Cleanware HT-E Installation, Operation And Service Manual

UNDERCOUNTER DISHMACHINES

DRAFT

INSTALLATION, OPERATION,

AND SERVICE MANUAL

HT-E

HT-E Manual • 07610-004-64-85-A

REVISION HISTORY

Revision

Letter

A DRAFT JH N/A DRAFT

Revision

Date

Made by Applicable ECNs Details

iii

NOMENCLATURE

HT-E

Undercounter dishmachine; high-temperature, hot-water

sanitizing, with a booster tank, drain pump, and

detergent and rinse-aid dispensers.

The manufacturer provides

technical support for the

dishmachine detailed in

this manual. We strongly

recommend that you refer to

this manual before making a

call to our technical support

sta. Please have this manual

open when you call so that our

sta can refer you, if necessary,

to the proper page. Technical

support is not available

on holidays.

Contact technical support tollfree at 1-888-800-5672.

Technical support is available

for service personnel only.

iv

TABLE OF CONTENTS

GUIDES

Symbols ...................................................................................................................................... 1

Abbreviations .............................................................................................................................. 1

SPECIFICATIONS

Machine Dimensions .................................................................................................................. 2

Operating Parameters ................................................................................................................ 3

Electrical Requirements ............................................................................................................. 4

INSTALLATION

Installation Instructions ............................................................................................................... 5

Inspection......................................................................................................................... 5

Unpacking ........................................................................................................................ 5

Plumbing .......................................................................................................................... 5

Water Supply Connections .............................................................................................. 5

Pressure Regulator .......................................................................................................... 6

Shock Absorber ............................................................................................................... 6

Connecting the Drain Line ............................................................................................... 6

Plumbing Check ............................................................................................................... 6

Electrical Power Connections .......................................................................................... 7

Voltage Check .................................................................................................................. 7

Surrounding Area ............................................................................................................. 7

Thermostats ..................................................................................................................... 8

Chemical Feeder Equipment ........................................................................................... 8

Priming Chemical Feeder Pumps .................................................................................... 8

Leveling............................................................................................................................ 8

OPERATION

Operating Instructions ................................................................................................................ 9

Preparation ......................................................................................................................9

Filling the Wash Tank ....................................................................................................... 9

Ware Preparation ............................................................................................................. 9

Washing a Rack of Ware ...............................................................................................10

Operational Inspection ................................................................................................... 10

Alarms ............................................................................................................................ 10

Draining.......................................................................................................................... 11

Shutdown & Cleaning .................................................................................................... 11

Deliming ......................................................................................................................... 13

Detergent Control...........................................................................................................14

v

TABLE OF CONTENTS

MAINTENANCE

Preventative Maintenance ........................................................................................................ 15

Drain Pump Cleanout ............................................................................................................... 15

TROUBLESHOOTING

Troubleshooting ........................................................................................................................ 16

PARTS

Tub & Frame ............................................................................................................................. 18

Electrical ................................................................................................................................... 20

Hoses ....................................................................................................................................... 22

Wash & Rinse Arms .................................................................................................................. 24

Plumbing Options ..................................................................................................................... 26

Miscellaneous Parts ................................................................................................................. 27

SCHEMATICS

208-230 V, 60 Hz, 1 Phase ....................................................................................................... 28

vi

GUIDES

NOTICE

SYMBOLS

- Risk of Injury to Personnel

!

WARNING

- Risk of Damage to Equipment

!

CAUTION

- Risk of Electrical Shock

- Caustic Chemicals

- Reference Data Plate

i

GUIDES

- Lockout Electrical Power

- Important Note

- Instructions Hyperlink

ABBREVIATIONS & ACRONYMS

ANSI - American National Standards Institute

CFM - Cubic Feet per Minute

dBA - Decibels Adjusted

GHT - Garden Hose Thread

GPH - Gallons per Hour

GPM - Gallons per Minute

GPG - Grains per Gallon

HP - Horse Power

Hz - Hertz

ID - Inside Diameter

kW - Kilowatts

MCA - Minimum Circuit Ampacity

MOP - Maximum Overcurrent Protection

NFPA - National Fire Protection Association

NPT - National Pipe Thread

OD - Outside Diameter

PRV - Pressure Regulating Valve

PSI - Pounds per Square Inch

V - Volts

07610-004-64-85-A

1

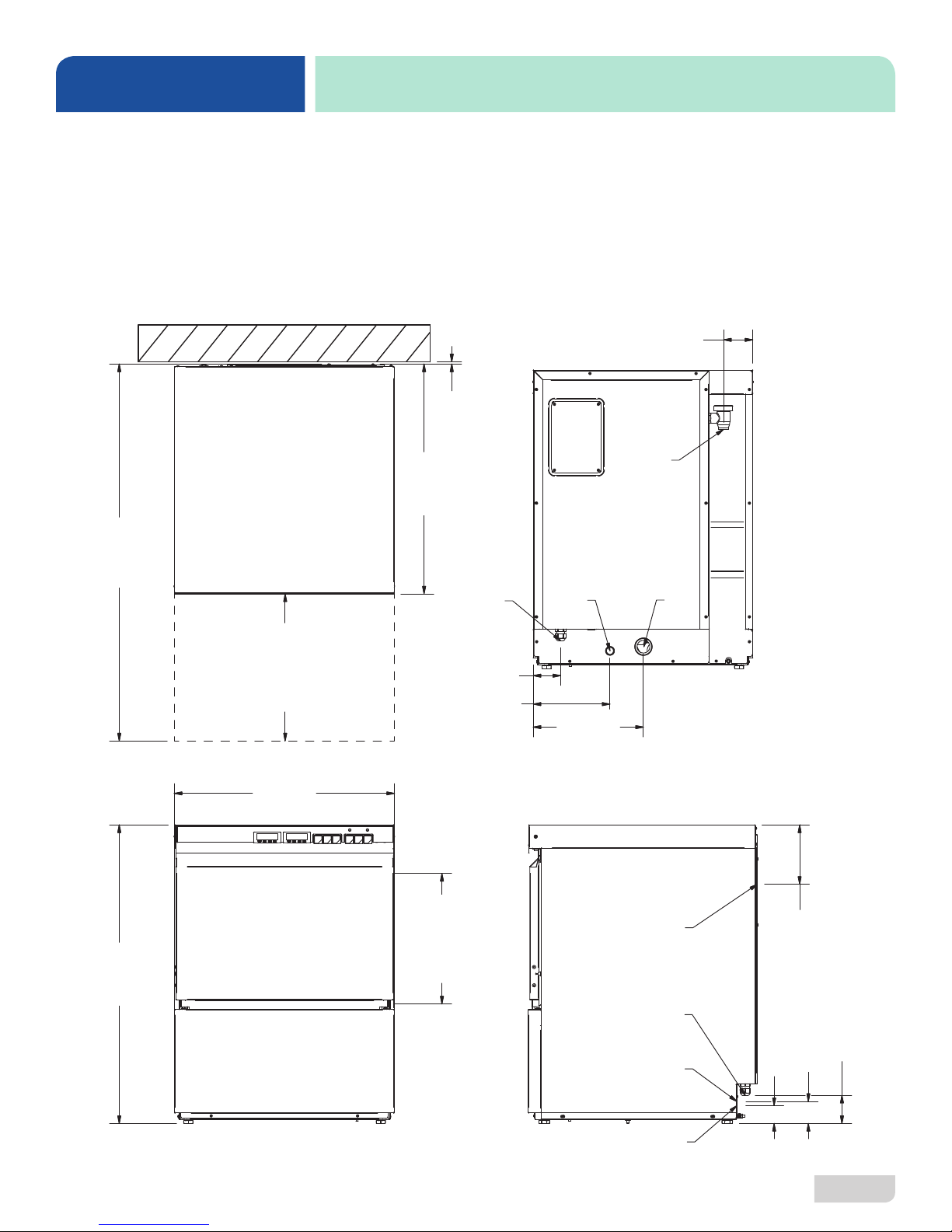

SPECIFICATIONS

LEGEND

A - Electrical Connection

B - Water Inlet (connection actually at end of pre-installed hose)

C - Drain Connection

D - Chemical Connection

All dimensions from the floor can be increased

2” using the machine’s adjustable feet.

]

m

/2

m

1

9

0

2

4

0

1

[

MACHINE DIMENSIONS

[79 mm]

]

m

/4

m

1

7

[

]

m

4

/

m

3

9

4

2

2

TOP BACK

[6

B

3 1/8

A

N

]

E

P

m

4

/

O

m

3

0

R

5

0

1

O

[4

O

D

23 3/4

[603 mm]

4

]

m

/8

m

1

6

2

1

3

[8

FRONT SIDE

1

[76 mm]

[210 mm]

E

]

C

m

N

A

m

R

6

A

5

E

[3

L

C

3

8 1/4

D

11 7/8

[302 mm]

C

B

A

C

]

m

8

/

m

3

2

6

6

[1

]

]

]

8

m

/

8

/

3

7

m

2

8

1

[4

m

m

3

m

6

m

0

[7

[6

07610-004-64-85-A

D

2

SPECIFICATIONS

NOTICE

OPERATING PARAMETERS

Operating Capacity (without Load Time): HT-E

Racks per Hour 32

Dishes per Hour 800

Glasses per Hour 1152

Operating Capacity (with Load Time):

Racks per Hour 25

Dishes per Hour 625

Glasses per Hour 900

Tank Capacity (Gallons):

Wash Tank XX

Booster Tank XX

Electrical Loads (as applicable):

Wash Motor HP 3/4

Wash Heater kW (208 V) 3.2

Wash Heater kW (230 V) 4.5

Booster Heater kW (208 V) 3.9

Booster Heater kW (230 V) 5.5

i

Always refer to the machine data plate for specic electrical and water requirements.

The material provided on this page is for reference only and is subject to change

without notice.

Sound Level:

Workplace-related Emission Value (dBA) 66

Water Temperatures (°F):

Minimum Wash Temperature 150

Minimum Rinse Temperature 180

Minimum Incoming Water Temperature 110

Water Consumption:

Gallons per Rack 0.69

Gallons per Hour 22.1

Other Water Requirements:

Water Flow Pressure (PSI) 20 ± 5

Flow Rate Minimum (GPM) 4.6

Water Line Connection Size 3/4" GHT

Water Line Size (NPT) 1/2"

Drain Line Size (NPT) 1" ID

1 3/8" OD

07610-004-64-85-A

3

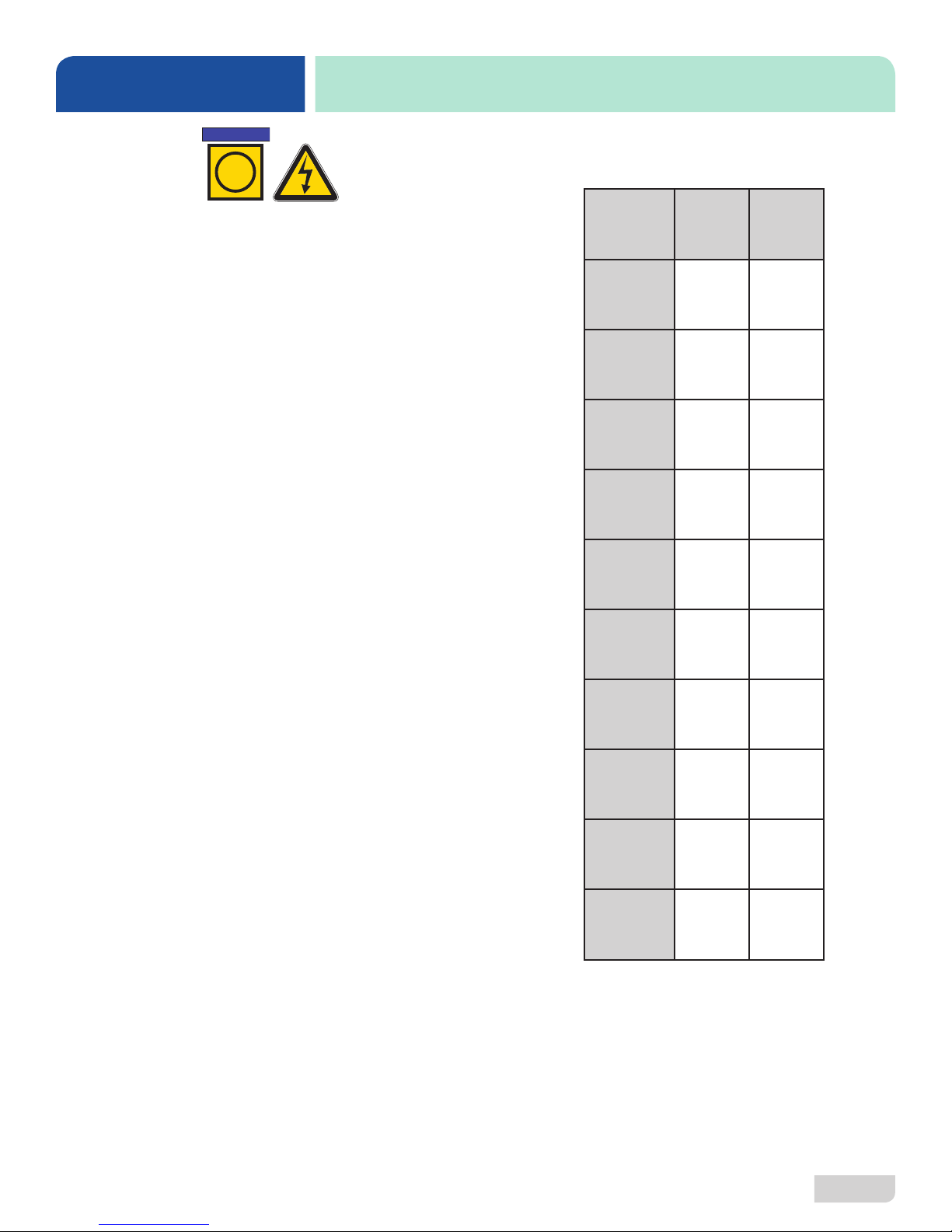

SPECIFICATIONS

NOTICE

i

ELECTRICAL REQUIREMENTS

Electrical Characteristics

HT-E

All electrical ratings provided in this manual are for reference

only. Always refer to the machine data plate to get exact electrical

information for this machine. All electrical work performed on

machines should be done in accordance with applicable

local, state, territorial, and national codes. Work should only

be performed by qualied electricians and authorized service

agents.

Note that all electrical wiring used in the HT-E must be rated, at

a minimum, for 212 °F (100 °C), and that only copper conductors

must be used.

Where applicable, heating element amperage draws have been

adjusted for the assumed input voltage. The manufacturer

assumes incoming voltages will be either 208 or 230 Volts. Some

heating elements used in the machines are rated for other voltages,

such as 240 Volts and 480 Volts. Always verify the amperage

draw of the machine in operation when sizing circuit protection.

Available Electrical Characteristics:

• 208 V, 60 Hz, Single-phase

• 230 V, 60 Hz, Single-phase

VOLTS 208 230

PHASE 1 1

FREQ 60 60

WASH

MOTOR

AMPS

DRAIN

MOTOR

AMPS

RINSE

MOTOR

AMPS

WASH

HEATER

AMPS

BOOSTER

HEATER

AMPS

3.8 A 3.8 A

0.3 A 0.3 A

1.8 A 1.8 A

15.2 A 16.8 A

21.7 A 24.0 A

07610-004-64-85-A

TOTAL

LOAD

MCA 26.8 A 28.8 A

MOP 30.0 A 30.0 A

25.8 A 27.8 A

4

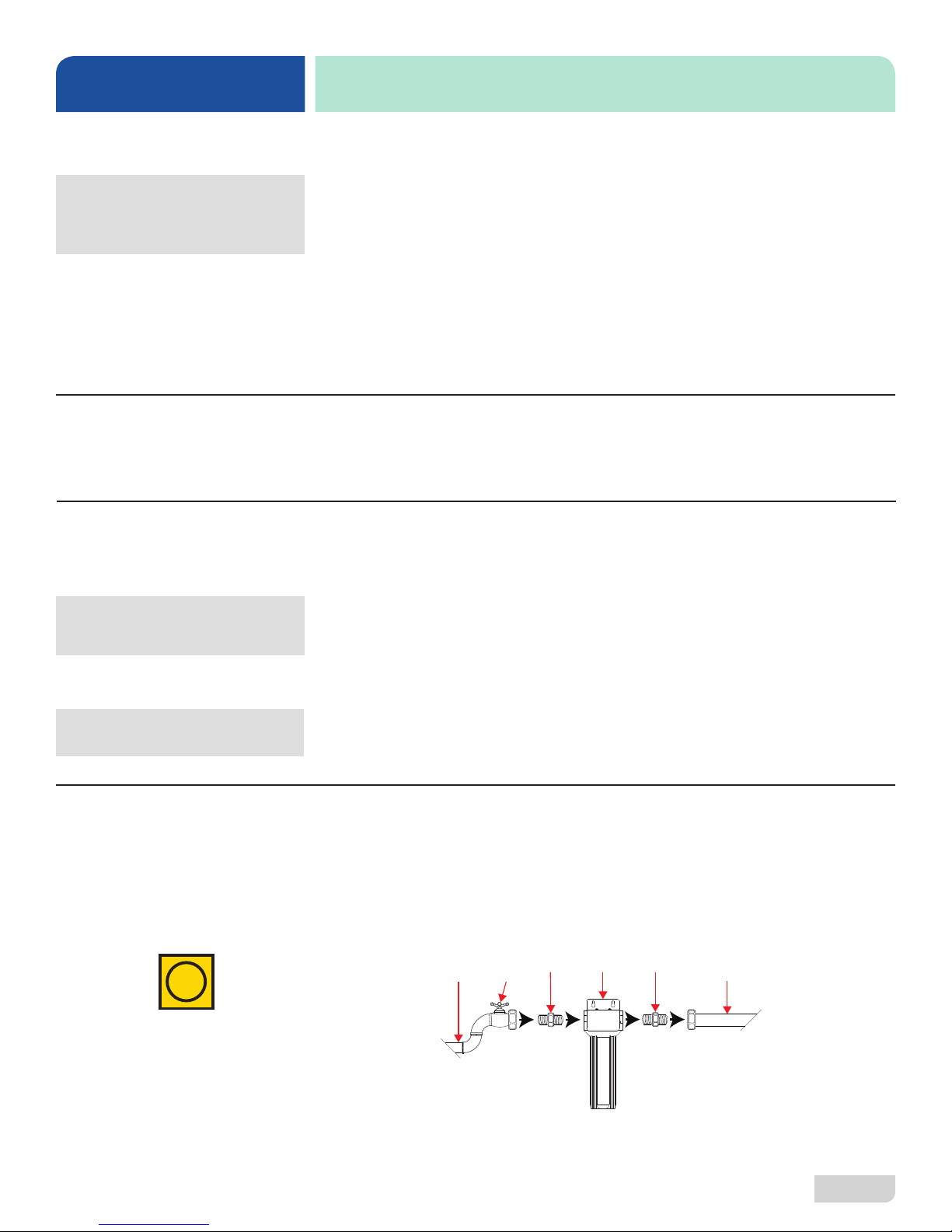

INSTALLATION

Shut-off

Adapter AdapterSPS Machine

Facility

INSTRUCTIONS

INSPECTION

Do not throw away

packaging if damage is

evident!

UNPACKING

PLUMBING

The plumber must ush

the incoming water line!

Before installing machine, check packaging and machine for damage. Damaged

packaging might be an indication of damage to the machine. If there is any type

of damage to both packaging and machine, do not throw away the packaging. The

machine has been inspected at the factory before shipping and is expected to arrive

in new, undamaged condition. However, rough handling by carriers or others might

result in damage to the machine while in transit. If this occurs, do not return machine to

the manufacturer. Instead, contact the carrier and ask them to send a representative

to the site to inspect the damage and request that an inspection report be completed.

Contact the carrier within 48 hours of receiving the machine as well as the dealer that

sold you the machine.

The machine should be unpacked and removed from the pallet before installing. Open

the front door and remove all materials from inside. Once unpacked, verify there are no

missing parts. If a part is missing, contact the manufacturer immediately.

All plumbing connections must adhere to local, state, territorial, and national codes.

The installing plumber is responsible for ensuring the incoming water lines are ushed

of debris before connecting to the machine. Note that chips and materials from cutting

processes can become lodged in the solenoid valves and prevent them from opening

or closing. Any valves found to be fouled or defective because of foreign matter

left in the water line, and any subsequent damage, are not the responsibility of the

manufacturer.

A water hardness test

must be performed.

WATER SUPPLY

CONNECTIONS:

WATER HARDNESS

HIGHER THAN 3 GPG

i

A water hardness test must be performed. If water hardness is higher than 3 GPG,

install a water softener or install the optional Scale Prevention System (SPS). See the

next section and the Plumbing Options page for more information on the SPS.

If water hardness is higher than 3 GPG and a water softener is not being used, install

the SPS into the water line between the facility water line and machine water line.

Observe proper inlet/outlet water directions. A water shut-o valve should be installed

before installing the SPS to allow access for service. The water supply must be

capable of the minimum “ow” pressure at the recommended temperature indicated

on the data plate.

Example

Water Line

Valve

*Adapters needed will vary.

Water Line

07610-004-64-85-A

5

Loading...

Loading...