ClearSpan 106186 User Manual

CLEARSPAN™ GREENHOUSES

ClearSpan™

Round Style Clear View Greenhouses

©2011 ClearSpan™

All Rights Reserved. Reproduction

is prohibited without permission.

Revision date: 07.22.11

Photo may show a different but similar model.

STK# DIMENSIONS

106185 20' W x 10' 7" H x 20' L

106186 20' W x 10' 7" H x 24' L

106187 20' W x 10' 7" H x 36' L

106188 20' W x 10' 7" H x 48' L

1

CLEARSPAN™ GREENHOUSES

LOCATION

Choosing the proper location is an important step before

you begin to assemble the structure.

The following suggestions and precautions will help you

determine whether your selected location is the best

location.

YOU MUST READ THIS DOCUMENT BEFORE YOU

BEGIN TO ASSEMBLE THE SHELTER.

Thank you for purchasing this ClearSpan™ greenhouse.

When properly assembled and maintained, this product will

provide years of reliable service. These instructions include

helpful hints and important information needed to safely

assemble and properly maintain the greenhouse. Please

read these instructions before you begin.

If you have any questions during the assembly, contact

Customer Service at 1-800-245-9881 for assistance.

SAFETY PRECAUTIONS

Wear eye protection.•

Wear head protection.•

Wear gloves when handling metal tubes.•

Use a portable GFCI (Ground Fault Circuit Interrupter) •

when working with power tools and cords.

Do not climb on the greenhouse or framing during or •

after construction.

Do not occupy the greenhouse during high winds, •

tornadoes, or hurricanes.

Provide adequate ventilation if the structure is •

enclosed.

Do not store hazardous materials in the greenhouse.•

Never erect the structure under power lines.•

Identify whether underground cables and pipes are •

present before preparing the site or anchoring the

structure.

Location should be away from structures that could •

cause snow to drift on or around the building.

Do not position the greenhouse where large loads •

such as snow and ice, large tree branches, or other

overhead obstacles could fall.

Always check local building codes before you begin. •

SITE

After choosing a location, proper preparation of the site is

essential. The following site characteristics will help ensure

the integrity of the structure.

A level site is required• . The site must be level to

properly and safely erect and anchor the structure.

If the site is not level, use footings to provide a secure •

base to assemble the structure. Pre-cast concrete

blocks, pressure-treated wood posts, or poured

footings are all acceptable when properly used. (Some

shelters use ground posts or rafter feet.)

Drainage: Water draining off the structure and from •

areas surrounding the site should drain away from the

site to prevent damage to the site, the structure, and

contents of the structure.

Provide proper ingress and egress to prevent •

entrapment.

ANCHORING INSTRUCTIONS

Prior to assembling this greenhouse, please read the

MUST READ document included with the shipment.

WARNING: The anchor assembly is an integral part

of the greenhouse construction. Improper anchoring

may cause greenhouse instability and failure of the

structure. Failing to anchor the greenhouse properly

will void the manufacturer’s warranty and may cause

serious injury and damage.

2

WARNING: The individuals assembling this structure

are responsible for designing and furnishing all

temporary bracing, shoring and support needed during

the assembly process. For safety reasons, those who

are not familiar with recognized construction methods

and techniques must seek the help of a qualified

contractor.

Revision date: 07.22.11

ASSEMBLY PROCEDURE

Following the instructions as presented will help ensure

the proper assembly of your greenhouse. Failing to follow

these steps may result in an improperly assembled and

anchored greenhouse and will void all warranty and

protection the owner is entitled to.

The steps outlining the assembly process are as follows:

Verify that all parts are included in the shipment. Notify 1.

Customer Service for questions or concerns.

Read these instructions, the Must Read document, and 2.

all additional documentation included with the shipment

before you begin assembling the greenhouse.

Gather the tools, bracing, ladders (and lifts), and 3.

assistance needed to assemble the greenhouse.

Check the weather 4. before you install the roof cover

and any panels (if equipped). Do not install covers or

panels on a windy or stormy day.

Re-evaluate the location and site based on the 5.

information and precautions presented in the

documentation included with the shipment.

Prepare the site (if applicable).6.

Assemble the frame components in the order they are 7.

presented in these instructions.

Assemble the frame including the struts (if equipped). 8.

Consult the 9. MUST READ document and properly

anchor the assembled frame.

Install the end wall framing. (End walls are optional 10.

items for some shelter types.)

Install, tighten, and secure the end wall end panels and 11.

doors.

Install, tighten (if applicable), or secure the main cover. 12.

Read the care and maintenance information at the end 13.

of these instructions.

Complete and return all warranty documents as 14.

instructed.

LIST OF WORDS AND PHRASES

CLEARSPAN™ GREENHOUSES

Band Clamp: • Clamp used to connect the end wall

framing to the rafter pipe. In some cases, band

clamps are also used to connect diagonal struts to the

assembled frame.

Clip or Fabric Clip:• A short, half-section piece of

conduit (cut lengthwise) used to secure the end panel

cover to the leg or rafter assembly. The clip or fabric

clip is typically fastened in place using self tapping Tek

screw.

Conduit: • An assembly of pipes used to secure the

main cover and end panels (if equipped). Purlins

and some strut assemblies also consist of connected

pipes to form a conduit. Each pipe joint of a conduit

assembly is secured with a self-tapping Tek screw to

prevent separation. Some conduit assemblies are used

to secure larger end panels and main covers. These

conduits typically consist of sections of PVC tubing

glued at the joints.

Cross Connector: • Any one of the metal brackets

used to "connect" or secure a purlin to a rafter. Crossconnectors are typically pictured on the Pictorial Parts

Guide page or in the Quick Start section (if present).

End Panel: • Fabric or material used to cover the end

wall assemblies. End wall assemblies are optional for

many shelters.

Must Read Document:• This document includes

building and shelter anchoring instructions, steps for

end wall reinforcement, safety precautions, and notices

and warnings. The Must Read document is sent with

all shelters and buildings. If you did not receive a Must

Read document, contact Customer Service to request

one.

On-Center:• Term used to describe a measurement

taken from the vertical center of the rafter or frame

member to the vertical center of another.

Purlin:• The pipe assembly that runs perpendicular to

the rafters or framework that supports the main cover.

Purlins are found on the sides and roof areas of the

assembled frame, are evenly spaced, and typically run

from the front to the back of the shelter.

Plain or Straight Pipe:• A term used to describe a pipe

that has the same diameter or width throughout its

entire length.

Before you begin, it is important to become familiar with the

words and phrases used in this instruction manual.

These words and phrases are common to most

ClearSpan™ shelters and identify the different parts of

the shelter. (Some are used in this document. Others may

not apply to this particular shelter.) These terms describe

the shipped parts and can also be found on the materials

list/spec sheets included with the shipment. To aid in the

assembly, read through the following definitions before you

begin to assemble your shelter.

Revision date: 07.22.11

Strut:• A strut is usually a length of pipe with two

flattened ends and is used for diagonal bracing of the

shelter frame. A strut is typically secured to the frame

work by special brackets and bolts.

Swaged End or Swaged Pipe:• The term “swaged''

refers to the tapered end of the pipe or tube. Swaged

ends of a pipe can be inserted into couplers and the

straight ends of other pipes.

Tek Screw:• A self-tapping fastener used to secure pipe

joints and to fasten brackets to rafters.

3

CLEARSPAN™ GREENHOUSES

REQUIRED TOOLS

The following list identifies the main tools needed to

assemble the shelter. Additional tools and supports may be

needed depending on the structure, location, and

application.

SPECIAL NOTE: Baseboards for Frame

These instructions describe installing a baseboard

(recommended) at ground level along each side of the

frame. The baseboard runs from the front to the back of the

frame.

Tape measure or measuring device•

Marker to mark locations on the pipes•

Variable speed drill and impact driver (cordless with •

extra batteries works best)

Metal-cutting saw•

Wrenches and impact socket set, or an adjustable •

wrench

Scissors, utility knife, or tin snips•

Hammers and gloves•

Adjustable pliers and self-locking pliers•

Ladders, work platforms, and other machinery for lifting •

designed to work safely at the height of the building

Rope/cable for temporary rafter bracing during frame •

assembly

UNPACK AND IDENTIFY PARTS

The following steps will ensure that you have all the

necessary parts before you begin to assemble the shelter

frame.

This baseboard is not included with the shipment and must

be supplied by the customer. Treated or recycled plastic

lumber works well for a baseboard.

Use the included 1/4" x 4" (FAH009B) carriage bolts

and the 1/4" zinc nuts (FALB01B) to attach a customersupplied baseboard. Depending on the dimensions of the

baseboard, alternative customer-supplied fasteners may be

needed.

During the installation, align the baseboard with the center

of the end rafter. Do not allow the baseboard to extend

beyond the end rafters at either end of the frame. Doing so

will interfere with the installation of the end wall corrugated

panels.

The baseboard, when installed properly, helps prevent the

ground posts from sinking into the ground when anchored.

Depending on the building, it also provides a surface to

attach struts or other building components.

Consult these instructions or contact Customer Service for

additional information regarding baseboards.

Unpack the contents of the shipment and place where 1.

you can easily inventory the parts. Refer to the Bill of

Materials/Spec Sheets.

Verify that all parts listed on the Bill of Materials/Spec 2.

Sheets are present. If anything is missing or you have

questions, consult the Pictorial Parts Guide and all

diagrams for clarification, or contact Customer Service.

NOTE: At this time, you do not need to open the plastic

bags containing smaller parts such as fasteners or

washers (if equipped).

QUICK START GUIDE

For a quick overview of the building and its components,

consult the information and diagrams in the Quick Start

section near the back of these instructions.

4

Revision date: 07.22.11

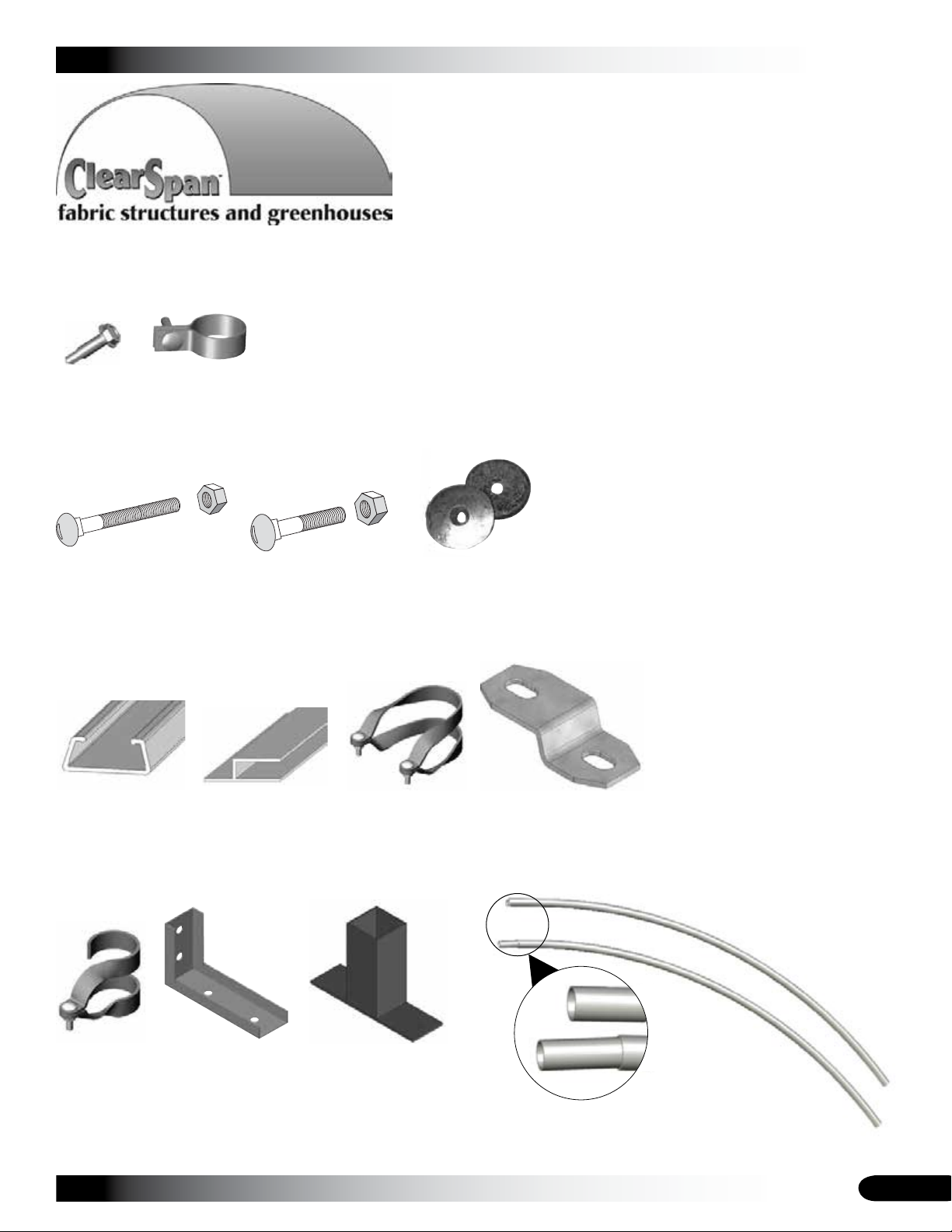

The following graphics and photos will help you identify the

different parts. (Some parts are not shown.)

CLEARSPAN™ GREENHOUSES

FA4482B

Tek Screw

(short)

FAH009B & FALB01B

Carriage Bolt & Hex Nut

102197

Aluminum

U-Channel Profile

QH1402

Band Clamp

104548

End Cap Profile

Doors/Fans/Vents

FAH320B & FALB32B

Carriage Bolt & Hex Nut

102548

Cross Connector

102921

Neo-bonded

Galvanized Washers

104074

Square-to-Round Tube

Connect Bracket

102856

End Clamp

Revision date: 07.22.11

QH1330

Angle Bracket

104624

Square Tube Fitting

Plain

Swaged

Swaged and Plain Rafter Sections

5

CLEARSPAN™ GREENHOUSES

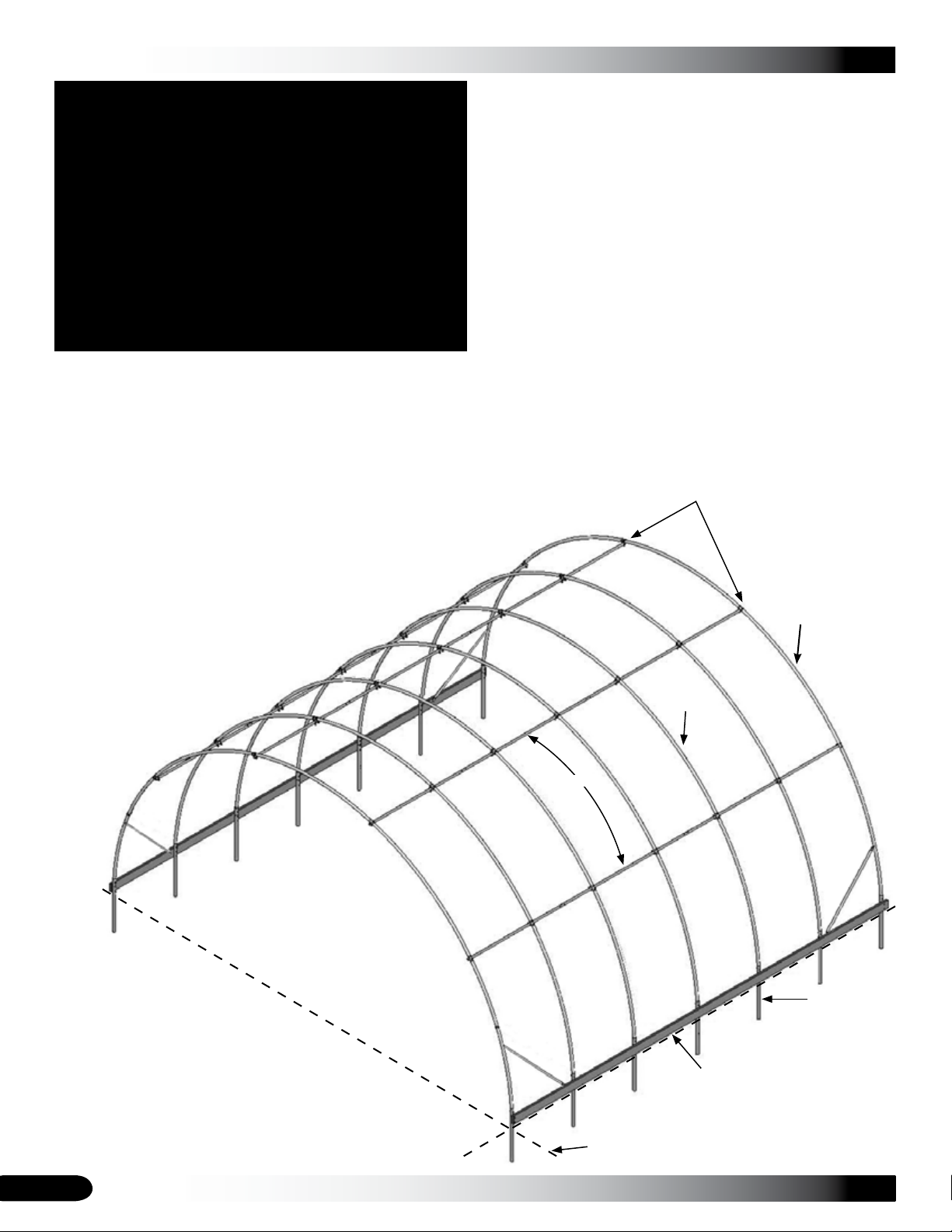

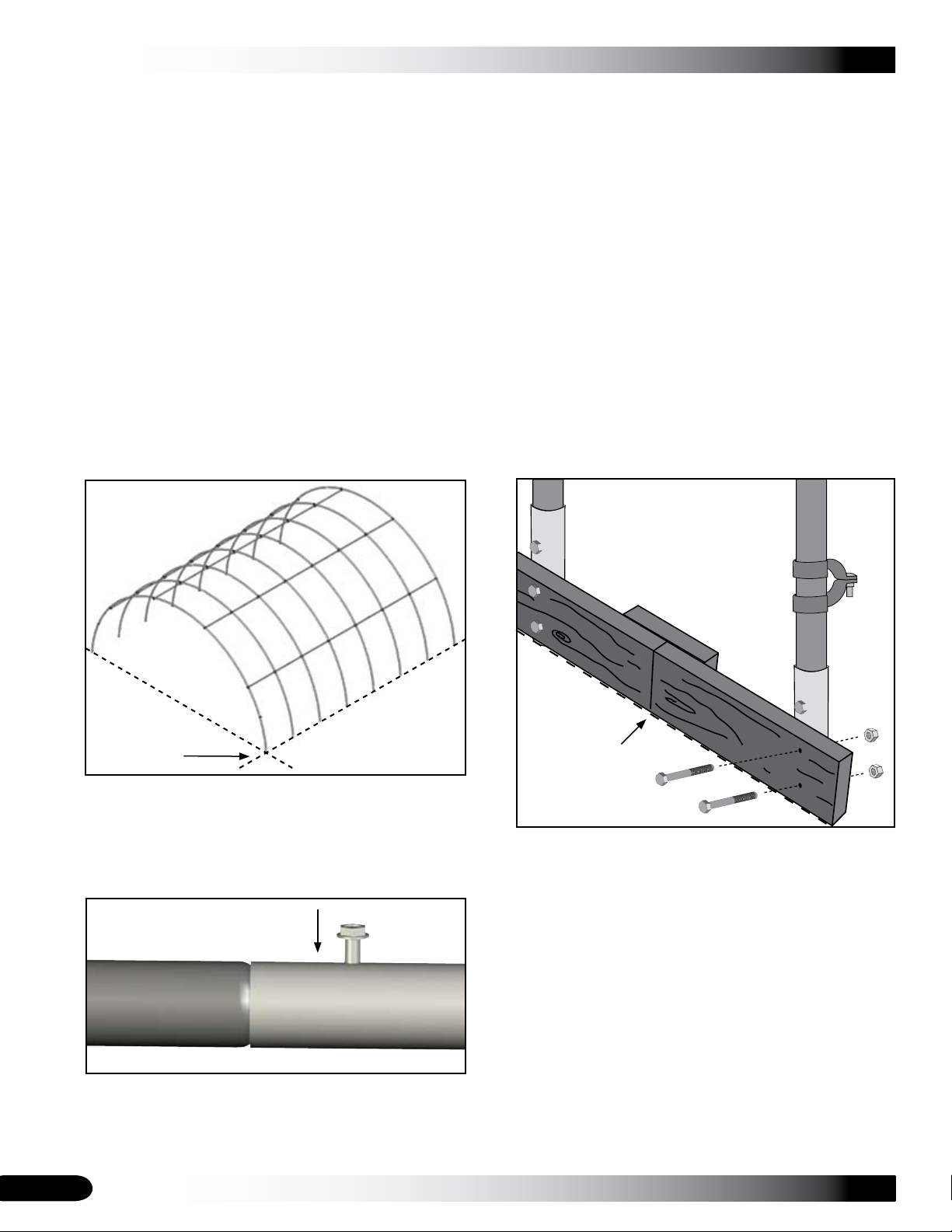

OVERVIEW

This section describes assembling your Round Style

Greenhouse. For details, please see section, Assembling

the Round Style Greenhouse Components. See illustration

below to identify main parts of greenhouse.

Locate the required parts for each assembly procedure.1.

Assemble the rafters and frame.2.

Round Style Clear View

Greenhouse

ATTENTION: Position purlins evenly during the

frame assembly. Use the rafter pipe joints as

guides when installing the end clamps, cross

connectors, and purlins.

Attach customer-supplied baseboards and install struts.3.

Prepare and attach end panels. 4.

Install the polycarbonate roof panels.5.

Assemble and install sliding doors.6.

Interior

Rafter

Purlins

End Rafter

Frame shown may differ slightly from actual frame.

6

Ground

Post

Baseboard is

supplied by

customer.

Ground

Level

Revision date: 07.22.11

LAY OUT THE BUILDING SITE

After the site is prepared, lay out the building site.

Taking these steps before assembling the shelter saves

time and ensures that the structure is positioned as

desired.

Drive ground posts to the proper depth. Width of the shelter

is measured from the center of one ground post to the

center of the remaining ground post.

SQUARE THE SITE

Gather the parts:

Ground posts•

5/16" x 2-1/2" machine bolts •

5/16" nuts•

Identify a corner where a ground post will be positioned 1.

and drive the first ground post into the ground.

NOTE: Insert the ground post driver into the top of

the ground post to protect the post and drive the post

into the ground. The top of the post will be eleven (11)

inches above the finished grade when properly driven.

Ground

Post

CLEARSPAN™ GREENHOUSES

Use a transit or line level to drive the second corner 3.

post to the same depth as the first ground post.

String a line at least as long as the building from the 4.

first stake at 90°.

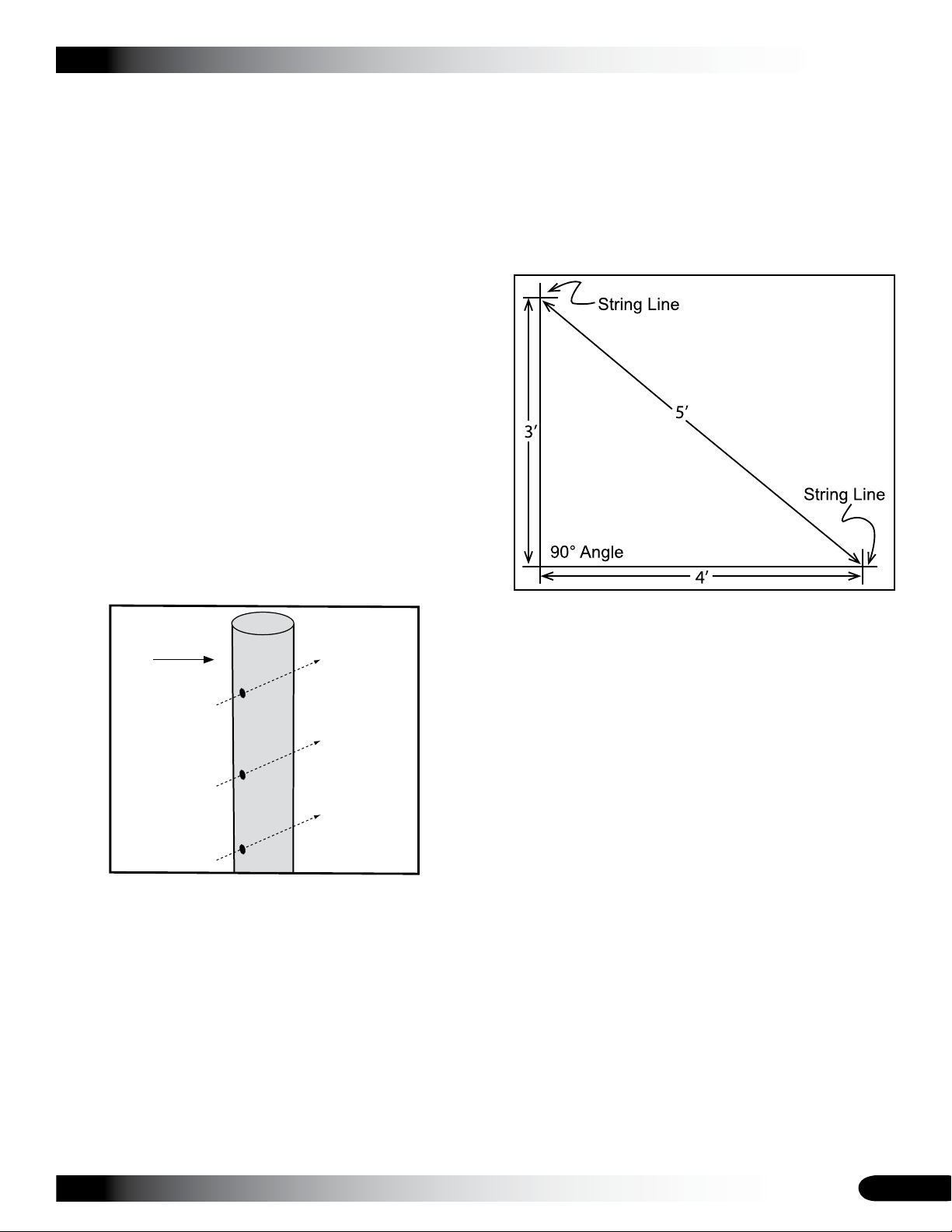

NOTE: A transit can be used to ensure an accurate 90°

angle, or the 3-4-5 rule can be used. Refer to diagram.

Using multiples of 3-4-5 such as 6-8-10 or 12-16-20

helps to maintain an accurate 90° angle.

After squaring the position of the building, measure 5.

the length (center-to-center) and drive the next corner

ground post.

Outside of

Shelter

Inside of

Shelter

ATTENTION: Position the pre-drilled holes facing to the

inside/outside of the shelter so they can be aligned with

the bolt holes in the rafter legs.

To align the bolt holes in the ground posts with those

in the rafter after driving the ground posts, insert a

tapered rod or pry bar into a ground post bolt hole and

turn the post using the rod or pry bar.

After the first corner ground post is in place, string a 2.

line the width of the building (center-to-center) and

drive the second ground post into the ground just

enough to hold it in place.

Repeat the same step for the last corner post. 6.

NOTE: The distance measured diagonally between

corner posts must be equal for the building to be

square.

Check all dimensions (and adjust if needed) before 7.

driving the remaining posts to the required height.

After all corner posts are accurately installed, tie a 8.

string line between the tops of the corner ground posts

on the same side of the shelter. The string is used to

identify the tops of all remaining ground posts. The

string must remain tight and level.

Use a tape measure to mark the 48" on-center 9.

locations of the remaining ground posts.

Drive the remaining ground posts into the ground at the 10.

required 48" on-center width and the height identified

by the string.

NOTE: Verify that the holes in the ground posts are in

the proper position and that each post is plumb and

driven to the correct depth. See Step 1 if needed.

Continue with the 11. Rafter Assembly steps that follow.

Revision date: 07.22.11

7

CLEARSPAN™ GREENHOUSES

ASSEMBLING THE ROUND STYLE GREENHOUSE

FRAME COMPONENTS

After the site is prepared and an inventory of parts is

complete, continue with the rafter assembly.

NOTE: All rafter assemblies consist of rafter tubes and

purlin clamps. Consult the Front Profile diagram in the

Quick Start section of these instructions before and during

the rafter assembly process.

Assistance is required to assemble the greenhouse frame.

RAFTER ASSEMBLY

Slide four (4) end purlin clamps (two on each side of 2.

the peak) over the rafter pipes.

Gather the parts:

Rafter pipe (#• 20R1601)

Rafter pipe (#• 20R1602)

Rafter pipe (#• 20R1601D)

End clamps (#• 102856)

Tek screws (#• FA4482B)

Magnetic nut setter 3/8'' x 2-9/16"•

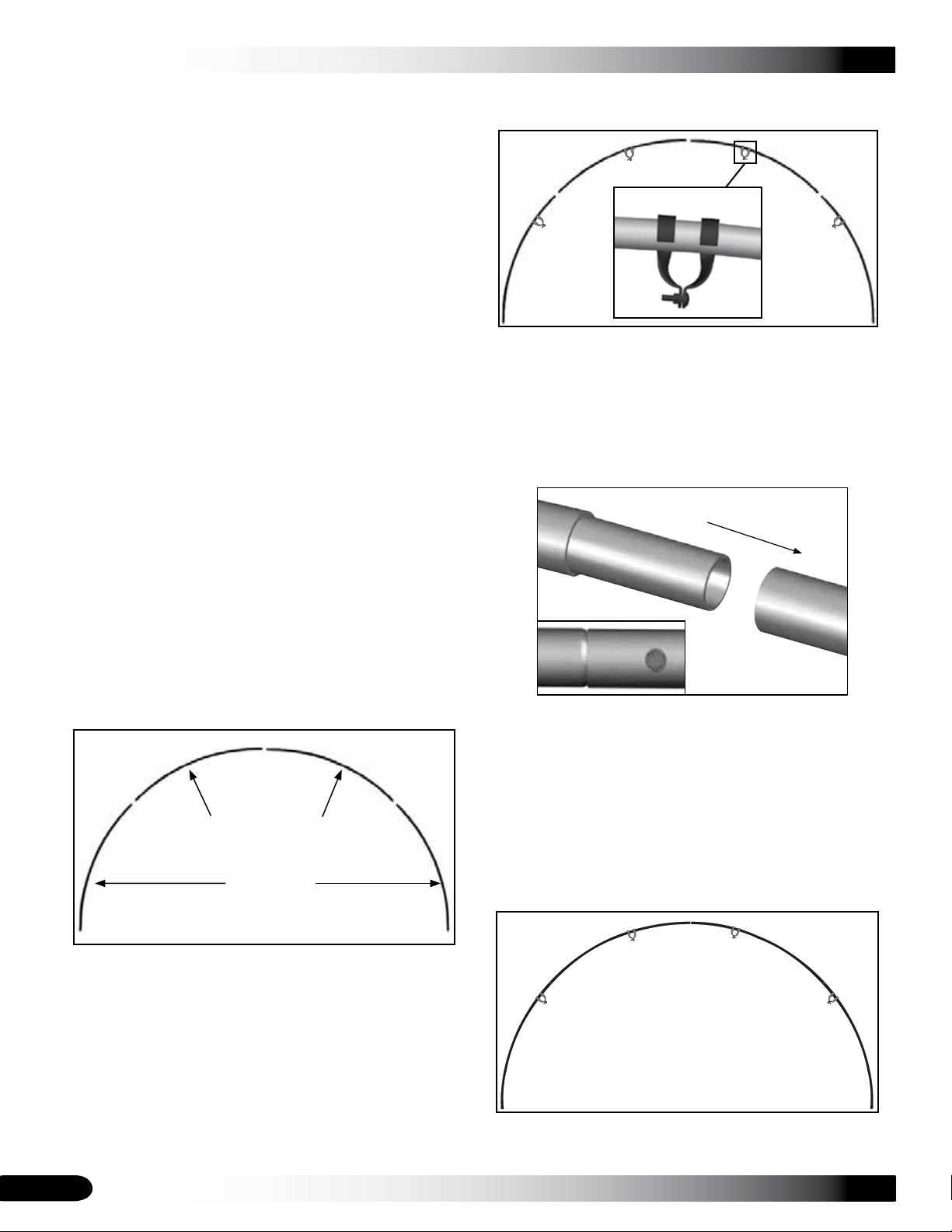

END RAFTER ASSEMBLY

The end rafters include purlin end clamps and band

clamps. Install the purlin end clamps before the different

pipes of the rafters are connected. The band clamps for the

side struts are installed when the two (2) end rafters are set

onto the ground posts.

Select the four (4) pipes needed to assemble the first 1.

end rafter and arrange on a level surface.

(#20R1601)

(#20R1601D)

(#20R1602)

End clamp as seen from outside the assembled rafter.

NOTE: Consult the Front Profile diagram in the Quick

Start section for proper end clamp placement and

position.

After slipping the clamps over the rafter pipes, insert 3.

the swaged end of the rafter pipes into the plain ends

of the pipes to assemble the rafter.

Diagram shows a similar connection.

Once the rafter is assembled, install a Tek screw 4.

through the rafter pipes to secure each joint. See the

diagram above.

IMPORTANT: Verify that you are installing the screw

through the pipe that contains the swaged end of the

adjacent pipe. To prevent damage to the cover and end

panels (if equipped), position the Tek screws so the

heads do not contact the cover when it is installed.

Assembled End Rafter

Repeat steps to assemble the remaining end rafter and 5.

set both end rafters aside.

8

Revision date: 07.22.11

RAFTER ASSEMBLY (continued)

INTERIOR RAFTER ASSEMBLY

Complete the following steps for the interior rafters.

CLEARSPAN™ GREENHOUSES

FRAME ASSEMBLY

After all ground posts are driven in place and rafters are

assembled, assemble the frame.

Select the pipes for the first interior rafter assembly and 1.

position these on the ground as shown.

(#20R1601)

(#20R1601D)

(#20R1602)

IMPORTANT: Interior rafters do not use end clamps.

Instead, cross connectors are attached during the

frame assembly.

Insert the swaged ends of the rafter pipes into the plain 2.

ends of the pipes and secure each joint with a Tek

screw.

NOTE: The baseboards (strongly recommended) shown in

the diagrams throughout these instructions are not included

and must be supplied by the customer.

ASSEMBLE AND PRE-MARK THE PURLINS

The following steps describe one way to speed the

assembly process. Pre-marking the purlins ensures that an

accurate spacing of the rafter assemblies is achieved and

maintained during assembly.

Those familiar with the assembly of similar structures

may elect to skip this procedure and continue with the

ASSEMBLE THE FRAME procedure on the next page.

Gather the parts:

Pipe 1.315'' x 75'' swaged (#131S075)•

Pipe 1.315'' x XX'' plain (#131P0XX)•

Marker and tape measure•

NOTE: The purlins are part of the assembled frame and

run perpendicular to the rafter assemblies. Each purlin

consists of 1.315" x 75" (#131S075) swaged pipes (number

is determined by shelter length) and one (1) 1.315" x XX"

(#131P0XX) plain pipe.

The XX" represents the remaining length required to reach

the end of the shelter. Consult the Spec Sheet for part

identification.

NOTE: For longer frames, it may be easier to assemble

a few rafters at a time and then begin to assemble the

frame.

Once rafters are assembled, assemble the frame.3.

Revision date: 07.22.11

Select the required pipe sections for one purlin and 1.

connect these by inserting the swaged ends of the

pipes into the plain ends until the entire purlin is

assembled.

NOTE: Assemble the purlins in a location that is

accessible during the assembly of the frame, but will

not interfere with the process of lifting and setting the

rafters.

Verify that each pipe joint is properly seated. 2.

NOTE: These pipes are separated during the assembly

procedure. Do not fasten them together at this time.

For the 48" rafter spacing, measure forty-eight and 3.

three-quarters inches (48-3/4") from one end of the

assembled purlin and mark the distance on the pipe.

NOTE: This first measurement is three-quarters (3/4)

of an inch longer than the on-center rafter spacing

to account for the length of purlin pipe that extends

through the end purlin clamp of the first end rafter.

9

CLEARSPAN™ GREENHOUSES

FRAME ASSEMBLY (continued)

From the location marked in the previous step, 4.

measure forty-eight inches (48") and make another

mark on the assembled purlin.

Secure the leg pipes to the ground posts using the 2.

5/16" x 2 1/2" machine bolts and nuts.

Rafter

Continue to mark the purlin in 48" intervals until all 5.

locations are marked. These marks help to maintain

the 48" on-center rafter spacing of the shelter during

assembly.

Repeat this procedure until all assembled purlins are 6.

marked.

After assembling all rafters and pre-marking the purlins, 7.

assemble the frame.

ASSEMBLE THE FRAME

After all ground posts are driven in place, rafters are

assembled and purlins pre-marked, assemble the frame.

Gather the Parts:

All rafter assemblies and pre-marked purlins•

Band clamps (#• QH1402)

Cross connector (#102548)•

5/16" x 2-1/2" machine bolts and 5/16" nuts •

Lifts, ladders, and assistants•

Band

Clamp

Outside of

Shelter

Inside of

Shelter

Ground

Post

Use rope or cable to brace the rafter in position. 3.

Rope or cable to temporarily brace rafters•

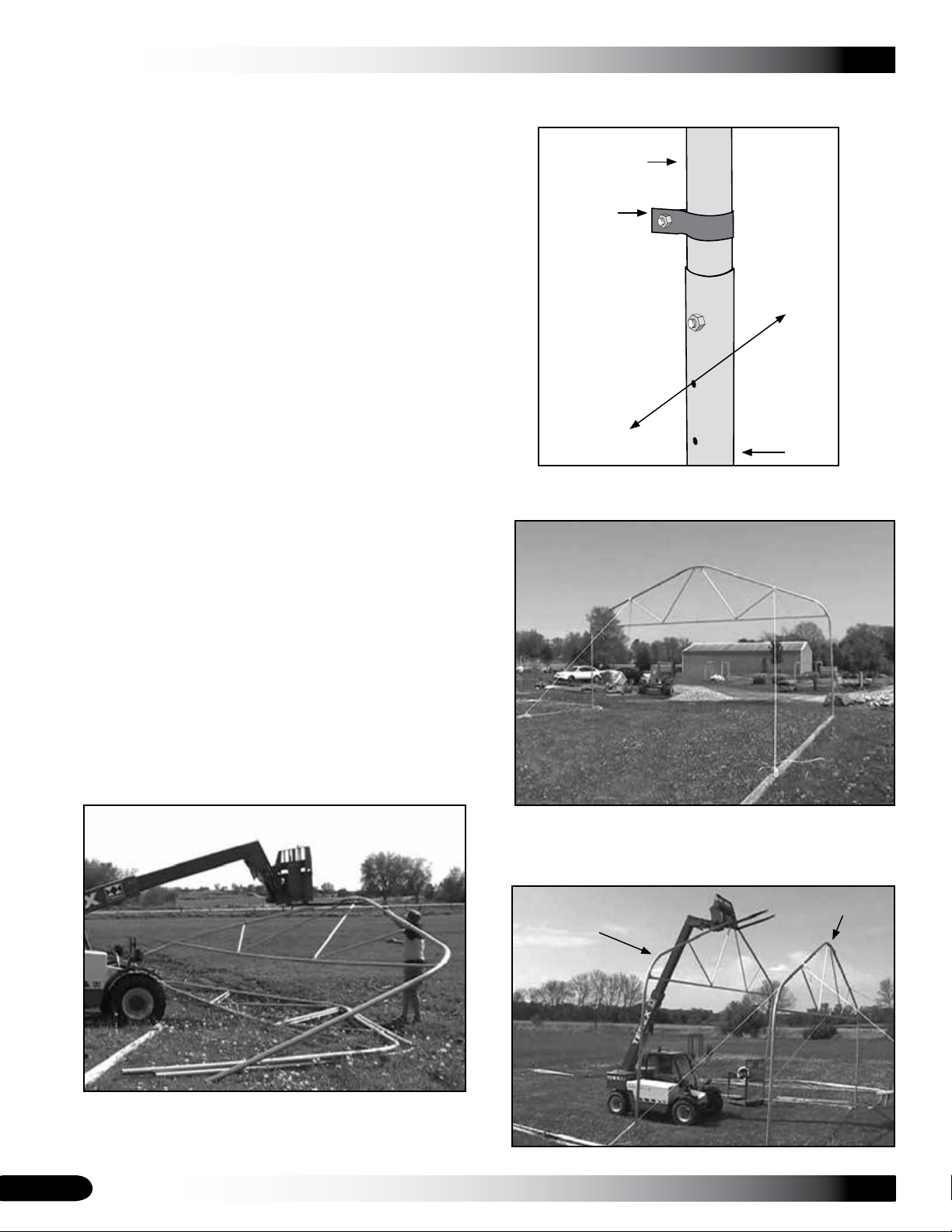

Carefully stand the 1. first end rafter, slide a band clamp

onto each rafter leg, and place the leg pipes in the first

set of ground posts.

Brace the rafter in place to keep it straight. Depending

on the frame size, a lift and additional assistants may

be needed. Consult Quick Start section for details.

Rafter shown differs in design.

Carefully position the first interior rafter in place and 4.

secure the leg pipes to the ground posts.

End Rafter

1st Interior Rafter

Rafter shown differs in design.

ATTENTION: Stand the rafter so the nuts and bolts of

the end clamps are to the inside of the frame.

10

Rafter shown differs in design.

Revision date: 07.22.11

FRAME ASSEMBLY (continued)

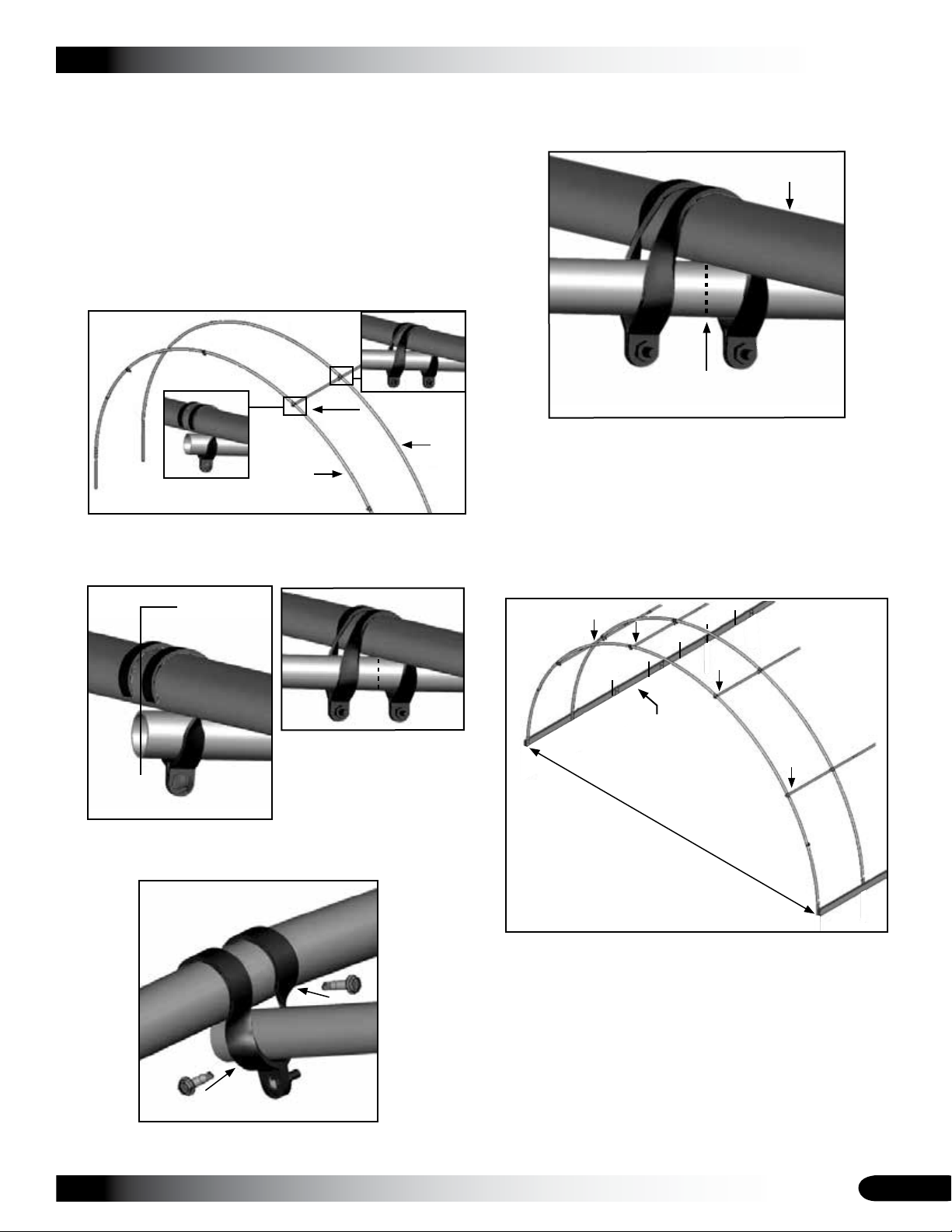

As the second rafter is steadied, remove one section of 5.

pipe from one assembled purlin.

NOTE: Work from the end of the purlin where the

first measurement was taken during the pre-marking

procedure if that procedure was used.

Insert the purlin pipe through an upper end clamp of 6.

the end rafter and through a cross connector placed in

the same position on the interior rafter. Consult Quick

Start section for purlin location per frame.

End Rafter

Align the plain end of the purlin with the center of the 7.

end rafter and rotate the purlin pipe so that the first

mark is visible (near the clamp of the interior rafter).

Do not allow the

purlin to extend

beyond the end

rafter.

Interior

Rafter

CLEARSPAN™ GREENHOUSES

Move to the interior rafter and align the mark on the 10.

purlin with the center of the rafter to maintain the proper

rafter spacing.

Interior Rafter

Purlin

Align mark with

center of rafter.

Verify that the rafter spacing is forty-eight inches (48") 11.

on-center (adjust as needed) and tighten the cross

connector.

Secure the cross connector to the rafter using a Tek 12.

screw. See Quick Start section if needed.

Repeat Steps 6-12 to install the first section of each 13.

purlin assembly for the first two rafters.

End rafter view

Tighten the end clamp and secure it to the rafter with a 8.

Tek screw.

End Rafter

Step 9

Install Tek screw through end clamp and into the purlin 9.

pipe.

Purlin

Interior rafter

Customer-supplied

baseboards: See next

section for installation tips.

20' wide

center-to-center

Choose another interior rafter assembly and set it 14.

in position. DO NOT USE THE REMAINING END

RAFTER.

Secure the rafter legs to the ground posts as previously 15.

described and steady the rafter.

Remove another section of purlin pipe from each pre-16.

marked purlin assembly and attach these to the rafter.

Verify that the distance between the rafters is 48" 17.

center-to-center. Adjust the rafter forward or backward

as needed to maintain this dimension.

Revision date: 07.22.11

11

CLEARSPAN™ GREENHOUSES

FRAME ASSEMBLY (continued)

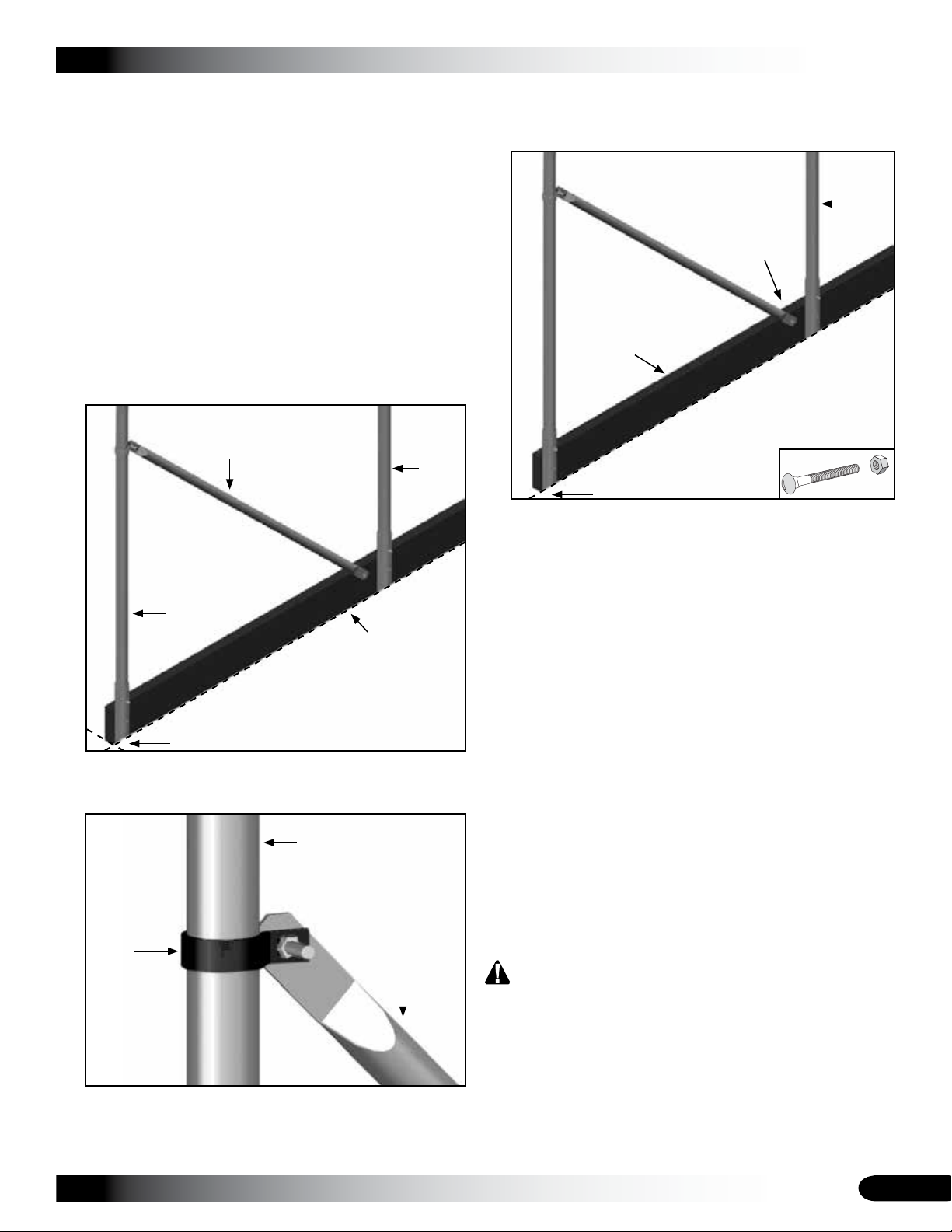

BASEBOARD INSTALLATION (RECOMMENDED)

Secure each purlin pipe joint with a Tek screw. 18.

Repeat the above steps as needed to stand and secure 19.

the remaining interior rafters and purlins to complete

the frame assembly.

Slide a band clamp onto each leg of the remaining 20.

end rafter, secure the rafter to the ground posts, and

attach the purlins to it. Verify that the end clamps are

positioned with the nut and bolt to the inside of the

assembled frame. Refer to the Quick Start section and

previous diagrams if needed.

NOTE: If the last end rafter is plumb and the purlin

extends beyond the end of the rafter, cut the last

section of purlin pipe to the required length.

Typically purlins do not require cutting. Verify that you

have correctly assembled the purlin using the correct

pipes before cutting any pipe to length.

Gather the parts:

Treated or recycled plastic lumber• (supplied by

customer).

1/4" x 4" carriage bolts and nuts (may not work for •

baseboards with a thickness greater than 1-1/2")

NOTE: The following procedure describes one way

to install the recommended baseboards. The size

and type of the baseboard you choose may require

the use of alternative steps. When properly installed,

baseboards run the length of the frame.

On the outside of the frame, attach the first baseboard

to the ground posts using the 1/4" x 4" carriage bolts

and nuts. Continue adding baseboards to complete

the first run. Splices are made between posts as

shown below in the illustration. Use a short section of

baseboard to secure separate baseboards at a splice.

Dashed line shows

ground level.

Frame length may differ from actual frame.

Once all rafters are set and all purlins are in place and 21.

secure, return to each pipe splice of each purlin and

rafter and verify that a Tek screw is installed to secure

the joint. Install a Tek screw if needed.

Inside of

Shelter

Outside of

Shelter

Ground

Level

NOTE: The boards should be at ground level or slightly

into grade to prevent the shelter from sinking and to

create a seal along the bottom. After installing the

baseboards, continue with these instructions.

This baseboard is not included with the shipment and must

be supplied by the customer. Treated or recycled plastic

lumber works well for a baseboard.

The baseboard, when installed properly, helps prevent the

ground posts from sinking into the ground when anchored.

Depending on the building, it also provides a surface to

attach struts or other building components.

Remove any temporary bracing (if needed) and install 22.

the baseboards and side struts.

12

ATTENTION: To prevent interfering with the installation of

the end wall panels, do not allow the end of the baseboard

to extend beyond the end of the end rafter.

Revision date: 07.22.11

SIDE STRUT INSTALLATION

There are four (4) side struts for the shelter. These struts

are positioned between the end rafters and the first interior

rafter on each side of the shelter.

Complete these steps to install the four (4) side struts:

CLEARSPAN™ GREENHOUSES

Attach the remaining end of the strut to the baseboard 3.

using a lag screw or nut and bolt (not included). See

the diagram that follows for location.

Photo shows the strut attached

to the inside of the customersupplied baseboard.

End

Rafter

Gather the parts:

Struts•

Band clamps (#• QH1402)

Lag screw or nut and bolt (supplied by customer)•

Locate one strut and position it between one end rafter 1.

leg and the leg of the first interior rafter as shown

below.

Strut

End Rafter

Baseboard is required to

secure strut as shown.

Customer supplies the

baseboard.

Ground Level

Attach one end of the strut to the band clamp as shown 2.

in the diagram below.

Attach strut

as shown.

Baseboard

Interior

Rafter

Ground Level

NOTE: A baseboard provides a place to attach each

strut and helps keep the ground posts at the required

depth. The customer is responsible for providing a

baseboard for this frame.

If no baseboard is used, place a band clamp around

the rafter just above the ground post and secure the

lower end of the strut to the band clamp (not shown).

Repeat the above steps to attach the remaining side 4.

struts to the shelter.

After securing the struts, verify that all clamps are 5.

secured with a Tek screw to the rafters.

Continue the next procedure to anchor the assembled 6.

frame.

End Rafter

Band Clamp

Strut

NOTE: Head of bolt on the band clamp must face the

polycarbonate panels.

Revision date: 07.22.11

ANCHOR THE ASSEMBLED FRAME

At this point, anchor the greenhouse frame. Consult the

MUST READ document for anchoring information and

suggestions. Please call customer service at 1-800-2459881 for additional anchoring information.

CAUTION: The anchor assembly is an integral part of

the greenhouse construction. Improper anchoring may

cause instability and failure of the structure to perform

as designed. Failing to anchor the shelter properly

will void the manufacturer’s warranty and may cause

serious injury and damage.

13

Loading...

Loading...