Clementoni Science & Play TechnoLogic Mechanics Laboratory 75025 Assembly Instructions Manual

2

MECHANICS

Laboratory

Constructions

-

Stacking two beams

12

-

Stacking beams with two pegs

13

-

Joining beams

14

-

Stacking three beams

15

-

Stacking beams perpendicularly

16

-

Stacking with an angled beam

17

-

Build a square with beams

18

-

Stacking four beams

19

-

Build a cuboid

20

-

Build a simple bridge

21

-

Assemble cogwheels on a rod

22

-

Using pulleys

23

-

Build a class 1 lever: pincers

24

-

Build a class 2 lever: nutcracker

25

-

Build a class 2 lever: wheelbarrow

26

12

to

41

Build a class 3 lever: tongs

-

27

Build the lever's fulcrum and weight

-

28

Assemble and test a mechanically advantaged lever

-

29

Assemble and test a mechanically neutral lever

-

30

Assemble and test a mechanically disadvantaged lever

-

31

Assemble a set of scales

-

32

Build and test a seesaw

-

33

Assemble the test stand for reverse rotation

-

34

Build and test forward rotation

-

35

Assemble and test reciprocating motion

-

36

Build and observe right-angle rotation

-

37

Assemble a vertical gearbox

-

38

Build a horizontal to vertical gearbox

-

39

An ancient war machine: the battering ram

-

40

Build a catapult

-

41

WARNING

In order to ensure correct

function of the electric

motor, a small quantity of

grease is added during the

manufacturing process. As

grease can melt at high

temperatures, it may dirty

the motor. However, it can

simply be wiped off with a

piece of kitchen paper or a

napkin. The grease used is

neither toxic nor hazardous.

Only for use by children aged 8 years and older.

WARNING!

Instructions for parents are included and have to

be observed.

5HDGDQGNHHSWKLVERRNOHWIRUIXWXUHUHIHUHQFH

INSTRUCTIONS FOR SUPERVISING ADULTS: this toy is suitable for children aged 8 years and over. Adult

supervision is recommended during assembly and when handling and installing electrical components.

REMOVING AND INSTALLING THE BATTERIES

Make sure that the equipment is switched off.

1 Use a screwdriver to loosen the screw that secures the cover to the battery chamber.

2 Remove the old batteries.

3 Insert (4 x 1.5V AA/LR6). Make sure the positive and negative ends of the batteries match the direction indi-

cated on the battery chamber.

4 The batteries must be inserted by an adult.

5 Close the battery chamber and tighten the screw.

6 Make sure that the equipment is working properly.

INSERTING THE BATTERIES

Ask an adult for help!

Power supply: 6V DC

Batteries: 4 x 1.5V AA/LR6

Batteries not included.

OTHER RECOMMENDATIONS:

• Batteries are dangerous if swallowed; keep away from children.

• Always remove batteries prior to long-term storage.

• Do not try to open the batteries.

• Do not throw batteries into a fire.

INSTRUCTIONS FOR CORRECT USE OF PRODUCTS WITH REPLACEABLE BATTERIES

WARNING!

• Batteries must be installed by an adult.

• The + and - symbols on the batteries must be lined up correctly.

• Old batteries must be removed from the product.

• The power terminal block must not be short-circuited.

• Never touch the contacts inside the battery case, as this could cause a short circuit.

• The rechargeable batteries must be removed prior to being charged. Only recharge under adult supervision.

• Never attempt to recharge non-rechargeable batteries.

• Different types of batteries or new and used batteries should not be used at the same time.

INSTRUCTIONS FOR BATTERY DISPOSAL

The symbol indicates that dead batteries must be disposed of in accordance with current regulations

for waste disposal. Chemical symbols for mercury (Hg), cadmium (Cd) and/or led (Pb) which appear

below the crossed out wheelie bin symbol indicate that there is a significant percentage of the relative

substance in the battery. These substances are highly damaging to the environment and human health. The

correct disposal of batteries allows their isolation and the targeted treatment of harmful substances, and

allows recycling of precious primary materials, reducing negative effects on persons and the environment.

The disposal of worn-out batteries in landfills or the environment significantly increases the risk of water

pollution. Pursuant to European Directive 2013/56/EU, it is prohibited to dispose of batteries and accumulators

as urban waste and consumers are obliged to participate in separated waste collection so as to facilitate the

treatment and recycling of the same.

2

HOW TO DISPOSE OF BATTERIES:

Discharge the batteries completely by leaving on the product until the batteries have fully run out. Remove

the batteries from the product before disposal. Dispose of all batteries in accordance with current regulations, by using the appropriate containers at an authorised recycling centre or by returning them to the shop

where they were purchased. Returning them is free! Penalties are applied for incorrect disposal.

INSTRUCTIONS FOR THE DISPOSAL OF ELECTRICAL AND ELECTRONIC DEVICES SUBJECT TO SEPARATE WASTE DISPOSAL

IMPORTANT! The crossed out wheelie bin symbol indicates that in European Union member states

(Dir. 2012/19/EU) and in those that adopt separated waste collection systems, all components of the

product marked by this symbol (or indicated as such in the product instructions) are subject to separated waste collection laws at the end of their life. It is prohibited to dispose of such components as

mixed urban waste.

HOW TO DISPOSE OF ELECTRICAL AND ELECTRONIC DEVICES:

• It is mandatory to separately collect those components marked by the symbol (or indicated as

such in the relevant documentation) and deliver them to authorised recycling centres for the purposes

established, or where possible, to return the product for disposal back to the shop when a similar

product is purchased, or for free in the event the external dimensions of the component are less than

25 cm.

• Users of the product play a critical role in ensuring the correct disposal of electrical and electronic

equipment that has reached the end of its life. It is therefore important for each user to be aware of their

role and to always dispose of electrical/electronic waste in accordance with current legislation, thereby

contributing to the correct management of waste and encouraging its reuse, recycling and/or recovery.

WARNING!

Components marked by the symbol contain substances that are harmful to the environment and human

health. It is therefore prohibited to dispose of them as mixed urban waste or together with other domestic waste.

Incorrect disposal may result in damage to the environment and may be punished by the law. These components

should not be used improperly. In particular, it is prohibited to remove the electrical and electronic parts from

the toy or use the toy if damaged. These actions could cause health hazards.

N.B.: The above information only relates to the parts of the toy marked with the prohibitive symbol

(or those parts indicated in the information leaflet as being subject to this restriction).

Other product components (cards, accessories, etc.) and their packaging are not subject to the above described

indications and must be disposed of according to the methods provided for by current standards. These other

components do not need to be delivered to authorised recycling centres for electrical and electronic equipment

or returned to the shop when a new product is purchased.

Domestic users (non-professional) are invited to contact their local retailer, the public waste disposal authorities

or the Customer Service Department of CLEMENTONI S.p.A. (Tel. +39 071 75811; fax +39 071 7581234;

e-mail: info@clementoni. it) for further information about the correct way to dispose of the product.

Registered on the electronic and electrical manufacturers’ register: REGISTRATION IN PROGRESS.

3

INTRODUCTION

The MECHANICS LABORATORY is a construction toy system that enables children to create all kinds of

machines, from simple models like pincers, tongs and carts, to more complex assemblies like cars and

cranes with electric motors.

The illustrated booklet consists of three parts and describes all the steps necessary to build each model.

It is essential to refer to this booklet, starting with Part I and then moving on to Part II and finally Part III.

A class 1 lever: pincers

Car with manual gearbox

and electric motor

Children can use their inventiveness to create their own realistic models which follow the essential principles of

physics and mechanics.

The child's developing mind, aided by their imagination, will seek to understand the relationships and distances

between the various parts as they build the model, contributing to the child's blossoming creativity.

The activities have varying degrees of difficulty and are suitable for children aged 7-8 years and over, depending

on the child’s own individual abilities.

TABLE OF CONTENTS

Safety advice

Instructions for correct use of products with replaceable batteries

Introduction

Parts list

How the pieces are made

Characteristics of the kit components

Activities

Crane with electric motor

page

page

page

page

page

page

page

2

2

4

5

5

5

7

4

PARTS LIST

Double beam 15 holes 4 pcs

Double beam 11 holes 4 pcs

Double beam 9 holes 4 pcs

Double beam 7 holes 4 pcs

Double beam 5 holes 4 pcs

Double beam 3 holes 4 pcs

Beam with pins 4 pcs

Beam with pegs 4 pcs

Right angle gearbox 2 pcs

Single beam 3 holes 4 pcs

Angled beam (top) 4 pcs

Angled beam (bottom) 2 pcs

Short single peg 32 pcs

Long single peg 32 pcs

Short double peg 32 pcs

Long collar 24 pcs

Short collar 24 pcs

Rod 1 2.7 cm long 2 pcs

Single beam 15 holes 4 pcs

Single beam 13 holes 4 pcs

Single beam 9 holes 4 pcs

Single beam 7 holes 4 pcs

Single beam 5 holes 4 pcs

Rod 2 3.6 cm long 4 pcs

Rod 3 5.4 cm long 10 pcs

Rod 4 7.2 cm long 2 pcs

Rod 5 8.1 cm long 2 pcs

Rod 6 11.7 cm long 2 pcs

5

Cogwheel with 10 teeth 1 pc

Cogwheel with 18 teeth 5 pcs

Cogwheel with 26 teeth 1 pc

Car body 2 pcs

Cogwheel with 41 teeth 1 pc

Spool 1 pc

Pulley 4 pcs

Hook 1 pc

Crank 2 pcs

Steering wheel 1 pc

Wheel rim 4 pcs

String (150 cm long) 1 pc

Electric motor 1 pc

Battery compartment 1 pc

Elastic band 3 pcs

Small tyre (for pulley) 4 pcs

Large tyre 4 pcs

6

Toothed rod 1 pc

ACTIVITIES

Before you start building, observe carefully how the parts of the kit are made!

If you get stuck, ask an adult for help.

WARNING!

• Take care when detaching the parts from the plastic frame. Use your hands to gently rotate

each element. Never just pull them off.

• Youwillndthattherodstintothevariousdifferentparts,suchasthe collars and

cogwheels etc., with varying degrees of resistance and tightness. Try adjusting the position of

therodintheholetoachieveabettert,ifnecessary.

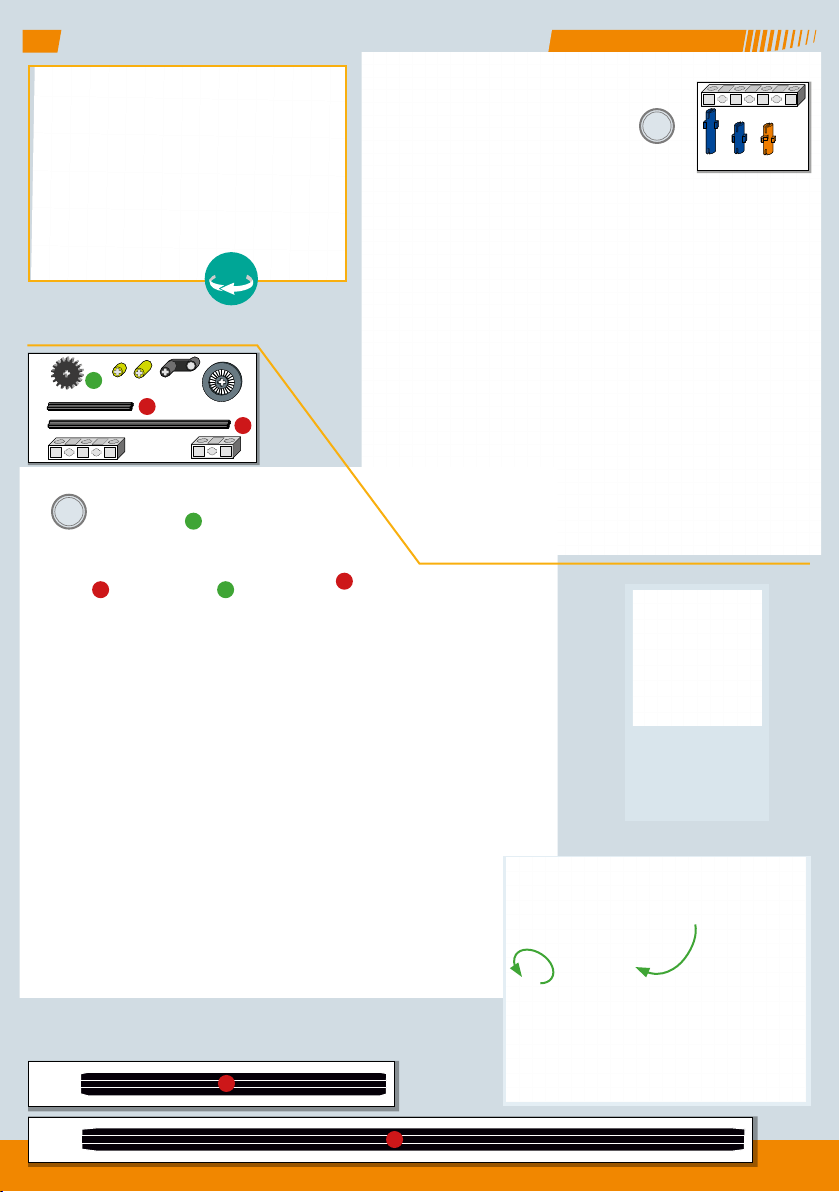

Warning! In the assembly steps, different icons indicate when the model needs to be

rotated, when to tighten the pieces, when to use a beam with pins or one with pegs.

•

Key

Rotate the

180°

model.

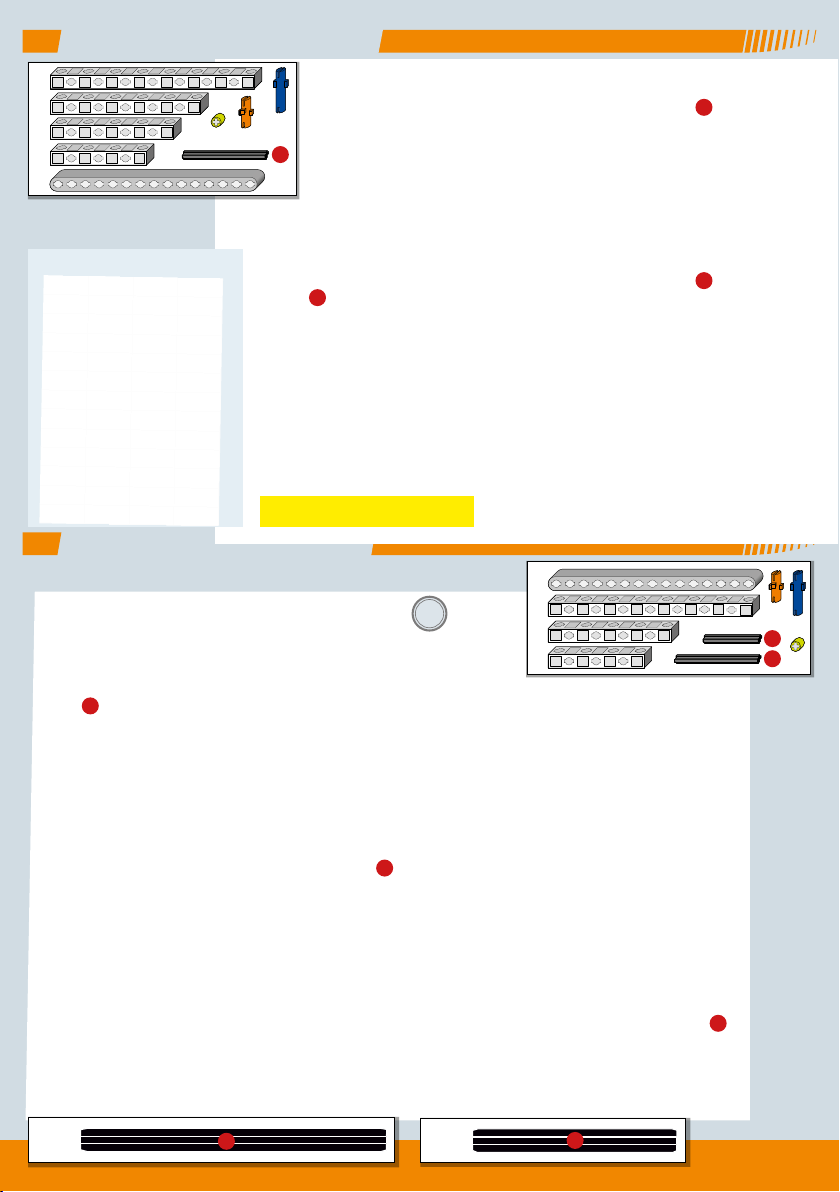

Stacking two beams

12

Stacking beams with two pegs

13

The two pegs make the construction very strong!

The pieces need

to be tightened

Beam

with pins

Beam with

pegs

X1 X2

Assembled beams

X2 X2

Joining beams

14

Assembled beams

X2 X3

Assembled beams

7

Stacking three beams

15

Stacking beams perpendicularly

16

X2

X3

Assembled beams

X1 X2

Stacking with an angled beam

17

8

X2

Assembled beams

X1

X1

Assembled beams

Build a square with beams

18

Stacking four beams

19

X4 X4

Final assembled model

X4 X4 X2

3

3

3

Final assembled model

1:1

3

9

Build a cuboid

20

1

X3

X2

X8

X2

Semi-assembled

model

2

X1

X2

X8

X2

10

Final assembled

model

Build a simple bridge

21

Assemble cogwheels on a rod

22

41

26

18

4

X1

X4

X4

Final assembled

model

X1

X1

41

26

X1

4

18

X1

1:1

Using pulleys

23

Create a pulley system using the pulley

and string.

4

Try it out as a spinning top!

Transform the pulley into a wheel with the elastic band.

2

1:1

2

assembled model

Final

X1

X1 X1

2

11

SIMPLE MACHINES

Since ancient times humans

have made use of many of these

mechanisms to increase our

strength and accomplish much

greater things than we could

with our bodies alone.

Seesaw

Wheelbarrow

Pincers

Nutcracker

Scales

A simple machine is a mechanical device that can be used to balance and overcome RESISTANCE

(weight, resistance force = R) with EFFORT (human strength=E).

Pulley

LEVERS

A lever is a simple machine that is made

up of a rigid bar which can rotate around a

fixed point called the fulcrum.

FULCRUM EFFORTRESISTANCE

• Pairs of levers also obey this principle.

• Levers are classified by the relative positions of the EFFORT, RESISTANCE and FULCRUM.

12

Build a class 1 lever: pincers

24

1

3

2

X4

3

X1

1

X8 X2

X1

X1

X4 X2X2

X2

3

1

X2

1:1

1:1

3

THE FULCRUM lies between the

RESISTANCE and the EFFORT.

1

Final assembled model

3

13

Build a class 2 lever: nutcracker

25

X2

X2

X1

2

X4X2 X2

X2

2

Build a class 2 lever: wheelbarrow

26

X2

X2

X1

X2X2

3

X2

X4 X4

X1

X1

The RESISTANCE lies between

the EFFORT and

the FULCRUM.

Final assembled model

3

14

1:1

1:1

The RESISTANCE lies

between the EFFORT

and the

FULCRUM.

2

Final assembled model

3

Build a class 3 lever: tongs

27

1

X4

X2

X1

X2

X1

X1

X2

3

X4

2

X3

X1

X2

X2

Final assembled model

3

The EFFORT lies

between the

RESISTANCE and

the FULCRUM.

1:1

3

15

Scientific analysis: mechanical advantage with levers

A lever is a simple machine built by man designed to reduce the force needed to do work. There are two

forces that are applied to the bar: one is the EFFORT and the other is the RESISTANCE. A lever provides a

MECHANICAL ADVANTAGE. You can calculate a lever's mechanical advantage by considering the length of

the arms of the EFFORT and RESISTANCE forces. The length of the arms corresponds to the distance from the

fulcrum to the point where the force is applied.

ra

ea

R

FULCRUM

Key: = EFFORT arm

ea

ra

= RESISTANCE arm

E

= EFFORT force

R

= RESISTANCE force

CONDITIONS FOR EQUILIBRIUM x = x

MECHANICAL ADVANTAGE A = /

ASSEMBLE AND TEST THE LEVERS

Build the lever's fulcrum and weight

28

1

E

ra

R E

X1

X4

X1

ea

R

E

X3

X2

X7

16

X2

2

3

X1

3

X4X2

ASSEMBLING THE

WEIGHT

X1

X1

X2

X2

X1

X1

Assembled weight

In Activities 29-30-31 try moving the fulcrum and then applying downward pressure to the EFFORT arm with your hand to see the differences

between the levers.

Assemble and test a mechanically advantaged lever

29

FULCRUM

Find the equilibrium of this type of mechanical

EFFORT

device: position the weight (RESISTANCE) on one

side of the lever and gently press down with your

hand (EFFORT) on the other side.

3

3

3

X2

X2

X2

X2

X1

RESISTANCE

X2

X2

X2

X2

Note the position of the fulcrum!

• The EFFORT arm is longer.

• The EFFORT is less than the RESISTANCE.

TRY IT OUT!

1:1

3

Note: slide

a collar

onto

the rod at the

fulcrum to

secure

the

lever, as shown

.

Final assembled model

17

Assemble and test a mechanically neutral lever

30

FULCRUM

Find the equilibrium of this type of

mechanical device: position the weight

(RESISTANCE) on one side of the lever

and gently press down with your hand

(EFFORT) on the other side.

Note the position of the fulcrum!

• The arms are the same.

• The EFFORT is equal to the RESISTANCE.

EFFORT

RESISTANCE

Note: slide a collar

onto the rod at the

fulcrum to secure

the

TRY IT OUT!

Final assembled model

Assemble and test a mechanically disadvantaged lever

31

FULCRUM

X1

Find the equilibrium of this type of mechanical

device: position the weight (RESISTANCE) on

one side of the lever and gently press down

with your hand (EFFORT) on the other side.

EFFORT

X1

lever, as shown

.

Note the position of the fulcrum!

• The RESISTANCE arm is longer.

• The EFFORT is greater than the

RESISTANCE.

TRY IT OUT!

18

RESISTANCE

Note: slide

a collar

the rod at the

fulcrum to

secure

lever, as shown

Final assembled model

onto

the

.

Assemble a set of scales

32

X2

X2

X1

X2

X1

X3

X4

X3X6

3

3

The scales are is a class 1 lever

Final assembled model

Build and test a seesaw

33

2

3

TRY IT OUT!

3

X2

1

X2

X2

X2

X2

X1

X2

X4

2

3

X6

1:1

3

2

3

1:1

2

19

In the third century BC, Archimedes

was a great scientist and experimenter

with levers.

Note

: the lever of the seesaw must

rotate freely around the fulcrum.

X2

X4

2

Try it yourself: find the equilibrium

of the seesaw by varying the weight

and distances from the fulcrum of

the Resistance and Effort forces.

TRY IT OUT!

20

The seesaw is a class 1 lever

Final assembled model

COGWHEELS

Cogwheels transmit motion between suitably positioned axles (rods) via teeth.

• In a pair of cogwheels, if one turns in one direction the other turns in the opposite direction. One

of the two wheels transmits the motion (driving wheel) while the other receives it (driven wheel).

•

To maintain the same direction of rotation a third cogwheel must be inserted between the two.

• With two different cogwheels, the smaller one, with only a few teeth, is called the pinion, while

the other one, with lots of teeth, is called the crown wheel. Multiple cogwheels make up a gear

train.

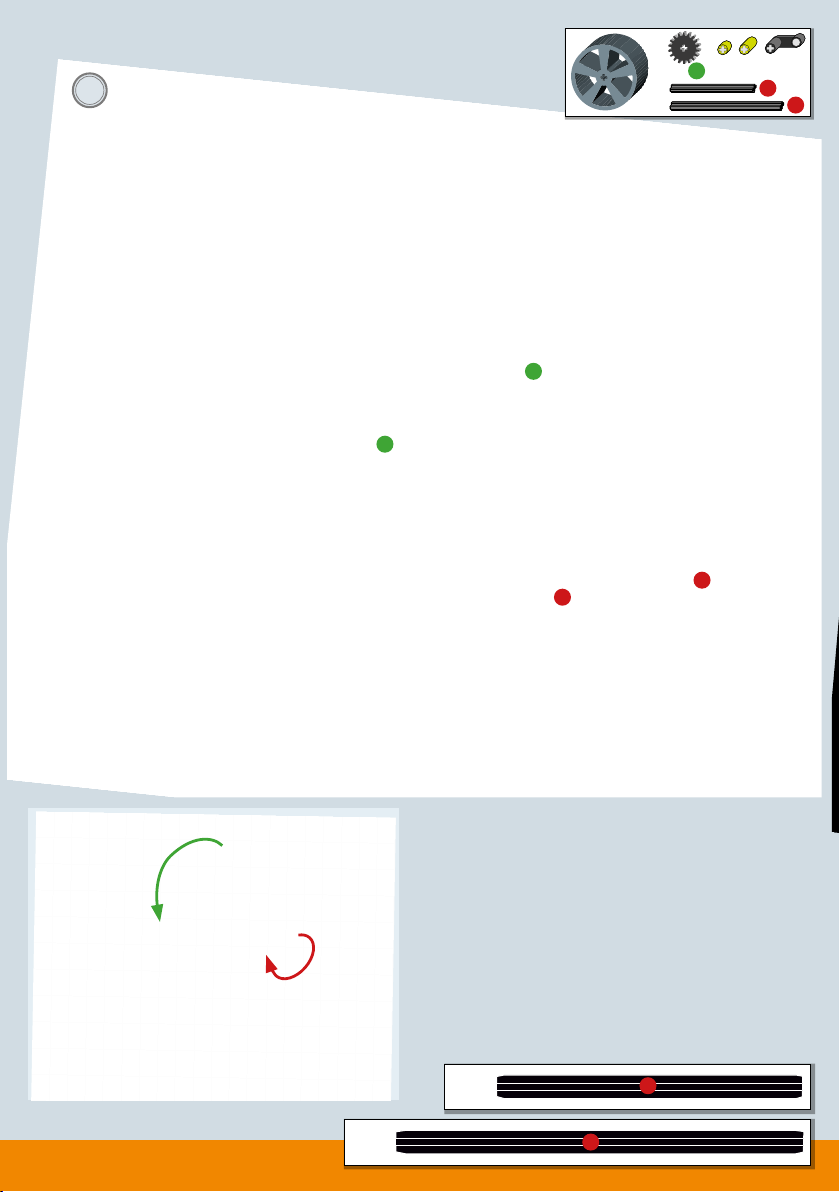

Assemble the test stand for reverse rotation

34

X2

X2

X4

X2

X12

1

Assembled

stand

21

X1

X2

X2

2

18

18

X1

X1

X1 X1

18

3

4

Anticlockwise

22

Clockwise

Final assembled model

1:1

1:1

3

4

3

4

Build and test forward rotation

35

X1

X3

18

X2

X1

X1X1X4

3

4

Stand assembled in

Activity 34

12

18

18

18

4

3

3

Clockwise

Clockwise

1:1

1:1

3

4

Final assembled model

23

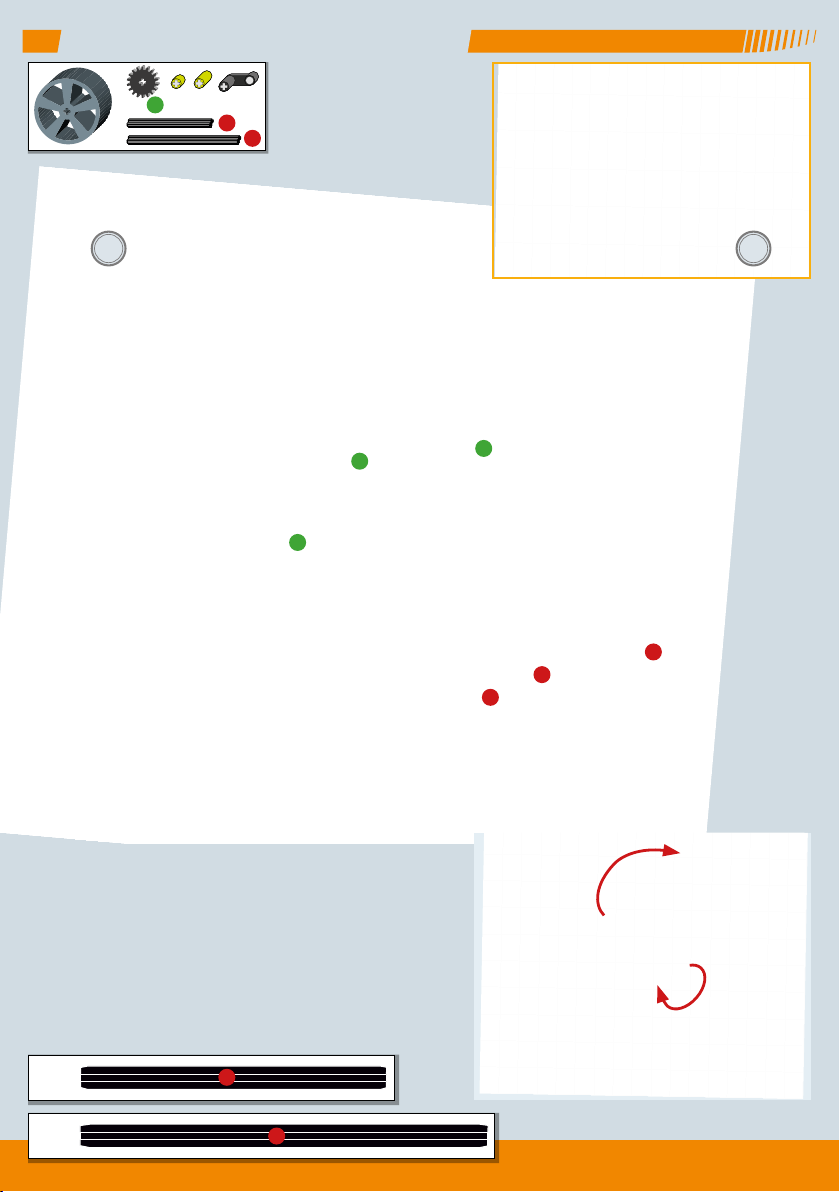

Assemble and test reciprocating motion

36

X1

X2

X2

41

X1

2

X1

26

4

X5X4

X1

X1

X1

Stand assembled in

Activity 34

2

4

4

1

180°

26

24

Final assembled model

1:1

41

2

1:1

4

2

2

Build and observe right-angle rotation

37

Stand assembled in

Activity 34

1

180°

2

X3

X4 X2X4

X2

18

X2 X1

X5

X1

X1

X2

3

X1

3

6

X1

6

18

18

3

The two cogwheels

must engage with

each other at right

angles, with the two

rods almost touching.

1:1

1:1

3

6

Final assembled model

25

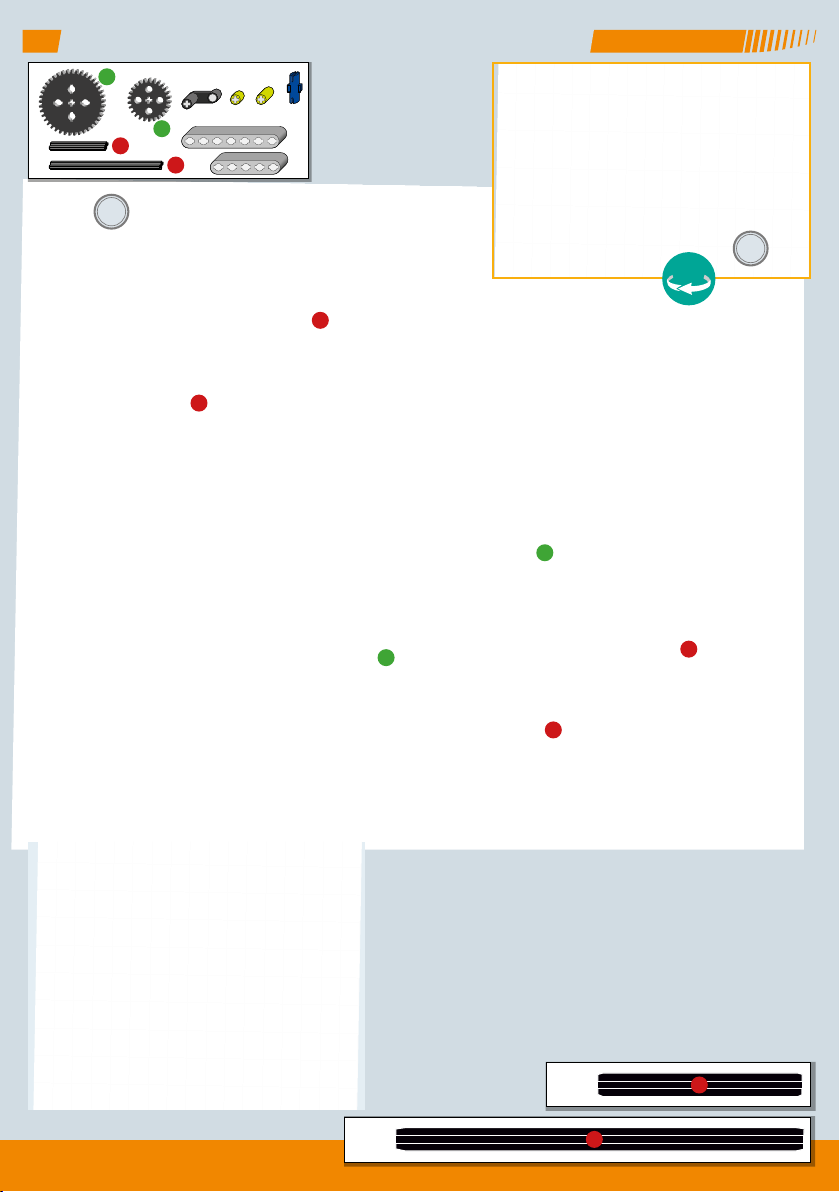

Assemble a vertical gearbox

38

X2 X4

X2

X1

X1

Stand assembled in

Activity 34

12

180°

3

41

X1

26

41

180°

1:1

X1

10

X1

X1

X1X2X1

2

4

10

2

4

Final assembled model

2

1:1

4

Build a horizontal to vertical gearbox

39

26

X2

X1

X1

2

2

Stand assembled in

Activity 38

1

2

GEAR RATIO

Watch the cogwheels carefully as they turn and compare the

number of rotations completed by each wheel. By the time the

larger cogwheel has completed one rotation the smaller one

willhavecompletedfour.Youcanconrmthisbydividingor

working out the ratio between the number of teeth on each

cogwheel.

Example: how to calculate the gear ratio.

41 teeth (larger wheel)

10 teeth (smaller wheel)

= 4.1 rotations

1:1

26

Final assembled model

2

27

An ancient war machine: the battering ram

40

1

X4

X2 X2

X2

Front

X2

X1

26

X1

X2

X1

X3

X1

1

2

3

X1

41

X3X2

X2

5

2

28

1:1

3

5

41

1

1:1

1

3

5

3

3

2

26

1:1

1:1

2

1

X2X6

X1

X4

X4

X1

X1

4

X1

X2

X1

X10

3

3

X2

X3

X1

X1

4

Final assembled model

3

1:1

1:1

3

4

Front

3

4

29

Build a catapult

41

X4

X1

5

X1

Technical facts and curiosities

Third century BC

Archimedes perfected the

catapult, a war machine in

use in Greece at the time of

Alexander the Great.

It is a torsion machine which,

in his time, drew its energy

from tightening bundles of

rope and hair (torsion ropes).

On release, the tension in the

ropes launched the bowl of

the catapult forwards,

hurling large rocks and stone

into the air.

Technical and scientific

information

X2

1

5

2

X2

X2

X4 X2X2

Its design was derived from

the study of physics and

mathematics.

The dimensions of the

elastic bands (torsion ropes)

were chosen in relation to

the weight of the stones

and distance to the target

(range).

30

1:1

5

X3

X2

X1

3

X2

2

X2

X2

X6

3

3

3

X1

X4

X1

X1

X2

6

3

2

4

1:1

1:1

2

3

Final assembled model

1:1

1:1

3

6

3

6

31

Clementoni S.p.A.

Zona Industriale Fontenoce, s.n.c.

- 62019 Recanati (MC) - Italy

Tel. +39 071 75 811 - Fax +39 071 75 81234

www.clementoni.com

Loading...

Loading...