Page 1

•

Unpacking

Open the cardboard box, take out the polystyrene wrapping and separate it,

freeing the projector.

Remove the plastic bag from the smoke machine and position this on a horizontal top.

5

GOLDEN FOG

ENGLISH

1000

2000

2000 DMX

®

INSTRUCTIONS MANUAL

Carefully read this instructions manual in its entirety and keep it safe for future

reference.

It is essential to know the information and comply with the instructions given

in this manual in order to ensure the fitting is installed, used and serviced correctly and safely.

CLAY PAKY S.p.A. disclaims all liability for damage to the fitting or to other

property or persons deriving from installation, use and maintenance that have

not been carried out in conformity with this instructions manual, which must

always accompany the fitting.

CLAY PAKY S.p.A. reserves the right to modify the characteristics stated in

this instructions manual at any time and without prior notice.

Congratulations on choosing a Clay Paky product! We thank you for your custom. Please note that this product, as all the others in the rich Clay Paky

range, has been designed and made with total quality to ensure excellent

performance and best meet your expectations and requirements.

•

Installation

Make sure all the parts for fixing the smoke machine are in a good state of repair.

Make sure the point of anchorage is stable before positioning the fitting.

•

Minimum distance of flammable materials

The fitting must be positioned so that any flammable materials are at least 1 metre

(3’ 3”) from every point on the surface of the fitting.

•

Direction and distance of the jet of smoke

Never turn the jet of smoke onto people or items that are flammable or can get

damaged or dirtied by the jet of smoke.

Installation above people is not permitted.

•

Maximum ambient temperature

For the fitting to operate well and reliably, the ambient temperature should not

exceed 35°C (95°F).

•

IP20 protection rating

The fitting is protected against penetration by solid bodies with a diameter of over

12mm (0,47”) (first digit 2), but not against dripping water, rain, splashes or jets of

water (second digit 0).

•

Protection against electrical shock

This fitting is classified, in accordance with the type of protection against electrical

shock, in Class I. It must therefore be connected to a power supply system with

efficient earthing.

It is, moreover, recommended to protect the supply lines of the projectors from indirect contact and/or shorting to earth by using appropriately sized residual current devices.

•

Hooking up to the supply mains

The operations for connecting to the electricity mains must be carried out by a

qualified electrical installer.

Check that the mains frequency and voltage correspond to the frequency and voltage for which the smoke machine is designed, given on the rear panel.

This panel also gives the input power. Refer to this to evaluate the maximum number of fittings to connect to the electricity line in order to avoid overloading.

•

Maintenance

Before starting any maintenance work or cleaning the fitting, cut off power from

the supply mains.

After switching off, do not touch the smoke nozzle for at least 1 hour to avoid

getting burnt.

•

Temperature of the external surface

The maximum temperature that can be reached on the external surface of the fitting, in a thermally steady state, is 60°C (140°F) except for on the smoke nozzle

where it reaches 300°C (572°F).

The products referred to in this manual conform to the European Community Directives to which they are subject:

• Low Voltage 73/23

• Electromagnetic Compatibility 89/336

SAFETY INFORMATION

1

UNPACKING AND PREPARATION

2

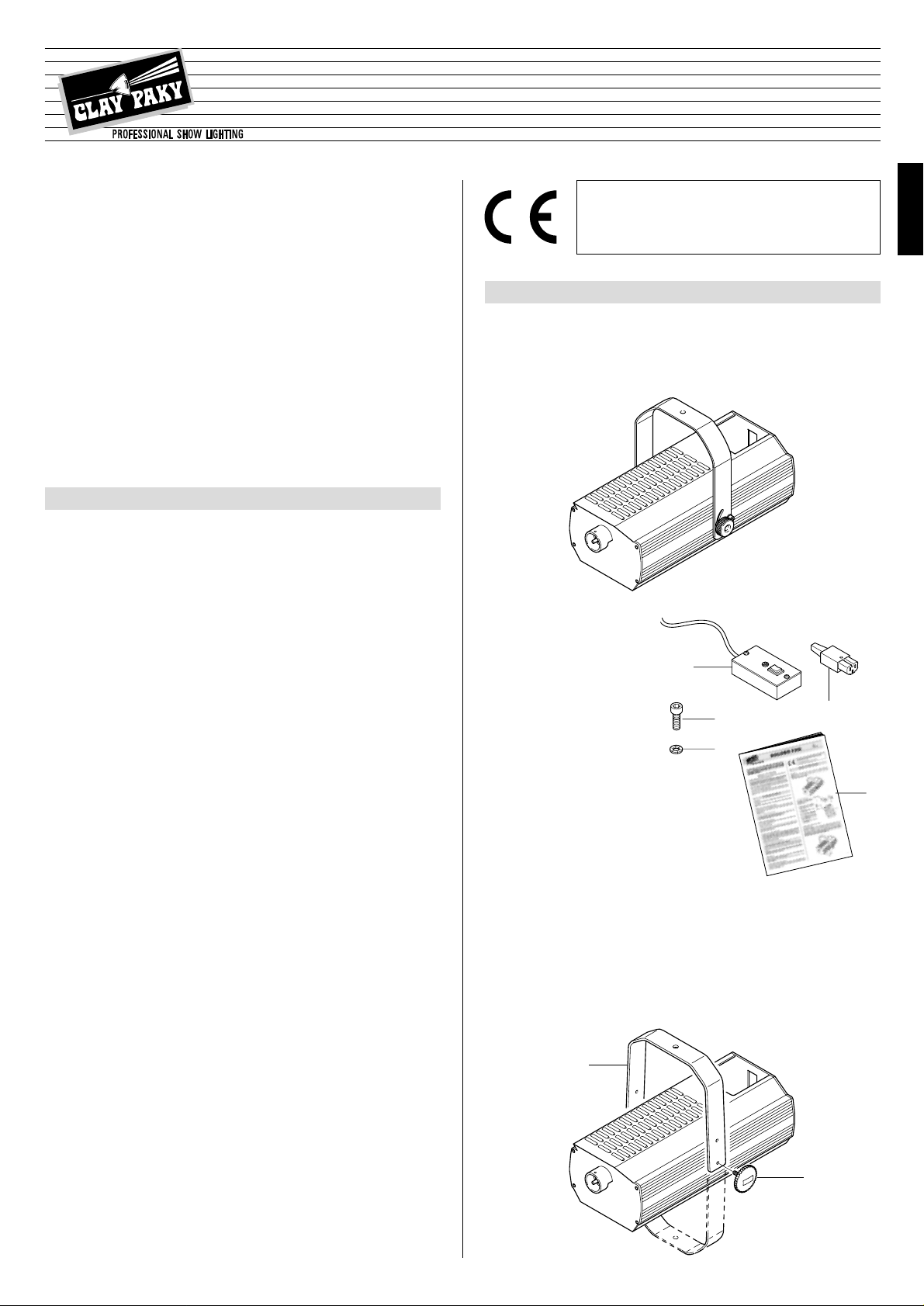

• Packing contents

Besides the smoke machine, the

packing also contains the following

accessories:

- Remote control (1) code

177034/801 (for GOLDEN FOG

1000 and 2000 models only).

- Socket for mounting on cable code 030210 (2).

- 2 screws (3) code 020002/029 (models 2000 and 2000 DMX only).

- 4 toothed washers (4) code

020201/005 (models 2000 and

2000 DMX only).

- This instructions manual code

099595 (5).

1

5

2

3

4

•

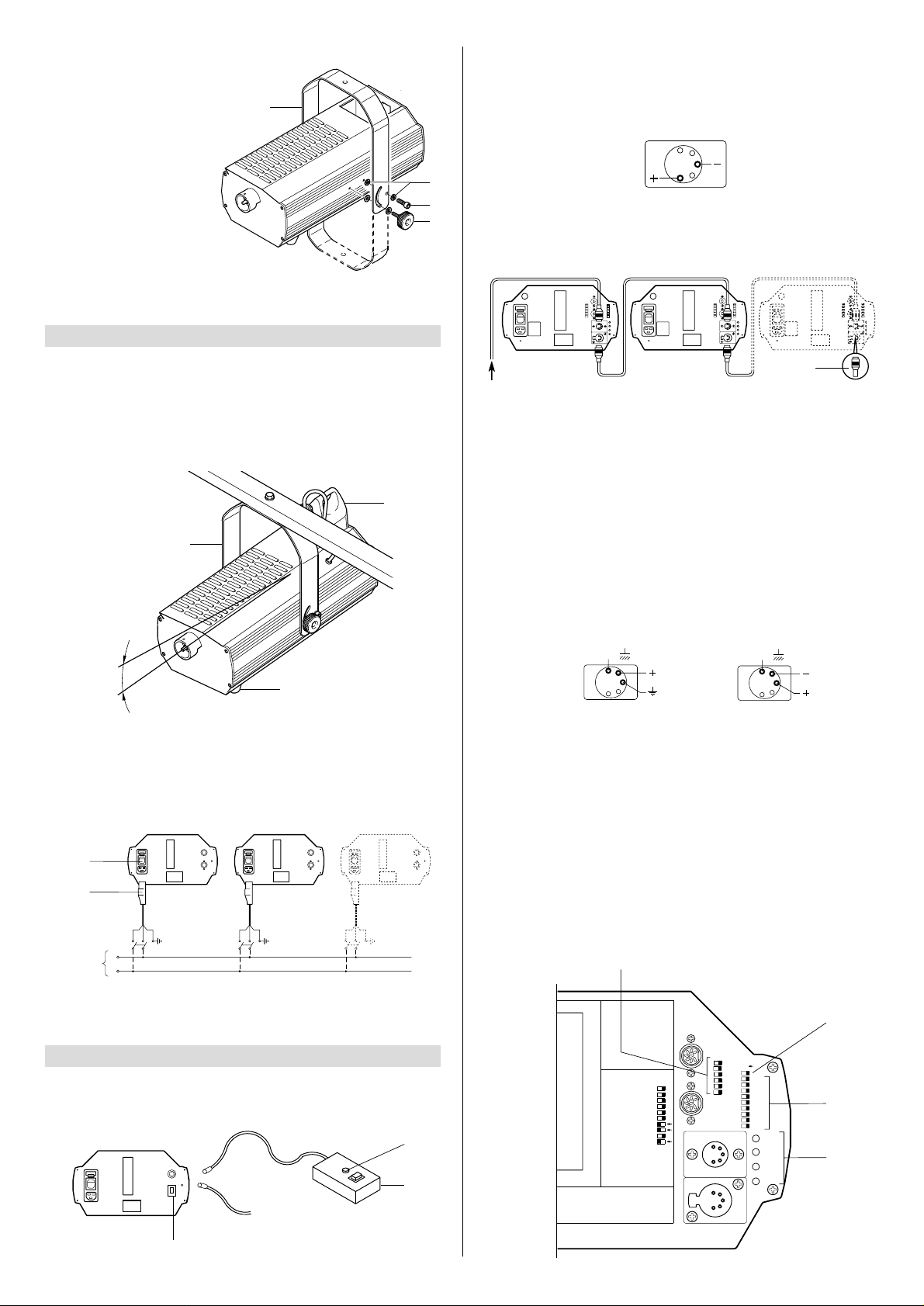

Projector mounting

GOLDEN FOG 1000

Position the bracket (6) according to the desired angle and lock it with the knobs

(7). The bracket (6) can be height adjusted by using the two holes on the bracket; it

can moreover also be mounted towards the bottom of the fitting. These last steps

require fully extracting the knobs (7), putting the bracket (6) back into the desired

position and reinserting the knobs (7), tightening them appropriately.

6

7

ENGLISH

Page 2

6

AUTO

256

128

64

32

4

16

8

1

2

START ADDRESS SELECT

ON

1

2

3

4

5

6

CHANNEL SELECT

1

4

8

FLUID

EMPTY

DATA

ERROR

PMX

DMX

SIGNAL

SCREEN

SIGNAL

RS232/423

(PMX)

1

2

3

45

SIGNAL

SCREEN

SIGNAL

54

3

2

1

DMX

512

GOLDEN FOG 2000 and 2000 DMX

Secure the bracket (6) to the body

of the smoke machine with the aid

of the screws (3) and toothed washers (4) specially supplied, then

position the bracket (6) according

to the desired angle and lock it

with the knobs (7).

The bracket (6) can also be mounted towards the bottom of the fitting. To do this, it is necessary to

fully extract the knobs (7) and

screws (3), reposition the bracket

(6) as preferred, put the knobs (7)

and screws (3) back in, together

with the toothed washers (4), then

lock the bracket (6) with the appropriate angle.

•

Installing the fitting

The fitting needs to be installed horizontally, the angle the machine makes must

be no greater than 30° so that no liquid will come out of the tank (8).

The GOLDEN FOG smoke machine can be stood "on the floor" on its rubber feet

(9).

If the fitting is installed "on the ceiling" it must be secured using solely the specific

mounting (6), through the hole in the centre of it. Use a screw ø10mm with nut

and spring washer.

INSTALLATION

3

MAX. 30°

•

Mains power connection

Each fitting should be connected with its own switch so it can be switched on and

off individually from a distance.

The smoke machine has to be hooked up to the electricity mains via the specific

socket (2) supplied.

L

N

Mains

10

2

0-10V

1

12

11

GOLDEN FOG fittings are equipped with a switch with an indicator light (10) that

shows when the fitting is switched on.

GOLDEN FOG 1000 and 2000

0-10V analogue or remote control connection

CONNECTING CONTROL SIGNALS FOR

4

Smoke emission can be controlled by pressing button (11) on the rear panel of

the machine or the button on the low-voltage remote control (1) supplied with the

machine. The indicator light (12) on the remote control (1) warns that the boiler is

at temperature. It is also possible to control the fitting with a 0-10V analogue signal via a cable terminated with a Cannon 5-pin XLR plug.

54

3

2

1

GOLDEN FOG 2000 DMX

RS232/423(PMX)-DMX 512 connection

13

DMX 512

RS232/423

The connection between GOLDEN FOG 2000 DMX and the control unit and

between different fittings must be made with a cable in conformity with EIA RS485 specifications: braided, bipolar, shielded, 120Ω of characteristic impedance,

22-24 AWG, low capacity.

IMPORTANT: Do not use a microphone cable or any other cable with different

characteristics to the ones specified above.

IMPORTANT: The wires must make no contact with each other or with the metal

casing of the connectors. The casing needs to be connected to the braid of the

shield and to pin 1 of the connectors.

•

Fitting codes

Each GOLDEN FOG 2000 DMX occupies one control channel. For this to be correctly addressed to each fitting, it is necessary to code the machines.

This has to be done on each single smoke machine, switching the microswitches

(14) according to the following table. Coding can also be done with the machine

switched off.

16

14

17

15

The terminations need to be made with male/female connectors type XLR with 5

pins.

If you use the DMX signal it is necessary to give the last fitting a terminal plug

(13) with a resistance of 120Ω (minimum 1/4 W) between terminals 2 and 3.

If using the RS232/423(PMX) signal, the terminal is not required.

7

3

4

6

8

6

9

Page 3

7

Golden Fog 1 - Channels 01

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

1

2

4

8

163264

128

256

TEST

OFF

ON

OFF

ON

CODE

ON

OFF

ON

OFF

ON

OFF

OFF

ON

Golden Fog 2 - Channels 02

Golden Fog 3 - Channels 03

Golden Fog 4 - Channels 04

Golden Fog 5 - Channels 05

Golden Fog 6 - Channels 06

Golden Fog 7 - Channels 07

Golden Fog 8 - Channels 08

Golden Fog 9 - Channels 09

Golden Fog 10 - Channels 10

Golden Fog 11 - Channels 11

Golden Fog 12 - Channels 12

0-10 V analogue connection with decoding

0-10V 0-10V 0-10V

Is

FOG

1

2

3

45

67

8

ANALOGUE

INPUTS 0 - 10 V

On the back of the GOLDEN FOG 2000 DMX there is a selector with 6 microswitches (15) that make it possible to control 6 fittings simultaneously on separate

channels, switching over the microswitches according to the following table.

Golden Fog

1

ON

OFF

ON

OFF

ON

OFF

ON

OFF

1

2

3

4

5

6

OFF

ON

OFF

ON

CODE

Golden Fog

2

Golden Fog

4

Golden Fog

3

Golden Fog

5

Golden Fog

6

•

Automatic operation

Turning the AUTO microswitch (16) onto ON puts the fitting onto automatic operation. Keeping the microswitch on this position, the frequency of the sprays of

smoke delivered depends on the level set on the DIL microswitches (14) normally used to select the address; there are therefore 512 possibilities for adjustment.

If automatic operation is activated, the four LEDs (17) on the rear panel come on

alternately from the bottom upwards.

When the machine is controlled via the control unit (AUTO microswitch on the

OFF position) the frequency of the sprays varies as the adjustment potentiometer moves forward.

After completing all the preliminary operations and installation, fill the tank with

smoke machine liquid, press the switch, wait for the boiler to reach temperature,

then check that smoke is generated and everything works properly.

IMPORTANT: Use solely CLAY PAKY smoke liquid in the light, medium and

heavy versions. Other types of fluid could impair the operation of the smoke machine and/or seriously damage some components.

On the rear panel of the GOLDEN FOG 2000 DMX model there is an indicator light (18 – “Fluid Empty”) to signal the liquid has finished.

USE

5

18

AUTO

256

128

64

32

4

16

8

1

2

START ADDRESS SELECT

ON

1

2

3

4

5

6

CHANNEL SELECT

1

4

8

FLUID

EMPTY

DATA

ERROR

PMX

DMX

•

Replacing fuses

To replace the fuses, press the tab

(19) and take out the fuse-holder box

(20). Replace blown fuses with new

ones of the type specified on the label

(21) on the fuse-holder box (20).

Put it back in so the tab (19) clicks home.

•

Periodical cleaning

Every time before use, clean any drops

of fluid off the outlet pipe (22).

Approximately every 1000 hours of

operation, have qualified personnel

check the machine.

MAINTENANCE

6

19

20

21

22

ENGLISH

5 AT

5x20

250 V

FUSE

200V 220V 240V

50 Hz 60 Hz

60 Hz

CODE

C.81005

SERIAL NUMBER

IF11153

Page 4

GOLDEN FOG 1000

GOLDEN FOG 2000 and 2000 DMX

8

TECHNICAL DATA

8

Power supply

•

200 - 240V 50/60Hz

Input power

•

GOLDEN FOG 1000: 1,000 VA

•

GOLDEN FOG 2000: 2,000 VA

•

GOLDEN FOG 2000 DMX: 2,000 VA

Tank capacity

•

GOLDEN FOG 1000: 1 litre

•

GOLDEN FOG 2000 and 2000DMX: 2 litres

Consumption and maximum delivery

•

GOLDEN FOG 1000: 27 g/min

•

GOLDEN FOG 2000: 55 g/min

•

GOLDEN FOG 2000 DMX: 46 g/min

Pre-heating time

•

GOLDEN FOG 1000:

5 min.÷ 5 min. 30 sec.

•

GOLDEN FOG 2000:

4 min.÷ 4 min. 30 sec.

• GOLDEN FOG

2000 DMX:

4 min.÷ 4 min. 30 sec.

Smoke delivery time

•

GOLDEN FOG 1000: continuous

•

GOLDEN FOG 2000: 60”/65”

•

GOLDEN FOG 2000 DMX: 30 sec. at

100%, continuous with adjustment

CONTROL SYSTEMS

•

GOLDEN FOG 1000 - 2000

- Manual control

- Remote manual control

- 0-10V analogue input

•

GOLDEN FOG 2000 DMX

- Serial digital input

RS232/423(PMX) or DMX512

- 0-10V analogue input

INDICATORS

•

GOLDEN FOG 1000 - 2000

- Machine ready indicator light

on remote control

- Power light

•

GOLDEN FOG 2000 DMX

- Power light

- Fluid finished indicator light

- Automatic operation

- DMX signal reception

- PMX signal reception

- Error in receiving signals

SAFETY DEVICES

Power supply automatically cut off in the

event of the boiler overheating.

Weight and dimensions

•

GOLDEN FOG 1000:

Weight 7.5 Kg (16 lbs 8 ozs)

•

GOLDEN FOG 2000:

Weight 11 Kg (24 lbs 3 ozs)

•

GOLDEN FOG 2000 DMX:

Weight 12 Kg (26 lbs 6 ozs)

A mm

270 (10.63”)

310 (12.20”)

B mm

490 (19.29”)

490 (19.29”)

C mm

230 (9.06”)

340 (13.39”)

No mains supply.

Check the supply socket

is powered and/or fuse

conductivity.

Signal transmission cable shortcircuited or disconnected.

Replace cables.

Cannon not properly inserted.

Insert the Cannon on the back

of the machine.

No liquid in tank. Fill the tank with liquid.

Internal mechanical part broken. Call an authorized technician.

Tube not inserted properly. Put the tube back into the tank.

Wrong address. Check the digital address.

Electronics broken. Call an authorized technician.

THE LED ON THE REMOTE CONTROL FAILS TO COME ON

THE FITTING WILL NOT SWITCH ON

NO SMOKE IS GENERATED

TROUBLE

THE TUBE FAILS TO DRAW LIQUID

IT FAILS TO WORK WITH DIGITAL SIGNALS

POSSIBLE CAUSES

CHECKS AND REMEDIES

•

•

•

•

•

•

•

•

TROUBLESHOOTING

7

A

B

C

Loading...

Loading...