Page 1

5

Alimentazione

L

N

ATLAS

ENGLISH

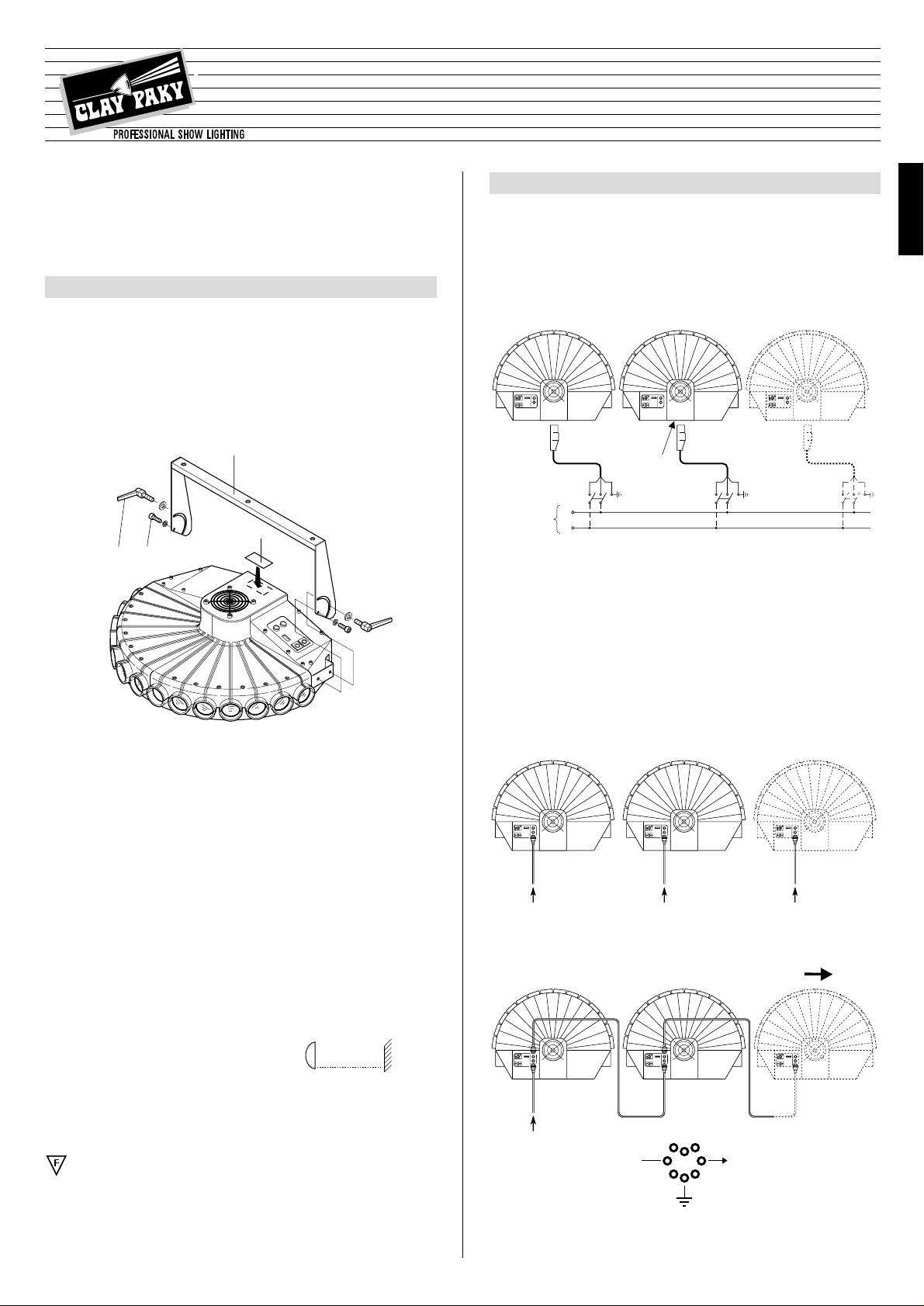

• Unpacking

Open the cardboard box, remove the projector from the packing and position it on a

horizontal support surface.Remove the components contained in the bags inside the

packing.

Identify the light bulb change label (1) on the appliance and, if necessary, replace it

with one of the optional multi-language labels.

Ensure that this label is never removed since it contains important safety information.

IMPORTANT: Carefully read all parts of the instruction manual. Knowledge of

the information and prescriptions contained in this document is essential for

correct, safe use of the appliance.

PROJECTOR INSTALLATION

1

5

POWER SUPPLY AND SET-UP

2

The projector is set up to operate at the power supply voltage and frequency shown

on the electrical data label (5) on the back of the projector itself. Ensure that these

values correspond to the electricity mains network voltage and frequency.

IMPORTANT: connection to a power supply system with efficient grounding is

mandatory (Class I appliance).

• Control signal connection

• Mains power connection

The operations described in this heading must be carried out by a licensed electrician.

The projector must be connected to the electricity mains network using the special socket provided.It is recommended that each projector is connected through

its own switch, so that it can be individually switched on and off remotely.

0 - 10V 0 - 10V 0 - 10V

0 - 10V

- Simultaneous and equal projector operation

- Independent projector operation

0-10V CONNECTION

The connection between projector and control unit and between several projectors

must be made with a shielded two-pole cable with Cannon 5 PIN XLR plug and socket at the ends.

Is

STOP

INSTRUCTION MANUAL

• Projector support preparation

Fix bracket (2) with the special screws (3) and lock it by tightening handles (4).

• Fitting the light bulb

Refer to the instructions for changing the light bulb in paragraph 5 MAINTENANCE.

• Projector installation

The projector can be fixed in any position, with its operating characteristics remaining unchanged.

IMPORTANT: Fix the projector in the required position using the special holes

in bracket (2).

The use of two 12 mm ø screws complete with nuts and spring washers is

recommended.

Ensure the stability of the fixing point before positioning the projector.

• Minimum distance of the lighted objects

The projector must be positioned so that the objects

struck by the light beam are at a distance of at least

0.5 m (1’ 8”) from the lens of the projector itself.

• Minimum prescribed distance of flammable materials from every point of the

body of the appliance: 0.07 m (3”).

Assembly of the appliance on normally flammable surfaces is permissible.

IMPORTANT: For better and more reliable operation of the appliance, the ambient temperature must not exceed 35° C (95° F). Protection level IP 20: the appliance is protected against penetration of solid bodies with a diameter of more than

12 mm (0.5”) (first figure 2), while it is not proof against drips, rain, sprays and jets

of water (second figure 0).

HMI 575

Mains

ENGLISH

4

3

1

2

®

(

1’ 8”

0.5 m

)

HMI 575

Page 2

6

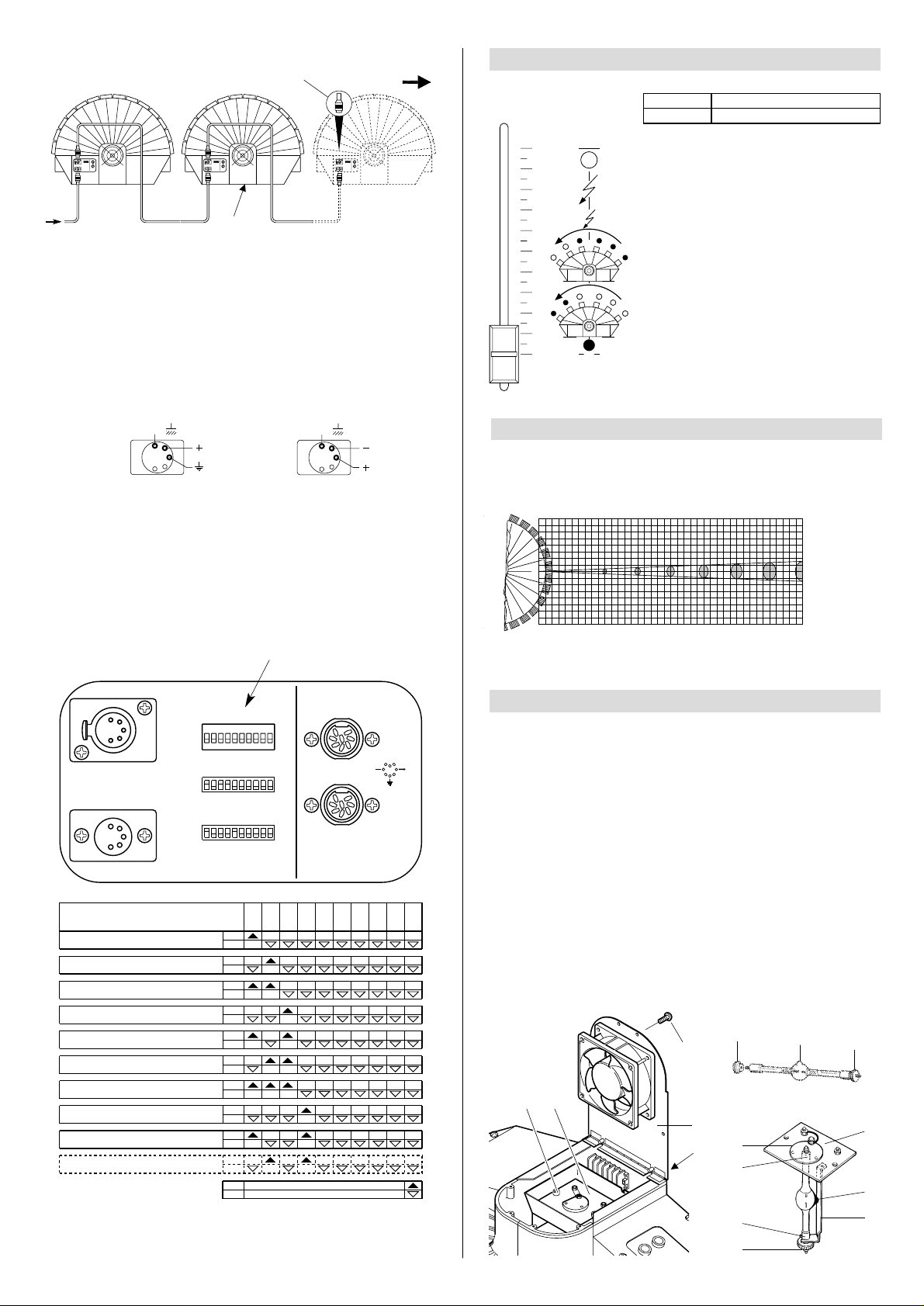

CHANNEL FUNCTION

3

• STOP/STROBE - channel 1

With the cursor at 0% all bands are

obscured. In the cursor interval

between 0% and 25% the bands are

progressively opened from right to

left, creating a fan effect.From 25%

to 54.7% the bands are progressively obscured from right to left. From

54.7% to 95% a strobe effect is

obtained with an increasing frequency from 1 flash every four seconds

to 2 flashes/second.The aperture is

fixed from 95% to 100%.

CHANNEL

1 STOP/STROBE

FUNCTION

0

1

2

3

4

5

6

7

8

9

10

The connection between projector and control unit and between several projectors

must be made with a shielded two-pole cable with Cannon 5 PIN XLR plug and

socket at the ends.

For DMX connection the terminal pin (6) with a resistance of 100

Ω

between terminals 2 and 3 on the last projector. The terminal is not needed if an

RS232/423(PMX) signal is used.

It is essential that the wires do not come into contact with each other or with

the metal casing of the pin.

The casing of the plug/socket must be connected to the screen braid and to

foot 1 of the connectors.

After having performed all the operations described above, press switch (7) and

check that the light bulb switches on and that the automatic reset sequence starts.

• Projector coding (for digital signals)

Each ATLAS occupies one control channel. For this to be correctly addressed to each

projector, a coding operation must be perfor med for the projectors themselves.The

operation must be performed for each single ATLAS by setting the microswitches

according to the table below.

Setting the TEST switch to ON for a few seconds gives automatic reset with the projector switched on. Leaving the TEST switch ON gives the complete self-test; return

the switch to OFF at the end of the operation.

SIGNAL

SCREEN

SIGNAL

54

3

2

1

DMX

512

LENS

4

1

0

BEAM OPENING

m

0 5 10 15 20 25 30 35 40 DISTANCE m

0 0,1 0,14 0,18 0,22 0,26 0,30 0,34 0,38 DIAMETER m

1

HMI 575

6400 1600 710 400 256 177 130 100 lux

0” 16’ 5” DISTANCE ft in32’ 10” 49’ 3” 65’ 7” 82’ 98’ 5” 114’ 10” 131’ 3”

0” 4” DIAMETER ft in6”

7”

9” 10” 12” 1’ 1” 1’ 3”

595 149 66.0 37.2 23.8 16.4 12.1 9.29 fc

LIGHT BAND AND LIGHTING VALUE DIAGRAMS

Beam angle (0,5°)

MAINTENANCE

5

TEST

256

128643216842

1

ON

10987654321

DIGITAL INPUT

DIP

ANALOGUE INPUTS

STOP

Is

0-10V

Projector

4

- Channels

4

Projector

5

- Channels

5

Projector

6

- Channels

6

Projector

7

- Channels

7

Projector

8

- Channels

8

Projector

9

- Channels

9

Projector

10

- Channels

10

Projector

3

- Channels

3

Projector

2

- Channels

2

Projector

1

- Channels

1

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

124

8

163264

128

256

TEST

OFF

ON

OFF

ON

OFF

ON

CODE

IMPORTANT: the projector must be disconnected from the power supply before any

operation is started.

The maximum temperature of the appliance's outer surface in heat regime conditions

is 80° C (176° F). After switching off, do not remove any part of the appliance for 7

minutes, as shown in light bulb changing label (1).

After this time the probability of the bulb exploding is virtually nil.

If necessary, replace the bulb and wait a further 15 minutes to prevent burns. The

appliance is designed to retain splinters produced by a possible explosion of the b ulb .

It is mandatory to fit the lenses and moreover, if they show visible signs of damage

they must be replaced with original spare parts.

• Light bulb changing

Remove screws (8) and open fan hatch (9).

Unscrew knobs (10) of light bulb change plate (11) and remove it from the projector.

Slacken off ring-nut (12) of the light bulb to be replaced and remov e it from plate ( 13),

grasping it by its mount (14).Extract the new bulb from its pack, remove ring-nut (15)

and slacken of the other one (12).Screw the light bulb directly into bulb change plate

(13), grasping it by its mount (14). Position strip (16) in correspondence with mount

(17) and fully tighten ring-nut (12). Replace light bulb change plate (11) in the projec-

tor and tighten knobs (10). Close fan hatch (9) and fully tighten screws (8).

RS 232-423

DMX 512

RS 232/423(PMX) - DMX 512

7

6

18

15

12

8

9

1

11

10

13

14

17

12

16

11

18

Spotlight selection

SCREEN

RS232/423

(PMX)

1

2

45

SIGNAL

3

SIGNAL

Page 3

7

250V

10AT

5 x 20

FUSE

POSSIBLE REASONS

CHECKS & REMEDIES

TROUBLESHOOTING

6

No mains power supply. Check that power is reaching the

supply socket and/or that the fuses

are not blown.

THE PROJECTOR WILL NOT START UP

THE ELECTRONICS ARE INOPERABLE

DEFECTIVE PROJECTION

REDUCED LIGHTING

•

••

•

•

•

•

Light bulb blown or defective. Replace the bulb

(see instructions).

Signal transmission cable shortcircuited or disconnected.

Replace the cables.

Incorrect coding. Check the coding

(see instructions).

Fault in the electronic circuits.

Broken lenses.

Contact an authorised technician.

Contact an authorised technician.

TECHNICAL DATA

CONSTRUCTIONAL DETAILS

Devices

• Automatic power supply cut-off in

the case of overheating or a cooling

system breakdown.

• Automatic power supply cut-off

when the cover is opened.

Cooling

Forced ventilation cooling system

using axial fans.

Body

• Of diecast extruded aluminium

• Painted with epoxy powders

Stand

Made of steel painted with epoxy powders

Work position

It will operate in any position.

Weights and size

Weight: 27 kg (59 lbs 6 ozs)

ELECTRICAL

& MECHANICAL DETAILS

Power supplies available

• 220 - 240V 50Hz

• 200 - 220V 60Hz

• 200V 50Hz

• 200V 60Hz

• 260V 50Hz

The projector is designed to operate

at the mains frequency and voltage

given on the electrical data label on

the base of the appliance.

Light bulb

Metal iodides fed by a special incorporated power supply unit.

• Type HMI 575W

– Cap SFc 10-4

– Colour temperature 5600 K

– Light flux 49000 lm

– Average life 750 h

Power absorbed

1500 VA at 220V 50Hz

Motors

N. 1 step-by-step motor, operating in

microsteps and totally controlled by a

microprocessor.

COMMAND SYSTEMS

Channels

N. 1 control channel

Inputs

ATLAS is designed to analogue or

digital control signals transmitted

from control units or computers.

• Serial digital input

RS232/423(PMX) or DMX 512

• Analogue input 0 - 10V

7

ENGLISH

FAULTS

The products to which this manual refer comply with the

following European Union Directives:

• Low Voltage 73/23

• Electromagnetic Compatibility 89/836

WIRING DIAGRAM

With the desire to constantly improve the quality of its products, Clay Paky reser ves the

right to change the specifications mentioned in this document without prior notice.Thus

they should not be taken as binding.

8

• Fuse replacement

To replace the fuses, press tongue (19) and remove fuse box (20).

Replace the blown fuses with new ones of the type shown on label (21) located on

fuse box (20).

Return this by pushing it in until tongue (19) clicks.

• Periodic maintenance

Periodic cleaning of the parts subject to dust and grease deposits is indispensable

for keeping the projector's light yield unchanged.

Perfect operation can be ensured for a long time by following the directions given

below.

Use a soft cloth dampened with a liquid detergent for cleaning glass to remove dirt

from the lenses and filters.

IMPORTANT: do not use solvents or alcohol.

Parts that need frequent cleaning.

An annual general cleaning of the inside is also recommended, removing the dust

with a brush and sucking it out with a normal vacuum cleaner.

IMPORTANT: to ensure maximum uniformity of the light beams, the light bulb must

be located with protuberance (18), visible on the bulb, pointing towards the rear of

the projector.

CAUTION: The appliance is fitted with a high pressure light bulb with an

external starter.

- Carefully read the “User Instructions” provided by the light bulb's manufacturer.

- Replace the light bulb immediately if it is damaged or warped by heat.

1920

21

(24.8”)

630

(15.7”)

400

(28.5”)

725

Loading...

Loading...