Page 1

INSTALLATION / OPERATION / MAINTENANCE

DESCRIPTION

This manual contains information for installation, operation and maintenance of the Cla-Val 100-03 Powercheck, an automatic valve

designed for use where independent operating pressure is desired,or

when line fluid is unsuitable as an operating medium.

This valve is a hydraulically operated, diaphragm type, globe or angle

pattern valve. It is single seated and incorporates into its design two

operating chambers sealed from one another by a flexible synthetic

rubber diaphragm. Pressure applied to the upper chamber closes the

valve; when applied to the lower chamber, it opens the valve.

With proper pilot controls, the valve can be held in any intermediate

position between fully open and tightly closed unless a static condition

or pressure reversal occurs, in which case the valve closes to prevent

return flow regardless of the diaphragm position.

INSTALLATION

Allow sufficient room around the valve assembly to make adjustments

and for disassembly.

NOTE: BEFORE THE VALVE IS INSTALLED, PIPE LINES SHOULD

BE FLUSHED OF ALL CHIPS, SCALE AND FOREIGN MATTER.

MODEL

100-03

Powercheck Valve

TROUBLE SHOOTING

It is recommended that gate or block valves be installed on both the

upstream and downstream sides of the 100-03 to facilitate isolating

the valve for preventative maintenance.

Place the valve in the line with flow through the valve in the direction

indicated on the inlet name plate or by flow arrows and with the cover

"UP" Other positions are not acceptable due to the check feature.

When a pilot control system is installed on the Powercheck Valve, use

care to prevent damage. If it is necessary to remove fittings or components, be sure they are kept clean and replaced in the exact order

of removal.

After the valve is installed and the system is first pressurized, vent air

from the cover chamber and tubing by loosening fittings at all high

points.

Principle of Operation

→

Four - Way Control

→

Four - Way Control

The following trouble shooting information deals strictly with

the Powercheck Valve; however some "possible causes" will

refer to components that may exist in the variety of control

systems available for the valve. All trouble shooting is possible without removing the valve from the line.

SERVICE SUGGESTIONS

(Service Suggestions Chart)

CAUTION: Extreme care should be taken when servicing the

valve. Gate or line block valves must be closed upstream and

downstream of the valve before starting disassembly. When

there are no block or gate valves to isolate the Powercheck

Valve it should be realized that the valve cannot be serviced

under pressure. Steps must be taken to remedy this situation

before proceeding.

→

Four - Way Control

When operating pressure below the

Full Open Operation

diaphragm is applied and pressure is

relieved from the cover chamber, the

valve is held open allowing full flow.

Note: For optimum operation of built-in check feature, installation with stem vertically up is recommended.

Tight Closing Operation

When pressure below the diaphragm is

relieved and operating pressure is

applied to the cover chamber, the valve

closes drip-tight.

Check Action

When a static condition or pressure

sal occurs, the split stem design allows the

valve to instantly check closed. Return flow

is prevented regardless of the diaphragm's

position.

rever-

Page 2

SERVICE SUGGESTIONS

SYMPTOM

Valve fails

to close.

Valve fails

to open.

Valve closes but

leakage occurs.

O-Ring

failure.

POSSIBLE

CAUSE

Stem stuck in open

position.

Worn diaphragm or

loose upper stem

nut.

Foreign object on

valve seat.

Pressure not being

released from

power unit chamber.

Operating pressure

not getting into

valve cover.

Insufficient line

pressure.

Stem stuck in

Closed or semiopen

position.

Worn diaphragm or

loose upper stem

nut.

Foreign object on

top of disc retainer.

Pressure not being

released from cover

chamber.

Operating pressure

not applied into

power unit chamber.

Worn disc or seat.

Mineral deposits on

stem cause abrasion on O-ring.

TEST

PROCEDURE

Vent power unit

chamber. Apply

pressure to cover

chamber. Valve

should close.

Apply pressure in

power unit chamber

and vent cover.

Continuous flow

from cover indicates

this trouble.

Valve opens okay,

but only closes part

way.

Make sure pressure

is being released by

opening a fitting

into the chamber. It

valve then closes,

refer to remedy.

Use pressure

gauge or loosen

cover plug to check

for pressure.

Check line pressure.

Vent cover. Apply

pressure to power

unit chamber.

Apply pressure in

power unit chamber

and vent cover.

Continuous flow

from cover indicates

this problem.

Valve closed okay

but won't open all

the way.

Open a fitting or

remove a plug from

cover chamber. It

cover chamber

vents and valve

opens, see remedy.

Loosen a fitting in

this chamber to

check for pressure

at this point.

The best procedure

here is to disassemble the valve

and inspect these

parts.

Remove pressure

from both cover and

power unit chambers and apply line

pressure to valve.

Open line from

power unit chamber

and observe continuos flow.

REMEDY

Disassemble,exami

ne all internal parts

for cause of the

sticking condition

and clean off scale

deposits.

Disassemble and

replace diaphragm

or tighten the valve

stem nut.

Try operating valve

a few times. This

might dislodge the

object. If this fails,

disassemble and

remove the obstruction.

Check control system. Tube line or

nipple might be

plugged up.

Clean tubing or

pipe fittings into

cover chamber.

Open CK2

Valve

Establish line pressure.

Disassemble,

examine all internal

parts for cause of

the sticking problem, and clean off

scale deposits.

Disassemble and

replace diaphragm

or tighten valve

stem nut.

Try operating valve

a few times. This

might dislodge the

object It this tails,

disassemble and

remove the obstruction.

Check control system. Check lines or

pipe fittings. Clean

out any plugged

lines.

Clean tubing or

pipe fittings into

power unit chamber.

Replace worn parts.

Disassemble and

replace O-ring.

Isolation

in control lines.

FREEDOM OF MOVEMENT

The following procedures can be used to determine if the

valve opens and closes fully. During this test the diaphragm

can be checked for damage.

The Powercheck Valve will have a control to open and close

the valve. Position the control so that pressure is applied to

the cover chamber (above the valve diaphragm). This will

close the Powercheck Valve. Check the drain from the control

that discharges to atmosphere.

Once the liquid from the lower diaphragm chamber is drained

the discharge should stop. If the discharge continues after the

normal time it takes to drain then the diaphragm is damaged,

or the stem nut is loose, or the stem o~ring is leaking If the

discharge is continuous from both chambers then there is a

possibility that the diaphragm or the pilot control is damaged.

If the valve is equipped with a "Dry Drain" (control drain piped

to downstream end of the valve) then same procedure is followed except the CK2 Shutoff Cock on the downstream end

of the valve must be closed and the drain line disconnected

and drained to atmosphere. It can then be checked as above.

Measurement of the vertical travel of the stem (diaphragm

assembly) will make it possible to determine if the travel, or

stroke is restricted. The following chart provides this measurement. It is necessary to have either the X101 Valve

Position Indicator or X105 Limit Switch Assembly installed on

the valve to visually check the travel.

Mark the position of the stem on the X101 or X105 when the

valve is closed. Reposition the control so that pressure is apt

plied below the diaphragm and the cover chamber is drained.

Determine the extent of the stem travel. Check this movement with the stem travel chart. If the stroke is different than

listed (5% to 10%) then there is good reason to believe something is mechanically restricting the stroke of the valve at one

end of its travel. If it is determined that f low does not stop

through the valve when in the indicated "closed" position, the

obstruction probably is between the disc and the seat, or in

the power unit chamber below the diaphragm. If the flow

stops, the obstruct tion is likely in the cover chamber above

the diaphragm or possibly above the disc retainer. Refer to

the sectional view under Principle of Operation.

If operation of the valve a few times does not dislodge the foreign object obstructing the diaphragm assembly (stem)

movement then the valve must be disassembled and the

problem located and corrected. See disassembly instructions.

STEM TRAVEL

(fully open tp fully closed)

VALVE SIZE

INCHES

1

1 1/4

1 1/2

2

2 1/2

3

4

6

8

10

12

14

16

MM

25

32

40

50

65

80

100

150

200

250

300

350

400

TRAVEL

INCHES

0.3

0.4

0.4

0.6

0.7

0.8

1.1

1.7

2.3

2.8

3.4

3.9

4.5

MM

8

10

10

15

18

20

23

43

58

71

86

99

114

Page 3

MAINTENANCE

Preventative Maintenance

The Cla Val Powercheck Valves require no lubrication or packing and a minimum of maintenance. However. a periodic

inspection schedule should be established to determine how

the fluid velocity as well as the substances occurring in natural

waters are effecting the valve. These substances can be dissolved minerals, colloidal and suspended particles. Effect of

these actions or substances must be determined by inspection.

DISASSEMBLY

First mark the side of the valve cover, power unit body an valve

body so that reassembly of these parts will be exact) as

removed.

The Powercheck Valve inspection or maintenance can be

accomplished without removal of the valve body from the line.

Shut off pressure to the valve, both inlet, outlet and independent operating pressure when used.

WARNING: Maintenance personnel can be injured and equip

ment and property damaged if disassembly is attempted with

pressure in the system.

After pressure has been released from the valve control system

and operating chambers of the valve, remove the controls and

tubing. Obtain a schematic of the assembly or note and sketch

position of tubing and controls for reassembly. Replacing tubing

into the control ports exactly as removed is necessary. Failure

to reassemble properly will cause the valve to malfunction and

possibly cause serious damage.

CAUTION: During service performed on the stem assembly.

the stem surfaces must not be damaged. If a vice or other holding device is used to grip the stem. soft jaws of brass or copper

must be used to protect the precision ground surface of the

stainless steel stem. If the stem is marred no amount of careful

dressing can restore the stem to its original condition.

Inspect the threads on the stem. Mineral deposits that prevent

the nuts from turning must be cleaned from the threads.

A 5% solution of muriatic acid will soften mineral or scale

deposits to assist in removal of nuts and the general cleaning

of parts. Flush the parts thoroughly with water immediately after

cleaning. Care must always be exercised when handling acid.

Read the warning label on the acid container to be sure of correct method of use and disposal after use.

Hold the stem in a vice with soft jaws (see above) when removing the stem nut. Slide off the assembly leaving a completely

disassembled upper stem assembly. Remove the disc and disc

retainer from the lower stem. Refer to the sectional view of the

valve size being serviced. This will assist in the disassembly

procedure outlined above. Reassembly instructions outline

proper procedure and quantity of spacer washers. This is especially important if the disc is replaced.

Check the upper and lower stems for scale and freedom of

movement. Insert the lower stem into the stem (upper). The

insertion fully of these parts must be free from binding or resistance. Clean and polish the telescoping parts. Restricted movement of these parts could cause the check feature to fail to

function.

Remove cover nuts and cover. If the valve has been in service

for any length of time' chances are the cover will have to be

loosened by driving upward along the edge of the cover with a

dull cold chisel. See Figure 1.

Valve Cover

Dull Cold Chisel

(Angle upward as

much as possible)

Hammer

FIGURE 1.

NOTE:

When block and tackle or a power hoist is to be used to lift the

valve cover insert a proper size eye bolt in place of the center

cover plug. Pull cover straight up to keep from damaging the

power unit stem bearing and upper stem.

Power unit body can now be lifted from the valve body. The

stem with diaphragm will be removed with the power unit body.

The disc retainer assembly with lower stem will separate

(check feature) from the upper stem and power unit body.

Inspection Of Parts

Returning to the valve body in the line. the seat should now b

inspected for damage. If the seat requires removal use the following tools. Seats in valve sizes1/2" and 3/4" can be remove

with a hex socket wrench. Seats in valve sizes 1" through 6"

should be removed with accessory X-109 Seat Removing Too

available from the factory. Seats in valve sizes 8" through 16"

may be removed with a screw driver. If upon removal of the

screws the seat cannot be lifted out, it will be necessary to use

a hard rubber mallet and tap the seat loose.

Any buildup of mineral or scale should be cleaned from the

valve body at this time. Inspection of the cover and power unit

body surfaces that contact the diaphragm is important. Clean

and smooth. with wet or dry emery paper. any roughness that

could damage the diaphragm. Inspect and recondition the surface on the upper and lower diaphragm washers The perimeter

if the diaphragm washers is the most likely area to cause

diaphragm wear if the surface is not smooth. Take extra care to

make this a smooth finish

Inspect the power unit body bearing insert O-ring that is in contact with the stem If it is worn. nicked or cut. replace it.

The cover bearing should also be checked for excessive wear,

using the upper end of the stem to check for excessive lateral

movement. A special tool for each size valve is available from

the factory to remove the cover bearing. Cover bearing replacement is seldom necessary.

Inspect the diaphragm for cracks or chafing. Replace the

diaphragm if damaged

Inspect the disc and replace if the surface is damaged or worn

If a new disc is not available. the existing disc can be turned

over, exposing the unused surface for contact with the seat.

The disc guide should be checked and cleaned of scales and

mineral deposits. Due to the close tolerance between the outer

periphery of the disc guide and the inner area of the valve seat,

no scale or mineral deposits should be overlooked.

Page 4

REASSEMBLY

To reassemble, reverse the order of disassembly

If the disc has been removed, it is important that correct

pressure be on the disc from the disc guide when the

lower stem nut is tight. Use sufficient spacer washers to

obtain slight pressure (by visual indention) on the disc.

Indention should be slight. Refer to seat and disc detail

drawings for location of spacer washers for various valve

sizes.

NOTE: New discs will usually require a different number

of spacer washers to obtain the right amount of "grip" on

the disc.

Place the lower stem assembly onto the seat with the

disc in contact with the valve seat. If a large spring (4",

6", 8" only) was removed upon disassembly, replace on

top of the disc retainer.

The power unit body with gasket, (body to power unit) or

O-ring, can be installed on the body. Be sure the power

unit section is replaced exactly in the same position as

removed. The end of the lower stem will be visible in the

center of the power unit bearing. Care must be taken so

the power unit bearing or lower stem is not damaged

during this assembly. A hoist may be necessary for larger valve sizes.

NOTE: Valves 4" thru 16" use an O-ring body to power

unit seal. During placement onto the body apply a light

weight grease into the power unit groove to hold the Oring in place when installing on the body.

Install on the upper stem the lower diaphragm washer,

the diaphragm, the upper diaphragm washer, then screw

the stem nut and tighten securely so the upper and lower

diaphragm washer cannot be turned on the stem. During

the tightening of the upper stem nut, the stem should be

held in a vice with soft brass jaws. The upper stem and

diaphragm assembly can now be lowered into the power

unit bearing, the hollow end of the stem sliding on to the

end of the lower stem. Move the upper stem and

diaphragm assembly up and down to check freedom of

movement of the lower and upper stem.

CAUTION: Do not lubricate or grease the hollow end of

upper stem or upper end of the lower stem. This could

cause the check feature to become inoperative.

Replace cover chamber spring on the upper diaphragm

washer.

NOTE: Some valves may not have a cover chamber

spring.

Place the cover on the power unit body aligning the

index marks. Secure the cover with 8 stud nuts Tighten

the nuts firmly with a cross-over pattern until all nuts are

tight:

NOTE: Valve sizes 1" thru 3" are bolted with 8 nuts

(power unit body to valve body) and 8 nuts (cover to

power unit body). Tighten stud nuts firmly with crossover pattern until all nuts are tight.

When the stem is removed from the valve a tool can be

fabricated to check for unrestricted stem movement after

reassembly, and also check for correct stem travel.

Valves size 1 1/4" thru 24/2" are threaded 10-32 UNF

(internal threads) on the top of the stem. Valve sizes 3"

and 4" are threaded ,1/4 -28 UNF. Valve sizes 6" thru 14"

are threaded 34-24 UNF. The 16" valves are threaded,1/2-20 UNF.

A length of rod threaded on one end can be threaded

into the stem through the plug hole in the center of the

cover. It is possible with this rod to move the diaphragm

assembly up from the seat freely, returning to the seat by

its own weight. Larger valve sizes may require a tee

handle to assist lifting heavier assemblies. The stroke of

the stem should correspond closely with the chart.

Reinstall the control system and tubing exactly as it was

before disassembly.

The Powercheck Valve can be tested for tight closure as

well as the tightness of the seal across the diaphragm.

inlet line pressure, or independent operating pressure

can also be used to check the freeness and travel of the

diaphragm assembly. Refer to the operation paragraph

and principle of operation sectional views for opening

and closing operation.

The downstream or outlet shutoff valve remains closed.

If the control system has a pilot or control that can position the valve to a closed position, put the control in a

position to close the Powercheck. Lacking a control, inlet

pressure must be connected to the cover of the

Powercheck Valve.

Open upstream gate or line block valve just enough to

allow flow.

Have the power unit body, center section, open to

atmosphere. The power unit body will be atmospheric if

the control is being used.

Partially disconnect a fitting on the discharge side of the

valve. Do not remove fully unless there is no pressure.

After the valve is in the closed position for a few minutes,

all draining of the power unit body should stop. This will

indicate a good seal across the valve seat and the

diaphragm.

USEFUL INFORMATION OR HINTS

1.The approximate volume of liquid discharged from the

chamber above the diaphragm when the valve moves

from the fully closed position to fully open is as follows:

VALVE SIZE

1/2"

3/4"

1"

1 1/4"

1 1/2"

2"

2 1/2"

3"

4"

6"

8"

10"

12"

14"

16"

DISPLACEMENT

0.340 Fl. Oz.

0.340 Fl. Oz.

0.700 Fl. Oz.

0.020 Gal.

0.020 Gal.

0.032 Gal.

0.043 Gal.

0.080 Gal.

0 169 Gal

0.531 Gal.

1.260 Gal.

2.510 Gal.

4.000 Gal.

6.500 Gal.

9.570 Gal.

.01 Liters

.01 Liters

.02 Liters

.10 Liters

.10 Liters

.10 Liters

.20 Liters

.30 Liters

.60 Liters

2.00 Liters

4.75 Liters

9.50 Liters

15.14 Liters

24.60 Liters

36.20 Liters

Page 5

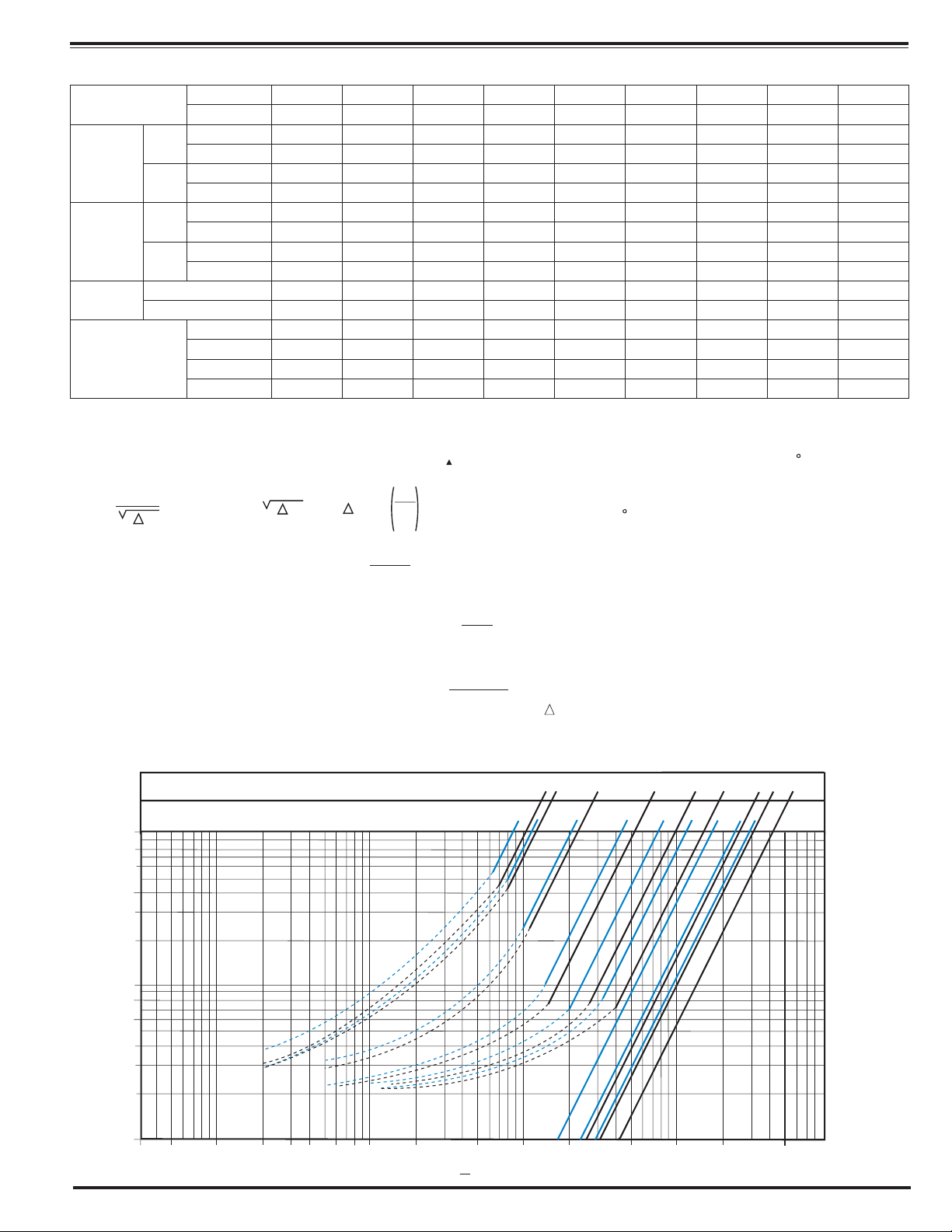

Functional Data

Valve Size

C

V

Factor

Equivalent

Length

of

Pipe

K

Factor

Liquid Displaced from

Cover Chamber When

Valve Opens

*Estimated

C

Factor

V

Formulas for computing C Factor, Flow (Q) and Pressure Drop

Q

=

C

V

K Factor (Resistance Coefficient)

The Value of K is calculated from the formula:

(U.S. system units)

Equivalent Length of Pipe

Equivalent lengths of pipe (L) are determined from the formula:

(U.S. system units)

Fluid Velocity

Fluid velocity can be calculated from the following formula:

(U.S. system units)

Inches 21⁄2 3 4 6 8 10 12 14 16

Globe

Pattern

Angle

Pattern

Globe

Pattern

Angle

Pattern

Globe Pattern

Angle Pattern

mm.

Gal./Min. (gpm.)

Litres/Sec. (l/s.)

Gal./Min. (gpm.)

Litres/Sec. (l/s.)

Feet (ft.)

Meters (m.)

Feet (ft.)

Meters (m.)

Fl. Oz

U.S. Gal.

ml

Litres

65 80 100 150 200 250 300 350 400

85 115 200 440 770 1245 1725 2300 2940

20 28 48 106 185 299 414 552 706

101 139 240 541 990 1575 2500* 3060* 4200*

24 33 58 130 238 378 600 734 1008

53 85 116 211 291 347 467 422 503

16 26 35 64 89 106 142 129 154

37 58 80 139 176 217 222* 238* 247*

12 18 25 43 54 66 68 73 75

4.6 6.0 5.9 6.2 6.1 5.8 6.1 5.0 5.2

3.3 4.1 4.1 4.1 3.7 3.6 2.9 2.8 2.6

— — — — — — — — —

.04 .08 .17 .53 1.26 2.51 4.0 6.5 9.6

163 303 643 — — — — — —

— — — 2.0 4.8 9.5 15.1 24.6 36.2

V

2

Q

K =

P

=

894d

C

v

C

V

4

2

=

C

P

Q

P

V

V =

( P):

L =

.4085 Q

d

K

12 f

2

d

Model 100-03

Where:

C

=

U.S. (gpm) @ 1 psi differential at 60 F water

V

(l/s) @ 1 bar (14.5 PSIG) differential

=

at 15 C water

=

inside pipe diameter of Schedule 40 Steel Pipe (inches)

d

friction factor for clean, new Schedule 40 pipe

=

f

(dimensionless) (from Cameron Hydraulic Data,

18th Edition, P 3-119)

Resistance Coefficient (calculated)

=

K

=

Equivalent Length of Pipe (feet)

L

=

Flow Rate in U.S. (gpm) or (l/s)

Q

=

Fluid Velocity (feet per second) or (meters per second)

V

=

Pressure Drop in (psi) or (bar)

P

or

Model 100-03 Flow Chart (Based on normal flow through a wide open valve)

2

Angle Valve Sizes (Inches)

Globe Valve Sizes (Inches)

100

80

60

40

30

psi

20

10

8

Pressure Drop —

6

4

3

2

1

53

10 20 30 40 60 80 100 200 500 1000 2000 5000 10,000 20,000 50,000

Flow Rate gpm (water)

1/2

34

21/2

3

6

1046

8

810

14

12

16

14

12

16

Page 6

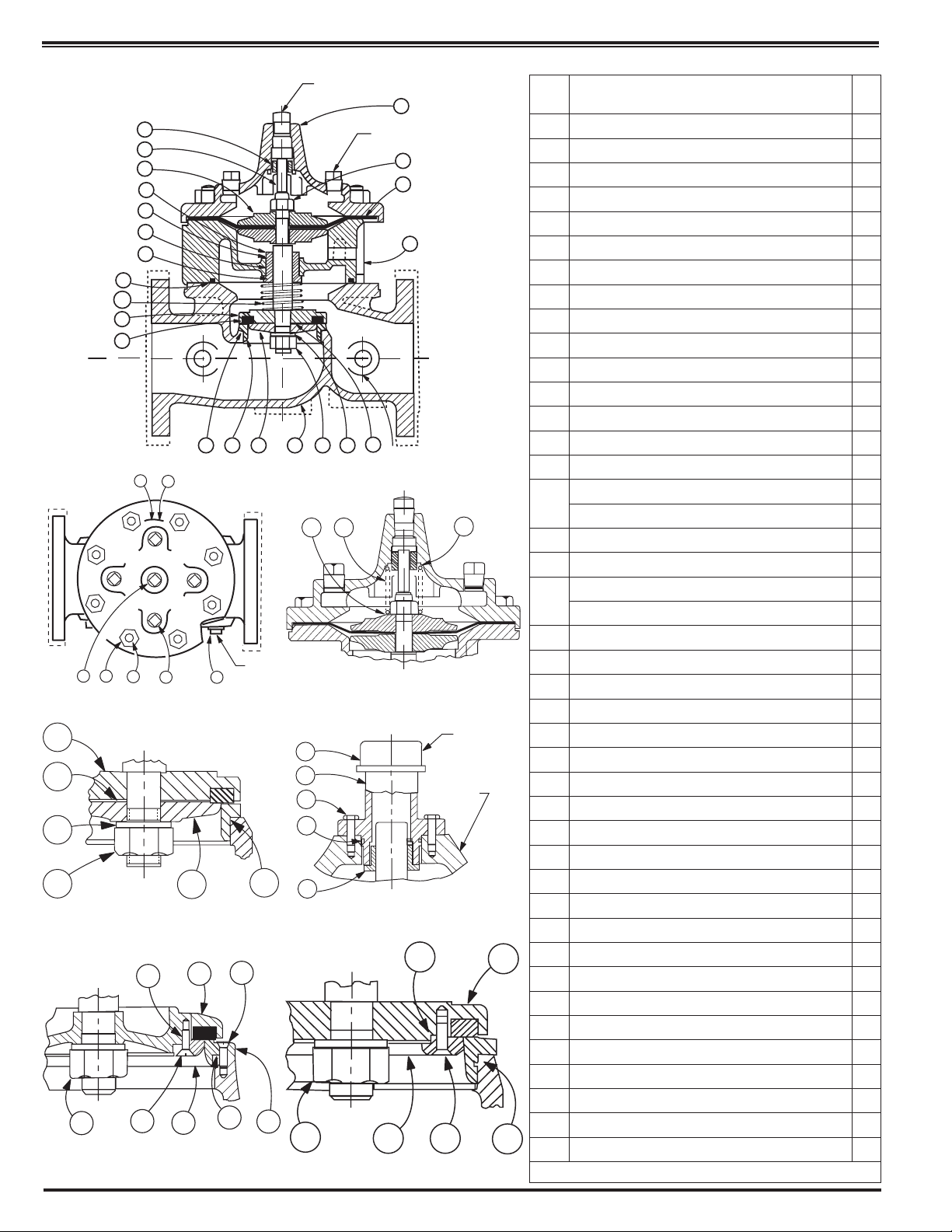

100-03 Powercheck Valve 1” - 3” Sizes

30

37

39

31

25

22

32

21

19

34

19

10

1 3 2

19

14

38

Cover View

36

24

J

NPT

7

Model 100-03KH

1” - 3”

Seat & Disc Details

33

16

35

15

20

ITEM

NO.

1 Center Cover Plug 1

2 Cover Plug

Hex Nut (4”-16” only) A/R

3

4 Cover Bearing 1

5 Cover 1

6 Pipe Cap (16” only) 1

7 Body Plug

8 Hex Bolt (16” only) 8

O-Ring (16” only) 1

9*

Gasket (1” - 3” only) 1

10*

11 Upper Stem Nut 1

12 Diaphragm Washer 2

Diaphragm 1

13*

14 Nameplate 1

Stem O-Ring 1

15*

Bearing Retainer (1” -3” only) 1

16

Bearing Ring Retainer (4” - 16” only) 1

17 Powerunit Body 1

Bearing O-Ring (4” - 16” only) 1

18*

Hex Bolt (1” - 3” only)

19

Stud (4” - 16” only)

20 Powerunit Body 1

21 Lower Stem Nut 1

22 Spacer Washer

23 Screw, Flat Hd (6” - 16” Only)

24 Disc Guide 1

25 Disc Retainer 1

Disc 1

26*

27 Upper Stem 1

28 Screw, Flat Hd (8” - 16” only)

29 Seat 1

30 Body 1

31 Spring (100PCKH / 100CAKH only) 1

32 Lockwasher 1

Seat O-Ring 1

33*

Gasket, Bearing (1” - 3” only) 1

34*

35 Screw FIL. Hd (1”-2 1/2” Bolt HX Hd (3”) 4

36 Upper Spring Washer (100PCKCH / 100PCAKCH) 1

37 Lower Spring Washer (100PCKCH / 100PCAKCH) 1

38 Drive Screw 2

39 Lower Spring (1” - 10” only) 1

40 Lower Stem 1

41 Cover Bearing Housing (16” only) 1

PART DESCRIPTION Qty

*Recommended Spare Parts

A/R

A/R

A/R

A/R

A/R

A/R

A/R

Page 7

G

4

J

27

12

17

16

18

15

10

39

25

26

INLET

29

33

14

38

1 3 2

19

7

Cover View

25

22

32

21

1”-4” Sizes (Seat and Disc Detail)

21

8”-16” Sizes (Seat and Disc Detail)

22

23

24

24

25

28

33

24

J

100-03 Powercheck Valve 4” - 16” Sizes

NPT

5

K

NPT

11

13

20

OUTLET

21

30

NPT

33

29

32

22

H

NPT

37

31

36

1 1/4” - 4” Sizes (No-Core Cover)

6

41

8

9

4

NPT

COVER

16” Cover Bearing Housing Detail

22

21

6” Sizes (Seat and Disc Detail)

24

23

25

33

ITEM

NO.

1 Center Cover Plug 1

2 Cover Plug A/R

3 Hex Nut (4”-16” only) A/R

4 Cover Bearing 1

5 Cover 1

6 Pipe Cap (16” only) 1

7 Body Plug A/R

8 Hex Bolt (16” only) 8

9* O-Ring (16” only) 1

10* Gasket (1” - 3” only) 1

11 Upper Stem Nut 1

12 Diaphragm Washer 2

13* Diaphragm 1

14 Nameplate 1

15* Stem O-Ring 1

Bearing Retainer (1” -3” only) 1

16

Bearing Ring Retainer (4” - 16” only) 1

17 Powerunit Body 1

18* Bearing O-Ring (4” - 16” only) 1

Hex Bolt (1” - 3” only) A/R

19

Stud (4” - 16” only) A/R

20 Powerunit Body 1

21 Lower Stem Nut 1

22 Spacer Washer A/R

23 Screw, Flat Hd (6” - 16” Only) A/R

24 Disc Guide 1

25 Disc Retainer 1

26* Disc 1

27 Upper Stem 1

28 Screw, Flat Hd (8” - 16” only) A/R

29 Seat 1

30 Body 1

31 Spring (100PCKH / 100CAKH only) 1

32 Lockwasher 1

33* Seat O-Ring 1

34* Gasket, Bearing (1” - 3” only) 1

35 Screw FIL. Hd (1”-2 1/2” Bolt HX Hd (3”) 4

36 Upper Spring Washer (100PCKCH / 100PCAKCH) 1

37 Lower Spring Washer (100PCKCH / 100PCAKCH) 1

38 Drive Screw 2

39 Lower Spring (1” - 10” only) 1

40 Lower Stem 1

41 Cover Bearing Housing (16” only) 1

PART DESCRIPTION Qty

*Recommended Spare Parts

Page 8

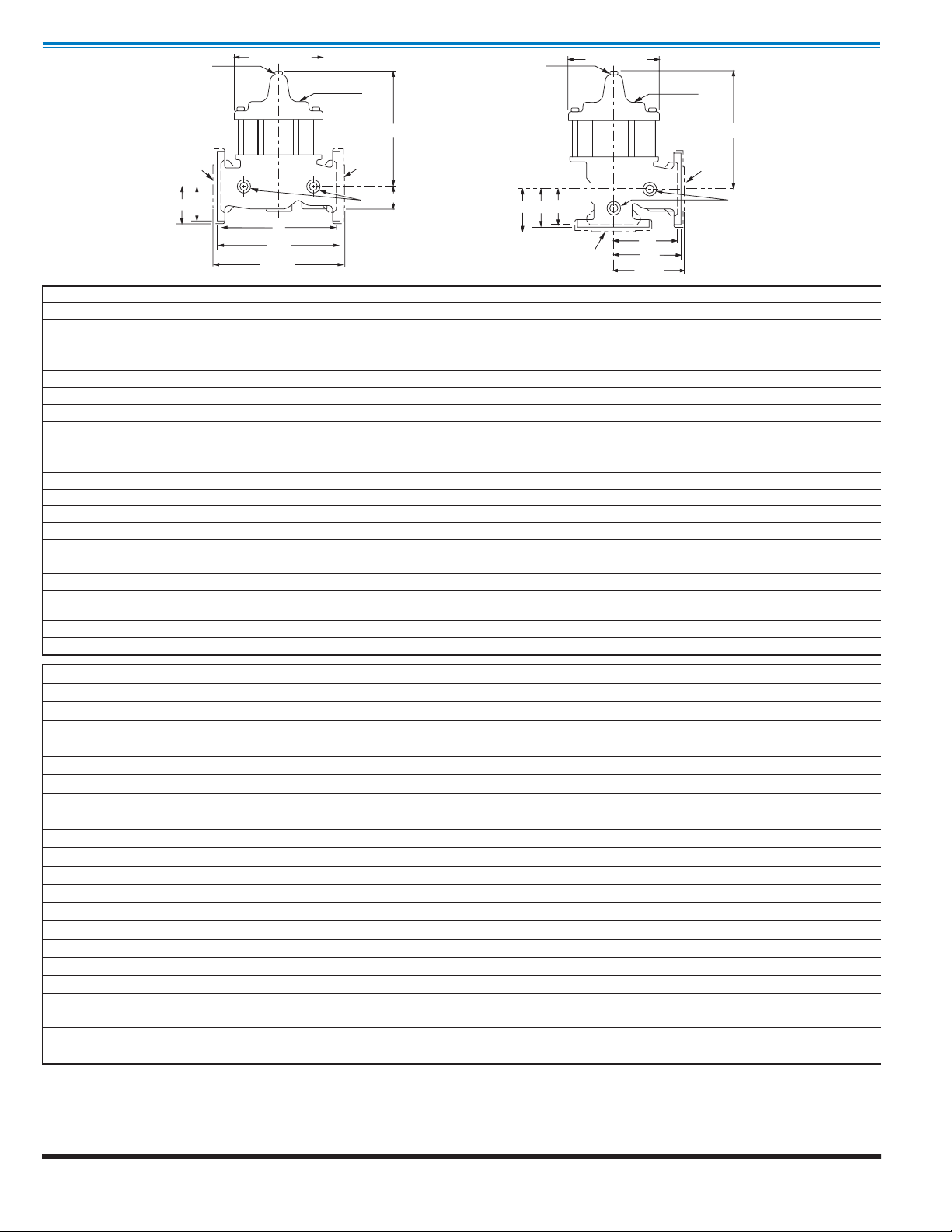

Dimensions

CLA-VAL

Copyright Cla-Val 2009 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

J

B (DIAMETER)

J

K

B (DIAMETER)

Model 100-03

K

OUTLET

C

H

100-03 (Angle)

100-03 (Globe)

INLET

FF

C

OUTLET

E

F

A

AA

AAA

H

GGG

GG G

INLET

D

DD

DDD

Valve Size (Inches) 2 1⁄2 3 4 6 8 10 12 14 16

A Threaded

AA 150 ANSI

AAA 300 ANSI

B Dia.

C Max.

D Threaded

DD 150 ANSI

DDD 300 ANSI

E

F 150 ANSI

FF 300 ANSI

G Threaded

GG 150 ANSI

GGG 300 ANSI

H NPT Body Tapping

J NPT Cover Center Plug

K NPT Cover Tapping

Valve Stem Internal

Thread UNF

Stem Travel

Approx. Ship Wt. Lbs.

11.00 12.50 — — — — — — —

11.00 12.00 15.00 20.00 25.38 29.75 34.00 39.00 41.38

11.62 13.25 15.62 21.00 26.38 31.12 35.50 40.50 43.50

8.00 9.12 11.50 15.75 20.00 23.62 28.00 32.75 35.50

10.31 11.19 14.25 18.44 21.81 23.38 29.31 32.12 35.00

5.50 6.25 — — — — — — —

5.50 6.00 7.50 10.00 12.69 14.88 17.00 19.50 20.69

5.81 6.63 7.81 10.50 13.19 15.56 17.75 20.25 21.75

1.69 2.06 3.19 4.31 5.31 9.25 10.75 12.62 15.50

3.50 3.75 4.50 5.50 6.75 8.00 9.50 10.50 11.75

3.75 4.13 5.00 6.25 7.50 8.75 10.25 11.50 12.75

4.00 4.50 — — — — — — —

4.00 4.00 5.00 6.00 8.00 8.62 13.75 14.88 15.69

4.31 4.38 5.31 6.50 8.50 9.31 14.50 15.62 16.50

1

⁄2

1

⁄2

1

⁄2

10-32

1

1

1

1

⁄4-28

1

⁄4-28

3

⁄4

3

⁄4

3

⁄4

⁄2

⁄2

⁄2

3

⁄8-24

3

⁄4

3

⁄4

3

⁄4

1 1 1 1 1

1 1

1

1

⁄4 11⁄2

1 1 1 1 1

3

⁄8-24

3

⁄8-24

3

⁄8-24

3

⁄8-24

1

⁄2-20

0.7 0.8 1.1 1.7 2.3 2.8 3.4 4.0 4.5

65 95 190 320 650 940 1675 2460 3100

2

Valve Size (mm) 65 80 100 150 200 250 300 350 400

A Threaded

AA 150 ANSI

AAA 300 ANSI

B Dia.

C Max.

D Threaded

DD 150 ANSI

DDD 300 ANSI

E

F 150 ANSI

FF 300 ANSI

G Threaded

GG 150 ANSI

GGG 300 ANSI

H NPT Body Tapping

J NPT Cover Center Plug

K NPT Cover Tapping

Valve Stem Internal

Thread UNF

Stem Travel

Approx. Ship Wt. Kgs.

279 318 — — — — — — —

279 305 381 508 645 756 864 991 1051

295 337 397 533 670 790 902 1029 1105

203 232 292 400 508 600 711 832 902

262 284 362 468 554 594 744 816 889

140 159 — — — — — — —

140 152 191 254 322 378 432 495 526

148 168 198 267 335 395 451 514 552

43 52 81 109 135 235 273 321 394

89 95 11 4 140 171 203 241 267 298

95 105 127 159 191 222 260 292 324

102 114 — — — — — — —

102 102 127 152 203 219 349 378 399

110 111 135 165 216 236 368 397 419

1

⁄2

1

⁄2

1

⁄2

10-32

1

1

1

1

⁄4-28

1

⁄4-28

3

⁄4

3

⁄4

3

⁄4

⁄2

⁄2

⁄2

3

⁄8-24

3

⁄4

3

⁄4

3

⁄4

1 1 1 1 1

1

1

1 1

⁄4 11⁄2

1 1 1 1 1

3

⁄8-24

3

⁄8-24

3

⁄8-24

3

⁄8-24

1

⁄2-20

18 20 28 43 58 71 86 102 11 4

30 43 86 145 295 426 760 1116 1406

2

Cla-Val Control Valves operate with maximum efficiency when mounted in horizontal piping with the main valve cover UP, however, other positions are acceptable. Due to component size and weight of 8 inch and larger valves, installation with cover UP is advisable. We recommend

isolation valves be installed on inlet and outlet for maintenance. Adequate space above and around the valve for service personnel should be

considered essential. A regular maintenance program should be established based on the specific application data. However, we recommend

a thorough inspection be done at least once a year. Consult factory for specific recommendations.

N-100-03 (R-1/09)

Loading...

Loading...