Page 1

Class 1, Inc. • A Unit of IDEX Corporation

www.class1.com

Class 1

Valve

manual

607 NW 27th Avenue • OCALA, FL 34475 USA

800.533.3569 • FAX: 352.629.2902

Class 1 Manual p/n 119138 – 04/14/10

Page 2

Class 1 Valve Manual

Table of Contents

1. Introduction & Specifications .................................................................................................... 3

2. Ball Valve Identification ............................................................................................................... 4

3. Ball Valve Actuators .................................................................................................................... 5

i. Remote Handle

ii. Direct Handle

iii. Rack Linkage

iv. Electric

4. Safety Information ........................................................................................................................ 9

5. Installation .................................................................................................................................... 11

i. Principles of Operation

ii. Installation Guidelines

iii. Direct and Remote Handle Installation

iv. Electric Actuator Installation

v. Slow Close Assembly Installation

vi. Rack Linkage Installation

6. Maintenance ................................................................................................................................ 23

i. After Each Use

ii. Monthly

iii. Valve Exploded Parts List

iv. Valve Repair Kits

7. Troubleshooting ......................................................................................................................... 26

2

p/n: 119138

Page 3

Class 1 Valve Manual

1. Introduction & Specifications

The new Class 1 four-piece stainless steel ball valves were created for reliability, corrosion resistance,

customization, and ease of maintenance.

Class 1 Stainless Steel Ball Valve

• The Class 1 stainless steel ball valves are available in 2.0”, 2.5”, and 3.0” sizes.

• Ball valves are composed of four main components: valve body assembly, inlet and discharge flange

adapters, and actuator.

• The center bodies are constructed of 304 stainless steel, and the balls are machined from 304

stainless steel.

• The stainless steel ball valves are bi-directional.

• The stainless steel ball valves use a single-piece seat and seal.

• A wide variety of 304 stainless steel valve end flanges are available to meet most of your plumbing

connection needs.

• Removing three of the four bolts on both flanges allows the valve to swing away from the plumbing,

and provide access to the waterway.

• For each valve size, the same stem geometry is used for all actuation options, eliminating the need

to change or remove the stem. For many options, only one bolt is required to add or remove a

valve handle.

• All valves are designed to meet or exceed NFPA 1901 standards.

3

p/n: 119138

Page 4

Class 1 Valve Manual

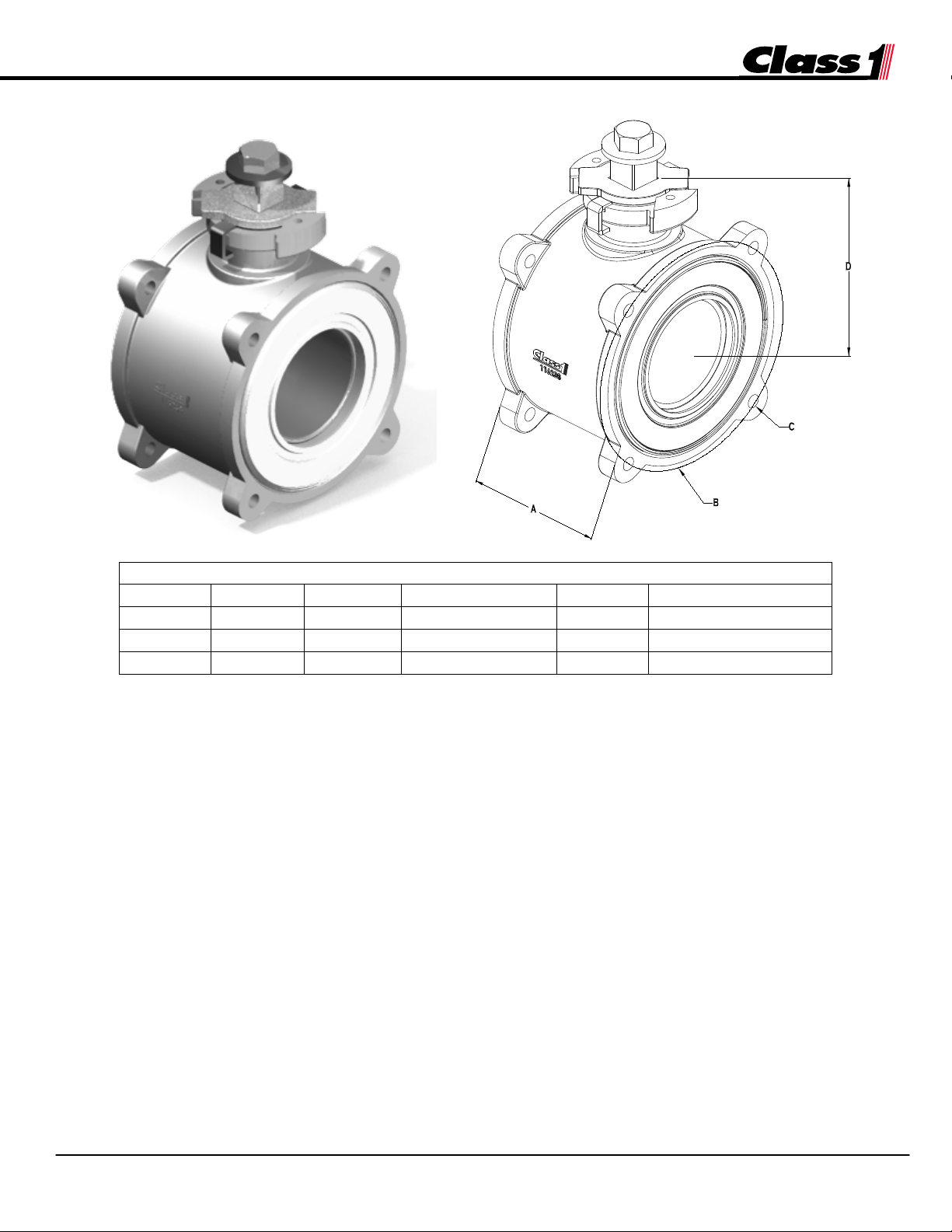

Center Body Assembly Dimensions

Size A B C D

Cast Body Part #

2.0”

3.00”

4.50”

3/8-16 Threads

3.44”

116237

2.5”

3.50”

5.375”

3/8-16 Threads

3.70”

116238

3.0”

3.98”

6.115”

3/8-16 Threads

4.08”

116239

2. Ball Valve Identification

Class 1 Stainless Steel Ball Valve – Center Body Assembly

A = width, valve center body; B = bolt circle; C = mounting threads; D = height, valve centerline to top of stop plate

4

p/n: 119138

Page 5

Class 1 Valve Manual

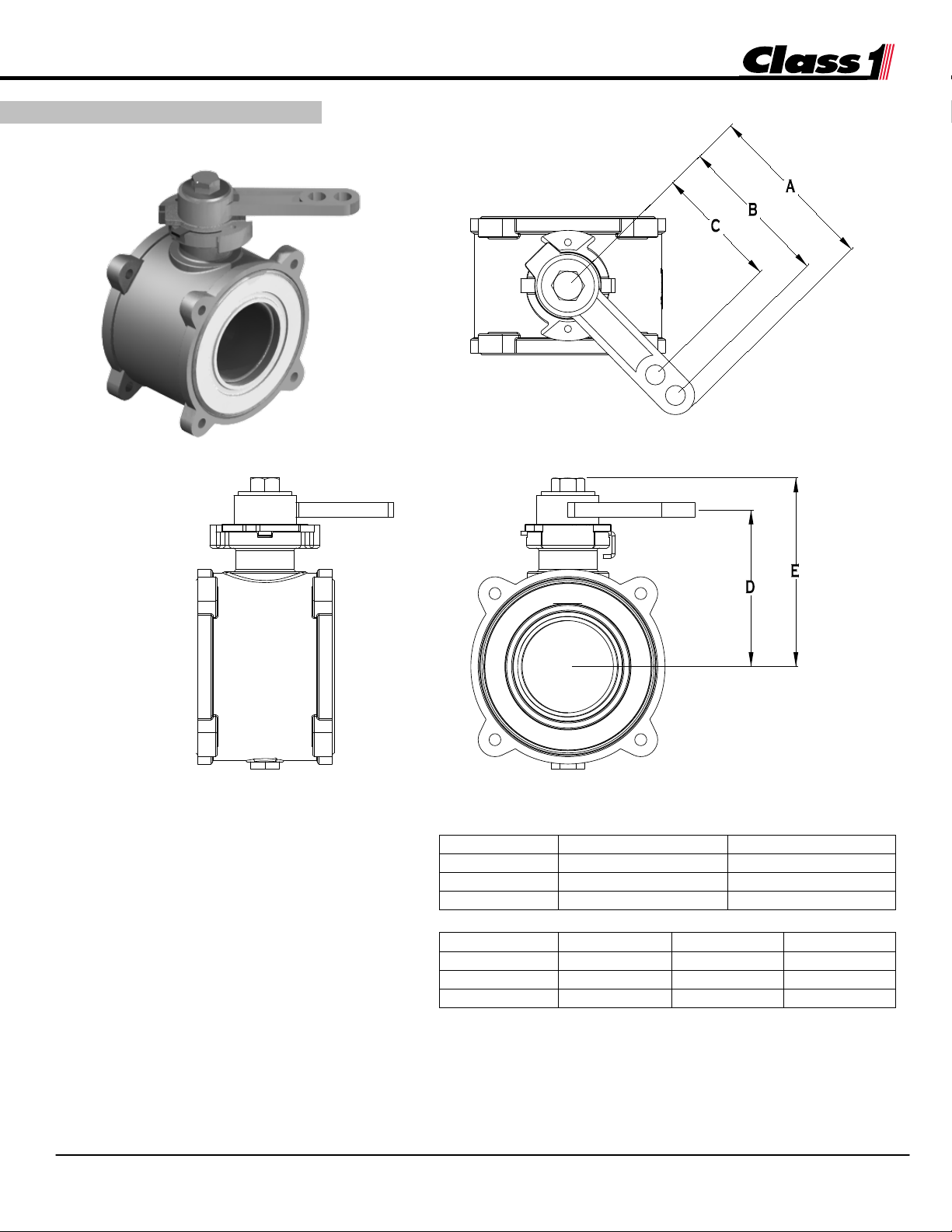

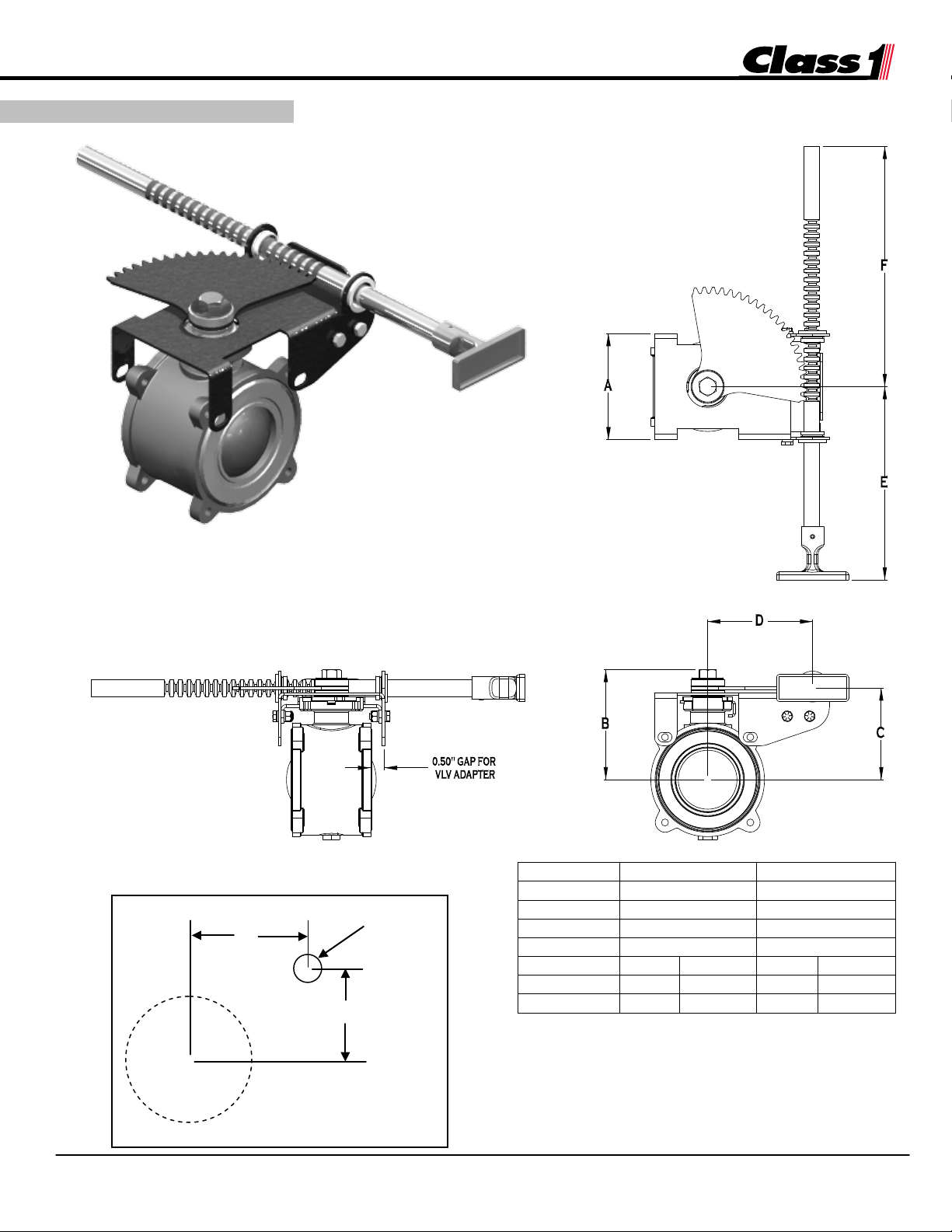

3.1 REMOTE HANDLE

Dimensions

Short Lever

Long Lever

A

4.50”

6.63”

B

4.00”

6.13”

C

3.25”

4.00”

Dimensions

2.0” Valve

2.5” Valve

3.0” Valve

D

3.82”

4.08”

4.46”

E

4.65”

4.91”

5.29”

F

5.30”

5.56”

5.94”

A = valve center to handle length;

3. Actuators

(115164)

B = valve center to outside hole;

C = valve center inside hole;

D = valve center to handle centerline;

E = valve center to top of assembly;

F = valve center to top of slow close

assembly (not shown)

5

p/n: 119138

(116303)

Page 6

Class 1 Valve Manual

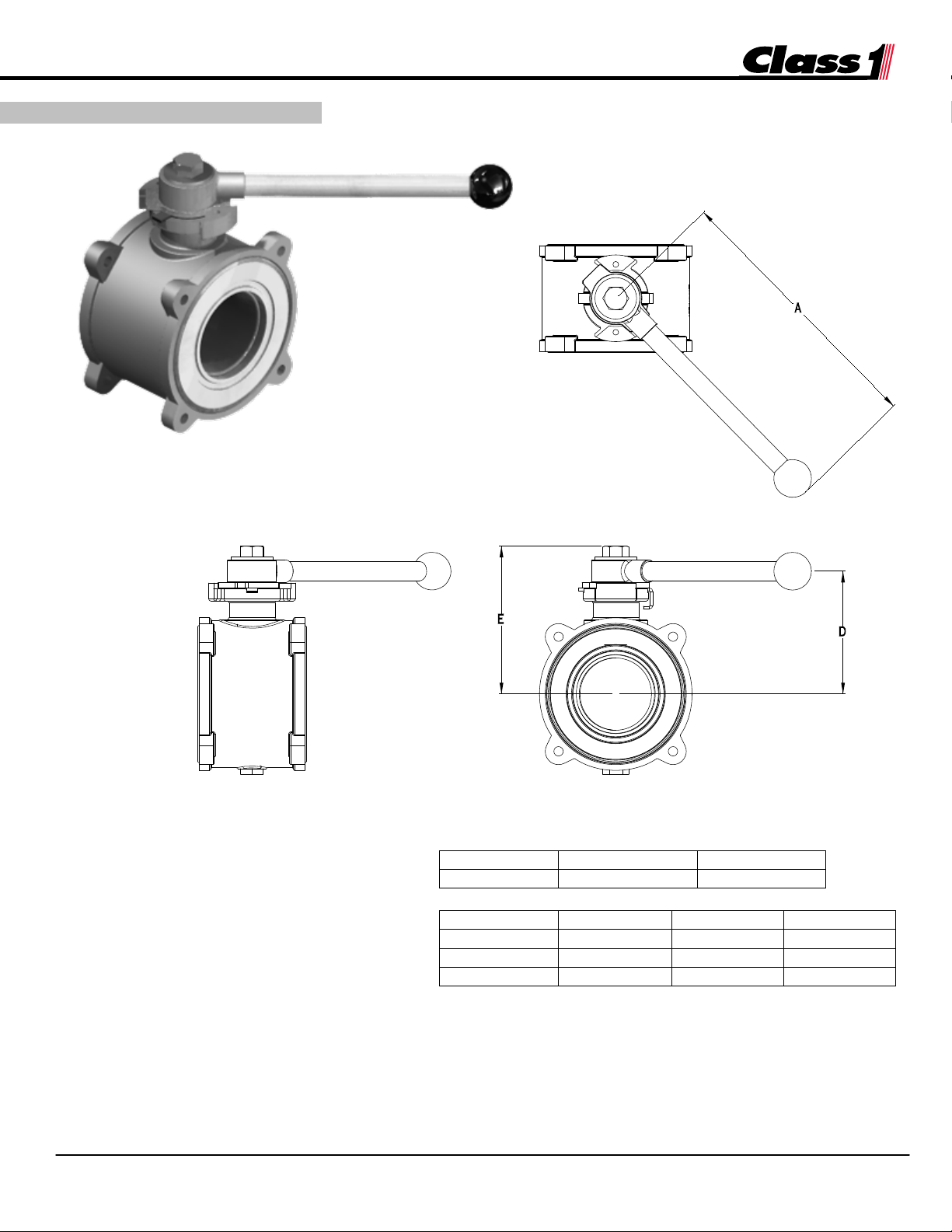

Dimensions

Short Handle

Long Handle

A

9.00”

9.50”

Dimensions

2.0” Valve

2.5” Valve

3.0” Valve

D

3.82”

4.08”

4.46”

E

4.65”

4.91”

5.29”

F

5.30”

5.56”

5.94”

A = valve center to handle length;

3. Actuators

3.2 DIRECT HANDLE

D = valve center to handle centerline;

E = valve center to top of assembly;

F = valve center to top of slow close

assembly (not shown)

[Use shim 119260 with all direct handle actuators. See Section 6.3 on page 24 for installation details.]

6

p/n: 119138

Page 7

Class 1 Valve Manual

Dimensions

2.5” Valve

3.0” Valve

A

4.75”

5.25”

B

4.90”

5.28”

C

4.094”

4.469”

D

4.675”

4.675”

E

15.40”

8.63”

15.40”

8.63”

F

3.93”

10.70”

3.93”

10.70”

3. Actuators

A = width of bracket;

Valve Center

D

Ø1.00”

C

Rod/Handle Cut-Out

3.3 RACK LINKAGE

7

p/n: 119138

OPEN CLOSED OPEN CLOSED

B = valve center to top of assembly;

C = valve center to handle centerline (height);

D = valve center to handle centerline (offset);

E = valve center to front of handle;

F = valve center to back of rod

Page 8

Class 1 Valve Manual

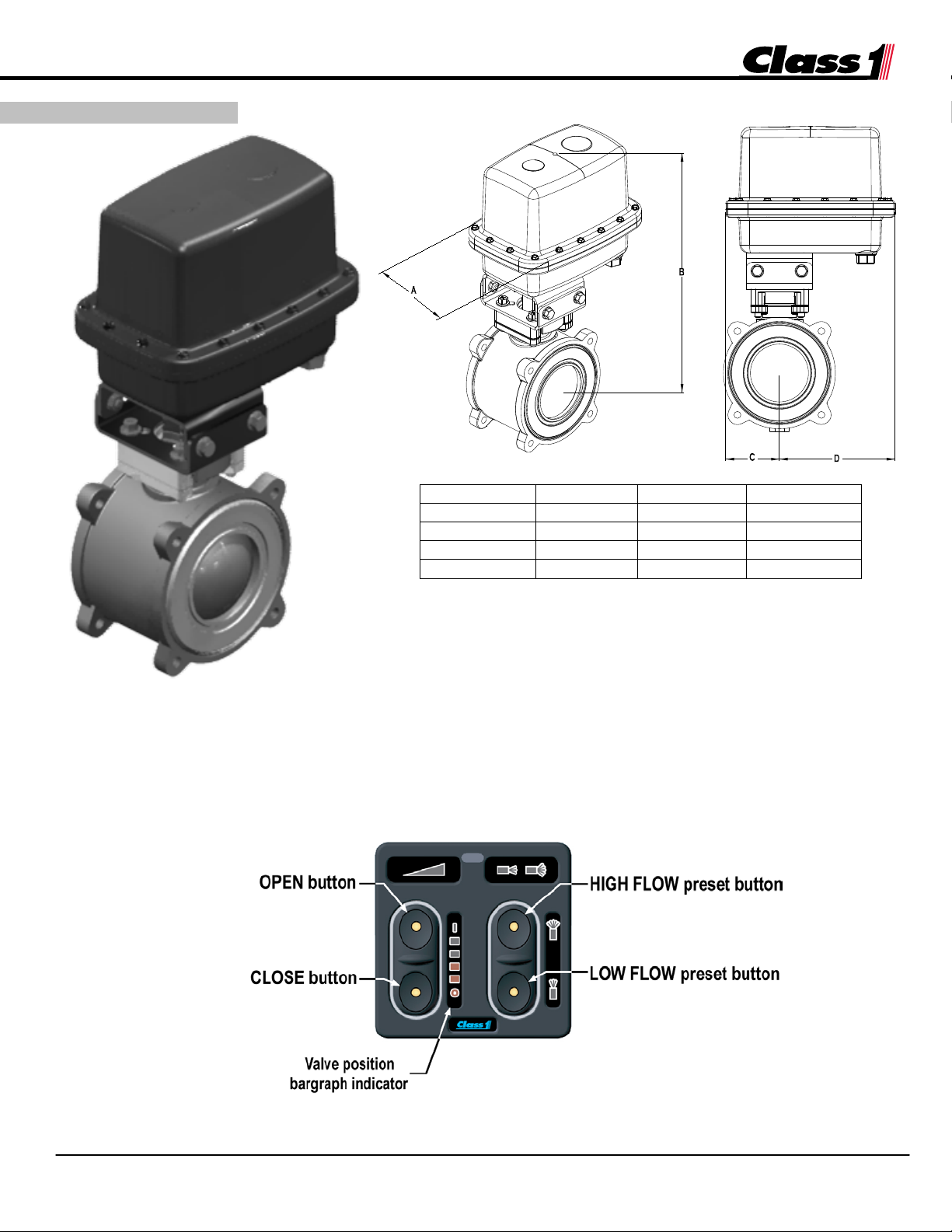

Dimensions

2.0” Valve

2.5” Valve

3.0” Valve

C

2.10”

2.43”

2.43”

D

4.35”

5.23”

5.23”

3. Actuators

A = width of actuator;

3.4 ELECTRIC

Electric actuators require Class 1 controller 117010 to operate.

The 117010 smart switch uses position feedback from the actuator to display

the valve’s open/close position. The smart switch can also be field programmed

for both high- and low-flow preset valve positions.

A 4.29” 5.16” 5.16”

B 9.32” 11.20” 11.58”

B = valve center to top of assembly;

C = valve center to actuator short side (length);

D = valve center to actuator long side (length)

117010 Smart Switch

8

p/n: 119138

Page 9

Class 1 Valve Manual

4. Safety Information

!

!

The Class 1 ball valves are designed for optimum safety of its

operators. For added protection, please follow the safety guidelines

listed in this section and adhere to all warning, danger, caution, and

important notes found within this manual.

The following section must be carefully read, understood, and

followed by all installers and operators before attempting to install or

operate Class 1 Valves. Failure to follow the installation and

maintenance requirements discussed below may result in serious

personal injury and/or damage to equipment.

When developing departmental apparatus operating procedures,

incorporate the warnings and cautions as written herein.

• READ ALL INSTRUCTIONS THOROUGHLY BEFORE BEGINNING ANY

INSTALLATION OR SERVICE PROCESS.

• Use care when removing the Class 1 valve from its packaging to prevent personal injury

and/or damage to the unit.

o The weight of the Class 1 ball valves varies according to size. Check your bill of

lading for the approximate weight. Where deemed necessary, be certain to use

proper lifting support devices or additional personnel.

• Before beginning any inspection, installation, maintenance, or service of any kind on the

valves, verify that the pressure has been released from the system. Lock out the equipment

in the system in accordance with the manufacturer’s recommendations.

• Installation should be performed by a trained and qualified installer. Be sure the installer has

sufficient knowledge, experience, and proper tools before attempting any installation.

o The installer is responsible for observing all instructions and safety precautions in his

or her daily routine as dictated by regional safety ordinances or departmental

procedures.

• DO NOT tamper with or disconnect safety features which could affect safe operation of

the valve and/or cause personal injury.

• Do not weld in proximity to the valve. Heat transfer from the welding process will damage

the plastic valve seals.

• No modifications or additions may be made to the Class 1 valve without prior written

permission from:

Class 1, Inc.

607 NW 27th Avenue

Ocala, FL 34475 USA

Telephone: (352) 629-5020

Fax: (352) 629-2902

• Disconnect all power sources before servicing an electric valve.

o Electrical systems have the potential to cause sparks during service or repair.

Eliminate explosive or hazardous materials in the environment during installation or

service.

9

p/n: 119138

Page 10

Class 1 Valve Manual

MODEL

RATED OPERATING PRESSURE

C20 (2.0”)

400 psi (1724 kPa)

C25 (2.5”)

400 psi (1724 kPa)

C30 (3.0”)

400 psi (1724 kPa)

4. Safety Information

o Electric motors and wiring are protected by a circuit breaker. DO NOT remove or

bypass the circuit breaker, as severe damage to the electric motor or apparatus

wiring could occur.

• Be careful that NO part of your body (head, feet, arms, legs, fingers, hair, etc.) is in an area

of rotating or moving parts.

• Certain internal parts of the Class 1 valve assembly may be under tension. When servicing

the valve, wear eye protection and exercise care when removing these parts.

• Fasteners used for the assembly of the Class 1 valves are plated Grade 8 steel.

• Foreign materials, like metal chips or shavings, can destroy the plastic seals on the valves.

Machine connected parts and remove foreign materials prior to installing the Class 1 valve.

• If your Class 1 valve includes the Slow-Close option, do not tamper with the slow-close

actuator. There are no serviceable parts inside. The actuator must never be disassembled.

Contact Class 1 for a replacement assembly.

o Current NFPA 1901 Standards specify that a minimum of three seconds is required

to open or close a 3” or larger valve.

• DO NOT exceed the rated Class 1 valve operating pressure, shown below:

10

p/n: 119138

Page 11

Class 1 Valve Manual

5. installation

Evaluate the best location for the valve installation, taking the following into consideration:

• Customer requirements

• Discharge location on the vehicle

• Maintenance accessibility

• Linkage Geometry – Refer to Hale Products service bulletin SB92 for details.

• Valve actuation

o Manual – left or right close; actuator position: left, right, top, or bottom; push rod or

handwheel

o Electric – wiring path; securing wire harness and mounting the controls

o Clearance around the actuator

• Control panel layout

5.1 Principals of Operation

• The Class 1 ball valve controls flow with a stainless steel internal ball. The valve uses a quarter-

turn design to minimize travel and is operated by manual lever, remote push rod, electric actuator,

or gear-driven actuator.

• The “swing out for service” design allows for watertight operation that is easy to use and easy to

maintain.

5.2 Installation Guidelines

• Pump body and compartment – Examine the pump body and the available space inside the pump

compartment to decide the best pump discharge opening to use. Account for space restrictions

from piping and valve control linkages throughout the compartment.

• Fasteners – Verify that all fasteners used on Class 1 valves are plated Grade 8 steel. Apply Loctite

#242 or equivalent to any threaded fasteners used to install an inlet or outlet valve adapter. Install

and tighten fasteners in a cross pattern, to ensure an even, watertight seal between the valve and

adapter. Torque the fasteners to a maximum 45 ft-lbs (Grade 8). [Refer to Hale Products

document ES018-002 – Torque Values for Threaded Fasteners, for more details.]

• NPT fittings – Use a joint sealing compound (Loctite or equivalent) on all NPT threaded adapter

fittings.

• Victaulic® connection – If the valve outlet adapter uses a Victaulic® fitting, connect the appropriate

coupling seal with a Victaulic® approved lubricant. Follow the recommended Victaulic® installation

procedures.

11

p/n: 119138

Page 12

Class 1 Valve Manual

Hex bolt & washer

5. installation

!

!

• Electric actuators – If an electric actuator is used, route the wire harness away from potentially hot

and/or moving parts. Secure the harness every 10” – 12” (254mm – 309mm) to prevent excessive

movement.

• Testing – After installation, verify that the valve cycles properly from fully OPENED to fully

CLOSED without excessive effort. If equipped with a hand wheel or electric control, verify that

the indicator lights sequence properly, indicating valve OPEN, CLOSE, or in between. Pressure

test valve connections before placing apparatus into service.

5.3 Direct and Remote Handle Installation

1. Remove the hex bolt and washer from the valve stem.

2. Slide the handle over the valve stem, so that it is seated on top of the stop plate.

3. As needed, adjust the handle and stop plate orientation so that the valve is open or closed with the

correct handle position.

4. Apply Loctite #242 or equivalent to the hex bolt and reinstall the bolt and washer to secure the

handle. Torque the bolt to 40 ft-lbs. [As the screw is tightened, ensure that the valve retaining bracket

is aligned so that it slides into the grooves on the valve body.]

5. Open and close the valve several times to check for smooth operation.

IMPORTANT

Retaining bracket seated in

groove (both sides) – Step 4

Handle

Stop plate

12

p/n: 119138

Page 13

Class 1 Valve Manual

Pins flush

with flat side

Bracket Base

Lower Bracket

Shims

Bottom

Plates

Actuator

Stem Adapter

5. installation

5.4 Electric Actuator Installation

5.4-1 Electric Actuator Assembly Parts 5.4-2 Valve with Stem and Insulator in Place

1. Remove the hex bolt and washer from the valve stem. (These are no longer needed.) Also

remove the stop plate, valve stem retainer (bend if necessary), and wave spring (see valve exploded

view for part details—Section 6.3). Keep the valve stem and valve stem insulator bushing in place.

[Figure 5.4-2]

2. Press the two (2) small dowel pins into the bracket base [Figure 5.4-3], so that they are flush with

the flat side.

3. Place the bracket base onto the top of the valve, aligning the dowel pins with the holes on the

valve. [Figure 5.4-4]

5.4-3 Bracket Base with Dowel Pins 5.4-4 Bracket Base Mounted onto Valve

4. Place the lower bracket on the bracket base. (Orientation of the bracket base affects the orientation of

the electric actuator, and must be determined by the installer.) Insert the four (4) long bolts through

the lower bracket and bracket base. [Figure 5.4-5]

13

p/n: 119138

Page 14

Class 1 Valve Manual

5. installation 5. installation

Incorrect Orientation –

5. Add the bottom plates and thread the long bolts into the plates. (Loctite use is recommended.)

Orient the bottom plates so that the ridges face down, toward the valve body. Torque four bolts

in a criss-cross pattern to a maximum value of 11 ft-lbs. (Discard shims – they are not needed.)

[Figures 5.4-6 through 5.4-8]

Figure 5.4-5 Lower Bracket with Four Long Bolts Figure 5.4-6 Adding the Bottom Plates

Ridge must face DOWN,

toward valve body

Figure 5.4-7 Fastening the Bottom Plates Figure 5.4-8 Incorrect Orientation of Bottom Plates

6. Install the valve stem adapter onto the valve stem. [Figure 5.4-9]

7. Attach the upper bracket and actuator to the lower bracket, using the three smaller hex bolts and

nuts. (You may have to rotate the valve stem to allow the adapter to sit correctly. Loctite use is

recommended.) [Figure 5.4-10]

8. Connect all wiring and harnesses.

9. Using the smart switch panel, open and close the valve a few times to ensure it is working properly.

Check the lights on the smart switch to verify that the ball is in the OPEN/CLOSE position as

indicated. If the OPEN switch closes the valve, remove the actuator, rotate the valve stem and ball

90°, and reattach the electric actuator.

14

p/n: 119138

Page 15

Class 1 Valve Manual

5. installation

Figure 5.4-9 Valve Stem Adapter Installed

Figure 5.4-10 Upper Bracket & Actuator Connected to Lower Bracket

15

p/n: 119138

Page 16

Class 1 Valve Manual

Bottom Plate

Base Bracket

Upper Bracket

Short Bolts &

Nuts

Bottom Bracket

Long Bolts

5. installation

& Actuator

Figure 5.4-11 Complete Installation of Electric Actuator

16

p/n: 119138

Page 17

Class 1 Valve Manual

5. installation

5.4.1 Utilizing the KZCO EH2 Series Electric Actuator (for 2.0” Class1 Valves)

The diagram below shows the typical layout using the SPS Electric Valve controller (117010) with KZCO

EH2 series electrical actuator (p/n 117234-003). The harness part number is 117593-XX (where XX is

the length in feet – 05, 10, 15, 20, 25, 30).

Harness p/n 117593-XX

(where XX is the length in feet – 05, 10, 15, 20, 25, 30).

KZCO EH2 series electrical actuator positioning details

Opening: positive polarity on pin B (white wire), ground polarity on pin A (green wire).

Valve moves in counter-clockwise direction (as viewed from top).

Fully open, voltage feedback = 2.80V (± 0.25V).

Closing: positive polarity on pin A (green wire), ground polarity on pin B (white wire).

Valve moves in clockwise direction (as viewed from top).

Fully closed, voltage feedback = 1.00V (± 0.25V).

17

p/n: 119138

Page 18

Class 1 Valve Manual

5. installation

5.4.2 Utilizing the KZCO EH5 Series Electric Actuator (for 2.5” & 3.0” Class1 Valves)

The diagram below shows the typical layout using the SPS Electric Valve controller (117010) with KZCO

EH5 series electrical actuator (p/n 117234). The harness part number is 117008-XX (where XX is the

length in feet – 05, 10, 15, 20, 25, 30).

Harness p/n 117008-XX

(where XX is the length in feet – 05, 10, 15, 20, 25, 30).

KZCO EH5 series electrical actuator positioning details

Opening: positive polarity on pin 3 (white wire).

Valve moves in counter-clockwise direction (as viewed from top).

Fully open, voltage feedback = 2.80V (± 0.25V).

Closing: positive polarity on pin 2 (green wire).

Valve moves in clockwise direction (as viewed from top).

Fully closed, voltage feedback = 1.00V (± 0.25V).

18

p/n: 119138

Page 19

Class 1 Valve Manual

Mating connector: AMP 794781-1

PIN

DIR

CIRCUIT

DESCRIPTION

1

◄

Supply (+)

Vehicle power (positive, +12VDC to +32VDC)

2 ----

Not used

3 ----

Not used

4

►

Reference (+)

Valve position supp ly reference (positive, +5VDC)

5

◄

Position signal

Valve position signal (analog, 0-5VDC)

6 ----

Not used

7 ----

Not used

8

►

Valve motor A

Valve direction contr ol (± polarity, direction based)

9

►

Valve motor B

Valve direction contr ol (± polarity, direction based)

10

◄

Supply (-)

Vehicle power (g round)

5. installation

5.4.3 SPS Electric Valve Controller Connection Description

The module has one connector and the following definitions apply:

Mating terminals: AMP 770988-1

Seal: AMP 794772-0

Wire seal: AMP 794758-1

Cavity plug: AMP 794995-1

Recommended wire gage: 18-26 AWG

IN

OUT

IN

OUT

OUT

IN

(1)

(1)

(1)

CLOSE = positive polarity Valve motor A, ground polarity Valve motor B

OPEN = ground polarity Valve motor A, positive polarity Valve motor B

Connector pin position detail (SPS view).

19

p/n: 119138

Page 20

Class 1 Valve Manual

5. installation

Slow Close Assembly

5.5 Slow Close Assembly Installation

1. Remove the bolt and washer threaded into the valve stem. (If no handle is attached, install a direct

or manual handle.

2. Align the slow close assembly so that the two (2) spring pins on the slow close can be pressed into

the top of the valve body. There is a 90° slot on the slow close assembly that allows space for a

handle. Align the four (4) inner pins, so that they slide into the space between the handle and valve

stem (see picture below).

3. Secure slow close assembly with new 1.75” long hex bolt, p/n 116300-001. Torque the bolt to a

40 ft-lbs. [The original 1.00” bolt is no longer required.]

4. Open and close the valve several times to ensure the slow close assembly is working properly.

• An internal stop was designed into the slow close assembly and orientation of this stop may

prevent correct handle movement. If this occurs, remove the slow close assembly, rotate the

ball valve 90°, and reinstall the slow close assembly.

5. Do NOT remove the top four (4) bolts and attempt to service the slow close. There are no

serviceable parts in this assembly.

Installed on 2.5” Class1 Valve

20

p/n: 119138

Page 21

Class 1 Valve Manual

Inner Pins on Bottom

5. installation

of Slow Close

Slow Close Installation – (Upper Piece & Inner

Installing Slow Close Assembly onto Valve & Handle Components Removed for Clarity)

5.6 Rack Linkage Installation

1. Remove the bolt and washer threaded into the valve stem. Remove any attached lever or handle.

2. Remove the top two bolts, washer, and lock washer on both valve flange adapters on the valve.

3. Attach the main bracket (Item 2) with these four bolts, washer, and lock washer. Torque these

bolts to the specifications shown in Section 5.2.

4. Install the two bushings and snap rings (Items 7 & 8). Orient the bushings so that the snap rings are

on the inside of the main bracket.

5. Install the lock bracket (Item 3), using four bolts (Item 8), eight washers (Item 9), and four lock nuts

(Item 10).

6. With the valve attached to the pump manifold, install the rack rod with handle (Items 11-13)

through the pump panel and brass bushings.

7. With the valve in the closed position, install the two gear spacers (Item 5) and the gear (Item 4).

For correct vertical placement, the gear should be in-between the two gear spacers. [As you install

the gear, adjust the rack rod so that the first tooth and first groove are aligned.]

8. Install the original bolt and washer (Items 15 and 14) and torque the bolt to 40 ft-lbs.

9. Adjust the lock bracket (Item 3) so that there is a 1/16” gap between the bracket and the rack rod.

10. If the rack rod operation is difficult or the rack and gear teeth appear to bind, adjust the position of

the main bracket (Item 2) to increase/decrease the distance between the rack rod and the gear.

21

p/n: 119138

Page 22

Class 1 Valve Manual

Item

2.5” Valve P/N

3.0” Valve P/N

Description

1

C25-0000-00-0

C30-0000-00-0

Valve Center Body

2

119417

117376

Main Bracket

4

117374

117374

Gear

6

119881

119881

Brass Bushing

7

106623

106623

Snap Ring

8

018-1206-02-0

018-1206-02-0

Hex Head Bolt 1/4-20 x 0.75” G5 Zinc

9

097-0020-02-0

097-0020-02-0

Flat Washer 1/4”

10

110-1200-11-0

110-1200-11-0

Nut Nylock 1/4”

11

117372

117372

Rack Rod

12

100294

100294

Handle

13

100379

100379

Roll Pin

15

113303

113303

Hex Head Bolt 1/2-13 x 1.00” SST

5. installation

3 119418 117371 Lock Bracket

5 117373 117373 Gear Spacer

14 106949 106949 Washer Flat 1/2” (Included with valve)

(Included with valve)

22

p/n: 119138

Page 23

Class 1 Valve Manual

6. Maintenance

!

!

WARNING – Before beginning any inspection, maintenance, or service to the

equipment, verify that the pressure has been released from the system. Lock

out the equipment, in accordance with the manufacturer’s recommendations.

Open discharge valves, remove the suction tube caps, and discharge valve caps

to release any residual pressure.

6.1 After Each Use

• If the system is operated with salt water, foam, or contaminated water, flush the valve with fresh

water, in accordance with your department/company procedures.

• Open and close the valve to verify that it still operates smoothly.

6.2 Monthly

• Inspect the valve actuator, push rods, and drive shafts (if equipped) for wear, corrosion, or foreign

• If accessible, visually inspect the valve to make sure there is no debris caught between the valve

debris. Lubricate all ball joints, universal joints, and exposed bearings and wear points with an approved

lubricant.

body and valve ball.

23

p/n: 119138

Page 24

Class 1 Valve Manual

Item

2.0” Valve P/N

2.5” Valve P/N

3.0” Valve P/N

Description

1

116237

116238

116239

Valve Body

2

116254

116254

116255

Valve Stem

3

040-2100-00-0

040-2100-00-0

040-2100-00-0

O-Ring 210 Buna-N

4

116288

116288

116288

Valve Thrust Washer

6

116287

116287

116287

Valve Wave Spring

8

117301

117302

117303

Valve Ball

9

116256

116256

116257

Trunnion

10

116896

116896

040-1140-00-0

O-Ring 111 (2”/2.5”) 114 (3”) Buna-N

11

116270

116191

116259

Valve Seal

12

116260

116260

116260

Valve Stop Plate

13

106949

106949

106949

Washer Flat 1/2”

Shim

6. Maintenance

6.3 Valve Exploded Parts List

5 116289 116289 116289 Valve Stem Insulator Bushing

7 116261 116261 116261 Valve Retainer

14 113303 113303 113303 Hex Head Bolt 1/2-13 x 1.00 SST

15* 119260 119260 119260

24

p/n: 119138

*(For use in direct handle locking valves only)

Page 25

Class 1 Valve Manual

2.0” Class 1 Valve Repair Kits

Level 1 Kit

Level 2 Kit

Level 3 Kit

1

040-2100-00-0

1

O-Ring 210 Buna-N

2

116896

1

O-Ring 111 Buna-N

3

116270 2 Valve Seal

4

116288

1

Valve Thrust Washer

5 116289

1

Valve Stem Insulator Bushing

6 116287

1

Valve Wave Spring

7

117301 1 Valve Ball

2.5” Class 1 Valve Repair Kits

1

040-2100-00-0

1

O-Ring 210 Buna-N

3

116191 2 Valve Seal

4

116288

1

Valve Thrust Washer

5

116289

1

Valve Stem Insulator Bushing

6 116287

1

Valve Wave Spring

7

117302 1 Valve Ball

3.0” Class 1 Valve Repair Kits

Level 1 Kit

Level 2 Kit

Level 3 Kit

1

040-2100-00-0

1

O-Ring 210 Buna-N

2

040-1140-00-0

1

O-Ring 114 Buna-N

3

116259 2 Valve Seal

4

116288

1

Valve Thrust Washer

5 116289

1

Valve Stem Insulator Bushing

6 116287

1

Valve Wave Spring

6. Maintenance

6.4 Valve Repair Kits

Item Part Number QTY Description

Item Part Number QTY Description

2 116896 1 O-Ring 111 Buna-N

p/n 119251

Level 1 Kit

p/n 119254

p/n 119252

Level 2 Kit

p/n 119255

p/n 119253

Level 3 Kit

p/n 119256

Item Part Number QTY Description

7 117303 1 Valve Ball

p/n 119257

p/n 119258

p/n 119259

25

p/n: 119138

Page 26

Class 1 Valve Manual

7. Troubleshooting

!

!

The information in this chapter lists the possible causes and suggested solutions for

standard Class 1 valve applications and troubleshooting. Before calling Class 1 or a Class 1

authorized parts service center for assistance, please attempt to eliminate the problem with this

information.

If you cannot correct the problem, please collect the following information before calling

your Class 1 Customer Service Technician or Service Center for assistance:

• Valve Size

• Valve Location (Discharge #1, Pony Suction, etc.)

• Type of Actuator Attached to Valve (swing handle, push-pull T-handle control, top-

mount control, electric controller, rack linkage, etc.)

• Truck Manufacturer

• Truck Build Date

WARNING! Before beginning any inspection, installation, maintenance, or service of

any kind on the equipment, verify that the pressure has been released from the system.

Lock out the equipment, in accordance with the manufacturer’s recommendations.

26

p/n: 119138

Page 27

Class 1 Valve Manual

SIZE

BODY PART NUMBER

2.0”

116237

2.5”

116238

3.0”

116239

7. Troubleshooting

Class 1 Valve

Class 1 Valve – eight short mounting bolts

(Class 1 logo with 6-digit part number)

Valve Identification in the Field – 700 & 800 Series Valves by Hale Products

Hale 700 series valve – four long mounting bolts Hale 800 series valve – eight short mounting bolts

(Hale logo with flow direction arrow on casting) (Hale logo with flow direction arrow on casting)

27

p/n: 119138

Page 28

Class 1 Valve Manual

7. Troubleshooting 7. Troubleshooting

CONDITION: Valve operation requires excessive effort to OPEN or CLOSE.

REMEDY:

• If equipped with slow-close actuator, remove the slow-close module and operate the valve. If the valve

operates normally, replace the slow-close actuator.

•

If equipped with the gear actuator, verify that the gear actuator, actuator handle, and drive shaft are

not damaged or bent, and are lubricated. Remove the gear actuator and operate the actuator and

valve separately, to determine which components are at fault.

•

Loosen and re-torque the 3/8”-16 adapter flange mount bolts to 45 ft-lbs (Grade 8) in a criss-cross

pattern to ensure an EVEN seal.

•

Remove the outlet adapter. Inspect the valve ball, valve seals, valve stem, and o-ring seals for foreign

debris, deterioration, or damage. Replace as necessary.

CONDITION: Valve leaks.

REMEDY:

• Isolate the location of the leak. Is the valve leaking internally (leaking when closed) or externally

(through the seal to an inlet or outlet adapter)?

•

Shut down the pump and verify system pressure has been relieved. See warning at beginning of this

chapter.

EXTERNAL LEAK

• Between valve and adapter – Loosen the four adapter mounting bolts and re-torque to 45 ft-lbs (Grade

:

8) in a criss-cross pattern to ensure an EVEN seal.

•

Remove the leaking valve seal and visually inspect for foreign debris, deterioration, or damage (cracks,

splits, flat spots, etc), especially around the adapter / seal interface. Replace parts as necessary.

•

Valve stem area – Remove outlet adapter, valve handle/lever, and ball. Remove the valve stem and

inspect all o-rings for deterioration or damage (cracks, splits, flat spots, etc.). Replace parts as

necessary.

INTERNAL LEAK (through ball):

• OPEN and CLOSE the valve several times and visually inspect the valve ball to ensure the valve closes

completely.

•

Loosen the four adapter mounting bolts and re-torque to 45 ft-lbs (Grade 8) in a criss-cross pattern to

ensure an EVEN seal on both the adapters and the ball.

28

p/n: 119138

Page 29

Class 1 Valve Manual

7. Troubleshooting

• Remove both valve seals and visually inspect them for foreign debris, deterioration, or damage (cracks,

splits, flat spots, etc), especially around the valve ball / seal interface. Replace parts as necessary.

•

Remove the valve ball and visually inspect the outer surface for scratches or marks that would prevent

full contact with the valve seal. Replace the ball if necessary.

CONDITION: Valve does not fully OPEN or CLOSE – manual operation.

REMEDY:

• Inspect the actuator lever or handle for proper installation on the valve stem. (The valve must open or

close fully before the stop plate makes contact with the valve body.) Adjust handle orientation as

needed.

•

Inspect the valve ball and valve seals for foreign debris, deterioration, or damage that could cause

interference between the valve ball and seals or body.

If you require replacement parts for your Class 1 valve, please order the

appropriate repair kit, shown in Section 6.4.

29

p/n: 119138

Page 30

Class 1 Valve Manual

Class 1, Inc. • A Unit of IDEX Corporation

(P/N 114659)

119416

607 NW 27th Avenue • OCALA, FL 34475 USA

800.533.3569 • FAX: 352.629.2902

www.class1.com

30

p/n: 119138

Loading...

Loading...