Page 1

SOD CUTTER

OPERATOR’S/PARTS

MANUAL

SC-12

SC-16

SC-18

SC-20

SC-24

Schiller-Pfeiffer, Inc.

1028 Street Road • Southampton, PA 18966

Telephone: 1-800-366-6268

Page 2

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Thank You . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Read This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Directions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

OWNER’S RECORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

PRE-DELIVERY CHECK LIST. . . . . . . . . . . . . . . . . . . . . . . 1

DELIVERY CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Handle Fuel Safely - Avoid Fires. . . . . . . . . . . . . . . . . . . 2

Read Safety Signs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operate Safely . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Protect Children . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Avoid Tipping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operate Safely On Slopes . . . . . . . . . . . . . . . . . . . . . . . . 2

Practice Safe Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 2

Start Engine Safely. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ENGINE STARTING PROCEDURES . . . . . . . . . . . . . . . . . . 2

Engine Oil Level Check . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Transmission Oil Level Check . . . . . . . . . . . . . . . . . . . . . 2

Starting Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Stopping Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

OPERATING THE SOD CUTTER. . . . . . . . . . . . . . . . . . . . . 3

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

BLADE ANGLE (PITCH) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

GENERAL MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . 3

TROUBLESHOOTING CHART . . . . . . . . . . . . . . . . . . . . . . 4

SOD CUTTER PARTS MANUAL . . . . . . . . . . . . . . . . . . . . . 5

Main Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power Train Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Handle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

ONE YEAR LIMITED WARRANTY . . . . . . . . . . . . . . . . . 10

Page 3

1

PRE-DELIVERY CHECK LIST

Check the following before you deliver the sod cutter to the

customer.

1. Guards and shields fastened in place.

2. Decals fastened and legible.

3. Tire pressure.

4. Gas lever on engine turned on.

5. All eight lubrication points greased.

6. 2:1 gearbox oil level.

7. Engine oil level.

8. Air cleaner.

9. Touch up scratches.

10. Chain tight.

11. Engine belt tight.

12. Levers working properly.

13. All controls.

14. Add fuel, start engine, test run.

DATE SET UP __________/__________/__________

DELIVERY CHECK LIST

Review the operators manual with the customer.

Explain the following:

1. Classen Mfg., Inc. warranty.

2. Safe operation and service.

3. How to use controls.

4. Operating the machine correctly.

5. Transporting the sod cutter.

6. Correct fuel and lubricants.

7. Daily and periodic inspections.

8. Changing oil after break-in period.

9. Servicing the sod cutter regularly and correctly.

10. Classen Mfg., Inc. parts and service.

11. Give the customer the operators manual and

encourage customer to read it.

DATE DELIVERED __________/__________/__________

SIGNATURE _______________________________________

INTRODUCTION

THANK YOU

Thank you for purchasing the Classen Model SC-20, SC-18, or

SC-12 sod cutter.

READ THIS MANUAL

Read this manual carefully to learn how to operate sod cutter

correctly. Failure to do so could result in personal injury or

equipment damage.

This manual should be considered a permanent part of your

sod cutter and should remain with it if you sell it.

WARRANTY

Refer to back page.

MEASUREMENTS

U.S. units of measure are used in this manual.

SERIAL NUMBERS

Write frame and engine serial numbers, plus model numbers in

"Owners Record" section below. Your dealer needs these

numbers when you order parts. The serial number is located on

a sticker on the center section of the frame.

DIRECTIONS

"Right Hand" and "Left Hand" sides of the sod cutter are

determined by facing the back of the sod cutter as you would

operate the machine.

OWNER’S RECORD

DATE PURCHASED _________________________________

SOD CUTTER MODEL NUMBER______________________

SOD CUTTER SERIAL NUMBER______________________

ENGINE MODEL NUMBER___________________________

ENGINE SERIAL NUMBER___________________________

Page 4

2

SAFETY

HANDLE FUEL SAFELY - AVOID FIRES

Handle gasoline with care; it is highly flammable. Use an

approved gasoline container.

Fill the fuel tank outdoors.

DO NOT fill tank completely full.

DO NOT

smoke while you fill fuel tank.

DO NOT remove gas cap if engine is running.

READ SAFETY

SIGNS

Carefully read and follow all caution stickers.

WARNING

ALL GUARDS MUST BE IN PLACE

WHILE MACHINE IS IN OPERATION

OPERATE SAFELY

Carefully read this manual and operate sod cutter correctly.

PROTECT CHILDREN

Keep children and pets out of the area where you are cutting

sod.

AVOID TIPPING

Make sure you do not get too close to sharp drop-offs to avoid

tipping sod cutter over.

OPERATE SAFELY ON SLOPES

You may cut sod any direction on slopes, however, make sure

you do this carefully. Cutting on slopes can be dangerous. To

avoid any accidents, make sure to leave yourself room to

correct the problem if one arises. Always park your sod cutter

on level ground.

PRACTICE SAFE MAINTENANCE

Keep all machine parts in good condition and fastened in

place. Fix damages immediately. Replace worn or broken

parts. Whenever you work on the sod cutter, disconnect spark

plug wire.

START ENGINE SAFELY

Make sure hands and feet are out of the way of moving parts

when starting engine.

WARNING

KEEP HANDS & FEET AWAY

FROM MOVING PARTS

ENGINE STARTING

PROCEDURES

NOTICE: There are two locations on this engine that require

oil, both the crankcase and the transmission

(gearbox). Running the engine or gearbox with a

low oil level can cause engine damage. Refer to the

engine manual for complete engine information

and recommendations.

ENGINE OIL LEVEL CHECK

1. BEFORE CHECKING ENGINE:

• make certain the engine is level

• the engine switch is in the OFF position

• the sod cutter blade is NOT engaged

• the drive wheels are disengaged.

2. Remove the filler cap/dipstick and wipe it clean.

3. Insert and remove the dipstick without screwing it

into the filler neck. Check the oil level shown on the

dipstick.

4. If the oil level is low, fill to the edge of the oil filler

hole with the recommended oil. SAE 10W-30 is

recommended for general use. Refer to engine oil

recommendations in engine manual for other

viscosities and information.

5. Screw in the filler cap/dipstick securely.

TRANSMISSION OIL LEVEL CHECK

1. Check the transmission oil level with the engine

stopped and in a level position.

2. Remove the filler cap/dipstick and wipe it clean.

3. Insert and remove the dipstick without screwing it

into the filler hole. Check the oil level shown on the

dipstick.

4. If the oil level is low, add oil to reach the upper limit

mark on the dipstick. Use the same oil that is

recommended for the engine, SAE 10W-30.

5. Screw in the filler cap/dipstick securely.

STARTING ENGINE

1. Turn fuel cock to the "open" position.

2. Turn choke on (closed).

3. Turn ignition switch to "on".

4. Move throttle lever on engine to half throttle position.

5. Pull recoil starter rope until engine starts.

6. After engine is warm, turn off choke (open).

7. Allow engine to run one minute before cutting sod.

8. Check engine rpm setting before operating. DO NOT

exceed 3600 rpm.

ST

OPPING ENGINE

1. Turn throttle to "slow" position.

2. Turn off ignition switch.

Page 5

3

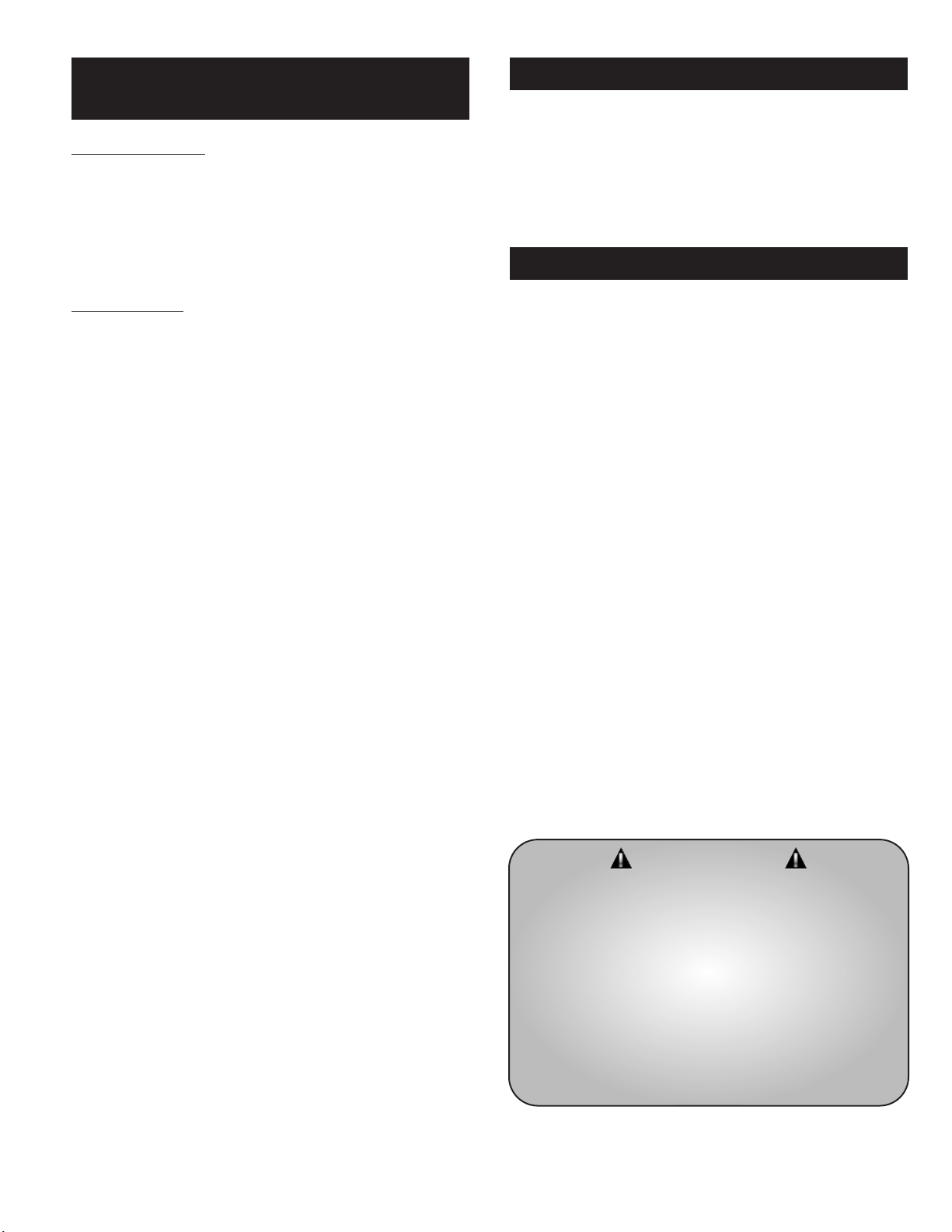

OPERATING THE

SOD CUTTER

PREPARA

TION

1. Police lawn area for obstacles and debris (i.e.

sprinklers, hoses, toys, etc.). Remove all items.

2. Make sure underground sprinkler heads and other

hidden obstacles are marked to prevent damage.

3. Mark other areas where sod cutting will be a problem

or too risky (i.e. mud, tree roots, steep hills).

OPERATING

1. Start the engine. CAUTION: To avoid injury, do not

place your feet or other body parts under the blade

while starting the engine.

2. Select the correct cutting depth desired up to 2 1/2

inches. Loosen the tee handle from the depth gauge

plate, located under the height adjustment bar, (#3 on

illustration) and put it to the correct height setting.

Tighten the tee handle.

3. Push the wheel drive handle (#5 on illustration) and

the cutter blade handle (#4 on illustration) to the "on"

position toward the engine.

4. Raise the main handle upward so the front nose of the

sod cutter rests on the ground.

5. Loosen the 1/2" handle nut (#2 on illustration) and

lower the height adjustment bar to rest on the depth

gauge. Now tighten the 1/2" handle nut securely so it

will not loosen with the vibration of the machine.

6. Go to the back of the machine and lower the handle

until the cutting blade rests on the ground. You are

now ready to cut sod.

7. Turn the throttle to the desired operating speed by

twisting the throttle control (#6 on illustration) toward

you. Maximum engine rpm is recommended for

smooth operation.

8. After cutting a short distance, stop machine by letting

the twist grip throttle control go back to its original

position. Check thickness of cut and adjust if necessary.

9. At the end of each cutting pass, lift up on the handle

bar to clear the cutting blade from the sod. Retard the

throttle control and turn machine around into the

position for the next cut.

10. When finished cutting sod, reverse steps 6 through 3,

leaving the wheel drive handle on for transportation.

BLADE ANGLE (PITCH)

Under normal operating conditions, the blade angle is slight

(blade bottom is flat). In extremely hard soil or when cutting

with a dull blade, the blade may want to ride out of the ground.

At this time, it may help to angle the blade down. A short trial

run will indicate what blade angle is best. To do this, you will

loosen the pitch adjustment bolt (#7 on illustration) and move

it slightly toward the engine, then retighten bolt and nut.

GENERAL MAINTENANCE

To keep the sod cutter in good operating condition, perform

the following:

• Keep blade sharp; a sharp blade cuts cleaner, faster and

more uniformly and places less load on the machine.

Sharpen cutting edge on bevel or top side only.

• Keep drive belt at proper tension and free of oil and

dirt at all times.

• Check engine oil level and air filter element daily.

• Check for loose bolts and connections.

• All grease fittings are pressurized type. Use a good

grade Lithium Base Grease or equivalent. Grease

eccentric arms sparingly every 4 hours of service, all

others daily. Wipe off all grease fittings before and after

each greasing (there are a total of 8 grease fittings).

• To make sure the chain on the front drive wheels is

tight, you will need to remove the chain guard to

check this. If tightening is required, loosen nuts and

bolts on the 3/4" pillow block bearings and push the

bearings toward the back of the sod cutter until chain

is tight. Make sure both bearings go back evenly to

keep jackshaft running even with the frame. After

doing this, retighten nuts and bolts on the bearing and

replace the chain guard.

• Engine (refer to Honda owner’s manual).

SAFETY WARNING

DO NOT STORE GASOLINE (FUEL)

UNNECESSARILY OVER LONG PERIODS OF

TIME. TO PREVENT POSSIBLE EXPLOSION,

STORE ONLY IN AN APPROVED "SAFE"

CONTAINER. TO PREVENT EXPLOSION OF

VAPORIZED FUEL, DO NOT STORE MACHINE

WITH FUEL IN TANK OR CARBURETOR IN AN

ENCLOSURE WITH OPEN FLAME.

(EXAMPLE: FURNACE OR WATER HEATER

PILOT LIGHT.)

Page 6

4

TROUBLESHOOTING

CHART

PROBLEM CAUSE REMEDY

Blade will not stay in ground a. Bottom of blade is rounded

off

a. Blade should be sharpened

or replaced

Belts jump off a. Wrong type of belt

b. Pulley misalignment

a. Use only the special factory

belt

b. Realign pulley

NOTES:____________________________________________________________________________________________________

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

Page 7

5

SOD CUTTER

PARTS MANUAL

SC-12/5.5 – S.N. 000372 & UP

SC-12/8.0 – S.N. 000136 & UP

SC-16/5.5 – S.N. 000104 & UP

SC-18/5.5 – S.N. 003956 & UP

SC-18/8.0 – S.N. 000413 & UP

SC-20/5.5 – S.N. 000141 & UP

SC-20/8.0 – S.N. 000164 & UP

SC-24/8.0 – S.N. 000147 & UP

Page 8

6

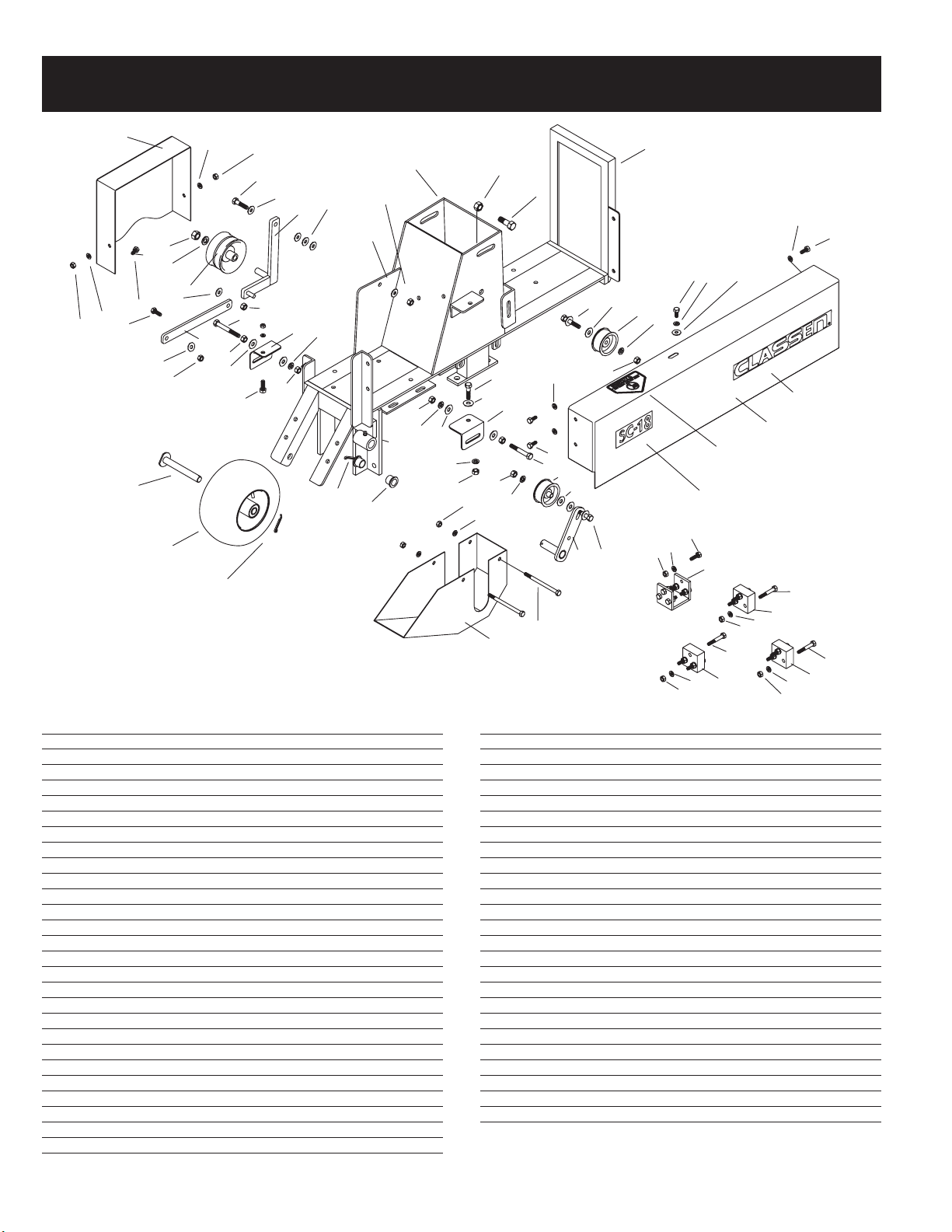

SOD CUTTER MAIN FRAME

1 C400235 1 SOD CUTTER FRAME

2 C500131 2 1/2" LOCK NUT

3 C500150 2 1/2" x 1-1/2" BOLT

4 C400232 1 SMALL GUARD

5 C400114 1 DUAL DRIVE CLUTCH ARM

6 C500101 4 5/16" NUT

7 C500115 9 5/16" LOCK WASHER

8 C500140 6 5/16" x 3/4" BOLT

9 C500146 2 3/8" x 1-1/2" BOLT

10 C500083 6 5/16" FLAT WASHER

11 C300069 1 DRIVE LINKAGE ARM

12 C100208 1 DUAL DRIVE DOUBLE IDLER PULLEY

13 C500106 1 1/2" NUT

14 C500006 1 1/2" LOCK WASHER

15 C300002 1 AXLE PIN

16 C100017 1 TIRE & WHEEL ASSEMBLY, 9x350x4

17 C500016 2 5/32" x 1-1/2" COTTER PIN

18 C400233 1 CHAIN GUARD

19 C500168 2 5/16" x 5" BOLT

20 C500041 2 3/8" LOCK NUT

21 C400234 1 LARGE GUARD

22 C500130 6 3/8" LOCK WASHER

23 C500129 8 3/8" NUT

24 C100010 2 IDLER PULLEY

25 C500042 14 3/8" FLAT WASHER

26 C500091 2 3/8" x 2" BOLT

27 C100021 2 BRASS BUSHING

28 C500001 1 GREASE FITTING, 1/4" x 28

29 C400010 1 CLUTCH ARM

30 C300134 1 L.H. BELT ADJUSTMENT CLIP

31 C500043 2 3/8" x 1" BOLT

32 C500159 1 3/8" x 3" BOLT

33 C100074 2 DECAL, "CLASSEN"

34 C100262 2 DECAL, "SC-12"

34 C100417 2 DECAL, "SC-16"

34 C100131 2 DECAL, "SC-18"

34 C100260 2 DECAL, "SC-20"

34 C100345 2 DECAL, "SC-24"

35 C100069 1 DECAL, "DANGER"

36 C100096 1 DECAL, "ALL GUARDS"

37 C100132 1 DECAL, "CUTTER BLADE"

38 C100133 1 DECAL, "SLOW/FAST"

39 C100134 1 DECAL, "WHEEL DRIVE"

40 C100106 1 DECAL, SERIAL NUMBER

41 C100073 1 LUBRICATION TAG

42 C300004 1 R.H. BELT ADJUSTMENT CLIP

43 C500154 1 3/8" x 2-1/2" BOLT

44 C400237 1 BUMPER

45 C400011 2 12" BLADE ADAPTOR

46 C500133 12 5/16" x 1" BOLT

47 C300133 2 16" BLADE ADAPTOR

48 C500142 6 5/16" x 2" BOLT

49 C300047 2 20" BLADE ADAPTOR

50 C400188 2 24" BLADE ADAPTOR

1

3

2

20

10

10

5

10

9

6

7

4

7

6

13

14

12

11

25

20

15

16

17

27

17

28

19

6

7

18

23

22

24

25

26

29

8

7

26

25

24

22

23

8

7

10

8

7

21

33

34

35

30

32

23

25

31

22

23

9

25

42

43

22

23

23

22

25

44

SC-12

SC-16

SC-20

SC-24

8

20

25

31

46

7

6

45

48

47

7

6

48

49

7

6

48

50

7

6

QTY/PER

KEY PART NO. SHEET DESCRIPTION

QTY/PER

KEY PART NO. SHEET DESCRIPTION

Page 9

7

1 C100005 1 HONDA 5.5 hp ENGINE w/DEFLECTOR

1 C100114 1 HONDA 8.0hp ENGINE w/DEFLECTOR

2 C100028 1 PULLEY w/ HUB & BOLTS, 4" x 22mm

3 C100024 1 B56 V-BELT, 5.5hp MODEL

3 C100113 1 B59 V-BELT, 8.0hp MODEL

4 C500011 1 3/16" x 1 3/4" SQUARE KEY

5 C500029 2 1/4" x 3/4" BOLT

6 C100023 1 HUB, TAPERLOCK

7 C100022 1 PULLEY, TAPERLOCK

8 C100008 1 REDUCTION BOX, and KEYS

9 C500174 8 1/2" x 1 3/4" BOLTS

10 C500042 8 3/8" FLAT WASHER

11 C200031 1 PULLEY, DUAL DRIVE 5" SPLIT, and KEY

12 C500004 1 1/4" x 1" SQUARE KEY

13 C500130 10 3/8" LOCK WASHER

14 C500129 12 3/8" NUT

15 C100026 1 6934 V-BELT

16 C100011 2 BX31 DRIVE V-BELT (ONLY 1 BELT ON SC-12)

17 C500003 4 1/4" x 7/8" HALF MOON KEY

18 C700002 2 ECCENTRIC HUB

19 C100004 4 1" PILLOW BLOCK w/COLLAR

20 C600003 1 ECCENTRIC SHAFT

21 C500034 8 1/2" FLAT WASHER

22 C500006 16 1/2" LOCK WASHER

23 C500106 16 1/2" NUT

24 C200002 1 6" PULLEY w/ 1" HUB

SOD CUTTER POWER TRAIN ASSEMBLY

QTY/PER

KEY PART NO. SHEET DESCRIPTION

QTY/PER

KEY PART NO. SHEET DESCRIPTION

25 C500181 1 1/4" x 1-1/2" SQUARE KEY

26 C100207 1 SHEAVE, DUAL DRIVE DOUBLE V-BELT

26 C100014 1 SHEAVE, SINGLE DRIVE (MODEL SC-12)

27 C500147 8 5/16" x 1-1/2" BOLT

28 C100013 2 3/4" PILLOW BLOCK w/ COLLAR

29 C500083 8 5/16" FLAT WASHER

30 C500115 8 5/16" LOCK WASHER

31 C500101 8 5/16" NUT

32 C200039 1 JACKSHAFT, w/SPROCKET & HUB

33 C100307 1 #40 CHAIN

34 C100025 1 CONNECTING LINK

35 C500158 8 1/2" x 3-1/2" BOLT

36 C700024 4 DRIVE WHEEL (2 WHEELS ON SC-12)

37 C300001 1 DRIVE SHAFT SPACER

38 C600004 1 DRIVE SHAFT

39 C500154 1 3/8" x 2-1/2" BOLT

40 C300004 1 R.H. BELT ADJUSTMENT CLIP

41 C500136 4 1/4" NUT

42 C500137 4 1/2" LOCK WASHER

43 C100027 1 THROTTLE SPRING

44 C500157 2 1/4" x 3-1/2" BOLT

45 C500146 4 3/8" x 1-1/2" BOLT

46 C200001 1 DRIVE SHAFT SPROCKET

47 C500159 1 3/8" x 3" BOLT

48 C500043 2 3/8" x 1" BOLT

49 C200001 1 L.H. BELT ADJUSTMENT CLIP

17

3

18

45

10

8

13

7

47

14

14

10

9

19

21

22

23

6

8

15

24

25

40

48

14

48

11

49

11

20

28

10

29

14

32

39

41

16

30

29

31

42

27

28

18

16

17

44

26

35

27

43

1

13

41

42

34

22

14

12

17

9

38

46

37

19

21

22

23

2

25

33

5

4

23

36

Page 10

8

SOD CUTTER HANDLE ASSEMBLY

1

2

3

4

5

29

7

8

9

10

11

12

13

6

6

15

16

17

18

19

20

21

22

23

6

24 23

23

24

27

26

25

6

4

28

29

30

49

28

4

28

29

20

6

40

QTY/PER

KEY PART NO. SHEET DESCRIPTION

1 C100018 1 L.H. HANDLE GRIP

2 C400006 1 MAIN HANDLE

3 C300068 1 HANDLE BRACE

4 C500043 6 3/8" x 1" BOLT

5 C100019 1 TWIST GRIP THROTTLE

6 C500041 9 3/8" LOCK NUT

7 C500118 2 1/4" x 1 3/4" BOLT

8 C500136 2 1/4" NUT

9 C500137 3 1/4" LOCK WASHER

10 C100007 4 RUBBER GRIP

11 C400008 2 HANDLE ENGAGEMENT

12 C500019 2 SMALL HANDLE SPRING

13 C500139 2 1/4" LOCK NUT

14 C100029 1 12" CUTTING BLADE

14 C100416 1 16" CUTTING BLADE

14 C100016 1 18" CUTTING BLADE

14 C100110 1 20" CUTTING BLADE

14 C100329 1 24" CUTTING BLADE

15 C500154 2 3/8" x 2 1/2" BOLT

16 C500042 2 3/8" FLAT WASHER

17 C400074 1 WHEEL DRIVE ADJUSTMENT ARM

18 C500025 2 3/8" FINE NUT

19 C500026 2 3/8" CLEVIS YOKE

20 C500134 2 3/8" x 1-1/4" BOLT

21 C500146 2 3/8" x 1-1/2" BOLT

22 C500133 8 5/16" x 1" BOLT

23 C500101 12 5/16" NUT

24 C500115 10 5/16" LOCK WASHER

25 C500074 2 5/16" x 1-3/4" BOLT

26 C500001 7 GREASE FITTING, 1/4" x 28

27 C400110 1 PIVOT ASSEMBLY

28 C500130 6 3/8" LOCK WASHER

29 C500129 6 3/8" NUT

30 C400007 1 CUTTING BLADE ADJUSTMENT ARM

31 C500007 1 1/2" HANDLE NUT

32 C500006 6 1/2" LOCK WASHER

33 C500034 10 1/2" FLAT WASHER

34 C400001 1 HEIGHT ADJUSTMENT BAR

35 C400002 1 PITCH ADJUSTMENT BAR

36 C300039 1 DEPTH GAUGE

37 C400036 1 1/4" THREADED T HANDLE

38 C200005 1 HEIGHT ADJUSTMENT BOLT

39 C200004 1 PITCH ADJUSTMENT BOLT

40 C500106 4 1/2" NUT

41 C500152 2 1/2" x 2-3/4" BOLT

42 C500151 2 1/2" x 3" FINE BOLT

43 C100001 12 3/4" NYLON WASHER

44 C100002 12 SEAL

45 C600001 6 STEEL SLEEVE

46 C800001 2 ECCENTRIC ARM

47 C100003 6 BEARING

48 C800002 2 BLADE ARM

49 C100006 1 THROTTLE CABLE w/ END CLAMP

50 C500088 1 1/4" FLAT WASHER

QTY/PER

KEY PART NO. SHEET DESCRIPTION

Page 11

9

4

43

D

34

31

32

33

SEE DIAGRAM A

33

35

10

38

10

32

40

22

23

24

42

SEE DIAGRAM B

41

33

32

40

39

40

37

14

9

50

36

SEE MAIN FRAME

PAGE FOR BLADE

ADAPTOR PART NUMBERS

3

4

43

44

45

46

47

26

DIAGRAM B

NOTE: When installing seals, make sure

spring side of seal is away from bearing.

48

43

44

45

47

26

44

43

DIAGRAM A

Page 12

10

ONE YEAR LIMITED WARRANTY

Effective January 1, 1994

For the period of one year from the date of purchase, CLASSEN MFG., INC. will repair or replace for the original purchaser (90

days if used for rental purposes) free of charge, any part or parts found upon the examination of our factory authorized service

station, or by the factory in Norfolk, Nebraska, to be defective in material or workmanship. All transportation charges on parts

submitted for repair or replacement under this warranty shall be borne by the purchaser.

This warranty does not include engines or engine parts, tires, batteries, or gearboxes that are covered under separate warranties

furnished by their manufacturer or supplier, nor does it include normal maintenance parts, including but not limited to, spark plugs,

points, filters, blades, and lubricants.

All service under this warranty will be furnished or performed by our factory authorized service stations.

There is no other expressed warranty. Implied warranties, including those of merchantability and fitness for a particular purpose, are

limited to one year from the date of purchase or 90 days if the product is rented and to the extent permitted by law any and all

implied warranties are excluded. The above remedy of repair and replacement of defective parts is the purchaser's exclusive remedy

for any defect, malfunction or breach of warranty. Liability for incidental or consequential damages under any and all warranties is

excluded to the extent permitted by law.

NORMAL RESPONSIBILITIES OF THE SELLER AND THE USER

1. The Distributor or Dealer is responsible for the proper assembly and preparation of the product for delivery to the end user.

2. The User is responsible for reading the Manual and Instructions.

3. The User is responsible for proper operation and maintenance as described in the manual.

4. The User is responsible for the replacement of wear items such as blades, belts, tires, batteries, etc.

5. The User is responsible for damage due to improper operation and maintenance, as well as abuse.

All claims must be received by the factory 30 days after the end of the warranty period to receive warranty consideration.

Schiller-Pfeiffer, Inc.

1028 Street Road • Southampton, PA 18966

Telephone: 1-800-366-6268

©2006 Classen, Division of Schiller-Pfeiffer, Inc. 3/06

Page 13

CORTADOR DE TEPE

MANUAL DEL

OPERADOR/PIEZAS

SC-12

SC-16

SC-18

SC-20

SC-24

Schiller-Pfeiffer, Inc.

1028 Street Road • Southampton, PA 18966

Teléfono: + (877) 596 6337

Page 14

ÍNDICE

INTRODUCCIÓN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Gracias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Lea este manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Mediciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Números de serie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Instrucciones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

REGISTRO DEL PROPIETARIO . . . . . . . . . . . . . . . . . . . . . 1

LISTA DE COMPROBACIÓN ANTERIOR A LA ENTREGA

. . . 1

LISTA DE COMPROBACIÓN DE ENTREGA. . . . . . . . . . . 1

SEGURIDAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Manipule el combustible con cuidado – Evite los

incendios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Lea los letreros de seguridad . . . . . . . . . . . . . . . . . . . . . . 2

Haga funcionar de forma segura . . . . . . . . . . . . . . . . . . . 2

Proteja a los niños . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Evite los vuelcos. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Haga funcionar de forma segura en pendientes . . . . . . . 2

Practique un mantenimiento seguro . . . . . . . . . . . . . . . . . 2

Arranque el motor de forma segura . . . . . . . . . . . . . . . . . 2

PROCEDIMIENTOS DE ARRANQUE DEL MOTOR. . . . . 2

Compruebe el nivel de aceite del motor . . . . . . . . . . . . . 2

Compruebe el nivel de aceite de la transmisión . . . . . . . 2

Arranque del motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Parada del motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CÓMO HACER FUNCIONAR EL CORTADOR DE TEPE. 3

Preparación. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ÁNGULO DE LA HOJA (INCLINACIÓN). . . . . . . . . . . . . . 3

MANTENIMIENTO GENERAL . . . . . . . . . . . . . . . . . . . . . . 3

TABLA DE LOCALIZACIÓN Y RESOLUCIÓN DE

PROBLEMAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

MANUAL DE PIEZAS DEL CORTADOR DE TEPE. . . . . . 5

Bastidor principal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Conjunto del sistema de transmisión . . . . . . . . . . . . . . . . 7

Conjunto de manillar . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

GARANTÍA LIMITADA DE UN AÑO . . . . . . . . . . . . . . . . 10

Page 15

1

LISTA DE COMPROBACIÓN ANTERIOR A LA ENTREGA

Compruebe lo siguiente antes de entregar el cortador de tepe al

cliente.

1. Protectores y pantallas sujetos en posición.

2. Calcomanías sujetas y legibles.

3. Presión de los neumáticos

4. Palanca de gasolina del motor en la posición

encendida.

5. Los ocho puntos de lubricación engrasados.

6. Nivel de aceite de la caja de engranajes 2:1

7. Nivel de aceite del motor.

8. Filtro de aire.

9. Retoque las rayaduras.

10. Cadena tensada.

11. Correa del motor tensada.

12. Palancas funcionando debidamente.

13. Todos los controles.

14. Añada combustible, arranque el motor, haga una

prueba de funcionamiento.

FECHA DE CONFIGURACIÓN _______/_______/_______

LISTA DE COMPROBACIÓN DE ENTREGA

Revise el manual del operador con el cliente.

Explique lo siguiente:

1. Garantía de Classen Mfg., Inc.

2. Operación y servicio seguros.

3. Cómo usar los controles.

4. Funcionamiento correcto de la máquina.

5. Transporte del cortador de tepe.

6. Combustible y lubricantes correctos.

7. Inspecciones diarias y periódicas.

8. Cambio de aceite después del período de rodaje.

9. Cómo efectuar el servicio del cortador de tepe de

forma regular y correcta.

10. Piezas y servicio de Classen Mfg., Inc.

11. Dé el manual del operador al cliente y anímele a que

lo lea.

FECHA DE ENTREGA __________/__________/__________

FIRMA ___________________________________________

INTRODUCCIÓN

GRACIAS

Gracias por comprar el cortador de tepe Classen modelo SC20, SC-18 o SC-12.

LEA ESTE MANUAL

Lea detenidamente este manual para aprender el

funcionamiento correcto del cortador de tepe. De no hacer

esto se pueden producir lesiones personales o daños en los

equipos.

Este manual debe considerarse parte permanente de su cortador

de tepe y debe permanecer con el mismo si lo vende.

GARANTÍA

Consulte la última página.

MEDICIONES

En este manual se usan unidades de medida de EE.UU.

NÚMEROS DE SERIE:

Escriba los números de serie del bastidor y del motor, más los

números de modelo en la sección de “Registro del

propietario”. Su distribuidor necesita estos números al pedir

piezas. El número de serie está ubicado en un adhesivo en la

sección central del bastidor.

INSTRUCCIONES

Los lados “derecho” e “izquierdo” del cortador de tepe vienen

determinados haciendo frente a la “parte trasera” de la

máquina como si estuviera haciendo funcionar máquina.

REGISTRO DEL PROPIETARIO

FECHA DE COMPRA ________________________________

N° DE MODELO DEL CORTADOR DE TEPE ____________

N° DE SERIE DEL CORTADOR DE TEPE _______________

NÚMERO DE MODELO DEL MOTOR__________________

NÚMERO DE SERIE DEL MOTOR_____________________

Page 16

2

SEGURIDAD

MANIPULE EL COMBUSTIBLE CON

CUIDADO – EVITE LOS INCENDIOS

Manipule la gasolina con cuidado, ya que es muy inflamable.

Use un recipiente de gasolina aprobado.

Llene el depósito de combustible al aire libre.

NO llene el depósito completamente.

NO fume mientras llene el depósito de combustible.

NO quite la tapa de la gasolina con el motor en

funcionamiento.

LEA LOS LETREROS DE SEGURIDAD

Lea detenidamente y siga las instrucciones de todas las

calcomanías de precaución.

HAGA FUNCIONAR DE FORMA SEGURA

Lea detenidamente este manual y haga funcionar el cortador de

tepe correctamente.

PROTEJA A LOS NIÑOS

No deje que se acerquen los niños y los animales al área donde

esté cortando tepe.

EVITE LOS VUELCOS

Asegúrese de no acercarse demasiado a los desniveles grandes

para evitar que se vuelque el cortador de tepe.

HAGA FUNCIONAR LA UNIDAD CON

SEGURIDAD EN LAS PENDIENTES

Puede cortar tepe en cualquier dirección en las pendientes, no

obstante, asegúrese de hacerlo con cuidado. El corte en

pendientes puede ser peligroso. Para evitar accidentes,

asegúrese de dejarse sitio para corregir el problema en caso de

que surja un problema. Estacione siempre el cortador de tepe

sobre un terreno horizontal.

PRACTIQUE EL MANTENIMIENTO SEGURO

Mantenga todas las piezas de la máquina en buenas

condiciones y sujetas en posición. Arregle los daños de

inmediato. Reemplace las piezas desgastadas o rotas. Siempre

que trabaje en el cortador de tepe, desconecte el cable de la

bujía.

ARRANQUE EL MOTOR DE FORMA

SEGURA

Asegúrese de no acercar las manos y los pies a las piezas

móviles al arrancar el motor.

PROCEDIMIENTOS DE

ARRANQUE DEL MOTOR

AVISO: Hay dos lugares en este motor que requieren aceite: el

cárter y la transmisión (caja de engranajes).El

funcionamiento del motor o de la caja de engranajes con

un bajo nivel de aceite puede causar daños en el motor.

Consulte el manual del motor para obtener información

completa y recomendaciones del motor.

COMPRUEBE EL NIVEL DE

ACEITE DEL

MOTOR

1. asegúrese de que el motor esté horizontal

• el interruptor del motor está en la posición APAGADA

• la hoja del cortador de tepe NO esté conectada

• las ruedas de impulsión estén desconectadas.

2. Quite la tapa del tubo de llenado/varilla indicadora de

nivel y límpiela.

3. Introduzca y saque la varilla indicadora de nivel sin

atornillarla en el cuello del tubo de llenado. Compruebe

el nivel de aceite mostrado en la varilla indicadora.

4. Si el nivel de aceite es bajo, llene hasta el borde del

agujero de llenado de aceite con el aceite recomendado.

Se recomienda aceite SAE 10W-30 para uso general.

Consulte las recomendaciones de aceite del motor en el

manual del motor para averiguar otras viscosidades e

información.

5. Atornille bien la tapa del tubo de llenado/varilla

indicadora de nivel.

COMPRUEBE EL NIVEL DE ACEITE DE LA

TRANSMISIÓN

1. Compruebe el nivel de aceite de la transmisión con el

motor parado y en posición horizontal.

2. Quite la tapa del tubo de llenado/varilla indicadora de

nivel y límpiela.

3. Introduzca y saque la varilla indicadora de nivel sin

atornillarla en el agujero del tubo de llenado. Compruebe

el nivel de aceite mostrado en la varilla indicadora.

4. Si el nivel de aceite es bajo, eche aceite hasta alcanzar la

marca del límite superior en la varilla indicadora de

nivel. Use el mismo aceite que se recomienda para el

motor SAE 10W-30.

5. Atornille bien la tapa del tubo de llenado/varilla

indicadora de nivel.

ARRANQUE DEL MOTOR

1. Gire la llave de paso de combustible a la posición

“abierta”.

2. Active el estrangulador (cerrado).

3. Ponga el interruptor de arranque en “encendido”.

4. Mueva la palanca del acelerador del motor a la posición

semiabierta.

5. Tire de la cuerda del motor de arranque hasta que

arranque el motor.

6. Desactive el estrangulador (abierto) después de que se

haya calentado el motor.

7. Deje que funcione el motor durante un minuto antes de

empezar a cortar tepe.

8. Compruebe el ajuste de las rpm del motor antes de

hacerlo funcionar. NO supere las 3600 rpm.

P

ARADA DEL MOTOR

1. Gire el acelerador a la posición “lenta”.

2. Ponga el interruptor de arranque en apagado.

ADVERTENCIA

LOS PROTECTORES DEBEN ESTAR EN POSICIÓN

MIENTRAS LA MÁQUINA ESTÉ EN

FUNCIONAMIENTO

ADVERTENCIA

NO ACERQUE LAS MANOS Y LOS PIES A LAS

PIEZAS MÓVILES

Page 17

3

OPERACIÓN DEL

CORTADOR DE TEPE

PREPARACIÓN

1. Observe el área del césped para ver si hay obstáculos

y objetos sueltos (por ejemplo, aspersores, mangueras,

juguetes, etc). Quite todos los componentes.

2. Asegúrese de que las cabezas de los aspersores

subterráneos y otros obstáculos ocultos estén

marcados para impedir daños.

3. Marque otras áreas en que el corte de tepe pueda ser

un problema o demasiado arriesgado (por ejemplo,

barro, raíces de árboles, cuestas inclinadas).

OPERACIÓN

1. Arranque el motor. PRECAUCIÓN: Para evitar

lesiones, no ponga los pies ni ninguna otra parte del

cuerpo debajo de las hojas al arrancar el motor.

2. Seleccione la profundidad de corte correcta deseada

hasta 2 1/2”. Afloje el asa en te de la placa del calibre

de profundidad, ubicada debajo de la barra de ajuste

de altura, (N° 3 de la ilustración) y póngalo en el

ajuste de altura correcto. Apriete el asa en T.

3. Empuje el manillar de impulsión de las ruedas (N° 5

de la ilustración) y el manillar de la hoja de corte (N°

4 de la ilustración) a la posición de “encendido”,

hacia el motor.

4. Suba el manillar principal de modo que la punta

delantera del cortador de tepe quede apoyada sobre el

terreno.

5. Afloje la tuerca del manillar de 1/2” (N° 2 en la

ilustración) y baje la barra de ajuste de altura para que

se apoye en el calibre de profundidad. Apriete bien

ahora la tuerca del manillar de 1/2” de modo que no

se afloje con las vibraciones de la máquina.

6. Vaya a la parte trasera de la máquina y baje el

manillar hasta que la hoja de corte quede apoyada en

el terreno. Ahora estará listo para cortar tepe.

7. Ponga el acelerador a la velocidad de operación

deseada girando el control del acelerador (N° 6 de la

ilustración) hacia usted. Se recomiendan unas rpm del

motor máximas para lograr una operación uniforme.

8. Después de cortar una pequeña distancia, pare la

máquina dejando que el control de giro del acelerador

vuelva a su posición original. Compruebe el espesor

del corte y ajústelo si es necesario.

9. Al final de cada pasada de corte, levante la barra del

manillar para sacar la hoja de corte del tepe. Retrase

el control del acelerador y dé la vuelta a la máquina

para colocarla para el próximo corte.

10. Cuando haya terminado de cortar el tepe, invierta los

pasos 6 a 3, dejando el manillar de impulsión de las

ruedas en la posición de encendido para el transporte.

ÁNGULO DE LA HOJA (INCLINACIÓN)

En condiciones de operación normales, el ángulo de la hoja es

pequeño (la parte inferior de la hoja es plana). En suelos muy

duros o al cortar con una hoja sin afilar, es posible que la hoja

trate de salirse del terreno. En este momento, tal vez convenga

inclinar la hoja hacia abajo. Tras efectuar una prueba corta se

sabrá cuál es el mejor ángulo de la hoja. Para hacer esto, debe

aflojar el perno de ajuste de inclinación (N° 7 de la ilustración)

y moverlo ligeramente hacia al motor, y después volver a

apretar el perno y la tuerca.

MANTENIMIENTO GENERAL

Realice lo siguiente para mantener el cortador de tepe en

buenas condiciones de operación:

• Mantenga la hoja afilada; una hoja afilada produce

cortes más limpios, más rápidos y de manera más

uniforme y somete a la máquina a menos carga. Afile

la cuchilla por el lado biselado o lado superior

solamente.

• Mantenga la correa de impulsión a la tensión

adecuada y sin aceite ni suciedad en todo momento.

• Compruebe a diario el nivel de aceite del motor y el

elemento del filtro de aire.

• Compruebe si hay pernos y conexiones sueltos.

• Todas las graseras son del tipo a presión. Use una

buena grasa a base de litio o equivalente. Engrase

ligeramente los brazos excéntricos cada 4 horas de

servicio y los demás a diario. Limpie las graseras

antes y después de engrasarlas (hay un total de 8

graseras).

• Para asegurarse de que esté ajustada la cadena de las

ruedas de impulsión delanteras, tendrá que quitar el

protector de la cadena para comprobarlo. Si es

necesario tensar, afloje las tuercas y los pernos de las

chumaceras de 3/4” y empuje éstas hacia la parte

trasera del cortador de tepe hasta que se tense la

cadena. Asegúrese de que ambas chumaceras lleguen

hasta el fondo por igual para que el eje intermedio

funcione de modo uniforme con el bastidor. Después

de hacer esto, vuelva a apretar las tuercas y los pernos

en la chumacera y vuelva a colocar el protector de la

cadena.

• Motor (consulte el manual del propietario de Honda).

ADVERTENCIA DE SEGURIDAD

NO GUARDE LA GASOLINA (COMBUSTIBLE) DE

FORMA INNECESARIA DURANTE PERÍODOS

LARGOS PARA IMPEDIR UNA POSIBLE

EXPLOSIÓN, GUARDE SOLAMENTE EN UN

RECIPIENTE APROBADO “SEGURO”. PARA

IMPEDIR LA EXPLOSIÓN DE COMBUSTIBLE

VAPORIZADO, NO GUARDE LA MÁQUINA CON

COMBUSTIBLE EN EL DEPÓSITO O EN EL

CARBURADOR EN UN RECINTO CON UNA

LLAMA ABIERTA. (EJEMPLO: LUZ PILOTO DE

UNA CALDERA O UN CALENTADOR DE AGUA).

Page 18

4

PROBLEMA CAUSA SOLUCIÓN

La hoja no permanece en el

terreno

a. La parte inferior de la hoja

está redondeada

a. La hoja debe afilarse o

reemplazarse

Las correas saltan y se salen a. Tipo de correa equivocado

b. Polea desalineada

a. Use solamente la correa de

fábrica especial

b. Vuelva a alinear la polea

NOTAS:____________________________________________________________________________________________________

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

Control de giro del acelerador

Manillar de la hoja de corte

(lado derecho)

Manillar de impulsión de las

ruedas (lado izquierdo)

Tuerca del manillar de 1/2”

Perno de ajuste de altura

Barra de ajuste de altura

Perno de ajuste de inclinación

CUADRO DE LOCALIZACIÓN Y RESOLUCIÓN

DE PROBLEMAS

Page 19

5

CORTADOR DE TEPE

MANUAL DE PIEZAS

SC-12/5.5 – N/S 000372 y sig.

SC-12/8.0 – N/S 000136 y sig.

SC-16/5.5 – N/S 000104 y sig.

SC-18/5.5 – N/S 003956 y sig.

SC-18/8.0 – N/S 000413 y sig.

SC-20/5.5 – N/S 000141 y sig.

SC-20/8.0 – N/S 000164 y sig.

SC-24/8.0 – N/S 000147 y sig.

Page 20

6

BASTIDOR PRINCIPAL EL CORTADOR DE TEPE

1 C400235 1 BASTIDOR DEL CORTADOR DE TEPE

2 C500131 2 TUERCA DE TRABA DE 1/2”

3 C500150 2 PERNO DE 1/2” x 1 1/2”

4 C400232 1 PROTECTOR PEQUEÑO

5 C400114 1

BRAZO DEL EMBRAGUE DE IMPULSIÓN DOBLE

6 C500101 4 TUERCA DE 5/16”

7 C500115 9 ARANDELA DE TRABA DE 5/16”

8 C500140 6 PERNO DE 5/16” x 3/4”

9 C500146 2 PERNO DE 3/8” x 1 1/2”

10 C500083 6 ARANDELA PLANA DE 5/16”

11 C300069 1 BRAZO DE ARTICULACIÓN DE IMPULSIÓN

12 C100208 1 POLEA LOCA DOBLE DE IMPULSIÓN DOBLE

13 C500106 1 TUERCA DE 1/2”

14 C500006 1 ARANDELA DE TRABA DE 1/2”

15 C300002 1 PASADOR DE EJE

16 C100017 1

CONJUNTO DE NEUMÁTICO Y RUEDA DE 9 x 350 x 4

17 C500016 2 PASADOR DE ALETA DE 5/32” x 1 1/2”

18 C400233 1 PROTECTOR DE CADENA

19 C500168 2 PERNO DE 5/16” x 5”

20 C500041 2 TUERCA DE TRABA DE 3/8”

21 C400234 1 PROTECTOR GRANDE

22 C500130 6 ARANDELA DE TRABA DE 3/8”

23 C500129 8 TUERCA DE 3/8”

24 C100010 2 POLEA LOCA

25 C500042 14 ARANDELA PLANA DE 3/8”

26 C500091 2 PERNO DE 3/8” x 2”

27 C100021 2 MANGUITO DE LATÓN

28 C500001 1 GRASERA DE 1/4” x 28

29 C400010 1 BRAZO DEL EMBRAGUE

30 C300134 1

PRESILLA DE AJUSTE DE LA CORREA IZQUIERDA

31 C500043 2 PERNO DE 3/8” x 1”

32 C500159 1 PERNO DE 3/8” x 3”

33 C100074 2 CALCOMANÍA “CLASSEN”

34 C100262 2 CALCOMANÍA “SC-12”

34 C100417 2 CALCOMANÍA “SC-16”

34 C100131 2 CALCOMANÍA “SC-18”

34 C100260 2 CALCOMANÍA “SC-20”

34 C100345 2 CALCOMANÍA “SC-24”

35 C100069 1 CALCOMANÍA DE “PELIGRO”

36 C100096 1

CALCOMANÍA DE “TODOS LOS PROTECTORES”

37 C100132 1 CALCOMANÍA “HOJA DE CORTADOR”

38 C100133 1 CALCOMANÍA “LENTO/RÁPIDO”

39 C100134 1 CALCOMANÍA “RUEDA DE IMPULSIÓN”

40 C100106 1 CALCOMANÍA DE “NÚMERO DE SERIE”

41 C100073 1 ETIQUETA DE LUBRICACIÓN

42 C300004 1

PRESILLA DE AJUSTE DE LA CORREA DERECHA

43 C500154 1 PERNO DE 3/8” x 2 1/2”

44 C400237 1 TOPE

45 C400011 2 ADAPTADOR DE HOJA DE 12”

46 C500133 12 PERNO DE 5/16” x 1”

47 C300133 2 ADAPTADOR DE HOJA DE 16”

48 C500142 6 PERNO DE 5/16” x 2”

49 C300047 2 ADAPTADOR DE HOJA DE 20”

50 C400188 2 ADAPTADOR DE HOJA DE 24”

1

3

2

20

10

10

5

10

9

6

7

4

7

6

13

14

12

11

25

20

15

16

17

27

17

28

19

6

7

18

23

22

24

25

26

29

8

7

26

25

24

22

23

8

7

10

8

7

21

33

34

35

30

32

23

25

31

22

23

9

25

42

43

22

23

23

22

25

44

SC-12

SC-16

SC-20

SC-24

8

20

25

31

46

7

6

45

48

47

7

6

48

49

7

6

48

50

7

6

CADA./POR

CLAVE N° DE PIEZA.

HOJA DESCRIPCIÓN

CADA./POR

CLAVE N° DE PIEZA.

HOJA DESCRIPCIÓN

Page 21

7

1 C100005 1 MOTOR HONDA DE 5,5 HP CON DEFLECTOR

1 C100114 1 MOTOR HONDA DE 8,0 HP CON DEFLECTOR

2 C100028 1 POLEA CON CUBO Y PERNOS DE 4” x 22 mm

3 C100024 1 CORREA TRAPECIAL B56 MODELO DE 5,5 HP

3 C100113 1 CORREA TRAPECIAL B59 MODELO DE 8,0 HP

4 C500011 1 CHAVETA CUADRADA DE 3/16” x 1 3/4”

5 C500029 2 PERNO DE 1/4” x 3/4”

6 C100023 1 CUBO TAPERLOCK

7 C100022 1 POLEA TAPERLOCK

8 C100008 1 CAJA DE REDUCCIÓN Y CHAVETAS

9 C500174 8 PERNOS DE 1/2” x 1 3/4”

10 C500042 8 ARANDELA PLANA DE 3/8”

11 C200031 1

POLEA DE IMPULSIÓN DOBLE DE 5” DIVIDIDA Y CHAVETA

12 C500004 1 CHAVETA CUADRADA DE 1/4” X 1”

13 C500130 10 ARANDELA DE TRABA DE 3/8”

14 C500129 12 TUERCA DE 3/8”

15 C100026 1 CORREA TRAPECIAL 6934

16 C100011 2

CORREA TRAPECIAL BX31 (SOLAMENTE 1 CORREA EN SC-12)

17 C500003 4 CHAVETA DE MEDIA LUNA DE 1/4” x 7/8”

18 C700002 2 CUBO EXCÉNTRICO

19 C100004 4 CHUMACERA DE 1” CON COLLAR

20 C600003 1 EJE EXCÉNTRICO

21 C500034 8 ARANDELA PLANA DE 1/2”

22 C500006 16 ARANDELA DE TRABA DE 1/2”

23 C500106 16 TUERCA DE 1/2”

24 C200002 1 POLEA DE 6” CON CUBO DE 1”

CONJUNTO DEL TREN DE FUERZA DEL CORTADOR DE TEPE

CADA./POR

CLAVE N° DE PIEZA.

HOJA DESCRIPCIÓN

CADA./POR

CLAVE N° DE PIEZA.

HOJA DESCRIPCIÓN

25 C500181 1 CHAVETA CUADRADA DE 1/4” x 1 1/2”

26 C100207 1

ROLDANA DE CORREA TRAPECIAL DOBLE DE IMPULSIÓN DE DOBLE

26 C100014 1

ROLDANA DE IMPULSIÓN INDIVIDUAL (MODELO SC-12)

27 C500147 8 PERNO DE 5/16” x 1 1/2”

28 C100013 2 CHUMACERA DE 3/4” CON COLLAR

29 C500083 8 ARANDELA PLANA DE 5/16”

30 C500115 8 ARANDELA DE TRABA DE 5/16”

31 C500101 8 TUERCA DE 5/16”

32 C200039 1

EJE INTERMEDIO CON RUEDA DENTADA Y CUBO

33 C100307 1 CADENA N° 40

34 C100025 1 ESLABÓN

35 C500158 8 PERNO DE 1/2” x 3 1/2”

36 C700024 4 RUEDA DE IMPULSIÓN (2 RUEDAS EN SC-12)

37 C300001 1 ESPACIADOR DEL EJE DE IMPULSIÓN

38 C600004 1 EJE DE IMPULSIÓN

39 C500154 1 PERNO DE 3/8” x 2 1/2”

40 C300004 1

PRESILLA DE AJUSTE DE LA CORREA DERECHA

41 C500136 4 TUERCA DE 1/4”

42 C500137 4 ARANDELA DE TRABA DE 1/2”

43 C100027 1 RESORTE DEL ACELERADOR

44 C500157 2 PERNO DE 1/4” x 3 1/2”

45 C500146 4 PERNO DE 3/8” x 1 1/2”

46 C200001 1 RUEDA DENTADA DEL EJE DE IMPULSIÓN

47 C500159 1 PERNO DE 3/8” x 3”

48 C500043 2 PERNO DE 3/8” x 1”

49 C200001 1

PRESILLA DE AJUSTE DE LA CORREA IZQUIERDA

17

3

18

45

10

8

13

7

47

14

14

10

9

19

21

22

23

6

8

15

24

25

40

48

14

48

11

49

11

20

28

10

29

14

32

39

41

16

30

29

31

42

27

28

18

16

17

44

26

35

27

43

1

13

41

42

34

22

14

12

17

9

38

46

37

19

21

22

23

2

25

33

5

4

23

36

Page 22

8

CONJUNTO DE EMPUÑADURA DEL CORTADOR DE TEPE

1

2

3

4

5

29

7

8

9

10

11

12

13

6

6

15

16

17

18

19

20

21

22

23

6

24 23

23

24

27

26

25

6

4

28

29

30

49

28

4

28

29

20

6

40

CADA./POR

CLAVE N° DE PIEZA.

HOJA DESCRIPCIÓN

1 C100018 1 ASIDERO DEL MANILLAR IZQUIERDO

2 C400006 1 MANILLAR PRINCIPAL

3 C300068 1 TIRANTE DEL MANILLAR

4 C500043 6 PERNO DE 3/8” x 1”

5 C100019 1 ACELERADOR DE GIRO

6 C500041 9 TUERCA DE TRABA DE 3/8”

7 C500118 2 PERNO DE 1/4” x 1 3/4”

8 C500136 2 TUERCA DE 1/4”

9 C500137 3 ARANDELA DE TRABA DE 1/4”

10 C100007 4 ASIDERO DE CAUCHO

11 C400008 2 ACCIONADOR DEL MANILLAR

12 C500019 2 RESORTE DE MANILLAR PEQUEÑO

13 C500139 2 TUERCA DE TRABA DE 1/4”

14 C100029 1 HOJA DE CORTE DE 12”

14 C100416 1 HOJA DE CORTE DE 16”

14 C100016 1 HOJA DE CORTE DE 18”

14 C100110 1 HOJA DE CORTE DE 20”

14 C100329 1 HOJA DE CORTE DE 24”

15 C500154 2 PERNO DE 3/8” x 2 1/2”

16 C500042 2 ARANDELA PLANA DE 3/8”

17 C400074 1

BRAZO DE AJUSTE DEL MANDO DE LA RUEDA

18 C500025 2 TUERCA FINA DE 3/8”

19 C500026 2 HORQUILLA DE 3/8”

20 C500134 2 PERNO DE 3/8” x 1 1/4”

21 C500146 2 PERNO DE 3/8” x 1 1/2”

22 C500133 8 PERNO DE 5/16” x 1”

23 C500101 12 TUERCA DE 5/16”

24 C500115 10 ARANDELA DE TRABA DE 5/16”

25 C500074 2 PERNO DE 5/16” x 1 3/4”

26 C500001 7 GRASERA DE 1/4” x 28

27 C400110 1 CONJUNTO DE PIVOTE

28 C500130 6 ARANDELA DE TRABA DE 3/8”

29 C500129 6 TUERCA DE 3/8”

30 C400007 1 BRAZO DE AJUSTE DE LA HOJA DE CORTE

31 C500007 1 TUERCA DE MANILLAR DE 1/2”

32 C500006 6 ARANDELA DE TRABA DE 1/2”

33 C500034 10 ARANDELA PLANA DE 1/2”

34 C400001 1 BARRA DE AJUSTE DE ALTURA

35 C400002 1 BARRA DE AJUSTE DE INCLINACIÓN

36 C300039 1 CALIBRE DE PROFUNDIDAD

37 C400036 1 ASA EN T ROSCADA DE 1/4”

38 C200005 1 PERNO DE AJUSTE DE ALTURA

39 C200004 1 PERNO DE AJUSTE DE INCLINACIÓN

40 C500106 4 TUERCA DE 1/2”

41 C500152 2 PERNO DE 1/2” x 2 3/4”

42 C500151 2 PERNO FINO DE 1/2” x 3”

43 C100001 12 ARANDELA DE NILÓN DE ?”

44 C100002 12 SELLO

45 C600001 6 MANGUITO DE ACERO

46 C800001 2 BRAZO EXCÉNTRICO

47 C100003 6 COJINETE

48 C800002 2 BRAZO DE LA HOJA

49 C100006 1

CABLE DEL ACELERADOR CON ABRAZADERA DE EXTREMO

50 C500088 1 ARANDELA PLANA DE 1/4”

CADA./POR

CLAVE N° DE PIEZA.

HOJA DESCRIPCIÓN

Page 23

9

4

43

D

34

31

32

33

SEE DIAGRAM A

33

35

10

38

10

32

40

22

23

24

42

SEE DIAGRAM B

41

33

32

40

39

40

37

14

9

50

36

SEE MAIN FRAME

PAGE FOR BLADE

ADAPTOR PART NUMBERS

3

4

43

44

45

46

47

26

DIAGRAM B

NOTE: When installing seals, make sure

spring side of seal is away from bearing.

48

43

44

45

47

26

44

43

DIAGRAM A

VEA EL DIAGRAMA B

VEA EL DIAGRAMA A

CONSULTE EN LA PÁGINA DEL BASTIDOR

PRINCIPAL LOS NÚMEROS DE PIEZA DEL

ADAPTADOR DE LA HOJA

DIAGRAMA A

DIAGRAMA B

NOTA: Al instalar sellos, asegúrese de que el

lado del resorte del sello apunte en sentido

contrario al cojinete.

Page 24

10

UN AÑO DE GARANTÍA LIMITADA

En vigor el 1 de enero de 1994

Durante el período de un año contado a partir de la fecha de compra, CLASSEB MFG., INC. reparará o reemplazará al comprador

original (90 días si se alquila) de forma gratuita, cualquier pieza o piezas que después de examinarlas en nuestra estación de servicio

autorizada de nuestra fábrica, o en la fábrica de Norfolk, Nebraska, tenga defectos de materiales o fabricación. Los costos de

transporte de las piezas enviadas para su reparación o reemplazo, según los términos de esta garantía, deberán correr a costa del

comprador.

Esta garantía no incluye los motores o piezas de motor, neumáticos, baterías o cajas de engranajes cubiertos por garantías separadas

suministradas por su fabricante o proveedor, ni incluye las piezas de mantenimiento normales, incluidas bujías, puntas, filtros, hojas

y lubricantes, pero sin limitarse a éstas.

Todos el servicio según esta garantía será suministrado o efectuado por nuestras estaciones de servicio autorizadas de fábrica.

No existe ninguna otra garantía explícita. Las garantías implícitas, incluidas las de comerciabilidad e idoneidad para un cierto fin,

están limitadas a un año contado a partir de la fecha de compra o 90 días si se alquila el producto y en la medida que lo permita la

ley, se excluyen todas y cada una de las garantías implícitas. El remedio anterior de reparación y reemplazo de piezas defectuosas es

el remedio exclusivo por cualquier defecto, funcionamiento defectuoso o violación de garantía. En la medida que lo permita la ley,

se excluye la responsabilidad por daños emergentes o concomitantes según cualquiera y todas las garantías.

RESPONSABILIDADES NORMALES DEL VENDEDOR Y DEL USUARIO

1. El distribuidor o el concesionario es responsable del montaje y de la preparación apropiados del producto para su entrega al

usuario final.

2. El usuario es responsable de leer el manual de instrucciones.

3. El usuario es responsable de la operación y el mantenimiento apropiados según se describe en el manual

4. El usuario es responsable de reemplazar los artículos que se desgasten como hojas, correas, neumáticos, baterías, etc.

5. El usuario es responsable de los daños debidos al funcionamiento y al mantenimiento indebidos, así como a los abusos.

Todas las reclamaciones deben ser recibidas por la fábrica 30 días después del final del período de garantía para que sean

consideradas según la garantía.

Schiller-Pfeiffer, Inc.

1028 Street Road • Southampton, PA 18966

Teléfono: + (877) 596 6337

©2006 Classen, una División de Schiller-Pfeiffer, Inc. 3/06

Loading...

Loading...