ?

Yes

Is there

120 VAC between

L2 and W F on t h e

water board ?

No

No

No

Supply power

to the s t eamer.

Supply cold

water to the

Replac e the

on/off rocker

No

steamer.

switch .

Remove

the wire from th e H I

terminal on the water

board. Is th er e 12 0

VAC between L2 and

WF?

No

Replac e the

water boar d

Replace wiri n g

to drain

solenoid.

Replac e the

wiring to the

intermittent

blowdown

timer .

No

the s t eam er have

blowdown timer?

No

between ter m i nals

2&3 on the timer?

Replac e the

wiring to the fi ll

solenoid.

Replace the f il l

solenoid

Does

the opt i onal

intermittent

Yes

Is

there 120 VAC

Yes

Replac e the

intermittent

blowdown

timer.

No

No

No

Yes

Is there

120 VAC across

the coil of the f il l

solenoid?

Yes

Is

water leaving the

fill solenoid?

Yes

Is there

120 VAC across

the coil of the

drain valve?

Yes

Is water draining

from the

generator?

Yes

Replac e the

drain valve.

No

Yes

Is there

debris on the HI

probe extension?

Yes

Clean or

replac e t he

probes

extension.

If water

is leaving the fill

solenoid and not

draining from th e

generator where is it

going? check for

leaks..

No

Replac e the

wire to the Hi

probe.

Page 16

PROBLEM:

Gas boiler

won't ignite

Boiler won't heat.

start

Supply gas to

the Steamer.

Is there gas to th e

No

Replac e the

gas valve.

unit?

Yes

With

spark and gas ther e

should be fire.

Recheck the gas

pressure and burners

No

and

igniter.

Yes

Is there gas to th e

manifold (the

proper pressure

for the initi al stage

is printed no t he

side of the valve.)?

Is there 24 VA C to

the ignition

module?

Is there s park t o

the igniter and 2 4

VAC to the gas

val v e f or 4

seconds?

Is there flam e at

No

the burner?

Is there at leas t

1.5 micro amps

DC to the burner

ground terminal at

the ignition

module?

Yes

Yes

Yes

Yes

No

See Boiler

won't build

pressure.

No

No

Replac e the

ignition module

After replacing the

ground wire to the

burner ground

terminal , is th er e

1.5 micro amps

DC to the ignition

module?

No

Replac e the

ignition wire

PROBLEM: Gas Boiler Overfills

Replace the f il l

solenoid

With the HI probe

emersed in water

is there 120 VAC

No

between ter m i nals

L2 and W F on t h e

Replac e the

ignition module

Boiler over fills

water board .?

With a jumper

across termin als

HI and C on the

Yes

waterboard, i s

there 120 VAC

between L2 and

WF?

No

The pr obe

circuit is open.

Check continu i t y of t h e

probe wire and

probe.

Yes

Yes

Replac e ;the

water boar d

Page 17

PROBLEM:

Gas Boiler Over

Pressurizes

(15# Safet y

valve opens)

Replace

operating

pressure

switch

Replac e the

safety valve.

No

service manual f or

Yes

Boiler over

pressurizes

Does operating

pressure switch

open at pr oper

setting (chec k

that st eam er)?

Does the 15#

safety valve op en

with little or no

pressure on the

gauge after i t h as

been repl aced?

No

Delime the

boiler.

Yes

Does the pressure

No

Does the burner

continue to burn

with operating

pressure switch

open?

No

in the gauge

continue to ris e

with no burners

on?

Yes

Yes

Replac e g as

valve.

Replac e the

weeper val ve .

The

ignition module

has gone into

lockout. See

Boiler won't

ignite

PROBLEM: Gas Boiler Stops Producing Steam

Boiler stops

steaming

Does th e am ber

light in the reset

No

switch come on?

Yes

Is the temperature

sensitive dot

(surrounded by a

yellow circ le) on

the water board

white?

No

Replace

the water board . I t h as

reached a temperatur e of

over 180

degrees.

Yes

Does boiler have

the opt i onal

Secondary Low

Water Cut Out?

Yes

Will Boiler stop

making steam

with SLWCO

temporarily

bypassed?

No

No

Yes

Delime boiler

Yes

Are the probes

covered with

scale?

No

Is high pressure

switch opening

prematurely?

No

Replac e the

water boar d

Yes

Replace high

pressure switch

Does SLWCO

open and c l ose as

float is moved up

and down?

No

Replace

Secondary Low

Water Cut Out

switch.

Yes

Install delay

timer for

SLWCO

Page 18

DESCALE PROCEDURE FOR

TWO & THREE PROBE GENERATOR BASE STEAMERS

STEP BY STEP PROCEDURE

IMPORTANT WARNING: BEFORE REMOVING THE HAND HOLE PLATE TO DESCALE

ANY STEAM GENERATOR, MAKE SURE THERE IS NO WATER OR PRESSURE BUILT UP

IN THE GENERATOR. CHECK THE OUTER SURFACE OF THE GENERATOR T O MAKE

SURE IT IS COLD. TURN THE YELLOW HANDLE ON THE MANUAL FILL VALVE 90

DEGREES TO THE BODY TO PREVENT ANY WATER FROM ENTERING THE UNIT. THIS

LIQUID DESCALER IS DESIGNED TO BE USED WITH NO HEAT APPLIED TO THE

GENERATOR.

STEP #1

Before opening the hand hole plate in the generator make sure the red power switch is in the off position.

Open the electric circuit box in front of the generator and look for two black square solid state timers

mounted on the side. If there are two solid state timers in the box, this unit has a TDS blowdown. The

timer mounted on top is a one-second timer. Remove the white wire from the terminal marked number 3

on the TDS timer to prevent the purge from coming on.

To open the hand hole plate, loosen and remove the nut and bar across the generator opening. Place the

end of a two x four on the hand hole plate. Rap the end of the wood with a hammer in various places until

the plate and gasket fall inside the generator.

Remove any scale build-up that can be taken out by hand or with a small vacuum cleaner. IF THE

GENERATOR HAS PREVIOUSLY BEEN REPLACED WITH A NICKEL PLATE D ONE, DO

NOT SCRAPE OR SCRATCH THE SURFACE. Assess the scale build-up above the water level on

the tubes and the top to determine the number of descalings that will be needed.

Use 2 gallons of liquid cleaner regardless of the size of the boiler. If there is a heavy build-up of scale

(1/4” or more) on the upper tubes (above the water level) and across the top of the generator, it will have

to be descaled twice.

After removing the scale and determining the number of descalings needed, replace the hand hole plate

with the old gasket still on the plate.

STEP #2

Remove the safety relief valve from the front of the generator. This will be the port of entry for the liquid

1

Page 19

descaling agent. REMEMBER TO MOVE THE YELLOW HANDLE ON THE WATER FILL

VALVE TO ALIGN WITH THE VALVE BODY. Before applying the descaler, turn on the power

switch to close the drain valve. This will also energize the fill valve.

STEP #3

Using a funnel and tubing, pour the liquid descaler into the generator through the port the safety relief

valve was removed from.

STEP #4

After the descaling agent has been introduced into the generator, replace the safety relief valve.

1. Place the upper compartment timer switch in the manual position. As the generator is filling

with water, this will allow any air in the top to escape.

2. To completely fill the generator with water, bypass the water level probe:

a. Remove the black wire at the terminal marked HI on the water level control board that

connects to the water level probe.

b. When the water begins to enter the upper cooking compartment, CAREFULLY replace

the black wire on the water level control. This will turn the water off.

STEP #5

DO NOT PRESS THE AMBER STEAM SWITCH. THIS CHEMICAL WORKS BEST WHEN

COLD.

STEP #6

Wait 1-2 hours to allow for descaling of the generator. Drain the generator by turning off the red POWER

switch. The drain and fresh water solenoid valves will open for three minutes allowing the generator to

flush out. After draining, fill the generator with fresh water and repeat the flush process by turning off the

power switch.

STEP #7

After the generator has been rinsed out, remove the hand hole plate and gasket as explained in STEP #1.

Observe the edges and surfaces of the hand hole and the plate for excessive wear-and corrosion. Replace

the used hand hole plate gasket with a new one and install new anodes.

For the anodes to work properly, the hanger must be firmly connected to the support rod. Make sure no

scale or debris is between the support and the hanger. It must be a metal to metal connection.

Do not use a gasket sealing material on the hand hole plate gasket. When tightening the nut on the bar,

make sure that at least 1/16” of gasket material is showing all of the way around the inside of the hand

hole plate.

Reinstall the wire removed from the purge timer in the electric box.

2

Page 20

STEP #8

Bring the steamer up to pressure by pressing the red power switch to fill the generator and then the amber

switch when the light comes on. After twenty (20) minutes the generator should have steam in it. Check

for steam leaks around the hand hole. If any leaks are found repeat the process for replacing the gasket.

3

Page 21

1333 East 179th Street

Cleveland, Ohio 44110

Phone: (216) 481- 4900

Fax: (216) 481- 3782

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Loading...

Loading...