Page 1

Schiller-Pfeiffer, Inc.

1028 Street Road • Southampton, PA 18966

Telephone: 1-800-366-6268

TRS-20 TURF RAKE

(Serial No. 00127 & UP)

TSS-20 TURF SEEDER

(Serial No. 00143 & UP)

OPERATORS / PARTS MANUAL

Page 2

2

THANK YOU

Thank you for purchasing a CLASSEN TRS-20/

TSS-20.

READ THIS MANUAL

Read this manual carefully in its entirety. It

contains assembly, operating, maintenance,

adjustment instructions and a parts list for your

TRS-20/TSS-20. By following the operating and

maintenance instructions you will prolong the life

of your equipment and maintain its maximum

efficiency. Failure to do so could result in personal

injury or equipment damage. This manual

should be considered a permanent part of your

TRS-20/TSS-20 and should remain with it if you

sell it.

WARRANTY

Refer to last page.

MEASUREMENTS

U.S. Units of measure are used in this manual.

SERIAL NUMBERS

Write frame and engine serial numbers, plus model

numbers in “Owner’s Record” section below. You

may need these numbers when you order parts.

The serial number sticker plate is located near

the left rear corner of the TRS-20/TSS-20 frame.

ORDERING PARTS

When ordering parts, always give the serial number

and model of your TRS-20/TSS-20 as well as the

quantity, part number and description of the part

needed.

DIRECTIONS

“Right Hand” and “Left Hand” sides of the

TRS-20/TSS-20 are determined by facing the “back”

of the unit as you would operate the machine.

TABLE OF CONTENTS

INTRODUCTION ......................................2

Thank You ............................................................2

Read This Manual ................................................2

Warranty................................................................2

Measurements ......................................................2

Serial Numbers......................................................2

Ordering Parts ......................................................2

Directions ..............................................................2

Pre-Delivery Check List ........................................3

Delivery Check List ..............................................3

Owner’s Record......................................................3

SAFETY PRECAUTIONS ..........................4

Training ................................................................4

Preparation Safety ................................................4

Engine Safety ........................................................4

Operational Safety ................................................4

OPERATION ..............................................5

Preparation ............................................................5

Starting Engine......................................................5

Transporting TURF RAKE/ TURF SEEDER..........5

Operating TURF RAKE/ TURF SEEDER ..............5

OPTIONAL BLADE ASSEMBLIES ............6

Changing Blade Assemblies ..................................6

Replacing Shaft Assembly Only ............................6

Recommended Height Adjustments......................6

GENERAL MAINTENANCE ......................8

TURF RAKE/ TURF SEEDER Maintenance ........8

Engine Maintenance..............................................8

MACHINE STORAGE ................................8

Storing TURF RAKE/ TURF SEEDER ..................8

Operation After Extended Storage ........................8

CARE FOR HYDRAULIC SYSTEM ............9

PARTS MAIN FRAME ASSEMBLY ..........10

PARTS SELF PROPELLED ASSEMBLY ....11

PARTS HANDLE ASSEMBLY ....................12

SEEDER/MULTIPURPOSE

BLADE ASSEMBLY ..................................13

SLICER BLADE ASSEMBLY ....................13

SEED BOX ASSEMBLY ............................14

SEEDER TIRE SCRAPE INSTALLATION 15

SEED BOX INSTALLATION ....................15

SAFETY DECALS ....................................16

NOTES ....................................................17

WARRANTY ............................................18

INTRODUCTION

Page 3

3

PRE-DELIVERY

CHECK LIST

CHECK THE FOLLOWING BEFORE YOU

DELIVER THE TRS-20/TSS-20 TO THE

CUSTOMER.

1. Guards and shields fastened in place.

2. Decals fastened and legible.

3. Gas lever on engine turned on.

4. All lubrication points greased.

5. Air cleaner.

6. Touch up scratches.

7. Add engine oil (refer to Engine manual)

8. Add fuel, start engine, test run.

DATE SET UP

__________/__________/__________

DELIVERY CHECK LIST

REVIEW THE OPERATORS MANUAL WITH

THE CUSTOMER.

1. Classen Mfg., Inc. warranty.

2. Safe operation and service.

3. How to use controls.

4. Operating the machine correctly.

5. Transporting the TRS-20/TSS-20.

6. Correct fuel and lubricants.

7. Daily and periodic inspections.

8. Changing oil after break-in period.

9. Servicing the TRS-20/TSS-20 regularly

and correctly.

10. Classen Mfg., Inc. parts and service.

11. Give the customer the Operator’s Manual

and encourage customer to read it.

DATE DELIVERED

__________/__________/__________

SIGNATURE _______________________________

OWNER’S RECORD

DATE PURCHASED

__________________________________________

TRS-20/TSS-20 SEEDER MODEL NUMBER

__________________________________________

ENGINE MODEL NUMBER

__________________________________________

TRS-20/TSS-20 SERIAL NUMBER

__________________________________________

ENGINE SERIAL NUMBER

__________________________________________

Page 4

4

SAFETY PRECAUTIONS

TRAINING

1. Regard the unit as a piece of power

equipment and teach this regard to all who

operate this unit.

2. Read the instructions carefully. Be familiar

with the controls and the proper use of the

equipment.

3. Never allow children, teenagers or people

unfamiliar with these instructions to use

this piece of equipment.

4. Avoid operating unit while people,

especially children or pets, are nearby.

Keep in mind that the operator or user

is responsible for accidents or hazards

occurring to other people or their property.

5. Be sure you know how to stop the

TRS-20/TSS-20 at a moment’s notice.

6. When using the TRS-20/TSS-20, make

certain frame plate is attached at all times

when not bagging.

PREPARATION SAFETY

1. The use of personal protective equipment,

such as (but not limited to) protection for the

eyes, ears, feet and head is recommended.

2. While operating, always wear substantial

foot wear and long trousers. Do not operate

the equipment when barefoot or wearing

open sandals.

3. Area should be free of all obstacles

and debris.

ENGINE SAFETY

1. Handle gasoline with care; it is highly

flammable.

2. Use an approved gasoline container.

3. Always add fuel before starting the engine.

4. Fill the fuel tank outdoors.

5. If fuel is spilled, do not attempt to start the

engine. Move away from the area of the spill

and avoid creating any source of ignition

until fuel vapors have dissipated.

OPERATIONAL SAFETY

1. Carefully read and follow all

caution stickers.

2. Operate only in daylight or good

artificial light.

3. Do not operate machine unless all guards,

shields and covers are in place and in

proper working condition.

4. It is essential all operator safety mechanisms

be connected and in operating condition

prior to use.

5. Do not change the engine governor settings

or over-speed the engine. Operating an

engine at excessive speed may increase the

hazard of personal injury.

6. Disengage all blade and drive clutches

(release bail) before starting.

7. Start the engine carefully with feet well

away from the blades.

8. Do not put hands, feet or clothing near

rotating parts while the unit is being

operated.

9. Travel up and down slopes at a 45° angle

rather than across, to prevent unit from

tipping over.

10. Exercise extreme caution when changing

direction on slopes. Do not get too close

to sharp drop-offs or operate unit on

excessively steep slopes.

11. Use caution when backing up or pulling

the unit towards you.

12. Stop the blades if unit has to be tilted for

transportation, when crossing surfaces (i.e.

sidewalks, driveways, stepping stones, etc.)

or when transporting the unit to and from

the area being worked on.

13. Never pick up or carry a TRS-20/TSS-20

while the engine is running.

WARNING

DO NOT FILL TANK COMPLETELY FULL.

DO NOT

SMOKE WHILE YOU FILL FUEL TANK.

DO NOT

REMOVE GAS CAP IF ENGINE

IS RUNNING.

DO NOT

OPERATE ENGINE IN A

CONFINED SPACE WHERE DANGEROUS

CARBON MONOXIDE FUMES CAN COLLECT.

Page 5

5

OPERATION

PREPARATION

1. Carefully read this manual and operate

TRS-20/TSS-20 correctly.

2. Always check machine on level ground.

3. Visually check all moving parts and all

fasteners, if loose or broken, tighten or

replace. Check for broken or bent blades,

replace if necessary.

4. Lubricate all fittings after every four hours

of using machine, using a pressurized gun

with standard lithium base lubricant (see

“General Maintenance” section). Wipe off

fittings before and after lubricating.

5. Add oil to the engine crankcase with engine

resting in a level position (refer to engine

manufacturer’s Owner’s Manual for the

correct type and amount of oil).

6. Fill the fuel tank according to engine

manufacturer specifications.

7. Police lawn area for obstacles and debris

(i.e. sprinklers, hoses, toys, etc.)

8. Mark underground sprinkler heads and

other hidden obstacles to prevent damage.

STARTING ENGINE

1. Turn fuel cock to the “open” position

2. Turn choke on (closed).

3. Turn ignition switch to “on”.

4. Move throttle control to high RPM setting.

Do not exceed 3600 rpm.

5. Pull recoil starter rope until engine starts.

6. After engine is warm, turn off choke (open).

7. Allow engine to run one minute before

operating.

8. Check engine rpm setting before operating,

DO NOT

exceed 3600 rpm.

TRANSPORTING THE TRS-20/

TSS-20

1. Position height adjustment lever to the

start/transport position (see Fig. 1).

2. Start Engine, drive up ramps, make sure

the blades do not hit the ramps or vehicle.

3. Slow the throttle to desired speed for

loading.

4. To clear sidewalks, driveways, etc., press

down on handle, raising front of the

TRS-20/TSS-20.

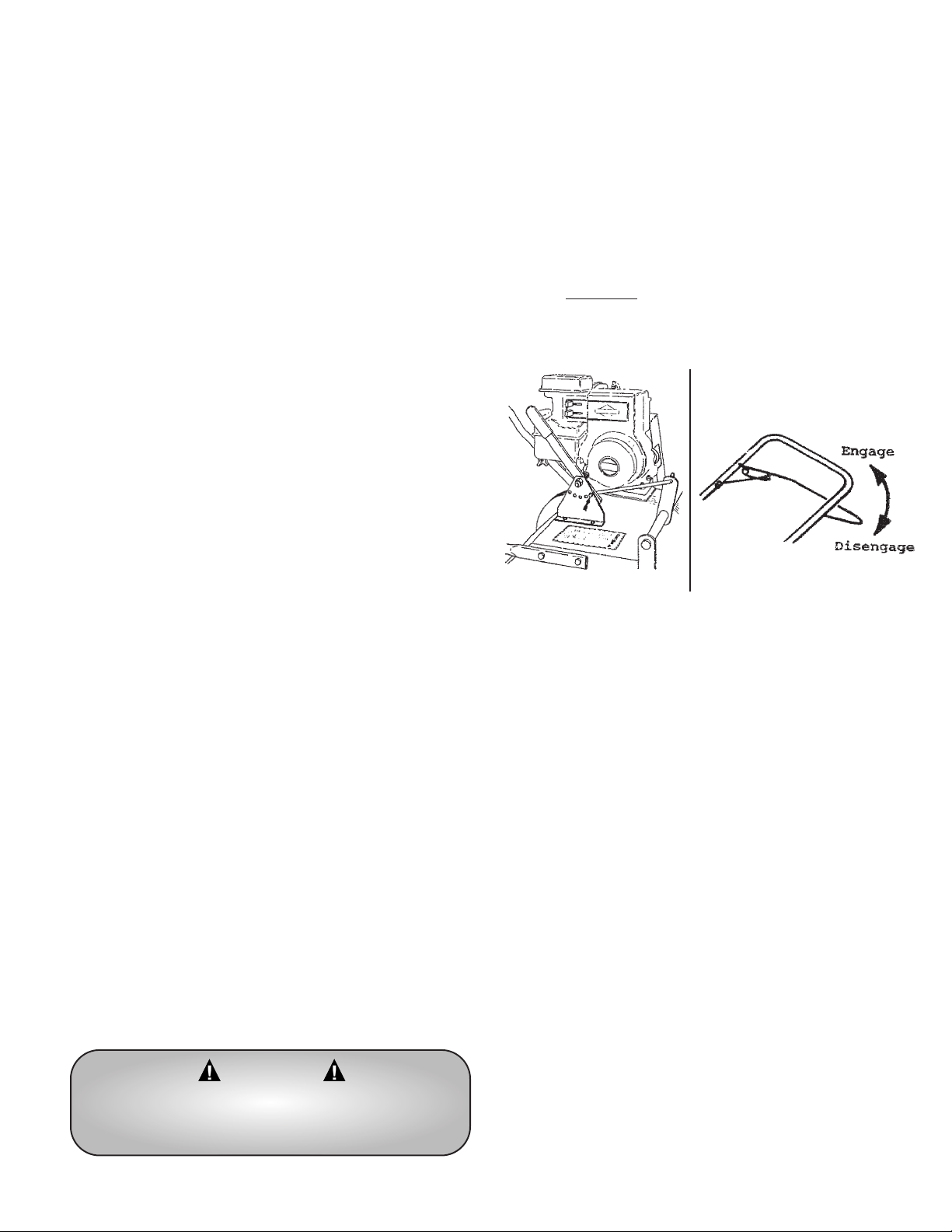

OPERATING THE TRS-20/TSS-20

1. Put speed lever in neutral position.

2. Start engine.

3. Engage bail.

4. Move speed lever forward, to move forward.

5. Move speed lever backwards, to reverse.

6. Drive TRS-20/TSS-20 to area to be raked

or seeder.

7. Move height adjustment lever to the

appropriate setting for the shaft assembly

being used. (see “Optional Shaft

Assemblies” section)

8. Lift bail to engage the main shaft. Release

bail to stop.

14. Stop the engine and disconnect the spark

plug wire:

a) before checking, cleaning or working

on unit

b) after striking a foreign object (inspect

the unit for damage and make repairs

before restarting and operating)

15. Stop the engine:

a) whenever you leave the unit

b) before refueling

c) before clearing blockages.

16. Reduce the throttle setting during engine

run-out and, if the engine is provided with

shut-off valve, turn the fuel off at the

conclusion of operating.

17. Before shutting off, put drive lever in neutral.

CAUTION

TO AVOID INJURY, DO NOT PLACE YOUR FEET

OR OTHER BODY PARTS UNDER THE BLADES

WHILE STARTING THE ENGINE.

Fig. 1

Fig. 2

Page 6

6

OPTIONAL BLADE

ASSEMBLIES

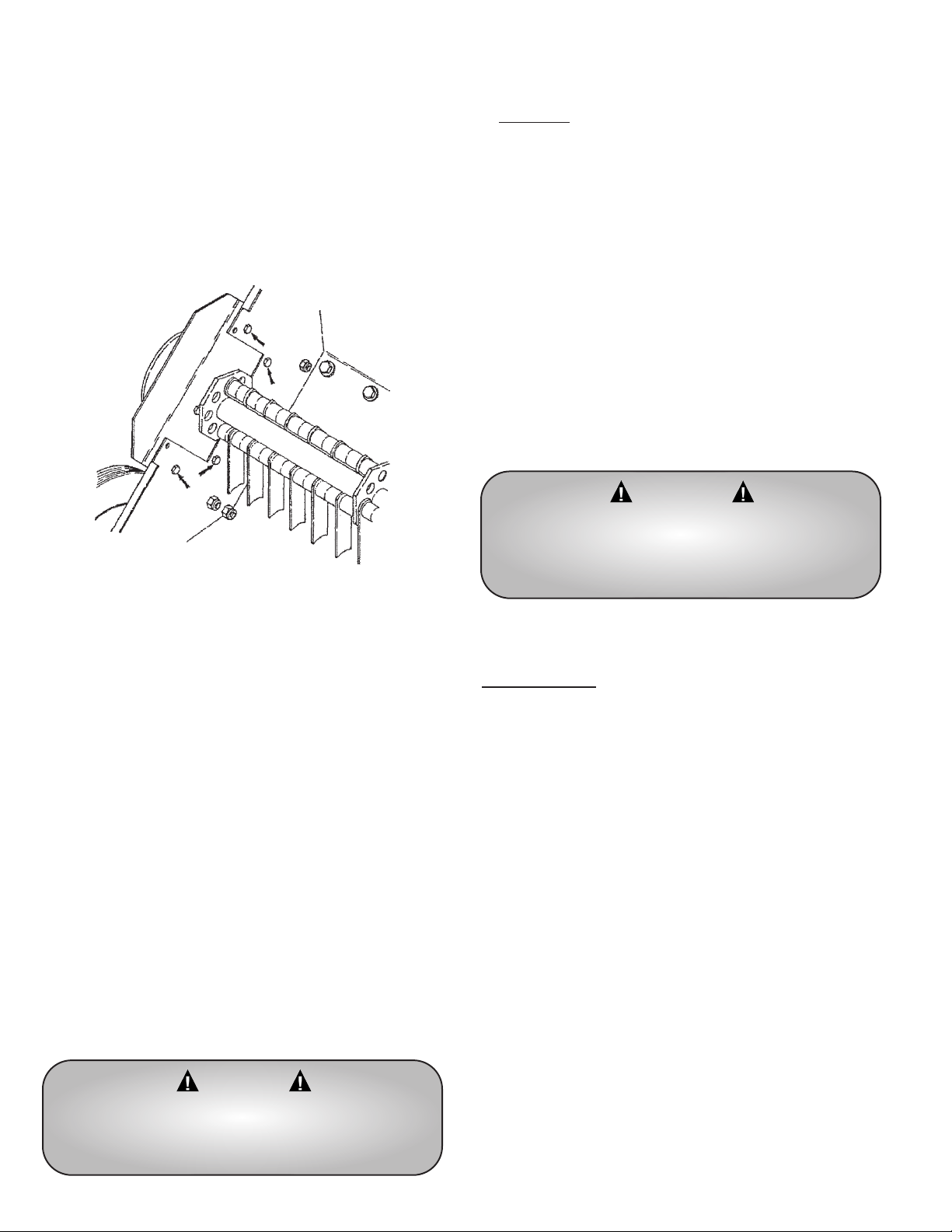

CHANGING BLADE ASSEMBLIES

Within minutes your machine can be converted to

a turf rake, turf seeder or turf slicer by purchasing

the optional blade assemblies available complete

with side plates, bearings and drive pulley.

Changing the blade assembly can be done quickly

as described below.

1. Set unit up on block allowing enough

distance beneath machine to change

blade assembly.

2. After removing the belt shield, remove the

twelve bolts on the left side and three on

the right side which hold the blade

assembly to the main body (see Fig. 3).

3. Remove the belts from both sides and

remove the entire blade assembly. There is

no need to loosen any set screws.

4. Next install the optional blade assembly

and fasten with six 1/4” x 5/8” bolts on

each side. Tighten all bolts on both shields.

Center the shaft and tighten the two set

screws in each bearing using Pro Lock

(nut type, medium strength).

5. When changing back to the original shaft it

will not be necessary to loosen any set

screws. Only the bolts in the belt shields

and the eight bolts holding the shaft will

need to be removed.

CAUTION

BE CERTAIN THAT THE SET SCREWS ARE

TIGHTENED PROPERLY IN BEARINGS AND PULLEY

WHEN REASSEMBLING.

REPLACING SHAFT

ASSEMBLY ONLY

If replacing the existing shaft assembly, only follow

steps 1 through 3 above. Proceed with the

following steps.

1. Remove the two drive pulleys and bearing

plates from the main shaft (one on each

side). Replace with new shaft. Reinstall the

bearing plates and drive pulleys on the new

shaft using Pro Lock (retaining 1, medium

strength) on the shaft and Pro Lock (nut

type, medium strength) on the set screws.

The pulleys will be positioned on the shaft

by bolts, the 1/4” lock washer and the

pulley retainer washer.

2. Route the belt behind the idler pulleys and

roll the belts onto the lower pulleys then

reinstall the belt shields.

RECOMMENDED HEIGHT

ADJUSTMENTS

Raking Height

When using the Turf Rake with its raking (flail)

blade assembly adjust the raking height as follows.

Normal height is set by placing the Turf Rake on a

hard surface making sure one satellite shaft is at

dead bottom. Adjust the wheels so the raking

fingers on the bottom shaft just touch the ground.

DO NOT set the fingers so that they will penetrate

the ground as this will counteract the centrifugal

force of the fingers and prevent the from raking

properly.

With repeated use, raking side of the fingers will

begin to wear. To give the fingers a new square

raking edge, remove the end plates and turn the

entire main shaft assembly 180° and replace it on

the Turf Rake. NOTE: Use Pro-Lock (retaining 1,

medium strength) on the 7” pulley on the

main shaft.

To prolong the life of the main shaft, extra holes

are provided. If the circular holes holding the

satellite shafts become distorted, rotate all four

satellite shafts to the next set of holes.

WARNING

CAUTION: BE CERTAIN THAT THE SET SCREWS

ARE TIGHTENED PROPERLY IN BEARINGS AND

PULLEY WHEN REASSEMBLING.

Fig. 3

Page 7

7

Seeding/Multipurpose Height

The seeding/multipurpose blades are used for

cutting grooves for over-seeding and can also be

used for verticutting grasses. To set the height

properly place unit on the lawn surface and adjust

the wheel height up (see Fig. 4 ). Adjusting the

wheel height up lowers the blades.

Seeding

The proper height setting for over-seeding is

approximately 1/4” into the ground. Adjust the

wheel height up approximately one notch. If

set deeper, grass seed being applied may not

germinate.

For best results, over-seed in two passes of 1/2

application rate at right angles or in a criss-cross

pattern. Water heavily immediately after seeding

then lightly for 10-14 days keeping soil moist.

Slicing

The proper height setting for slicing or aerating is

1/2” to 3/4” into the ground. Adjust the wheel

height up one or two notches.

For crawling grasses such as Zoysia, Bermuda,

Bahia, etc. raise the wheels only one notch.

Crawling grasses should not be sliced too deeply.

For single strand grasses like Bluegrass or Rye,

aerate in perpendicular directions for more even

slicing. For example, slice in a North-South

direction on the first pass, switching to an

East-West direction on the second pass.

As the seeder/multipurpose blades wear they may

be rotated to provide a new cutting edge. The

wheels may be raised to allow the blades to

penetrate deeper into the ground.

CAUTION

BE CERTAIN THAT THE SET SCREWS ARE

TIGHTENED PROPERLY IN BEARINGS AND PULLEY

WHEN REASSEMBLING.

Slicing Height

The slicer blade assembly is recommended for

slicing, verticutting or aerating when a thinner

blade is preferred. This is the recommended blade

for use on golf course greens. To set the height

properly place unit on the lawn surface and adjust

the wheel height up (see Fig. 4). Adjusting the

wheel height up lowers the blades.

The proper height setting for slicing or aerating is

1/2” to 3/4” into the ground. Adjust the wheel

height up one or two notches.

For crawling grasses such as Zoysia, Bermuda,

Bahia, etc. raise the wheels only one notch.

Crawling grasses should not be sliced too deeply.

For single strand grasses like Bluegrass or Rye,

aerate in perpendicular directions for more even

slicing. For example, slice in a North-South

direction on the first pass, switching to an

East-West direction on the second pass.

As the slicer blades wear they may be rotated to

provide a new cutting edge. The wheels may be

raised to allow the blades to penetrate deeper into

the ground.

Fig. 4

Page 8

8

GENERAL

MAINTENANCE

TO KEEP THE TRS-20/TSS-20 IN

GOOD OPERATING CONDITION,

PERFORM THE FOLLOWING:

• When replacement parts are required, use

genuine Classen parts or parts with

equivalent characteristics including type,

strength, and material. Failure to do so may

result in product malfunction and possible

injury to the operator and/or bystanders.

• Keep all safety decals legible. Remove all

grease, dirt and debris from decals. Any

safety decal that becomes illegible should

be replaced immediately (see ‘Safety

Decals” section). Safety decals can be

affixed by peeling off the backing and

applying to clear, dry surface. Smooth

out to remove any air bubbles.

• Do not operate equipment without shields

in place.

• Do not make any adjustments or perform

any maintenance while the engine is

running.

• Check engine mounting bolts frequently to

maintain proper tightness.

• Thoroughly clean off blades when

application is completed and apply a light

coat of oil to prevent rust on blades.

• Keep belt free of oil and dirt.

• Check for worn or deteriorating

components that could create a hazard.

When new components are installed, be

sure that current safety decals are affixed to

the replaced components. Safety decals can

be affixed by peeling off the backing and

applying to clear, dry surface. Smooth out

to remove any air bubbles.

ENGINE MAINTENANCE

• Refer to engine manufacturer’s

Owner’s Manual.

• Check engine oil level with engine resting

in a level position.

• Inspect air filter element and replace if

necessary.

• If carburetor adjustment is necessary, stand

to one side and keep feet and hands clear

while making adjustments.

MACHINE STORAGE

STORAGE INSTRUCTIONS

Before the TRS-20/TSS-20 is put into storage for

any period exceeding 30 days, the following steps

should be taken.

1. Drain all fuel from fuel tank and fuel lines.

2. Start engine and run until all fuel is used

from carburetor float bowl.

3. While engine is still warm, drain the

crankcase oil and replace with the proper

weight oil corresponding to the season the

TRS-20/TSS-20 will next be used (refer to

engine manufacturer’s Owner’s Manual).

4. Remove the spark plug and squirt a small

quantity of engine oil into the cylinder.

Turn the engine over a few times to

distribute that oil.

OPERATION AFTER EXTENDED

STORAGE

To put TRS-20/TSS-20 into operation after an

extended storage:

1. Check for loose parts and tighten

if necessary.

2. Check for cracked or broken blades

and replace,

3. Check that all safety decals are in place

and legible.

4. Fill fuel tank.

5. Check engine oil level with engine in level

position (refer to engine manufacturer’s

Owner’s Manual).

6. Start engine.

7. Check for fuel leaks.

SAFETY WARNING

TO PREVENT POSSIBLE EXPLOSION OR IGNITION

OF VAPORIZED FUEL, DO NOT STORE EQUIPMENT

WITH FUEL IN TANK OR CARBURETOR OR NEAR

OPEN FLAME (I.E. FURNACE, WATER HEATER,

PILOT LIGHT).

Page 9

9

CARE FOR HYDRAULIC SYSTEM

To keep the hydraulic system in working order,

there are a few steps needed to take place. If

synthetic oil were used we would suggest a full

synthetic oil such as Mobil 1 15W50, Quaker

State Full Synthetic 5W50, or a similar oil.

Oil viscosity is very important to transmission

life. For optimum performance the oil viscosity

should maintain a viscosity of 13 cSt [70 SUS].

The minimum oil viscosity to prevent component

wear is 9 cSt [55 SUS]. These Viscosity

requirements are for an oil temperature of 110

degrees Celsius [230 degrees Fahrenheit]

Typically; standard SEA 20W-50 multi-viscosity

motor oils will meet this requirement. If the

operating temperature is elevated then synthetic

oil with greater viscosity index, or more viscosity

at elevated temperatures, may be needed to meet

viscosity requirements.

System Start-up: (purging air from system).

Factory Fills unit with SAE 20W-50 multiviscosity

motor oil. This will need to be checked when

setting up with instructions below.

At system start-up, several things need to be

accomplished to ensure a properly running

system.

1. Fill the BDU case and expansion level and

ensure they do not empty during the

following procedure.

2. Start engine and increase throttle to at least

2/3 speed.

3. Open bypass valve by depressing bypass

plunger and holding.

4. Adjust control linkage such that

transmission control is stroking

full forward.

5. Move and hold control in forward for

3 seconds; repeat two additional times.

6. Close bypass valve be releasing

bypass plunger.

7. With engine still at same speed,

repeat step 5.

8. Move control to neutral.

9. Check engine speed. Adjust to

recommended maximum engine speed.

10. Adjust neutral position.

11. Adjust forward control stop to

recommended axle speed.

12. Adjust reverse control stop to

recommended axle speed.

13. If axle speed is not achieved ensure

linkage allows proper movement of

transmission control.

14. If transmission control lever is rotating

fully but recommended axle speed is not

achieved, repeat start-up procedure.

15. Refill expansion tank oil to

recommended level.

Page 10

10

PARTS MAIN FRAME ASSEMBLY

Page 11

11

PARTS SELF PROPELLED ASSEMBLY

Page 12

12

PARTS HANDLE ASSEMBLY

Page 13

13

SEEDER/MULTIPURPOSE BLADE ASSEMBLY

SLICER BLADE ASSEMBLY (OPTIONAL)

QTY/PER

KEY PART NO. MACHINE DESCRIPTION

1 700025 1 Shaft w/ Blade Holders, Multipurpose

2 100310 26 Blade w/ 15/16” Holes, Multipurpose

3 500216 52 Bolt, 5/16-18 x 314 Grade 8

4 500217 52 Nut, 5/16-18 Tap Lock

5 600030 1 Shaft/Blades Sub-Assembly, Multipurpose

6 900026 1 Complete Multipurpose Shaft Assembly

(Includes Shaft, Blades, End Plates,

Bearings, Pulley, Key & Fasteners)

- Not Shown

QTY/PER

KEY PART NO. MACHINE DESCRIPTION

1 700025 1 Shaft w/ Blade Holders, Multipurpose

2 300032 26 Blade, Slicer Square

3 500180 52 Bolt, 1/4-20 x 3/4 Grade 8

4 500160 52 Nut, 1/4-20 Top Lock

5 600024 1 Shaft/Blades Sub-Assembly, Multipurpose

6 900016 1 Complete Slicing Shaft Assembly

(Includes Shaft, Blades, End Plates,

Bearings, Pulley, Key & Fasteners)

- Not Shown

Page 14

14

QTY/PER

KEY PART NO. MACHINE DESCRIPTION

1 500068 8 1/4” NYLOC NUT

2 100140 1 GAUGE w/ BOLT & WING NUT

3 500089 2 1/4” x 1-1/2” BOLT

4 100142 1 CONTROL LEVER GRIP

5 100141 1 CABLE CONTROL LEVER

6 500118 3 1/4” x 1-3/4” BOLT

7 100139 1 CONTROL CABLE (NOT SHOWN)

8 100127 1 FRICTION WASHER

9 100229 3 #8 x 3/4” BLACK SCREW

10 100144 2 HOUSING CLIP

11 100357 1 SEED BOX

12 500226 1 3/16 LOCK WASHER

13 100355 2 8” SEED BOX DRIVE WHEEL

14 100067 2 SHAFT GUARD

15 400038 1 MOUNTING BRACKET

16 100078 1 VINYL SEED BOX COVER

17 400039 1 STABILIZING BRACKET

TSS-20 SEED BOX ASSEMBLY

QTY/PER

KEY PART NO. MACHINE DESCRIPTION

18 500088 10 1/4” FLAT WASHER

19 900033 1 COMPLETE SEED BOX ASSEMBLY

20 500069 3 1/4” x 5/8” BOLT

21 500227 1 3/16” FLAT WASHER

22 300116 1 SIDE PLATE

23 400209 1 AXLE

24 100356 2 BEARING

25 500223 2 3/16 x 1” BOLT

26 500224 3 3/16” NUT

27 100358 2 SHUT-OFF END CLIP

28 100359 1 SHUT-OFF ASSEMBLY

29 100074 1 DECAL, “CLASSEN”

30 500225 1 3/16” x 3/4” BOLT

31 100020 1 PLASTIC TIE

32 400040 2 CONNECTING PINS

33 500096 1 5/32” x 3” HAIR PIN

34 500016 1 5/32” x 1-1/4” COTTER PIN

Page 15

15

SEEDER TIRE SCRAPE INSTALLATION

SEED BOX INSTALLATION

For shipping purposes only, the seed box assembly is attached to machine improperly.

To set your machine correctly for operation, remove hairpin clip (A) from upper connecting rod (B). Slide upper rod out, allowing “A

shaped” stabilizing bracket (C) on seed box to sit over lower connecting rod. (When mounted properly, wheels of seed box should be

resting on front wheels of machine.) Reinsert rod and clip.

Page 16

16

SAFETY DECALS

QTY/PER

KEY PART NO. MACHINE DESCRIPTION

1 100074 2 Decal, “Classen”

2 100060 1 Decal, “CAUTION - Muffler and Shields

May Exceed 150°”

3 100340 1 Decal, “TRS-20” (Turf Rake only)

4 100071 1 Decal, “Bail Engagement”

5 100061 1 Decal, “CAUTION - Operating Instructions”

QTY/PER

KEY PART NO. MACHINE DESCRIPTION

6 100341 1 Decal, “TSS-20” (Turf Seeder only)

7 100069 1 Decal, “DANGER, Keep Hands and Feet Away”

8 100070 1 Decal, “DANGER - Carbon Monoxide”

9 100138 1 Decal, “Seed Application Chart” (Turf Seeder only)

10 100228 1 Decal, “CAUTION - Catcher Bag (Turf Rake only)

11 100054 1 Manual, Operators/Parts (Not Shown)

Page 17

17

NOTES

Page 18

9/07

TWO YEAR LIMITED WARRANTY

Effective April 1, 2007

For the period of two years from the date of purchase, CLASSEN MFG., INC. will repair or replace for the original purchaser free

of charge, any part or parts found upon the examination of our factory authorized service station, or by the factory in Norfolk,

Nebraska, to be defective in material or workmanship. All transportation charges on parts submitted for repair or replacement under

this warranty shall be borne by the purchaser.

This warranty does not include engines or engine parts, tires, batteries, or gearboxes that are covered under separate warranties

furnished by their manufacturer or supplier, nor does it include normal maintenance parts, including but not limited to, spark plugs,

points, filters, blades, and lubricants.

All service under this warranty will be furnished or performed by our factory authorized service stations.

There is no other expressed warranty. Implied warranties, including those of merchantability and fitness for a particular purpose, are

limited to two years from the date of purchase and to the extent permitted by law, any and all implied warranties are excluded. The

above remedy of repair and replacement of defective parts is the purchaser’s exclusive remedy for any defect, malfunction or breach

of warranty. Liability for incidental or consequential damages under any and all warranties is excluded to the extent permitted

by law.

NORMAL RESPONSIBILITIES OF THE SELLER AND THE USER

1. The Distributor or Dealer is responsible for the proper assembly and preparation of the product for delivery to the end user.

2. The User is responsible for reading the Manual and Instructions.

3. The User is responsible for proper operation and maintenance as described in the manual.

4. The User is responsible for the replacement of wear items such as blades, belts, tires, batteries, etc.

5. The User is responsible for damage due to improper operation and maintenance, as well as abuse.

All claims must be received by the factory 30 days after the end of the warranty period to receive warranty consideration.

Schiller-Pfeiffer, Inc.

1028 Street Road • Southampton, PA 18966

Telephone: 1-800-366-6268

©2007 Classen, Division of Schiller-Pfeiffer, Inc.

Loading...

Loading...