Page 1

350-07/3650-07

Page 2

Page 3

Page 4

Page 5

Description

The CIa-VaI Model 100-01 Hytrol Valve is a main valve for

CIa-VaI Automatic Control Valves. It is a hydraulically operated,

diaphragm-actuated, globe or angle pattern valve.

This valve consists of three major components; body, diaphragm

assembly, and cover. The diaphragm assembly is the only

moving part. The diaphragm assembly uses a diaphragm of nylon

fabric bonded with synthetic rubber. A synthetic rubber disc,

contained on three and one half sides by a disc retainer and disc

guide, forms a seal with the valve seat when pressure is applied

above the diaphragm. The diaphragm assembly forms a sealed

chamber in the upper portion of the valve, separating operating

pressure from line pressure.

Installation

1. Before valve is installed, pipe lines should be flushed of all

chips, scale and foreign matter.

2. It is recommended that either gate or block valves be

installed on both ends of the 100-01 Hytrol Valve to facilitate

isoIating the valve for preventive maintenance and repairs.

3. Place the valve in the line with flow through the valve in the

direction indicated on the inlet nameplate. (See “Flow Direction”

Section)

4. Allow sufficient room around valve to make adjustments and

for disassembly.

5. CIa-VaI 100-01 Hytrol Valves operate with maximum effic iency

when mounted in horizontal piping with the cover UP, however,

other positions are acceptable. Due to size and weight of the

cover and internal components of 8 inch and larger valves,

installation with the cover UP is advisable. This makes internal

parts readily accessible for periodic inspection.

6. Caution must be taken in the installation of this valve to insure

that galvanic and/or electrolytic action does not take place. The

proper use of dielectric fittings and gaskets are required in all

systems using dissimilar metals.

7. If a pilot control system is installed on the 100-01 Hytrol Valve,

use care to prevent damage. If it is necessary to remove fittings

or components, be sure they are kept clean and replaced

exactly as they were.

8. After the valve is installed and the system is first pressurized,

vent air from the cover chamber and pilot system tubing by

loosening fittings at all high points.

Tight Closing Operation

When pressure from the valve inlet (or

an equivalent independent operating

pressure) is applied to the diaphragm

chamber the valve closes drip-tight.

Full Open Operation

When pressure in diaphragm chamber

is relieved to a zone of lower pressure

(usually atmosphere) the line pressure

(5 psi Min.) at the valve inlet opens the

valve.

Modulating Action

Valve modulates when diaphragm pressure is held at an intermediate point

between inlet and discharge pressure.

With the use of a Cla-Val. "modulating

control," which reacts to line pressure

changes, the pressure above the

diaphragm is varied, allowing the valve

to throttle and compensate for the

change.

Principles of Operation

Three Way

Pilot Control

Three Way

Pilot Control

Restriction

Modulating

Control

100-01

Hytrol Valve

MODEL

INSTALLATION / OPERATION / MAINTENANCE

Page 6

2

Flow Direction

The flow through the 100-01 Hytrol Valve can be in one of two

directions. When flow is “up-and-over the seat,” it is in “normal”

flow and the valve will fail in the open position. When flow is “overthe seat-and down,” it is in “reverse” flow and the valve will fail in

the closed position. There are no permanent flow arrow markings.

The valve must be installed according to nameplate data.

BRIDGEWALL INDlCATOR

Normal Flow Reverse Flow

Troubleshooting

The following troubleshooting information deals strictly with the

Model 100-01 Hytrol Valve. This assumes that all other components of the pilot control system have been checked out and are

in proper working condition. (See appropriate sections in

Technical Manual for complete valve).

Three Checks

The 100-01 Hytrol Valve has only one moving part (the diaphragm

and disc assembly). So, there are only three major types of problems to be considered.

First: Valve is stuck - that is, the diaphragm assembly is not free

to move through a full stroke either from open to close or vice

versa.

Second: Valve is free to move and can’t close because of a worn

out diaphragm.

Third: Valve leaks even though it is free to move and the

diaphragm isn’t leaking.

Closed isolation valves in control system, or in main line.

Lack of cover chamber pressure.

Diaphragm damaged. (See Diaphragm Check.)

Diaphragm assembly inoperative.

Corrosion or excessive scale build up on valve stem.

(See Freedom of Movement Check)

Mechanical obstruction. Object lodged in valve.

(See Freedom of Movement Check)

Worn disc. (See Tight Sealing Check)

Badly scored seat. (See Tight Sealing Check)

Closed upstream and/or downstream isolation

valves in main line.

Insufficient line pressure.

Diaphragm assembly inoperative. Corrosion or excessive

buildup on valve stem. (See Freedom of Movement Check)

Diaphragm damaged. (For valves in "reverse flow" only)

After checking out probable causes and remedies, the following three checks can be used to diagnose the nature of the

problem before maintenance is started. They must be done in the order shown.

Open Isolation valves.

Check upstream pressure, pilot system, strainer, tubing, valves, or needle

valves for obstruction.

Replace diaphragm.

Clean and polish stem. Inspect and replace any damaged or badly eroded

part.

Remove obstruction.

Replace disc.

Replace seat.

Open isolation valves.

Check upstream pressure. (Minimum 5 psi flowing line pressure differential.)

Clean and polish stem. Inspect and replace any

damaged or badly eroded part.

Replace diaphragm.

Fails to Close

Fails to Open

CAUTION:

Care should be taken when doing the troubleshooting checks on

the 100-01 Hytrol Valve. These checks do require the valve to

open fully. This will either allow a high flow rate through the

valve, or the downstream pressure will quickly increase to the

inlet pressure. In some cases, this can be very harmful. Where

this is the case, and there are no block valves in the system to

protect the downstream piping, it should be realized that the

valve cannot be serviced under pressure. Steps should be

taken to remedy this situation before proceeding any further.

(cast into side of valve body)

SYMPTOM PROBABLE CAUSE REMEDY

Recommended Tools

1. Three pressure gauges with ranges suitable to the installation to be put at Hytrol inlet, outlet and cover connections.

2. Cla-Val Model X101 Valve Position Indicator. This provides visual indication of valve position without disassembly

of valve.

3. Other items are: suitable hand tools such as screwdrivers, wrenches, etc. soft jawed (brass or aluminum) vise,

400 grit wet or dry sandpaper and water for cleaning.

All trouble shooting is possible without removing the valve from the

line or removing the cover. It is highly recommended to permanently

install a Model X101 Valve Position Indicator and three gauges in

unused Hytrol inlet, outlet and cover connections.

Page 7

Diaphragm Check (#1 )

1. Shut off pressure to the Hytrol Valve by slowly closing upstream

and downstream isolation valves. SEE CAUTION.

2. Disconnect or close all pilot control lines to the valve cover and

leave only one fitting in highest point of cover open to atmosphere.

3.With the cover vented to atmosphere, slowly open upstream

isolation valve to allow some pressure into the Hytrol Valve body.

Observe the open cover tapping for signs of continuous flow. It is

not necessary to fully open isolating valve. Volume in cover chamber capacity chart will be displaced as valve moves to open position. Allow sufficient time for diaphragm assembly to shift positions. If there is no continuous flow, you can be quite certain the

diaphragm is sound and the diaphragm assembly is tight. If the

fluid appears to flow continuously this is a good reason to believe

the diaphragm is either damaged or it is loose on the stem. In

either case, this is sufficient cause to remove the valve cover and

investigate the leakage. (See “Maintenance” Section for procedure.)

Freedom of Movement Check (#2)

4. Determining the Hytrol Valve’s freedom of movement can be

done by one of two methods.

5. For most valves it can be done after completing Diaphragm

Check (Steps 1, 2, and 3). SEE CAUTION. At the end of step 3

the valve should be fully open.

6. If the valve has a Cla-Val X101 Position Indicator, observe the

indicator to see that the valve opens wide. Mark the point of maximum opening.

7. Re-connect enough of the control system to permit the application of inlet pressure to the cover. Open pilot system cock so

pressure flows from the inlet into the cover.

8. While pressure is building up in the cover, the valve should

close smoothly. There is a hesitation in every Hytrol Valve closure,

which can be mistaken for a mechanical bind. The stem will

appear to stop moving very briefly before going to the closed position. This slight pause is caused by the diaphragm flexing at a

particular point in the valve’s travel and is not caused by a

mechanical bind.

9. When closed, a mark should be made on the X101 Valve position indicator corresponding to the “closed” position. The distance

between the two marks should be approximately the stem travel

shown in chart.

10. If the stroke is different than that shown in stem travel chart

this is a good reason to believe something is mechanically restricting the stroke of the valve at one end of its travel. If the flow does

not stop through the valve when in the indicated “closed” position,

the obstruction probably is between the disc and the seat. If the

flow does stop, then the obstruction is more likely in the cover. In

either case, the cover must be removed, and the obstruction located and removed. The stem should also be checked for scale buildup. (See “Maintenance, section for procedure.)

11. For valves 6” and smaller, the Hytrol Valve’s freedom of movement check can also be done after all pressure is removed from

the valve. SEE CAUTION. After closing inlet and outlet isolation

valves and bleeding pressure from the valve, check that the cover

chamber and the body are temporarily vented to atmosphere.

Insert fabricated tool into threaded hole in top of valve stem, and

lift the diaphragm assembly manually. Note any roughness. The

diaphragm assembly should move smoothly throughout entire

valve stroke. The tool is fabricated from rod that is threaded on

one end to fit valve stem and has a “T” bar handle of some kind

on the other end for easy gripping. (See chart in Step 4 of

“Disassembly” Section.)

12. Place marks on this diaphragm assembly lifting tool when the

valve is closed and when manually positioned open. The distance

between the two marks should be approximately the stem travel

shown in stem travel chart. If the stroke is different than that

shown, there is a good reason to believe something is mechanically restricting the stroke of the valve. The cover must be

removed, and the obstruction located and removed. The stem

should also be checked for scale build-up. (See “Maintenance”

Section for procedure.)

Tight Sealing Check (#3)

13. Test for seat leakage after completing checks #1 & #2 (Steps

1 to 12). SEE CAUTION. Close the isolation valve downstream of

the Hytrol Valve. Apply inlet pressure to the cover of the valve, wait

until it closes. Install a pressure gauge between the two closed

valves using one of the two ports in the outlet side of the Hytrol.

Watch the pressure gauge. If the pressure begins to climb, then

either the downstream isolation valve is permitting pressure to

creep back, or the Hytrol is allowing pressure to go through it.

Usually the pressure at the Hytrol inlet will be higher than on the

isolation valve discharge, so if the pressure goes up to the inlet

pressure, you can be sure the Hytrol is leaking. Install another

gauge downstream of isolating valve. If the pressure between the

valves only goes up to the pressure on the isolation valve

discharge, the Hytrol Valve is holding tight, and it was just the isolation valve leaking.

STEM TRAVEL

(Fully Open to Fully Closed)

Valve Size (inches) Travel (inches)

Inches MM Inches MM

1 1/4 32 0.4 10

1 1/2 40 0.4 10

250 0.615

2 1/2 65 0.7 18

380 0.820

4 100 1.1 28

6 150 1.7 43

8 200 2.3 58

10 250 2.8 71

12 300 3.4 86

14 350 4.0 100

16 400 4.5 114

20 500 5.6 143

24 600 6.7 165

30 800 7.5 190

36 900 8.5 216

COVER CHAMBER CAPACITY

(Liquid Volume displaced when valve opens)

Valve size (inches) Displacement

Gallons Liters

1 1/4 .020 .07

1 1/2 .020 .07

2 .032 .12

2 1/2 .043 .16

3 .080 .30

4 .169 .64

6 .531 2.0

8 1.26 4.8

10 2.51 9.5

12 4.00 15.1

14 6.50 24.6

16 9.57 36.2

20 12.00 45.4

24 29.00 109.8

30 42.00 197.0

36 90.00 340.0

3

Page 8

Maintenance

Preventative Maintenance

The Cla-Val Co. Model 100-01 Hytrol Valve requires no lubrication or

packing and a minimum of maintenance. However, a periodic inspection schedule should be established to determine how the operating

conditions of the system are affecting the valve. The effect of these

actions must be determined by inspection.

Disassembly

Inspection or maintenance can be accomplished without removing

the valve from the line. Repair kits with new diaphragm and disc are

recommended to be on hand before work begins.

WARNING: Maintenance personnel can be injured and equipment

damaged if disassembly is attempted with pressure in the valve. SEE

CAUTION.

1. Close upstream and downstream isolation valves and independ-

ent operating pressure when used to shut off all pressure to the

valve.

2. Loosen tube fittings in the pilot system to remove pressure from

valve body and cover chamber. After pressure has been released

from the valve, use care to remove the controls and tubing. Note and

sketch position of tubing and controls for re-assembly. The schematic in front of the Technical Manual can be used as a guide when

reassembling pilot system.

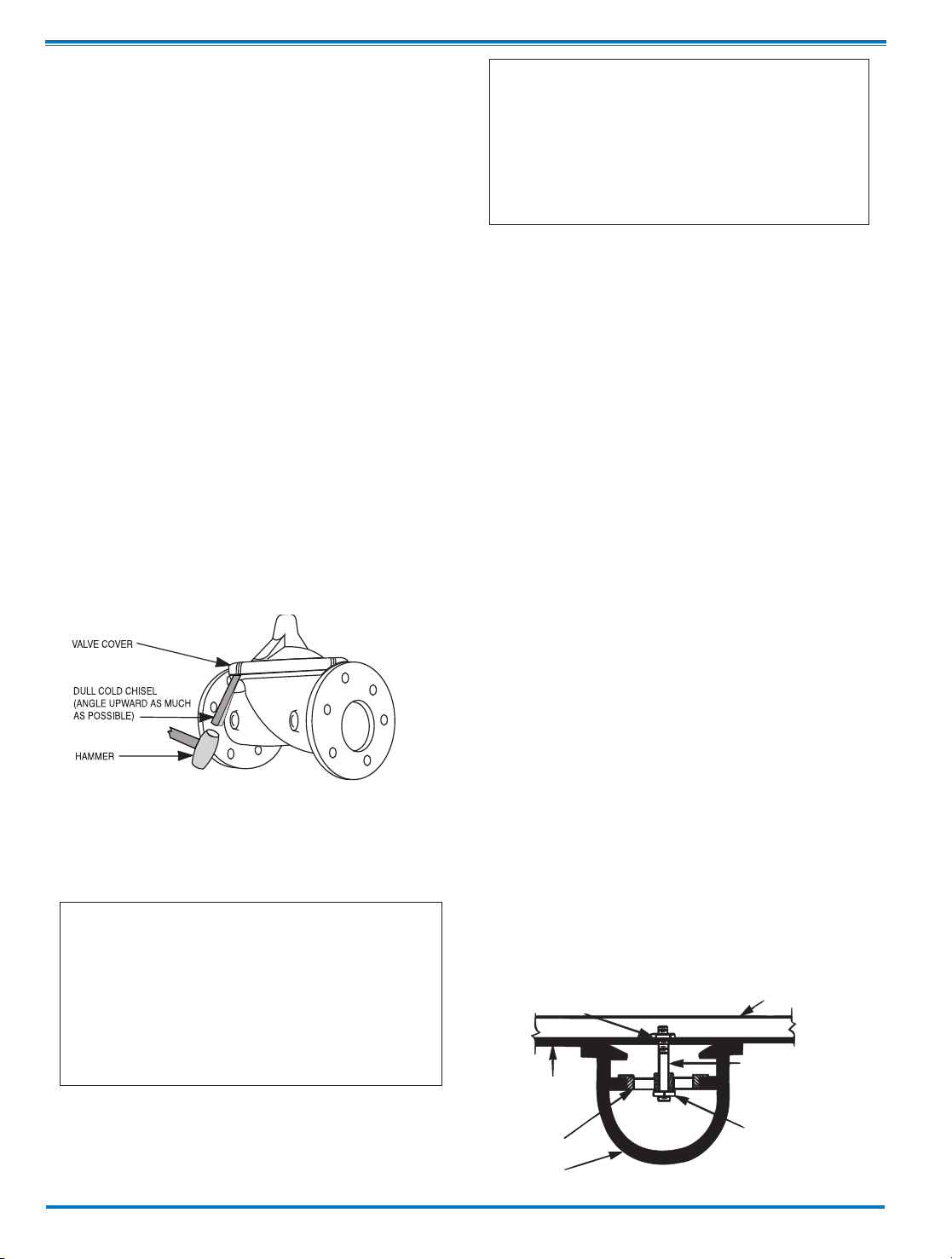

3. Remove cover nuts and remove cover. If the valve has been in

service for any length of time, chances are the cover will have to be

loosened by driving upward along the edge of the cover with a dull

cold chisel.

On 6” and smaller valves block and tackle or a power hoist can be

used to lift valve cover by inserting proper size eye bolt in place of

the center cover plug. on 8” and larger valves there are 4 holes (5/8”

— 11 size) where jacking screws and/or eye bolts may be inserted

for lifting purposes. Pull cover straight up to keep from damaging

the integral seat bearing and stem.

4. Remove the diaphragm and disc assembly from the valve body.

With smaller valves this can be accomplished by hand by pulling

straight up on the stem so as not to damage the seat bearing.

On large valves, an eye bolt of proper size can be installed in the

stem and the diaphragm assembly can be then lifted with a block and

tackle or power hoist. Take care not to damage the stem or bearings.

The valve won't work if these are damaged.

5. The next item to remove is the stem nut. Examine the stem

threads above the nut for signs of mineral deposits or corrosion.

If the threads are not clean, use a wire brush to remove as much

of the residue as possible. Attach a good fitting wrench to the nut

and give it a sharp “rap” rather than a steady pull. Usually

several blows are sufficient to loosen the nut for further removal.

On the smaller valves, the entire diaphragm assembly can be held

by the stem in a vise equipped with soft brass jaws before

removing the stem nut.

The use of a pipe wrench or a vise without soft brass jaws scars

the fine finish on the stem. No amount of careful dressing can

restore the stem to its original condition. Damage to the finish of

the stem can cause the stem to bind in the bearings and the valve

will not open or close.

6. After the stem nut has been removed, the diaphragm assembly

breaks down into its component parts. Removal of the disc from

the disc retainer can be a problem if the valve has been in service for a long time. Using two screwdrivers inserted along the outside edge of the disc usually will accomplish its removal. Care

should be taken to preserve the spacer washers in water, particularly if no new ones are available for re-assembly.

7. The only part left in the valve body is the seat which ordinarily

does not require removal. Careful cleaning and polishing of inside

and outside surfaces with 400 wet/dry sandpaper will usually

restore the seat’s sharp edge. If, however, it is badly worn and

replacement is necessary, it can be easily removed.

Seats in valve sizes 1 1/4” through 6” are threaded into the valve

body. They can be removed with accessory X109 Seat Removing

Tool available from the factory. On 8” and larger valves, the seat

is held in place by flat head machine screws. Use a tight-fitting,

long shank screwdriver to prevent damage to seat screws. If upon

removal of the screws the seat cannot be lifted out, it will be necessary to use a piece of angle or channel iron with a hole drilled

in the center. Place it across the body so a long stud can be inserted through the center hole in the seat and the hole in the angle

iron. By tightening the nut a uniform upward force is exerted on

the seat for removal.

NOTE: Do not lift up on the end of the angle iron as this may force

the integral bearing out of alignment, causing the stem to bind.

VALVE STEM THREAD SIZE

Valve Size Thread Size (UNF Internal)

1 1/4"

—2 1/2" 10—32

3"—4" 1/4—28

6"—14" 3/8—24

16" 1/2—20

20 3/4-16

24" 3/4-16

30” 3/4-16

36” 3/4-16

COVER CENTER PLUG SIZE

Valve Size Thread Size (NPT)

1 1/4"

—1 1/2" 1/4"

2"—3" 1/2"

4"—6" 3/4"

8"—10" 1"

12" 1 1/4"

14" 1 1/2"

16" 2"

20” & 24" 2"

30” & 36” 2”

NUT

ANGLE OR CHANNEL IRON

LONG STUD OR BOLT

NUT OR BOLT HEAD

DO NOT

LIFT

VALVE SEAT

VALVE BODY

4

Page 9

Lime Deposits

One of the easiest ways to remove lime deposits from the valve

stem or other metal parts is to dip them in a 5-percent muriatic

acid solution just long enough for the deposit to dissolve. This

will remove most of the common types of deposits. CAUTlON:

USE EXTREME CARE WHEN HANDLING ACID. Rinse parts in

water before handling. If the deposit is not removed by acid, then

a fine grit (400) wet or dry sandpaper can be used with water.

Reassembly

1. Reassembly is the reverse of the disassembly procedure. If a

new disc has been installed, it may require a different number of

spacer washers to obtain the right amount of “grip” on the disc.

When the diaphragm assembly has been tightened to a point

where the diaphragm cannot be twisted, the disc should be compressed very slightly by the disc guide. Excessive compression

should be avoided. Use just enough spacer washers to hold the

disc firmly without noticeable compression.

2. MAKE SURE THE STEM NUT IS VERY TIGHT. Attach a good

fitting wrench to the nut and give it a sharp “rap” rather than a

steady pull. Usually several blows are sufficient to tighten the

stem nut for final tightening. Failure to do so could allow the

diaphragm to pull loose and tear when subjected to pressure.

Test Procedure After Valve Assembly

There are a few simple tests which can be made in the field to

make sure the Hytrol Valve has been assembled properly. Do

these before installing pilot system and returning valve to

service. These are similar to the three troubleshooting tests.

1. Check the diaphragm assembly for freedom of movement

after all pressure is removed from the valve. SEE CAUTlON.

Insert fabricated tool into threaded hole in top of valve stem, and

lift the diaphragm assembly manually. Note any roughness,

sticking or grabbing. The diaphragm assembly should move

smoothly throughout entire valve stroke. The tool is fabricated

from rod that is threaded on one end to fit valve stem (See chart

in Step 4 of “Disassembly” section.) and has a “T” Bar handle of

some kind on the other end for easy gripping.

Place marks on this diaphragm assembly lifting tool when the

valve is closed and when manually positioned open. The distance between the two marks should be approximately the stem

travel shown in stem travel chart. (See “Freedom of Movement

Check” section.) If the stroke is different than that shown, there

is a good reason to believe something is mechanically restricting

the stroke of the valve. The cover must be removed, the obstruction located and removed. (See “Maintenance” Section for

procedure.)

Inspection of Parts

After the valve has been disassembled, each part should be

examined carefully for signs of wear, corrosion, or any other

abnormal condition. Usually, it is a good idea to replace the rubber parts (diaphragm and disc) unless they are free of signs of

wear. These are available in a repair kit. Any other parts which

appear doubtful should be replaced. WHEN ORDERlNG

PARTS, BE SURE TO GIVE COMPLETE NAMEPLATE DATA,

ITEM NUMBER AND DESCRlPTlON.

NOTE: If a new disc isn’t available, the existing disc can be

turned over, exposing the unused surface for contact with the

seat. The disc should be replaced as soon as practical.

3. Carefully install the diaphragm assembly by lowering the stem

through the seat bearing. Take care not to damage the stem or

bearing. Line up the diaphragm holes with the stud or bolt holes

on the body. on larger valves with studs, it may be necessary to

hold the diaphragm assembly up part way while putting the

diaphragm over the studs.

4. Put spring in place and replace cover. Make sure diaphragm

is Iying smooth under the cover.

5. Tighten cover nuts firmly using a cross-over pattern until all

nuts are tight.

6. Test Hytrol Valve before re-installing pilot valve system.

Due to the weight of the diaphragm assembly this procedure is

not possible on valves 8” and larger. on these valves, the same

determination can be made by carefully introducing a low

pressure-less than five psi) into the valve body with the cover

vented. SEE CAUTION. Looking in cover center hole see the

diaphragm assembly lift easily without hesitation, and then

settle back easily when the pressure is removed.

2. To check the valve for drip-tight closure, a line should be

connected from the inlet to the cover, and pressure applied at the

inlet of the valve. If properly assembled, the valve should hold

tight with as low as ten PSI at the inlet. See “Tight Sealing

Check” section.)

3. With the line connected from the inlet to the cover, apply full

working pressure to the inlet. Check all around the cover for any

leaks. Re-tighten cover nuts if necessary to stop leaks past the

diaphragm.

4. Remove pressure, then re-install the pilot system and tubing

exactly as it was prior to removal. Bleed air from all high

points.

5. Follow steps under “Start-Up and Adjustment” Section in

Technical Manual for returning complete valve back to service

.

5

Page 10

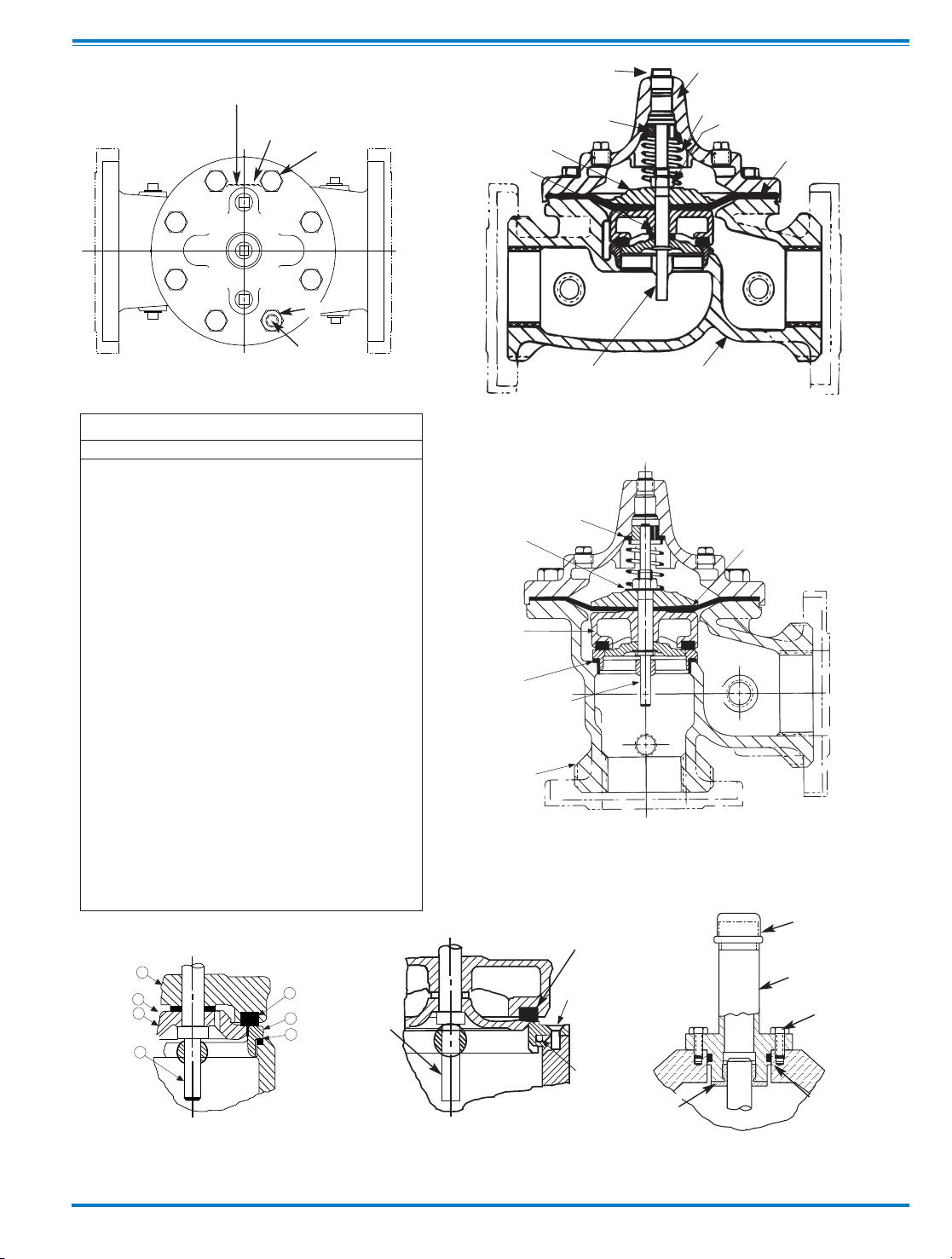

1

5

8

10

14

16

6

17

7

9

OUTLE

T

INLET

GLOBE PATTERN

9

26

27

12

15

14

16

INLET

OUTLET

ANGLE PATTERN

22

23

13

12

14

10

11

15

23

TOP VIEW

8" - 24" SEAT DETAIL

1 1/4" - 6" SEAT DETAIL

16" COVER DETAIL

4

24

2

25

13

31

28

30

29

5

14

3

Item Description

1. Pipe Plug

2. Drive Screws (for nameplate)

3. Hex Nut (8” and larger)

4. Stud (8” and larger)

5. Cover Bearing

6. Cover

7. Stem Nut

8. Diaphragm Washer

9. Diaphragm

10. Spacer Washers

11. Disc Guide

12. Disc Retainer

13. Disc

14. Stem

15. Seat

16. Body

17. Spring

22. Flat Head Screws (8” and larger)

23. Seat O-Ring

24. Hex head Bolt (1 1/4” thru 4”)

25. Nameplate

26. Upper Spring Washer (Epoxy coated valves only)

27. Lower Spring Washer (Epoxy coated valves only)

28. Cover Bearing Housing (16” only)

29. Cover O-Ring (16’” only)

30. Hex Bolt (16” only)

31. Pipe Cap (16” only)

PARTS LIST

6

Page 11

100-01

Hytrol Valve Service Data

MODEL

INSTALLATION / OPERATION / MAINTENANCE

Description 100-01 Hytrol Valve

The CIa-VaI Model 100-01 Hytrol Valve is a main valve for

CIa-VaI Automatic Control Valves. It is a hydraulically operated,

diaphragm-actuated, globe or angle pattern valve.

This valve consists of three major components; body, diaphragm

assembly, and cover. The diaphragm assembly is the only

moving part. The diaphragm assembly uses a diaphragm of nylon

fabric bonded with synthetic rubber. A synthetic rubber disc,

contained on three and one half sides by a disc retainer and disc

guide, forms a seal with the valve seat when pressure is applied

above the diaphragm. The diaphragm assembly forms a sealed

chamber in the upper portion of the valve, separating operating

pressure from line pressure.

Description 100-20 600 Series Hytrol Valve

The CIa-VaI Model 100-20 Hytrol Valve (600 Series main valve)

have only one part -the body- that is different from standard 100

Series Cla-Val main valve parts. The remaining parts of the 600

series main valve are standard Cla-Val main valve parts. All serv-

ice and maintenance information for the standard 100 Series

main valves also apply to the 600 series main valves.

The most important thing to remember when ordering main

valve repair kits and replacement parts, except for the body, all

other parts are going to be for a smaller size main valve. Cla-

Val identifies main valve parts with the flange size of the stan-

dard 100 Series main valve. Refer to the "Main Valve Sizes”

chart below.

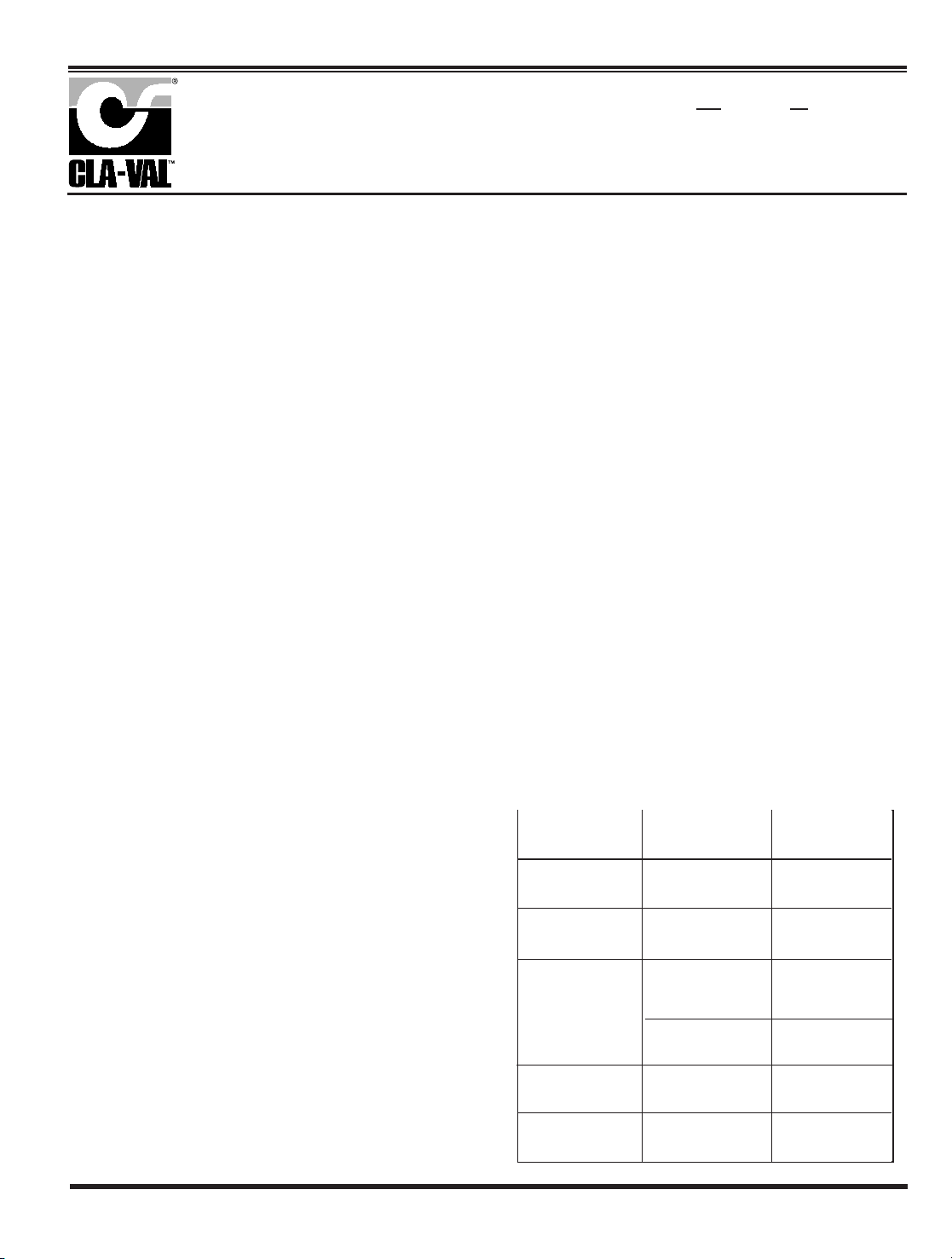

HYTROL Service Data

HYTROL SIZE

Stem

Travel

Cover Capacity

Displacement

Valve Stem

Thread

UNF-Internal

Cover

Center

Plug

NPT

Cover Nut or Bolt

Cover

Lifting

Holes

UNC

Cover Plug Cover Torque

Stem Nut**

Stem Nut Torque

(ft. Lbs.)

100-01

100-20

Thread

(Bolt)

Socket

Qty Thread

Socket ft. Lbs. in. Lbs.

Thread

Socket

(Long)

inches mm inches mm inches mm

Gallons

Liters

Lubed DRY

1"

25 0.3 8 1/4"

1/4" - 20 (B)

7/16" 8

4

48 3/8" - 24

4

6

1 1/4"

32

0.4

10

0.020

0.07

10 - 32

1/4" 5/16" - 18 (B) 1/2"

8

8 96 7/16" -20 6 10

1 1/2" 40 0.4 10 0.020 0.07

10 - 32

1/4" 5/16" - 18 (B) 1/2"

8

8 96 7/16" -20 6 10

2" 50 0.6 15 0.032

0.12 10 - 32

1/2" 3/8" - 16 (B) 9/16" 8 3/8" 7/16" 12

1/2" - 20

3/4" 10 15

2 1/2"

65 0.7 18

0.043 0.16

10 - 32

1/2" 7/16" - 14 (B) 5/8" 8 1/2" 9/16" 20

5/8" - 18 15/16" 21

30

3" 80 4" 100 0.8

20

0.080 0.30

1/4 - 28 1/2"

1/2" - 13 (B)

3/4" 8 1/2" 9/16" 30 5/8" - 18

15/16"

21 30

4" 100 6" 150 1.1 23

0.169 0.64

1/4 - 28 3/4"

3/4" - 10 (B)

1 1/8" 8 3/4" 5/8" 110 3/4" - 16

1 1/16"

40

60

6" 150 8" 200 1.7 43 0.531 2.00 3/8 - 24 3/4"

3/4" - 10 (B) 1 1/8"

12 3/4"

5/8" 110

7/8" - 14

1 5/16"

85 125

8"

200 10"

250

2.3 58

1.26 4.80 3/8 - 24

1"

3/4" - 10

1 1/4" 16 5/8" - 11

1" 13/16" 110

1 1/8" -12 1 13/16"

125

185

10" 250 12" 300 2.8 71 2.51 9.50

3/8 - 24

1" 7/8" - 9 1 7/16"

20

3/4" - 10

1"

13/16" 160 1 1/2" -12 1 7/8" 252 375

12" 300 16" 400 3.4 86 4.0 15.10

3/8 - 24

1 1/4" 1 1/8" - 7 1 13/16"

20

3/4" - 10

1" 13/16" 390 1 1/2" -12 2 1/2" 270 400

14" 350 3.9

99

6.5

24.60

3/8 - 24 1 1/2" 1 1/4" - 7

2" 20

1" - 8

1" 13/16" 545 1 1/2" -12

2 1/2"

280 420

16"

400

20", 24"

600

4.5

114

9.6 36.20

1/2 - 20

2" 1 1/4" - 7

2" 20

1" - 8

1" 13/16" 545 2" - 16 3" 500 750

20" 500 5.63

143

12 45.40

3/4 - 16 1 1/2" 1 3/8" - 6

2 1/8" 24

1" - 8

1" 13/16" 670

2 1/4" - 16

3 1/2" 930

N/R

24" 600

30"

800 6.75 165

29.0

108.80 3/4 - 16*

3/4"

1 1/2" - 12 2 3/8" 24

1 1/8"- 7

1" 13/16"

800

3" - 12

Special

1350

N/R

* Adapter

p/n 2594101E

inside 1/4" - 28"

Grade 5 Bolts

"Heavy" Grade Nuts

Tighten cover nuts in a "star" cross-over pattern

** Must Use ONLY

Cla-Val Supplied part

Page 12

COVER

PIPE PLUG

COVER BEARING

SPRING

STEM NUT

DIAPHRAGM WASHER

DISC RETAINER

BODY

*

SPACER WASHERS

DISC GUIDE

SEAT

PIPE PLUG

STEM

SEAT O-RING

STUD

8" and Larger

*

DIAPHRAGM

*

DISC

*

Repair Parts

Seat Screw

8" and Larger

(Globe

or

Angle)

PIPE PLUG

HEX NUT

8" and Larger

Cover Bolt

6" and Smaller

KO

DISC GUIDE

KO

SEAT

KO Anti-Cavitation

Trim Option

N-100-01 (R-3/2011

CLA-VAL

Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

BOLT/NUT TORQUING PROCEDURES ON VALVE COVERS

4

BOLTS

6

BOLTS

8

BOLTS

12

BOLTS

16

BOLTS

20

BOLTS

4

3

2

1

65

4

3

2

1

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

20

19

18

17

16

15

14

13

12

11

Follow this procedure when reassembling MAIN Valve:

1. Tightens bolts/nuts in a “Star” or “Cross-Over” pattern following the

numbers shown above to insure that cover seats evenly on the diaphragm

material and body.

2. Torque the bolt/nuts in three stages with a "Star" or "Cross-Over" pattern

for each stage:

A. To approximately 10% of final torque.

B. To approximately 75% of final torque.

C. To final required torque.

3. Valves that are to be tested to 375 PSI or higher should be retorqued

after 24 hours.

100-01 Hytrol Main Valve Assembly

Page 13

UNDERSTANDING THE 600 SERIES VALVES

In 1987, Cla-Val introduced the Model 100-20 Hytrol as the basic

main valve for the 600 Series of automatic control valves. To

identify all new valves using the 100-20 Hytrol, an existing catalog number is modified. Making a 600 Series catalog number is

simply done by using a "6" in front of the two digit catalog numbers or replacing the "2" with a "6" in three digit catalog numbers. Current schematics reflect both catalog numbers together

separated by a slash ( i.e. - 90-01/690-01, 58-02/658-02, 21001/610-01, etc). Since these two valves 'share' the same catalog

number and schematic, they provide the same function in a system. The only difference between the two valves is the relative

capacity of the two main valve series.

The 100-01 Hytrol is the basic main valve for Cla-Val automatic

control valves. This valve is the current version of the Clayton

Hytrol valve design originated in 1936. The 100-01 Hytrol is

designed as a full flow area valve. This means that the inlet,

seat and outlet openings are the same size. Thus, the pressure

drop is kept to a minimum for this globe style design.

The 100-20 Hytrol valve has all of the basic features and advantages of the original 100-01 Hytrol. Only one part has been

changed - the body. It is designed with different size inlet, seat

and outlet openings. The 100-20 Hytrol has inlet and outlet

flanges one valve size larger than the seat opening size. This

results in what is sometimes called a ''reduced port' main valve.

For example, a 4" 100-20 valve has a 3" seat. Note: valve size

is always determined by the flange size. The following chart

compares the 100-01 and the 100-20 main valves.

600 Series Hytrol Valve

100-20

MODEL

INSTALLATION / OPERATION / MAINTENANCE

SERVICE AND MAINTENANCE OF 600 SERIES

VALVES

The 600 series main valves have only one part -the body- that is

different from standard 100 Series Cla-Val main valve parts. The

remaining parts of the 600 series main valve are standard ClaVal main valve parts. All service and maintenance information

for the standard 100 Series main valves in this manual also

apply to the 600 series main valves.

The most important thing to remember when ordering main valve

repair kits and replacement parts, except for the body, all other

parts are going to be for a smaller size main valve. Cla-Val identifies main valve parts with the flange size of the standard 100

Series main valve. Refer to the "Main Valve Sizes Comparison"

chart. For example, if you are servicing a 6" 100-20 Hytrol and

needed a repair kit, you would order a repair kit for a 4" 100-01

Hytrol. This kit is also suitable for a 6" 100-20 Hytrol. Complete

Technical Manuals include a repair kit data sheet N-RK that

shows this relationship.

When you order repair parts, it is a good idea to include valve

nameplate data (size, catalog number, and part number) and

description of the parts desired. Do this to be sure parts will fit

the valve you are working on and not be too big for it. Pilot controls and repair kits maintenance information remain the same

for 100 or 600 Series valves.

Cla-Val Main Valves

Catalog Number

The 100-20 Hytrol is available only in ductile iron, 150 and 300

pressure class, and Bronze trim standard. Available extra cost

main valve options include stainless steel trim, epoxy coating,

Dura-Kleen stem, Delrin sleeved stem, and high temperature rubber parts. All four basic main valves have a 600 Series version

available with all of the same benefits and size relationships.

The following chart shows the relationship of Cla-Val main valve

catalog numbers.

Catalog Name

Hytrol

Powertrol

Powercheck

Hycheck

Circa 1936

100 (Angle =2100)

100P & 100PA

100PC & 100PCA

181

100-Series

100-01

100-02

100-03

100-04

600 Series

100-20

100-21

100-22

100-23

(Reduced Internal Port)

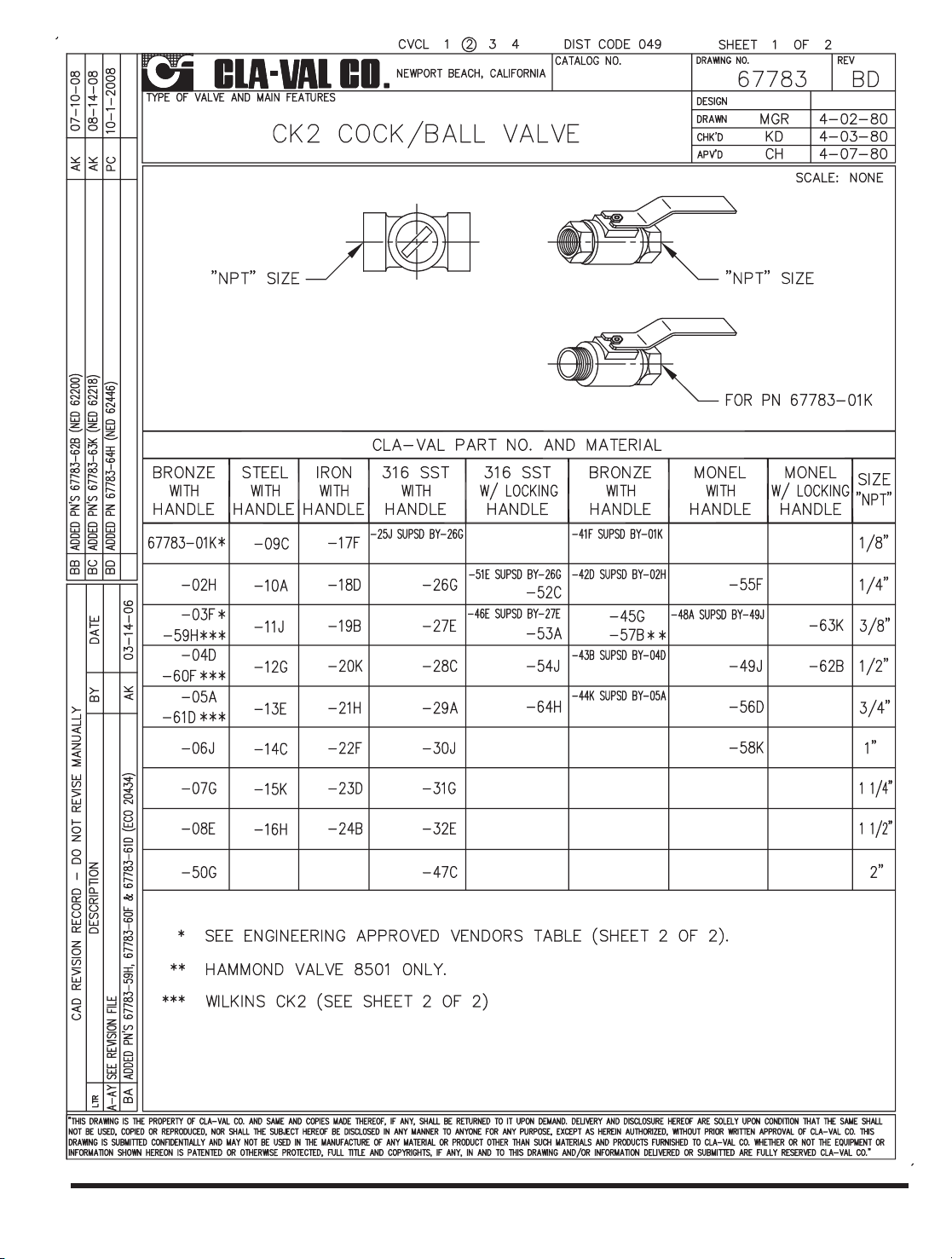

Basic Main Valve Size Comparison

Globe Pattern Valves

Flange Size (inch)

Seat Size

100-01 (100 Series) 100-20 (600 Series)

3 3 2

4 4 3

6 6 4

8 8 6

10 10 8

12 12 10

14 14 ---16 16 12

18 ---- 16

20 20 16

24 24 16

30 30 24

36 36 30

42 ---- 36

48 ---- 36

Angle Pattern Valves

Flange Size (inch)

Seat Size

100-01 (100 Series) 100-20 (600 Series)

4 4 3

6 6 4

8 8 6

Page 14

CLA-VAL

Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

N-100-20 (R-3/2011)

100-20

PARTS LIST

NO. DESCRIPTION

1 Pipe Plug

2 Drive Screws (for nameplate)

3 Hex Nut (8" and larger)

4 Stud (8" and larger)

5 Cover Bearing

6 Cover

7 Stem Nut

8 Diaphragm Washer

9 Diaphragm

10 Spacer Washers

11 Disc Guide

12 Disc Retainer

13 Disc

14 Stem

15 Seat

16 Body

17 Spring

22 Flat Head Screws (10" and larger)

23 Seat O-Ring

24 Hex Bolt (3 " Thru 6")

25 Nameplate (Mounted on inlet flange)

26 Upper Spring Washer (Epoxy coated valves only)

27 Lower Spring Washer (Epoxy coated valves only)

28 Cover Bearing Housing (20" & 24" & 30")

29 Cover Bearing Housing O-Ring (20"& 24" & 30")

30 Hex Bolt (20" & 24")

31 Pipe Cap (20" & 24 & 30"")

11

14

12434

5

17

16

26

14

7

8

9

27

14

13

22

12

15

31

28

5

30

29

10" — 24" SEAT DETAIL

20" — 24" COVER DETAIL

TOP VIEW

12

13

15

OUTLET

GLOBE

INLET

ANGLE

INLET

6

8

9

2

25

3" — 6" COVER DETAIL

23

11

WHEN ORDERING PARTS, BE SURE TO GIVE COMPLETE

NAMEPLATE DATA, ITEM NUMBER AND DESCRIPTION.

10

Page 15

RDH051228,TB_300-SingleModeControls32.doc,6/16/2006

Technical Bulletin

300 Series (Single-Mode) Electronic Actuated Pilot Controls

Introduction

CDB-32, CDHS-32, CRA-32, CRD-32, and CRL-32 are pilot controls for Cla-Val 300 Series Electronic Actuated

Control Valves. These controls offer the same hydraulic control of the valve as existing manually-set controls, along

with additional remote electronic setpoint adjustment capabilities. The new pilot controls consist of a modified pilot

control sub-assembly, and the 130VC-2 Electronic Actuator with mounting components. Complete controls are valve

mounted with an accessory X56 Mounting Assembly.

I. O. M. Information

A. The 130VC-2 wiring diagram is included with this technical bulletin. The 5-wire cable is permanently attached to

actuator and should be terminated in suitable junction box. Care should be used when attaching to wires to avoid

damage. There are no user serviceable parts inside the actuator and tampering or opening it will void the warranty.

B. For Installation, Operation and Maintenance information only on the pilot sub-assembly use instructions in the

appropriate N-sheet for the manually adjusted pilot control. Since the 130VC-2 Electronic Actuator changes the

setpoint adjustment of the control, all other service and maintenance information remains the same for both. See

table below.

C. Additional service notes:

1. Before disassembly of pilot subassembly from 130VC-2 actuator, adjust pilot control to full minimum range setting

with laptop computer and 130VC-2 software to ensure full adjustment range when reassembled.

2. Note orientation of sub-assembly ports and bracket. Coupler and blue Aluminum bracket will remain attached to

actuator. Loosen and remove jam nut and washer from sub-assembly cover as sub-assembly is removed from

130VC-2 bracket. Count number of turns counterclockwise of pilot adjustment shaft from minimum range set position

to full out stop position. See pilot drawing.

3. After servicing the pilot sub-assembly, re-establish minimum spring setting by manually turning adjusting screw

counterclockwise until it stops (full out stop position). Then, turn in same number of turns found in step 2 to minimum

range set position.

4. Do not lubricate coupler slots. A small amount of waterproof anti-seize grease is used only on sub-assembly

adjusting screw threads and contact point with spring guide inside cover.

5. Reinstall sub-assembly to bracket with jam nut and washer. Check coupler slots and adjusting screw pin are lined

up while installing actuator to bracket. Be sure to retain original alignment of sub-assembly with bracket when

tightening jam nut and washer. A slight manual adjustment of adjusting screw may help align the coupler to adjusting

screw. See pilot assembly drawing.

6. After reinstalling onto valve, use laptop computer and 130VC-2 software to reset range values.

Pilot Control Pilot Assembly

Drawing

Sub-Assembly

IOM (ref. only)

Sub-Assembly

Drawing

Sub-Assembly

Repair Kit

CDB-32 205580 N-CDB-7 201935 9170023H

CDHS-32 205137 N-CDHS-11A 76832 20287401E

CDHS-32A 205333 N-CDHS-11B 205332 9170028G

CRA-32 N-CRA 82528 9170001D

CRD-32 205129 N-CRD 70899 9170002B

CRL-32 205130 N-CRL-5A 90846 20666E

Page 16

•

Simplified Remote Valve Set-Point Control

•

12-24VDC Input Power

•

Easy Interfacing to SCADA Systems

•

Accurate Pressure Control

•

Reliable Hydraulic Operation

•

Submersible (IP-68)

The Cla-Val Model CRL-32 Electronic Actuated Pressure Sustaining Pilot

Control provides remote set-point adjustment and accurate pressure sustaining control on Cla-Val 350 Series Control Valves. Remote set-point

command signals can be from any SCADA-type control system that uses

analog 4-20 mA signals. The CRL-32 senses upstream pressure with a

remote hydraulic connection. Operating on 12 to 24 VDC and consuming

very little power, it is an ideal control system for remote valve sites that

may even be solar powered. Existing manually-set Cla-Val 50 Series

Pressure Sustaining control valves can be retrofitted with CRL-32 to add

remote set-point control of minimum inlet pressure. Verification of inlet

pressure may be sent to SCADA system from customer supplied pressure

sensor attached upstream of valve.

The CRL-32 consists of a hydraulic pilot and integral controller that

accepts a 4-20 mA remote set-point and positions the pilot to maintain a

minimum pressure at valve inlet within preset limits. Pressure settings are

linear between these settings. Special USB connector cable and free

downloadable software is required to change built-in electronic range limits for upstream sustained pressure. Continuous internal monitoring of

actuator position results in smooth transitions between pilot set-points with

no backlash or dithering. When power or control input fail, the CRL-32

pilot remains in automatic hydraulic control assuring system stability under

all conditions.

Electronic Actuated

Pressure Sustaining Pilot Control

Remote

Set-Point

SCADA

Computer

Remote Telemetry Unit

(Customer Supplied)

Optional

Process Variable

Transmitter of

Upstream Pressure

(Customer Supplied)

Upper

Zone

CLA-VAL

350 Series

Electronic Actuated

Pressure Sustaining Valve

with CRL-32 Pilot Control

Flow

CLA-VAL

CRL-32

Control

Lower Zone

Typical Applications

The CRL-32 is installed on Cla-Val 350 Series valves that maintain minimum upstream pressure by relieving excess pressure to lower zone

and require this pressure setting to be changed from a remote location.

It is also an effective solution for lowering costs associated with "confined space" requirements by eliminating the need for entry in valve

structure for set point adjustment. Additional pilot controls, hydraulic

and/or electronic, are also available to perform multiple functions to fit

exact system requirements.

CRL-32

MODELS

Page 17

Adjustment Ranges

0 to 75 psi

20 to 200 psi

End Connection

1/2" NPT

Temperature Range

Water: to 180°F

Materials

Pilot Control: Bronze ASTM B62

Trim:Stainless Steel Type 303

Rubber:Buna-N

®

Synthetic Rubber

Available with optional Stainless Steel or Monel

materials at additional cost. Consult factory for details.

Note: Shipping Weight: 8 Lbs.

PO Box 1325 Newport Beach CA 92659-0325

Phone: 949-722-4800 Fax: 949-548-5441

CLA-VAL

CLA-VAL CANADA CLA-VAL EUROPE

4687 Christie Drive

Beamsville, Ontario

Canada LOR 1B4

Phone: 905-563-4963

Fax: 905-563-4040

Chemin dés Mesanges 1

CH-1032 Romanel/

Lausanne, Switzerland

Phone: 41-21-643-15-55

Fax: 41-21-643-15-50

©COPYRIGHT CLA-VAL 2008 Printed in USA

Specifications subject to change without notice.

www.cla-val.com

E-CRL-32 (R-1/08)

Represented By:

CRL-32 Purchase Specifications

The Electronic Actuated Pressure Sustaining Pilot Control shall have an integral hydraulic pilot and electronic controller contained in

a IP-68 rated submersible enclosure to provide interface between remote telemetry and valve set-point control. It will compare a

remote analog command signal with an internal position sensor signal and adjust the hydraulic pilot control spring mechanism to a

new set-point position. 4-20 mA actuator position feedback output shall be supplied standard.

If power fails the valve shall continue to control to the last set-point command. If the Remote Set-Point signal is lost the actuator is

programmable to go to either the 4mA, Last, or 20mA command set-point. No mechanical adjustments shall be necessary to the actuator. The low and high position range adjustment shall be accomplished only with valve manufacturer's components and instructions

to be supplied in a separate kit.

The Electronic Actuated Pressure Sustaining Pilot Control shall be Cla-Val Model CRL-32 as manufactured by Cla-Val, Newport Beach, CA.

When Ordering, Please Specify

1. Catalog CRL-32

2. Adjustment Range

3. Materials - Pilot Control

4. X56 Mounting Kit (Specify Valve Size)

Ranging software makes it easy to set low (4mA) and

high (20mA) set-point limits.

Pilot Control Subassembly Specifications

Supply Power Input: 12V to 24V DC

No Load draw: 50 mA

Max. Load draw: 250 mA

Remote Command Input: 4-20 mA analog signal

Position Feedback Signal: 4-20 mA

Speed of Rotation: Adjustable On/Off time, max 6 rpm

Diagnostic: LED Indicator

Loss of Power: Actuator will remain in last commanded

position.

Loss of Signal Programmable - 4mA, Last, or 20mA

Electrical Connections: Single, permanently attached cable with

color-coded power supply and signal wires

Mechanical Specifications:

Environmental

Protection Class: IP-68 (Temporary submersible)

Ambient Temperature: 15

° to 150° F (-10° to 65° C)

Materials

Enclosure and Bracket: Anodized Aluminum

Coupling Assembly: Stainless Steel

Gear Train: Stainless Steel, permanently lubricated

Options:

Re-ranging software - free download from www.cla-val.com.

USB connection cable required when changing range

parameters or restoring range parameters after servicing

pilot control subassembly.

130VC-2 Electronic Actuator Specifications

Page 18

12 - 24 VDC Power

Supply

+

-

4-20 Milliamp Source

+

-

1

2

3

Red

Wire

Black

Wire

Yellow

Wire

+

-

+

-

In

Out

SCADA

Setpoint Command

Field Wiring Diagram

CLA-VAL

Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

N-130VC-2 Wiring Diagram (R-3/2011)

FIELD WIRING STEPS:

The 5-wire cable is permanently attached to 130VC-2 Actuator and should be terminated in suitable junction box for all

field wires. Care should be used when attaching to wires to avoid damage. Installation of suitable protection from

lightning is recommended.

A.) Attach 12 to 24 VDC power to 130VC-2 Actuator permanent cable. Black wire (2) is common for - power;

Red wire (1) is for + power. No load current draw is 60 mA, Maximum load current draw is 800 mA, Polarity

Protected.

B.) Attach 4 to 20 mA analog Remote Command Input to 130VC-2 Actuator permanent cable. Black wire (2) is

common for - return; Yellow wire (3) is for + sink. Non-isolated.

C.) Blue and Green wires are not used at this time.

IMPORTANT NOTICE:

Do not connect power supply to Command Input (Yellow wire) as this can damage the actuator and is not covered by

warranty.

Factory default for 130VC-2 Actuator range is 32 Series pilot subassembly full spring range scaled to match the 4 to 20 mA

Remote Command Input signal. Range Parameter Kit sets scale limits to values less than pilot spring range during

valve start-up and when servicing pilot sub-assembly. Kit includes: 1) Special Cla-Val USB communications cable

(p/n20519203A order separately) and 2) Special software as free download from Cla-Val web-site: www.cla-val.com.

Consult factory for details.

130VC-2

MODEL

Page 19

130VC-2 Electronic Actuator for 32 Series Pilot Controls

130VC-2

MODEL

INSTALLATION / OPERATION / MAINTENANCE

130VC-2 Electronic Actuator

for 32 Series Pilot Controls

Thank you for purchasing a 32 Series Electronic Control with

130VC-2 “e-Drive” Actuator. With proper maintenance, the actuator will perform indefinitely and provide very accurate and reliable

valve control. It is built with the latest technology utilizing the highest quality components.

32 Series Controls

The 32 Series Actuated Pilot Controls for 300 Series Valves

consist of a hydraulic pilot subassembly and 130VC-2 Actuator.

The Cla-Val Model CDHS-32, CRA-32, CRD-32, and CRL-32 pilot

controls are factory set to full adjustment range of the pilot subassembly. The 130VC-2 Actuator accepts a 4 - 20 mA remote

command set-point and positions spring-loaded hydraulic pilot

subassembly as it maintains set-point of pressure or flow rate. The

pilot subassembly is automatically linear between the limit settings.

32 Series Control Operation

A.) The 130VC-2 actuator allows 32 Series Controls to be

used in valve remote control applications where a simple change

of pilot set-point is needed. The pilot spring range is factory default

scaled to a 4 - 20 mA command input signal. SCADA instrumentation provides set-point control and verification communication

based on this scale.

B.) Other suitable valve remote control applications are

where 4 - 20 mA command input signal is calibrated to specific high

and low range values. SCADA instrumentation provides set-point

control and verification communication based on system dynamic

conditions and valve’s re-ranged scale. Using a laptop computer,

the 130VC-2 actuator is calibrated in the field to specific minimum

and maximum pressure or flow control settings that are in direct

proportion to 4 - 20 mA command signal. Once values are established, the valve will be linear between limits and set-point will not

exceed limits throughout the 4 - 20 mA signal range. For example,

when actuator is calibrated to 4 mA = 50 psi to 20 mA = 100 psi, a

12 mA command signal will result in a 75 psi set point.

32 Series Actuator Hardware Set-up

BEFORE running actuator or software program, complete the

following hookup steps:

A.) Use good field wiring practices for low voltage DC analog

instrumentation wiring (use 18-gauge twisted pair shielded wire

minimum). Avoid potential ground loops. Avoid over tightening

wiring connector fasteners.

B.) The enclosure is rated IP-68 (similar to NEMA 6P) submersible for short periods of time. It is not intended for continuous

underwater use. Consult Cla-Val factory technical support if you

have questions.

C.) The five-wire cable is permanently attached to 130VC-2

actuator and should be terminated in suitable junction box for all

field wires. Care should be used when attaching to wires to avoid

damage. Installation of suitable protection from lightning is recommended.

D.) There are no user serviceable parts inside the actuator

and tampering or opening it will void the warranty.

CAUTION! The five-wire actuator cable is permanently attached.

Internal damage not covered by warranty will occur if cable is

shortened or removed.

FIELD WIRING STEPS:

Download Wiring Diagram from website (www.cla-val.com)

A.) Attach 12 to 24 VDC power to 130VC-2 Actuator cable.

Black wire is common for - power; Red wire is for + power. Provide

minimum 800 mA supply.

B.) Attach 4 to 20 mA analog Remote Command Input (from

SCADA system or loop calibrator) to 130VC-2 Actuator cable.

Black wire is common for - return; Yellow wire is for + sink.

C.) Blue and Green wires are not used at this time.

CAUTION! Do NOT Mix connections to Red, Yellow, or Black

wires. Serious damage to 130VC-2 Actuator will occur if 24 VDC

+ positive power is connected to Black or Yellow wires and not to

Red wire. Damage is NOT covered by warranty.

D.) After wiring is complete and actuator is powered, it can be

used with 4 - 20 mA remote command input signal scaled to factory default pilot control adjustment range (Operation A, above).

Troubleshooting Actuator Set-up

1.) The actuator LED will remain red for approximately 30

seconds after power on, and then will switch to green indicating

actuator is OK and that internal start-up test is complete.

2.) The actuator LED blinks red if there is a problem. After

resolving the problem, reset the actuator by turning power off for

ten seconds then on again.

3.) If other problems occur, please contact Cla-Val factory

technical support.

32 Series Software Kit

For Operation A (above) applications, no changes to the 32 Series

control preset values are needed. For Operation B (above) applications, the 32 Series Software kit is used to ONLY change factory-set values of: 1) range limits (high and low), 2) rotational speed

of actuator, and 3) loss of signal mode. It is used only for set-up of

32 Series pilot controls during initial valve start-up or during valve

repair.

The Cla-Val 130VC-2 Software Kit is required to communicate

between your Windows XP laptop computer and 130VC-2

Actuator. It consists of a free software program, a special USB

connector cable, and these instructions. The software is obtained

by downloading from our website. Only one cable is needed to

work with all 130VC-2 Actuators. Replacement cables (p/n

20519203A) can be ordered at extra cost.

Do not use this software for remote control of 130VC-2 Actuator.

Page 20

Page 2

1) Select NO automatic updates.

2) Select install from a list and NOT

automatic.

3) Select and browse to file:

C\Program Files\CLA-VAL\e-Drive

Setup or to where you saved the folder.

4) Microsoft validation - press Continue.

5) Installation started - press OK

6) Press Finish Installation completed.

Software Download Instructions

Supported Operating Systems are Windows XP and XP Service Pack 2

1) Go to Cla-Val website (www.cla-val.com) and navigate to 32 Series actuator software download page. Click the

Download 130VC-2 Range Software button to start the download.

2) Do one of the following:

_ To start the installation immediately, click RUN to run

this program from its current location. Highly recommended.

_ To copy the download to your computer for installa-

tion at a later time, click SAVE to save this program.

3) This program will automatically be installed in new eDrive folder in C: Program Files/Cla-Val folder on your computer. A

new Cla-Val folder is created in Program Files folder and an "eDrive" icon link is created on Desktop to start program.

Communications Cable Driver

When 130VC-2 communications cable is installed in your laptop

computer USB port for the first time, Windows will search your

computer for the cable USB driver. If Windows Plug-and-Play does

not automatically find the driver and connect to actuator, then the

cable driver must be set-up manually. Windows will take you stepby-step through the manual set-up process. The cable USB driver

is installed during software download. You will have to browse to

the Cla-Val folder created during download where the driver file is

located. Use the following instructions to manually activating the

cable driver.

Page 21

1) First, be sure hardware set-up and wiring to actuator is completed. Connect laptop computer to actuator using special USB

cable. Be sure computer is on and actuator is powered. Check that Actuator LED is steady green.

2) Start the CLA-VAL actuator software by clicking on “e-Drive” desktop icon. After program opens, the Configuration mode

tab will be displayed as default. System values are displayed for pressure or flow settings. Click on setting range values

and enter new system pressure or flow values for 4 mA and 20 mA settings. Engineering Units can be changed to PSI to

Bar or Kpa, GPM to L/S and inches to meters.

3) Click on Read parameters button to display Calibration tab window with system values and display of General Information.

The date of last calibration, the average and total working time since first power up, the number of starts, the serial

number, the Firmware version, and the maximum and minimum recorded temperature inside the actuator are displayed.

Also, Calibration tab window will open without clicking on Read parameters button.

4) Open Configuration tab window to change Rotation Speed. Change speed by adjusting actuator on and off times to equal

slower or faster net rotation speed. Factory default setting of one second on and five seconds off is a net rotation speed of

about one rpm. Longer off times will slow down the actuator. Maximum ratio of 1/1 is a net speed of six rpm. Click on

download to actuator button to make this parameter change without affecting other settings.

Slower rotation speeds are recommended.

5) Open Calibration tab mode to set (Loss-of-Signal mode). Select one of three options for actuator action upon

loss of 4 - 20 mA command input signal. If actuator has power it will do one of the following:

Go to 4 mA: Actuator will decrease pilot setting to 4 mA position.

Last position: Actuator will stay in last position. Highly recommended

Go to 20 mA: Actuator will increase pilot setting to 20 mA position.

Click on download to actuator button to make this parameter change.

In the event of loss of power, actuator will stay in last position and valve will control at last set-point.

Starting Actuator Software

32 Series Actuator and Software Set-up

Change 130VC-2 Actuator configuration from factory default settings,

by using free download software from website (www.cla-val.com). To

set up a communication link with 130VC-2 Actuator, first install

software and cable driver and then special USB communications

cable in laptop computer. After installing driver and communication

cable, the actuator must be powered for link to work. Follow hardware set-up and wiring diagram instructions. Your computer must

be on before powering the actuator.

Hardware set-up steps must be completed before program will

communicate and change 130VC-2 factory default settings. Until

wiring and power connections are made to the actuator, the software program can be opened, but new parameters can not be created or stored or sent to actuator. Changes to parameters must be

done "live" and while control valve is operating.

Install Special Communications CABLE

On 130VC-2 Actuator, remove small protective plastic cover and

attach Special Communications Cable to connector using short

orange wire and attach other cable end to computer USB port.

When finished running software and downloading settings to actuator, remove cable and reinstall small protective plastic cover.

Troubleshooting Actuator Software Set-up

Problem Check

The software is not opening

Are you using Windows XP or

Windows 2000?

No connection to actuator Check if the USB driver is working

Page 3

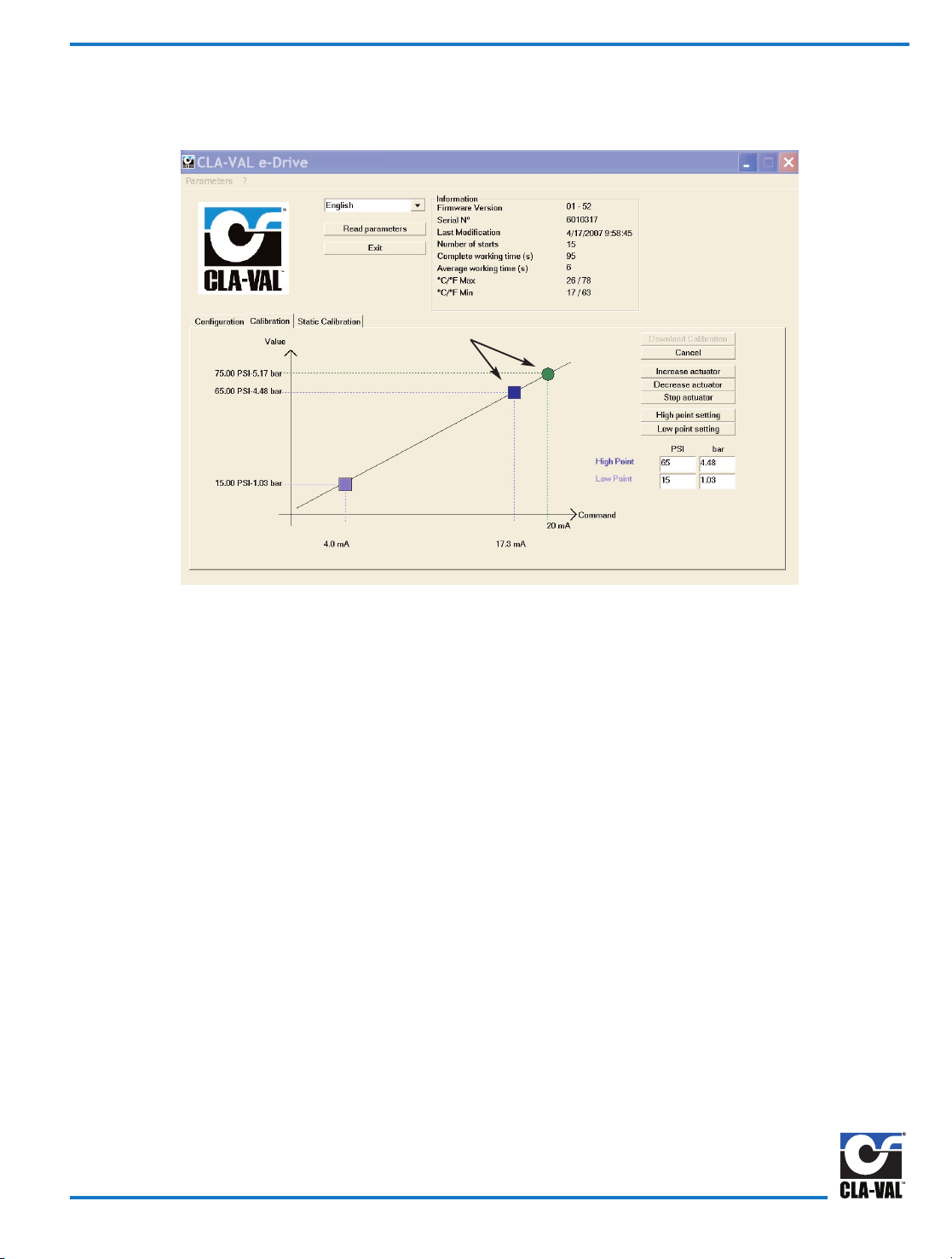

Fig. 1

Page 22

1) In Calibration Tab mode, click “Calibration Mode” button. This will allow temporary manual control of actuator for setting new

pilot control limits. These values will then be sent to actuator at completion of calibration. Check that actuator LED is

blinking red/green during calibration mode process. All High and Low point settings steps must be completed in order

shown. Use the cancel button to input new values.

2) Look at pressure gauge or flow sensor, use Increase actuator or Decrease actuator buttons until desired LOW pressure or

flow point (same value used in Configuration tab window and showing in Low Point window) is reached. Press Stop

actuator button to stop actuator. Use good quality gauges and be as precise as possible. If calibrating CDHS-32 for flow

rate using an orifice plate, a calibrated differential pressure gauge or transmitter is recommended.

3) Once desired low pressure or flow is reached and actuator is topped, click Low point setting button.

4) Look at pressure gauge or flow sensor, use Increase actuator or Decrease actuator buttons until desired HIGH pressure or

flow point (same value used in Configuration tab window and showing in High Point window) is reached. Press Stop

actuator button to stop actuator.

5) Once the high pressure or flow is reached and actuator is stopped, click High point setting button.

6) Finally, click Download calibration button to store values in actuator. High point, Low point, Loss-of-Signal, and Rotation

speed settings are sent to actuator. Actuator LED will change to green when complete. Unplug cable from actuator and

replace protective cap. 130VC-2 Actuator is now ready to accept 4 - 20 mA command signal from permanent cable Yellow

and Black wires.

Calibration - Actuator Limits Settings

Fig. 2

Page 4

Page 23

In some instances it may not be physically possible to reach desired system High pressure point due to possibility of putting

too much pressure in a zone. Projection calibration mode is an ideal solution for this situation.

1) Look at pressure gauge or flow sensor, use Increase actuator or Decrease actuator until HIGH pressure point is reached.

Press the Stop actuator button. Use good quality gauges and be as precise as possible. If calibrating CDHS-32 for flow

rate using an orifice plate, a calibrated differential pressure gauge or transmitter is recommended. Once low pressure or

flow is reached, click on Low point setting button.

2) Look at pressure gauge or flow sensor and use Increase actuator or Decrease actuator buttons to increase pressure or

flow as close as is practical to desired HIGH pressure point.

3) Enter this value in projected High point calibration window.

4) Next, click on the High point setting button, and then click on the Download calibration button. The actuator automatically

projects range to desired high point value entered in Configuration tab window.

5) New projected High point, Low point, Loss-of-Signal, and Rotation speed settings are sent to actuator. Actuator LED will

change to green when complete. Unplug cable from actuator and replace protection cap, actuator is now ready to accept

4 - 20 mA command signal from permanent cable Yellow and Black wires.

Calibration - Projection to New HIGH Value Point

Fig. 3

Page 5

Projected High Calibration

Page 24

In some applications it may not be physically possible to reach the low pressure point due to not being able to lower pressure

in a zone. Projection calibration mode is an ideal solution for this situation.

1) Look at pressure gauge or flow sensor and use Increase actuator or Decrease actuator until LOW pressure point is

reached. Press the Stop actuator button. Use good quality gauges and be as precise as possible. If calibrating CDHS-32

for flow rate using an orifice plate, a calibrated differential pressure gauge or transmitter is recommended. Once high

pressure or flow is reached and actuator stopped, click on high point setting button.

2) Look at the pressure gauge or flow sensor and use Increase actuator or Decrease actuator buttons to decrease pressure

or flow as close as practical to desired LOW pressure point.

3) Enter this value in the projected Low point calibration window.

4) Next click on Low point setting button, and then click on Download calibration button. The actuator automatically projects

range to desired low point value entered in Configuration tab window.

5) New projected Low point, High point, Loss-of-Signal, and Rotation speed settings are sent to actuator. Actuator LED will

change to green when complete. Unplug cable from actuator and replace protection cap, actuator is now ready to accept

4 - 20 mA command signal from permanent cable Yellow and Black wires.

If it is not practical to reach both high and low system value settings, then both projection procedures can be used. Allow

at least one fourth of total range between high and low starting points. Accuracy of projected values is based on

accuracy of initial value and any error will be magnified when projected from starting point.

Calibration - Projection to New LOW Value Point

Fig. 4

Page 6

Projected Low Calibration

Page 25

Static calibration can create low and high pressure points for the 4 and 20 milliamp signals without rotating the actuator.

1) Determine high and low pressure that corresponds to the 4-20 mA signals.

2) Open the "Static Calibration" mode.

3) Use existing system pressure as a reference point or change using the increase.

4) Once desired reference setting is attained, consult spring chart to obtain pressure change per pilot revolution.

5) Calculate the number of turns between the reference pressure and the low and high values.

6) Enter these numbers into the "Turn to low and to high points". Numbers must be positive and can contain up to

decimal points.

7) Click "Download Calibration" button to complete actuator setup.

8) Click cancel button to restart calibration.

Example: Required pressure range for 4-20 mA signals is 55 to 95 psi and system pressure is 70 psi. The 20-105 CRD-32 is

13 psi per turn. Therefore, 95 minus 55 divided by 13 = 1.92 turns is entered into the high point window. For the

low point settings: 70 minus 55 = 1.15 turns which is entered into the low point window.

(Remember to click "Download Calibration" button).

Spring Chart - PSI change per complete pilot revolution

CRD 15 -75 = 10.2 psi per turn

CRD 2-105 = 13 psi per turn

CRD 30-300 = 29 psi per turn

Static Calibration

Fig. 5

Page 7

Page 26

Troubleshooting FAQ

What are the default settings for the 130VC-2 actuator?

Factory default setting for 130VC-2 Actuator range parameter is the full pilot spring range scaled to match the 4 to 20 mA

Remote Command Input analog signal. Factory default setting for 130VC-2 Actuator rotation speed is one rpm with 24

VDC power.

How do I get the software to work with the actuator?

To set up a link with 130VC-2 Actuator, first install cable driver and then the special USB communications cable. After

installing driver and communication cable, the Actuator must be powered for link to work. Follow wiring diagram and hardware hookup instructions. Download Wiring Diagram from website (www.cla-val.com).

How do I install Special USB Communication Cable?

When 130VC-2 communications cable is installed in your laptop computer USB port for the first time, Windows will search

your computer for the cable USB driver. If Windows Plug and Play does not automatically find the driver and connect to

actuator, then the cable driver must be set up manually. Windows will take you step-by-step through the manual set up

process. The cable USB driver is installed during software download. You will have to browse to the Cla-Val folder created during download where the driver file is located. Details are in this manual.

My computer does not have a USB port

Older laptop computers with only Serial port may have a problem using USB to Serial adapter with special USB connector

cable and communicating with 130VC-2 actuator. Make sure the USB to Serial adapter cable is less than 18 inches long.

Also, USB extension cables should not be used because they will degrade signals and cause problems. If problem persists, consult Cla-Val factory technical support.

Can I set both high and low setting points by projection?

Both projection procedures can be used if it is not practical to reach high and low settings. Allow at least one fourth of total

range between high and low starting points. Accuracy of projected values is based on accuracy of initial value and any

error will be magnified when projected from starting point.

Why is actuator LED still blinking red/green after I downloaded the settings?

Once the calibration mode button is activated, all steps must be done before downloading is begun. Actuator LED will show

green when downloading is successful and complete.

Can I make a file ahead of time and download it to 130VC-2 later?

All hardware hookup steps must be completed before program will communicate and change 130VC-2 parameters. Until

wiring and power connections are made to the actuator, this program can be opened, but new parameters can not be created or stored or sent to the actuator. Changes to parameters must be done "live" and while control valve is operating.

Actuator LED will show green when downloading is successful and complete.

Can I make a file ahead of time and download it to 130VC-2 later?

All hardware hookup steps must be completed before program will communicate and change 130VC-2 parameters. Until

wiring and power connections are made to the actuator, this program can be opened, but new parameters can not be created or stored or sent to the actuator. Changes to parameters must be done "live" and while control valve is operating.

CLA-VAL EUROPE

Chemin des Mésanges 1

CH-1032 Romanel/

Lausanne, Switzerland

Phone: 41-21-643-15-55

Fax: 41-21-643-15-50

E-mail: cla-val@cla-val.ch

CLA-VAL FRANCE

Porte du Grand Lyon 1

ZAC du Champ du Périer

France - 01700 Neyron

Phone: 33-4-72-25-92-93

Fax: 33-4-72-25-04-17

E-mail: cla-val@cla-val.fr

CLA-VAL

PO Box 1325 Newport Beach CA 92659-0325

800-942-6326 Fax: 949-548-5441 Web Site: cla-val.com E-mail: claval@cla-val.com

©COPYRIGHT CLA-VAL 2007 Printed in USA S

p

ecifications subject to change without notice.

CLA-VAL CANADA

4687 Christie Drive

Beamsville, Ontario

Canada LOR 1B4

Phone: 905-563-4963

Fax: 905-563-4040

E-mail sales@cla-val.ca

CLA-VAL UK

Dainton House, Goods Station Road

GB - Tunbridge Wells

Kent TN1 2 DH England

Phone: 44-1892-514-400

Fax: 44-1892-543-423

E-mail: info@cla-val.co.uk

N-130VC-2 (R-7-07)

Appendix A

Page 27

Page 28

Page 29

Page 30

DESCRIPTION

The CRL Pressure Relief Control is a direct acting, spring loaded,

diaphragm type relief valve. It may be used as a self-contained valve or

as a pilot control for a Cla-Val Main valve. It opens and closes within

very close pressure limits.

INSTALLATION

The CRL Pressure Relief Control may be installed in any position. The

control body (7) has one inlet and one outlet port with a side pipe plug

(24) at each port. These plugs are used for control connections or gauge

applications. The inlet in the power unit body (6) is the sensing line port.

A flow arrow is marked on the body casting.

OPERATION

The CRL Pressure Relief Control is normally held closed by the force of

the compression spring above the diaphragm; control pressure is applied

under the diaphragm.

When the controlling pressure exceeds the spring setting, the disc is lifted

off its seat, permitting flow through the control.

When controlling pressure drops below spring setting, the spring returns

the control to its normally closed position.

ADJUSTMENT PROCEDURE

The CRL Pressure Relief Control can be adjusted to provide a relief setting at any point within the range found on the nameplate.

Pressure adjustment is made by turning the adjustment screw (9) to vary

the spring pressure on the diaphragm. Turning the adjustment screw

clockwise increases the pressure required to open the valve.

Counterclockwise decreases the pressure required to open the valve.

When pressure adjustments are complete the jam nut (10) should be

tightened and the protective cap (1) replaced. If there is a problem of

tampering, lock wire holes have been provided in cap and cover. Wire

the cap to cover and secure with lead seal.

DISASSEMBLY

The CRL Pressure Relief Control does not need to be removed from the

line for disassembly. Make sure that pressure shut down is accompanied

prior to disassembly. If the CRL is removed from the line for disassembly

be sure to use a soft jawed vise to hold body during work.

Refer to Parts List Drawing for Item Numbers.

1. Remove cap (1), loosen jam nut (10) and turn adjusting

screw counterclockwise until spring tension is relieved.

2. Remove the eight screws (4) holding the cover (3) and

powerunit body (6). Hold the cover and powerunit together

and place on a suitable work surface.

See NOTE under REASSEMBLY.

3. Remove the cover (3) from powerunit body (6). The spring

(12) and two spring guides (11).

4. Remove nut (13) from stem (19) and slide off the belleville washer

(14), the upper diaphragm washer (15) and the diaphragm (16).

5. Pull the stem (19) with the disc retainer assembly (21) through the

bottom of powerunit. The lower diaphragm washer (17) will slide off

of stem top.

6. Remove jam nut (23) and disc retainer assembly (21) from stem.

Use soft jawed pliers or vise to hold stem. The polished surface of

stem must not be scored or scratched.

7. The seat (22) need not be removed unless it is damaged. If removal

is necessary use proper size socket wrench and turn counterclock

wise.

Note: Some models have an integral seat in the body (7).

INSPECTION