Page 1

A–Series

Setup and Installation Guide

Revision 1.6.05.10.2013

Page 2

Technical Support

See the Support Web site for documentation, technical updates, drivers and downloads,

warranty information, and software revisions.

Web:

Email: support@clearcube.com

Phone: (512) 652-3400 or call toll free (866) 652-3400 (United States)

http://www.clearcube.com/support/

Corporate Headquarters

ClearCube Technology, Inc.

3700 W Parmer Ln

Austin, Texas 78727

Email:

Phone: (512) 652-3500 or call toll free (866) 652-3500 (United States)

Fax: (512) 652-3501

Or your local ClearCube Reseller or Authorized Service Provider

Copyrights

© 2013 by ClearCube Technology, Inc. All rights reserved. Under copyright laws, this

publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopying, recording, storing in an information retrieval system, or translating, in

whole or in part, without the prior written consent of ClearCube Technology, Inc.

This information is subject to change without notice and ClearCube shall not be liable for any

direct, indirect, special, incidental or consequential damages in connection with the use of this

material.

info@clearcube.com

Trademarks

ClearCube™, Sentral™, Blade Switching BackPack™, PC Blade™, C/Port™, and I/Port™

are trademarks of ClearCube Technology, Inc. Product and company names mentioned herein

are trademarks or trade names of their respective companies.

Patents

The ClearCube Architecture and its components described in this user manual are protected by

numerous granted and pending U.S. and international patents.

Granted patents include: US05926172, US05966056, US05994952, US06012101 ,

US06020839, US06037884, US06038616, US06119146, US06148182, US06167241,

US06385666, US06421393, US06426970, US06633934, US06708247, US06735658, and

US06886055.

Patents pending include: US S/N 09/755378, US S/N 10/279475, US S/N 10/198719, US S/N

10/198650, US S/N 10/409219, US S/N 09/728667, US S/N 09/728669, US S/N 10/411804,

US S/N 10/411908, US S/N 10/458853, US S/N 10/364584, US S/N 10/301536, US S/N

60/411066, US S/N 10/662933, US S/N 10/662889, US S/N 10/662932, US S/N 10/662968,

US S/N 10/301563, US S/N 10/662936, US S/N 10/301518, US S/N 10/662955 and US S/N

10/662954.

Inquiries regarding patented technology should be directed to ClearCube Corporate

Headquarters.

Page 3

Contents

How to Use This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

FCC Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

California Proposition 65 Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

WEEE Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Medical and Clinical Use of ClearCube Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Chapter 1. A–Series Architecture and Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 A–Series Blade PCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1.1 Blade PC Overview, Identification Labels, and Serial Number . . . . . . . . . . . . . . . . . . . . 3

1.1.1.1 Blade PC Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.1.2 Blade PC Identification Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1.1.3 Blade PC Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1.2 A6106D Blade PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1.3 A6105D Blade PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 A–Series Chassis and Expansion Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Cloud Desktops: Zero Clients and Thin Clients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4 Monitor Support and Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 2. Site Preparation and Network Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 About Your Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.1 Inspecting Your Shipment and Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.2 Unpacking Your Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 Rack and Cabinet Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.1 Space and Floor Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.2 Cooling and Airflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3 Chassis and Blade Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.1 Power Input Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.2 Power Circuit Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

iii

Page 4

2.4 Chassis Expansion Backplane and Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.4.1 Chassis Ports and Supported Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.4.2 Ethernet Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4.3 Supported Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5 Example Deployment Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5.1 Dedicated PCoIP Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.5.2 Shared Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 3. Chassis and Blade PC Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1 Tools for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2 Installing an A–Series Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2.1 Chassis Container Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.2.2 Chassis AC Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2.3 Mounting A–Series Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2.3.1 Cabinet Mounting Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2.3.2 Using a Chassis Accessory Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2.3.3 Using a Chassis Rapid–Mount Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2.3.4 Removing a Rapid–Mount Kit Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2.4 Attaching and Removing the Expansion Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.2.4.1 Attaching the Expansion Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.2.4.2 Removing the Expansion Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.2.5 Chassis Power and Failover Power Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.2.5.1 To Enable Chassis Failover Power Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.2.5.2 To Power Chassis without Failover Power Feature . . . . . . . . . . . . . . . . . . . . . . . . 31

3.3 Configuring A–Series Blade PCs before Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.3.1 Viewing Pre-OS Video (BIOS and Network Boot, PXE Boot) . . . . . . . . . . . . . . . . . . . 31

3.3.1.1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.3.1.2 Connecting Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.3.1.3 Create Session and View Video . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.3.2 Operating System Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.3.2.1 Using the Default Operating System Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.3.2.2 Custom Operating System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.3.2.3 Installing a Custom Image from an Image File Server . . . . . . . . . . . . . . . . . . . . . . 37

3.4 Installing Blade PC in a Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

iv

Page 5

3.5 Removing Blade PC from a Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 4. Upgrading and Maintaining Blade PCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.1 Use Authorized Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.2 Replacing Components: Permitted and Prohibited Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.3 Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.3.1 A6106D Memory Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.3.2 A6105D Memory Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.3.3 General Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.3.4 Population Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.3.5 Installing DIMMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.4 Hard Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.4.1 A6106D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.4.2 A6105D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.5 BIOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.5.1 Clearing BIOS Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.5.1.1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.5.1.2 Required Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.5.1.3 Setting up Zero Client and Blade PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.5.1.4 Connecting Zero Client and Blade PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.5.1.5 Clearing Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.5.2 Updating (Flashing) BIOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.5.3 Recovering BIOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Appendix A. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Appendix B. Regulatory Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Appendix C. Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

C.1 Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

C.2 Return Merchandise Authorization (RMA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

C.3 Power Cord Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Appendix D. Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

v

Page 6

vi

Page 7

How to Use This Guide

This guide explains how to install and set up ClearCube Technology, Inc. A–Series chassis,

blades and components necessary for managed desktop environments. We recommend that

you familiarize yourself with the ClearCube architecture and product descriptions and read

through all installation and setup procedures before beginning installation.

If you encounter any issues, contact ClearCube Support using the contact information

provided on the inside front cover of this manual and in Appendix C. “Support”

FCC Warning

This equipment generates and uses radio frequency energy and, if not installed and used in

strict accordance with the instructions in this manual, may cause interference to radio and

television reception. Changes or modifications not expressly approved by ClearCube

Technology, Inc. could void the user's authority to operate the equipment under FCC rules.

on page 61.

California Proposition 65 Statement

WARNING: ClearCube products contain chemicals, including lead, known to the

State of California to cause cancer, birth defects, or other reproductive harm.

Wash hands after handling.

ClearCube products should be disposed of in accordance with local laws governing computer

equipment disposal.

WEEE Information

The products described in this document are subject to regulation under the European Union

Directive 2002/96/EC, that mandates separate waste collection, treatment, and recycling of

electronic products. This directive is commonly known as WEEE, for Waste from Electrical

and Electronic Equipment, and its intent is to promote the safe and sensible disposal of

products that have outlived their usefulness.

ClearCube Technology, Inc. vii

Page 8

The “crossed-out” trash bin symbol, shown above, identifies products that should be recycled,

not simply discarded. ClearCube Technology, Inc. supports the reuse, recycling, recovery, and

responsible disposal of all products.

ClearCube Technology, Inc. is committed to meeting the requirements of the European Union

WEEE Directive. The goal of the directive is to reduce the environmental impact due to the

disposal of electrical and electronic equipment that has reached the end of its useful service life.

ClearCube products are sold exclusively to commercial and industrial customers and not to

private households. Under the WEEE legislation terms, commercial and industrial customers

have the responsibility to ensure that all electrical and electronic equipment is disposed of

properly and in accordance with all applicable laws and local regulations. For more

information, email r

Materials used in this product, if not disposed of properly, could have adverse effects on the

environment and on human health. Do not dispose of these products in unsorted municipal

waste containers. Deliver electronic waste only to an approved recycling facility, a treatment

facility, or both. If one is not available, contact ClearCube for assistance.

ecycle@clearcube.com, or call (866) 652-3400 or +1 (512) 652-3400.

Medical and Clinical Use of ClearCube Products

ClearCube products are not designed with components and testing for a level of reliability

suitable for use in or in connection with surgical implants or as critical components in any life

support systems whose failure to perform can reasonably be expected to cause significant

injury to a human. Applications of ClearCube products involving medical or clinical treatment

can create a potential for death or bodily injury caused by product failure, or by errors on the

part of the user. Because each end-user system environment is customized and differs from

ClearCube testing platforms and because a user may use ClearCube products in combination

with other products in a manner not evaluated or contemplated by ClearCube, the user is

ultimately responsible for verifying and validating the suitability of ClearCube products

whenever ClearCube products are incorporated in a system, including, without limitation, the

appropriate design, process and safety level of such system or application.

viii A–Series Setup and Installation Guide

Page 9

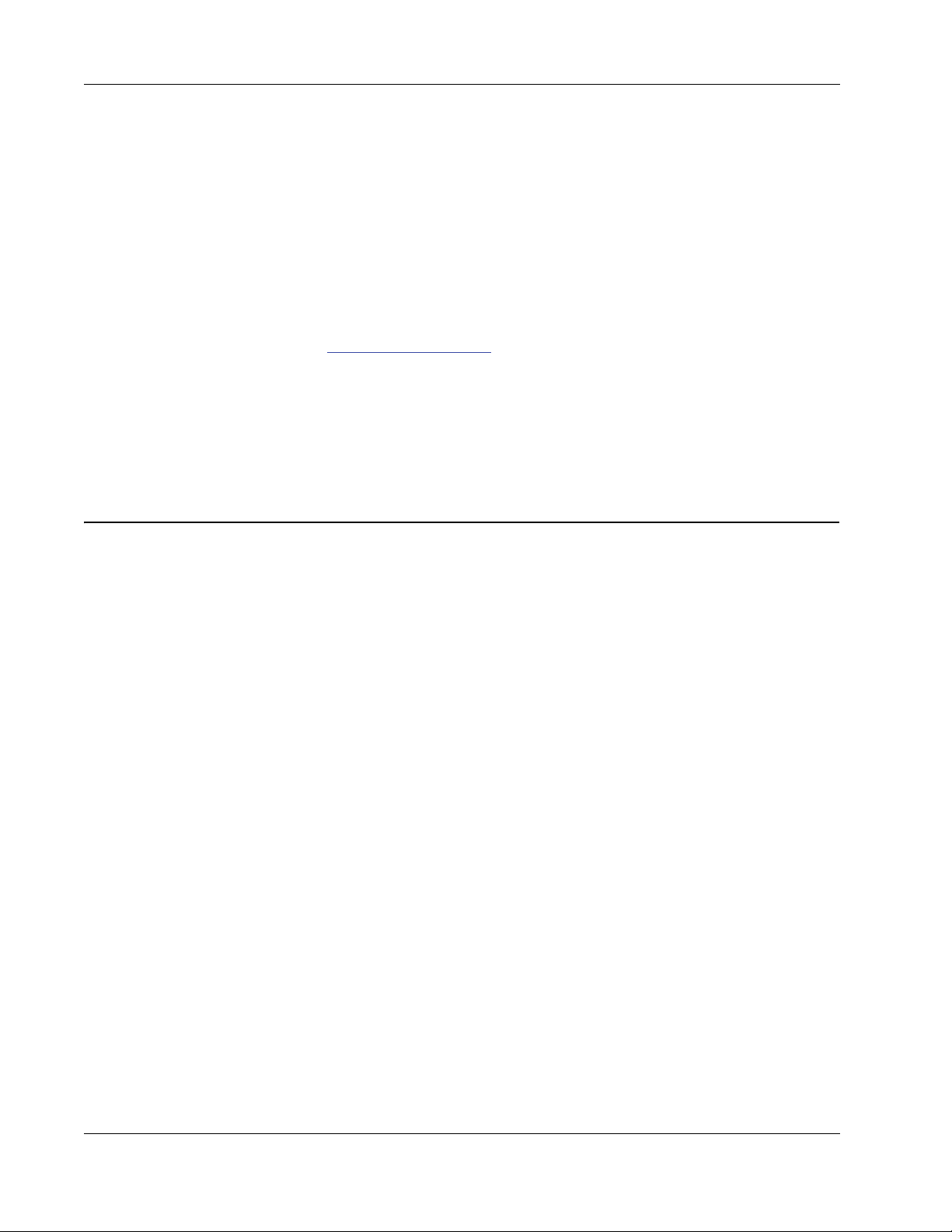

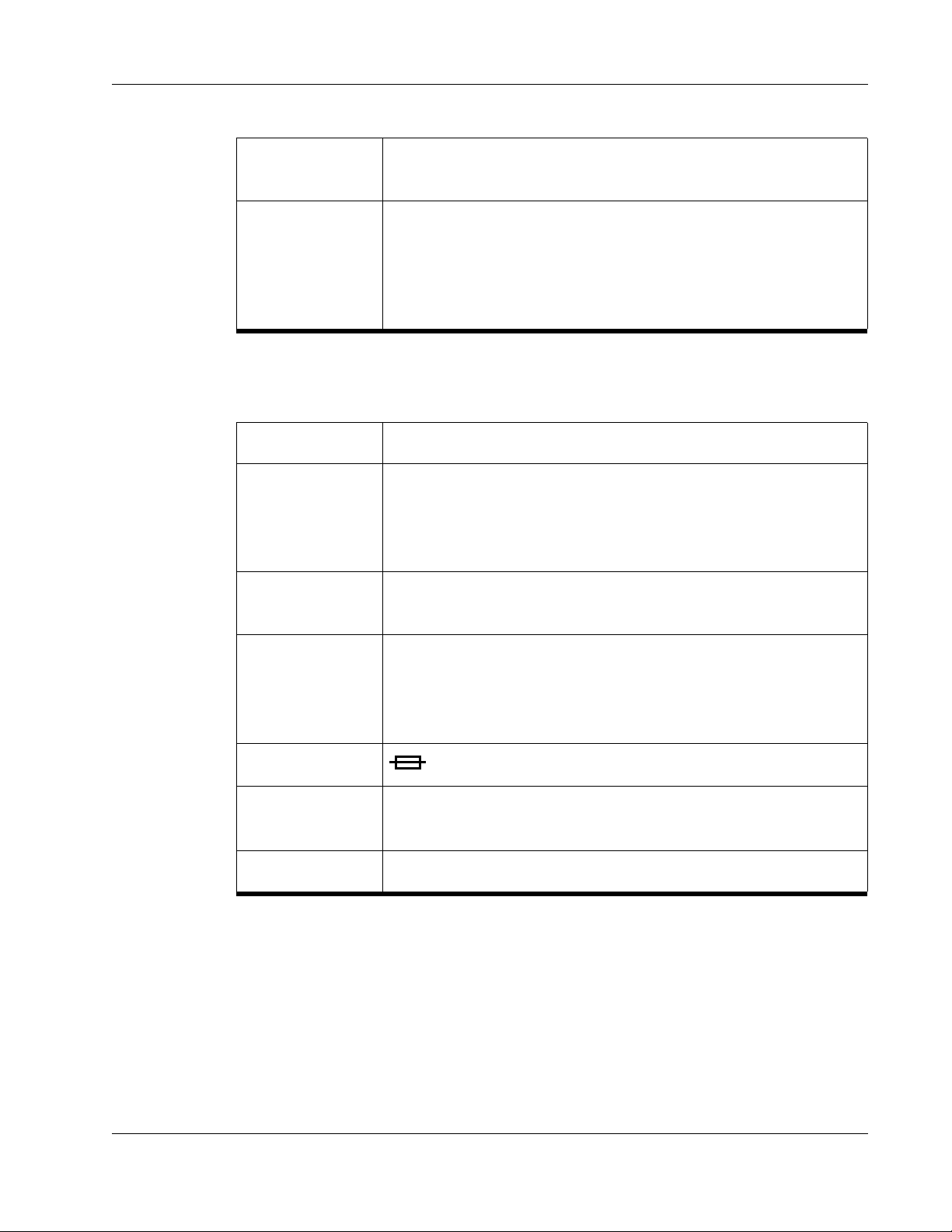

Symbols

Symbols are displayed on the hardware described in this document to convey specific

information to the operator and service person. It is important to understand the intended

meaning of these symbols. The following list shows each symbol displayed on ClearCube

Technology, Inc. products and explains the meaning of each symbol.

Refer to Manual

Used on the equipment’s rating label to direct the operator or service person to

this manual for additional information.

Shock Hazard

This symbol indicates the presence of electric shock hazards. Enclosures marked

with these symbols should only be opened by qualified service personnel. Refer

to the manual for additional information.

Power

Identifies the soft-start switch located on a blade used to power a blade on and

off.

Fuse

Located on equipment rating label. Symbol is accompanied with the

specifications needed for replacement. Only qualified technicians should

perform this operation.

Protective Earth Terminal

This symbol identifies the terminal that is used to connect all metal parts of an

enclosure through an external conductor to ground for protection against

electrical shock in a fault condition.

Ground Bond Terminal

This symbol identifies the ground bond terminal. This terminal is used to

connect the ground bonding conductor, or the combination of conductive parts,

to earth ground for safety purposes.

Equipment Protection Class II

May be located on the power adapter’s rating label. Indicates that equipment is

double–insulated from hazardous voltages. Not to be confused with Class 2, a

US National Electrical Code (NEC) circuit classification.

ClearCube Technology, Inc. ix

Page 10

The following caution and warning symbols are used in this document to indicate situations

that merit checking this or another manual, or situations that could result in damage to

equipment or physical injury.

CAUTION: A Caution notice in this manual indicates that equipment

damage or minor injury may result if proper procedures are not followed.

WARNING: A Warning notice in this manual indicates that catastrophic

equipment damage or serious injury, including death, may result if proper

procedures are not followed.

Safety Guidelines

Before undertaking any troubleshooting or maintenance procedure, carefully read all

WARNING and CAUTION notices. Equipment displaying warning or caution notices

contains voltage hazardous to human life and is capable of inflicting personal injury.

• Installations—You must install ClearCube equipment in accordance with local electrical

codes. Equipment might be subject to inspection.

• Chassis grounding—ClearCube’s chassis is designed with a three-conductor IEC 60320

appliance inlet that—with the proper power cord—connects the building’s external

protective earthing conductor to all accessible metal parts of the enclosure. To minimize

shock hazard, make sure your electrical power outlet has an appropriate earth safety

ground that is connected each time you power on the equipment.

Swedish safety regulations require the following statement:

—Apparaten skall anslutas till jordat uttag när den anslutas till ett nätuerk.—

Finnish safety regulations require the following statement:

— Laite on liitettävä suojamaadoituskoskettimilla varustettuun pistorasiaan.—

• Power cord selection—ClearCube or ClearCube distributors provide power cords that are

specifically designed for use with particular pieces of equipment and are approved for use

by the local authority having jurisdiction in the country where the equipment is put into

service. Refer to the installation sections of this manual for specific power cord

requirements. For information about obtaining replacement power cords, see

Appendix C. “Support”

on page 61.

• Power adapters—ClearCube or ClearCube distributors provide power adapters that are

specifically designed for use with particular pieces of equipment and are approved for use

x A–Series Setup and Installation Guide

Page 11

by the local authority having jurisdiction in the country where the equipment is put into

service. Refer to the installation sections of this guide for specific power cord

requirements. For information about obtaining replacement power adapters, see

Appendix C. “Support”

on page 61.

• IT power systems—ClearCube equipment has been evaluated and found to be compatible

with IT power distribution systems with a phase-to-phase voltage not to exceed 240 V.

• Live circuits—Operating personnel and service personnel must not remove protective

covers when operating the ClearCube chassis. Adjustments and service to internal

components must be undertaken by qualified service technicians. During any service of

this product, other than replacing a Blade PC or externally accessible modules on the

expansion backplane, the main connector to the premise wiring must be disconnected.

Dangerous voltages may be present under certain conditions. Use extreme caution.

• Explosive atmosphere—Do not operate the chassis in conditions where flammable gases

are present. Under such conditions this equipment is unsafe and may ignite the gases or

gas fumes.

•

Part replacement—

Only service equipment with parts that are exact electrical and

mechanical replacements. Contact your authorized ClearCube Technology, Inc. reseller for

information about replacement parts. Installation of parts that are not direct replacements will

void the warranty and may cause harm to personnel operating the chassis. Furthermore,

damage or fire may occur if replacement parts are unsuitable.

• Modification—Do not modify any part of the chassis or Blade PC from its original

condition. Modifications may result in hazards.

ClearCube Technology, Inc. xi

Page 12

xii A–Series Setup and Installation Guide

Page 13

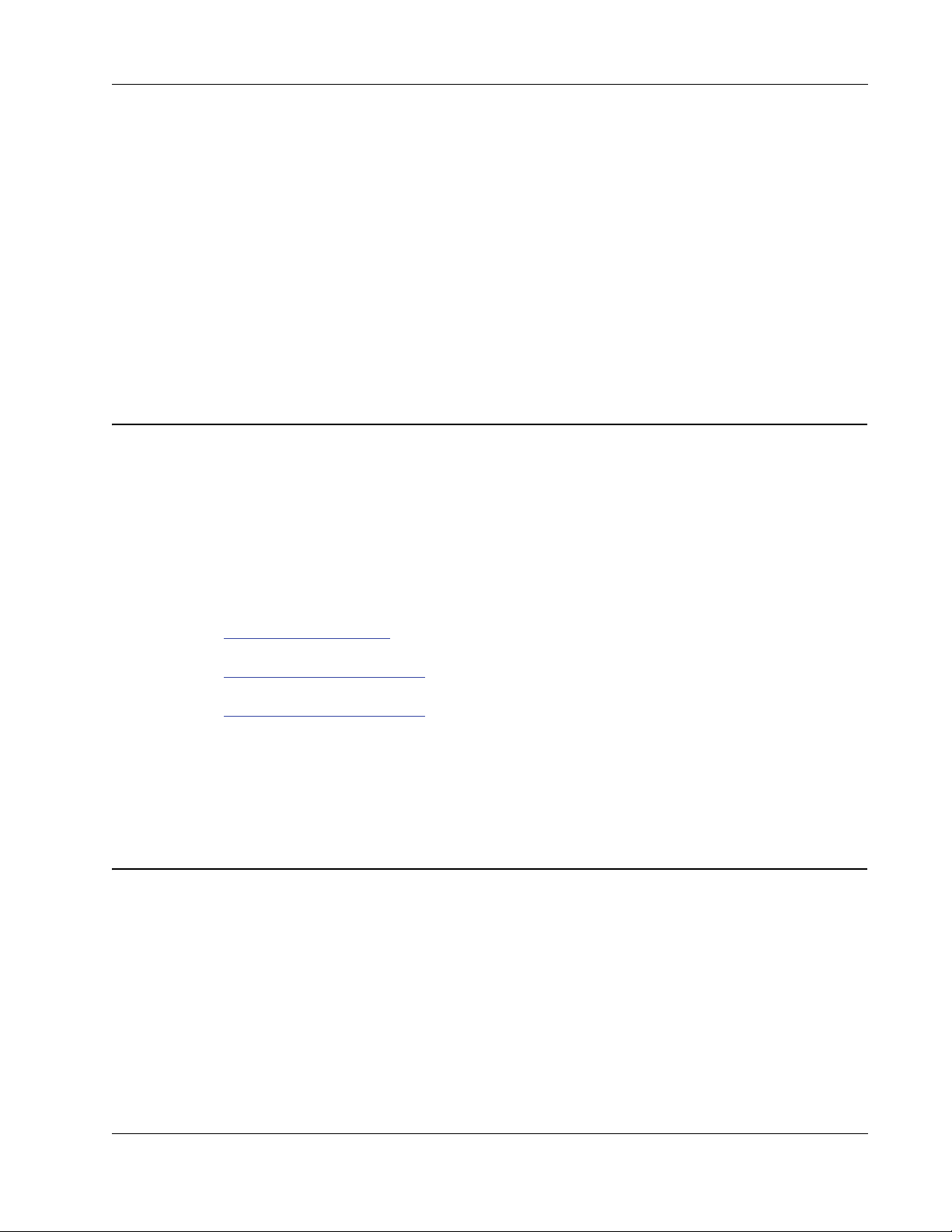

Chapter 1. A–Series Architecture and

Product Overview

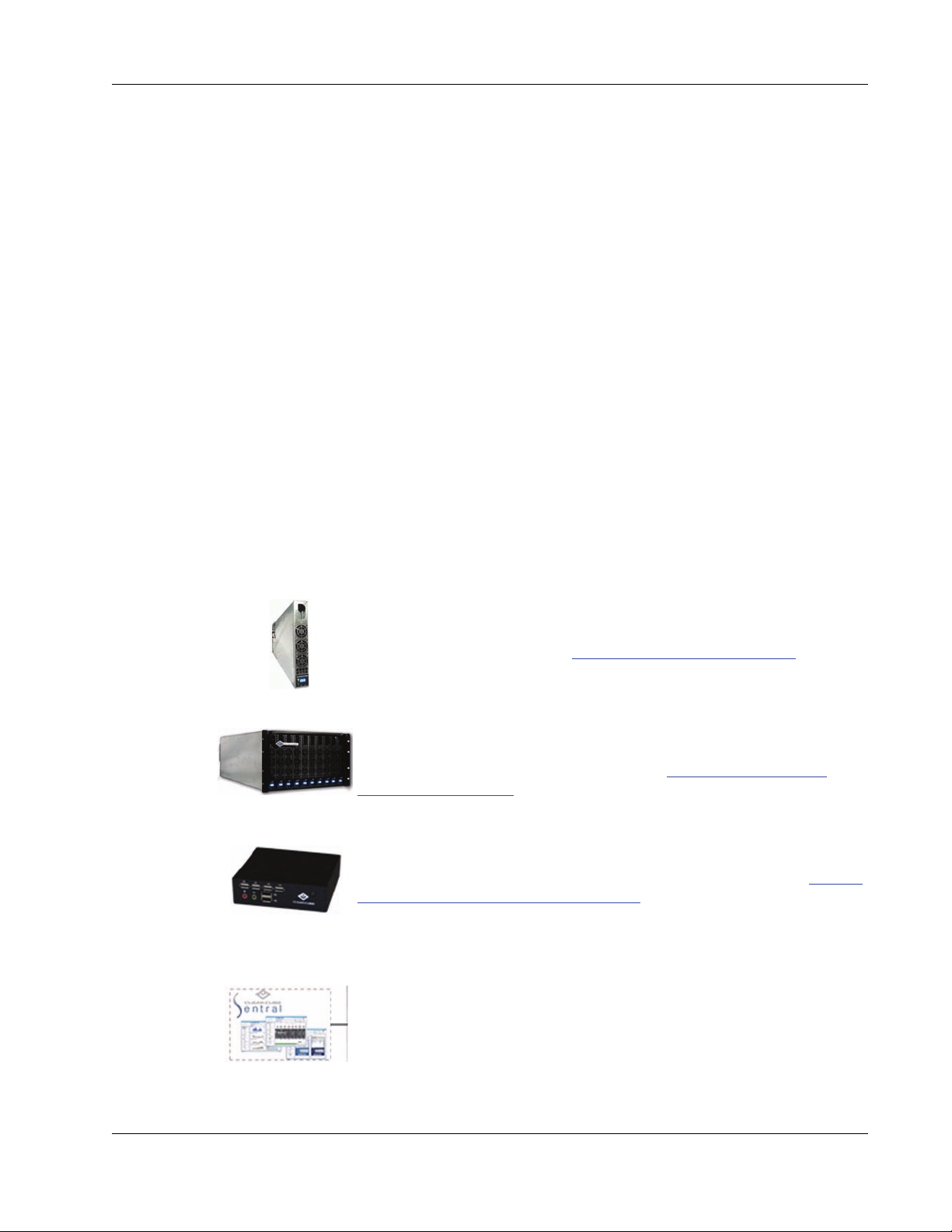

ClearCube A–Series architecture delivers PC functionality to users from a secure, centralized

location. This architecture increases IT manageability and security, and provides

mission-critical reliability, performance, and uptime improvements with lowered costs.

Replacing a traditional PC with a ClearCube Cloud Desktop (zero client or thin client) saves

space, eliminates or reduces fan noise, and simplifies cabling. The key components of the

ClearCube architecture include (devices not shown to scale):

Blade PCs

Computers in a dense form factor that use Intel

typically remotely located. See “A–Series Blade PCs”

information about blades.

Chassis

Hold multiple Blade PCs and enable you to manage all external cables

connect to blades from a single location. See “A–Series Chassis and

Expansion Backplane” on page 7 for more information about chassis.

Cloud Desktop (zero client or thin client)

Physical devices, typically placed on a desk, to which you can connect

peripherals such as a monitor, keyboard, an d po inti ng d ev ice. See “Cloud

Desktops: Zero Clients and Thin Clients” on page 9 for more information

about zero clients and thin clients.

System management software and hardware

ClearCube Sentral™ is a software suite that provides system mana gement

capabilities (including connection brokering, mass storage lockout,

alerting, and much more) for your ClearCube environment. Sentral takes

advantage of monitoring hardware that is built into blades, chassis, and

Cloud Desktops. For more information about Sentral, see ClearCube

Sentral Administrator’s Guide.

®

CPUs. Blades are

on page 2 for more

A–Series Setup and Installation Guide 1

Page 14

Chapter 1. A–Series Architecture and Product Overview

Centralized Virtual

Desktops

Power Users

Knowledge Users

Task Users

VMware View

Client

Thin Client

Zero Client

Chassis

Zero Client

Network

Infrastructure

The picture below shows the A–Series architecture components.

Figure 1. A–Series architecture

1.1 A–Series Blade PCs

ClearCube A–Series Blade PCs are computers with Intel processors that deliver full PC

functionality to users, including USB functionality, from a centralized location. Each A–Series

Blade PC contains all the industry-standard components of a desktop PC:

• Processor

•Memory

2 A–Series Setup and Installation Guide

Page 15

• Hard disk

A–Series Blade PCs

• Video support (PCoIP

®

host card, GPU or graphics card, or integrated graphics)

• PCoIP host card (depending on configuration)

®

•Ethernet

network interface card (NIC)

You can connect USB peripherals to a Blade PC through USB ports on a Cloud Desktop (zero

client or thin client). You can install software on your Blade PC through a cloud desktop

network connection or by using peripherals connected to the USB ports.

1.1.1 Blade PC Overview, Identification Labels, and Serial Number

This figures in this section show

• An overview of an A–Series blade detailing the LCD bezel, buttons, and indicators, and

• all identification labels on a blade.

ClearCube Technology, Inc. 3

Page 16

Chapter 1. A–Series Architecture and Product Overview

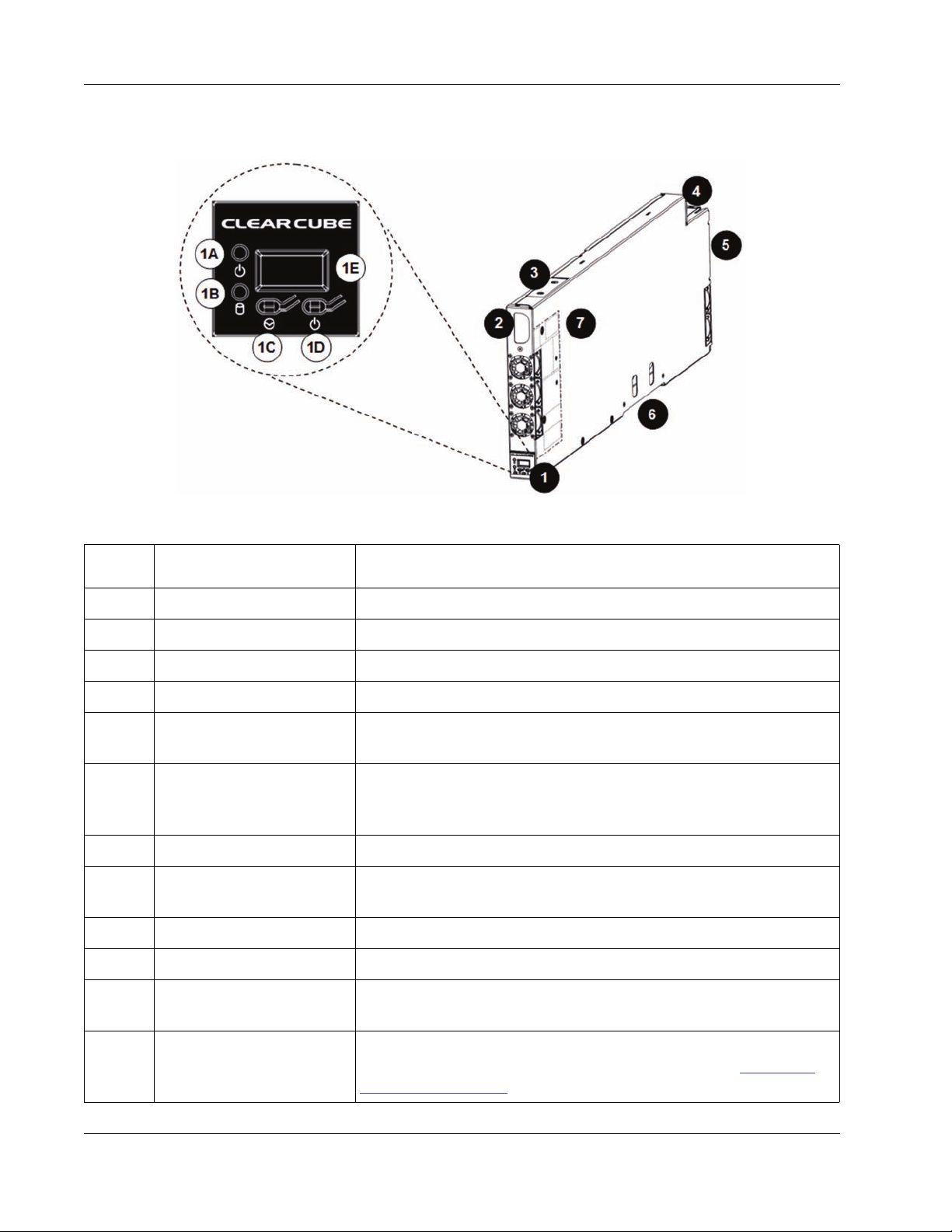

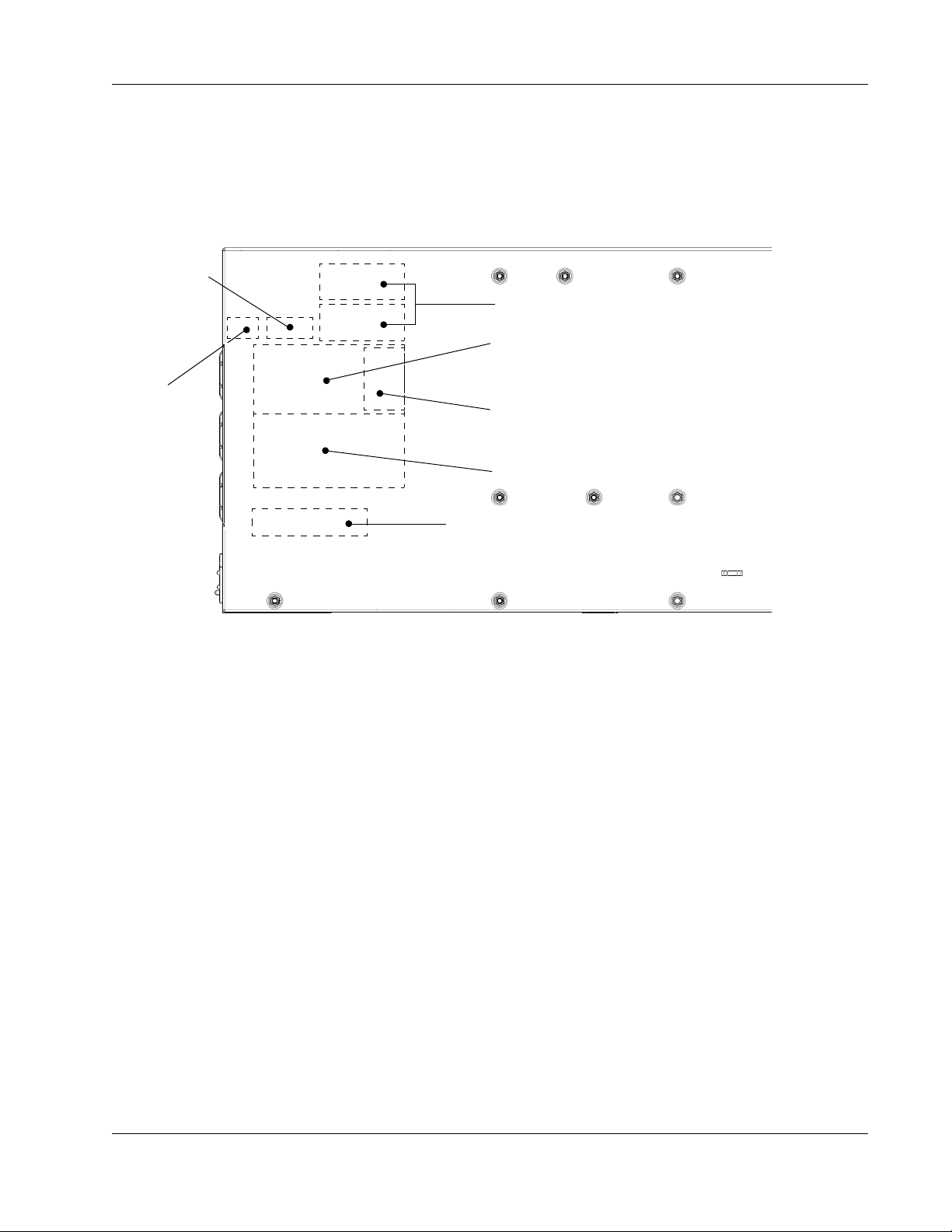

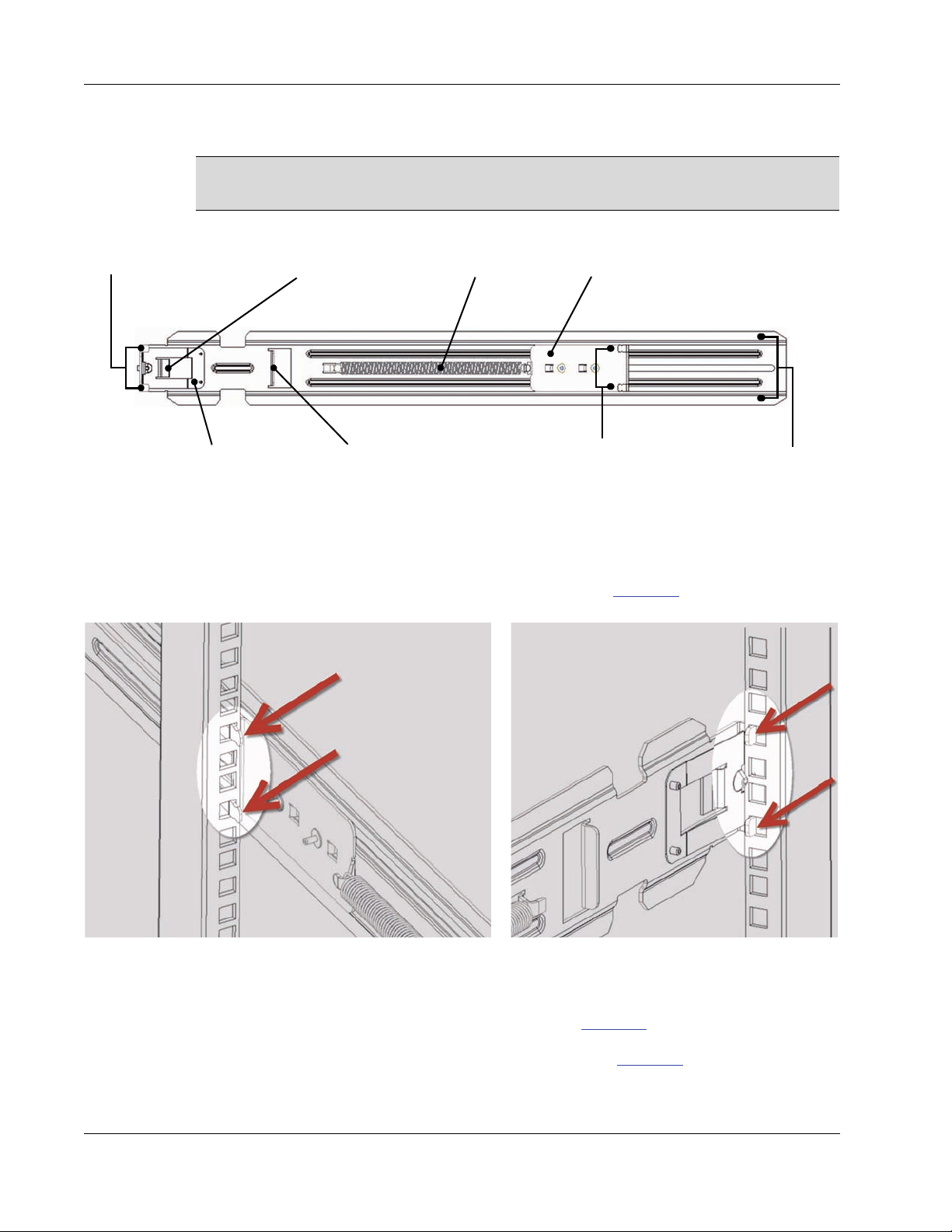

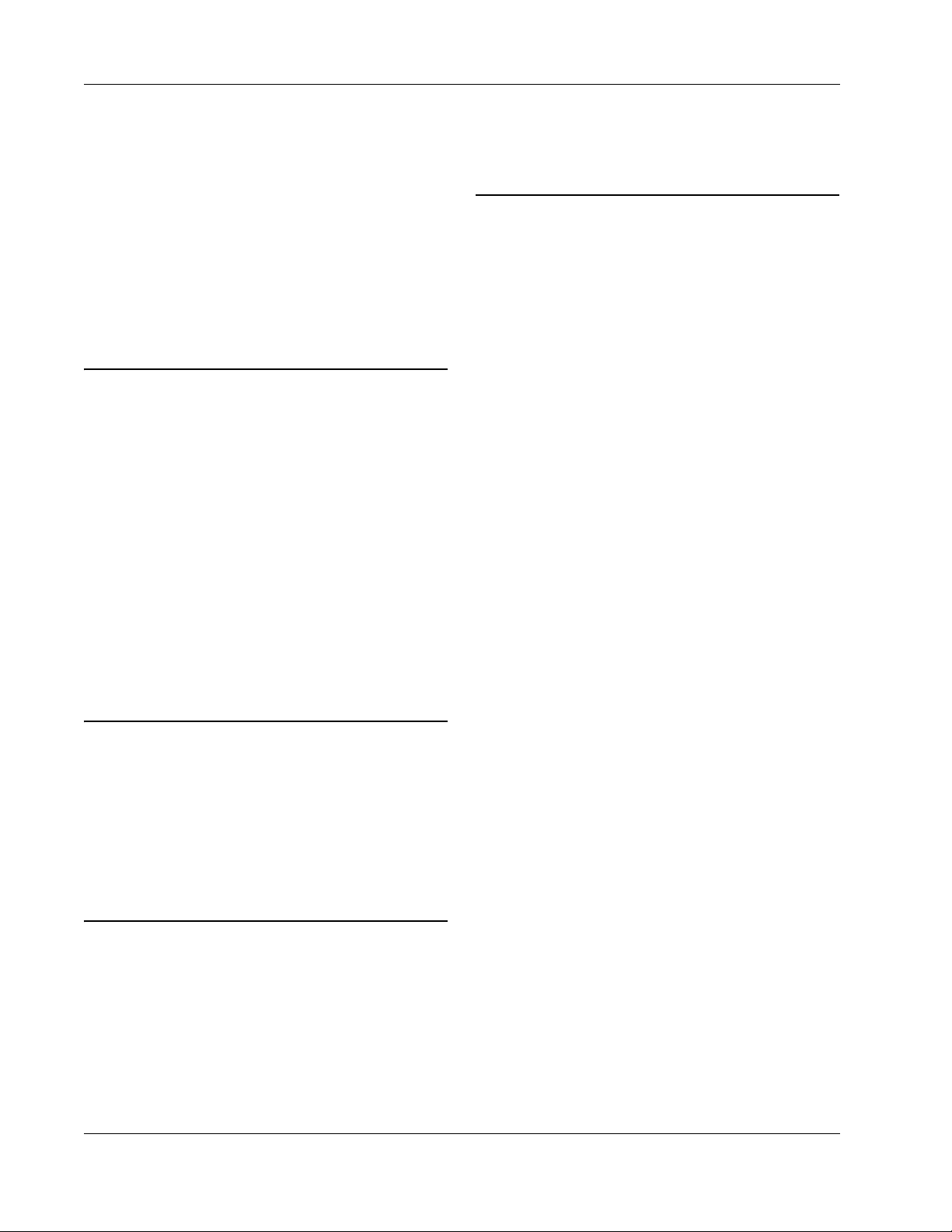

1.1.1.1 Blade PC Components

The picture and table below show each A–Series blade component.

Figure 2. A–Series blade components and features

Figure

Number

1 LCD bezel Provides indicators and power-related buttons.

1A Power indicator Illuminated when blade is powered on.

1B Drive activity indicator Flashes to indicate storage drive activity.

1C Reset button Press to reset blade power.

1D Power button

1E Display

2 Handle Use to aid insertion and removal from chassis.

3 I/O access slot

4 Power connector Connects to the AC power backplane on A3100 chassis.

5 Ethernet ports Connect to Ethernet ports on the A–Series chassis backplane.

Part Function

Press to power on or power off blade. Press and hold for 3 seconds

to force power off.

Displays boot codes and blade serial number. ClearCube Sentral

management suite enables the LCD to display user-defined strings

and to blink for identification purposes.

Provides access to select motherboard I/O ports for configuration

outside of a chassis.

Storage drive carrier

6

(A6106D model only)

7 Video configuration label

4 A–Series Setup and Installation Guide

Holds up to two storage drives (hard drives), connecting directly to SATA

connectors inside the blade. Does not support hot-swap operation.

Provides important blade configuration information, including video

host card MAC address, serial number, and more. See "Blade PC

Identification Labels" on page 5 for more information.

Page 17

A–Series Blade PCs

Intel Inside

Label

Blade Serial Number and MAC Label

Video Configuration Label(s)

System Configuration Label

Regulatory Label

Operating System COA Label

Host Card

Firmware

Revision Label

1.1.1.2 Blade PC Identification Labels

Labels on A–Series blades provide a variety of important information about the blade. Each

A–Series blade has a serial number. By default, the last three digits of the serial number are

displayed on the blade LCD. The serial number is also printed on a label adjacent to the fans

on the front of the blade, as shown in the following figure.

Figure 3. A–Series serial number and configuration labels

1.1.1.3 Blade PC Serial Number

The blade serial number (located on a label shown in the section above) is useful if yo u need to

identify a blade or a blade model. A–Series blade serial numbers use the following syntax:

• A6106D

AVCnnnnn (where AVC is the serial number prefix, and nnnnn is a five-digit number.)

• A6105D

AMBnnnnn (where AMB is the serial number prefix, and nnnnn is a five-digit number.)

The following sections detail the features of each A–Series blade.

1.1.2 A6106D Blade PC

Features of the A6106D include:

• Intel Q77 Express Chipset.

• Two Intel PRO 10/100/1000 Ethernet ports.

• One DVI-I port (for bench top configuration and setup only).

ClearCube Technology, Inc. 5

Page 18

Chapter 1. A–Series Architecture and Product Overview

•USB ports

– Inside chassis:

Two USB 2.0 ports

– On benchtop:

Two USB 3.0 ports (for bench top configuration and setup only)

• Four 240-pin DDR3 SDRAM DIMM sockets supporting:

– Up to 32 GB maximum total system memory using 4 Gb memory technology.

– Non-ECC DIMMs.

– DDR3 1600 MHz, 1333 MHz and 1066 MHz DIMMs.

• Supports dual- and quad-monitor zero clients compatible with PC–over–IP

®

(PCoIP)

technology.

• Front-mounted LCD:

– Displays last three number of serial number by default.

– Able to display user-specified text through ClearCube Sentral and to blink to aid in

identification.

1.1.3 A6105D Blade PC

Features of the A6105D blade include:

• Intel Q57 Express Chipset.

• Two 10/100/1000 Ethernet ports.

• One DVI-I port and one DVI-D port (for bench top configuration and setup).

• Two USB ports (for bench top configuration and setup).

• Chassis and standalone operation.

• Four 240-pin DDR3 SDRAM DIMM sockets supporting:

– 16 GB maximum total system memory using 2 Gb memory tech nology.

– Non-ECC DIMMs.

– DDR3 1333 MHz and DDR3 1066 MHz DIMMs.

– DDR2 800 DIMMs with SPD timings of only 5-5-5 or 6-6-6 (tCL-tRCD-tRP).

• Supports zero clients compatible with PC–over–IP (PCoIP) technology.

• Front-mounted LCD:

– Displays last three number of Blade PC serial number by default.

– Able to display user-specified text through ClearCube Sentral and to blink to aid in

identification.

6 A–Series Setup and Installation Guide

Page 19

A–Series Chassis and Expansion Backplane

1.2 A–Series Chassis and Expansion Backplane

The following sections describe the A3100 chassis and the expansion backplane.

The list below shows dimensions and features of the A3100 chassis.

•6U high

• Compatible with industry-standard, 19-inch racks and cabinets (see Figure 6

for examples)

• Holds up to 10 A–Series blades (70-blade maximum density in a 42U rack)

• Chassis mounts to rack or cabinet with:

– Rack ears (in cluded), or

– Optional chassis rapid–mount kit (see “Using a Chassis Rapid–Mount Kit”

for more information)

• Removable front bezel.

• Expansion backplane—A modular component that provides signal connectors and a

chassis ID, or an electronic asset tag, for blades.

The picture below shows a rack containing A3100 chassis and A–Series blades.

on page 13

on page 25

ClearCube Technology, Inc. 7

Page 20

Chapter 1. A–Series Architecture and Product Overview

Chassis with Front Bezel and Rack Ears Front Bezel Removed

Rear of Chassis with

Expansion Backplane

The following figure shows an A3100 chassis with front bezel, rack ears, and expansion

backplane.

Figure 4. The A3100 chassis with front bezel, rack ears, and expansion backplane

The A3100 chassis contains an expansion backplane, a modular component that contains all

signal connectors and a chassis ID for A–Series blades. Figure 5

A3100 chassis and with an expansion backplane.

An A–Series blade connects to the expansion backplane when you insert and seat the blade in

an A3100 chassis. To connect power and Ethernet to a blade in an A3100 chassis, plug power

and Ethernet cables into the expansion backplane. The expansion backplane enables you to

remove the blade from the chassis without disconnecting any cables.

on page 9 shows detail of an

8 A–Series Setup and Installation Guide

Page 21

Cloud Desktops: Zero Clients and Thin Clients

Expansion

Backplane

A3100 ChassisAC Tray

The figure below shows the rear of an A3100 chassis with an expansion backplane attached.

Figure 5. Rear view of A3100 chassis with expansion backplane and AC tray

For more information, see

• “Chassis and Blade Power Requirements”

• “Chassis Expansion Backplane and Cabling”

• “Example Deployment Diagrams”

on page 18.

on page 15

on page 16, and

1.3 Cloud Desktops: Zero Clients and Thin Clients

ClearCube Cloud Desktops include zero clients using PCoIP technology and thin clients

(typically with embedded operating systems). Cloud Desktops connect to Blade PCs over a

standard Ethernet network. Zero clients and thin clients deliver video and peripheral signals to

a user from a Blade PC, allowing users to work over standard switched networks.

Cloud Desktops extend the ClearCube product line to let IT managers use their existing IP

network and cabling infrastructure, regardless of the distance between users' physical locations

and their centralized Blade PCs or other remote computing devices. ClearCube management

software—Sentral—enables IT administrators to manage assets and users, perform connection

brokering, and more.

For detailed instructions about setting up, using, and managing Cloud Desktops, see I/Port

User’s Guide. For information bout PCoIP technology, see PC-over-IP™ System User’s

Guide on the Support site at www.

ClearCube Technology, Inc. 9

clearcube.com/support/.

Page 22

Chapter 1. A–Series Architecture and Product Overview

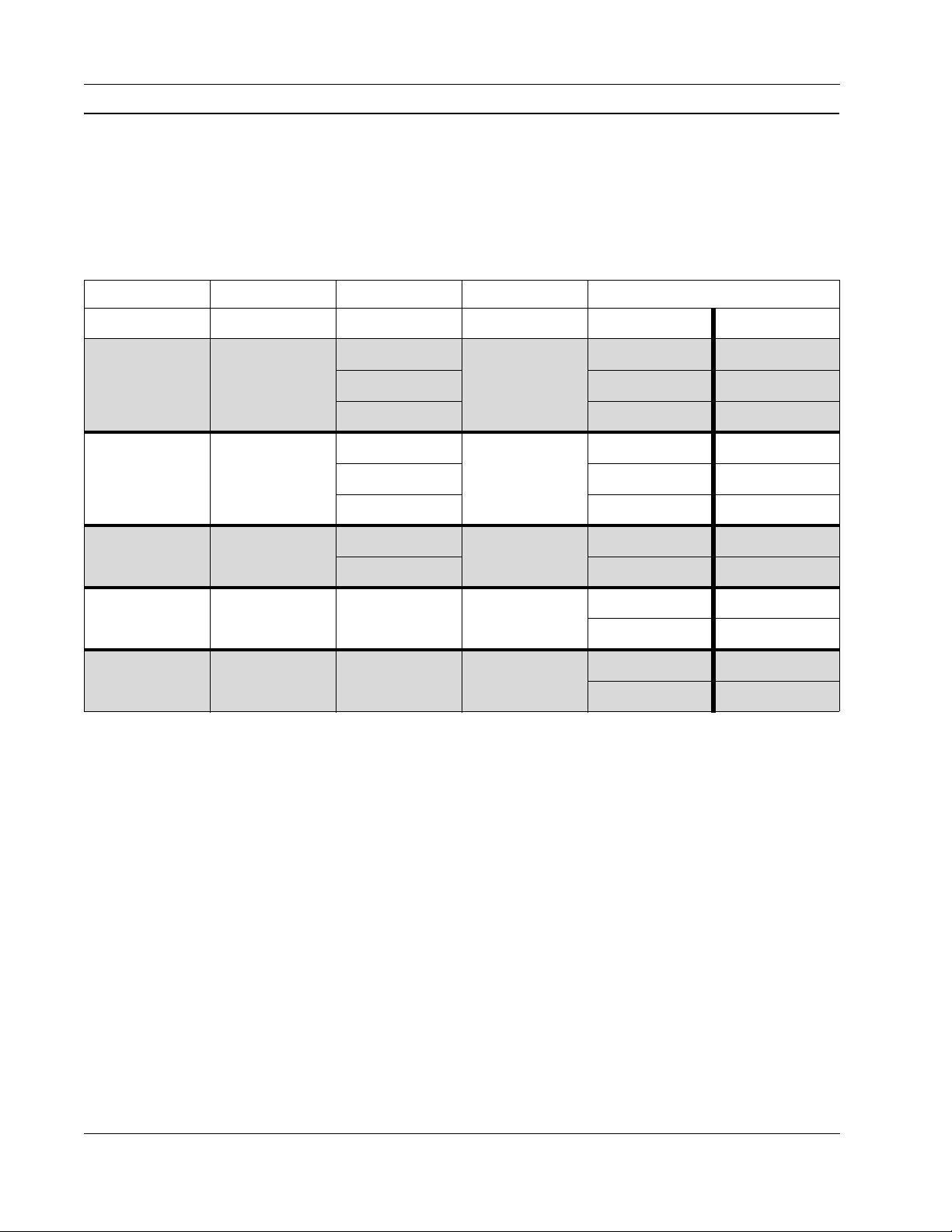

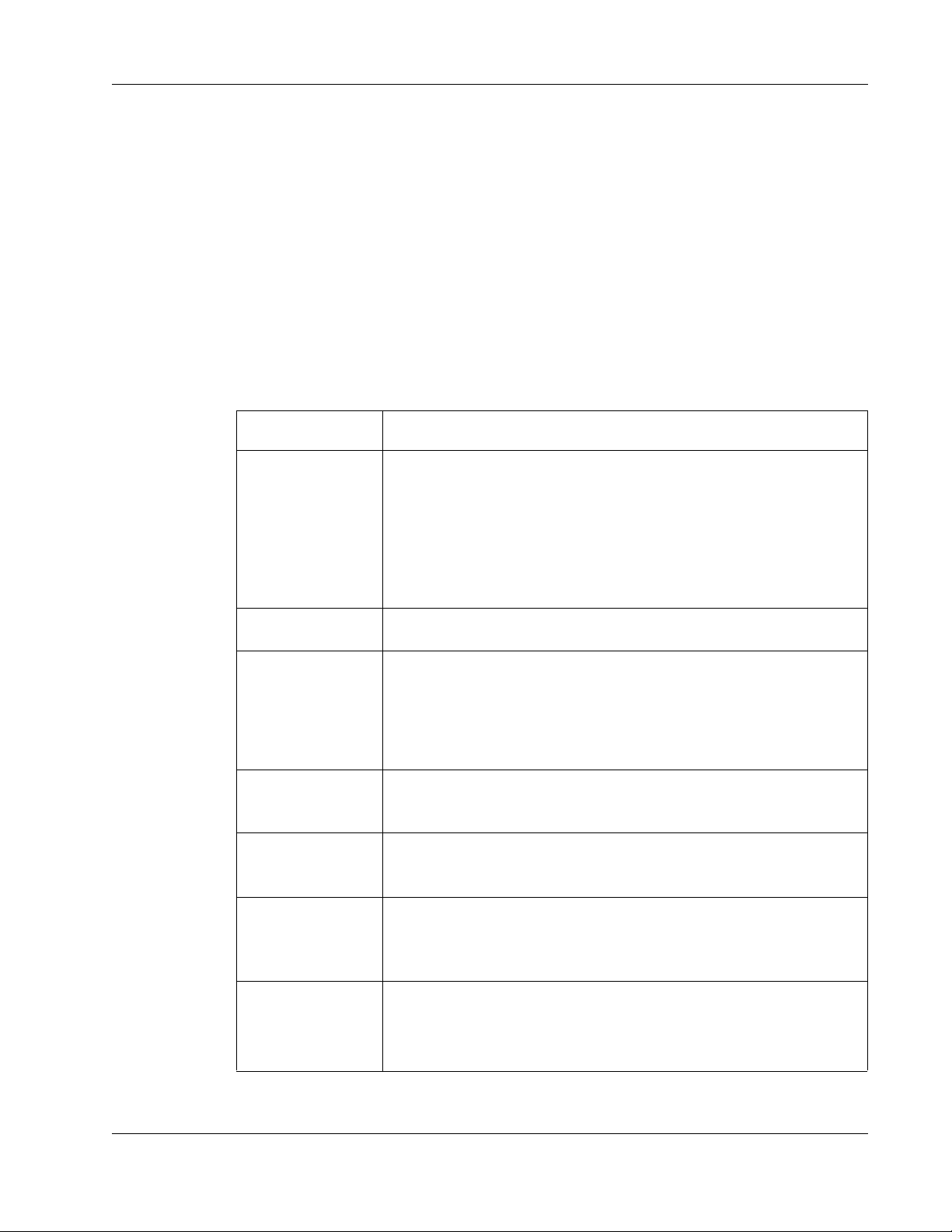

1.4 Monitor Support and Requirements

A–Series Blade PCs support up to four monitors. The table below shows GPU, host card, and

zero client combinations that provide the specified number of monitors and resolutions.

Various GPU and zero client options are available.

Table 1. Monitors, resolution, and device requirements

Monitors Resolution GPU Host Card Zero Client

Copper Fiber

Quadro 2000

1

2560 x 1600

Quadro 4000 CD9624 CD7624

V5422

NVS 310 — CD7822

Quadro 2000

2

1920 x 1200

Quadro 4000 CD9624 CD7624

V5422

NVS 310 — CD7822

Quadro 2000

2

2560 x 1600

V5442

Quadro 4000 CD9754

2

4

2560 x 1600

1920 x 1200

NVS 510 V5442

NVS 510 V5442

†.This model connects to displays using DisplayPort cables.

CD9622 CD7622

CD9622 CD7622

CD9752

†

†

CD7752

CD7754

CD9642 CD7642

CD9644 CD7644

CD9642 CD7642

CD9644 CD7644

†

†

10 A–Series Setup and Installation Guide

Page 23

Chapter 2. Site Preparation and Network

Planning

This chapter describes preliminary steps to take after receiving your A–Series shipment, and

describes the hardware and environmental requirements for your A–Series products. The

following list identifies each of the topics discussed in this chapter.

• “About Your Shipment”

• “Rack and Cabinet Requirements”

• “Space and Floor Support”

• “Cooling and Airflow”

• “Chassis and Blade Power Requirements”

• “Chassis Expansion Backplane and Cabling”

on this page

on page 14

on page 14

2.1 About Your Shipment

This section details precautions to follow before unpacking your shipment and the order in

which to unpack each device in your shipment.

2.1.1 Inspecting Your Shipment and Devices

on page 13

on page 15

on page 16

Examine the outside of all containers in your shipment before opening them.

If you find any external damage to the containers that yo u receive, do not open them.

NOTE

A–Series Setup and Installation Guide 11

Notify the shipper that damage has occurred and request that they inspect the

containers before you unpack them.

Page 24

Chapter 2. Site Preparation a nd Net work Planning

If you discover damaged devices after unpacking your shipment:

• Contact the shipper to notify them of the damage.

• Contact ClearCube Support for a replacement. For information about contacting Support,

see Appendix C. “Support”

CAUTION: Do not use a Blade PC that shows any sign of damage. Using a

damaged blade can cause extensive damage.

2.1.2 Unpacking Your Shipment

ClearCube components are typically shipped in separate containers. The following list

describes the components shipped for typical installations and specifies the order in which you

should unpack your shipment.

on page 61.

NOTE

To protect ClearCube devices, keep them in their shipping containers until you

install, insert, or connect the devices.

1. Chassis—Only unpack before attaching to a previously-installed rack or cabinet.

2. Blade PCs—Only unpack before inserting in an A–Series chassis.

3. Zero client and thin client—Only unpack before connecting to a Blade PC. Cloud

Desktops (zero clients and thin clients) are shipped with or without power supplies and

keyboards, depending on the devices that you use in your environment. See the

documentation included with your zero clients or thin clients for instructions about setting

up, configuring, and using them.

Save shipping containers and packing materials at least until your ClearCube

NOTE

See “Installing an A–Series Chassis”

installing chassis. See “Installing Blade PC in a Chassis”

installation is complete and tested. Use shipping containers for RMAs (see "Return

Merchandise Authorization (RMA)" on page 61 for more information).

on page 21 for instructions about unpacking and

on page 38 for instructions about

installing blades.

12 A–Series Setup and Installation Guide

Page 25

2.2 Rack and Cabinet Requirements

Rack Cabinet

Before installing ClearCube components, it is important to properly prepare the site where you

will install the chassis and Blade PCs. This section explains how to plan for cabinet, rack and

chassis installation. The pictures below show two options for holding ClearCube chassis. A

standard 42U rack or cabinet can hold as many as seven A3100 chassis.

Rack and Cabinet Requirements

Figure 6. A fully-loaded rack with A3100 chassis and a standard 19-inch cabinet

CAUTION: Equipment racks and cabinets can become highly unsta ble if not

adequately secured. Read and follow the manufacturer's specifications and

recommendations for mounting. Additional ClearCube guidelines are

provided throughout this section that—with the manufacturer's

requirements—will ensure a safe installation.

Fully-enclosed electrical cabinets are the preferred option for mounting your ClearCube

chassis. When using cabinets, make sure that:

ClearCube Technology, Inc. 13

Page 26

Chapter 2. Site Preparation a nd Net work Planning

• Front and rear panels and doors are vented to provide sufficient airflow for intake and

exhaust.

• Ensure that you have at least 34 inches (86 cm) of interior depth measured from the front

of the unit to accommodate the cabling that exits from the rear of the chassis.

• Provide adequate space at the back of the rack or cabinet to allow servicing the cables and

equipment.

You can fit cabinets with casters to improve mobility and to ease access when servicing.

WARNING: When installing chassis in a cabinet enclosure, never use only

one set of mounting brackets at the front. Select a cabinet tha t has an

adjustable center rail or rear rail in addition to the front rail. ClearCube's

adjustable mounting kit is required to attach the chassis to both the front

and center/rear rails.

2.2.1 Space and Floor Support

Before installing racks, chassis, and blades, verify that your rack and floor can support the

weight of a fully-loaded rack. If your initial installation contains fewer than seven chassis,

ensure that your rack and floor can support the weight of a fully-loaded rack so you can add

additional blades and chassis in the future. If you are installing other equipment in the rack or

cabinet, take this additional weight into consideration.

Seven fully-loaded chassis (including expansion backplanes) weigh approximately 1347.5

pounds (612 kilograms), not including any cabling. One 42U rack can hold up to seven

chassis, creating a load of greater than 225 pounds per square foot (1099 kilograms per square

meter) for each of the roughly 6 square feet (0.56 square meters) of floor space required for

each rack.

NOTE

When planning for the space required in your data center, include 36 inches in front

of each cabinet to provide adequate room when your remove blades from chassis.

WARNING: Improper structural support could cause the rack or cabinet to lean

and cause the floor to buckle and potentially case structural damage.

2.2.2 Cooling and Airflow

The following sections detail items to consider when addressing cooling and airflow for

A3100 chassis.

A–Series chassis draw cool air (25 degrees Celsius) in through the front of the chassis, and

exhausts it out the back.

14 A–Series Setup and Installation Guide

Page 27

Chassis and Blade Power Requirements

• Ensure that the air conditioning and ventilation system for the installation area can

accommodate your installation’s thermal load. Contact ClearCube Support for detailed

power and cooling requirements tables.

• The rear of the chassis has air vents for Blade PC fans. The fan openings must be at least

five inches from any airflow-impeding barriers such as walls, the rear of the rack door or

panel, large bundles of cables, and so on. The availability of an air exit path from these

fans is imperative for the efficient operation of units. Failure to provide sufficient air

venting will result in a thermal overload of Blade PCs. If the chassis is installed in a

cabinet, use a fully vented rear door or panel.

CAUTION: Failure to provide sufficient space and room ventilation will

result in overheating that can cause eventual unit failure not covere d as

part of unit warranty.

• Each chassis produces varying amounts of heat, depending on processor activity. Contact

ClearCube Support for detailed power and cooling requirements tables. See

Appendix C. “Support”

on page 61 for information about contacting ClearCube Support.

2.3 Chassis and Blade Power Requirements

Your ClearCube system centralizes computing components in a single location, which

centralizes power requirements in one area. Although the ClearCube solution reduces the

overall power required when compared to traditional PCs, the power demands in the IT center

are increased. Use the power and current specifications in this section and in the power and

cooling requirements documentation available on the ClearCube Support site to ensure that

your facilities can provide the required power safely without tripping circuit breakers.

2.3.1 Power Input Considerations

A3100 chassis hold up to 10 blades and have four A/C power inputs (two inputs for each half

of the chassis). For each half of the chassis, one input powers the blades in that half (blades 1

to 5 or blades 6 to 10) and the other input is a redundant backup.

• You must connect both powers cords to the chassis for failover power.

• The maximum steady-state current draw of a single fully loaded chassis ranges between 7

and 12 amps at 120 VAC per input, based on the level of user activity.

• Peak initial current draw of a fully-populated chassis is 16.3 amps at 120 VAC per input.

See ClearCube Support for detailed power and cooling requirements tables. See

Appendix C. “Support”

on page 61 for information about contacting ClearCube Support.

ClearCube Technology, Inc. 15

Page 28

Chapter 2. Site Preparation a nd Net work Planning

2.3.2 Power Circuit Considerations

If you are putting multiple chassis on a single power circuit, ensure that the circuit can safely

handle the combined peak currents of the chassis.

peak current, you must have additional power system capacity installed by a qualified electrician.

CAUTION: Make sure your power strips, power grid, and circuit breakers can

safely provide the required current. Ensure that any extension cords used

meet local safety regulations and local fire codes.

Contact ClearCube for detailed power and cooling requirements tables. See

Appendix C. “Support”

on page 61 for information about contacting ClearCube Support.

If your existing power circuit cannot handle the

2.4 Chassis Expansion Backplane and Cabling

This section shows

• expansion backplane network ports and features

• maximum number of Ethernet cables the expansion backplane supports

• supported cable types for A–Series blades and chassis.

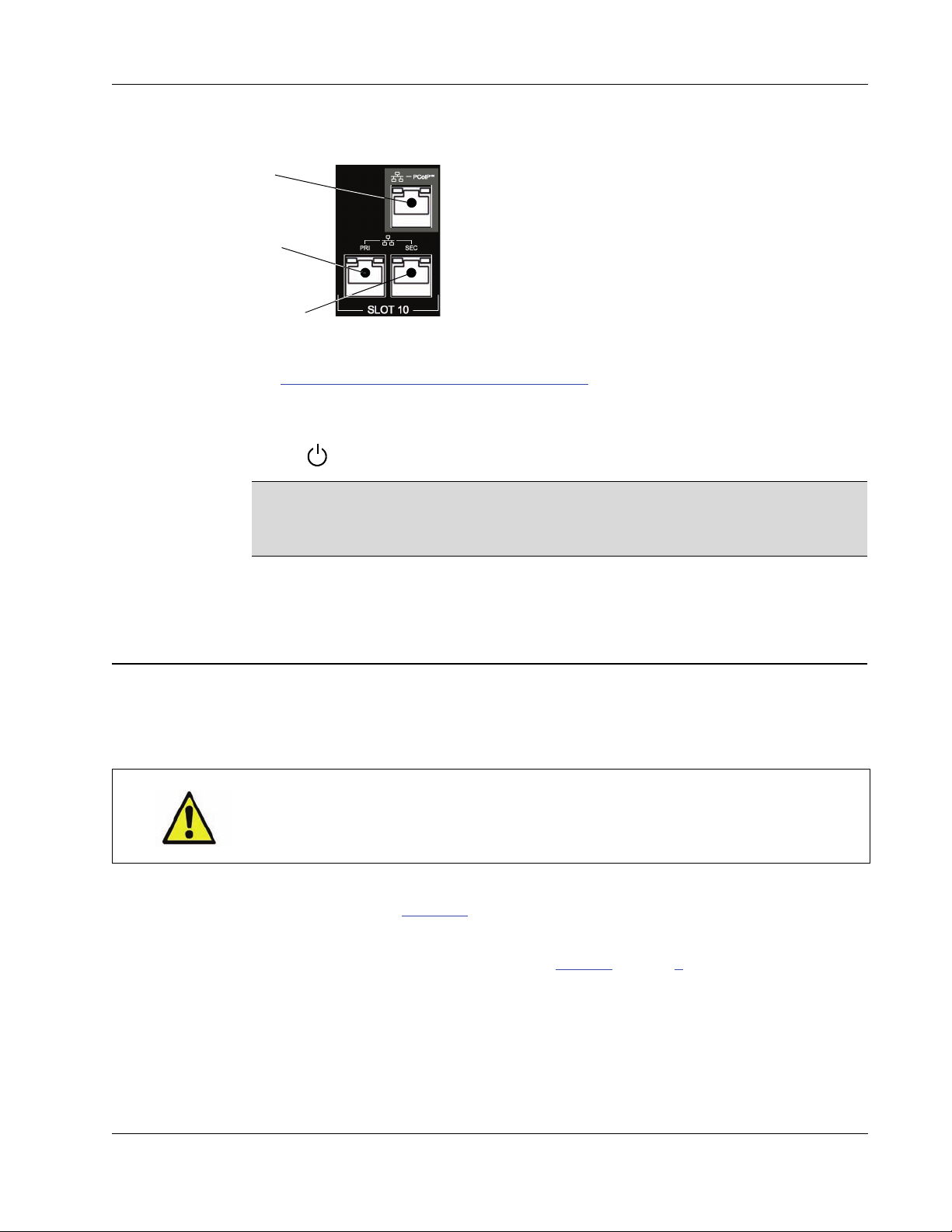

2.4.1 Chassis Ports and Supported Protocols

Network ports on the A3100 expansion backplane (on the rear of the chassis, shown in the

pictures below) support various network functions and protocols. All ports are standard RJ45

Ethernet ports. The list below shows each network port on the expansion backplane, shows the

protocols each supports, and notes any blade model differences.

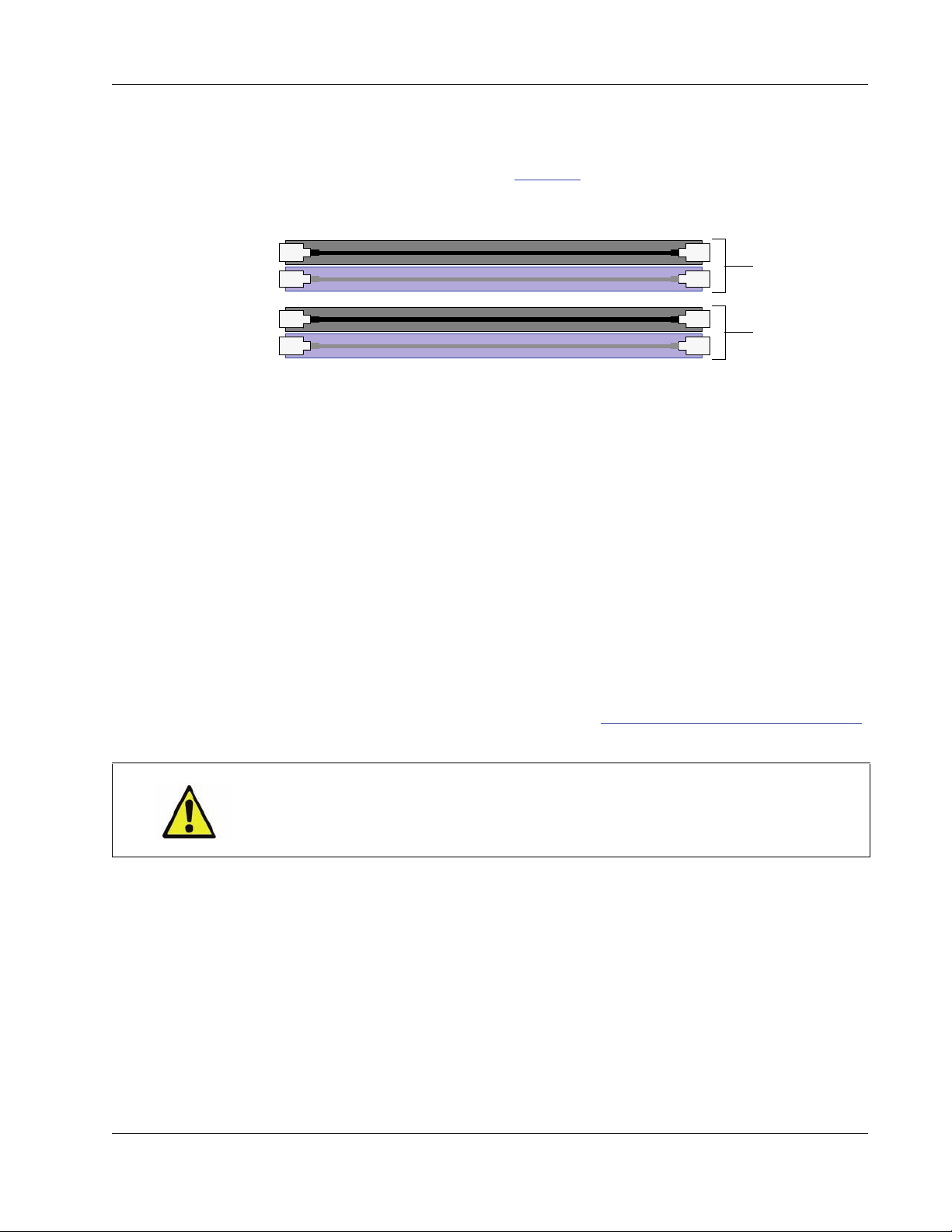

PCoIP

Primary

Secondary

• PCoIP Port — This port is dedicated to all PCoIP traffic

from the PCoIP host card in an A–Series blade.

• Pri (Primary Port) — This port is for standard network

traffic.

• Sec (Secondary Port) — This port is for standard

network traffic for A6106D blades. A6105D blades do

not support the secondary port.

16 A–Series Setup and Installation Guide

Page 29

Chassis Expansion Backplane and Cabling

Ethernet Dedicated

PCoIP

Ethernet

A3100 Chassis

and

Expansion Backplane

A6106D Blade

Ethernet Dedicated

PCoIP

Unsupported

A6105D Blade

The picture below shows the rear of the A3100 chassis and expansion backplane port

assignments for A6106D and A6105D blades.

Figure 7. A3100 chassis expansion backplane with A6106D and A6105D blades

2.4.2 Ethernet Cable Requirements

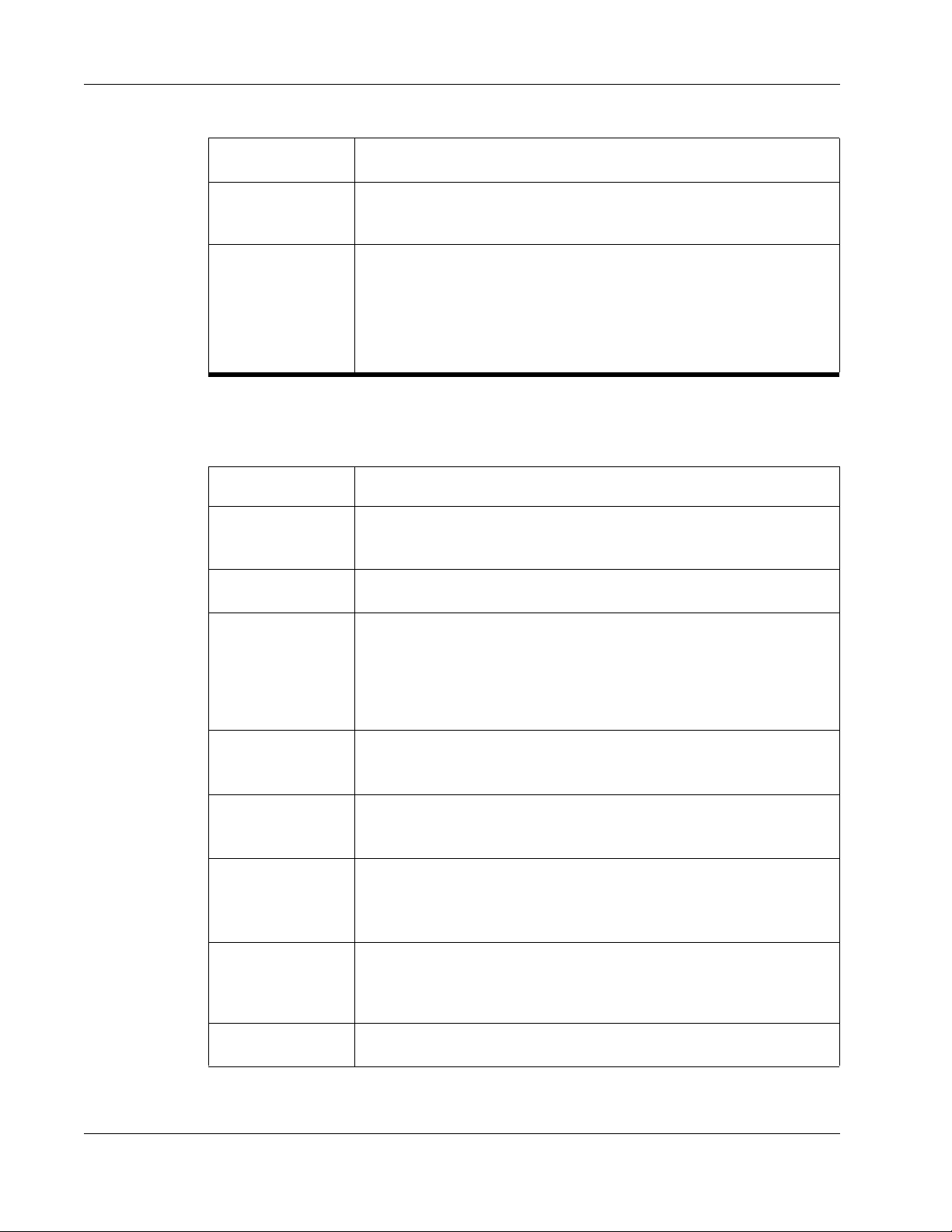

The table below shows, for each blade model, the

• purpose and number of Ethernet cables, and

• the total number of Ethernet cables for each blade model and for a fully-populated chassis.

Table 2. The number of Ethernet cables by Blade PC model and for fully-loaded chassis

Purpose of Cable or Total A6106D Blade PC A6105D Blade PC

PCoIP cable

Primary

Network Adapter cable

Secondary

Network Adapter cable

Total cables for each Blade PC

Maximum cables for each chassis

11

11

1 Not supported

32

30 20

ClearCube Technology, Inc. 17

Page 30

Chapter 2. Site Preparation a nd Net work Planning

2.4.3 Supported Cables

The A3100 chassis uses standard network cables with RJ-45 connectors to connect to Ethernet

networks. The list below shows supported network cable types:

•CAT5

•CAT5e

•CAT6

•CAT6e

Network connections follow standard Ethernet guidelines.

2.5 Example Deployment Diagrams

Each fully-loaded chassis requires up to 30 network cables (depending on blade model and

deployment type) for connections to network hubs or switches (see “Chassis Ports and

Supported Protocols” on page 16 for more information).

18 A–Series Setup and Installation Guide

Page 31

Example Deployment Diagrams

2.5.1 Dedicated PCoIP Network

The picture below is a high-level diagram of a deployment where PCoIP host cards and zero

clients are optimized by isolating PCoIP traffic on a dedicated PCoIP network (using physical

or virtual LANs).

Figure 8. A–Series deployment optimized by isolating PCoIP traffic

ClearCube Technology, Inc. 19

Page 32

Chapter 2. Site Preparation a nd Net work Planning

2.5.2 Shared Network

The picture below is a high-level diagram of a deployment where PCoIP traffic (from host

cards and zero clients) and regular network traffic is on the same network.

NOTE

To optimize PCoIP traffic, ClearCube recommends using dedic at ed net wo rks

(physical or virtual LANs) as shown above.

Figure 9. A–Series deployment with shared PCoIP and regular network traffic

20 A–Series Setup and Installation Guide

Page 33

Chapter 3. Chassis and Blade PC

Installation

Installing ClearCube products is a series of simple tasks that you can perform in a short

amount of time. The following instructions are intended for IT technicians who are familiar

with computer systems and familiar with configuring hardware. This chapter discusses the

following topics:

• “Tools for Installation”

• “Installing an A–Series Chassis”

• “Installing Blade PC in a Chassis”

on this page

on this page

on page 38

3.1 Tools for Installation

You can perform all installation tasks with the following tools:

• #2 Phillips screwdriver—Required.

• 1/4–inch nut driver with magnetic tip—Optional. Suggested for removing and replacing

the self-tapping sheet metal screws located on the A3100 chassis.

3.2 Installing an A–Series Chassis

Mount your A–Series chassis on a standard, 19-inch rack or cabinet to hold your A–Series

blades. The following list describes the chassis components.

• Front Bezel—A removable bezel at the front of the chassis that protects blades and

provides labels for buttons and indicators.

A–Series Setup and Installation Guide 21

Page 34

Chapter 3. Chassis and Blade PC Installation

• Expansion backplane—Provides signal connectors for Blade PCs.

This modular component might be shipped separately from your chassis. If the

NOTE

expansion backplane is not included in your A3100 chassis, see "Attaching and

Removing the Expansion Backplane" on page 28 for instructions about how to

insert the expansion backplane.

The following sections describe:

• The contents of your chassis shipment container. See “Chassis Container Contents”

on this

page for more information.

• How to mount a chassis. See “Mounting A–Series Chassis”

on page 23 for more

information.

The following sections assume that you already have appropriate blade racks, cabinets, or both

correctly installed with adequate space for the chassis you are mounting.

3.2.1 Chassis Container Contents

The list below shows how to unpack your A–Series chassis container.

1. Open the chassis box.

2. Remove the packing material

3. Remove the chassis and set it on a flat working surface.

4. Check the chassis for any visible damage. If you find any product damage, immediately

contact the shipper for an on-site inspection.

A–Series chassis are shipped with the following items:

• Chassis—AC power cords are shipped in a separate container, as described in “Chassis

AC Power Cords” on page 23.

• Quick Start Guide—Briefly describes how to install the chassis and how to install blades

in the chassis.

• Chassis accessory kit—Allows universal mounting in standard, 19-inch racks or cabinets.

The chassis accessory kit includes the following:

– Four rack-mount brackets

– Chassis ground strap and mounting hardware

– Mounting h ardware

See "Using a Chassis Rapid–Mount Kit"

22 A–Series Setup and Installation Guide

on page 25 for information about mounting a kit.

Page 35

Installing an A–Series Chassis

3.2.2 Chassis AC Power Cords

Chassis AC power cords are shipped in different containers than A–Series chassis. Only use

power cords included with your shipment. Chassis shipped to countries with a:

• 100–130-volt power system use power cords rated at 15 amps

• 250-volt power system use power cords rated at 10 amps

• 250-volt power system use power cords rated at 13 amps

3.2.3 Mounting A–Series Chassis

Mount your A–Series chassis to a four-post rack or cabinet using the kit you purchased. The

list below shows each kit.

• Chassis accessory kit— Included with each A–Series chassis. The kit fits all standard,

four-post, 19-inch racks and includes front and back mounting brackets and all necessary

hardware. See “Using a Chassis Accessory Kit”

the kit.

on page 24 for instructions about using

—OR—

• Chassis rapid-mount kit—Compatible with racks and cabinets with four posts and

square mounting holes for snap-in rack nuts. Not all third-party racks are compatible with

the chassis rapid–mount kit. See “Using a Chassis Rapid–Mount Kit”

instructions about using the kit.

NOTE A–Series chassis do not support two-post enclosures.

Before mounting your chassis, ensure that you have the tools listed in “Tools for Installation”

on page 21.

CAUTION: To avoid equipment damage and potentia l personal injury, install

the chassis without blades installed.

on page 25 for

3.2.3.1 Cabinet Mounting Considerations

A–Series chassis draw cool air in through the front of the chassis and exhausts it out the back.

If you mount your A–Series chassis in a cabinet-style enclosure, ensure that:

• There is at least 34 inches (86 cm) of interior depth measured from the front of the

enclosure to accommodate the cabling and air flow that exits from the rear of each chassis.

• If the cabinet enclosure front doors are not vented, add an additional 4 inches (11 cm) in

front of the chassis for proper airflow.

• The spacing between the front and back rails is no more than 30 inches (76 cm).

ClearCube Technology, Inc. 23

Page 36

Chapter 3. Chassis and Blade PC Installation

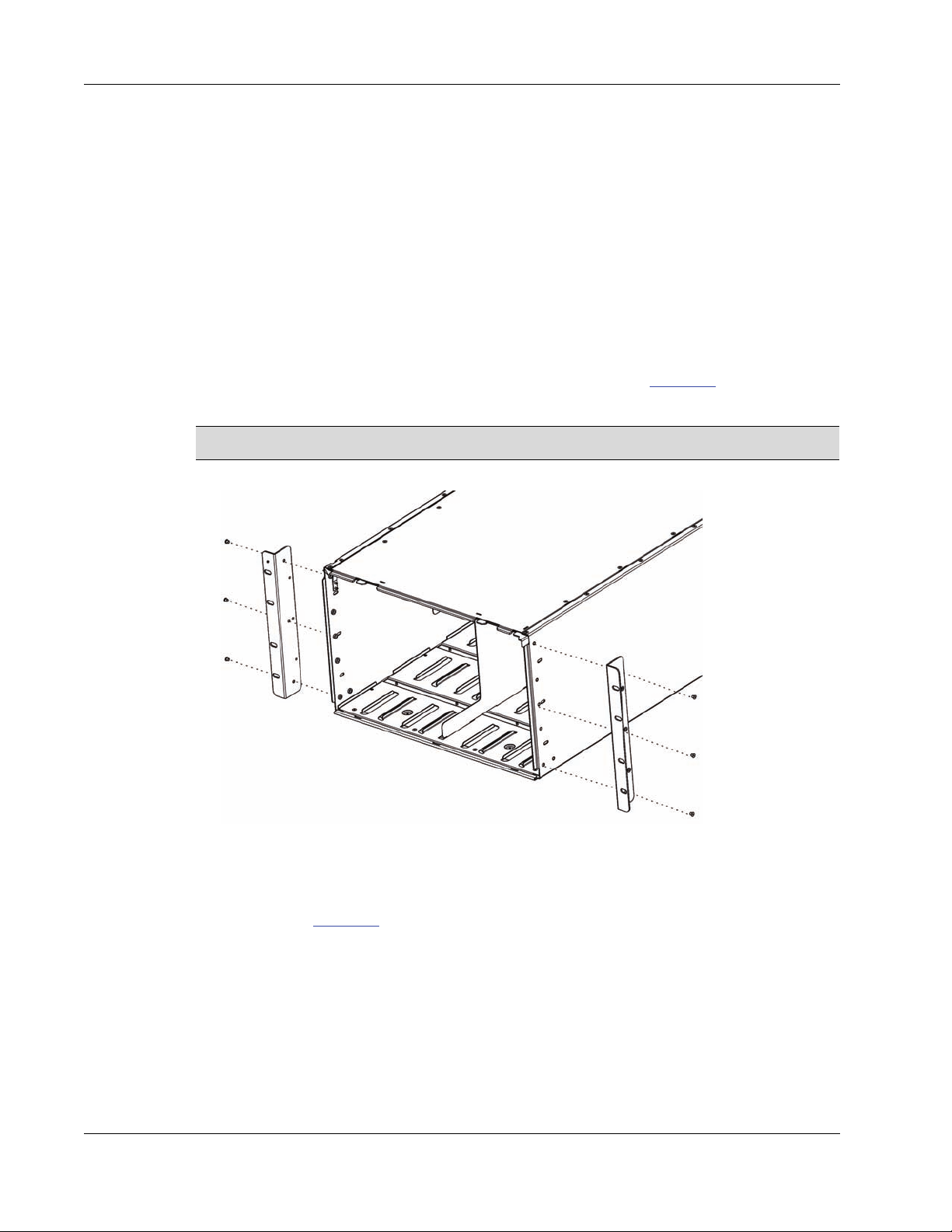

3.2.3.2 Using a Chassis Accessory Kit

Using the brackets and hardware included in your kit, you can install an A–Series chassis from

the front or from the rear of the rack.

To install a chassis using the chassis accessory kit, perform the following steps.

1. When installing in a cabinet enclosure, loosely attach the adjustable rear mounting

brackets to the chassis with three screws on each side.

2. Position the chassis in the cabinet so that the front of the chassis lines up with the front rail

and then slide the adjustable rear brackets into place. Tighten the screws that hold the rear

brackets in place.

3. With the rear brackets firmly attached to the chassis, slide the chassis into the cabinet from

the rear. Open the front bezel of the chassis (latch is shown in Figure 20

then attach the front brackets with three screws on each side.

NOTE You can attach front brackets from the inside or from the outside of the chassis.

on page 38) and

Figure 10. Attaching front brackets

4. Using th e hardware provided with your cabinet, attach the chassis mounting brackets to

the cabinet rails.

5. As shown in Figure 11

below, attach one end of the ground strap (included with the

chassis) to the chassis and attach the other end to the rack frame with the two 10-32 screws

24 A–Series Setup and Installation Guide

Page 37

Installing an A–Series Chassis

Attach End to Rack Frame

supplied in your shipment. Obtain a cage nut to attach the strap to your cage. Ensure that

the rack is properly grounded.

Figure 11. Chassis ground strap attached to the Dual Input Module (located above the expansion backplane)

g

6. Supply power to the chassis.

a. Attach the AC power cords included with the chassis to the rear panel power

connectors on the chassis.

b. Connect the AC power cords to a surge-protected power source such as an

uninterruptible power supply (UPS) or power strip. Use the cable retention clamps

(included with your chassis) to secure the power cables.

ClearCube products shipped to countries using 100-130-volt power systems

NOTE

include power cords rated at 15 amps. ClearCube products shipped to countries

using 208-240-volt power systems include power cords rated at 10 amps. See

"Safety Guidelines"

on page x for more information.

Ensure that all rooms or data centers in which you install Blade PCs are clean before you begin

installing blades. ClearCube recommends completing all additional chassis hardware

installation and preliminary network cabling for zero clients and thin clients (if applicable)

before you begin installing any Blade PCs.

3.2.3.3 Using a Chassis Rapid–Mount Kit

The chassis rapid–mount kit is compatible with most four-post racks and cabinets. To install a

chassis with the chassis rapid–mount kit, perform the following steps.

1. Ensure that you:

– Install your chassis from the front of the rack or cabinet.

– Begin installing chassis at the bottom of the rack or cabinet to provide support for

each chassis before it is securely mounted. This simplifies getting the chassis square

and level in the rack.

2. Unscrew the thumbscrew holding each pair of chassis and rack brackets together, and then

slide the brackets apart.

– The bracket co ntaining springs is the rack bracket and is installed on the rack.

– The solid bracket is the chassis bracket, and it is screwed to the chassis.

3. Remove the front rack ears that are currently on the A3100 chassis.

ClearCube Technology, Inc. 25

Page 38

Chapter 3. Chassis and Blade PC Installation

Locking Latch

Main Bracket Finger Handle

Spring Slider

Flanges

Slider (Back)

Rack Ears

Front Rack Ears

Slider Ears Inserted

in Rear Post

Front Ears

Inserted in Front Post

4. Mount the chassis bracket to the chassis with four flathead screws included in your kit.

Repeat on the other side of the chassis.

NOTE

You can use the chassis and rack brackets on either side of your rack or cabinet;

that is, the brackets are not specific to either side of your enclosure.

Figure 12. Rack bracket for chassis rapid–mount kit

5. Determine the location and holes to use to mount the rack ears on the rack bracket. A

guide is provided with the chassis rapid–mount kit.

6. Insert the slider rack ears, as shown in the left portion of Figure 13

on this page, in the

back side of the rear rack post.

26 A–Series Setup and Installation Guide

7. Pull the rack bracket forward and insert the front rack ears into holes on the front side of

the front post, as shown in the right-hand portion of Figure 13

Figure 13. Rack bracket attachment points

8. Push forward on the ears until the locking latch, shown in Figure 12

on this page.

on page 26, snaps and

locks into place. To ensure that the bracket is level, check that you placed the front and

rear ends of the bracket in corresponding holes on the front and rear post. If you need to

Page 39

Installing an A–Series Chassis

reposition the brackets, remove them as described in “Removing a Rapid–Mount Kit

Bracket” on this page.

9. With the other rapid–mount kit bracket, repeat steps

4 through 6 on the opposite side of

the rack, ensuring that the bracket is in the appropriate, mirrored orientation. Ensure that

the brackets are level with each other.

10. Slide the chassis and brackets onto the rack brackets from the front. Ensure the U channels

on the chassis bracket engage the flanges on the rack bracket.

11. Slide the chassis all the way onto the rack brackets until flush with the front of the rack

and tighten the thumb screws.

12. Attach the ground strap provided with each chassis to the chassis and to the rack, and

ensure that the rack is properly grounded. Use a 10-32 screw and cage nut (not included)

to attach the strap to your cage.

CAUTION: High Leakage Current. Connect chassis earth ground before

supplying AC power to the chassis.

13. Supply power to the chassis (see “Chassis Power and Failover Power Feature”

on page 30

for information about the chassis failover power feature).

a. Attach the AC power cords included with the chassis to the power connectors on the

chassis AC tray (see Figure 14

on page 28).

b. Connect the AC power cords to a surge-protected power source such as an

uninterruptible power supply (UPS) or power strip, and use the cable retention clamps

to secure the power cables.

ClearCube products shipped to countries using 100–130-volt p ower systems include

NOTE

power cords rated at 15 amps. ClearCube products shipped to countries using

208–240-volt power systems include power cords rated at 10 amps. See "Safety

Guidelines" on page x for more information.

Ensure that all rooms or data centers in which you install Blade PCs are clean before you begin

installing blades. ClearCube recommends completing all additional chassis hardware

installation and preliminary network cabling for Cloud Desktops before you begin installing

any Blade PCs.

3.2.3.4 Removing a Rapid–Mount Kit Bracket

To remove a rapid–mount kit bracket (shown in Figure 13 on page 26), perform the steps

below.

1. Use your finger to pull the finger tab on the front of the bracket toward the rear of the

bracket.

2. Slide the ears forward and remove the bracket. Repeat on the other side.

ClearCube Technology, Inc. 27

Page 40

Chapter 3. Chassis and Blade PC Installation

Expansion

Backplane

A3100 Chassis

AC Tray

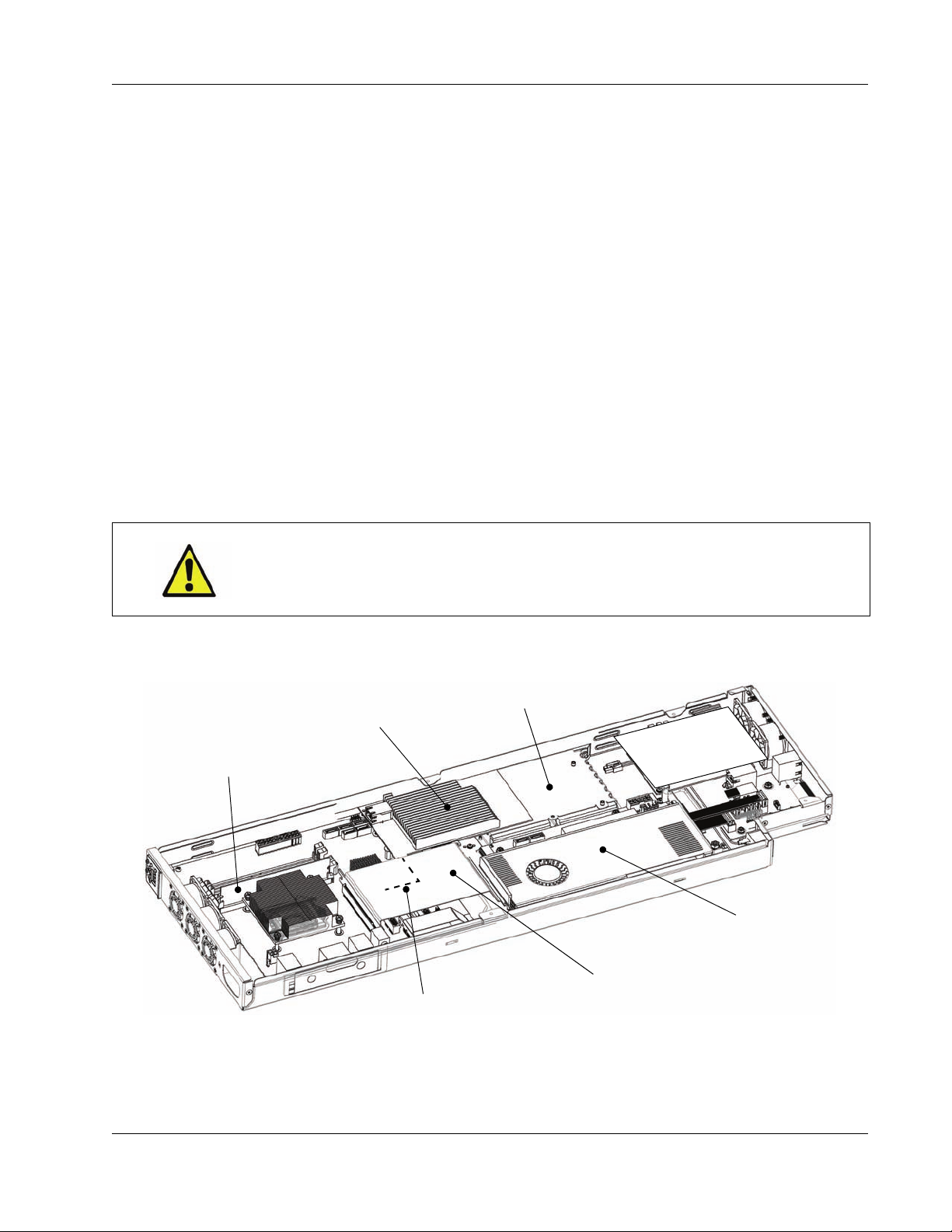

3.2.4 Attaching and Removing the Expansion Backplane

This section describes how to attach and remove the expansion backplane from the A3100

chassis. The following figure shows the rear of an A3100 chassis with an expansion backplane

attached.

Figure 14. Rear view of A3100 chassis with expansion backplane

The expansion backplane contains all signal connectors and an electronic asset tag for the

A3100 chassis.

3.2.4.1 Attaching the Expansion Backplane

Perform the following steps to attach the expansion backplane to an A3100 chassis.

1. Ensure that no AC power cords are connected to the chassis. If any AC power cords are

connected, remove them.

2. From the rear of the chassis, insert the hooks on each side of the expansion backplane into

the slots on each side of the chassis, then gently lower the backplane until it rests on the

28 A–Series Setup and Installation Guide

Page 41

Installing an A–Series Chassis

Expansion

Backplane Hooks

Chassis Slots for

Hooks

chassis. The following figure shows the backplane hooks and the corresponding slots on

the chassis.

Figure 15. Attaching the expansion backplane to a chassis

3. Insert the screws included in your kit into the flanges on the bottom edge of the backplane. Use

a #2 Phillips screwdriver to screw both screws into the chassis, as shown below.

Figure 16. Location of screws on the bottom edge of the expansion backplane

Connect power to the chassis, as described in “Chassis Power and Failover Power Feature”

below, to complete your chassis installation.

3.2.4.2 Removing the Expansion Backplane

Perform the following steps to remove the expansion backplane from an A3100 chassis.

1. Ensure that you disconnect all AC power cords from the chassis.

2. Use a #2 Phillips screwdriver to remove both screws from the flanges on the bottom edge

of the expansion backplane. Figure 16

3. Gently lift the expansion backplane straight up to remove the hooks on each side of the

backplane from the slots on the chassis.

ClearCube Technology, Inc. 29

above shows the location of the screws.

Page 42

Chapter 3. Chassis and Blade PC Installation

Power Receptacles for

Blades 6 to 10

Power Receptacles

for Blades 1 to 5

ABCD

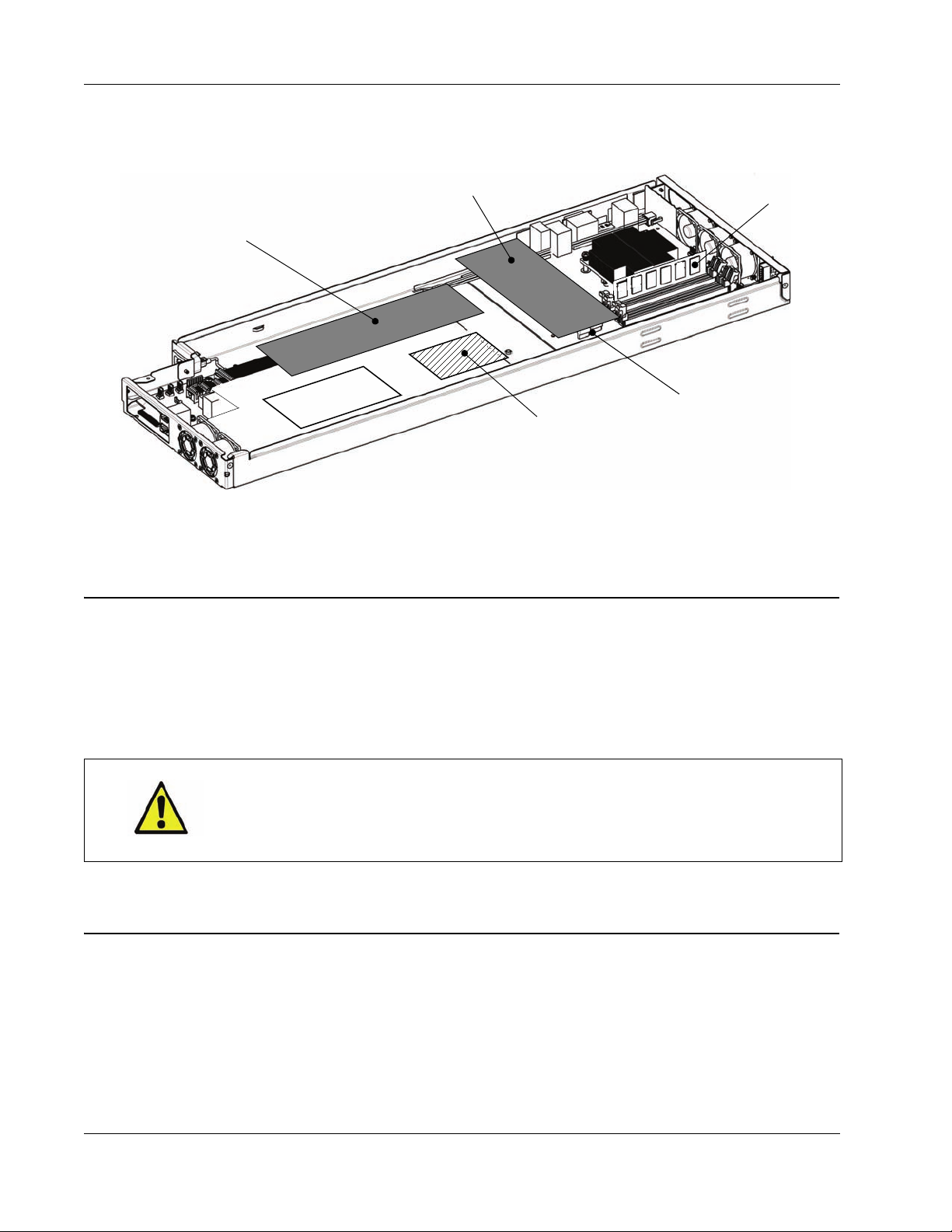

3.2.5 Chassis Power and Failover Power Feature

As shown in the following figure, the A3100 chassis has four power receptacles: two for each

half of the chassis providing power and redundant power.

Figure 17. The A3100 chassis power receptacles

To ensure the most reliable operation of the A3100 chassis, ClearCube recommends that all

chassis power sources are connected to an uninterruptible power supply (UPS).

If excessive power surges or voltage spikes damage the failover power feature, the

NOTE

damage might not be externally evident. Regulating, uninterruptible power supplies

can protect the A3100 from surges and spikes.

The A3100 chassis has four power receptacles:

• Receptacles A and B power blades in slots one through five (one receptacle provides

redundant power when both receptacles are populated—see sections below).

• Receptacles C and D power blades in slots six through ten (one receptacle provides

redundant power when both receptacles are populated—see sections below).

Dual receptacles for each half of the chassis provide failover power for each set of blades.

Power indicator LEDs are below each power receptacle. LEDs are illuminated when

receptacles receive power.

ClearCube recommends the following power configurations.

3.2.5.1 To Enable Chassis Failover Power Feature

Connect power to all power inputs.

• Receptacles A and C provide primary power.

• Receptacles B and D provide failover power. ClearCube recommends connecting the

cords in receptacles B and D to a backup power supply, such as a different power circuit or

to a UPS.

30 A–Series Setup and Installation Guide

Page 43

Configuring A–Series Blade PCs before Installation

3.2.5.2 To Power Chassis without Failover Power Feature

To power a chassis using primary power only (without the failover power feature), connect

power cords to receptacles B and D.

For the most reliable power configuration use the failover power feature, where

NOTE

If only one power cord is connected to an A–Series chassis, only the side of the chassis that is

connected to power will supply power to blades. Only use AC power cords supplied with the

chassis. See Appendix C. “Support”

Support to obtain replacement power cords.

NOTE

power receptacles A and C are powered by a different power source than

receptacles B and D.

on page 61 for information about contacting ClearCube

Based on the level of user activity, the maximum steady-state current draw of a single,

fully-loaded chassis ranges between 7 and 12 amps at 120 VAC on each side of the

chassis (that is, on each power supply). The peak initial current draw is 16 amps on

each input. If you place multiple chassis on a single power circuit, ensure that the

circuit can safely handle the combined currents of all the equipment on the circuit.

Contact ClearCube Support for detailed power and cooling requirements tables.

CAUTION: Ensure that your power strips, power grid, and circuit breakers

can safely provide the required current. Ensure that any extension cords

used meet local safety regulations and fire codes. Use peak current draws

when specifying uninterruptible power supply (UPS) capacity.

Contact ClearCube Support for detailed power and cooling requirements tables. See

Appendix C. “Support”

on page 61 for contact information.

3.3 Configuring A–Series Blade PCs before Installation

The sections below show how to configure A–Series Blade PCs.

3.3.1 Viewing Pre-OS Video (BIOS and Network Boot, PXE Boot)

This section describes how to view video output (such as power-on self test [POST] codes and

BIOS configuration utility screens) generated before a blade or VM operating system starts.

ClearCube Technology, Inc. 31

Page 44

Chapter 3. Chassis and Blade PC Installation

3.3.1.1 Before You Begin

Be sure to have the following:

• a switch connected to a DHCP network

• a Blade PC and a standard computer power cable appropriate for your region (such as a

120 V, IEC 60320 C13 connector with NEMA 5-15 inlet)

• a ClearCube zero client compatible with the blade’s video configuration (a dual zero client

for a dual host card or a quad zero client for a quad host card). The blade’s video

configuration is specified on a label on the side of the blade (shown in Figure 3

• a zero client power supply

• a monitor, appropriate video cable, and power cable

• a USB keyboard and a mouse, and

• two Ethernet cables.

These instructions assume that devices are connected to an imaging network or

other network with a DHCP server to provide IP addresses for the blade's PCoIP

host card and for the zero client. MAC addresses are specified on labels on the side

NOTE

of the blade and on the zero client. To identify the blade host card to connect to from

the zero client, you might need to consult DHCP tables. DHCP tables should show

each device's MAC address and the corresponding IP address assigned to the host

card and to the zero client.

on page 5).

3.3.1.2 Connecting Devices

The list below shows how to connect devices to view pre-OS video.

1. Remove the Blade PC from the chassis as described in “Removing Blade PC from a

Chassis” on page 39. Place the blade on a stable surface, such as a bench or on the top of a

desk.

2. Connect a USB keyboard to a port on the top of the blade. (Ensu re that you do not

disconnect the Ethernet cable that might be visible from this opening.)

3. Connect monitors to the zero client as described below.

NOTE

4. Connect the blade and the zero client to your network:

Connect a monitor to a zero client as described below. Do not connect a monitor

to a video port on the top of the blade.

32 A–Series Setup and Installation Guide

Page 45

Configuring A–Series Blade PCs before Installation

a. Connect an Ethernet cable to the blade's dedicated PCoIP port (the right-most port

on the rear of the blade). Connect the other end of the cable to a switch connected to

your network.

Figure 18. The dedicated PCoIP port on the rear of the blade

b. Conn ect the zero client to the same switch.

c. Optionally, if you are imaging the blade, connect an Ethernet cable to the left-most

LAN port on the rear of the blade and connect the other end of the cable to the switch

(see “Custom Operating System Requirements”

on page 35 for information about

system image requirements).

Figure 19. The LAN port on the rear of the blade

5. Conn ect the monitor and a mouse to the zero client.

6. Conn ect the power adapter to the zero client and then plug the cord into a power outlet.

Next steps: power on blade, create a PCoIP session, and view pre-OS video.

3.3.1.3 Create Session and View Video

The steps below show how to create a PCoIP session to view pre-OS video.

1. Connect a power cable to the external power connector at the rear of the blade and then

plug the cable into a power outlet.

ClearCube Technology, Inc. 33

Page 46

Chapter 3. Chassis and Blade PC Installation

2. Press the power button on the front of the blade to power it on, and then press the power

button on the front of the zero client to power it on.

3. From the monitors connected to the zero client, click the Connect button. After several

moments, the zero client will identify host cards to which it can connect. The zero client

on-screen display (OSD) displays one or more host card IP addresses and their

corresponding MAC addresses.

The video host card MAC address is shown on a label on the side of the Blade

NOTE

PC. The zero client MAC address is on a label on the rear or bottom of the zero

client.

4. Select the blade's host card from the list and click OK.

Result: The zero client connects to the Blade PC’s host card and displays the des kto p.

5. From the operating system, restart the Blade PC.

Result: The operating system displays shutdown messages and the screen goes bl ank.

6. Watch the keyboard lights. As soon as they blink or illuminate, press the F2 key

repeatedly for about 10 seconds.

Result: Pre-OS video is displayed.

7. After performing configuration steps, power off both devices. Remove the Blade PC and

zero client power cables from the power outlets and then remove the cables from each

device.

8. Remove peripherals from both devices.

9. Replace the blade in the chassis as shown in “Removing Blade PC from a Chassis”

on

page 39.

Next steps: You can now deploy your A–Series blade.

3.3.2 Operating System Images

The following sections describe how to:

• Install a customized operating system image on an A–Series Blade PC

• Prepare the default operating system image before deploying an A–Series blade

34 A–Series Setup and Installation Guide

Page 47

Configuring A–Series Blade PCs before Installation

3.3.2.1 Using the Default Operating System Image

If your blades were purchased with Windows operating systems, you must complete the

Windows Out of Box Experience (OOBE) on each blade. The steps below show how to

connect to a blade and complete OOBE.

NOTE

1. Complete the steps shown in sections “Before You Begin”

With one exception, the steps shown below are shown in previous sections. Be sure

to note the exception in the steps below.

on page 32 and in “Connecting

Devices” on page 32.

2. Begin the procedure shown in “Create Session and View Video”

reach step