Page 1

5

PIN SCAN

•

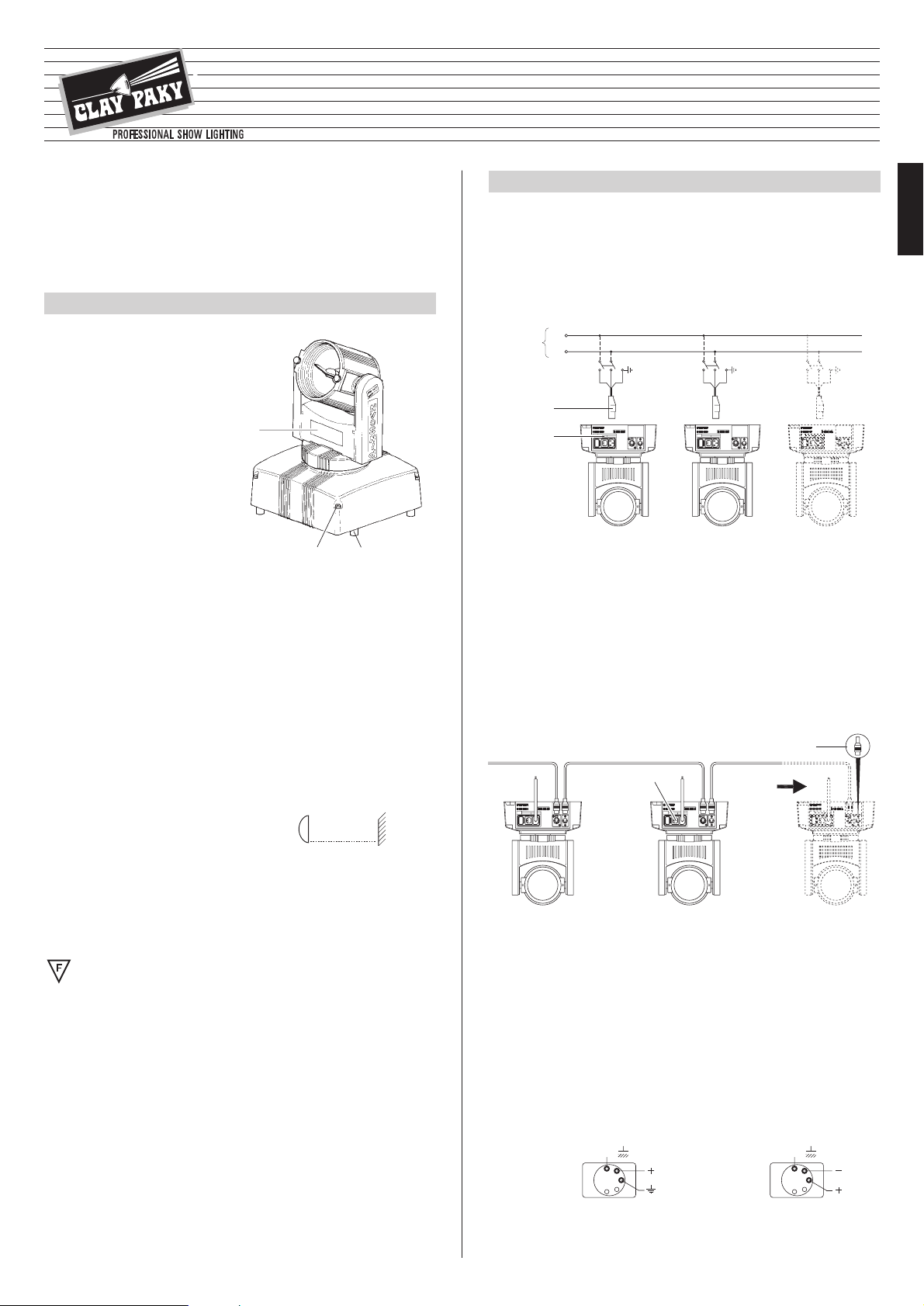

Unpacking

Open the box, remove the projector

from the packing and place it on a

flat, horizontal surface.

Unpack the standard accessories

supplied with the fixture. Inspect the

lamp change label (

1) and replace it

with one of the optional language

versions if necessary.

Make sure that the label is never

removed, as it displays important

safety information.

•

Connecting to the electrical power supply

The operations described in this heading must be carried out by a licensed electrician.

The projector must be wired up to the electrical power supply using the special socket

connector provided (

4).

It is good policy to connect projectors to the power supply by way of dedicated

switches, so that each can be turned on and off individually from a remote station.

The projector is designed to operate at the voltage and frequency indicated on the

electrical data plate (

5). Check that these two values correspond to the mains voltage

and frequency.

IMPORTANT: the projector must be connected to a power supply circuit

having a proper earth system (Class I appliance).

• Connecting the control signals

RS 232/423(PMX) - DMX 512

•

Fitting the lamp

Refer to the directions for replacement of the lamp given under heading 4 MAINTENANCE.

•

Installing the projector

The projector can be placed on the floor on the rubber feet (2) or installed on the ceiling or wall using the holes (

3) in the base.

Make certain that the anchorage is stable before positioning the projector.

•

Minimum distance from target objects

The projector must be positioned in such a way that

objects struck by the beam are located at least 1.3

m (4’ 3”) from the lens.

•

Minimum distance of inflammable materials from any part of the fixture:

m 0.1 (4”).

The fixture may be mounted on surfaces rated normally inflammable.

IMPORTANT: For better and more reliable operation of the fixture, the ambient

temperature must not exceed 35° C (95° F). Protection factor IP 20: the fixture is

protected against penetration of solid bodies more than 12mm (0.5”) in diameter (first

digit 2), but can be damaged by spray, jet, drip or rain water (second digit 0).

23

1

POWER SUPPLY AND INTERFACE

2

Projectors are wired up to the controller and one to the next using two-core

screened cable and Cannon 5 pin XLR type plug/socket connectors.

To connect a DMX line, a terminating plug (

8) with a 100Ω resistor wired between

pins 2 and 3 must be fitted to the last projector connected in series; the plug is not

required when using an RS232/423(PMX) signal.

ENGLISH

INSTALLING THE PROJECTOR

1

IMPORTANT: Read carefully. It is essential for the correct and safe use of the

equipment that erectors and operators should be fully conversant with the

information and instructions given in this manual.

INSTRUCTION MANUAL

ENGLISH

7

6

4

5

Mains

®

The wires must not come into contact with each other or with the metal

casing of the plug.

The casing of the plug/socket must be connected to the screen and to pin 1

of the connectors.

Having completed the operations described above, press the on/off switch (7).

Check that the lamp comes on and the auto-reset sequence starts.

SIGNAL

SCREEN

SIGNAL

54

3

2

1

DMX 512

SIGNAL

SCREEN

SIGNAL

RS232/423 (PMX)

1

2

3

45

12Vmax 100W

L

N

(4’ 3”)

1.3 m

12V - 100W

Page 2

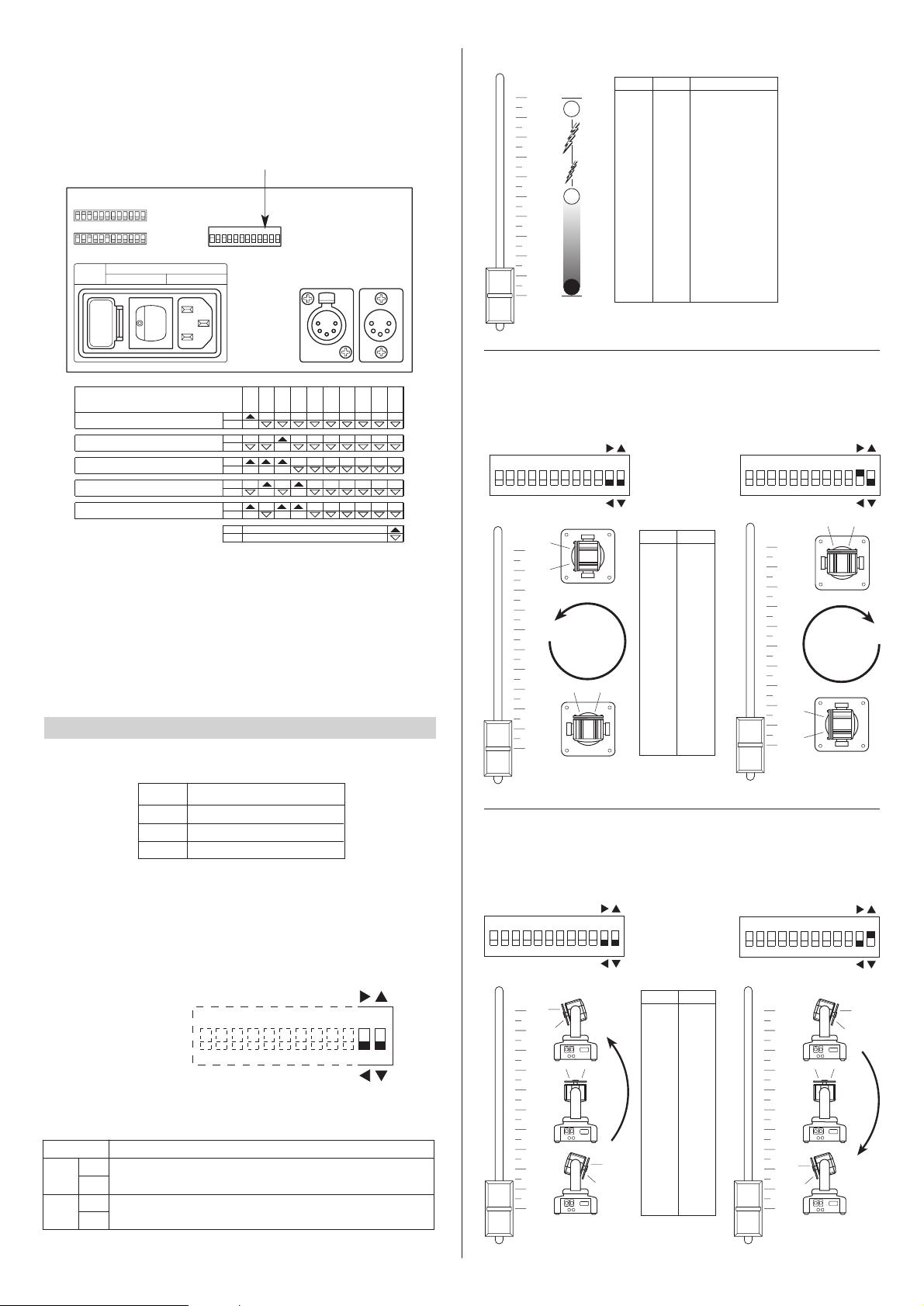

6

1

DIMMER / STOPPER / STROBE

2

PA N

3

TILT

CHANNEL FUNCTIONS AND OPTIONS

3

•

Projector address codes

A single PIN SCAN projector utilizes 3 control channels. To ensure that the different

projectors are addressed correctly by the controller, a code must be assigned to

each one.The operation is carried out on each PIN SCAN by setting the microswitches as indicated in the table below.

DIGITAL START ADDRESS AND OPTIONS SELECT

Projector 1

- Channels 1-3

124

8

163264

128

256

TEST

OFF

ON

CODE

Projector

2 - Channels 4-6

OFF

ON

Projector

3 - Channels 7-9

ON

OFF

Projector

4 - Channels 10-12

ON

OFF

Projector

5 - Channels 13-15

ON

OFF

OFF

ON

Setting the TEST switch to the ON position for a few seconds with the projector

powered-up, an auto-reset routine is carried out. Leaving the TEST switch at the

ON position for a longer period, a full self-test program will be completed; once the

operation has terminated, return the switch to the OFF position.

CHANNEL

FUNCTION

ON

Pan direction change.

OFF

ON

Tilt direction change

OFF

11

12

OPTION FUNCTION

TEST

256

128

64

32

16

8

4

2

1

ON

10987654321 11 1 2

PAN

TILT

OPTIONS

Select the options by setting the microswitches as indicated.

Spotlight selection

0

1

2

3

4

5

6

7

8

9

10

BIT % EFFETTO

244 - 255 95.5 - 100

APERTO

140 54.7

STROBO LENTO

APERTO

0 0.0

CHIUSO

243 95.0

STROBO VELOCE

128 - 139 50.0 - 54.2

• DIMMER / STOPPER / STROBE - channel 1

0

1

2

3

4

5

6

7

8

9

10

BIT %

2550100

0.0

• PAN - channel 2

Operation with option 11 OFF Operation with option 11 ON

TEST

256

128

643216

842

1

ON

10987654321

11 12

PAN

TILT

0

1

2

3

4

5

6

7

8

9

10

TEST

256

128

643216

842

1

ON

10987654321

11 12

PAN

TILT

0

1

2

3

4

5

6

7

8

9

10

BIT %

255

128

0

100

50.0

0.0

• TILT - channel 3

Operation with option 12 OFF Operation with option 12 ON

TEST

256

128

643216

842

1

ON

10987654321

11 12

PAN

TILT

0

1

2

3

4

5

6

7

8

9

10

TEST

256

128

643216

842

1

ON

10987654321

11 12

PAN

TILT

Page 3

7

• Changing fuses

To change the fuses, press the tab (8) and

pull out the fuse holder (

10). Replace any

blown fuse with one of the same type and

rating as indicated on the label (

10)

attached to the holder (

9). Insert the fuse

holder and push in to engage the tab (

8).

• Routine cleaning

To maintain the light output of the projector undiminished, parts that tend to accumulate dust and grease must be cleaned periodically.

To remove dirt from the reflector and filter use a soft cloth moistened with any liquid

detergent suitable for cleaning glass.

CAUTION: Do not use solvents or alcohol

IMPORTANT: isolate the projector from the electrical power supply before

commencing maintenance work of any description.

The maximum temperature on the outer surface of the projector under normal

operating conditions is 100°C (212° F).

After switching off, do not remove any part of the projector for at least 10 minutes; once

this time has elapsed, the risk of a lamp exploding is practically zero.If the lamp needs

changing, wait a further 15 minutes to avoid the risk of burns.

MAINTENANCE

4

ENGLISH

CAUTION:

- When fitting a new lamp read the manufacturer's instructions carefully.

- The lamp must always be changed without delay if damaged or deformed by heat.

•

Only use 12V halogen lamps with a maximum power of 100W made

with low pressure technology.

8

9

10

TROUBLESHOOTING

5

No electrical power supply.

Check that power is available at

the mains socket and/or that fuses

are intact.

PROJECTOR DOES NOT LIGHT UP

FAULTS

PROJECTION FAULTY

REDUCED BRIGHTNESS

POSSIBLE CAUSES CHECKS AND REMEDIES

•

•

••

•

Lamp expended or faulty.

Change lamp (see instructions).

Deposit of dust or grease.

Clean (see instructions).

Cooling

Forced ventilation cooling system using

axial flow fan.

Housing

•

Extruded die-cast aluminium.

• Epoxy powder coated finish.

Operating position

Will function in any position.

Weight and dimensions

Weight: 5.8 kg (12 lbs 12 ozs).

Power supply

•

100-120V 50/60Hz

• 200-240V 50/60Hz

Lamps

•

12V 90W (Halostar).

To be used with special Clay Paky

pencil beam parabola (2.5°).

• 12V/50-75-100W (Halospot).

Built-in reflector with different beam

apertures.

Power consumption

150VA max. (consumption varies in

relation to the lamp).

Channels

N. 3 control channels.

Inputs

•

RS232/423(PMX)

• DMX512

Moving body

•

Movement generated by two

microstepping motors with full microprocessor control.

• Range of adjustment:

- PAN = 360°

- TILT = 227°

• Resolution:

- PAN = ± 1.41°

- TILT = ± 0.89°

TECHNICAL DATA

6

(9.1”)

230

(9.1”)

230

(3.4”)

86

(12.8”)

max 325

(7.5”)

190

1

1

2

3

4

5

3

1

2

• Changing the lamp: type HALOSTAR 12V max 100W with G 6.35 fitting

• Changing the lamp: type HALOSPOT 12V max 100W with G 53 fitting

FUSE

5 x 20

1A T

250 V

Loading...

Loading...