Class C BD Laser MAX User Manual

0Index

1. General Information and Safety instructions ....................... 2

1.1.0 Scope and contents of the manual . . . . . . . . . . . . 2

1.1.1 How to store the manual . . . . . . . . . . . . . . . . . . . . . 2

1.2.0 Manufacturer's address . . . . . . . . . . . . . . . . . . . . . 2

1.3.0 Working conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.2 Improper Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4.0 Safety legislation . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4.1 General safety requirements . . . . . . . . . . . . . . . . . 2

1.5.0 Protection devices . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5.1 Personal protective equipment . . . . . . . . . . . . . . . 3

1.5.2 Safety signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.6.0 Residual risks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Machine description .............................................................4

2.1.0 Technical features . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.0 BD LASER MAX main features . . . . . . . . . . . . . . . . 4

2.2.1 Machine accessories . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.2 Parts- Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.0 Jaws supplied with the machine . . . . . . . . . . . . . . 5

3. Transport and installation ....................................................6

3.1.0 Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1.1 Opening the package . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2.0 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2.1 Unloading and handling the machine . . . . . . . . . . 6

3.3.0 Temporary storing . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3.1 Characteristics of the place of installation . . . . . 6

3.3.2 Temperature and humidity . . . . . . . . . . . . . . . . . . . 6

3.3.3 Working environment . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3.4 Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4.0 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4.1 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Start up ................................................................................7

4.1.0 Notice for machine use . . . . . . . . . . . . . . . . . . . . . . 7

4.1.1 Preliminary controls and setup . . . . . . . . . . . . . . . 7

4.2.0 Starting the consolle . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3.0 Language setting . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5. Setup ....................................................................................8

5.1.0 Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1.1 Search by car brand . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1.2 Search by code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1.3 Search by article . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

INDEX

5.2.0 Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

5.3.0 Calibrations Menu . . . . . . . . . . . . . . . . . . . . . . . . . . .9

5.3.1 Cutter Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.3.2 Jaw Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.4.0 Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.4.1 Keyonline Update . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.4.2 Keyonline via PC Update . . . . . . . . . . . . . . . . . . . . .11

5.4.3 Special . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

6. Key search ......................................................................... 13

6.1.0 Search menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.1.1 Search by record number . . . . . . . . . . . . . . . . . . . . 13

6.1.2 Search by code . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.1.3 Search by card . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.1.4 Search by cylinder brand . . . . . . . . . . . . . . . . . . . .14

6.1.5 Search by motorbike brand . . . . . . . . . . . . . . . . . . 14

6.1.6 Search by car brand . . . . . . . . . . . . . . . . . . . . . . . .14

6.1.7 Search by article . . . . . . . . . . . . . . . . . . . . . . . . . . .14

6.2.0 Bookmarks list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7. Modify and cut ................................................................... 15

7.1.0 Decode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

7.2.0 Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.3.0 Direct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

7.4.0 Key modify menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.5.0 Key cut menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

8. Archive, PC and user menu ................................................. 17

8.1.0 Archive Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8.2.0 PC Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

8.3.0 User Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9. Maintenance, Dismantling and disposal ............................ 18

9.1.0 General information . . . . . . . . . . . . . . . . . . . . . . . .18

9.1.1 Skills of maintenance personnel . . . . . . . . . . . . . .18

9.1.2 Type of Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 18

9.2.0 Ordinary maintenance . . . . . . . . . . . . . . . . . . . . . . 18

9.2.1 Checking and cleaning the fan . . . . . . . . . . . . . . .18

9.2.2 Cleaning the working area . . . . . . . . . . . . . . . . . . . 18

9.2.3 Cleaning the display . . . . . . . . . . . . . . . . . . . . . . . .18

9.2.4 Replacing the milling cutter . . . . . . . . . . . . . . . . .18

9.2.5 Replacing the fan . . . . . . . . . . . . . . . . . . . . . . . . . .19

9.2.6 Replacing the startup unit . . . . . . . . . . . . . . . . . . . 19

9.2.7 Inspecting and replacing the fuses . . . . . . . . . . . 20

9.2.8 Replacing the motor belt . . . . . . . . . . . . . . . . . . . . 20

9.2.9 Replacing the X axis sensor . . . . . . . . . . . . . . . . . 20

9.2.10 Replacing the Y axis sensor . . . . . . . . . . . . . . . . . 21

9.2.11 Replacing jaw parts . . . . . . . . . . . . . . . . . . . . . . . . 22

9.3.0 Waste disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

9.4.0 The WEEE directive . . . . . . . . . . . . . . . . . . . . . . . . 22

9.4.1 Disposal of the packing material . . . . . . . . . . . . . 22

ENGLISH

Class C Solutions Group BD LASER MAX Man. cod. B409652FG 1

GENERAL INFORMATION AND SAFETY

1

2

4

7

5

3

6

INSTRUCTIONS

ENGLISH

1General Information and Safety instructions

Glossary

01. Head

02. Neck

03. Shoulder

04. Blade

05. Tip

06. Back

07. Bitting

Laser-Style keys Such keys are called “Laser” on account of

their special bitting style across the profile.

Key sample The “original” key from which, through bit-

Key blank A key with no engraving that is cut following

ting, a duplicate key is obtained.

the profile of the key sample.

The user's and maintenance manual of the “BD LASER MAX” for the

duplication of Laser keys, contains all operation instructions on the

best way to use the machine while guaranteeing the safety of operators.

1.1.0 Scope and cont ent s of the m anua l

This manual provides basic information on the installation, operation

and maintenance of the key duplicating machine.

Users must follow the instructions contained in this manual scrupulously, especially those concerning safety norms and ordinary maintenance.

1.1.1 How t o st ore the m anu al

The manual must always be kept with the machine it refers to.

The manual must be stored in a safe place, away from dust and moisture and it must be accessible to all users who shall consult it any

time they are in doubt on how to operate the machine.

1.2.0 Manufacturer's address

Class C Solutions Group

CLEVELAND, OH

1-866-267-6776

OPTION #2

Website: www.mscdirect.com/ClassCSolutions

E-mail: info@classc.mscdirect.com

To facilitate communication please state:

- the name of the customer;

- the name of the customer.

1.3.0 Working conditions

1.3 .1 Inte nded use

The key cutting machine described in this manual has been designed

for the electronic code cutting and duplication of Laser-type keys,

using special adaptors.

1.3.2 Improper Use

The improper use of the machine includes using the tool to perform an

operation that it was not intended for. Should this occur the manufacturer shall take no responsibility for damage to materials or persons

and shall consider all warranties on the machine void.

1.4.0 Safety legislation

The key duplicating machine and its safety devices comply with macchine Council Directive 2006/42/EEC known as “Machine Directive“.

When employed for their intended use all machines marked CE comply with EU 'machine' directive 2006 /42/EEC known as “Machine Di-

rective“ and directives 2006/95/EEC, 2004/108/EEC.

Warning: Important!

Users must be informed about the instructions contained in the following screens.

Users must carefully follow the instructions contained

in this manual.

1.4.1 General safety requirements

Warning: Important!

Make sure that the grounding system is well

connected.

Always unplug the machine (turn off the main switch)

before servicing mobile parts that are electrically

operated.

Do not pour water or other liquids onto electrical cables

and connections.

2 BD LASER MAX Man. cod. B409652FG Class C Solutions Group

GENERAL INFORMATION AND SAFETY

D

C

A

B

INSTRUCTIONS

1.5 .0 Pro tec tio n dev ice s

a. Ground Connection

b. Protective eye guard

c. Emergency Button

1.5.1 Personal protective equipment

When operating and maintaining the key cutting machine users must

wear the following personal protective equipment:

Protective clothing Maintainers and key cutting machine operators

Safety glasses During key cutting operations operators must

Gloves If milling cutters are present, operators must

1.5 .2 Safe ty s ign s

The key cutting machine bears the following safety signs.

must wear protective clothing that complies

with the basic safety requirements currently in

force.

In case of slippery floors users must wear safety shoes with anti-slip soles.

wear eye protection (glasses or goggles).

wear protective gloves to avoid injuries.

- Wear safety glasses.

1.6 .0 Res idua l ri sks

When operating the machine the following residual risks - as well as

those connected with its use - must be taken into due consideration:

• Electrical hazard (A)

Since the machine is equipped with electrical devices, in case of faults there might be a risk of

electrocution. The power line must be fitted with

the appropriate control and protection devices (circuit breaker, thermal overload switch and differential switch).

• Mechanical hazard (D)

The machine is fitted with milling cutters used in

key cutting operations. Operators must watch out

to avoid cutting their hands when they are cutting

keys or changing tools.

ENGLISH

- Wear safety gloves.

Class C Solutions Group BD LASER MAX Man. cod. B409652FG 3

MACHINE DESCRIPTION

ENGLISH

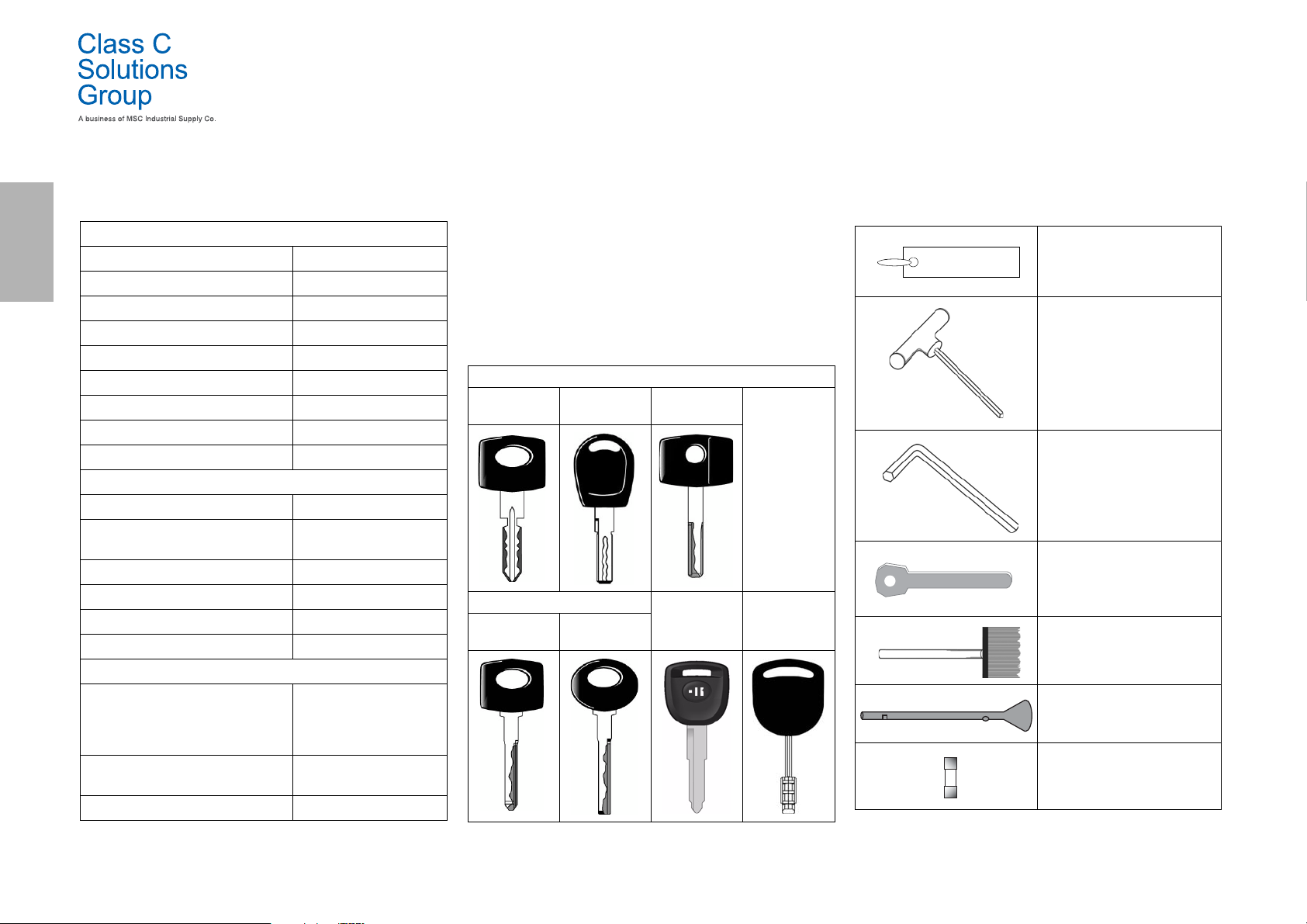

2Machine description

2.1.0 Technical features

Dimensions

Width 300 mm

Height 360 mm

Depth (Length) 360 mm

Weight 16,5 Kg

Dimensions Console

Width 200 mm

Height 150 mm

Depth (Length) 50 mm

Weight 0,8 Kg

Technical features

Power voltage 110/250 V 50/60 Hz

Absorption 125 W (machine) - 35W

(Stand By)

Motor Brushless 6000 rpm

Type o f c utter Ing carbide

Operating temperature 0° / + 40°C

Acoustic pressure level L

(A) 78,5 dB(A)

p

User Interface

Type 7” industrial colour touch

screen, 16:10, resolution

800x480 px, incorporated

CPU

Input / Output 2 USB 2.0 ports; 2 RS232

serial ports; 1 LAN port

CPU ARM Cortex A8

2.2.0 BD LASER MAX main features

Professional

BD LASER MAX

key cutting machines are electronic devices able to facilitate the duplication of a variety of keys that require the

use of fixed adaptors.

The BD LASER MAX has an aluminum body that reduces vibration

while guaranteeing noiseless operation and a longer cutter life.

The key cutting machine BD LASER MAX is used to duplicate the

following types of keys:

Laser-type keys

4 External

cuts

Laser-type keys with thin stem

Double exter-

nal bitting

Double inter-

nal bitting

Double exter-

nal bitting

Double exter-

nal bitting

Double bit-

ting flat keys

Tibbe-Ford

keys

2.2.1 Machine accessories

Jaw calibrating templates -994

Code RIC03444B

T- Handle hexagon wrench (long)

2,5mm

Code RIC03442B

T- Handle hexagon wrench (long)

3mm

Code RIC03440B

Hexagonal keys

Code RIC03438B

Setup blanks

Code RIC03448B

Brush

Code RIC03446B

Cutter insertion tool-994

Code RIC03436B

1 pc. - Rapid fuse 4A 5x20

Code RIC02592B

4 BD LASER MAX Man. cod. B409652FG Class C Solutions Group

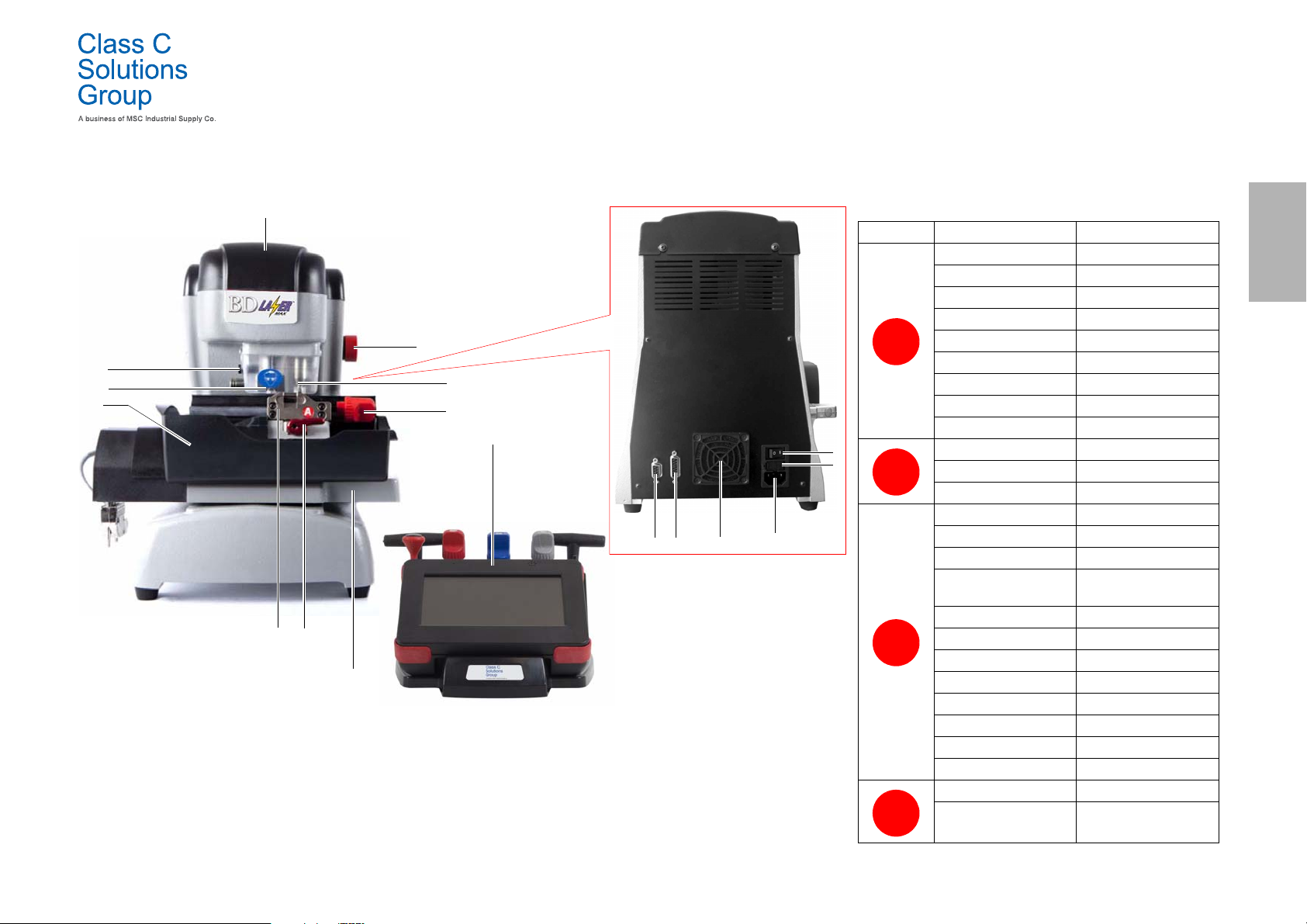

2.2.2 Parts- Machine 2.3.0 Jaws supplied with the machine

12

8

4

16

11

5

10

9

76

17

1314

15

2

1

3

1. Main switch

2. Power connection

3. Fuses holder

4. Tracer holder

5. Cutter

6. Jaw

7. Le v e rs to l oc k j aw

8. Levers to clamp jaw

9. Jaw support carriage

10. Container to collect waste

11. Protective eye guard

12. Emergency button

13. Serial port (RS232)

14. Input / Output

15. Fan filter

16. Patent pending

17. Console

ABC

D

Class C Solutions Group BD LASER MAX Man. cod. B409652FG 5

MACHINE DESCRIPTION

Jaw Car brands Key-system

Honda 4 External Track

Gm - Pontiac - GTO 2 External Track

Mercedes 4 External Track

Volvo 4 External Track

Volvo (V50 2004) 2 External Track

Saab 2 External Track

Vauxhall (U.K.) 2 External Track

Ford (U.K.) 2 External Track

Subaru - Outback 4 External Track

BMW 4 External Track

Volvo 2 External Track

Peugeot 4 External Track

Volkswagen 2 Inside Track

Audi 2 Inside Track

Lexus 4 Inside Track

Kia (Amanti: US +

Oprius: UK)

BMW 2 Inside Track

Saab 4 Inside Track

Porsche 2 Inside Track

Scoda (U.K.) 2 Inside Track

Seat (U.K.) 2 Inside Track

Vauxhall (U.K.) 2 Inside Track

Ford (U.K.) 2 Inside Track

Mazda - Millennia 4 Inside Track

Chrysler - Crossfire External Track

Mercedes External Track

4 Inside Track

ENGLISH

TRANSPORT AND INSTALLATION

6

5

22

3344

ENGLISH

3Transport and installation

3.1.0 Packaging

Packaging includes a cardboard box with the following dimensions:

Dimensions Macchina Console

Width 460 mm 460 mm

Height 460 mm 200 mm

Depth (Length) 435 mm 435 mm

3.1.1 Opening the package

Remove the machine and the console from the packing materials following the instructions below:

Key-cutting machine

1. Remove the seals or the tape to open the package.

2. Open the box that contains the key duplicating machine.

3. Remove carton “6” that contains the case with the kit of

accessories.

4. Remove carton “5” from the box.

5. Remove carton “2” and “4” from the box.

6. Free the machine from the packaging material.

Console

1. Remove the seals or the tape to open the package.

2. Open the box that contains the console.

3. Free the console from the packaging material.

IMPORTANT!

We recommend you to keep the packaging during the

warranty period.

3.2.0 Transport

The markings on the packing materials indicate how to handle the

machine during transport.

3.2.1 Unloading and handling the machine

The machine can be unloaded manually by 2 or 3 persons, or by using

a handling equipment (for example a lift truck).

Avoid dropping the machine, even a small damage

could impair its correct functioning.

3.3.0 Temporary storing

If the installation of the machine does not occur immediately, store

the machine in a dry and properly ventilated place.

• Apply an appropriate coating .

• Rubber parts must be protected against too low

temperatures. Never store them outdoors, not even for

short periods.

If the machine is stored or remains unused for long periods or if it is started a long time after delivery, gaskets

or retaining rings may undergo hardening thus causing

leaks or seizures.

3.3.1 Characteristics of the place of installation

The key cutting machine must be placed on a smooth level bench

about 90 - 110 cm (35 - 43 Inches) high, suitable for bearing the weight

of the machine and keep it horizontal, thus avoiding vibrations and

stress.

Allow a 30 cm (12 Inches) clearance around and above the key cutting

machine for correct functioning and maintenance.

3.3.2 Temperature and humidity

The tool should be used in rooms with a temperature range of 0 and 40

°C (273 K - 313 K) and a relative humidity lower than 50 - 60%.

3.3.3 Working environment

The machine must be used in a place protected from bad weather

(rain, hail, snow etc.).

If the machine is used in places exposed to corrosion,

maintenance shall be scheduled in such a way as to

prevent extreme wear of the components.

Do not use the machine in explosive or partially explosive atmospheres or in the presence of inflammable

liquids of gases.

3.3.4 Lighting

In the place of installation lighting must be appropriate, in order to allow the correct use and maintenance of the machine.

3.4.0 Connections

3.4.1 Grounding

Key cutting machines BD LASER MAX have been designed in

compliance with the safety legislation in force and feature appropriate safety devices to prevent work accidents. In particular the

machine was built with materials that:

•are self-extinguishing;

• protect against electrocution.

The machine must be grounded through the centralized circuit of the

place of installation.

Warning:

Make sure that the main voltage is compatible with the

machine voltage.

Make sure that the active power outlets are grounded.

Do not touch the machine when your hands and/or feet

are wet or humid.

Avoid any contact with grounded plates.

6 BD LASER MAX Man. cod. B409652FG Class C Solutions Group

Loading...

Loading...