Page 1

• Minimum distance of inflammable materials from any part of the fixture:

0.10 m (4”) for QS and HMI 1200 Basic versions, 0.07 m (3”) f or HMI 575 Basic v ersion.

The fixture may be mounted on surfaces rated normally inflammable.

IMPORTANT: For better and more reliable operation of the projector, the ambient

temperature must not exceed 35° C (95° F). Protection factor IP 20: the fixture is protected against penetration of solid bodies more than 12 mm (0.5”) in diameter (first

digit 2), but can be damaged by spray, jet, drip or rain water (second digit 0).

ENGLISH

SHADOW

POWER SUPPLY AND INTERFACE

2

• Connecting to the electrical power supply

The operations described in this heading must be carried out by a licensed

electrician.

It is good policy to connect projectors to the power supply by way of dedicated

switches, so that each can be turned on and off individually from a remote station.

INST ALLING THE PROJECTOR

1

IMPORTANT: Read carefully. It is essential for the correct and safe use of

the equipment that erectors and operators should be fully conversant with

the information and instructions given in this manual.

INSTRUCTION MANUAL

2

5

4

6

7

3

1

• Unpacking

Open the wooden box, remove the projector from the packing and place it on a flat

horizontal surface. Unpack the standard accessories supplied with the equipment.

Inspect the lamp change label (1) on the projector cover and replace it with one of the

optional language versions if necessary.

Make certain that the label is never removed, as it displays important safety

information.

• Initial assembly operations

Position the bracket (2) on the graduated plate (3) at the desired height, select the

required hole and insert the bushing (4), the chamfered washer (5) and the screw (6)

and tighten the assembly using the supplied Allen wrench.

The bracket can also be mounted on the top of the projector for truss mounting by

inverting the position of the graduated plate (3).

Position the support as desired and then secure it by tightening the knobs (7).

• Fitting the lamp

Refer to directions for replacement of the lamp given under heading 8 MAINTENANCE.

• Installing the projector

The projector can be mounted in any position without its operating characteristics

being affected.

IMPORTANT: for ceiling installation secure the projector in the desired position by

means of the holes in the support. Secure preferably using two ø12 mm bolts with

nuts and lock washers.

Make certain that the anchorage is stable before positioning the projector.

• Minimum distance from target objects

The projector must be positioned in such a way

that objects struck by the beam are separated from

the fixture by at least the distance specified on the

lamp change sticker next to the symbol shown in

the figure on the right.

The projector is designed to operate at the voltage and frequency indicated on the

electrical data plate (8) affixed to the rear end.

Check that these two values correspond to the mains voltage and frequency.

IMPORTANT: the projector must be connected to a power supply circuit having

a proper earth system (Class I appliance).

N

L

Mains

8

10

9

0 - 10V 0 - 10V 0 - 10V

• Connecting the control signals

SHADOW BASIC followspots can be controlled only from the integr ated control panel,

while SHADOW QS models can also be controlled from a remote external controller.

0-10V CONNECTION

When both the external 0-10V controller and the integrated control panel are connected, the higher level signal assumes priority.

The connection between projector and controller must be made using a multicore

cable with 8 wires of 0.25mm

2

section and a DIN 8 pin 45° plug/socket connector.

RS 232/423(PMX) - DMX 512 CONNECTION

- Several Shadow followspots can be controlled simultaneously from the integrated

control panel on one fixture.

7

ENGLISH

QS-ST HMI 1200

QS-LT HMI 1200

Basic HMI 1200

Basic HMI 575

®

(8’ 2”)

2.5 m

(5’ 11”)

1.8 m

HMI 1200

HMI 575

DIM 4

TEMP

1 IRIS

3 DIM

STOP

Is

COL 2

Page 2

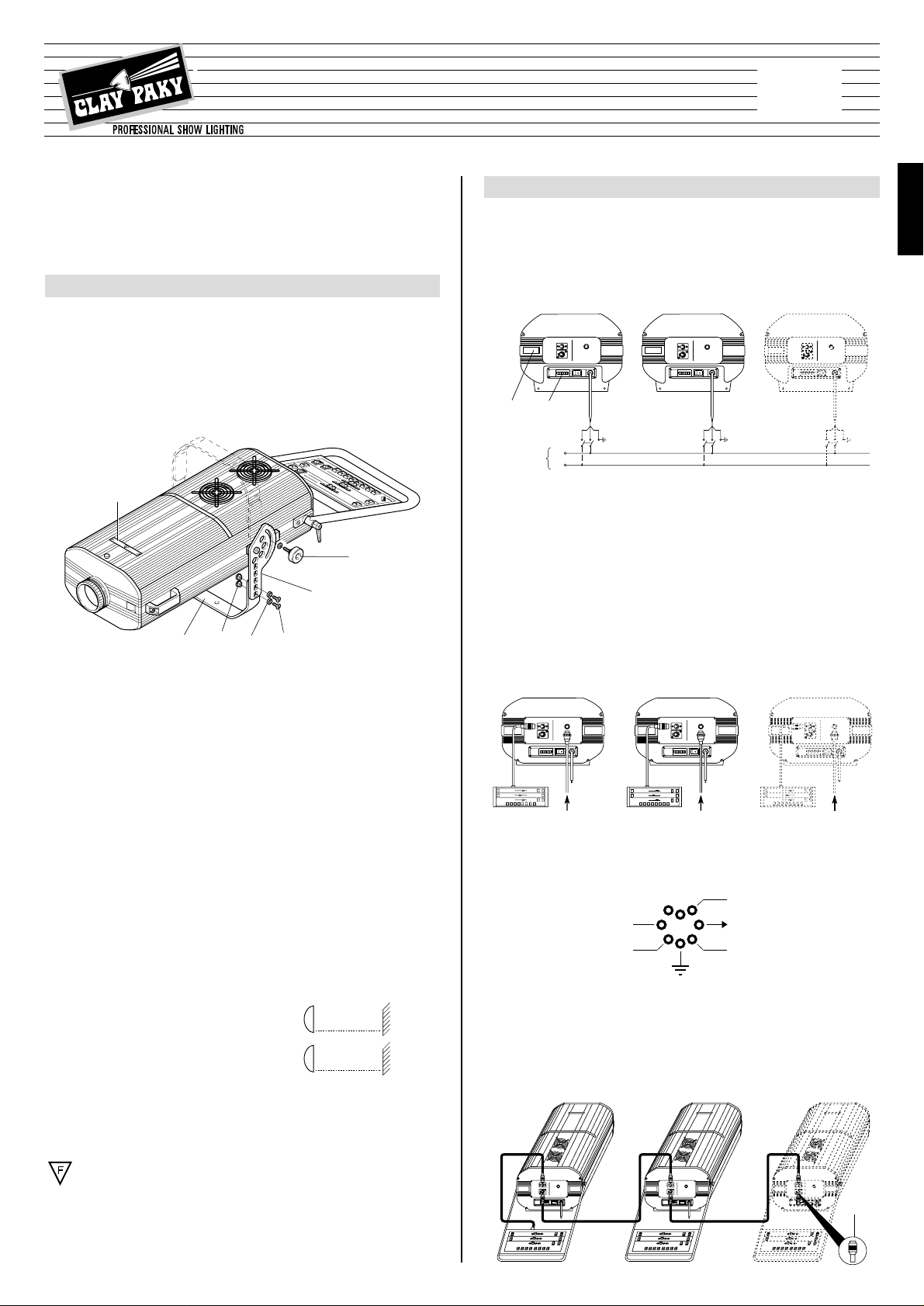

• COLOUR TEMPERATURE CONVERSION - channel 4

0

1

2

3

4

5

6

7

8

9

10

The warm filter is inserted from 0% to

33.2% of slider movement, no filter is

present from 33.7% to 67.0%, and the

cool filter is inserted from 67.5% to

100% of slider movement.

Cold Filter

Warm Filter

To enable independent operation of several Shadow projectors each must be

assigned a unique address code.This procedure calls for the presence of an authorized technician.

Projectors are wired up to the controller and one to the next using two-core screened

cable and Cannon 5 pin XLR type plug/socket connectors.

To connect a DMX line, a ter minating plug (9) with a 100 Ω resistor wired between

pins 2 and 3 must be fitted to the last projector connected in series; the plug is not

required when using an RS232/423(PMX) signal.

The wires must not come into contact with each other or with the metal casing

of the plug.

The casing of the plug/socket must be connected to the screen and to pin 1 of

the connectors.

Having completed the operations described above, press the on/off switch (10).

Check that the lamp comes on and that the auto-reset sequence starts.

CHANNELS FUNCTION (SHADOW QS)

3

FOCUSING

4

• IRIS - channel 1

0

1

2

3

4

5

6

7

8

9

10

The response of the iris to the movement of the potentiometer is linear and

continuous through the full 0… 100%

range, so that the slider can be

stopped in any position to obtain the

desired aperture diameter.

100%

0%

In the 0% to 50% range of adjustment

the dimmer opens gradually to maximum aperture. Strobe effect is produced from 54.7% to 95% with frequency increasing from 1 to 7 flashes/second. The aperture remains

fixed from 95% to 100% of the slider

range.

• DIMMER/STOPPER/STROBE - channel 3

• COLOUR WHEEL - channel 2

WHITE

RED

YELLOW

VIOLET

GREEN

ORANGE

BLUE

PINK

0

3

5

7

8

9

6

4

2

1

10

The change of colour in response to

movement of the potentiometer is linear and continuous, so that the slider

can be stopped in intermediate positions to obtain a two colour beam.

• Focusing - QS-ST version

Set up the channels as shown in

the table. Unscrew knob (11) and

move the lens (12) forwards and

back until the projected image is

perfectly sharp.Secure the lens by

tightening knob (11).

- When connected to an external controller , se v eral projectors can be controlled either

simultaneously or independently.

9

10

8

12 11

CHANNEL FUNCTION

1 IRIS

2 COLOUR WHEEL

3 DIMMER/STOPPER/ STROBE

4

COLOUR TEMPERATURE CONVERSION

POSITION

100% (

Maximum aperture

)

0% (

White

)

100% (

Open

)

0% (

White

)

CHANNEL FUNCTION

1 IRIS

2 COLOUR WHEEL

3 DIMMER/STOPPER/ STROBE

4 COLOUR TEMPERATURE CONVERSION

RS232/423

(PMX)

SCREEN

1

2

3

45

SIGNAL

SIGNAL

DMX

512

SCREEN

1

54

2

3

SIGNAL

SIGNAL

10

9

8

7

6

5

4

3

2

1

0

Page 3

• Focusing - QS-LT version

Tur n knob (13) on the rear of the projector

until the projected image is perfectly

sharp; this procedure can be checked

by means of the pointer (14) which

provides an indication of the focusing distance as shown on

label (15).

13

14

15

The controls are on the dedicated panel which can be tilted downwards through an

angle of 90° star ting from a position on the same axis as the projector body.

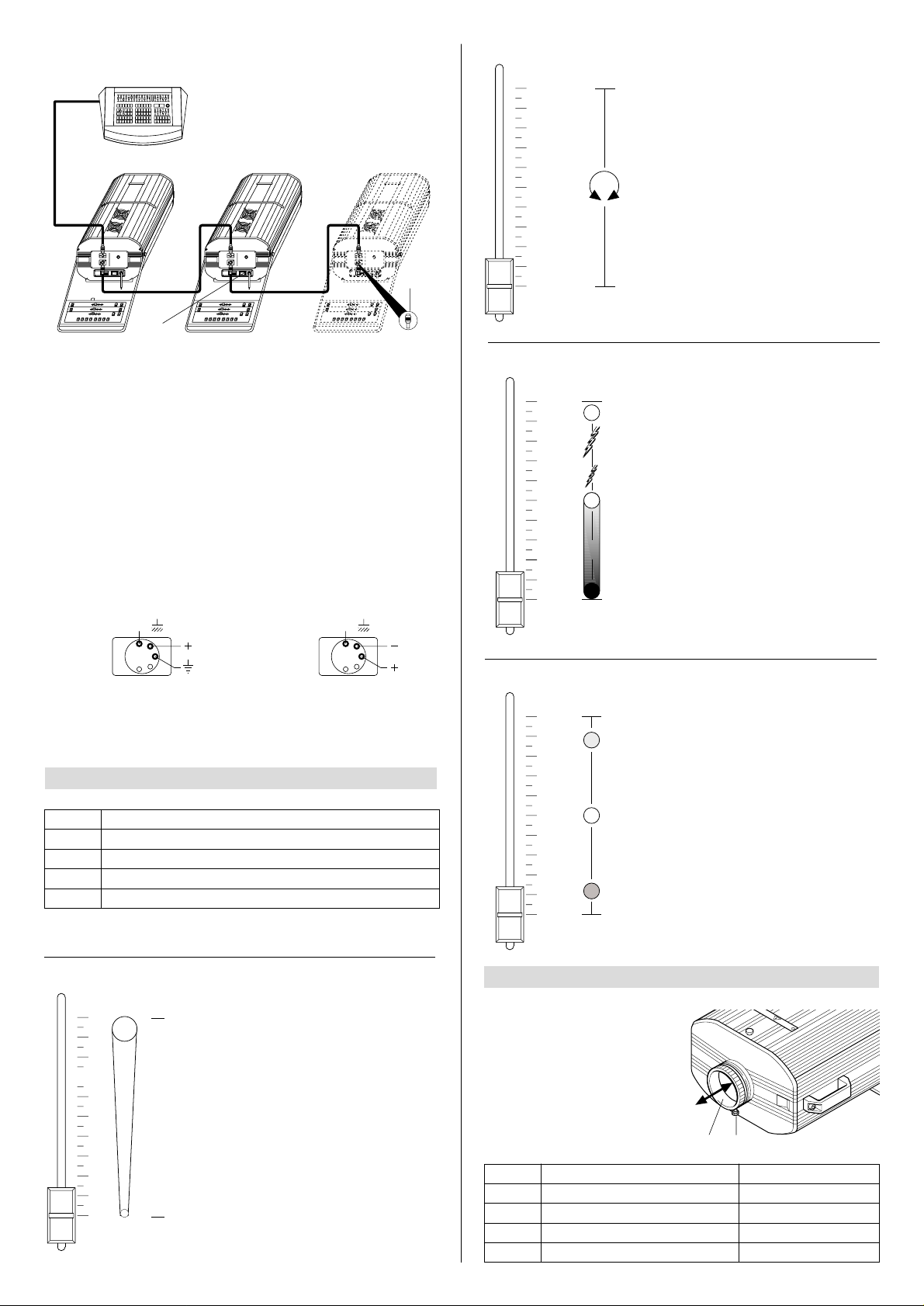

KEY

A) 8 push buttons with indicator lights for insertion of fixed colours with two-colour

beam function by pressing two adjacent buttons simultaneously;

B) 2 flash buttons for instant iris opening;

C) 2 flash buttons for instant stopper opening;

D) 1 potentiometer for iris aperture adjustment;

E) 1 potentiometer for adjusting the dimmer aperture or strobe frequency;

F) 1 potentiometer for adjusting the rotation speed of the colour wheel

(with selector I set to rainbow);

G) 1 dimmer or strobe selector;

H) 1 colour temperature conversion selector;

I) 1 rainbow effect or fixed colour selector.

QS CONTROL PANEL

5

AIH

G

FDE BCBC

KEY

A) 2 flash buttons for instant stopper opening;

B) 2 flash buttons for instant rainbow effect;

C) 2 flash buttons for instant iris opening;

D) 1 selector for dimmer or strobe effect;

E) 1 selector for rainbow effect or fixed colours;

F) 1 potentiometer for iris aper ture adjustment;

G) 1 potentiometer for rainbow speed adjustment or selection of fixed colour;

H) 1 potentiometer for dimmer aperture adjustment or strobe frequency.

BASIC CONTROL PANEL

6

DH

G

BAAB

CFE C

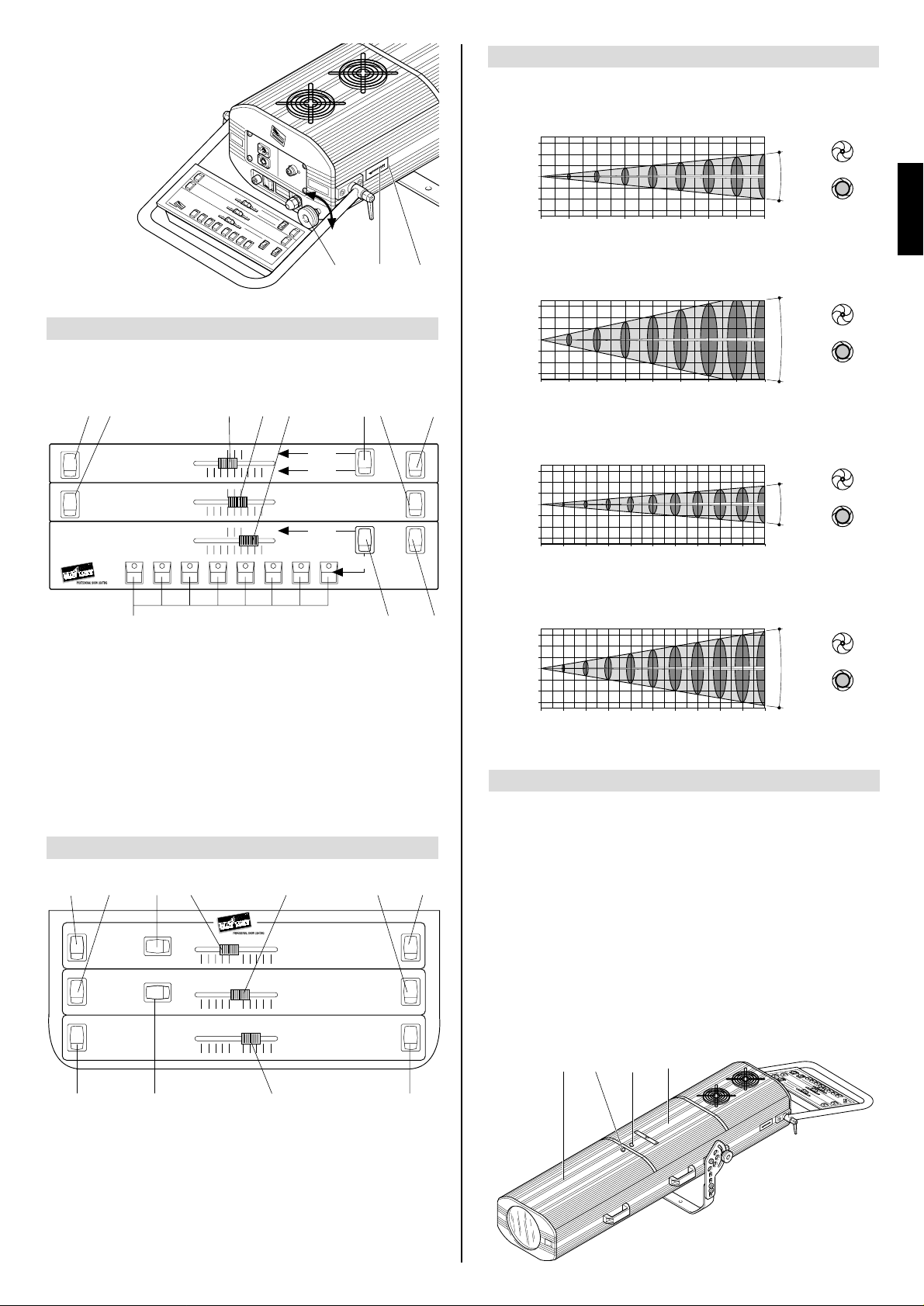

LENS UNITS

7

GRAPHS SHOWING BEAM DATA AND ILLUMINATION VALUES

MAINTENANCE

IMPORTANT: isolate the projector from the electrical power supply before commencing maintenance work of any description.

The maximum temperature on the outer surface of the projector under normal

operating conditions is 90°C (194° F) for QS and Basic HMI 1200 versions, and

80°C (176° F) for the Basic HMI 575 version.

After switching off, do not remove any part of the projector for at least 10 minutes, as

indicated on the lamp change label (1).

Once this time has elapsed, the risk of a lamp exploding is practically zero.If the lamp

needs changing, wait a further 20 minutes to avoid the risk of burns.In the event of a

lamp exploding, the projector is designed to prevent fragments of glass from being

scattered.The lenses supplied with the projector must be fitted at all times, and if visibly damaged must be replaced promptly with genuine spares.

• Opening the projector

Loosen knob (16) to remove the lamp access cover (17) or loosen knob (18) to

remove the front cover (19).Once the necessary work has been completed, refit the

cover and tighten with the relative knob.

8

19

18

17

16

ENGLISH

9

STROBE

DIMMER

FIXED

COLOURS

6.000 K

5.600 K

3.200 K

OPEN

OPEN

OPEN

STOP

OPEN

IRIS

COLOUR

WHITE RED YELLOW MAGENTA GREEN ORANGE BLUE VIOLET

®

OPEN SLOW FAST OPEN

0 % 100 %

CLOSED OPEN

0 % 10 %

SLOW FAST

0 % 10 %

RAINBOW

STOP

®

0 100

STROBO

5

STOP

HMI 1200 (lux)

HMI 1200

HMI 1200 (lux)

HMI 1200

HMI 1200 (lux)

HMI 1200

HMI 1200 (lux)

HMI 1200

6m

BEAM OPENING

6m

6m

BEAM OPENING

6m

6m

BEAM OPENING

6m

6m

BEAM OPENING

6m

QS-ST / BASIC - Standard objective

25600 6400 2844 1600 1000 711 520 400

(fc)

2,378 595 264 149 92.9 66.1 48.3 37.2

4

2

0

2

4

0 5 10 15 20 25 30 35 40

0” 16’ 5”

32’ 10” 49’ 3” 65’ 7” 82’ 98’ 5” 114’ 10” 131’ 3”

0 1,0 2,0 3,0 4,0 5,0 6,0 7,0 8,0

0” 3’ 3”

6’ 7” 9’ 10” 13’ 1” 16’ 5” 19’ 8” 23’ 26’ 3”

QS-ST / BASIC - Wideangle objective

3950 990 440 245 160 110 80 62

(fc)

367 92 40.9 22.8 14.9 10.2 7.43 5.76

4

2

0

2

4

0 5 10 15 20 25 30 35 40

0” 16’ 5”

32’ 10” 49’ 3” 65’ 7” 82’ 98’ 5” 114’ 10” 131’ 3”

0 2,2 4,3 6,5 8,6 10,8 12,9 15,0 17,2

0” 7’ 3”

14’ 1” 21’ 4” 28’ 3” 35’ 5” 42’ 4” 49’ 3” 56’ 5”

QS-LT - Standard objective

33750 8437 3750 2110 1350

3,135 784 348 196 125

(fc)

4

2

0

2

4

0 1020304050607080

0”

32’ 10” 65’ 7” 98’ 5” 131’ 3”

0 0,7 1,4 2,0 2,7 3,3 4,0 4,6 5,3

0”

2’ 4” 4’ 7” 6’ 7” 8’ 10” 10’ 10” 13’ 1” 15’ 1” 17’ 5” 19’ 8” 22’

164' 1" 196' 10" 229' 8" 262' 6" 295' 3" 328' 1"

90 100

6,0 6,7

QS-LT - Wideangle objective

10935 2730 1215 685 440

1,016 254 113 63.6 40.9

(fc)

4

2

0

2

4

0 1020304050607080

0”

32’ 10” 65’ 7” 98’ 5” 131’ 3”

0 1,3 2,7 4,0 5,3 6,6 8,0 9,3 10,6

0”

4’ 3” 8’ 10” 13’ 1” 17’ 5” 21’ 8” 26’ 3” 30’ 6” 34’ 9” 39’ 1” 43’ 8”

164' 1" 196' 10" 229' 8" 262' 6" 295' 3" 328' 1"

90 100

11,9 13,3

340415940 690 530

31.638.687.3 64.1 49.2

110120300 225 170

10.211.127.9 20.9 15.8

11,5°

DISTANCE m

DISTANCE ft in

DIAMETER m

DIAMETER ft in

24,6°

DISTANCE m

DISTANCE ft in

DIAMETER m

DIAMETER ft in

4°

DISTANCE m

DISTANCE ft in

DIAMETER m

DIAMETER ft in

7,4°

DISTANCE m

DISTANCE ft in

DIAMETER m

DIAMETER ft in

closed iris

open iris

closed iris

open iris

closed iris

open iris

closed iris

open iris

COLOUR

IRIS

RAINBOW

0 1005

0 1005

COLOUR

IRIS

Page 4

IMPORTANT: do not use solvents or alcohol

Parts that need cleaning frequently.

Parts that need cleaning monthly.

Internal components should also be given a general clean once a year, dislodging

dust and dirt with a brush and removing it simultaneously with a vacuum cleaner.

• Changing the lamp

Open the projector, loosen the two

side nuts (20) of the lamp to be

changed and remove it from the supports (21). Remove the new lamp from

its box, loosen the two side nuts (20)

and locate the lamp in the supports

(21). Finally, retighten the nuts.

• Changing the colour filters

Having opened the projector,

identify the filter to be

changed, grip firmly between

thumb and forefinger and push

against the spring clip (23)

until free of the fixed clips (24).

Bend the filter outwards and

remove.

Offer the new filter to the

spring clip (23) and anchor

behind the two fixed clips (24).

IMPORTANT: for uniform distribution of

the light beam, the lamp must be positioned so that the glass pip (22) on the

bulb does not coincide with the optical

axis of the projector. With this in mind,

locate the pip as high up as possible.

CAUTION: The projector uses a high pressure lamp with external starter.

- When fitting a new lamp, read the manufacturer's instructions carefully.

- The lamp must always be changed without delay if damaged or deformed by

heat.

20

21

25

2726

24

23

• Installing wide angle lenses

Remove the projector front

cover. Unscrew knobs (25),

rotate the front lens plate (26)

from the parking position to

the operating position in

alignment with the projector

axis and then perform the

same operation with the rear

lens plate (27).

Refit the knobs and secure

the two lens plates.

• Lubrication of sliding contact

parts - QS LT

To ensure perfect operation of sliding contact parts of the projector, lubricate sparingly at 6-monthly intervals using Kernite

Lube-K-AC grease.

• Routine cleaning

To maintain the light output of the projector undiminished, parts that tend to accumulate dust and grease must be cleaned periodically.

In most circumstances, the projector will give long and trouble-free service if these

simple guidelines are followed.

To remove dirt from the lenses and filters, use a soft cloth moistened with any liquid detergent suitable for cleaning glass.

TROUBLESHOOTING

9

10

No electrical power supply . Check that power is availab le at the

mains socket.

ELECTRONICS NOT WORKING

PROJECTOR DOES NOT LIGHT UP

PROJECTION FAULTY FAULTS

ANOMALIES

REDUCED BRIGHTNESS

POSSIBLE CAUSES

CHECKS AND REMEDIES

•

•

•

•

•

•

•

••

Lamp expended or faulty. Change lamp (see instructions).

Signal transmission cable shortcircuiting or disconnected.

Change cables.

Address codes incorrect.

See projector coding instructions.

Defect in electronic circuits. Contact an authorized technician.

Lenses broken. Contact an authorized technician.

Deposit of dust or grease. Clean (see instructions).

20

22

Page 5

TECHNICAL DATA

10

ELECTRICAL

MECHANICAL SPECIFICATIONS

Power supply

• 220 - 240V 50Hz

• 200 - 220V 60Hz

Lamp

Metal halide with special built-in power

supply.

• Type: HMI 1200W

- Cap: SFc 15.5-6

- Colour temperature: 6000 K

- Luminous flux: 110000 lm

- Average life: 750 h

• Type: HMI 575W

- Cap: SFc 10-4

- Colour temperature: 6000 K

- Luminous flux: 49000 lm

- Average life: 750 h

Power consumption

• QS-ST/LT HMI 1200:

1500VA at 230V 50Hz

• BASIC HMI 1200:

3000VA at 230V 50Hz

• BASIC HMI 575:

1500VA at 230V 50Hz

Motors

N. 4 (BASIC) N. 5 (QS) microstepping

motors with full microprocessor control.

OPTICAL SYSTEM

Main optical unit

• Base in diecast aluminium.

• Twin lens condenser.

• High luminous efficiency spherical

reflector.

Lens unit

QS-ST and BASIC

• Standard: 1:2.5/250mm

• Optional: wide angle for insertion

inside the projector.

QS-LT

Special optics with wide angle lens as

standard (manual insertion).

CONTROL SYSTEMS

Channels

N. 3 control channels (BASIC)

N. 4 control channels (QS)

Inputs

SHADOW QS is set up to accept analog

or digital signals from controllers or

computers:

• Digital serial input

RS232/423(PMX) or DMX512

• 0-10V analog input

CONSTRUCTION

FEATURES

Safety devices

• Power shuts off automatically in the

event of ov erheating or cooling system

failure.

• Power shuts off automatically when

cover is opened.

Cooling

Forced ventilation cooling system using

axial flow fans.

Housing

• Extruded diecast aluminium.

• Epoxy powder coated finish.

Mounting

• Steel bracket with epoxy powder coat-

ed finish.

• Six installation positions, 25 mm

apart.

• Bracket adjustable through 100° with

graduated scale for position finding.

Operating position

Will function in any position.

Weights and Dimensions

•

QS-ST HMI 1200: 38 kg ( 83 lbs 10 ozs)

• QS-LT HMI 1200: 49 kg

(107 lbs 13 ozs)

• Basic HMI 1200: 38 kg

( 83 lbs 10 ozs)

• Basic HMI 575: 30 kg

( 66 lbs)

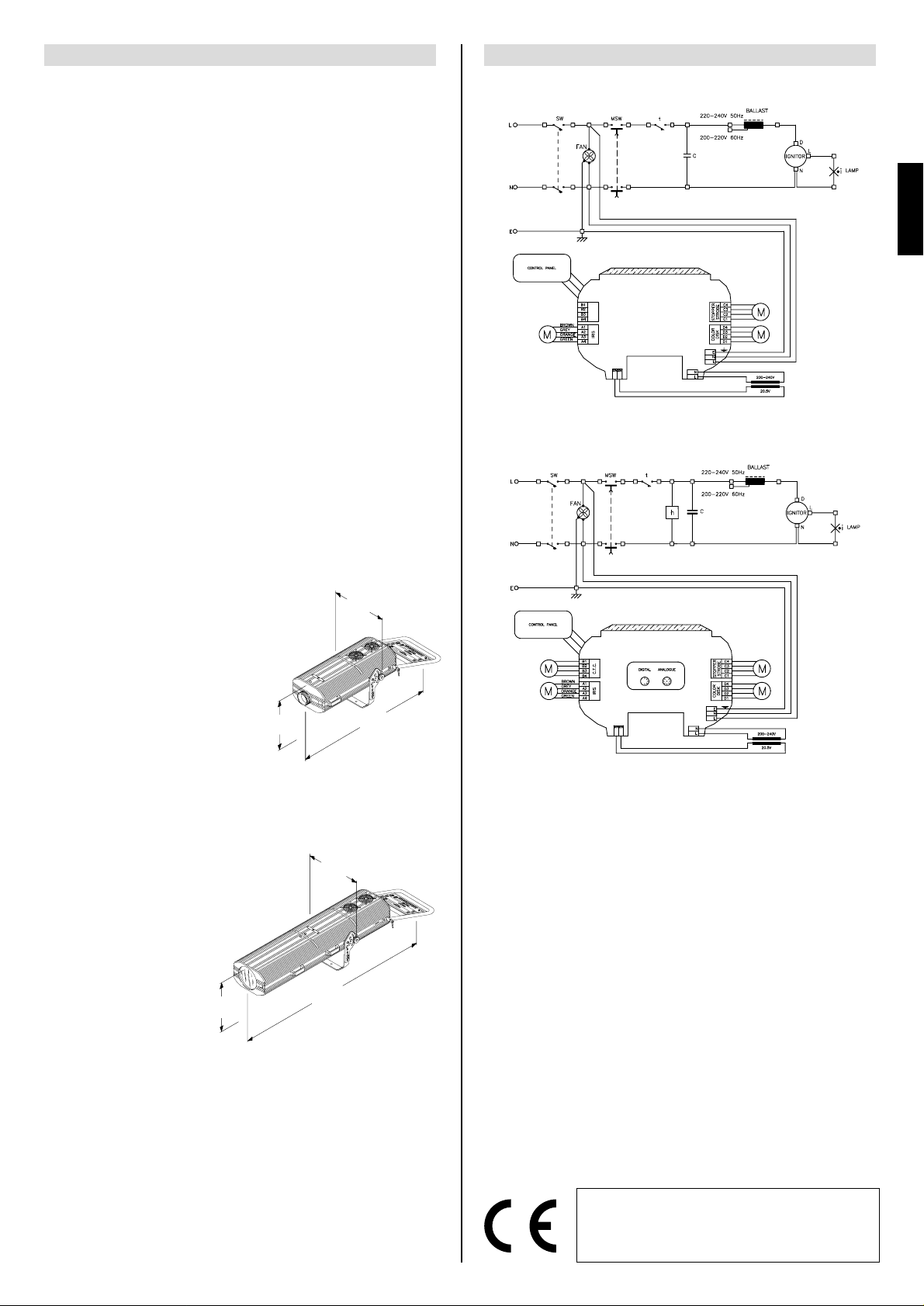

WIRING DIAGRAM

11

(67.5”)

1715

(17.1”)

435

(13”÷17.5”)

330÷445

(17.1”)

435

(13”÷17.5”)

330÷445

(46.3”)

1175

SHADOW Basic HMI 575

SHADOW Basic HMI 1200

SHADOW QS ST HMI 1200

SHADOW QS-LT HMI 1200

ENGLISH

11

The products referred to in this manual comply with

EC Directives on:

• Low Voltage 73/23

• Electromagnetic Compatibility 89/336

The specifications published in this manual are not binding, and may be revised or updated

at any time by Clay Paky without notice in the interests of improving product quality.

BASIC

QS-ST - QS-LT

Loading...

Loading...