Page 1

131-73/631-73

Page 2

Page 3

Page 4

Page 5

Principle of Operation

Powertrol Valve

100-02

DESCRIPTION

This manual contains information for installation, operation and maintenance of the Cla-Val Co. 100-02 Powertrol, an automatic valve

designed for use where independent operating pressure is desired,or

when line fluid is unsuitable as an operating medium.

This valve is a hydraulically operated, diaphragm type, globe or angle

pattern valve. it is single seated and incorporates into its design two

operating chambers sealed from one another by a flexible synthetic

rubber diaphragm. Pressure applied to the upper chamber closes the

valve; when applied to the lower chamber, it opens the valve.

With proper pilot controls, the valve can be held in any intermediate

position between fully open and tightly closed.

INSTALLATION

Allow sufficient room around the valve assembly to make adjustments

and for disassembly.

NOTE: BEFORE THE VALVE IS INSTALLED, PIPE LINES

SHOULD BE FLUSHED OF ALL CHIPS, SCALE AND FOREIGN

MATTER.

It is recommended that gate or block valves be installed on both the

upstream and downstream sides of the 100-02 to facilitate isolating

the valve for preventative maintenance.

Place the valve in the line with flow through the valve in the direction

indicated on the inlet name plate or by flow arrows.

Cla-Val Powertrol Valves operate with maximum efficiency when

mounted in horizontal piping with cover "UP,' however, other positions

are acceptable. Due to the size and weight of the cover and internal

assembly of 4" and larger valves, installation with the cover "UP" is

advisable. This makes periodic inspection of internal parts readily

accessible.

When a pilot control system is installed on the Powertrol Valve, use

care to prevent damage. If it is necessary to remove fittings or components, be sure they are kept clean and replaced in the exact order

of removal.

After the valve is installed and the system is first pressurized, vent air

from the cover chamber and tubing by loosening fit" sings at all high

points.

Full Open Operation

When operating pressure below the

diaphragm is applied and operating, pressure

is relieved from the cover chamber, the valve

is held open, allowing full flow.

Modulating Action

The valve holds any intermediate position

when operating pressure is equal above and

below the diaphragm. A Cla-Val four-way pilot

control with "lock" position can maintain this

balance by stopping flow in the pilot control

system.

Tight Closing Operation

When pressure below the diaphragm is

relieved and operating pressure is applied to

the cover chamber, the valve closes drip-tight.

4 - Way Control 4 - Way Control 4 - Way Control with lock

TROUBLE SHOOTING

The following trouble shooting information deals strictly with the

Powertrol Valve; however some 'impossible causes" will refer to components that may exist in the variety of control systems available for the

valve. All trouble shooting is possible without removing the valve from

the line.

CAUTION: Extreme care should be taken when servicing the valve.

Gate or line block valves must be closed upstream and downstream of

the valve before starting disassembly. When there are no block or gate

valves to isolate the Powertrol Valve it should be realized that the valve

cannot be serviced under pressure. Steps must be taken to remedy this

situation before proceeding.

1.

2.

3.

4.

5.

6.

MODEL

INSTALLATION / OPERATION / MAINTENANCE

(Full Internal Port)

Page 6

FREEDOM OF MOVEMENT

The following procedures can be used to determine if the

valve opens and closes fully. During this test the diaphragm

can be checked for damage.

1.The Powertrol Valve will have a control to open and close

the valve. Position the control so that pressure is applied to

the cover chamber (above the valve diaphragm). This will

close the Powertrol Valve. Check the drain from the control

that discharges to atmosphere.

Once the liquid from the lower diaphragm chamber is drained

the discharge should stop. If the discharge continues after the

normal time it takes to drain then the diaphragm is damaged,

or the stem nut is loose, or the stem o-ring is leaking. If the

discharge is continuous from both chambers then there is a

possibility that the diaphragm or the pilot control is damaged.

If the valve is equipped with a "Dry Drain" (control drain piped

to downstream end of the valve) then same procedure is followed except the CK2 Shutoff Cock on the downstream end

of the valve must be closed and the drain line disconnected

and drained to atmosphere. It can then be checked as above.

Measurement of the vertical travel of the stem (diaphragm

assembly) will make it possible to determine if the travel, or

stroke is restricted. The following chart provides this measurement. It is necessary to have either the X101 Valve

Position Indicator or X105 Limit Switch Assembly installed on

the valve to visually check the travel.

Mark the position of the stem on the X101 or X105 when the

valve is closed. Reposition the control so that pressure is

applied below the diaphragm and the cover chamber is

drained. Determine the extent of the stem travel. Check this

movement with the stem travel chart. If the stroke is different

than listed (5% to 10%) then there is good reason to believe

something is mechanically restricting the stroke of the valve

at one end of its travel. If it is determined that flow does not

stop through the valve when in the indicated "closed" position,

the obstruction probably is between the disc and the seat, or

in the power unit chamber below the diaphragm. If the flow

stops, the obstruction is likely in the cover chamber above the

diaphragm or possibly above the disc retainer. Refer to the

sectional view under Principle of Operation.

If operation of the valve a few times does not dislodge the foreign object obstructing the diaphragm assembly (stem) movement then the valve must be disassembled and the problem

located and corrected. See disassembly instructions.

INCHES

1

1 1/4

1 1/2

2

2 1/2

3

4

6

8

10

12

14

16

MM

25

32

40

50

65

80

100

150

200

250

300

350

400

INCHES

0.3

0.4

0.4

0.6

0.7

0.8

1.1

1.7

2.3

2.8

3.4

3.9

4.5

MM

8

10

10

15

18

20

23

43

58

71

86

99

114

SYMPTOM

Valve fails to

close.

Valve fails to

open.

Valve closes but

leakage occurs.

O-Ring failure

*POSSIBLE

CAUSE

Stem stuck in open position.

Worn diaphragm

or loose upper

stem nut

Foreign object on

valve seat.

Pressure not being

released from power

unit chamber.

Operating

pressure not

getting into valve

cover.

Insufficient

line pressure.

Stem stuck in

closed or semiopen position.

Worn diaphragm

or loose upper

stem nut.

Foreign object on

top of disc retainer

Pressure not being

released from

cover chamber.

Operating pressure not

applied into power

unit chamber.

Worn disc or seat.

Mineral deposits

on stem cause

abrasion on ring.

TEST

PROCEDURE

Vent power unit chamber. Apply pressure to

cover chamber. Valve

should close.

Apply pressure in

power unit chamber

and vent cover.

Continuous flow from

cover indicates this

trouble.

Valve opens okay but

only closes part way.

Make sure

pressure is being

released by opening a

fitting into the chamber. If valve then closes refer to remedy.

Use pressure gauge

or loosen cover plug

to check for pressure.

Check line pressure.

Vent cover. Apply

pressure to power unit

chamber.

Apply pressure in

power unit chamber

and vent cover.

Continuous flow from

cover indicates this

problem.

Valve closed okay

but won't open all

the way.

Open a fitting or

remove a plug from

cover chamber if

cover chamber vents

and valve opens, see

remedy.

Loosen a fitting in this

chamber to check for

pressure at this point.

The best procedure

here is to disassemble

the valve and inspect

these parts.

Remove pressure

from both cover and

power unit chambers

and apply line pressure to valve. Open

line from power unit

chamber and observe

continuos flow.

REMEDY

Disassemble, examine

all internal parts for

cause of the sticking

condition and clean off

scale deposits.

Disassemble and

replace diaphragm or

tighten the valve stem

nut.

Try operating valve a

few times. This might

dislodge the object. If

this fails, disassemble

and remove the

obstruction.

Check control

system. Tube line or

nipple might be plugged

up.

Clean tubing or pipe fittings into cover chamber. Open CK2 Isolation

Valve in control lines.

Establish line pressure.

Disassemble, examine

all internal parts for

cause of the sticking

problem, and clean off

scale deposits.

Disassemble and

replace diaphragm or

tighten valve stem nut.

Try operating valve a

few times. This might

dislodge the object. if

this fails disassemble

and remove the

obstruction.

Check control system.

Check lines or pipe fittings. Clean out any

plugged lines.

Clean tubing or pipe fittings into power unit

chamber.

Replace worn parts.

Disassemble and

replace O-ring.

*Assuming control system is functioning properly.

STEM TRAVEL

(Fully open to fully closed)

VALVE SIZE VALVE SIZE

Page 7

When block and tackle or a power hoist is to be used to lift the valve cover

insert a proper size eye bolt in place of the center cover plug. Pull cover

straight up to keep from damaging the power unit stem bearing and upper

stem.

On valves 1" and larger remove the power unit retaining nuts. The power

unit body can now be lifted from the valve body. The stem with diaphragm

assembly and disc retainer assembly will be removed with the power unit

body.

CAUTION: During service performed on the stem assembly, the stem surfaces must not be damaged. If a vice or other holding device is used to grip

the stem, soft jaws of brass or copper must be used to protect the precision

ground surface of the stainless steel stem. If the stem is marred no amount

of careful dressing can restore the stem to its original condition.

REASSEMBLY

To reassemble, reverse the order of disassembly.

1. If the disc has been removed, it is important that correct pressure be

on the disc from the disc guide when the lower stem nut is tight. Use sufficient spacer washers to obtain slight pressure (by visual indentation) on

the disc. This applies to 1" through 16" valves. Refer to seat and disc

detail drawings for location of spacer washers for various valve sizes.

Note: New discs will usually require a different number of spacer washers to obtain the right amount of 'grip (slight indentation) on the disc.

6. Inspect the threads on the stem. Mineral deposits that prevent the

nuts from turning must be cleaned from the threads A 5C.h solution of

muriatic acid will soften mineral or scale deposits to assist in removal of

nuts and general cleaning of parts. Flush the parts thoroughly with water

immediately after cleaning.

Care must always be exercised when handling acid. Read the warning

label on the acid container to be sure of correct method of use and disposal after use.

7. Remove the upper stem nut, upper diaphragm washer, diaphragm

and lower diaphragm washer. The stem with the disc retainer assembly

can now be removed from the power unit body

8. Hold the stem in a vice with soft jaws and remove the lower stem nut.

Remove the lock washer, disc retainer, space washer(s) and disc Refer

to the sectional view of the valve size being serviced. This will assist in

the disassembly procedure outlined above. The reassembly instructions

outlining proper procedure and quantity of space washers. This is especially important if the disc is replaced.

Inspection of Parts

1. Returning to the valve body in the line, the seat should now be

inspected for damage. if the seat requires removal use the following

tools. Seats in valve sizes 1/2" and 3/4" can be removed with a hex socket wrench. Seats in valve sizes 1" through 6" should be removed with

accessory X-109 Seat Removing Tool available from the factory. Seats

in valve sizes 3" through 16" may be removed with a screw driver. If upon

removal of the screws the seat cannot be lifted out, it will be necessary

to use a hard rubber mallet and tap the seat loose.

2. Any buildup of mineral or scale should be cleaned from the valve body

at this time. Inspection of the cover and power unit body surfaces that

contact the diaphragm is important. Clean and smooth, with wet or dry

emery paper, any roughness that could damage the diaphragm. Inspect

and recondition the surface on the upper and lower diaphragm washers.

The perimeter of the diaphragm washers is the most likely area to cause

diaphragm wear if the surface is not smooth. Take extra care to make

this a smooth finish.

3. Inspect the power unit body bearing insert o-ring that is in contact with

the stem. If it is worn, nicked or cut, replace it.

4. Inspect the diaphragm for cracks or chafing. Replace the diaphragm

if damaged.

Inspect the disc and replace if the surface is damaged or worn. If a new

disc is not available, the existing disc can be turned over, exposing the

unused surface for contact with the seat.

6. The disc guide should be checked and cleaned of scales and mineral

deposits. Due to the close tolerance between the outer periphery of the

disc guide and the inner area of the valve seat, no scale or mineral

deposits should be overlooked.

Valve Cover

Hammer

Dull Cold Chisel

(Angle upward as

much as possible)

MAINTENANCE

Preventative Maintenance

The Cla-Val Co Powertrol Valves require no lubrication or packing

and a minimum of maintenance. However, a periodic inspection

schedule should be established to determine how the fluid velocity

as well as the substances occurring in natural waters are affecting

the valve These substances can be dissolved minerals. colloidal

and suspended particles. Effect of these actions or substances

must be determined by inspection.

DISASSEMBLY

1. First mark the side of the valve cover, power unit body and valve body so

that reassembly of these parts will be exactly as removed.

2. The Powertrol Valve inspection or maintenance can be accomplished

without removal of the valve body from the line. Shut off pressure to the

valve, both inlet, outlet and independent operating pressure when used.

WARNING: Maintenance personnel can be injured and equipment and property damaged if disassembly is attempted with pressure in the system.

3. After pressure has been released from the valve control system and operating chambers of the valve, remove the controls and tubing. Obtain a

schematic of the assembly or note and sketch position of tubing and controls

for reassembly. Replacing tubing into the control ports exactly as removed is

necessary. Failure to reassemble properly will cause the valve to malfunction and possibly cause serious damage.

4. Remove cover nuts and cover. if the valve has been in service for any

length of time, chances are the cover will have to be loosened by driving

upward along the edge of the cover with a dull cold chisel. See Figure 1.

Page 8

INLET

INLET

1/8 NPT (THESE

TAPPED HOLES ARE

SHOWN 90" FROM

TRUE POSITION)

INLET

MODELS 100-02KH 100-02KHR, 100-02KHX

16

19

2

17

6

11

8

15

17

9

18

10

12

3

14

7

5

4

13

1

1/8 NPT

1. If the disc has been removed, it is important that correct

pressure be on the disc from the disc guide when the

lower stem nut is tight. Use sufficient spacer washers to

obtain slight pressure (by visual indention) on the disc.

Indention should be slight and no looseness evident. This

adjustment applies to 1 " through 16". Refer to seat and

disc detail drawings for location of spacer washers for various valve sizes.

NOTE: New discs will usually require a different number of

spacer washers to obtain the right amount of "grip'' on the

disc.

2. The stem, with the disc assembly, can now be inserted

through the power unit body. Note sectional view for correct position of the power unit body and stem assembly

3. Install on the cover end of the stem the lower diaphragm

washer,the diaphragm, the upper diaphragm washer, then

screw on the upper stem nut.

4. Tighten the upper stem nut securely so the diaphragm

and upper and lower diaphragm washer cannot be turned

on the stem. During the tightening of the upper stem nut

the lower stem nut can be held in a vice, or with a second

wrench.

5. Replace the gasket on the body. If an o-ring seal is used

as a gasket, valve size 4" through 16", a light coating of

grease can be applied to the power unit body groove to

hold the o-ring in place while installing on the body. The

power unit body must be replaced so that the index marks

applied in Disassembly Step 1 align. The control tubing will

then be able to be reassembled without difficulty.

6. Replace cover chamber spring on the upper diaphragm

washer. NOTE: Some valves may not have a cover chamber spring.

7. Place the cover on the power unit body aligning the

index marks. Secure the cover with 8 stud nuts. Tighten

the nuts firmly with a cross-over pattern until all nuts are

tight:

8. Reinstall the control system and tubing exactly as it was

before disassembly.

9.The Powertrol Valve can be tested for tight closure as well as

the tightness of the seal across the diaphragm.

a.The downstream or outlet shutoff valve remains closed

b. If the control system has a pilot or control that can position the

valve to a closed position, put the control in a position to close

the Powertrol. Lacking a control, inlet pressure must be tubed to

the Powertrol cover.

c. Open upstream gate or line block valve just enough to allow

flow.

d. Have the power unit body, center section, open to atmosphere

The power unit body will be atmospheric if the control is being

used.

e. Partially disconnect a fitting on the discharge side of the valve.

Do not remove fully unless there is no pressure.

f. After the valve is in the closed position for a few minutes, all

draining of the power unit body should stop. This will indicate a

good seal across the valve seat and the diaphragm.

100-02 POWERTROL

VALVE SIZES 1/2" & 3/4"

1 HEX NUT 10-32 (8)

2 COVER

3 POWER UNIT BODY

4 HEX NUT 1/4-28-NF-2 A.S.F. JAM

5 DIAPHRAGM WASHER (UPPER)

6 DIAPHRAGM

7 DIAPHRAGM WASHER (LOWER)

8 STEM

9 DISC GUIDE

10 DISC RETAINER ASSEMBLY

11 "O" RING

12 BODY TO BODY GASKET

13 STUD 10-32 (8)

14 PIPE PLUG 1/8 NPT

15 BODY

16 SPRING (USED ON 100-02KHR & 100-02 KHX

17 "O" RING

18 SEAT

19 NAMEPLATE

ITEM

NO.

DESCRIPTION

Page 9

1 CENTER COVER PLUG

2 COVER PLUG

3 STUD NUT

7 PLUG, PIPE, BODY

10 * GASKET "O" RING

14 NAMEPLATE

15 * O-RING, STEM

16 RETAINER BEARING (1”-3” ONLY)

19 BOLT, HEX HD. (1”-3” ONLY)

20 POWER UNIT BODY

21 LOWER STEM NUT

22 SPACER WASHER

24 DISC GUIDE

25 DISC RETAINER

30 BODY

31 SPRING (100-02KH/100PAKH ONLY)

32 LOCK WASHER - SPRING

33 * SEAT O-RING

34 * GASKET BEARING GASKET (1”-3" ONLY)

35 Screw Fil. HD. (1’-2 1⁄2”) / BOLT HEX. (3”)

36 UPPER WASHER SPRING (100PKCH)

37 LOWER WASHER SPRING (100PAKCH)

38 DRIVE SCREW

USEFUL INFORMATION OR HINTS

1. The approximate volume of liquid discharged from

the chamber above the diaphragm when the valve

moves from the fully closed positions to the fully open

is as follows:

1/2"

3/4"

1"

1 1/4"

1 1/2"

2"

2 1/2"

3"

4"

6"

8'

10"

12"

14"

16"

0.340 Fl. Oz

0.340 Fl. Oz.

0.700 Fl. Oz.

0.020 Gal.

0.020 Gal.

0.032 Gal.

0 043 Gal

0.080 Gal

0.169 Gal.

0 531 Gal.

1.260 Gal

2.510 Gal.

4.000 Gal.

6.500 Gal.

9.570 Gal.

.01 Liters

.01 Liters

.02 Liters

.10 Liters

.10 Liters

.10 Liters

.20 Liters

.30 Liters

.60 Liters

2.00 Liters

4.75 Liters

9.50 Liters

15.14 Liters

24.60 Liters

36.20 Liters

VALVE SIZE DISPLACEMENT

100-02 POWERTROL

VALVE SIZES 1" - 3"

13 2

7

19

14

38

NPT

J

16

19

34

19

10

30

35

15

20

37

31

36

25

22

32

21

24

33

Model 100-02KH

Seat & Disc Details

ITEM

NO.

PART DESCRIPTION

* RECOMMENDED SPARE PARTS

Page 10

ITEM

NO.

PART DESCRIPTION

CLA-VAL

Copyright Cla-Val 2017 Printed in USA Specifications subject to change without notice.

1701 Placentia Ave • Costa Mesa CA 92627 Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: info@cla-val.com • www.cla-val.com

©

N-100-02 (R-08/2017)

37

31

36

6

39

8

9

4

COVER

G

NPT

13 2

7

19

14

38

NPT

J

4

27

12

17

16

18

15

10

33

29

24

20

13

11

5

30

21

32

22

25

26

J

K

NPT

NPT

INLET

OUTLET

H

NPT

25

22

32

21

24

33

22

21

25

24

23

33

29

33

24

23

21

25

28

22

* RECOMMENDED SPARE PARTS

1 CENTER COVER PLUG

2 COVER PLUG

3 STUD NUT

4 COVER BEARING

5 COVER

6 PIPE CAP (16" ONLY)

7 PLUG, PIPE, BODY

8 BOLT HEX HD (16" ONLY)

9 * O-RING (16" ONLY)

10 * GASKET "O" RING

11 UPPER STEM NUT

12 UPPER DlAPHRAGM WASHER

13 * DIAPHRAGM

14 NAMEPLATE

15 * O-RING, STEM

16 RETAINER BEARING (1”-3” ONLY)

RING RETAINER BEARING (4”-16” ONLY)

17 POWER UNIT BEARING

18 * O-RING BEARING (4”-16” ONLY)

19 BOLT, HEX HD. (1”-3” ONLY)

STUD (4”-16” ONLY

20 POWER UNIT BODY

21 LOWER STEM NUT

22 SPACER WASHER

23 DISC GUIDE SCREW (6" - 16" ONLY)

24 DISC GUIDE

25 DISC RETAINER

26 * DISC

27 STEM

28 SEAT SCREW (8”-16” ONLY)

29 SEAT

30 BODY

31 SPRING (100-02KH/100PAKH ONLY)

32 LOCK WASHER - SPRING

33 * SEAT O-RING

34 * GASKET BEARING GASKET (1”-3" ONLY)

35 Screw Fil. HD. (1’-2

1

⁄2”) / BOLT HEX. (3”)

36 UPPER WASHER SPRING (100PKCH)

37 LOWER WASHER SPRING (100PAKCH)

38 DRIVE SCREW

39 COVER BEARING HOUSING (16" ONLY)

Page 11

Full Open Operation

When operating pressure below the

dia p h ragm is great e r th a n th e

pressure in the cover chamber, the

valv e is held o pen, allo wing full

flow.

Tight Closing Operation

Whe n p r e ssur e bel o w t h e

diaphragm is relieved and operating

pressure is applied to the cover

cha m b er, t h e val v e clos e s

drip-tight.

• Reduced Cavitation Design

• Drip-tight, Positive Seating

• Service Without Removal From Line

• Globe or Angle Pattern

• Every Valve Factory-Tested

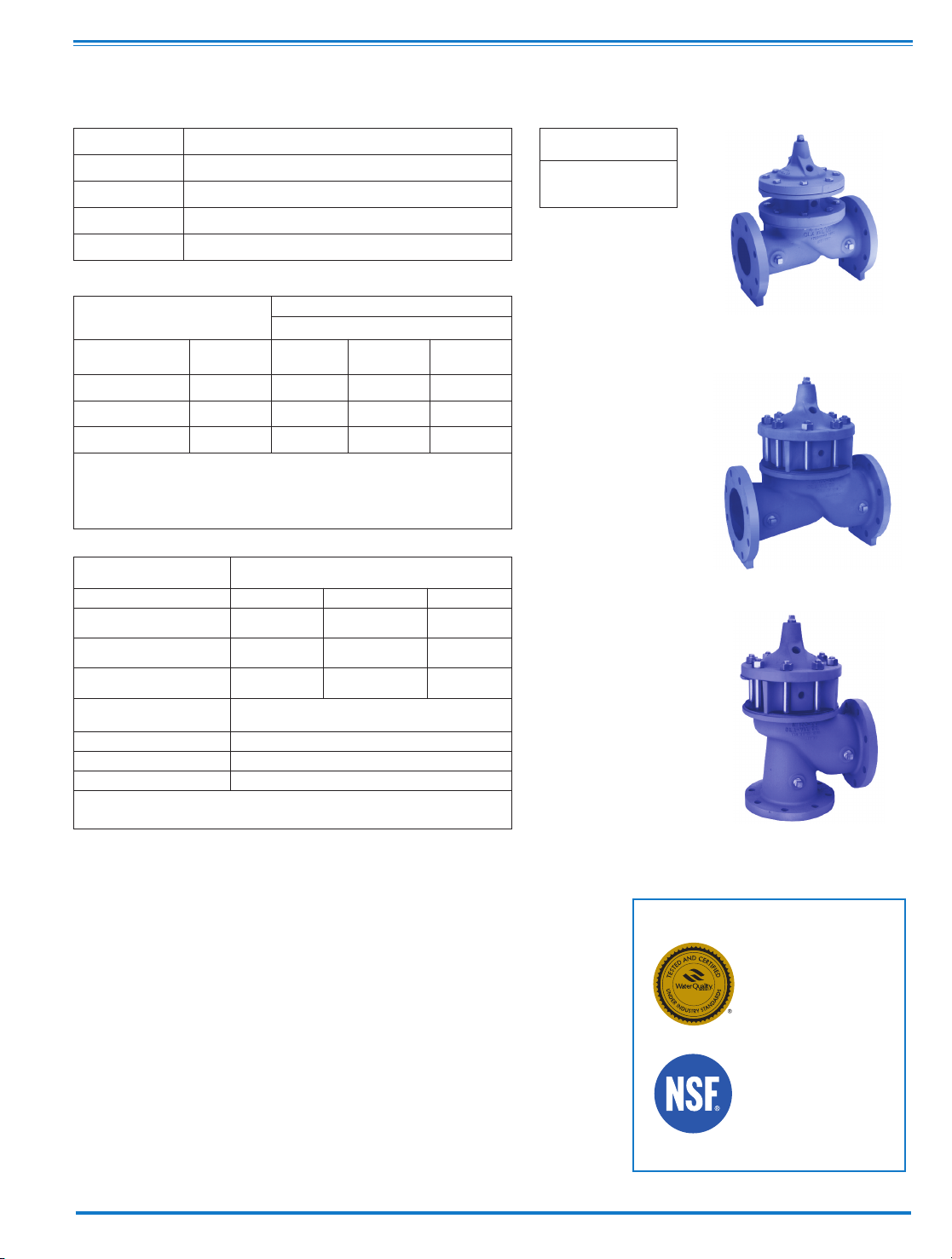

600 Series

Powertrol Valve

The Cla-Val Model 100-21 is a hydr au lically operated,

diaphragm actuated, globe or angle pattern valve. It consists

of four major components: the body, intermediate chamber,

diaphragm assembly and cover. The diaphragm assembly is

the only moving part.

The diaphragm assembly, which is guided top and center by

a precision machined stem, utilizes a non-wicking diaphragm

of nylon fabric bonded with synthetic rubber. The diaphragm

forms a seal between the cover chamber and intermediate

chamber. A synthetic rubber disc retained on three and onehalf sides forms a drip-tight seal with the renewable seat

when pressure is applied above the diaphragm. As pressure

above the diaphragm is relieved and pressure is applied

below the diaphragm, the valve opens wide for full flow. The

rate of closing or opening can be controlled by modulating

the pressure above or below the diaphragm.

The Model 100-21 is recommended where independent

op e rati n g p ress u re is desi r ed. The va l ve's pa c kles s

construction and simplicity of design assures a long life and

dependable operation. Available in various materials and in

a wide range of sizes. It's applications are many and varied.

100-21

Principle of Operation

The valve holds any intermediate

position when operating pressure is

equ a l abov e and be l ow th e

diaphragm. A Cla-Val four-way pilot

co n t rol with "l o ck" posi t ion can

maintain this balance by stopping

flow in the pilot control system.

Modulating Action

4 - Way Control

4 - Way Control

4 - Way Control with lock

MODEL

see page 2 for

approvals

Page 12

100-21 Powertrol Main Valve Specifications

4"/100 mm Globe, Flanged

6"/150 mm Globe, Flanged

6"/150 mm Angle, Flanged

Options

Epoxy Coating - suffix KC

An FDA approved fusion bonded epoxy

coating for use with cast iron, ductile iron

or steel valves. This coating is resistant to

various water conditions, certain acids,

chemicals, solvents and alkalies. Epoxy

coatings are applied in accordance with

AWWA coating specifications C116-03.

Do not use with temperatures above 175°F/

80° C.

Viton®Rubber Parts- suffix KB

Opt i onal d i aphr a g m, di s c and o-ri n g

fabric at ed w ith Viton®synthe ti c ru bber.

Viton®is well suited for use with mineral

aci d s, salt solu t ions , chl o rina t e d

hydrocarbons, and petroleum oils; and is

pri m aril y use d i n hig h t e m pera t ure

applications up to 250° F/120

°C

. Do not

use with epoxy coating above 175°F/

80° C

.

Heavy Spring

-

suffix KH

The heavy sp ring op tion is used in

applications where there is low differential

pre s sure ac r o ss t h e va lve, an d th e

additional spring force is needed to help the

valve close. This option is best suited for

valv es used in on-off (non- mo dulat ing)

service.

For assistance in selecting appropriate

valve options or valves manufactured

with special design requirements, please

contact our Regional Sales Office or

Factory.

Operating Temp. Range

Fluids

-40° to 180° F

-40° to 82° C

Component Standard Material Combinations

Body & Cover Ductile Iron Cast Steel Bronze

Available Sizes (inches) 3" - 30" 3" - 16" 3" - 16"

Available sizes (mm) 80 - 750 mm 80 - 400 mm 80 - 400 mm

Disc Retainer &

Diaphragm Washer

Cast Iron Cast Steel Bronze

Trim: Disc Guide,

Seat & Cover Bearing

Bronze is Standard

Stainless Steel is optional

Disc Buna-N®Rubber

Diaphragm Nylon Reinforced Buna-N®Rubber

Stem, Nut & Spring Stainless Steel

For material options on sizes not listed, consult factory.

Cla-Val manufactures valves in more than 50 different alloys.

Materials

A

vailable Sizes

Pattern Flanged

Globe (inches) 3", 4", 6", 8", 10", 12", 14", 16", 18", 20", 24", 30"

Globe (mm) 80mm - 750mm (all sizes)

Angle (inches) 4", 6", 8"

Angle (mm) 100, 150 and 200 mm

Pressure Ratings

(Recommended Maximum Pressure - psi)

Valve Body & Cover

Pressure Class

Flanged

Grade Material

ANSI

Standards*

150

Class

300

Class

ASTM A536 Ductile Iron B16.42 250 400

ASTM A216-WCB Cast Steel B16.5 285 400

UNS 87850 Bronze B16.24 225 400

Note: * ANSI standards are for flange dimensions only.

Flanged valves are available faced but not drilled.

Valves for higher pressure are available; consult factory for details

NSF International

recognizes Cla-Val

as complying with

NSF/ANSI 61 and all

applicable

requirements.

NSF/ANSI 372:

National Lead Free

Mandate “Reduction

of Lead in Drinking

Water Act”

Approvals

Page 13

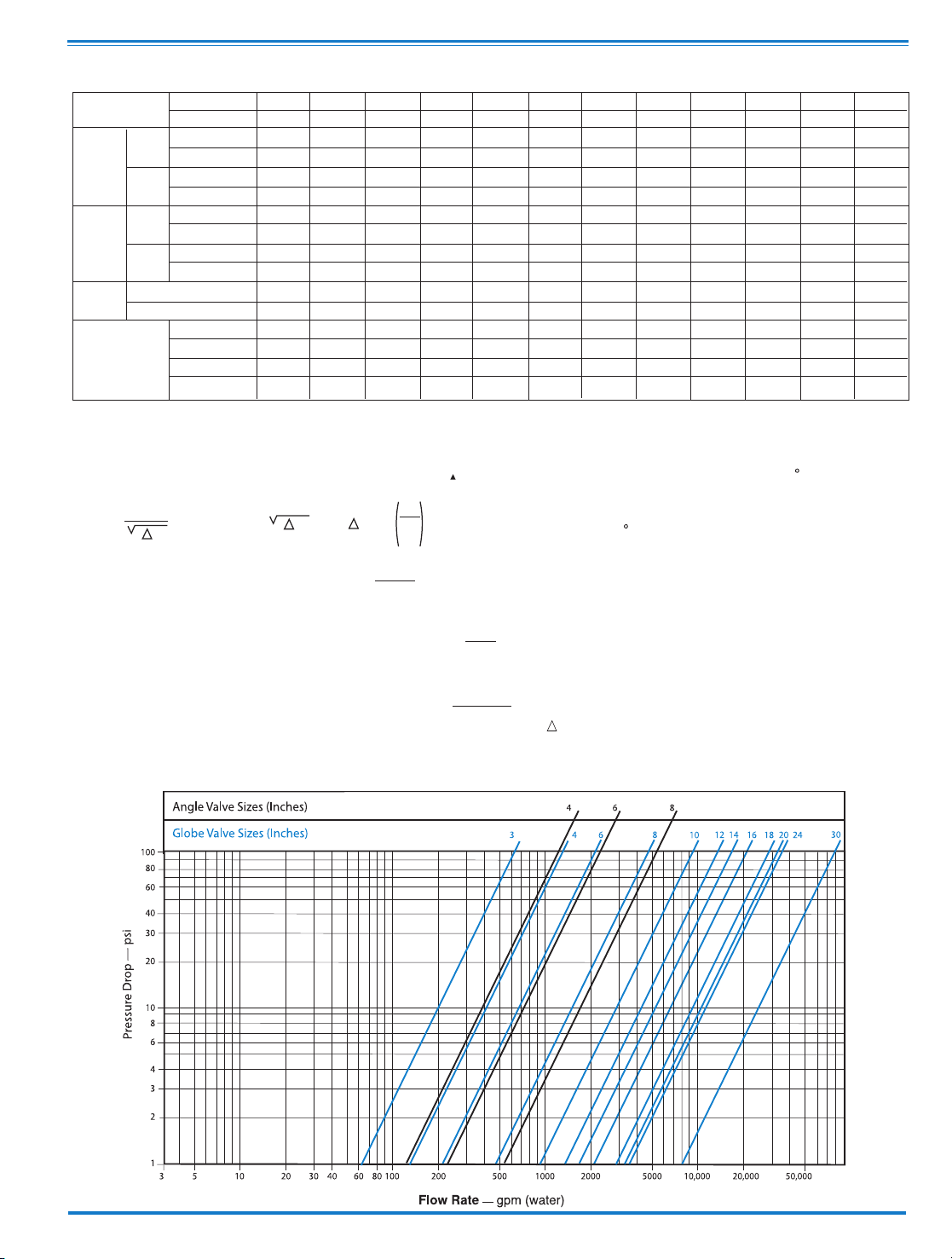

Model 100-21 Flow Chart (Based on normal flow through a wide open valve)

K =

894d

4

C

2

v

L =

K

12 f

K Factor (Resistance Coefficient)

The Value of K is calculated from the formula:

(U.S. system units)

Equivalent Length of Pipe

Equivalent lengths of pipe (L) are determined from the formula:

(U.S. system units)

Fluid Velocity

Fluid velocity can be calculated from the following formula:

(U.S. system units)

d

V =

.4085 Q

2

d

C

V

Factor

Formulas for computing C Factor, Flow (Q) and Pressure Drop

V

(

P):

C

V

=

Q

P

C

V

=

Q

P

C

V

=

Q

P

2

V

Where:

U.S. (gpm) @ 1 psi differential at 60 F water

(l/s) @ 1 bar (14.5 PSIG) differential

or

at 15 C water

inside pipe diameter of Schedule 40 Steel Pipe (inches)

friction factor for clean, new Schedule 40 pipe

(dimensionless) (from Cameron Hydraulic Data,

18th Edition, P 3-119)

Resistance Coefficient (calculated)

Equivalent Length of Pipe (feet)

Flow Rate in U.S. (gpm) or (l/s)

Fluid Velocity (feet per second) or (meters per second)

Pressure Drop in (psi) or (bar)

=

=

=

=

=

=

=

=

=

P

V

Q

L

K

f

d

C

3

8

0

6

2

1

5

—

—

293

8

9.3

—

—

2

0.6

—

—

.032

—

.

12

4

1

00

1

36

3

2.5

135

32

251

7

6.4

2

54

7

7.6

1

2.7

12.9

—

.08

—

.

30

6

1

50

2

29

5

5

233

56

777

2

37.1

7

51

2

29

2

3.1

22.3

—

.17

—

.

64

8

2

00

4

80

1

15

545

132

748

2

28.1

5

80

1

76.9

1

5.7

12.2

—

.53

—

2

.0

1

0

2

50

9

30

2

23

—

—

621

1

89.5

—

—

1

0.4

—

—

1.26

—

4

.8

1

2

3

00

1

458

3

50

—

—

654

1

99.4

—

—

8

.5

—

—

2.51

—

9

.5

1

4

3

50

1

725

4

14

—

—

750

228.7

—

—

8

.9

—

—

4

—

15.1

16

4

00

2

110

5

06

—

—

977

298.1

—

—

1

0.2

—

—

4

—

15.1

18

4

60

2

940

7

05

—

—

983

299.9

—

—

8

.4

—

—

9.6

—

36.2

20

5

10

3

400*

8

16

—

—

1125

343.2

—

—

8

.8

—

—

9.6

—

36.2

24

610

3500*

8

40

—

—

3

005

916.6

—

—

1

9.1

—

—

9

.6

—

36.2

30

750

7900*

1

895

—

—

2

130

649.6

—

—

1

0.5

—

—

2

9.0

—

110

G

lobe

Pattern

Angle

Pattern

G

lobe

P

attern

A

ngle

Pattern

E

quivalent

L

ength

of

Pipe

C

V

Factor

Functional Data Model 100-21

*

Estimated

Valve Size

Liquid Displaced

from Diaphragm

Chamber When

V

alve Opens

K

Factor

m

m

Gal./Min. (gpm.)

Litres/Sec. (l/s.)

Gal./Min. (gpm.)

L

itres/Sec. (l/s.)

F

eet (ft.)

M

eters (m.)

F

eet (ft.)

Meters (m.)

Fl. Oz

U

.S. Gal.

m

l

L

itres

I

nches

Globe Pattern

Angle Pattern

Page 14

CLA-VAL

1701 Placentia Ave • Costa Mesa CA 92627 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: info@cla-val.com • www.cla-val.com

Copyright Cla-Val 2017 • Printed in USA • Specifications subject to change without notice.

©

EE

D

E

Inlet

DD

AA

100-21

Flanged

F

A

C

(MAX)

K

J

H

Inlet

Outlet

FF

B

(Diameter)

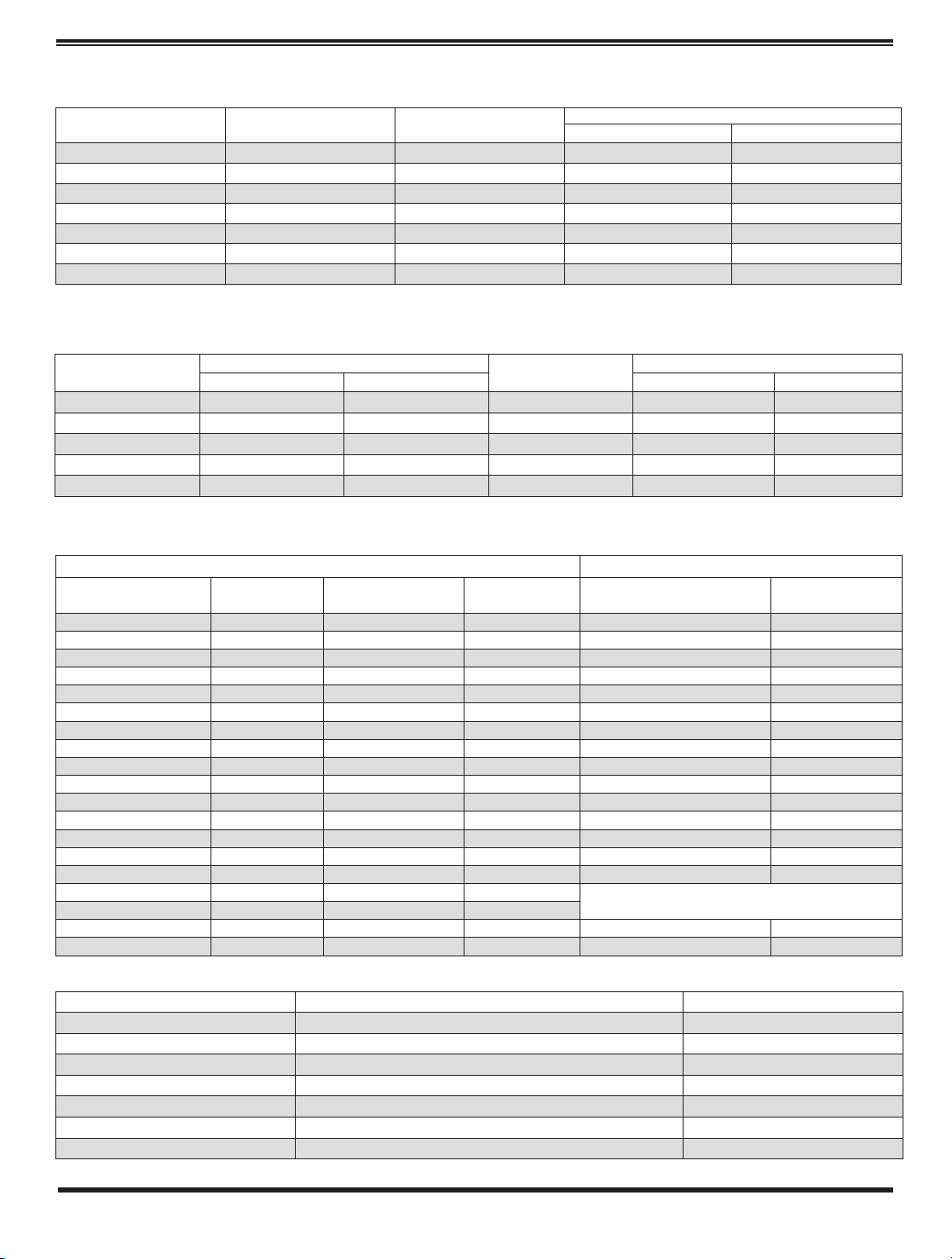

Cla-Val 100-21 Powertrol Main Valve Dimensions

Service and Installation

Cla-Val Control Valves operate with maximum efficiency when mounted in horizontal piping with the main valve cover UP, however, other

positions are acceptable. Due to component size and weight of 10 inch/250 mm and larger valves, installation with cover UP is advisable. We

recommend isolation valves be installed on inlet and outlet for maintenance. Adequate space above and around the valve for service personnel

should be considered essential. A regular maintenance program should be established based on the specific application data. However, we

recommend a thorough inspection be done at least once a year. Consult factory for specific recommendations.

E-100-21 (R-12/2017)

Valve Size (Inches)

A 150 ANSI

A

A 300 ANSI

B

Diameter

C Maximum

D 150 ANSI

DD 300 ANSI

E

EE 300 ANSI

F 150 ANSI

150 ANSI

FF 300 ANSI

H NPT Body Tapping

J NPT Cover Center Plug

K NPT Cover Tapping

Stem Travel

Approx. Ship Weight (lbs)

13.88

14.50

9.12

1

1.75

6

.94

7.25

5.50

5.81

4.50

5.00

0.50

0.50

0.50

0.80

135

4

1

7.75

1

8.62

1

1.50

15.25

8.88

9.38

6.75

7.25

5.50

6.25

0.75

0.75

0.75

1.10

230

6

8

21.38

22.38

15.75

2

0.25

10.69

11.19

7.25

7.75

6.75

7.50

0.75

0.75

0.75

1.70

480

1

2

3

0.00

3

1.50

2

3.62

27.25

9.50

10.25

1.00

1.00

1.00

2.80

1410

—

1

4

3

4.25

35.75

2

8.00

29.31

11.00

1.00

1.25

1.00

3.40

2215

—

1

8

42.12

4

3.62

3

5.44

35.00

15.88

15.88

1.00

2.00

1.00

4.50

2300

—

—

—

—

10.25

1

1.00

6

.62

9.25

3.25

4.12

0.38

0.50

0.38

0.60

70

3

—

—

—

—

—

—

—

—

—

—

1

6

3

5.00

3

6.62

28.00

34.12

11.75

12.75

1.00

1.25

1.00

3.40

2215

—

—

—

—

—

—

—

—

—

—

—

1

0

2

6.00

2

7.38

20.00

2

3.75

8.00

8.75

1.00

1.00

1.00

2.30

785

—

—

—

——

2

0

48.00

49.62

3

5.44

40.25

14.56

16.06

1.00

2.00

1.00

4.50

3400

—

—

—

24

48.00

4

9.75

3

5.44

40.25

17.00

19.00

1.00

2.00

1.00

4.50

3600

—

30

63.25

53.19

5

6.50

19.88

1.00

2.00

1.00

6.50

7700

—

—

—

Valve Size (Inches)

A

150 ANSI

AA 300 ANSI

B

Diameter

C Maximum

D 150 ANSI

DD 300 ANSI

E

EE 300 ANSI

F 150 ANSI

150 ANSI

FF 300 ANSI

H NPT Body Tapping

J NPT Cover Center Plug

K NPT Cover Tapping

Stem Travel

Approx. Ship Weight (lbs)

13.88

1

4.50

9

.12

11.75

6.94

7.25

5.50

5.81

4.50

5.00

0.50

0.50

0.50

0.80

135

4

1

7.75

1

8.62

11.50

1

5.25

8.88

9.38

6.75

7.25

5.50

6.25

0.75

0.75

0.75

1.10

230

6

8

21.38

22.38

1

5.75

20.25

10.69

11.19

7.25

7.75

6.75

7.50

0.75

0.75

0.75

1.70

480

12

30.00

31.50

23.62

2

7.25

9.50

10.25

1.00

1.00

1.00

2.80

1410

—

1

4

3

4.25

3

5.75

2

8.00

29.31

11.00

1.00

1.25

1.00

3.40

2215

—

18

4

2.12

43.62

35.44

3

5.00

15.88

15.88

1.00

2.00

1.00

4.50

2300

—

—

—

—

1

0.25

11.00

6.62

9.25

3.25

4.12

0.38

0.50

0.38

0.60

70

3

—

—

—

—

—

—

—

—

—

—

1

6

3

5.00

36.62

28.00

34.12

11.75

12.75

1.00

1.25

1.00

3.40

2215

—

—

—

—

—

—

—

—

—

—

—

10

26.00

27.38

20.00

2

3.75

8.00

8.75

1.00

1.00

1.00

2.30

785

—

—

—

——

2

0

48.00

4

9.62

3

5.44

40.25

14.56

16.06

1.00

2.00

1.00

4.50

3400

—

—

—

2

4

4

8.00

4

9.75

35.44

40.25

17.00

19.00

1.00

2.00

1.00

4.50

3600

—

3

0

6

3.25

5

3.19

56.50

19.88

1.00

2.00

1.00

6.50

7700

—

—

—

Valve Size (Inches)

A 150 ANSI

AA 300 ANSI

B Diameter

C Maximum

D 150 ANSI

DD 300 ANSI

E

EE 300 ANSI

F 150 ANSI

150 ANSI

FF 300 ANSI

H NPT Body Tapping

J NPT Cover Center Plug

K NPT Cover Tapping

Stem Travel

Approx. Ship Weight (lbs)

13.88

14.50

9.12

11.75

6.94

7.25

5.50

5.81

4.50

5.00

0.50

0.50

0.50

0.80

135

4

17.75

18.62

11.50

15.25

8.88

9.38

6.75

7.25

5.50

6.25

0.75

0.75

0.75

1.10

230

68

21.38

22.38

15.75

20.25

10.69

11.19

7.25

7.75

6.75

7.50

0.75

0.75

0.75

1.70

480

12

30.00

31.50

23.62

27.25

9.50

10.25

1.00

1.00

1.00

2.80

1410

—

14

34.25

35.75

28.00

29.31

11.00

1.00

1.25

1.00

3.40

2215

—

18

42.12

43.62

35.44

35.00

15.88

15.88

1.00

2.00

1.00

4.50

2300

—

—

—

—

10.25

11.00

6.62

9.25

3.25

4.12

0.38

0.50

0.38

0.60

70

3

—

—

—

—

—

—

—

—

—

—

16

35.00

36.62

28.00

34.12

11.75

12.75

1.00

1.25

1.00

3.40

2215

—

—

—

—

—

—

—

—

—

—

—

10

26.00

27.38

20.00

23.75

8.00

8.75

1.00

1.00

1.00

2.30

785

—

—

—

——

20

48.00

49.62

35.44

40.25

14.56

16.06

1.00

2.00

1.00

4.50

3400

—

—

—

24

48.00

49.75

35.44

40.25

17.00

19.00

1.00

2.00

1.00

4.50

3600

—

30

63.25

53.19

56.50

19.88

1.00

2.00

1.00

6.50

7700

—

—

—

Valve Size (mm)

A 150 ANSI

AA 300 ANSI

B Diameter

C Maximum

D 150 ANSI

DD 300 ANSI

E

EE 300 ANSI

F 150 ANSI

150 ANSI

FF 300 ANSI

H NPT Body Tapping

J NPT Cover Center Plug

K NPT Cover Tapping

Stem Travel

Approx. Ship Weight (kgs)

353

368

232

298

176

184

140

148

114

127

0.50

0.50

0.50

20

61

100

451

473

292

387

226

238

171

184

140

159

0.75

0.75

0.75

28

104

150 200

543

568

400

514

272

284

184

197

171

191

0.75

0.75

0.75

43

218

450

1070

1108

900

889

403

403

1.00

2.00

1.00

86

1044

—

—

—

—

260

279

168

235

95

105

0.38

0.50

0.38

15

32

80

—

—

—

—

400

889

930

711

867

298

324

1.00

1.25

1.00

86

1006

—

—

—

—

350

870

908

711

744

279

1.00

1.25

1.00

86

1006

—

—

—

—

—

300

762

800

600

692

241

260

1.00

1.00

1.00

71

640

—

—

—

—

250

660

695

508

603

203

222

1.00

1.00

1.00

58

356

—

—

—

——

500

1219

1260

900

1022

370

408

1.00

2.00

1.00

114

1544

—

—

—

—

—

—

600

1219

1264

900

1022

432

483

1.00

2.00

1.00

114

1634

—

—

—

—

750

1607

1351

1435

505

1.00

2.00

1.00

165

3496

—

—

—

Page 15

DESCRIPTION

Bulletin 8210’s are 2-way, normally closed internal pilot operated solenoid

valves. Valve bodies and bonnets are of brass construction. Standard

valves have a General Purpose, NEMA Type 1 Solenoid Enclosure.

Bulletin 8211’s are the same as Bulletin 8210’s except the solenoids are

equipped with an enclosure which is designed to meet NEMA Type 4,

Watertight, NEMA Type 7 (C or D) Hazardous Locations - Class 1, Group

C or D and NEMA Type 9 (E, For G) Hazardous Locations - Class 2,

Groups E, F or G. The Explosion-Proof/Watertight Solenoid Enclosures

are shown on separate sheets of installation and Maintenance

Instructions, Form Numbers V-5380 and V-5391.

OPERATION

Normally Closed: Valve is closed when solenoid is de-energized and

opens when solenoid is energized.

MANUAL OPERATOR

(Optional)

Valves with Suffix ‘MO’ in the catalog number are provided with a manual

operator which allows manual operation when desired or during an

interruption of electrical power. To operate valve manually, push in

knurled cap and rotate clockwise 180° Disengage manual operator by

rotating knurled cap counterclockwise 180° before operating electrically.

MANUAL OPERATOR LOCATION

(Refer to Figures 1 and 3)

Manual operator (when shipped from factory) will be located over the valve

outlet. Manual operator may be relocated at 90° increments by rotating valve

bonnet. Remove bonnet screws (4) and rotate valve bonnet with solenoid to

desired position. Replace bonnet screws (4) and torque in a crisscross

manner to 110 ± 10 inch pounds.

If valve is installed in the system and is operational, proceed in the

following manner:

WARNING:

Depressurize valve and turn off electrical

power supply.

1. Remove retaining cap or clip and slip the entire solenoid enclosure off

the solenoid base sub-assembly.

CAUTION:

When metal retaining clip

disengages, it will spring upwards.

2. Remove bonnet screws (4) and rotate valve bonnet to desired position.

3. Replace bonnet screws (4) and torque in a crisscross manner to 110 ±

10 inch pounds. Replace solenoid enclosure and retaining clip or cap.

INSTALLATION

Check nameplate for correct catalog number, pressure, voltage and

service.

TEMPERATURE LIMITATIONS

For maximum valve ambient and fluid temperatures, refer to chart. The

temperature limitations listed are for UL applications. For non-UL

applications, higher ambient and fluid temperature limitations are

available. Consult factory, Check catalog number on nameplate to

determine maximum temperatures.

POSITIONING/MOUNTING

This valve is designed to perform properly when mounted in any position.

However, for optimum life and performance, the solenoid should be

mounted vertical and upright so as to reduce the possibility of foreign

matter accumulating in the core tube area. For mounting bracket (optional

feature) dimensions, refer to Figure 2.

PIPING

Connect piping to valve according to markings on valve body. Apply pipe

compound sparingly to male pipe threads only; if applied to valve threads,

it may enter the valve and cause operational difficulty. Pipe strain should

be avoided by proper support and alignment of piping. When tightening

the pipe, do not use valve as a lever, Wrenches applied to valve body or

piping are to be located as close as possible to connection point.

IMPORTANT:

For the protection of the solenoid valve, install a strainer or

filter suitable for the service involved in the inlet side as close to the valve

as possible. Periodic cleaning Is required depending on the service

conditions. See Bulletins 8600, 8601 and 8602 for strainers.

WIRING

Wiring must comply with Local and National Electrical Codes. Housings

for all solenoids are provided with connections for 1/2 inch conduit. The

general purpose solenoid enclosure may be rotated to facilitate wiring by

removing the retaining cap or clip.

CAUTION:

When metal retaining clip

disengages, it will spring upwards. Rotate to desired position. Replace

retaining cap or clip before operating.

NOTE:

Alternating Current (A-C) and Direct Current (D-C) solenoids are

built differently. To convert from one to the other, It Is necessary to

change the complete solenoid including the solenoid base sub-assembly

and core assembly.

SOLENOID TEMPERATURE

Standard catalog valves are supplied with coils designed for continuous

duty service. When the solenoid is energized for a long period, the

solenoid enclosure becomes hot and can be touched with the hand only

for an instant. This is a safe operating temperature. Any excessive heating

will be indicated by the smoke and odor of burning coil insulation.

MAINTENANCE

WARNING:

Turn off electrical power supply and depressurize valve

before making repairs. It Is not necessary to remove the valve from the

pipe line for repairs.

CLEANING

A periodic cleaning of all solenoid valves is desirable. The time between

cleanings will vary, depending on media and service conditions. In

general, if the voltage to the coil is correct, sluggish valve operation,

excessive leakage or noise will indicate that cleaning is required.

PREVENTIVE MAINTENANCE

1. Keep the medium flowing through the valve as free from dirt and

foreign material as possible.

2. While in service, operate the valve at least once a month to insure

proper opening and closing.

3. Periodic inspection (depending on media and service conditions) of

internal valve parts for damage or excessive wear is recommended.

Thoroughly clean all parts, Replace any parts that are worn or damaged.

Construction

A-C Construction

(Alternating Current)

D-C Construction

(Direct Current)

Coil

Class

A

F

H

A, F

or H

Catalog

Number

Prefix

None or

DA

DF or

FT

HT

None, FT

or HT

Max.

Ambient

Temp.

°F

77

122

140

77

Max.

Fluid

Temp.

°F

180

180

180

150

INSTALLATION AND

MAINTENANCE INSTRUCTIONS

2-WAY INTERNAL PILOT OPERATED SOLENOID VALVES

DIAPHRAGM TYPE - 3/8, 1/2 AND 3/4 N.P.T.

NORMALLY CLOSED OPERATION

BULLETINS

8210

8211

ASCO

FORM NO. V-5848

Page 16

IMPROPER OPERATION

1. Faulty Control Circuit: Check the electrical system by energizing the

solenoid. A metallic click signifies that the solenoid is operating. Absence

of the click indicates loss of power supply. Check for loose or blown-out

fuses. open circuited or grounded coil. broken lead wires or splice

connections.

2. Burned-Out Coil: Check for open circuited coil. Replace coil if necessary.

3. Low Voltage: Check voltage across coil leads. Voltage must be at

least 85% of nameplate rating.

4. Incorrect Pressure: Check valve pressure. Pressure to valve must be

within range specified on nameplate.

5. Excessive Leakage: Disassemble valve and clean all parts. Replace

worn or damaged parts with a complete Spare Parts Kit for best results.

COIL REPLACEMENT

(Refer to Figures 1, 2 and 3)

Turn off electrical power supply and disconnect coil lead wires.

Proceed In the following manner:

1. Remove retaining cap or clip, nameplate and cover.

CAUTION:

When

metal retaining clip disengages. it will spring upwards.

2. Slip yoke containing coil, sleeves and insulating washers off the

solenoid base sub-assembly. For D-C Construction. slip spring washer.

coil and insulating washers off the solenoid base sub-assembly. Insulating

washers are omitted when a molded coil is used.

3. Reassemble in reverse order of disassembly paying careful attention

to exploded views provided for identification and placement of parts.

CAUTION:

Solenoid must be fully reassembled as the housing and

internal parts are part of and complete the magnetic circuit. Place

insulating washers at each end of con, If required.

VALVE DISASSEMBLY

Depressurize valve and turn off electrical power supply. For A-C

Construction, refer to Figures 1 and 2. For D-C Construction, refer to

Figure 3. Proceed In the following manner:

1. Disassemble valve in an orderly fashion. Pay careful attention to

exploded views provided for identification of parts.

2. Remove retaining cap or clip and slip the entire solenoid enclosure off

the solenoid base sub-assembly.

CAUTION:

When metal retaining clip

disengages, it will spring upwards.

3. Unscrew solenoid base sub-assembly and remove bonnet gasket.

Core assembly and core spring.

4. For A-C Construction without manual operator. remove valve bonnet

screws (4). Remove solenoid base sub-assembly. core assembly and

core spring.

5. Remove diaphragm spring (A-C Construction only). diaphragm

assembly and body gasket.

6. For normal maintenance, it is not necessary to disassemble the

manual operator unless external leakage is evident To disassemble,

remove stem pin. manual operator stem. stem spring and stem gasket.

7. All parts are now accessible for cleaning or replacement. Replace

worn or damaged parts with a complete Spare Parts Kit for best results.

VALVE REASSEMBLY

1. Reassemble in reverse order of disassembly paying careful attention

to exploded views provided for identification and placement of parts.

2. Replace body gasket and diaphragm assembly. Locate bleed hole in

diaphragm assembly approximately 45° from valve outlet.

3. Replace valve bonnet and bonnet screws. Torque bonnet screws (4) in

a crisscross manner to 110 ± 10 inch pounds.

4. For A-C Construction, the diaphragm spring. core assembly and core

spring must be installed prior to assembly of bonnet as this is the solenoid

base sub-assembly. Be sure diaphragm spring is installed properly.

Closed turns of spring to seat on diaphragm assembly. For valves with a

manual operator (see Figure 1), the small end of diaphragm spring seats

on diaphragm assembly.

5. Install core spring in core assembly. Be sure core spring is inserted

into core assembly with wide end in first. Closed end protrudes from top of

core assembly.

6. Replace bonnet gasket, core assembly, core spring and solenoid base

sub-assembly. Torque solenoid base sub-assembly to 175 ± 25 inch pounds

7. If removed, replace manual operator stem gasket. stem spring, stem

and stem pin.

8. Replace solenoid enclosure and retaining cap or clip.

9. After maintenance, operate the valve a few times to be sure of proper

opening and closing.

ORDERING INFORMATION

FOR SPARE PARTS KITS

When Ordering Spare Parts Kits or Coils

Specify Valve Catalog Number,

Serial Number and Voltage

Spare Parts Kits

Spare Parts Kits and Coils are available for ASCO valves.

Parts marked with an (*) are supplied in Spare Parts Kits

Bulletin 8210 -- A-C Construction

Manual Operator

(Catalog Number Suffixed “MO”)

Figure 1.

Page 17

Bulletin 8210 -- A-C Construction

General Purpose Solenoid Enclosure Shown

For Explosion-Proof/Watertight Solenoid Enclosure used on Bulletin 8211, see Form No. V-5391.

Figure 2.

Page 18

CLA-VAL

Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

N-V5848 (R-3/2011)

Bulletin 8210 -- D-C Construction

General Purpose Solenoid Enclosure Shown

For Explosion-Proof/Watertight Solenoid Enclosure used on Bulletin 8211, see Form No. V-5390.

Figure 3.

Page 19

DESCRIPTION

Bulletin 8262’s are 2-way normally closed, direct acting solenoid valves

having bodies of brass construction. Standard valves have a General

Purpose NEMA Type 1 Solenoid Enclosure. Valves may also be equipped

with a solenoid enclosure which is designed to meet NEMA Type 4

Watertight, NEMA Type 7 (C or D) Hazardous Locations-Class 1, Groups C

or D and NEMA Type 9 (E, For G) Hazardous Locations Class 2, Groups E, F

or G. Installation and Maintenance Instructions for Explosion-Proof/Watertight

Solenoid Enclosures are shown on Form Nos. V-5391 or V-5380.

OPERATION

Normally Closed: Valve is closed when solenoid is de-energized. Valve

opens when solenoid is energized.

NOTE:

Inlet port will either be marked “1” or “1N.” Outlet port will be marked “2.”

IMPORTANT:

No minimum operating pressure required.

INSTALLATION

Check nameplate for correct catalog number, pressure, voltage and service.

TEMPERATURE LIMITATIONS

For maximum valve ambient and fluid temperature, refer to chart below. For

higher ambient and fluid temperatures, consult factory. Check catalog number

and watt rating on nameplate to determine the maximum temperatures.

POSITIONING

Valve is designed to perform properly when mounted in any position.

However, for optimum life and performance, the solenoid should be

mounted vertical and upright so as to reduce the possibility of foreign

matter accumulating in the core tube area.

MOUNTING

For valve body and mounting bracket mounting dimensions, refer to

Figures 1 and 2.

PIPING

Connect piping according to markings on valve body. Apply pipe

compound sparingly to male pipe threads only; if applied to valve threads,

it may enter valve and cause operational difficulty. Pipe strain should be

avoided by proper support and alignment of piping. When tightening the

pipe, do not use valve as a lever. Wrenches applied to valve body or

piping are to be located as close as possible to connection point.

IMPORTANT:

For the protection of the solenoid valve. install a strainer or

filter suitable for the service involved in the inlet side as close to the valve

as possible. Periodic cleaning is required depending upon service

conditions. See Bulletins 8600, 8601 and 8602 for strainers.

WIRING

Wiring must comply with Local and National Electrical Codes. Solenoid

housings are provided with a 7/8 diameter hole for 1/2 inch conduit. The

general purpose solenoid enclosure may be rotated to facilitate wiring by

removing the retaining cap or clip.

CAUTION:

When metal retaining clip

disengages, it will spring upward. Rotate enclosure to desired position.

Replace retaining cap or clip before operating.

NOTE:

Alternating Current (A-C) and Direct Current (D-C) solenoids are

built differently. To convert from one to the other, it is necessary to change

the complete solenoid including the core assembly and solenoid base

sub-assembly.

SOLENOID TEMPERATURE

Standard catalog valves are supplied with coils designed for continuous

duty service. When the solenoid is energized for a long period, the

solenoid enclosure becomes hot and can be touched with the hand only

for an instant. This is a safe operating temperature. Any excessive heating

will be indicated by the smoke and odor of burning coil insulation.

MAINTENANCE

WARNING:

Turn off electrical power supply and depressurize valve

before making repairs. It is not necessary to remove the valve from the

pipe line for repairs.

CLEANING

A periodic cleaning of all solenoid valves is desirable. The time between

cleanings will vary depending upon media and service conditions in

general, if the voltage to the coil is correct. sluggish valve operatIon,

excessive noise or leakage will indicate that cleaning is required. Clean

valve strainer or filter when cleaning solenoid valve.

PREVENTIVE MAINTENANCE

1. Keep the medium flowing through the valve as free from dirt and

foreign material as possible.

2. While in service, operate the valve at least once a month to insure

proper opening and closing.

3. Periodic inspection (depending on media and service conditions) of

internal valve parts for damage or excessive wear is recommended

Thoroughly clean all parts. Replace any parts that are worn or damaged.

IMPROPER OPERATION

1. Faulty Control Circuit: Check the electrical system by energizing the

solenoid. A metallic click signifies the solenoid is operating. Absence of

the click indicates loss of power supply. Check for loose or blownout

fuses, open-circuited or grounded coil, broken lead wires or splice

connections.

2. Burned-Out Coil: Check for open-circuited coil. Replace coil if necessary.

3. Low Voltage: Check voltage across the coil leads. Voltage must be at

least 85% of nameplate rating.

4. Incorrect Pressure: Check valve pressure. Pressure to valve must be

within range specified on nameplate.

5. Excessive Leakage: Disassemble valve and clean all parts. Replace

worn or damaged parts with a complete Spare Parts Kit for best results.

COIL REPLACEMENT

Turn off electrical power supply and disconnect coil lead wires. Refer to

watt rating stamped on nameplate for identification of solenoid

construction. When you have determined the watt rating of solenoid,

select the correct paragraph below.

FIGURE 3 SHOWS A SOLENOID WITH A WATT RATING OF 6 A-C, 9.7 D.C,OR 9 A-C.

1. Remove retaining cap or clip, nameplate and cover.

CAUTION:

When

metal retaining clip disengages, it will spring upward.

2. Slip the yoke containing a coil, sleeves and insulating washers off the

solenoid base sub-assembly. Insulating washers are omitted when a

molded coil is used.

3. Slip coil, sleeves and insulating washers from yoke. 4. Reassemble in

reverse order of disassembly paying careful attention to exploded view

provided for identification and placement of parts.

Wattage

Coil

Class

Catalog

Number

Prefix

Max.

Ambient

Temp.

°F

Max.

Fluid

Temp.

°F

INSTALLATION AND

MAINTENANCE INSTRUCTIONS

2-WAY DIRECT ACTING SOLENOID VALVES

NORMALLY CLOSED OPERATION -- 1/4 N.P.T.

BULLETINS

8262

ASCO

FORM NO. V-5927

*Catalog Nos. 8262C200 and 8262B200 and valves with suffix

“W” in the catalog number are limited to 140°F fluid temperature.

16.7*

F

None

77 200

11.2*

A, F

or H

None, FT

or HT

77 150

9.7

A, F

or H

None, FT

or HT

77 120

9

F

None

77 180

A

None

77 180

6

F

FT

122 200

H

HT

140 200

Page 20

ORDERING INFORMATION

FOR SPARE PARTS KITS

When Ordering Spare Pans Kits or Coils,

Specify Valve Catalog Number,

Serial Number and Voltage.

SPARE PARTS KITS

Spare Parts Kits and Coils arc available for ASCO valves.

Parts marked with an asterisk (*) are supplied in Spare Parts Kit.

FIGURE 4 SHOWS A SOLENOID WITH A WATT RATING OF 105 A-C,

11.2 D.C OR 16.7 A.C

1. Remove retaining cap or clip, nameplate and housing.

CAUTION:

When metal retaining clip disengages, it will spring upward.

2. Slip spring washer, insulating washer and coil off the solenoid base

sub-assembly. Insulating washers are omitted when a molded coil is used.

3. Reassemble in reverse order of disassembly paying careful attention

to exploded views provided for identification and placement of parts.

CAUTION:

Solenoid must be fully reassembled as the housing and

internal parts are part of and complete the magnetic circuit. Place an

insulating washer at each end of coil, if required.

VALVE DISASSEMBLY AND REASSEMBLY

Depressurize valve and turn off electrical power supply. For valves with a

watt rating of 6 A-C, 9.7 D-C or 9 A-C, refer to Figure 3. For valves with a

watt rating of 10.5 A-C, 11.2 D-C or 16.7 A-C, refer to Figure 4.

Proceed in the following manner:

1. Remove retaining cap or clip and slip the entire solenoid enclosure off

the solenoid base sub-assembly.

CAUTION:

When metal retaining clip

disengages, it will spring upward.

2. Unscrew solenoid base sub-assembly and remove core assembly,

core spring and body gasket.

3. All parts are now accessible for cleaning or replacement. Replace

worn or damaged parts with a complete Spare Pans Kit for best results.

4. Reassemble in reverse order of disassembly paying careful attention

to exploded views provided for identification and placement of pans.

5. Replace body gasket, core assembly, core spring and solenoid base

sub-assembly. Torque solenoid base sub-assembly to 175 ± 25 inch pounds.

6. After maintenance, operate the valve a few times to be sure of proper

operation.

Figure 1

Body Molding

Figure 2

Mounting Bracket

Mounting Dimensions

Page 21

NOTE: A-C (ALTERNATING CURRENT) CONSTRUCTION SHOWN. FOR A-C CONSTRUCTION,

EITHER END OF THE SPRING MAY BE INSTALLED INTO TOP OF CORE ASSEMBLY. FOR D-C

(DIRECT CURRENT) CONSTRUCTION, INSTALL WIDE END OF CORE SPRING IN CORE ASSEMBLY

FIRST, CLOSED END OF CORE SPRING PROTRUDES FROM TOP OF CORE ASSEMBLY.

Figure 3

Bulletin 8262 (6 A-C, 9.7 D-C or 9 Watts A-C)

General Purpose Solenoid Enclosure Shown

For Explosion-Proof/Watertight Solenoid Enclosure, See Form No. V-5391

Page 22

CLA-VAL

Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

N-V5927 (R-3/2010)

Figure 3

Bulletin 8262 (10.5 A-C, 11.2 D-C or 16.7 Watts A-C)

General Purpose Solenoid Enclosure Shown

For Explosion-Proof/Watertight Solenoid Enclosure, See Form No. V-5380

Page 23

CLA-VAL

Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL-CK2 (R-3/2011)

Page 24

Page 25

CLA-VAL

Copyright Cla-Val 2018 Printed in USA Specifications subject to change without notice.

1701 Placentia Ave • Costa Mesa CA 92627 Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: info@cla-val.com • www.cla-val.com

©

INSTALLATION / OPERATION / MAINTENANCE

Flow Control

CV

MODEL

N-CV (R-06/2018)

DESCRIPTION

The CV Control is an adjustable restriction which acts as a

needle valve when flow is in the direction of the stem. When

flow is in the reverse direction, the port area opens fully to

allow unrestricted flow. When installed in the control system of

a Cla-Val automatic valve, it can be arranged to function as

either an opening or closing speed control.

OPERATION

The CV Flow Control permits full flow from port A to B, and

restricted flow in the reverse direction. Flow from port A to B

lifts the disc from seat, permitting full flow. Flow in the reverse

direction seats the disc, causing fluid to pass through the clearance between the stem and the disc. This clearance can be

increased, thereby increasing the restricted flow, by screwing

the stem out, or counter-clockwise. Turning the stem in, or

clockwise reduces the clearance between the stem and the

disc, thereby reducing the restricted flow.’

INSTALLATION

Install the CV Flow Control as shown in the valve schematic

All connections must be tight to prevent leakage.

DISASSEMBLY

Follow the sequence of the item numbers assigned to the

parts in the cross sectional illustration for recommended

o

rder of disassembly.

Use a scriber, or similar sharp-pointed tool to remove O-ring

from the stem.

INSPECTION

Inspect all threads for damage or evidence of crossthreading. Check mating surface of seat and valve disc for

excessive scoring or embedded foreign particles. Check

spring for visible distortion, cracks and breaks. Inspect all

parts for damage, corrosion and cleanliness.

CLEANING

After disassembly and inspection, cleaning of the parts can

begin. Water service usually will produce mineral or lime

deposits on metal parts in contact with water. These

deposits can be cleaned by dipping the parts in a 5-percent

muriatic acid solution just long enough for deposits to dissolve. This will remove most of the common types of

deposits. Caution: use extreme care when handling

acid. If the deposit is not removed by acid, then a fine grit

(400) wet or dry sandpaper can be used with water. Rinse

parts in water before handling. An appropriate solvent can

clean parts used in fueling service. Dry with compressed air

or a clean, lint-free cloth. Protect from damage and dust

until reassembled.

REPAIR AND REPLACEMENT

Minor nicks and scratches may be polished out using a fine

grade of emery or crocus cloth; replace parts if scratches

cannot be removed.

Replace O-ring packing and gasket each time CV Flow

Control is overhauled.

Replace all parts which are defective. Replace any parts

which create the slightest doubt that they will not afford completely satisfactory operation. Use Inspection steps as a

guide.

REASSEMBLY

Reassembly is the reverse of disassembly; no special tools

are required.

TEST PROCEDURE

No testing of the flow Control is required prior to reassembly

to the pilot control system on Cla-Val Main Valve.

Page 26

3/8" Flow Control

CV

2.12

MAX

STAMP PART NO. ON

SMOOTH SURFACE

RESTRICTED

FLOW

3/8 - 18 NPT

1.84

ADJUSTING STEM

(TURN CLOCKWISE TO

INCREASE RESTRICTION)

1

7

2

10

9

8

6

5

4

3

.85

FREE FLOW

BAR STOCK

CONFIGURATION

When ordering parts,

please specify:

• Number Stamped on Side

• Description (CV Flow Control)

• Part Description

• Material

CLA-VAL

Copyright Cla-Val 2018 Printed in USA Specifications subject to change without notice.

1701 Placentia Ave • Costa Mesa CA 92627 Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: info@cla-val.com • www.cla-val.com

©

PL-CV (R-03/2011)

PARTS LIST

ITEM DESCRIPTION QTY

1

Cap (SS only)

1

2

Nut, Jam

1

3

Seat

1

4

Gasket

1

5

Disc

1

6

Spring

1

7

Ring, Retaining

1

8

Stem

1

9

O-Ring

1

10

Housing

1

Page 27

CALIBRATION

1. When properly adjusted, the transmitter arm TOTAL arc of travel,

as valve moves from full closed to full open will be approximately

60 to 70 degrees. Thus, the transmitter-actuating arm will be horizontal

when the valve is halfway open (approximately 30 degrees up and

30 degrees down). At valve closed position the transmitter will have

a 4 mA output and at fully open position the transmitter will have a

20 mA output.

2. You will need the following tools to calibrate and align the X117C:

A.) A small flat blade screwdriver to fit the span and null

potentiometers.

B.) A ruler for measuring location of transmitter arm and valve

actuating stem and spool.

Valve Position Transmitter

X117C

DESCRIPTION

The Model X117C Valve Position Transmitter is designed to provide

analog signal (4 - 20 mA, 2 wire) output of valve position for Cla-Val

Main Valves. A stem extension is fitted to the main valve stem with

the position transmitter mechanically linked to it. The valve stem is

mechanically linked to the electronics for an output signal that is in

direct proportion to valve position. Optional limit switches (2 SPDT

or 2 DPDT) are provided on the Model X117CLS for signaling when

valve has reached fully open or closed position. Provisions are

made for bleeding air from valve cover through a small bleed screw

and washer located on one wrench flat of adapter.

INSTALLATION

Normally, the X117C is supplied mounted on the Cla-Val main

valve. If X117C has not been installed at factory, then install stem,

adapter, mounting bracket and transmitter (in order) as shown on

drawing 16767. Necessary field setting of the X117C requires

some adjustment to the position of the transmitter relative to the

stem and the spool, so you may need to loosen transmitter on the

bracket. Refer to Drawing No. 16767.

MODEL

INSTALLATION / OPERATION / MAINTENANCE

OPERATION

The signal from the position sensing linkage mechanism is converted

to a two-wire 4 to 20 mA current output appearing at the output

terminals. The voltage compliance range is 12.5 to 40 Volts DC.

Initial resistance will range from 975 ohms at transmitter full overtravel (Valve open) to 500 ohms at transmitter free position (Valve

closed)

Wiring

Orient transmitter and bracket to conduit. Loosen jam nut holding

transmitter and bracket to adapter for connecting transmitter to

field wiring conduit. Tighten jam nut after connection is made. After

unthreading housing from transmitter connect wires to OUTPUT

screw terminals. DO NOT USE HOUSING AS WIRING PULLBOX.

Use good field wiring practices for low voltage DC analog instrumentation wiring (suggest 18-gage multistrand wire minimum).

Avoid potential ground loops. See drawing for typical wiring connections. Calibration of transmitter should be done with a temporary