Page 1

SA-25

“STAND-AER™”

STAND ON AERATOR

(S.N. 173 and Up)

A Division of Schiller-Pfeiffer, Inc.

www.classen-mfg.com

1028 Street Road • Southampton, PA 18966

Toll Free: 1-877-596-6337 • Fax: 1-215-357-8045

Operator’s Manual and Parts List

Page 2

2

TABLE OF CONTENTS

SAFETY INSTRUCTION MANUAL . . . . . . . . . . . . . . . . . . 2

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

GENERAL SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . 2

OWNER/USER NOTICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

USER EXPERIENCE AND QUALIFICATIONS . . . . . . . . . 2

USER CLOTHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INSPECT AERATOR BEFORE EACH USE. . . . . . . . . . . . . 3

SCHEDULED AERATOR MAINTENANCE . . . . . . . . . . . . 3

WORK AREA CONDITIONS AND INSPECTION . . . . . . . 3

INITIAL OPERATING AND INSPECTION . . . . . . . . . . . . . 3

OPERATING ON SLOPES. . . . . . . . . . . . . . . . . . . . . . . . . . . 4

REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

OPERATION IN REVERSE . . . . . . . . . . . . . . . . . . . . . . . . . . 4

OPERATION IN FORWARD DIRECTION. . . . . . . . . . . . . . 4

OPERATING DURING ZERO-RADIUS TURNS. . . . . . . . . 4

FUEL SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

HYDRAULIC SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PRE-DELIVERY SERVICE OF AERATOR . . . . . . . . . . . . . 4

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . 5

INSPECT AERATOR BEFORE EACH USE. . . . . . . . . . . . . 5

HOW TO START AERATOR . . . . . . . . . . . . . . . . . . . . . . . . . 5

UNUSUAL NOISES OR IRREGULAR OPERATION . . . . . 5

HOW TO DRIVE AERATOR . . . . . . . . . . . . . . . . . . . . . . . . . 5

SERVICE AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 5

TIRE MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

BLEEDING AIR FROM THE HYDRAULIC SYSTEM . . . . 5

DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

MAIN FRAME ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . 6

MAIN FRAME PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . 7

POWER TRAIN ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . 8

POWER TRAIN PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . 9

HANDLE AND CONTROL ASSEMBLY . . . . . . . . . . . . . . 10

HANDLE AND CONTROL PARTS LIST . . . . . . . . . . . . . . 11

TINE FRAME ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . 12

HOSES AND ADAPTERS DESCRIPTION. . . . . . . . . . . . . 13

HYDRAULIC HOSES DESCRIPTION . . . . . . . . . . . . . . . . 14

TWO YEAR LIMITED WARRANTY . . . . . . . . . . . . . . . . . 16

SAFETY INSTRUCTION

MANUAL

Introduction

This aerator is built to the highest standards in the industry.

However, carelessness or operator error may result in serious

injury or death. Accident and hazard prevention are dependent

upon the awareness, concern, wisdom, and proper training of

the personnel involved in the operation, transport, maintenance,

and storage of the equipment. Make sure every operator is

properly trained and thoroughly familiar with all of the

information in this manual before operating the equipment.

General Safety Instructions

The Classen STAND-AER™ is designed with your safety in

mind. It has the following safety systems that you should be

familiar with:

• The warning decals on the aerator.

• You must be standing on the foot platform while the

engine is running before the machine will move.

• If you get off of the foot platform while the engine

is running, the machine will become idle.

• Letting go of the control arms will stop the

wheels instantly.

• Belt and chain guards must be in place.

• Rear wheels are provided to minimize the possibility of

tipping back and over on the operator. These should be in

the downward positions at all times for the exception of

loading unit into a vehicle or trailer. (Loading should

always be in reverse).

Owner/User Notice

The owner’s/user obligation is to instruct themselves and all

potential users in the safe operation of the equipment and be

sure they read and follow the instructions in this manual and

other material provided by Classen MFG., Inc. before using or

allowing others to operate the equipment. Do not use this unit

unless you carefully read, understand and follow the assembly,

installation, and safety instructions contained in the manual

and the warning decals provided on the unit. Do not let other

person’s use this unit unless you make sure they carefully read,

understand and follow these instructions. Never allow children

to operate or play on the unit.

User Experience & Qualifications

This product is designed for use by physically fit and

experienced persons. DO NOT allow children to operate this

unit. Do not allow adults to operate the aerator without the

proper instruction mentioned above. Never allow passengers

on the aerator.

Page 3

3

User Clothing

DO NOT operate the aerator while wearing sandals, tennis

shoes, or shorts. Always wear long non-baggy pants. Wear

high-top leather work boots with thick, textured tread at all

times. Hard or smooth soled shoes are too slippery for a good

footing on aerator platform. NEVER wear loose fitting

clothing which could get caught in the moving parts. Wearing

safety glasses, ear protection and safety shoes is advisable.

Inspect Aerator Before Each Use

DO NOT use the aerator if any parts are not maintained in

good operating condition. Examine the moving parts prior to

each use. Look for excessive wear, bald or worn tires, cracks in

parts, loose or missing bolts, cotter, lynch, or hair pins and

replace before operating the aerator. Make sure all safety

equipment provided with the aerator is in good operating order,

including all the warning decals. Inspect the rear wheels and

their respective bolts for tightness and proper operation. Ensure

that all parts of the hand-operated transmission control system

are tight and secure. This is to reduce the possibility that the

aerator could have a loss of control or safety.

Scheduled Aerator Maintenance

Replace worn rear drive tires with less than 3/32” of any tread

groove left. Grease all fittings (12 total) daily. Each grease

fitting should be filled until full.

• 4 fitting on the swing arm.

• 1 fitting on each of the front wheels.

• 1 fitting on the left and right control handles.

• 1 fitting on each tine disc hub.

• 1 fitting on each female rod end.

Check roller chains for wear. Apply a light coat of No. 30 oil

or penetrating chain lubricant to keep the chains in proper

running order.

Check roller chain(s) for tightness. Follow these steps:

Model SA-25

1. Disconnect spark plug.

2. Take off pulley guard(s).

3. Loosen nuts by turning counter clockwise

4. Retighten nut by turning clockwise against lock washer.

5. Replace pulley guard, nuts and lock washers and

retighten nuts.

DO NOT change the engine governor settings or over-rev the

engine contrary to engine manufacturer specifications. Keep

the Classen aerator in good operating condition, and keep

safety devices and shields in place and in working condition.

Keep all nuts and bolts tight to be sure the equipment is in safe

working condition. Replace worn tines. Make sure the engine

is turned off when doing ANY maintenance on unit. The

aerator should not be used after the tine strikes a foreign

object, until conducting a thorough inspection and any damage

is repaired. When changing tines, pull out and remove the 3/8”

snap lock pin (located in the upper-center of the foot platform

mount), and raise platform. Once platform is raised and

secured in the up position, you have access to the tines.

When you are done maintaining the tines, lower the platform,

and re-secure the 3/8” snap lock pin.

Work Area Conditions and Inspection

Prior to operating the unit carefully inspect all lawn/ground

areas where you plan to use the aerator for hidden, hard-to-see

objects or uneven ground that may be hidden in the grass.

Clear the work area of moveable objects such as wire, rocks,

sprinkler heads, glass, etc. that might damage the aerator or be

thrown. Remove, if possible, or mark the location of all

immovable objects or irregular areas and be sure not to hit

them with any part of the aerator. Obstacles such as holes,

abrupt changes in the ground contour, tree trunks, stumps or

roots, stub pipes protruding from the ground, paving edges,

etc. in the path of operation can abruptly turn or stop the

aerator. This could throw you off the aerator or into and

possibly over the control handle causing serious injury or

death. The faster you are moving the more potential there is

for injury. Aerate only in daylight or in good artificial light.

Keep away from drop-offs, the edges of ponds, streams, pools,

etc. especially at the bottom of slopes. Do not aerate when

children or others are around. Never operate the aerator in an

enclosed area without good, approved ventilation. Exhaust

fumes are dangerous.

Initial Operating Safety Guidelines

• Read and understand the warning decals on the unit.

• Keep a firm hold on the stationary handle at all times.

• Keep both feet on foot platform at all times.

• Know the controls and how to stop quickly.

• Before attempting to start engine, follow all

starting instructions.

• Look behind before backing up.

• Before leaving the operator’s position for any momentary

reasons, make sure the tines are up. Keep others from

coming near the aerator. Get back on the aerator as soon

as possible.

• When transporting, driving onto transport vehicles, into

buildings, across parking lots or otherwise not aerating, lift

tines up.

• When driving the machine onto a trailer, or transport

vehicle, always back the machine onto the unit, for fear of

tipping backwards.

• Before performing any maintenance, or repair service

always turn engine off.

• DO NOT allow inexperienced people to operate the

aerator until they have read and understood these safety

instructions. Operate the aerator at slower speeds while

becoming familiar with it.

• Speeding is dangerous for even an experienced operator.

Sudden stops from excessive speed may cause serious

injury.

Page 4

4

• Keep all shields and covers in place.

• Keep hands, feet, and clothing away from moving parts.

• Do not touch engine or muffler while engine is running or

soon after it is stopped. These areas can be so hot as to

cause severe burns.

• Be alert for traffic when crossing roads or operating

near roadways.

• Before crossing gravel drives, sidewalks or roads, lift tines

out of the ground.

Operation on Slopes

DO NOT operate on steep slopes. Do not operate aerator on

slopes steeper than you can feel secure about the ability of the

aerator. Do not operate the aerator at all when the grass is wet.

There is a danger of suddenly sliding sideways or down the

hill. When operating on a slope, travel across the grade

whenever possible, not an up or down pattern. Reduce speed

and exercise extreme caution on slopes and in sharp turns to

prevent tipping or loss of control. Be especially cautious when

changing direction on slopes.

Replacement Parts

Use of parts other than specified parts supplied by Classen

MFG., Inc., may compromise the safe use of the aerator and

is not recommended.

Operation in Reverse

Always keep a firm grip on the aerator handles with both

hands. Keep both feet firmly on the foot platform. Always lift

the tines out of the ground when reversing. Never aerate in

reverse. Operate the aerator very slowly, inching it backwards

until you become familiar with how the aerator operates and

always in an awkward location or position. Never place your

foot or feet on the ground near the back edge of the aerator

while backing up to prevent serious injury to feet or legs if

aerator were to run over you. Look behind you before backing

to prevent injuring yourself or anyone behind you.

Operation in Forward Direction

Always keep a firm grip on the aerator handles with both

hands. Operate the aerator slowly until you become familiar

with how the aerator handles. Do not operate the aerator faster

than conditions allow. For example hills, wet or bumpy ground

or dim light would all be conditions where you should work

slower than normal. Never operate the aerator at the highest

speed unless you are on a level, wide open area of clearly

visible ground or transporting on paved areas. Speeding with

the aerator is dangerous, and so is traveling faster than the

conditions should permit on this aerator. Sudden stops from

excessive speed or falling off the aerator may cause serious

injury or death.

Operating During Zero-Radius Turns

During zero-radius turns (when one aerator wheel rotates

backwards while the other is moving forward) drive extra

slowly to reduce the possibility of losing traction or control.

Fuel Safety

Handle gasoline with care – it is highly flammable. Do not

smoke while handling gasoline. Use an approved gasoline

container. Never remove the fuel cap or add gasoline to a

running or hot engine or an engine that has not been allowed to

cool for several minutes after running. Never fill the tank

indoors and always clean up spilled gas. NEVER store the

equipment with gasoline in the tank inside a building where

fumes may reach an open flame or spark. Allow the engine to

cool before storing in any enclosure.

Hydraulic Safety

Keep body and hands away from pin holes or fittings that eject

hydraulic fluid under high pressure. Use paper or cardboard

and not hands to search leaks. Make sure all hydraulic fluid

connections are tight and all hydraulic hoses and lines are in

good condition before starting the Classen aerator.

PRE-DELIVERY SERVICE

Pre-Delivery Service of Aerator

The Classen STAND-AER™ is shipped completely assembled

and has been adjusted at the factory. However, due to the

jostling of the shipping process and the amount of time elapsed

since this was done at the factory until you receive the machine

the following items need to be repeated again before starting

the aerator:

• Remove spark plug wire from spark plug.

• Inspect the aerator for any damage, unusual conditions or

missing parts.

• Inspect the aerator for all of its decals, especially the

warning decals.

• Check (and fill if necessary) engine oil level according to

the engine manufacturing recommendation. Refer to your

Honda manual.

• Check (and fill if necessary) hydraulic fluid level. Use

20W-50.

• Lubricate all moving parts. Re-grease after every use.

• Fill fuel tank with regular unleaded gasoline.

Page 5

5

OPERATING INSTRUCTIONS

Inspect aerator before each use

Do not use aerator if any parts are not maintained in good

operating condition. Examine the moving parts prior each use.

Look for excessive wear, bald drive tires or worn out front

tires, cracks in parts, loose or missing bolts, cotter, lynch, or

hair pins and replace before operating the aerator.

How to Start the Aerator

• Turn the ignition switch to the “On” position.

• Turn the choke on (if engine is cold).

• Pull engine rope until it starts.

• Turn the choke off once it’s running smoothly.

• Immediately step onto the foot platform after the engine

is running.

Unusual Noises or Irregular Operation

As you drive the aerator listen for any unusual noises and test

for irregular operation and adjust or service as necessary.

How to Drive the Aerator

You must stand on the aerator foot platform for the aerator to

move. Move the throttle speed to the desired speed. Once you

are standing on the foot platform, and the engine is set at the

desired speed, push both control handles away from you to go

forward, and pull them both towards you to go backwards. To

turn right pull the right control handle. To turn left pull the left

control handle. Let go of both the control handles to bring the

machine to idle position.

SERVICE AND

ADJUSTMENT

Tire Maintenance and Pressure

Excessively worn tire tread is dangerous on all hills. Replace

drive tires with less than 3/32” of any tread groove left. Use

only tires supplied by Classen. All six tires are foam filled and

do not hold air. You will not need to check air pressure.

How to Bleed Air from the Hydraulic System

When any of the hydraulic parts are disconnected or removed

or when the oil is changed, air must be bled from the system.

With the bypass valve (brass nut on each of the hydraulic

pumps with a hole in the middle) closed, slowly move the

control handles in both the forward and reverse directions. As

air is purged from the unit, the oil level in the reservoir will

drop and bubbles may appear in the fluid. Refill the reservoir

as necessary.

Place the control handles in the neutral position and open the

bypass valve using a 5/8” wrench. Slowly move the control

handles in both the forward and reverse directions to purge the

air from the closed circuit.

Close the bypass valve and run the unit in both directions for

several minutes, until any remaining air is purged from the

unit. Refill the reservoir as necessary. Check for any fluid

leaks, and check the reservoir level. Add fluid if necessary.

The transmission is now ready for operation. Check the

reservoir daily for proper fluid level. It should be filled to the

top, or about 4 quarts.

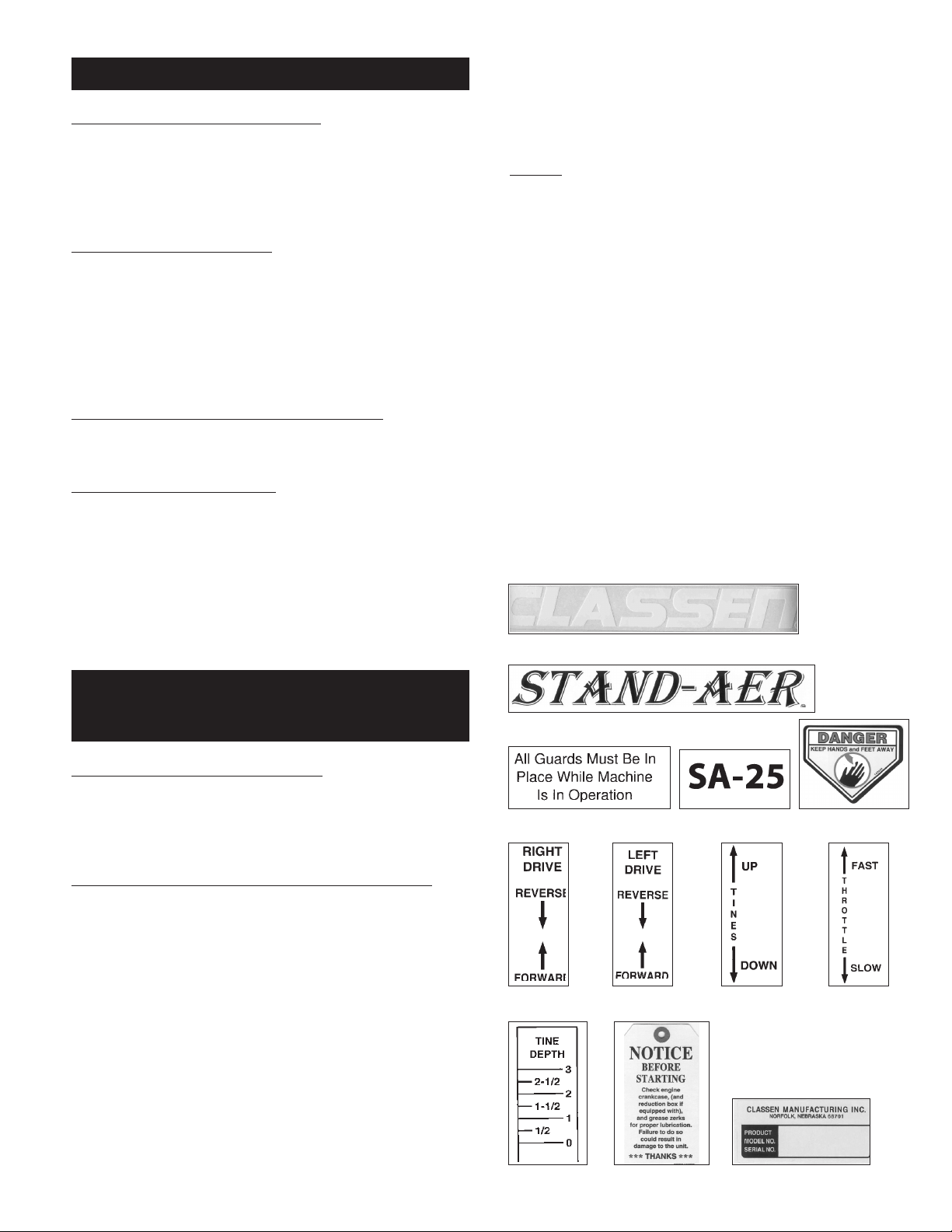

Decals

• (3) CLASSEN®decals located on front bumper and on

both sides of frame.

• (2) STAND-AER™ decals located on both sides of frame,

under CLASSEN®decal.

• (1) DANGER decal located on left side pulley guard.

• (1) ALL GUARDS decal located on right side

pulley guard.

• (2) SA-25 decals located on both sides of handle.

• (1) TINE DEPTH decal located on front left of machine.

• (1) R.H. FORWARD/REVERSE decal located on right

upper side of handle.

• (1) L.H. FORWARD/REVERSE decal located on left

upper side of handle.

• (1) THROTTLE FAST/SLOW decal located on lower

right side of handle.

• (1) SERIAL TAG located on lower left inside of handle.

• (1) LUBRICATION TAG twist tied to engine.

• (1) TINES decal located on upper left side of handle.

P/N 100074

P/N 100380

P/N 100096

P/N 100069

P/N 100424

P/N 100422

P/N 100421 P/N 100423

P/N 100350

P/N 100425 P/N 100073 P/N 100055

Page 6

6

Main Frame Assembly

SA-25 STAND ON AERATOR

Page 7

7

QTY/PER

KEY PART NO. SHEET DESCRIPTION

41 500026 4 3/8" CLEVIS YOKE

42 400201 1 CENTER PULLEY GUARD

43 400215 1 LINKAGE ARM HANDLE

44 500149 1 1/2" x 2" BOLT

45 500019 1 SMALL HANDLE SPRING

46 400210 1 THROTTLE PLATE

47 400211 1 PLATFORM

48 500065 4 COMPRESSION SPRING

49 500092 2 HAIR PIN

50 100363 2 3/8" x 3" CLEVIS PIN

51 500079 1 3/8" x 1-3/4" BOLT

52 100360 1 READY ROD

53 100352 1 HANDLE GRIPS, 11" x 1"

54 400212 1 PLATFORM MOUNT

55 100346 2 3/8" SNAP PIN

56 100381 1 3/8" SNAP LOCK PIN, SMALL

57 400220 1 PLATFORM MOUNT ASSEMBLY

58 400202 1 RIGHT HANDLE GUARD

59 100069 1 DECAL, "DANGER"

60 500083 6 5/16" FLAT WASHER

61 100442 1 GOVERNOR CABLE w/CONNECTING ENDS

62 300130 1 SWING ARM MOUNT

63 500232 1 3/8" STUD

64 100096 1 DECAL, "ALL GUARDS"

65 500053 4 5/8" FLAT WASHER

66 300131 4 2" MACHINERY WASHER

67 500182 2 3/16" x 1-1/2" COTTER PIN

QTY/PER

KEY PART NO. SHEET DESCRIPTION

1 100074 3 DECAL, "CLASSEN"

2 500135 4 1/2" x 2-1/2" BOLT

3 300121 1 WEIGHT BAR

4 500006 7 1/2" LOCK WASHER

5 500106 5 1/2" NUT

6 400208 1 SA-25 MAIN FRAME

7 500129 22 3/8" NUT

8 500130 22 3/8" LOCK WASHER

9 500042 10 3/8" FLAT WASHER

10 100010 2 IDLER PULLEY

11 500091 6 3/8" x 2" BOLT

12 500133 7 5/16" x 1" BOLT

13 300119 1 DEPTH GAUGE PLATE

14 500115 6 5/16" LOCK WASHER

15 500101 1 5/16" NUT

16 400203 1 LEFT HANDLE GUARD

17 400216 1 REAR WHEEL LINKAGE ARM

18 400226 2 FRONT WHEEL ASSEMBLY

19 500134 10 3/8" x 1-1/4" BOLT

20 400227 2 FRONT WHEEL PLATE

21 100043 4 IDLER SPROCKET

22 500034 25 1/2" FLAT WASHER

23 100365 1 CYLINDER

24 400214 2 PIVOT FLAT

25 500228 4 1/2" x 1-1/2" BOLT w/HOLE

26 500043 8 3/8" x 1" BOLT

27 500016 13 5/32" x 1-1/4" COTTER PIN

28 400218 1 SWIVEL PLATE

29 100380 2 DECAL, "STAND-AER"

30 500041 8 3/8" LOCK NUT

31 500230 1 1/2" x 2" BOLT w/HOLE

32 500001 6 1/4" x 28 GREASE FITTING

33 400206 1 SWING ARM

34 500146 4 3/8" x 1-1/2" BOLT

35 400213 1 REAR TIRE FRAME

36 100361 4 REAR WHEEL AXLE

37 100017 4 TIRE & WHEEL ASSEMBLY, 9 x 350 x4

38 500152 2 1/2" x 2-3/4" BOLT

39 400217 1 DEPTH GAUGE ROD

40 500025 4 3/8" FINE THREAD NUT

Page 8

8

Power Train Assembly

SA-25 STAND ON AERATOR

Page 9

9

QTY/PER

KEY PART NO. SHEET DESCRIPTION

41 500101 8 5/16" NUT

42 500115 8 5/16" LOCK WASHER

43 500163 8 5/16" x 3/4" CARRIAGE BOLT

44 500229 2 5 mm KEY

45 300129 2 SPACER

46 100418 2 SPLIT LOCK COLLAR

47 500233 1 3/8" x 1-1/2" FINE BOLT

48 500148 1 3/8" HEAVY WASHER

49 100429 2 50 x 12 SPROCKET

50 400219 1 ENGINE BRACKET

51 100364 1 #12 SPRING

52 100363 1 3/8" x 3" CLEVIS PIN

53 200052 2 CHAIN, 68 ROLLERS

54 100438 2

BEARING w/SET SCREW 1" 2 BOLT FLANGETTE

55 400225 1 3/8" LOCK NUT RING

56 100035 1 THROTTLE CABLE CONNECTING SPRING

QTY/PER

KEY PART NO. SHEET DESCRIPTION

1 500146 4 3/8" x 1-1/2" BOLT

2 500042 20 3/8" FLAT WASHER

3 100377 1 13 HP HONDA ENGINE

4 500130 34 3/8" LOCK WASHER

5 500129 38 3/8" NUT

6 500134 8 3/8" x 1-1/4" BOLT

7 100374 1 LEFT SIDE HYDRAULIC PUMP

8 100373 1 RIGHT SIDE HYDRAULIC PUMP

9 500079 8 3/8" x 1-3/4" BOLT

10 100382 1 CLUTCH

11 500181 1 1/4" x 1-1/2" KEY

12 100378 2 PUMP MOUNT

13 300118 4 PUMP BRACKET SPACER

14 100315 2 1B-34 PULLEY

15 100371 2 6941 V-BELT

16 100155 8 BEARING w/COLLAR, 1" 3-BOLT

17 100386 2 40 B-17 SPROCKET

18 300125 2 3/4" x 1.3125 O.D. SPACER

19 100385 2 40 B-16 SPROCKET

20 200047 2 1" x 13-1/2" SHAFT

21 500043 24 3/8" x 1" BOLT

22 200049 2 CHAIN, 102 ROLLER + 1/2

23 200050 2 CHAIN, 104 ROLLERS

24 200051 2 CHAIN, COUPLER w/CONN LINKS

25 100370 2 HYDRAULIC MOTOR, w/ 1/4" x 1" KEY

26 500135 2 1/2" x 2-1/2" BOLT

27 500006 10 1/2" LOCK WASHER

28 500106 10 1/2" NUT

29 500034 2 1/2" FLAT WASHER

30 100043 2 IDLER SPROCKET

31 100389 2 32 TOOTH SPROCKET

32 500150 8 1/2" x 1-1/2" BOLT

33 100367 2 MOTOR MOUNT

34 100388 2 LARGE REAR WHEEL

35 200048 2 1" x 7" REAR WHEEL SHAFT

36 400222 2 1" SHAFT w/B12 x 1" SPROCKET

37 300127 2 SPACER COLLAR

38 100248 4 BEARING w/COLLAR, 1" 2-BOLT FLANGETTE

39 200009 4 SPROCKET w/1" HUB, #40 X 36

40 300124 2 JACKSHAFT SPACER

Page 10

10

Handle and Control Assembly

SA-25 STAND ON AERATOR

Page 11

11

QTY/PER

KEY PART NO. SHEET DESCRIPTION

1 500043 16 3/8" x 1" BOLT

2 500029 2 1/4" x 3/4" BOLT

3 300137 2 FILTER MOUNT BRACKET

4 500130 16 3/8" LOCK WASHER

5 500129 16 3/8" NUT

6 500137 4 1/4" LOCK WASHER

7 100480 2 FILTER MOUNT

8 100481 2 OIL FILTER

9 100352 4 HANDLE GRIPS, 11" x 1”

10 400200 1 RIGHT HANDLE CONTROL

11 100368 1 THROTTLE CABLE

12 500073 2 5/16" x 1-1/4" BOLT

13 100354 2 FEMALE ROD END w/ ZERK

14 500101 4 5/16" NUT

15 400207 2 READY ROD, 3/8" x 5/16"

16 500158 2 1/2" x 3-1/2" BOLT

17 300117 2 BUSHING

18 500106 2 1/2" NUT

19 500006 2 1/2" LOCK WASHER

20 500134 2 3/8" x 1-1/4" BOLT

21 500026 2 3/8" CLEVIS YOKE

22 500041 2 3/8" LOCK NUT

23 500025 2 3/8" FINE THREAD NUT

24 400198 1 RIGHT SIDE HANDLE

25 100012 1 SPRING

26 100350 2 SA-25 DECAL

27 400197 1 LEFT SIDE HANDLE

28 100351 1 STOMACH GUARD PAD

29 300114 1 STOMACH GUARD PLATE

30 100353 1 VENT PLUG

31 400196 1 TOP MAIN HANDLE

32 100375 1 CONTROL VALVE

33 100376 1 CONTROL VALVE HANDLE

34 500042 2 3/8" FLAT WASHER

35 400199 1 LEFT HANDLE CONTROL

36 500001 2 1/4" X 28 GREASE FITTING

37 300135 1 CAP, HYDRAULIC

38 500234 2 1/4" x 3/4" LAG BOLT

39 100425 1 DECAL, "TINE DEPTH" (NOT SHOWN)

40 600001 2 STEEL SLEEVE

QTY/PER

KEY PART NO. SHEET DESCRIPTION

41 100421 1 DECAL, "RIGHT, FORWARD-REVERSE"

(NOT SHOWN)

42 100422 1 DECAL, "LEFT, FORWARD-REVERSE"

(NOT SHOWN)

43 100423 1 DECAL, "TINE, UP-DOWN" (NOT SHOWN)

44 100424 1 DECAL, "THROTTLE, FAST-SLOW"

(NOT SHOWN)

45 100055 1 DECAL, SERIAL TAG" (NOT SHOWN)

46 100073 1 LUBRICATION TAG (NOT SHOWN)

Page 12

12

Tine Frame Assembly

SA-25 STAND ON AERATOR

QTY/PER

KEY PART NO. SHEET DESCRIPTION

1 400204 1 TINE MOUNT FRAME

2 500041 12 3/8" LOCK NUT

3 100155 4 BEARING w/COLLAR, 1"-3 BOLT

4 500043 6 3/8" x 1" BOLT

5 300123 2 TINE SPACER

6 200009 2 SPROCKET w/1" HUB, 40 x 30

7 700031 2 TINE DISC SHAFT ASSEMBLY

8 500003 2 1/4" HALF MOON KEY

9 100032 36 TINE

10 500146 6 3/8" x 1-1/2" BOLT

11 100383 2 BEARING w/SET SCREWS, 1"-3 BOLT

12 100384 4 NYLON WASHER

13 500169 72 5/16" LOCK NUT

14 400221 2 TINE DISC w/HUB WELDED ON

15 500001 2 1/4" X 28 GREASE FITTING

16 500147 72 5/16" X 1-1/2" BOLT

17 200046 1 TINE SHAFT

18 100430 4 MR16RS BEARING

Page 13

13

Hoses and Adapters Description

SA-25 STAND ON AERATOR

QTY/PER

KEY PART NO. SHEET DESCRIPTION

1 600062 2 HOSE #1 (6C2AT x 23) w/1-6MJ-6MB, 2-6G-6FJX, 1-6MJ-6MB90

2 600063 2 HOSE #2 (6C2AT x 7-1/2) w/1-6MB-6MJ, 2-6G-6FJX, 1-6MJ-8MP90, 1-1 x 1/2 BLACK BUSHING

3 600057 1 HOSE #5 (8C2AT x 12) w/1-8MB-8MJ, 1-8G-8FJX, 1-10MB-8MJ, 1-8G-8FJX45

4 600051 1 HOSE #6 (8C2AT x 10) w/1-8MB-8MJ, 2-8G-8FJx45, 1-10MB-8MJ

5 600058 1 HOSE #7 (8C2AT x 12) w/1-8MB-8MJ, 2-8G-8FJX45, 1-10MB-8MJ

6 600052 1 HOSE #8 (8C2AT x 11-1/4) w/1-8MB-8MJ, 1-8G-8FJX, 1-10MB-8MJ, 1-8G-8FJX45

7 600053 1 HOSE #9 (6C2AT x 4-1/4) w/1-6MB-6MJ90, 2-6G-6FJX

8 600059 1 HOSE #10 (6C2AT x 22) w/1-6MB-6MJ90, 2-6G-6FJX

9 600054 1 HOSE #11 (8C2AT x 31) w/1-8MJ-12MP90, 2-8G-8FJX, 1-6MJ-6MJ-8MT TEE

10 600055 1 HOSE #12 (6C2AT x 22-3/4) w/1-6MJ-6MB, 1-6G-6FJx90M, 1-6MJ-4MB45, 1-6B-6FJX45

11 600060 1 HOSE #13 (6C2AT x 24-1/2) w/16MJ-6MB, 1-6MJ-4MB45, 1-6G-6FJX90M, 1-6G-6FJX45

12 600056 1 HOSE #14 (6C2AT x 26-3/4) w/2-6MJ-6MB, 1-6G-6FJX

13 600050 1 HOSE #15 (6C2AT x 25-1/2) w/1-6MJ-6MB, 1-6MJ-6MB45, 2-6G-6FJX

Page 14

14

Hydraulic Hoses Description

SA-25 STAND ON AERATOR

Page 15

15

See the complete line of Turf Care Products

from CLASSEN

Classen reserves the right to make changes or add improvements to its products at any time without incurring any obligation to make

such changes to products manufactured previously. Classen, or its distributors and dealers, accept no responsibility for variations

which may be evident in the actual specifications of its products and the statements and descriptions contained in this publication.

COMPACT AERATORS

CA-18H

CA-18B

SPLIT DRIVE AERATORS

TA-25D

TA-17D

SA-25

TURF AERATORS

TA-19D

TA-26D

TOW/3PT AERATORS

48RT

60RT

72RT

3 PT AERATORS

48R

60R

72R

84R

SOD CUTTERS

SC-12

SC-18

SC-20

SC-24

TURF RAKES

TR-20H

TR-20B

TR-20MH

TR-20MB

TR-20SH

TR-20SB

TRC-20H

TRC-20B

TRS-20H

TRS-20B

TURF SEEDERS

TS-20H

TS-20B

TSS-20H

TSS-20B

TRAILERS

AST

SAT

Page 16

TWO YEAR LIMITED WARRANTY

Effective April 1, 2007

For the period of two years from the date of purchase, CLASSEN MFG., INC. will repair or replace for the

original purchaser free of charge, any part or parts found upon the examination of our factory authorized

service station, or by the factory in Norfolk, Nebraska, to be defective in material or workmanship. All

transportation charges on parts submitted for repair or replacement under this warranty shall be borne by

the purchaser.

This warranty does not include engines or engine parts, tires, batteries, or gearboxes that are covered

under separate warranties furnished by their manufacturer or supplier, nor does it include normal

maintenance parts, including but not limited to, spark plugs, points, filters, blades, and lubricants.

All service under this warranty will be furnished or performed by our factory authorized service stations.

There is no other expressed warranty. Implied warranties, including those of merchantability and fitness

for a particular purpose, are limited to two years from the date of purchase and to the extent permitted by

law, any and all implied warranties are excluded. The above remedy of repair and replacement of defective

parts is the purchaser’s exclusive remedy for any defect, malfunction or breach of warranty. Liability for

incidental or consequential damages under any and all warranties is excluded to the extent permitted

by law.

NORMAL RESPONSIBILITIES OF THE SELLER AND THE USER

1. The Distributor or Dealer is responsible for the proper assembly and preparation of the product for

delivery to the end user.

2. The User is responsible for reading the Manual and Instructions.

3. The User is responsible for proper operation and maintenance as described in the manual.

4. The User is responsible for the replacement of wear items such as blades, belts, tires, batteries, etc.

5. The User is responsible for damage due to improper operation and maintenance, as well as abuse.

All claims must be received by the factory 30 days after the end of the warranty period to receive warranty

consideration.

© 2007 Schiller-Pfeiffer, Inc. 9/07

A Division of Schiller-Pfeiffer, Inc.

www.classen-mfg.com

1028 Street Road • Southampton, PA 18966

Toll Free: 1-877-596-6337 • Fax: 1-215-357-8045

Loading...

Loading...