Page 1

TECHNICAL PRODUCT DATASHEET

Total Pressure Governor

P/N 117155

FORM-ENG-0018 REV A 06-02-03

ISO 9001 CERTIFIED

607 NW 27th Ave

Phone: (352) 629-5020 or 800-533-3569

Ocala, FL 34475

Fax: (352)-629-2902

SUITABLE FOR EXTER NAL DISTRIBUTION

TPG

Page 2

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

TOTAL PRESSURE GOVERNOR (TPG)

TECHNICAL DATA SHEET

THROTTLE CONTROL

P/N 117155 REV

PAGE

DATE

BY AMS

1 OF 26

3/28/2012

1.23

1. REVISION LOG ........................................................................................................................................... 3

2. SYSTEM OVERVIEW .................................................................................................................................. 4

2.1. SYSTEM PART NUMBERS ........................................................................................................................... 4

2.2. HARNESS DETAIL (P/N 117666 AND P/N 117683) ....................................................................................... 4

3. TOTAL PRESSURE GOVERNOR OVERVIEW .......................................................................................... 6

3.1. DISPLAY .................................................................................................................................................. 7

3.2. INTERLOCK STATUS INDICATORS ............................................................................................................... 7

3.3. CONTROL SWITCHES ................................................................................................................................ 7

3.3.1. IDLE ................................................................................................................................................... 7

3.3.2. MENU/SILENCE ................................................................................................................................ 7

3.3.3. PRESET ............................................................................................................................................ 7

3.3.4. MODE ................................................................................................................................................ 7

3.3.5. INC..................................................................................................................................................... 7

3.3.6. DEC ................................................................................................................................................... 7

3.4. MODE INDICATOR ..................................................................................................................................... 7

3.5. BATTERY VOLTAGE MONITOR .................................................................................................................... 8

3.6. COOLANT TEMPERATURE MONITOR ........................................................................................................... 8

3.7. OIL PRESSURE MONITOR ........................................................................................................................... 8

4. OPERATION ................................................................................................................................................ 9

4.1. INITIALIZATION .......................................................................................................................................... 9

4.2. OPERATING MO D E SELECTION ................................................................................................................... 9

4.2.1. Throttle mode .................................................................................................................................... 9

4.2.2. Pressure mode ................................................................................................................................ 10

4.3. REQUIRED INTERLOCKING ....................................................................................................................... 11

4.4. PRESET SWITCH OPERATION................................................................................................................. 11

4.5. IDLE SWITCH OPERATION ....................................................................................................................... 12

4.6. STATUS AND WARNING MESSAGES .......................................................................................................... 12

5. GOVERNOR CONTROL SETUP MENU ................................................................................................... 13

5.1. ENGINE COMPATIBILITY ........................................................................................................................... 13

5.2. ENTER THE SETUP MENU ........................................................................................................................ 13

5.2.1. UNITS (unit of measure configuration) ............................................................................................ 16

5.2.2. PRESET RPM (throttle preset configuration) .................................................................................. 16

5.2.3. HI-IDLE (high idle configuration) ..................................................................................................... 16

5.2.4. PRESET PSI (pressure preset configuration) ................................................................................. 16

5.2.5. BRIGHT (display brightness) ........................................................................................................... 16

5.2.6. DISPLAY TEST ............................................................................................................................... 16

5.2.7. ROUND PSI (configure rounding of the pressure value) ................................................................ 16

5.2.8. ALERT TONE (configure alert tones) .............................................................................................. 16

5.2.9. SENSITIVITY (pressure sensitivity configuration) ........................................................................... 17

5.2.10. SENSOR CAL (pressure sensor calibration) .............................................................................. 17

5.2.11. 1st MODE (first active mode configuration) ................................................................................. 17

5.2.12. AUTO MODE (pressure mode automatically entered on pump engagement) ........................... 17

5.2.13. COMM STATUS (view the CAN communication status) ............................................................ 17

5.2.14. CONTROL (engine control message type) ................................................................................. 17

5.2.15. RPMidle (idle RPM value) ........................................................................................................... 18

5.2.16. RPMmaxi (maximum RPM value) ............................................................................................... 18

5.2.17. SourceID (CAN message source identification).......................................................................... 18

5.2.18. TSC1 RAMP (TSC1/PGN0 control mode RPM ramp speed) ..................................................... 18

Manual P/N 117684

Page 3

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

TOTAL PRESSURE GOVERNOR (TPG)

TECHNICAL DATA SHEET

THROTTLE CONTROL

P/N 117155 REV

PAGE

DATE

BY AMS

5.2.19. DISPLAY (primary display in pressure mode) ............................................................................ 18

5.2.20. PSI TIME-OUT (pressure time out) ............................................................................................. 18

5.2.21. ALLOW PRESET (allow RPM preset use when pressure is detected) ...................................... 18

5.2.22. WARNINGS (data monitor warning configuration) ..................................................................... 19

A. WARN ºF (User defined engine temperature high warning - Yellow LED).......................................................19

B. CRIT ºF (User defined engine temperature high critical - Red LED) ...............................................................19

C. WARN PSI (User defined oil pressure low warning - Yellow LED) ..................................................................19

D. CRIT PSI (User defined oil pressure low critical - Red LED) ...........................................................................19

5.2.23. XDUCR (discharge pressure transducer range) ......................................................................... 19

5.2.24. FACTORY DFLT (Set factory defaults) ....................................................................................... 19

5.2.25. POC ASSERT (Power On Cycle assertion) ................................................................................ 19

5.2.26. GOV GAIN (RPM change per step) ............................................................................................ 19

5.2.27. PRESS GAIN (PSI change per step) .......................................................................................... 19

5.2.28. DITHER (Engine handshake)...................................................................................................... 20

5.2.29. LAG ∆PSI (Pressure lag) ............................................................................................................ 20

5.2.30. PUMP HOURS ............................................................................................................................ 20

5.2.31. BCM1 VER (Body Control Message 1 version) .......................................................................... 20

5.2.32. SCANIA MODE? (Scania governor type) ................................................................................... 20

5.2.33. IDLE STEPS (Analog control idle) .............................................................................................. 20

5.2.34. OKAY2PUMP (Okay to pump interlock source).......................................................................... 20

5.2.35. SPN 3350 (TSC1 – SPN 3350) ................................................................................................... 21

5.2.36. SPN 696 (Engine Requested Speed Control Condition) ............................................................ 21

5.2.37. HI IDLE MODE ............................................................................................................................ 21

5.2.38. BUS INTLKS (Bus message control of throttle ready interlock) ................................................. 21

5.2.39. VOLTS (Voltage display calibration) ........................................................................................... 21

5.2.40. SMOOTHING (Pressure display averaging) ............................................................................... 21

5.2.41. ENGINE ID (Source ID of received engine messages) .............................................................. 22

2 OF 26

3/28/2012

1.23

6. SPECIAL FUNCTION PASSWORDS (SEE SECTION 5.2 FOR PROCEDURE ON ENTERING

PASSWORDS) ...................................................................................................................................................... 23

6.1. SETTING CONTROL MESSAGE TRANSMISSION REQUIREMENTS ................................................................... 23

6.2. SETTING CONTROL FOR SPECIFIC ENGINE TYPES ...................................................................................... 23

6.3. CONFIGURING TRANSMISSION OF HYDRAULIC PRESSURE GOVERNOR MESSAGE ........................................ 23

7. CONFIGURATION ..................................................................................................................................... 24

7.1. CONFIGURE THE UNIT OF MEASURE ......................................................................................................... 24

7.2. SELECT PRESSURE TRANSDUCER RANGE (300 PSI, 600 PSI) .................................................................. 24

7.3. ZERO CALIBRATE THE PRESSURE TRANSDUCER ....................................................................................... 25

7.4. CONFIGURE THE ENGINE CONTROL MET HOD ............................................................................................ 25

7.5. CONFIGURE THE IDLE VOLTAGE AND GAIN SETTING USING AUTO SCALE ................................................. 26

8. MOUNTING & INSTALLATION ................................................................................................................. 27

8.1. PANEL CUT OUT DIMENSIONS ................................................................................................................... 27

9. CONNECTOR DESCRIPTION................................................................................................................... 28

9.1. TPG CONNECTORS ................................................................................................................................ 28

9.2. PRESS URE SE NS O R CO NNECTOR ............................................................................................................ 28

10. MODULE OPERATING PARAMETERS ................................................................................................... 29

Manual P/N 117684

Page 4

FORM-ENG-0018 REV A 05-27-03

Rev

Date

Changes

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

1. Revision Log

PRODUCT GROUP

PRODUCT

TOTAL PRESSURE GOVERNOR (TPG)

TECHNICAL DATA SHEET

THROTTLE CONTROL

P/N 117155 REV

PAGE

DATE

BY AMS

3 OF 26

3/28/2012

1.23

1.00

1.10

1.20

1.21

1.22

1.23

3/4/2008 Initial revision

5/2/2008 Update connector description section. Update kit and optional part numbers.

3/24/2010 Added “Okay to pump” configuration information and detail.

4/13/2010 Revised wording in overview section 3.

3/2/2012 Added new feature listing for software versions 3.8 and 3.9

3/28/2012 Added error message for Throttle interlock to section 4.6

Manual P/N 117684

Page 5

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

TECHNICAL DATA SHEET

THROTTLE CONTROL

TOTAL PRESSURE GOVERNOR (TPG)

2. System Overvi ew

2.1. System part numbers

Total Pressure Governor (TPG) system kit 117690

Kit includes

Total Pressure Governor (TPG) QTY-1 117155

TPG main system harness QTY-1 117666

Transducer 0-300 PSI QTY-1 113557

Quick reference guide QTY-1 117685

Optional items

TPG analog signal harness (analog control option) 117683

Transducer 0-600 PSI 117179

Documentation (available from Class 1’s website - www.class1.com)

TPG system Manual (this man ual) 117684

Engine compatibility guide 117686

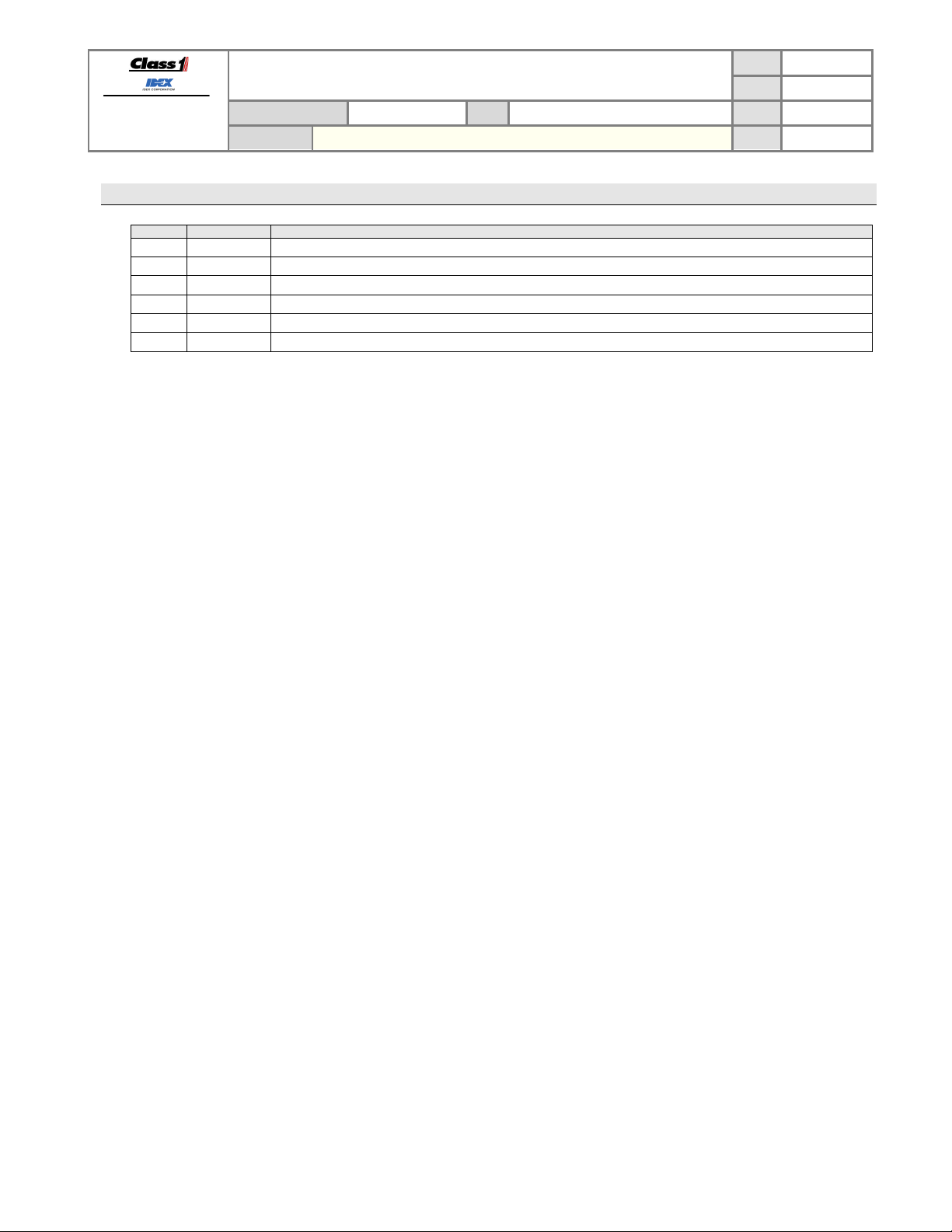

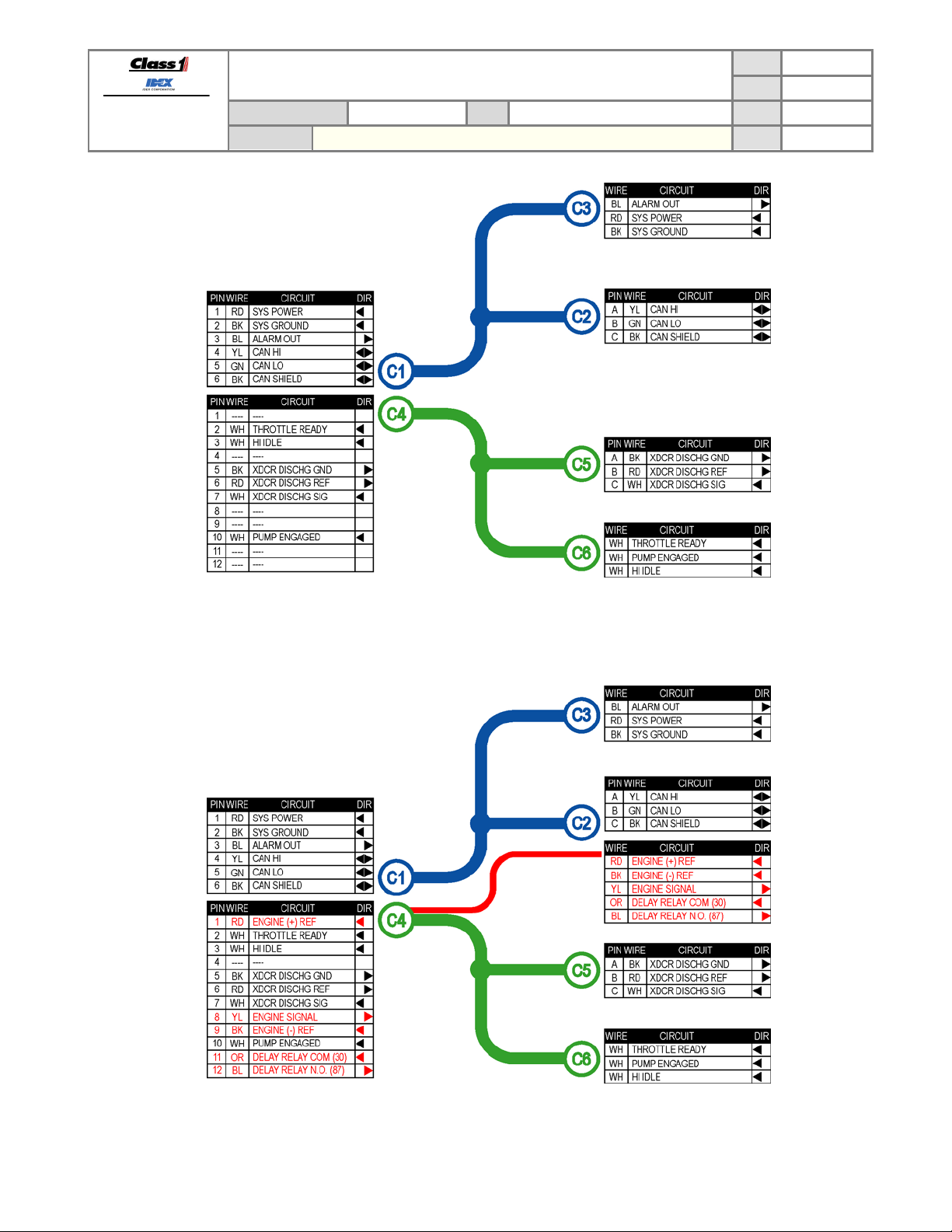

2.2. Harness detail (p/n 117666 and p/n 117683)

The main system harness (p/n 117666) is comprised of a pair of harnesses: the power/communication harness

(depicted below in blue) and the signals harness (depicted below in green).

When the analog signal control option is desired instead of the standard CAN control option then the analog control

option harness is also required (p/n 117683). This harness is actually a set of wires and pins which must be inserted

into connector C1 (depicted below with a red dashed line).

PAGE

DATE

P/N 117155 REV

BY AMS

4 OF 26

3/28/2012

1.23

Manual P/N 117684

Figure 1. Harness nomenclature.

Page 6

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

TOTAL PRESSURE GOVERNOR (TPG)

TECHNICAL DATA SHEET

THROTTLE CONTROL

P/N 117155 REV

PAGE

DATE

BY AMS

5 OF 26

3/28/2012

1.23

Figure 2. Harness wiring detail - p/n 117666.

Manual P/N 117684

Figure 3.

Harness wiring detail - p/n 117666 with analog option harness p/n 117683 (red).

Page 7

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

TECHNICAL DATA SHEET

THROTTLE CONTROL

TOTAL PRESSURE GOVERNOR (TPG)

3. Total Pressure Governor Overview

The Total Pressure Governor (TPG) p/n 117155 is an SAE J1939 Controller Area Network (CAN)

device that controls engine speed using data communications directly to the engine ECU or with an

analog control signal. By operating on the J1939 network, the governor is able to monitor engine

RPM and other pertinent data directly from the engine ECU. Engi ne inf ormation is available directly

so that NFPA required instrumentation is delivered through a single unit saving panel space and

delivering engine specific warnings as determined by each engine manufacturer.

Control algorithms are optimized to take advantage of the J1939 CAN data to yield crisp and

accurate control of engine and subsequently pump speed and pressure output.

For engines that may not support the data link control, an analog output signal is available to

provide precise control of the engine speed and pressure.

PAGE

DATE

P/N 117155 REV

BY AMS

6 OF 26

3/28/2012

1.23

Manual P/N 117684

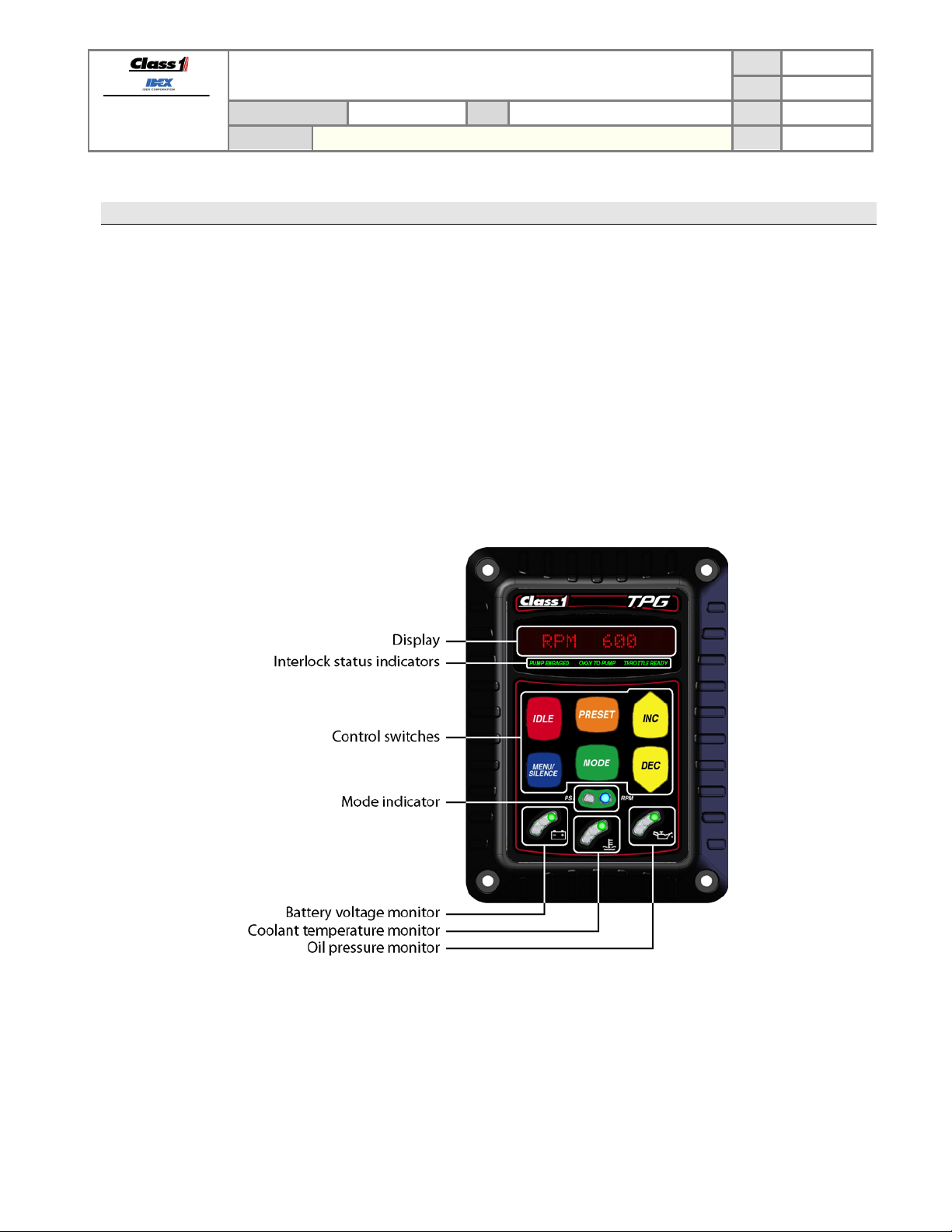

Figure 4. TPG controls and indicators.

Page 8

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

3.1. Display

The display shows the pertinent governor information: engine RPM, set pressure, warning and information messages.

3.2. Interlock status indicators

Backlit text indicates the status of the three (3) interlocks: pump engaged, okay to pump, and throttle ready. Throttle

ready and pump engaged are physical inputs into the TPG’s 12 pin connector (pins 2 and 10 respectively). Okay to

pump interlock status can be configured to beco me active when both the throttle ready and pump engaged interlocks

are present (default) or when the TPG’s pin 4 physical input is active (see section 5.2.34).

3.3. Control switches

The six (6) control switches are color coded and labeled for easy identification.

3.3.1. IDLE

The IDLE switch (red) forces the governor to idle mode (standby). Pressing and holding this button for one second

while in rpm or pressure mode will cause the engine to ramp down to its idle position.

3.3.2. MENU/SILENCE

The MENU/SILENCE switch (blue) is used to silence the alarm, cycle through the display items, and enter the

setup menu.

3.3.3. PRESET

The PRESET switch (orange) sets the governor to the configured preset engine RPM while in throttle mode, or

preset pressure while in pressure mode.

3.3.4. MODE

The MODE switch (green) sets the governor to either throttle mode (RPM) or pressure mode (PSI). The correct

interlocks must be present for the system to begin governor operation: throttle ready for RPM mode, throttle ready,

pump engaged, and okay to pump for PSI mode.

3.3.5. INC

The INC [increase] switch (yellow) is used to increase the engine RPM or pressure set point.

3.3.6. DEC

The DEC [decrease] switch (yellow) is used to decrease the engine RPM or pressure set point.

3.4. Mode indicator

The mode indicator consists of two (2) LEDs to show the governor’s current operating mode. The PSI LED (yellow)

indicates the governor is operating in pressure mode and the RPM LED (blue) indicates the governor is operating in

throttle mode. When both LEDs are OFF the governor is in idle mode (standby).

PRODUCT GROUP

PRODUCT

TECHNICAL DATA SHEET

THROTTLE CONTROL

TOTAL PRESSURE GOVERNOR (TPG)

P/N 117155 REV

PAGE

DATE

BY AMS

7 OF 26

3/28/2012

1.23

Manual P/N 117684

Page 9

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

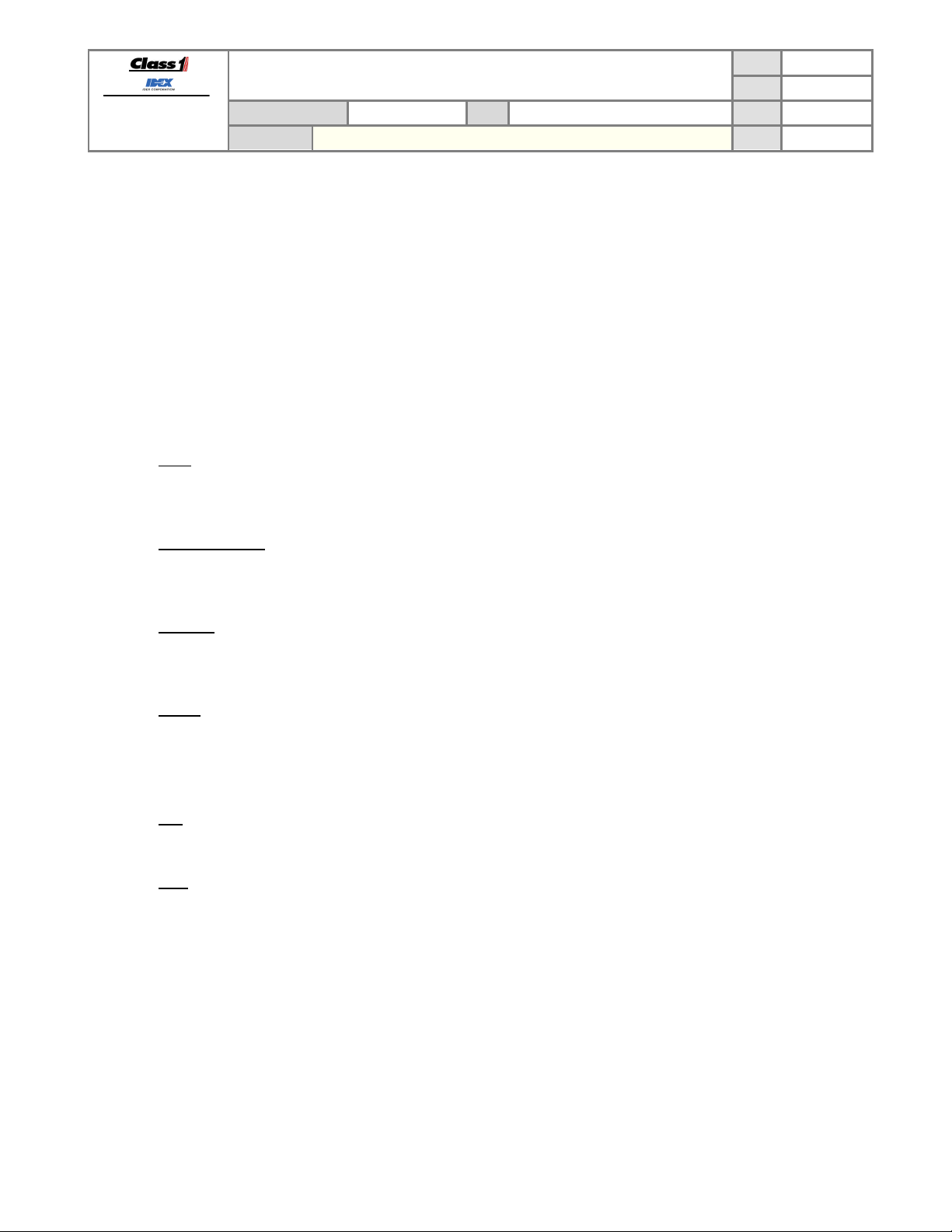

3.5. Battery voltage monitor

The battery voltage monitor is comprised of three (3) LEDs (green, yellow, and red). The active LED color indicates

the current system voltage’s range as measured by the power and ground inputs pins. The alarm will activate when

the voltage monitor is in condition RED.

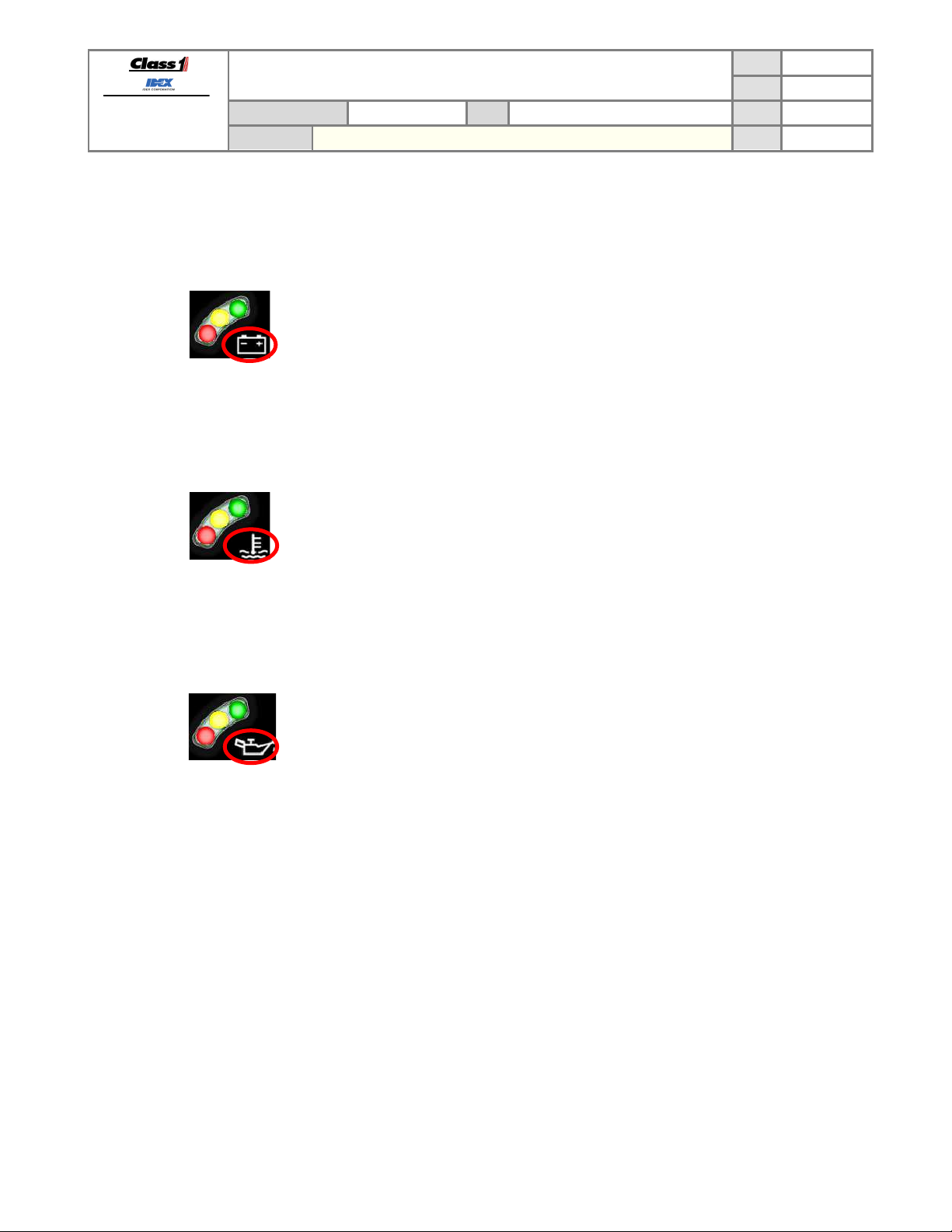

3.6. Coolant temperature monitor

The coolant temperature monitor is comprised of three (3) LEDs (green, yellow, and red). The active LED color

indicates the status of the coolant temperature as reported by the J1939 network data messages (DM1). The coolant

temperature status can also be set to react to user desired points (see section 5.2.22). The alarm will activate when

the coolant temperature monitor is in condition RED.

PRODUCT GROUP

PRODUCT

TOTAL PRESSURE GOVERNOR (TPG)

• GREEN 12.5VDC and higher

• YELLOW 12.4VDC to 11.9VDC

• RED 11.8VDC and lower

TECHNICAL DATA SHEET

THROTTLE CONTROL

P/N 117155 REV

PAGE

DATE

BY AMS

8 OF 26

3/28/2012

1.23

• GREEN No active error reported by engine for coolant temperature

• YELLOW Coolant temperature high WARNING – SPN 110, FMI 16

• RED Coolant temperature high CRITICAL – SPN 110, FMI 0

3.7. Oil pressure monitor

The oil pressure monitor is comprised of three (3) LEDs (green, yellow, and red). The active LED color indicates the

status of the oil pressure as reported by the J1939 network data messages (DM1). The oil pressure status can also

be set to react to user desired points (see section 5.2.22). The alarm will activate w hen the oil monitor is in con diti on

RED.

• GREEN No active error reported by engine for oil pressure

• YELLOW Oil pressure low WARNING – SPN 100, FMI 18

• RED Oil pressure low CRITICAL – SPN 100, FMI 1

Manual P/N 117684

Page 10

FORM-ENG-0018 REV A 05-27-03

PRESET

The display shows

The display shows the

The display shows

The TPG begins normal

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

4. Operation

4.1. Initialization

The TPG has a five (5) second power initialization cycle and during this time the display will show:

PRODUCT GROUP

PRODUCT

TOTAL PRESSURE GOVERNOR (TPG)

TECHNICAL DATA SHEET

THROTTLE CONTROL

P/N 117155 REV

PAGE

DATE

BY AMS

9 OF 26

3/28/2012

1.23

“–Class1 TPG–“

for 1 second.

software version number

for 1 second.

“Initializing”

for 3 seconds.

operation by displaying the

engine RPM.

4.2. Operating mode selection

The TPG has two operati ng m odes : throttle mode (RPM) and pressure mode (PSI).

Press the MODE switch to select an operating mode. An operating mode will only be activated if the

required interlock(s) are in place (see section 4.3).

There is no variation in engine RPM or pump pressure when changing between throttle mode and pressure mode.

Pressure mode is the desired operating mode because it offers protection from pressure changes that could

injure personnel.

4.2.1. Throttle mode

Throttle mode (RPM) maintains a set engine RPM and will not deviate until the operator changes the RPM with

the TPG’s control switches.

Throttle mode is typically used when…

• priming the pump

• connected to a stand pipe

(Proper interlocking is required for normal operation – refer to Required Interlocking section 4.3)

• the water supply pressure stability is questionable

• acting as a relay pumper

Press the MODE switch to select throttle mode. The display will

momentarily show “GOV=THROTTLE” and the RPM mode

indicator LED will illuminate blue.

Manual P/N 117684

Press the INC switch to increase or the DEC switch to decrease

the engine RPM set point.

Press the

configured preset RPM - as long as the pump pressure is less

than 10 PSI (see section

Configure the throttle mode preset through the Setup Menu

(see section 5.2.1).

Press the IDLE switch at any time to set the TPG back to

standby. The display will momentarily show “IDLE” and both

mode indicator LEDs will be off (see section 4.5).

switch to set the engine speed to the

4.4).

Page 11

FORM-ENG-0018 REV A 05-27-03

Press the MODE switch to select pressure mode. The display

Press the PRESET switch to set the pump pressure to the

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

4.2.2. Pressure mode

Pressure mode (PSI) maintains a set pump pressure by monitoring the pressure transducer and modifying the

pump speed by adjusting the engine RPM. The operator can modify the set pump pressure with the TPG’s control

switches.

Pressure mode (PSI) affords the most safety to the operator by not allowing potentially hazardous pressure

spikes. The TPG will maintain the set pump pressure even when discharge lines are actively opened and closed

as long as the water supply is sufficient. The TPG will automatically increase engine speed when pump pressure

has decreased due to discharge lines being opened. The increase in engine speed will return the pump pressure

to the desired set pressure (and vice-versa when discharge lines are closed).

PAGE

TECHNICAL DATA SHEET

PRODUCT GROUP

PRODUCT

(Proper interlocking is required for normal operation – refer to Required Interlocking section 4.3)

THROTTLE CONTROL

TOTAL PRESSURE GOVERNOR (TPG)

P/N 117155 REV

will momentarily show “GOV=PRESSURE” and the PSI mode

indicator LED will illuminate yellow.

It may be necessary to press the MODE switch twice depending

on the configured first mode (see section 5.2.5).

DATE

10 OF 26

3/28/2012

1.23

BY AMS

Press the INC switch to increase or the DEC switch to decrease

the pressure set point.

configured preset. The TPG will adjust the engine RPM to

maintain the preset pressure value (see section

Configure the pressure mode preset through the Setup Menu

(see section 5.2.4).

Press the IDLE switch at any time to set the TPG back to

standby. The display will momentarily show “IDLE” and both

mode indicator LEDs will be off (see section 4.5).

4.4).

There are five control properties which can be modified to improve pressure mode performance: pressure

sensitivity, PSI time-out, PSI increase step, pressure lag, and PSI gain.

CONTROL PROPERTY DESCRIPTION DEFAULT SECTION

Controls how much difference between the set pressure and

Pressure sensitivity

actual pressure that is allowed before the TPG actively

adjusts the engine RPM to bring the pump pressure back to

6 PSI 5.2.9

the set pressure.

When the pressure drops below 30 PSI for the number of

Pressure time-out

seconds configured the engine RPM will be reduced to idle,

the alarm will sound and the OPERATOR CMD warning will

3 SEC 5.2.14

be shown in the display window (see section 4.6).

Pressure Gain

The pressure change requested with each INC or DEC switch

press.

3 PSI 5.2.14

While th e increase button is held, controls how much

Pressure lag

pressure change between the desired pressure and actual

pressure can occur before the engine RPM is adjusted to

5 PSI 5.2.29

maintain desired pressure.

Manual P/N 117684

Page 12

FORM-ENG-0018 REV A 05-27-03

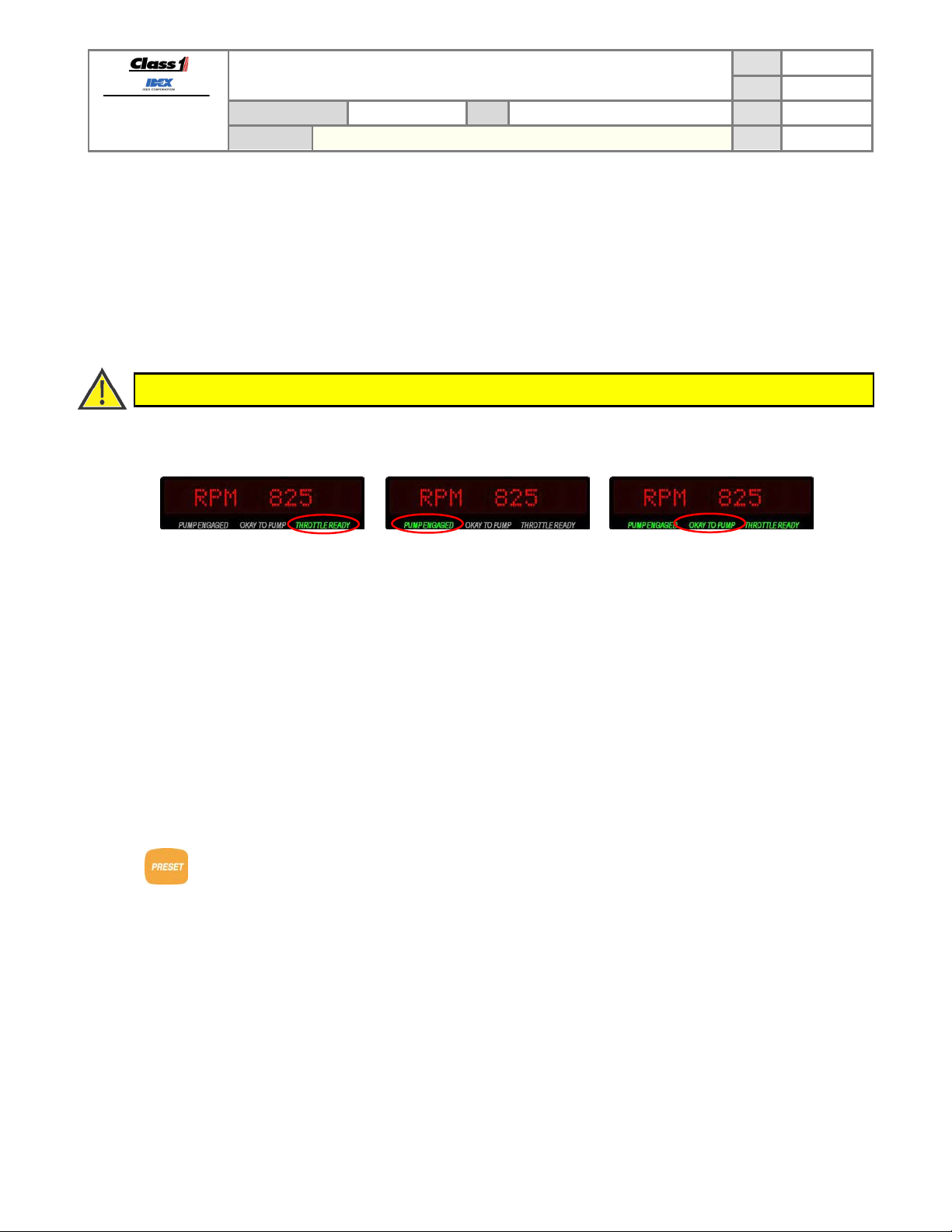

THROTTLE READY interlock

PUMP ENGAGED interlock

OKAY TO PUMP

Apply system power to pin 2 of the

Apply system power to pin 10 of the

When THROTTLE READY and

The PRESET switch brings the discharge pressure (or engine RPM, in throttle mode) to the configured

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

4.3. Required interlocking

The TPG requires interlocks before engi ne contr ol operations are permitted. The TPG provides two interlock inputs

that allow easy separation of pumping operations and throttle/high idle operations through two inputs dedicated as

system interlocks: THROTTLE READY (pin 2 of the 12-pin Deutsch connector) and PUMP ENGAGED (pin 10 of the

12-pin Deutsch connector).

A third interlock input (pin 4 of the 12-pin Deutsch connector) may be configured to control OKAY TO PUMP (menu

level 5, see section 5.2).

These interlock inputs are activated when system power is applied (positive polarity).

The OEM is responsible for creating safe and effecti ve interlocking routines.

The TPG utilizes back lit text below the main display to indicate interlock status.

PRODUCT GROUP

PRODUCT

TECHNICAL DATA SHEET

THROTTLE CONTROL

TOTAL PRESSURE GOVERNOR (TPG)

P/N 117155 REV

PAGE

DATE

BY AMS

11 OF 26

3/28/2012

1.23

12-pin Deutsch connector (through

OEM interlocking).

THROTTLE READY text illuminates

green.

The TPG will operate in throttle

mode (RPM) only.

4.4. PRESET switch operation

Using the PRESET switch is a method of smoothly and expeditiously attaining water pressure and flow, but it is not

intended to be the initial attack pressure. Attack pressures and flows should be determined by the actual fire status

and manually achieved for best operation.

PRESET is an operational convenience and needs to be considered as a fixed point (higher or lower than the current

point) that can be achieved with a single switch press.

Note: Initiating pumping operations is simplified by bringing the pump to a preset pressure with a single switch press.

Consequently, securing or reg aini ng contr ol operations can be aided by returning to this fixed pressure point with a

single switch press.

12-pin Deutsch connector (through

OEM interlocking).

PUMP ENGAGED text illuminates

green.

The TPG will not operate in any

mode until the THROTTLE READY

interlock is applied.

preset point (see section 5.2.2 and 5.2.4).

PUMP ENGAGED interlocks are

applied the OKAY TO PUMP text

illuminates green (default), unless

the OKAY TO PUMP interlock has

been configured to function with pin

4, then the OKAY TO PUMP text

only illuminates when pin 4 of the

12-pin Deutsch connector has

system power applied (through OEM

interlocking).

The TPG will operate in throttle

mode (RPM) or pressure mode

(PSI).

Manual P/N 117684

Page 13

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

4.5. IDLE switch operation

Note: In view of the fact that driveline stress can be induced by quick changes in engine speed, depending on rpm

and torque load, the engine speed is ramped to idle over a short duration to minimize the effect of driveline kick.

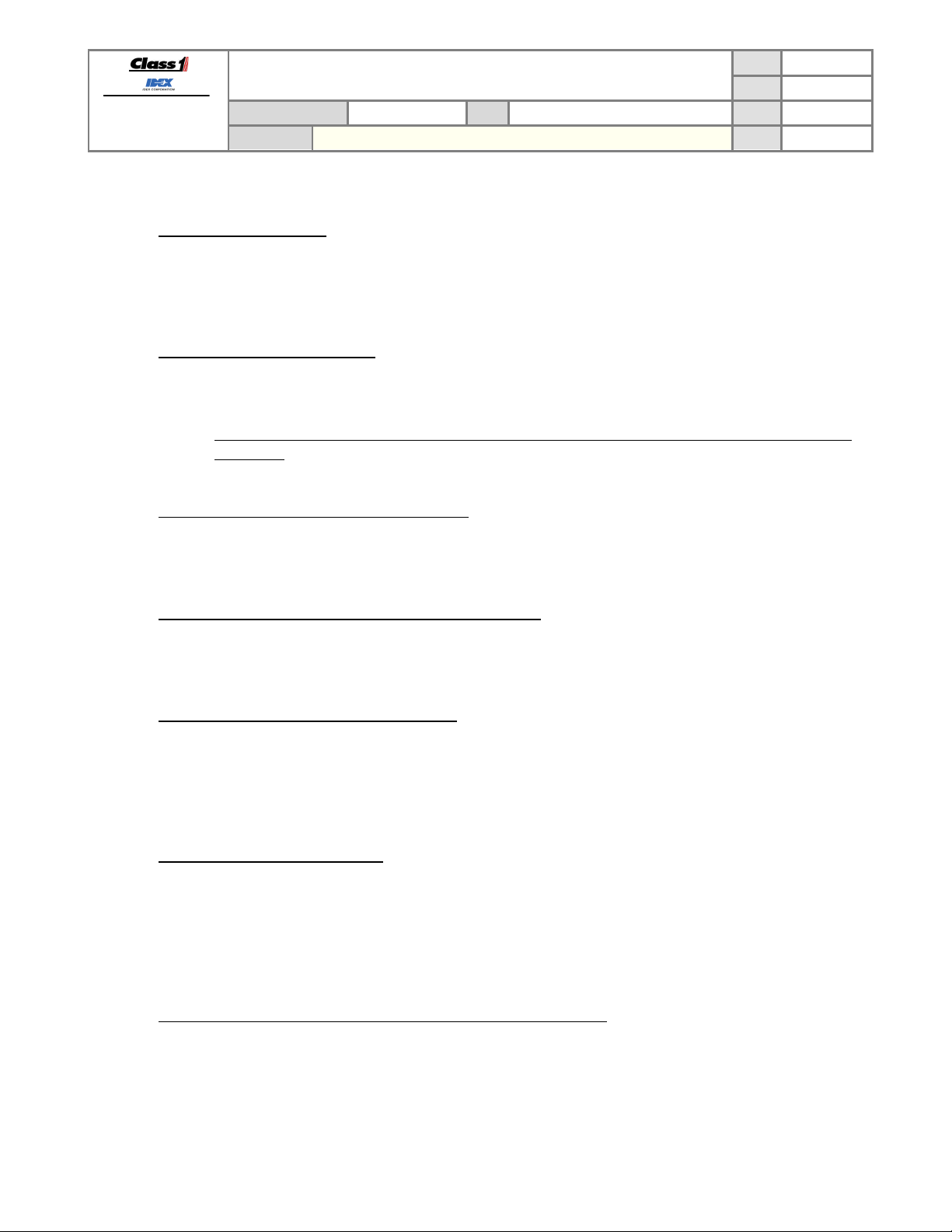

4.6. Status and warning messages

The table below details the TPG’s status and warning messages.

• These codes will flash on the display while the error/warning is active.

• Multiple errors/warnings may be sequenced on the display.

• Press and hold the MENU/SILENCE switch for one second to silence the active alarm.

PRODUCT GROUP

PRODUCT

TOTAL PRESSURE GOVERNOR (TPG)

Press and hold the IDLE switch for one second to release engine RPM control back to the engine ECU. The

engine RPM will promptly go to its configured curb idle (see section 5.2.15).

ERROR CODE DESCRIPTION

SENSOR FAIL

LOW PRESSURE

OPERATOR CMD

∆ RPM LIMIT

WATER SUPPLY

∆ PSI LIMIT

NO COMM DATA

CHECK ENGINE

STOP ENGINE

OUTPUT FAIL

SELECT MODE?

SWITCH FAIL

THROT INTLK?

PAGE

TECHNICAL DATA SHEET

THROTTLE CONTROL

P/N 117155 REV

DATE

BY AMS

Signal voltage from pressure sensor is less than +0.30VDC or greater than

+4.90VDC

Pump pressure is less than 15 PSI during pressure mode operation

Pump pressure was greater than 50 PSI, but has dropped to below 30 PSI

Engine speed change of greater than 200 RPM does not yield increase in PSI

PSI decreased while RPM was increased (while in pressure mode)

PSI increased 50 PSI over set pressure point

Not receiving CAN communication data from engine ECU

Received CHECK ENGINE warning from engine ECU via CAN message

Received STOP ENGINE warning from engine ECU via CAN message

Output signal voltage differs from expected (calculated) value (no longer

displayed in version 3.2 and above)

Increase or Decrease request when no active mode (PSI/RPM) selected

Switch panel reporting an improper switch combination

Throttle ready interlock is not present when mode button is pressed

12 OF 26

3/28/2012

1.23

Manual P/N 117684

Page 14

FORM-ENG-0018 REV A 05-27-03

Display shows MENU 04 SECS and begins counting down. Continue holding IDLE and MENU

level then release).

Enter a password while at idle to direct access a menu level.

INC, INC, DEC, INC, DEC, INC, DEC, INC = menulevel 5 (restricted)

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

TOTAL PRESSURE GOVERNOR (TPG)

5. Governor Control Setup Menu

5.1. Engine compatibility

The factory default settings of the TPG make it “out of the box” ready to operate a Cummins engine programmed with

the Emergency Vehicle Calibration. Typically, for the default configuration no values will require modification, other

than changing the desired engine rpm, high-idle rpm and pump pressure preset values.

The governor is capable of controlling any engine that allows J1939 PGN0 (Torque Speed Control) messages from a

unique source address. These engines include various Detroit Diesel DDEC engines, Mercedes Benz (MBE)

engines, Volvo, and others. Programming of the source address or other parameters on the engine ECM may be

required. The Scania engine allows control by proprietary J1939 messages and is supported by the TPG. In cases

where an engine does not support data link control, the TPG can be configured to control the engine with an analog

signal coupled to the engine remote PTO throttle input.

Contact Class 1 or visit our website (www.class1.com) for a complete engine compatibility list.

5.2. Enter the setup menu

The setup menu allows access to the configuration and calibration screens. There are 5 set up menus available:

menu level 1 (basic setup men u), menu level 2, menu level 3, menu level 4 (factory menu), and menu level 5

(restricted). All configurations and calibrations are saved in non-volatile memory and will not be lost with power

disruptions.

TECHNICAL DATA SHEET

THROTTLE CONTROL

P/N 117155 REV

PAGE

DATE

BY AMS

13 OF 26

3/28/2012

1.23

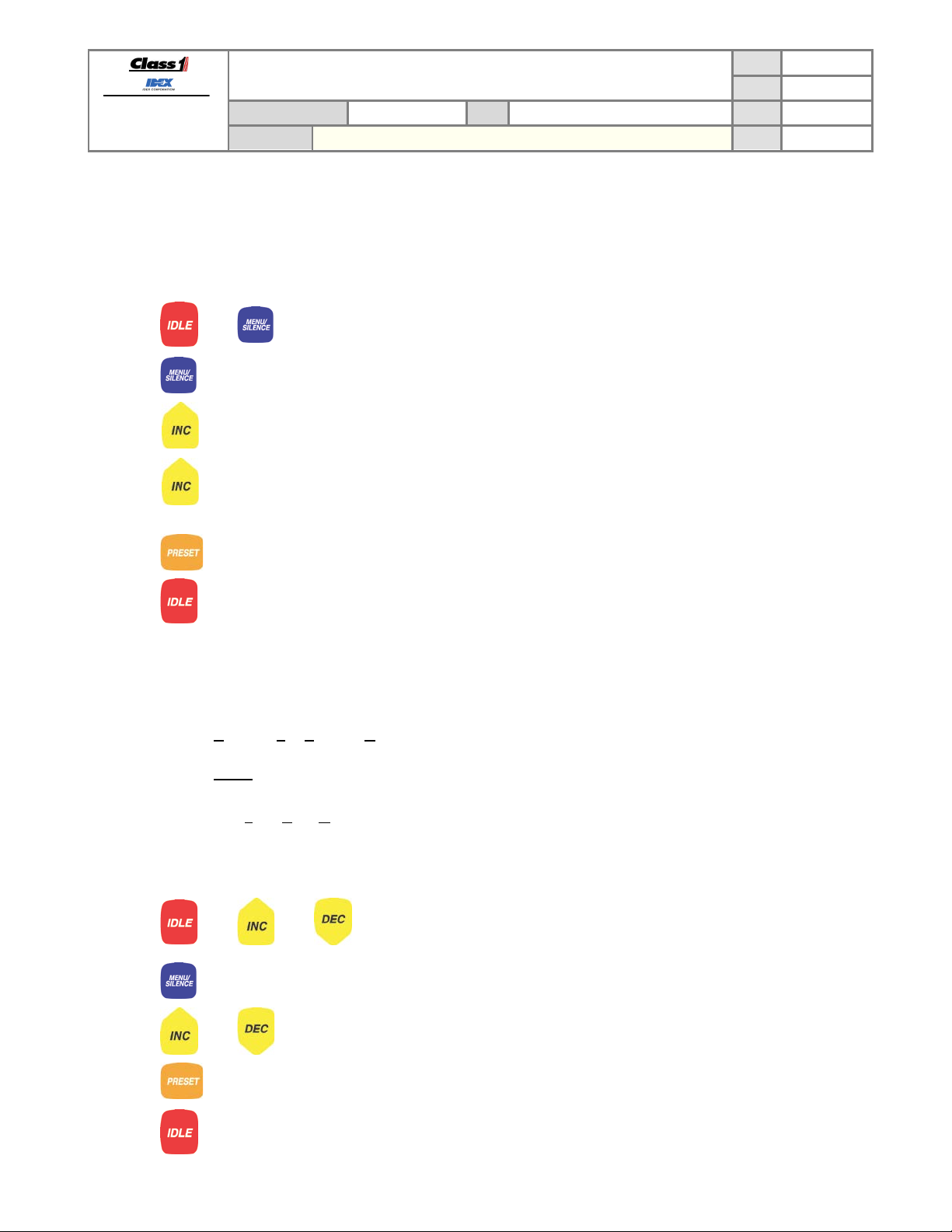

Standard menu level access

The standard menu level access method allows entry into menu levels 1, 2, or 3 only. Use the Direct menu level

access method to enter menu level 4 or 5. Once a menu level has been selected, subsequent menu access will

always enter that menu level and a system re-power is required to reset the first entry menu level.

+

until the display shows *SETUP MENU* (4 seconds) and then release the switches. (If menu level

2 or menu level 3 is desired continue to hold the switches until the display shows the desired menu

Press the MENU switch to cycle through the available setup menu items.

or

Press the INC or DEC switches to modify the current menu item.

Press the PRESET switch to store the configured menu item. The display will show ---STORED---.

Press the MODE switch to exit the setup menu. The display will show --EXITMENU-- and then

resume normal operation.

Direct menu level access

INC, DEC, DEC, INC, DEC, DEC, DEC, INC = menulevel 1

+

Manual P/N 117684

or

INC, DEC, DEC, INC, DEC, DEC, INC, DEC = menulevel 2

INC, DEC, DEC, INC, DEC, DEC, INC, INC = menulevel 3

INC, DEC, DEC, INC, DEC, INC, DEC, DEC = menulevel 4 (factory)

Page 15

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

Menu items in menu levels 1, 2, and 3

MENU ITEM DESCRIPTION DEFAULT MENU LEVEL

UNITS

PRESET RPM

HI-IDLE

PRESET PSI

BRIGHT

DISPLAY TEST

ROUND PSI

ALERT TONE

SENSITIVITY

-SENSOR CAL-

1ST MODE

AUTO MODE

COMM STATUS

CONTROL

RPM IDLE

RPM MAX

SOURCE ID

TSC1 RAMP

DISPLAY

PSI TIME-OUT

ALLOW PRESET

WARNINGS

WARN °F

CRIT °F

WARN PSI

CRIT PSI

PRODUCT GROUP

PRODUCT

Configures units of measure

Configures the throttle mode (RPM) preset (900 – 1400)

(Not available with message type ANLG)

Configures the high idle RPM preset (900-1400)

(Not available with message type ANLG)

Configures the pressure mode (PSI) preset (90 – 130)

Configures the display’s brightness level (1-15)

Tests all of the pixels of the main display

Configures the rounding of the pressure value

Alert tones are indicated by a double chirp of the alarm output and

do not indicate alarm conditions. Enable/disable the alert tones.

Configures the pressure sensitivity window (4 – 12)

Calibrates the zero point of the pressure sensor

Configures the first mode active when the MODE switch is pressed

(interlocks permitting)

Configures if governor automatically enters into psi mode upon

pump engagement.

(Only available when 1st mode menu item is set to PSI and menu level was 3 or greater)

Allows viewing of CAN messages per second and received errors

Configure control mode and message for engine

Configure / adjust the idle rpm

(Not available with message type ANLG)

Configure / adjust the maximum rpm commanded by governor

(Not available with message type ANLG or CFPG)

Configure the CAN source ID for the TPG

(only available with message type PGN0 or SCA N)

Configure the RPM ramp speed of TSC1/PGN0 control mode

(only available with message type PGN0)

Configure primary display while in pressure mode (rpm or pressure)

Configures the amount of seconds the TPG will wait after pressure

has dropped below 30 PSI before dropping to IDLE mode

Configure enable/disable rpm preset if pump is under pressure

Configures source of the panel warning LED’s (data bus or user

defined)

Configure the yellow (warning) engine temp setpoint

(only available when WARNINGS is set to Usr)

Configure the red (critical) engine temp setpoint

(only available when WARNINGS is set to Usr)

Configure the yellow (warning) oil pressure setpoint

(only available when WARNINGS is set to Usr)

Configure the red (critical) oil pressure setpoint

(only available when WARNINGS is set to Usr)

TECHNICAL DATA SHEET

THROTTLE CONTROL

TOTAL PRESSURE GOVERNOR (TPG)

P/N 117155 REV

PAGE

DATE

BY AMS

PSI / ºF

1000

1100

90

15

N/A

N

Y

+/- 6 PSI

142 COUNTS

PSI

NO

N/A

CFPG (Cummins)

700

2200

7

0

RPM

5

NO

Bus

-

-

-

-

14 OF 26

3/28/2012

1.23

1

1*

1*

1

1

1

1

2

2

2

2

3*

2

3

3*

3*

3*

3*

3

3

3

3

3*

3*

3*

3*

Manual P/N 117684

Page 16

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

MENU ITEM DESCRIPTION DEFAULT MENU LEVEL

XDCR

FACTORY DFLT

* Option dependent on other menu selections made

Menu items in menu level 4

MENU ITEM DESCRIPTION DEFAULT MENU LEVEL

POC ASSERT

GOV GAIN

PRESS GAIN

DITHER

LAG (∆PSI)

PUMP HOURS

BCM1 VER

SCANIA MODE

IDLE STEPS

* Option dependent on other menu selections made

PRODUCT GROUP

PRODUCT

TOTAL PRESSURE GOVERNOR (TPG)

Configures transducer type (300 or 600 psi) (300 default)

Returns all menu parameters to the factory default state

(Cummins Control – message type CFPG)

Configures when idle offset is asserted (with power on cycle or mode

switch)

(Only available with message type ANLG)

Configures the RPM change requested per INC or DEC switch press

(Only available with message type ANLG)

Configures the pressure change requested per INC or DEC switch

press

Configure the engine handshake

(Only available with message type PGN0)

Controls the response of the pressure increase when the INC button

is held while in pressure mode.

Set/reset the number of pump hours

Configures the Scania BCM version

(Only available with message type SCAN)

Configures the Scania engine control type: NORMAL or STIFF

(Only available with message type SCAN)

Configures the idle offset voltage for analog control mode

(Only available with message type ANLG)

TECHNICAL DATA SHEET

THROTTLE CONTROL

P/N 117155 REV

PAGE

DATE

BY AMS

300

N/A

NO

15

3 PSI

NO

5 PSI

N/A

1

NORMAL

32

15 OF 26

3/28/2012

1.23

3

3

4*

4*

4

4*

4*

4

4*

4*

4*

Menu items in menu level 5

MENU ITEM DESCRIPTION DEFAULT MENU LEVEL

OK2PUMP

SPN 3350

SPN 696

HIDLE MODE

BUS INTLKS

VOLTS

SMOOTHING

ENGINE ID

* Option dependent on other menu selections made

Manual P/N 117684

Configure the “okay to pump” interlock source

Configure the PGN0 control purpose

(only available with message type PGN0)

Configure the Engine Requested Speed Control Condition

(only available with message type PGN0)

Configure the high idle mode

Configure the bus interlocks

Calibrate the battery voltage display (+0.0 to +0.5 volts)

Configure pressure averaging (smoothing – NO, LO, HI)

Configure the CAN source ID where the TPG receives its engine

information from. Normally this will always be address 0 unless

some kind of interface module is used between the engine and TPG

NORM

P32

3

1

N

+0.0 volts

LO

0

5

5*

5*

5

5

5

5

5

Page 17

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

5.2.1. UNITS (unit of measure configuration)

This menu item allows configuration of the display units of measure.

Use the INC and DEC keys to select the desired units of measure. The options include

Range = PSI / ºF, kPa / ºC, bar / ºC [default = PSI / ºF]

5.2.2. PRESET RPM (throttle preset configuration)

This menu item allows configuration of the throttle mode preset.

The display will show PSETrpm XXXX. Use the INC and DEC switches to adjust the RPM value desired for the

throttle mode preset.

Range = 900 RPM to 1400 RPM (in 25 RPM steps). [default = 1000 RPM]

5.2.3. HI-IDLE (high idle configuration)

This menu item allows configuration of the high idle (fast idle) setpoint.

The display will show Hi-Idle= XXX. Use the INC and DEC switches to adjust the RPM value desired for the high

idle setpoint.

TECHNICAL DATA SHEET

THROTTLE CONTROL

TOTAL PRESSURE GOVERNOR (TPG)

PAGE

DATE

P/N 117155 REV

BY AMS

PSI/°F, kPa/°C, bar/°C.

16 OF 26

3/28/2012

1.23

Range = 900 RPM to 1400 RPM (in 25 RPM steps). [default = 1100 RPM]

5.2.4. PRESET PSI (pressure preset configuration)

This menu item allows configuration of the pressure mode preset.

The display will show PSETpsi XXX. Use the INC and DEC switches to adjust the PSI value desired for the

pressure mode preset.

Range = 90 PSI to 130 PSI (in 10 PSI steps) [default = 100 PSI]

5.2.5. BRIGHT (display brightness)

This menu item allows configuration the display’s brightness level.

The display will show BRIGHTNESS=X. Use the INC and DEC switches to adjust the value desired display

brightness.

Range = 1 to 15 (1 is dimmest sett i ng) [default = 15]

5.2.6. DISPLAY TEST

This menu item allows testing of all of the pixels of the main display and all of the LEDs.

The display will show DISPLAY TEST. Use the INC or DEC switch to turn on all of the LEDs and pixels in the

display.

5.2.7. ROUND PSI (configure rounding of the pressure value)

This menu item allows enabling/disabling of the “round to nearest 5” of the pressure value.

The display will show ROUND PSI: X. Use the INC and DEC switches to sel e ct Y (yes) or N (no).

Round PSI = Y (round to nearest 5) or N (don’t round). [default = N]

5.2.8. ALERT TONE (configure alert tones)

This menu item allows enabling/disabling of the alert tones. The alert tones are sounded through the external

alarm output (pin 3 of the 6-pin connector).

The display will show ALERT TONE:X. Use the INC and DEC switches to select Y (yes, enabled) or N (no,

disabled).

Range = Y (Alert tones ON) or N (Alert tones OFF). [default = Y]

Manual P/N 117684

Page 18

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

5.2.9. SENSITIVITY (pressure sensitivity configuration)

This menu item allows configuration of the pressure mode sensitivity window. This window dictates how much

pressure difference must occur before the TPG adjusts the engine RPM to maintain the desired set pressure.

The display will show GOV± XX PSI. Use the INC and DEC switches to adjust the PSI value desired for the

pressure mode sensitivity.

Range = 4 PSI to 12 PSI (in 1 PSI steps). [default = 6 PSI]

5.2.10. SENSOR CAL (pressure sensor calibration)

This menu item allows calibration of the pressure sensor.

The display will show –SENSOR CAL-. See section 7.3 for the calibration procedure.

5.2.11. 1st MODE (first active mode configuration)

This menu item allows configuration of the governor mode active when the MODE switch is first presse d.

The display will show 1

Proper interlocks must be established for the configured 1st mode to become active during operation.

TECHNICAL DATA SHEET

THROTTLE CONTROL

TOTAL PRESSURE GOVERNOR (TPG)

st

MODE=XXX. Use the INC and DEC switches to select the desired mode (PSI or RPM).

PAGE

DATE

P/N 117155 REV

BY AMS

17 OF 26

3/28/2012

1.23

Range = RPM (throttle mode) or PSI (pressure mode). [default = PSI]

5.2.12. AUTO MODE (pressure mode automatically entered on pump engagement)

This menu item allows configuration of automatically entering pressure mode when pump engagement occurs

(AUTO MODE?:Y). Note that this option will only be available if the 1

st

mode parameter (section 5.2.11) is set to

pressure mode (PSI). When this parameter is enabled, the governor will be put in pressure mode when the pump

is changed from a disengaged to an engaged position (interlocks permitting). Thereafter, when a user selects the

IDLE (standby) mode, the governor will remain in standby mode until a new mode is selected.

Range = Y1 (Automode ON, Throttle Ready first then Pump Engaged),

Y2 (Automode ON, Pump Engaged first then Throttle Ready),

N (Automode OFF). [default = N]

5.2.13. COMM STATUS (view the CAN communication status)

This menu item allows viewing of the number of CAN messages per second and received errors. This menu item is

only available when the CAN message type is set to CFPG.

The display will show COMM STATUS. Use the INC and DEC switches to toggle between message per second

and received errors.

5.2.14. CONTROL (engine control message type)

This menu item allows configuration of the CAN or ANALOG control message type.

CFPG – Cummins Fire Pressure Governor, uses Cummins proprietary control message to control engine speed.

PGN0 – Uses J1939, PGN0 – Torque Speed Control message to control engine speed.

SCAN – SCANia, uses the Scania bodywork control message 1.

ANLG – Uses analog voltage signal to control remote th rottle input on engine.

PWM – Uses pulse width modulation control signal (12-85%, 400 Hz).

VLVO – Uses Volvo specific PTO control commands for Volvo FE/FL series engines running through

a Volvo bodybuilder control module. This method should not be used when the TPG is directly

connected to the engine CAN bus. Volvo FM/FH series engines should use the standard PGN0

control mode and set the Engine ID variable to the address of the body builder module.

The display will show CONTROL=XXXX. Use the INC and DEC switches to adjust the control message type.

Range = CFPG, PGN0, SCAN, ANLG., PWM, VLVO [default = CFPG]

Manual P/N 117684

Page 19

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

5.2.15. RPMidle (idle RPM value)

This menu item allows configuration of the idle RPM.

The display will show RPMIdle=XXXX. Use the INC and DEC switches to adjust the RPM value desired for idle.

Note: cannot be adjusted below the engine’s curb idle sp eed .

Range = 650 RPM to 900 RPM (in 25 RPM steps). [default = 700 RPM]

5.2.16. RPMmaxi (maximum RPM value)

This menu item allows configuration of the maximum RPM that will be commanded when in PGN0 or SCANia

mode. The display will show RPMmaxi=XXXX. Use the INC and DEC switches to adjust the maximum RPM value

desired. This value cannot be adjusted above maximum governed speed.

Range = 1900 RPM to 2500 RPM (in 25 RPM steps). [default = 2200 RPM]

PRODUCT GROUP

PRODUCT

TOTAL PRESSURE GOVERNOR (TPG)

Note: When control type is configured for Volvo (VLVO) or MAN the minimum value can be set down to

1500 RPM.

TECHNICAL DATA SHEET

THROTTLE CONTROL

P/N 117155 REV

PAGE

DATE

BY AMS

18 OF 26

3/28/2012

1.23

5.2.17. SourceID (CAN message source identification)

This menu item allows configuration of the CAN source message ID number.

The display will show

SourceID=X. Use the INC and DEC switches to adjust the CAN source message ID.

Range = 0 – 255. [default = 7]

5.2.18. TSC1 RAMP (TSC1/PGN0 control mode RPM ramp speed)

This menu item allows configuration of the engine RPM ramp speed in TSC 1/P GN 0 control mode .

The display will show

TSC1 RAMP: X. Use the INC and DEC switches to adjust the ramp speed.

Range = 0 – 40. [default = 0]

5.2.19. DISPLAY (primary display in pressure mode) This menu item allow configuration of the display data while operating in pressure mode. The display can show

either engine speed (DISPLAY: RPM), or pump pressure (DISPLAY: PSI). The pump pressure will be displayed in

the correct units of measure (psi, kPa, or bar) selected by the user.

Note: The pressure display cannot be used as the master pressure gauge per NFPA 1901.

Range = RPM or PSI. [default = RPM]

5.2.20. PSI TIME-OUT (pressure time out)

This menu item allows configuration of the low pressure time out. When the TPG is governing in pressure mode

and the pressure falls below 30 PSI the TPG will wait the configured number of seconds to allow the pressure to

rise before dropping to IDLE.

The display will show PSI TIME-OUT. Use the INC and DEC switches to adjust the value desired for the pressure

time out.

Range = 3 seconds to 10 seconds (in 1 second steps). [default = 5 seconds]

5.2.21. ALLOW PRESET (allow RPM preset use when pressure is detected)

This menu item allows enabling/disabling of throttle mode preset usage when pump pressure over 10 PSI is

detected.

The display will show PRESET RPM=X. Use the INC and DEC switches to select Y (yes, enabled) or N (no,

disabled).

Range = Y (enabled) or N (disabled). [default = N]

Manual P/N 117684

Page 20

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

5.2.22. WARNINGS (data monitor warning configuration)

This menu item allows configuration of the source for engine warnings. Warnings can be determined by engine

diagnostic messages (DM1 messages) over the data bus (Bus), or at setpoints defined by the user based on J1939

oil pressure and engine temperature data (Usr).

The preferred and most accurate method is to use Bus warnings from the engine diagnostic system. Note that not

all engines support this feature, contact Class1 customer support for more information.

Range = Bus (bus controlled) or Usr (user configured). [default = Bus]

When the Usr configuration is selected the following setpoints will be assigned next.

A. WARN ºF (USER DEFINED ENGINE TEMPERATURE HIGH WARNING - YELLOW LED)

B. CRIT ºF (USER DEFINED ENGINE TEMPERATURE HIGH CRITICAL - RED LED)

C. WARN PSI (USER DEFINED OIL PRESSURE LOW WARNING - YELLOW LED)

D. CRIT PSI (USER DEFINED OIL PRESSURE LOW CRITICAL - RED LED)

5.2.23. XDUCR (discharge pressure transducer range)

This menu item allows configuration the discharge pressure transducer’s range (0 to 300 PSI, or 0 to 600 PSI).

The display will show XDCR= XXXPSI. Use the INC and DEC switches to adjust the value desired for the pressure

change per button press.

TECHNICAL DATA SHEET

THROTTLE CONTROL

TOTAL PRESSURE GOVERNOR (TPG)

PAGE

DATE

P/N 117155 REV

BY AMS

19 OF 26

3/28/2012

1.23

Range = 300 PSI or 600 PSI. [default = 300 PSI]

5.2.24. FACTORY DFLT (Set factory defaults)

This menu item allows setting the TPG back to the factory defaults.

The display will show FACTORY DFLT. Press the PRESET switch to load the defaults.

Refer to the menu level tables for the default values (section 5.2).

5.2.25. POC ASSERT (Power On Cycle assertion)

This menu item allows enabling/disabling of the analog control signal idle voltage assertion at power-up. When the

POC ASSERT is enabled the analog control signal will be set to the configured idle voltage at the start of the TPG’s

power cycle. If the POC ASSERT is disabled the analog control signal will be set to the minimum configured level

at the start of the TPG’s power cycle.

The display will show POC ASSERT:X. Use the INC and DEC switches to select Y or N.

Range = Y (enabled) or N (disabled). [default = N]

5.2.26. GOV GAIN (RPM change per step)

This menu item allows configuration of the RPM change per step. A larger number changes the RPM more with

each INC or DEC switch press.

The display will show GOV GAIN :XX. Use the INC and DEC switches to adjust the value.

Range = 0 to 35 [default = 15]

5.2.27. PRESS GAIN (PSI change per step)

This menu item allows configuration of the psi change per step. A larger number changes the PSI more with eac h

INC or DEC switch press.

The display will show X PSI/STEP. Use the INC and DEC switches to adjust the value.

Range = 1 to 5 [default = 3 PSI/STEP]

Manual P/N 117684

Page 21

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

5.2.28. DITHER (Engine handshake)

This menu item allows enabling/disabling of engine handshake. When enabled, the TPG will vary the engine speed

+/- 5 RPM around the desired engine speed. Some engines may require consistent RPM modification in order to

maintain remote RPM control.

The display will show DITHER=X. Use the INC and DEC switches to select Y or N.

Range = Y (enabled) or N (disabled). [default = N]

5.2.29. LAG ∆PSI (Pressure lag)

This menu item allows configuration of the pressur e lag which defines the maximum allowable difference that the

actual pressure is behind the commanded set-point before a “wait” (catch up) state is introduced while operating in

pressure mode.

The display will show LAG (∆PSI)=X. Use the INC and DEC switches to adjust the pressure lag value.

Range = 1 PSI to 20 PSI (in 1 PSI steps). [default = 5 PSI]

5.2.30. PUMP HOURS

This menu item allows setting/resetting of the total pump hours.

The display will show PUMP X.Xh. Use the INC and DEC switches to adjust the pump hours.

PRODUCT GROUP

PRODUCT

TECHNICAL DATA SHEET

THROTTLE CONTROL

TOTAL PRESSURE GOVERNOR (TPG)

P/N 117155 REV

PAGE

DATE

BY AMS

20 OF 26

3/28/2012

1.23

Range = 0.0 to 999.9 hours (in 0.1 hour steps). [default = 0]

5.2.31. BCM1 VER (Body Control Message 1 version)

This menu item allows configuration of the message configuration version transmitted in the Scania

Body Control Message 1.

The display will show BCM1 VER: X. Use the INC and DEC switches to adjust the value.

Range = 0 to 255. [default = 1]

5.2.32. SCANIA MODE? (Scania governor type)

This menu item allows configuration of the Scania requested governor type in the Body Control Message 1.

The display will show MODE: XXXXXX. Use the INC and DEC switches to adjust the value.

Range = NORMAL or STIFF. [default = NORMAL]

5.2.33. IDLE STEPS (Analog control idle)

This menu item allows the configuration of the analog control signal idle voltage.

The display will show IdleSteps:XX. Use the INC and DEC switches to adjust the value.

Range = 0 to 60 [default = 32]

5.2.34. OKAY2PUMP (Okay to pump interlock source)

This menu item allows the configuration of the “okay to pump” interlock source.

NORM – The OKAY TO PUMP text only illuminates when the throttle ready and pump engaged interlocks are

active.

PIN4 – The OKAY TO PUMP text only illuminates when pin 4 of the 12-pin Deutsch connector has power

applied.

The display will show OK2PUMP=X. Use the INC and DEC switches to adjust the value.

Range = NORM or PIN4 [default = NORM]

Manual P/N 117684

Page 22

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

5.2.35. SPN 3350 (TSC1 – SPN 3350)

This menu item allows configuration of the Torque Speed Control 1 (TSC1) control purpose message.

P03 – PTO governor control p ur pos e.

P32 – Temporary power-trai n control purpose.

The display will show SPN 3350:XXX

Range = P03 or P32. [default = P32]

5.2.36. SPN 696 (Engine Requested Speed Control Condition)

This menu item allows configuration of the CAN Engine Requested Speed Control Condition (SPN 696), as defined

in SAE J1939 for the TSC1/PGN0 speed control command. Possible values are:

0 – Transient optimized for driv eline dis eng aged and non-lo c kup con diti on s.

1 – Stability optimized for driv e line di seng age d and non-lockup conditions.

2 – Stability optimized for driveline engaged and/or and in lockup condition 1 (e.g. vehicle driveline).

3 – Stability optimized for driveline engaged and/or and in lockup condition 2 (e.g. PTO driveline).

The display will show SPN 696:X. Use the INC and DEC switches to adjust the Engine Requested Speed Control

Condition.

TECHNICAL DATA SHEET

THROTTLE CONTROL

TOTAL PRESSURE GOVERNOR (TPG)

. Use the INC and DEC switches to adjust the CAN purpose.

P/N 117155 REV

PAGE

DATE

BY AMS

21 OF 26

3/28/2012

1.23

Range = 0 to 3. [default = 3]

5.2.37. HI IDLE MODE

This menu item allows configuration of the high idle mode.

1 – Normal.

2 – Only allow high idle if engine speed > 600 RPM, transmission is in neutral, and okay to pump interlock is OFF.

Forces t he throttle ready interlock OFF when transmission is NOT in neutral or 4th gear.

The display will show HIDLE MODE:X

. Use the INC and DEC switches to adjust the value.

Range = 1 or 2. [default = 1]

5.2.38. BUS INTLKS (Bus message control of throttle ready interlock)

This menu item allows configuration of the bus interlocks.

N – Normal, throttle ready interlock ON with its physical input pin.

Y – Forces throttle ready interlock ON when transmission is in Neutral.

The display will show BUS INTLKS:X

. Use the INC and DEC switches to adjust the value.

Range = Y or N. [default = N]

5.2.39. VOLTS (Voltage display calibration)

This menu item allows calibration of the voltage display.

The display will show VOLTS XX.X V. Use the INC and DEC switches to adjust the voltage level.

Range = voltage + 0.0 to voltage + 0.5 [default = 0]

5.2.40. SMOOTHING (Pressure display averaging)

This menu item allows configuration of the smoothing (averaging) method of the pres sure d ispl ay .

NO – No averaging of pressure.

LO – Average of 4 pressure samples while within pressure stasis window.

HI – Average of 8 pressure samples while within pressure stasis window.

The display will show SMOOTHING:XX. Use the INC and DEC switches to adjust the value.

Range = NO, LO, or HI [default = NO]

Manual P/N 117684

Page 23

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

5.2.41. ENGINE ID (Source ID of received engine messages)

This menu item allows configuration of the CAN source ID for engine messages received by the TPG.

The display will show

EngineID=X. Use the INC and DEC switches to adjust the CAN engine source ID.

If the TPG continuously displays the NO COMM DATA message with the engine running and the CAN bus

connected verify the setting of this parameter. Where the TPG is directly connected to the engine’s CAN bus the

address should usually be 0 but if there is a gateway module between the engine and TPG then this parameter

needs to be set to the address from which the gateway module transmits.

Range = 0 – 255. [default = 0]

TECHNICAL DATA SHEET

THROTTLE CONTROL

TOTAL PRESSURE GOVERNOR (TPG)

PAGE

DATE

P/N 117155 REV

BY AMS

22 OF 26

3/28/2012

1.23

Manual P/N 117684

Page 24

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

TOTAL PRESSURE GOVERNOR (TPG)

TECHNICAL DATA SHEET

THROTTLE CONTROL

P/N 117155 REV

PAGE

DATE

BY AMS

23 OF 26

3/28/2012

1.23

6. Special Function Passwords (See section 5.2 for procedure on entering passwords)

6.1. Setting control message transmission requirements

DEC, INC, INC, INC, DEC, DEC, DEC, DEC

Engine control message is not transmitted when at idle (no mode selected) - displays message "NOTX AT IDLE" after

password is entered. This can be useful if there is more than one device on a vehicle which is controlling the RPM externally

over the CAN bus.

DEC, INC, INC, INC, DEC, DEC, DEC, INC

Engine control message is transmitted whenever the throttle interlock is active - displays message "TX AT IDLE" after

password is entered. This was the standard operation for TPG version 3.2 and below and is the default on newer versions.

6.2. Setting control for specific engine types

DEC, INC, DEC, INC, DEC, DEC, DEC, DEC

NORMAL_Engine = standard TSC1, no transmit at IDLE or without throttle ready interlock.

DEC, INC, DEC, INC, DEC, DEC, DEC, INC

NORMAL_Engine_2 = standard TSC1, but transmits at idl e without throttle ready interlock.

DEC, INC, DEC, INC, DEC, DEC, INC, DEC

FAW_Engine = special TSC1, transmits at idle without throttle ready interlock, always "speed control".

DEC, INC, DEC, INC, DEC, DEC, INC, INC

FAW_Engine_2 = special TSC1, transmits at idle without throttle ready interlock, standard "override disabled" and

"speed control".

DEC, INC, DEC, INC, DEC, INC, DEC, DEC

MAN_Engine = special TSC1, no transmit at IDLE or without throttle ready interlock.

DEC, INC, DEC, INC, DEC, INC, DEC, INC

MAN_Engine_2 = special TSC1, but transmits at idle without throttle ready interlock.

6.3. Configuring transmission of Hydraulic Pressure Governor message

DEC, INC, INC, DEC, DEC, DEC, DEC, DEC

Transmit HPG message (default) - displays message "HPG = ON" after password is entered.

DEC, INC, INC, DEC, DEC, DEC, DEC, INC

Don't transmit HPG message - displays message "HPG = OFF" after password is entered.

DEC, INC, INC, DEC, INC, DEC, DEC, DEC

HPG message transmits mode normally - displays message "HPG MODE = NOR" after password is entered.

DEC, INC, INC, DEC, INC, DEC, DEC, INC

HPG message transmits PSI mode always - displays message "HPG MODE = PSI" after password is entered.

Manual P/N 117684

Page 25

FORM-ENG-0018 REV A 05-27-03

INC, DEC, DEC, INC, DEC, DEC, INC, INC

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

TOTAL PRESSURE GOVERNOR (TPG)

7. Configuration

7.1. Configure the unit of measure

The TPG can be configured for English (PSI, ºF) of Metric (kPa or bar, ºC) units of measure.

TECHNICAL DATA SHEET

THROTTLE CONTROL

P/N 117155 REV

PAGE

DATE

BY AMS

24 OF 26

3/28/2012

1.23

Follow the sequence below to set the TPG’s unit of measure.

+

ONCE

ONCE

ONCE

ONCE

Display shows MENU 04 SECS and begins counting down. Continue holding IDLE and

MENU until the display shows *SETUP MENU* (4 seconds).

The display shows the menu item: UNITS: XXX/ºX.

Press the INC switch to select the desired unit of measure: PSI/ºF, kPa/ºC, or bar/ ºC.

Press the PRESET switch once. The display shows ---STORED---. The unit of

measure has been saved.

Press the IDLE switch once. The display shows —EXITMENU— and then restarts

normal operation.

7.2. Select pressure transducer range (300 PSI, 600 PSI)

Normally the default 300 PSI transducer is sufficient for most pump applications but if a higher pump pressure range

is required the TPG can be programmed to use a 600 PSI transducer.

Follow the sequence below to select the desired pressure transducer range.

Enter menu level 3 by pressing and holding the IDLE switch while entering

+

or

the following password.

ONCE

ONCE

Manual P/N 117684

Toggle the MENU/SILENCE switch until the display shows XDCR= XXX.

(XXX = 300 or 600)

Press the INC switch to select the desired pressure transducer range (300 or 600).

Press the PRESET switch once. The display shows --- STORED---. The pressure

transducer range has been saved.

Press the IDLE switch once. The display shows —EXITMENU— and then restarts

normal operation.

Page 26

FORM-ENG-0018 REV A 05-27-03

MENU 04 SECS

(2 seconds).

Press the INC switch and hold. The display shows DIS:LIVE=XXX. Verify the value is

DIS:ZERO=XXX.

Enter menu level 3 by pressing and holding the IDLE switch while entering

INC, DEC, DEC, INC, DEC, DEC, INC, INC

Press the IDLE switch once. The display shows —EXITMENU— and then restarts

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

7.3. Zero calibrate the pressure transducer

The pressure indicated by the TPG may not show ‘0’ when the pump discharge pressure is actually zero due to

ambient pressure and altitude at your locale.

TECHNICAL DATA SHEET

THROTTLE CONTROL

TOTAL PRESSURE GOVERNOR (TPG)

PAGE

DATE

P/N 117155 REV

BY AMS

25 OF 26

3/28/2012

1.23

Follow the sequence below to zero calibrate the pressure transducer.

+

3 times

ONCE

+ HOLD

ONCE

ONCE

Display shows

MENU until the display shows *SETUP MENU* (4 seconds) and then MENU LEVEL 2

The display shows the menu item: -SENSOR CAL-.

Press the INC switch once. The display shows INT:ZERO=XXX.

between 130 and 155. Release the INC switch. The display will show

Press the PRESET switch once. The display shows NEW ZERO=XXX. Verify the

value is between 130 and 155.

Press the IDLE switch once. The display shows —EXITMENU— and then restarts

normal operation.

and begins counting down. Continue holding IDLE and

7.4. Configure the engine control method

The TPG has 4 engine control methods to cover several engine types and configuration.

CFPG – Cummins Fire Pressure Governor, uses Cummins proprietary control message to control engine speed.

PGN0 – Uses J1939, PGN0 – Torque Speed Control message to control engine speed.

SCAN – SCANia, uses the Scania bodywork control message 1.

ANLG – Uses analog voltage signal to control remote throttle input on engine.

PWM – Uses pulse width modulation control signal (12-85%, 400 Hz).

VLVO – Uses Volvo specific PTO control commands for Volvo FE/FL series engines running through a bodybuilder

module.

+

ONCE

OR

ONCE

ONCE

Manual P/N 117684

or

The display shows the menu item: CONTROL=XXXX (CFPG, PGN0, SCAN, ANLG,

PWM)

Select the desired engine control method: CFPG, PGN0, SCAN, or ANLG

Press the PRESET switch once. The display shows ---STORED---. The engine control

method has been saved.

normal operation.

the following password.

Page 27

FORM-ENG-0018 REV A 05-27-03

Enter the Auto Scale mode by pressing and holding the IDLE switch while

shows STORING DATA.

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

7.5. Configure the IDLE voltage and GAIN setting using Auto Scale

A TPG set to Analog control mode (see section 5.2.14) may use the Auto Scale configure method to automatically set

the IDLE voltage (5.2.33) and GAIN setting (Error! Reference source not found.).

The engine must be running and the interlocks (as defined in section 4.3) must be enabled when running the Auto

Scale mode.

The TPG will actively control the engine RPM during Auto Scale. Make certain that all operational

precautions are observed and a trained operator is present.

+

or

TECHNICAL DATA SHEET

THROTTLE CONTROL

TOTAL PRESSURE GOVERNOR (TPG)

entering the following password.

INC, DEC, DEC, DEC, INC, DEC, DEC, DEC

The display shows: MODE = START

P/N 117155 REV

PAGE

DATE

BY AMS

26 OF 26

3/28/2012

1.23

Press the MODE button to start the Auto Scale.

The display shows: IDLE SET = X.X (where X.X is the current output voltage).

The TPG begins ramping the output voltage until it detects a change in RPM.

ONCE

Once IDLE point is detected the display shows FINDING GAIN

The TPG then configures the GAIN setting required and the display shows GAIN = XX

(where XX is the GAIN setting).

The Auto Scale mode completes by saving the IDLE and GAIN data and the display

Manual P/N 117684

Page 28

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

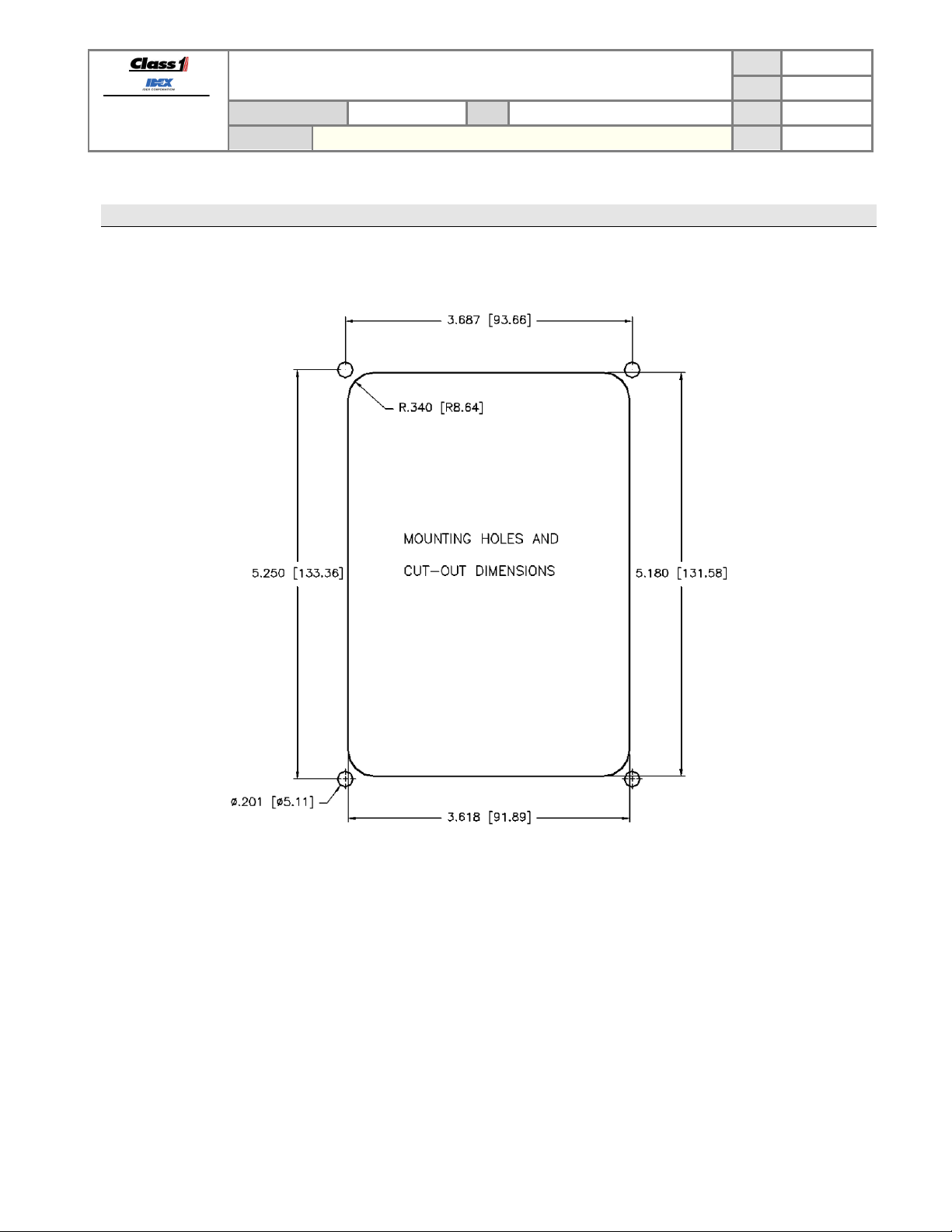

8. Mounting & installation

8.1. Panel cutout dimensions

TECHNICAL DATA SHEET

THROTTLE CONTROL

TOTAL PRESSURE GOVERNOR (TPG)

P/N 117155 REV

PAGE

DATE

BY AMS

27 OF 26

3/28/2012

1.23

Manual P/N 117684

Figure 5. Installation dimensions in inches [millimeters].

Page 29

FORM-ENG-0018 REV A 05-27-03

Mating connector: Deutsch DT06-6SA GRAY

PIN

CIRCUIT

DESCRIPTION

1

SUPPLY (+)

(

) – battery voltage

3

ALARM (-)

(OUTPUT) – alarm active

4

CAN HIGH

(

) – SAE J1939 CAN 2.0B, 250Kbits/s *

6

CAN SHIELD

(DATA) – SAE J1939 CAN 2.0B, 250Kbit s/s *

Mating connector: Deutsch DT06-12SA GRAY

PIN

CIRCUIT

DESCRIPTION

2

THROT INTLK

(INPUT) – throttle ready interlock

3

HI IDLE

(

) – high idle enable

4

OKAY TO PUMP

(

) – okay to pump interlock

5

Sensor GND

(OUTPUT) – pressure sensor ground

6

Sensor REF

(OUTPUT) – pressure sensor supply

7

Sensor SIGNAL

(

) – pressure sensor signal

8

ENG SIGNAL

(OUTPUT) – analog signal control (+0.5VDC to +4.5VDC) *

9

ENG REF (-)

(INPUT) – analog signal reference

10

PUMP INTLK

(

) – pump engaged interlock

12

RELAY N.O.

(OUTPUT) – remote throttle activate

Mating connector: Packard 12078090

PIN

CIRCUIT

DESCRIPTION

A

SUPPLY (-)

(INPUT) – pressure sensor ground

B

SUPPLY (+)

(

) – pressure sensor supply

C

Signal

(

) – pressure sensor signal

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

9. Connector Description

9.1. TPG connectors

The module has two connectors and the following definitions apply:

TECHNICAL DATA SHEET

THROTTLE CONTROL

TOTAL PRESSURE GOVERNOR (TPG)

P/N 117155 REV

PAGE

DATE

BY AMS

28 OF 26

3/28/2012

1.23

Mating sockets: Deutsch 0462-201-16141

Gold mating sockets: Deutsch 0462-201-1631

Wedge lock: W6S Recommended wire gage: 16-18 AWG

INPUT

(+9VDC…+32VDC)

2 SUPPLY (-) (INPUT) – battery ground

DATA

(ground polarity, 250mA)

5 CAN LOW (DATA) – SAE J1939 CAN 2.0B, 250Kbits/s *

* Gold pins recommended for CAN connections.

Mating sockets: Deutsch 0462-201-16141

Wedge lock: W12S Recommended wire gage: 16-18 AWG

1 ENG REF (+) (INPUT) – analog signal reference (+5VDC) *

INPUT

INPUT

INPUT

INPUT