Page 1

ISO 9001 CERTIFIED

607 NW 27th Ave

Phone: (352) 629-5020 or 800-533-3569

Ocala, FL 34475

Fax: (352)-629-2902

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

Intelli-Tank Level 40

Page 2

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

Intelli-Tank Level 40

PAGE

DATE 9/24/2008

BY AMS

1 of 25

1.

REVISION LOG ...........................................................................................................................................3

2. SYSTEM OVERVIEW..................................................................................................................................4

2.1. SCOPE .................................................................................................................................................... 4

2.2. PART NUMBERS........................................................................................................................................ 4

2.3. MODES OF OPERATION.............................................................................................................................4

3. OPERATION................................................................................................................................................5

3.1. LED INDICATIONS.....................................................................................................................................5

3.1.1. Initial power ON indications...............................................................................................................5

3.1.2. Level indications................................................................................................................................5

3.1.3. Error indications.................................................................................................................................6

3.2. MAGNETIC SWITCHES ............................................................................................................................... 7

3.3. CALIBRATION ........................................................................................................................................... 8

3.3.1. 1 Point Calibration.............................................................................................................................8

3.3.2. 2 Point Calibration (empty then full)..................................................................................................8

3.3.3. 2 Point Calibration (full then empty)..................................................................................................8

3.3.4. 5 Point Calibration.............................................................................................................................9

3.3.5. 9 Point Calibration.............................................................................................................................9

3.3.6. Calibration retention ..........................................................................................................................9

3.3.7. Invalid calibration...............................................................................................................................9

3.3.8. Calibration incomplete.....................................................................................................................10

3.4. SELF TEST ............................................................................................................................................. 10

3.5. SETTING THE DIM LED LEVEL ..................................................................................................................10

3.6. SHOW SOFTWARE VERSION, DEVICE SETTINGS, AND ERRORS ................................................................... 10

3.7. CONFIGURE THE COMMUNICATION METHOD .............................................................................................11

3.7.1. Configuring a display as a Master with 1-wire communications .....................................................11

3.7.2. Configuring a display as a Remote with 1-wire communications....................................................11

3.7.3. Configuring a display as a Master with CAN communications........................................................11

3.7.4. Configuring a display as a Remote with CAN communications......................................................11

3.8. CONFIGURE A CUSTOM MESSAGE SCROLL................................................................................................ 12

3.9. USE THE DISPLAY REFERENCE MARK ....................................................................................................... 12

3.10. SLOSH DAMPENING FEATURE ..................................................................................................................13

4. PASSWORD LIST .....................................................................................................................................14

5. INSTALLATION.........................................................................................................................................15

5.1. CUTOUT DIMENSIONS .............................................................................................................................15

5.2. OUTER BEZEL DIMENSIONS ..................................................................................................................... 15

5.3. LABEL ORIENTATION ...............................................................................................................................16

5.4. PRESSURE SENSOR ................................................................................................................................16

5.4.1. Approved fluids................................................................................................................................16

6. WIRING......................................................................................................................................................17

6.1. ITL40 CONNECTOR ................................................................................................................................17

6.2. PRESSURE SENSOR CONNECTOR ............................................................................................................ 17

6.3. COMMUNICATION WIRING EXAMPLES .......................................................................................................18

6.3.1. 1-wire method, 1 MASTER and 2 REMOTES.................................................................................18

6.3.2. 1-wire method, 2 MASTERS and 2 REMOTES..............................................................................18

6.3.3. CAN method, 1 MASTER and 2 REMOTES...................................................................................19

6.3.4. CAN method, 2 MASTERS and 2 REMOTES ................................................................................19

6.3.5. Terminating resistor requirement (CAN communication)................................................................20

MANUAL P/N:118253 PRINTED: 1/8/09

Page 3

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

Intelli-Tank Level 40

PAGE

DATE 9/24/2008

BY AMS

2 of 25

6.4. COMMUNICATION COMPATIBILITY WITH CLASS 1 PRODUCTS...................................................................... 20

6.4.1. 1-wire compatibility..........................................................................................................................20

6.4.2. CAN compatibility............................................................................................................................20

7. TROUBLESHOOTING...............................................................................................................................21

7.1. EVALUATION TABLE ................................................................................................................................21

7.2. USING THE DISPLAY TO VERIFY PRESSURE SENSOR SIGNAL VOLTAGE ........................................................22

8. GLOSSARY ....................................................................................................................... ........................23

9. TECHNICAL DETAILS..............................................................................................................................24

9.1. TECHNICAL DETAILS ............................................................................................................................... 24

9.2. WEEE (WASTE OF ELECTRICAL AND ELECTRONIC EQUIPMENT) DIRECTIVE............................................... 24

9.3. CE STATEMENT ......................................................................................................................................24

10. 板料信息声明 (ROHS 声明) – DECLARATION INFORMATION SHEET (ROHS DECLARATION) ........25

10.1. 产品中有毒和有害的物质或成份的名称和含量 – (NAMES AND CONTENTS OF THE TOXIC AND

HAZARDOUS SUBSTANCES OR ELEMENTS IN THE PRODUCTS) ............................................... 25

MANUAL P/N:118253 PRINTED: 1/8/09

Page 4

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

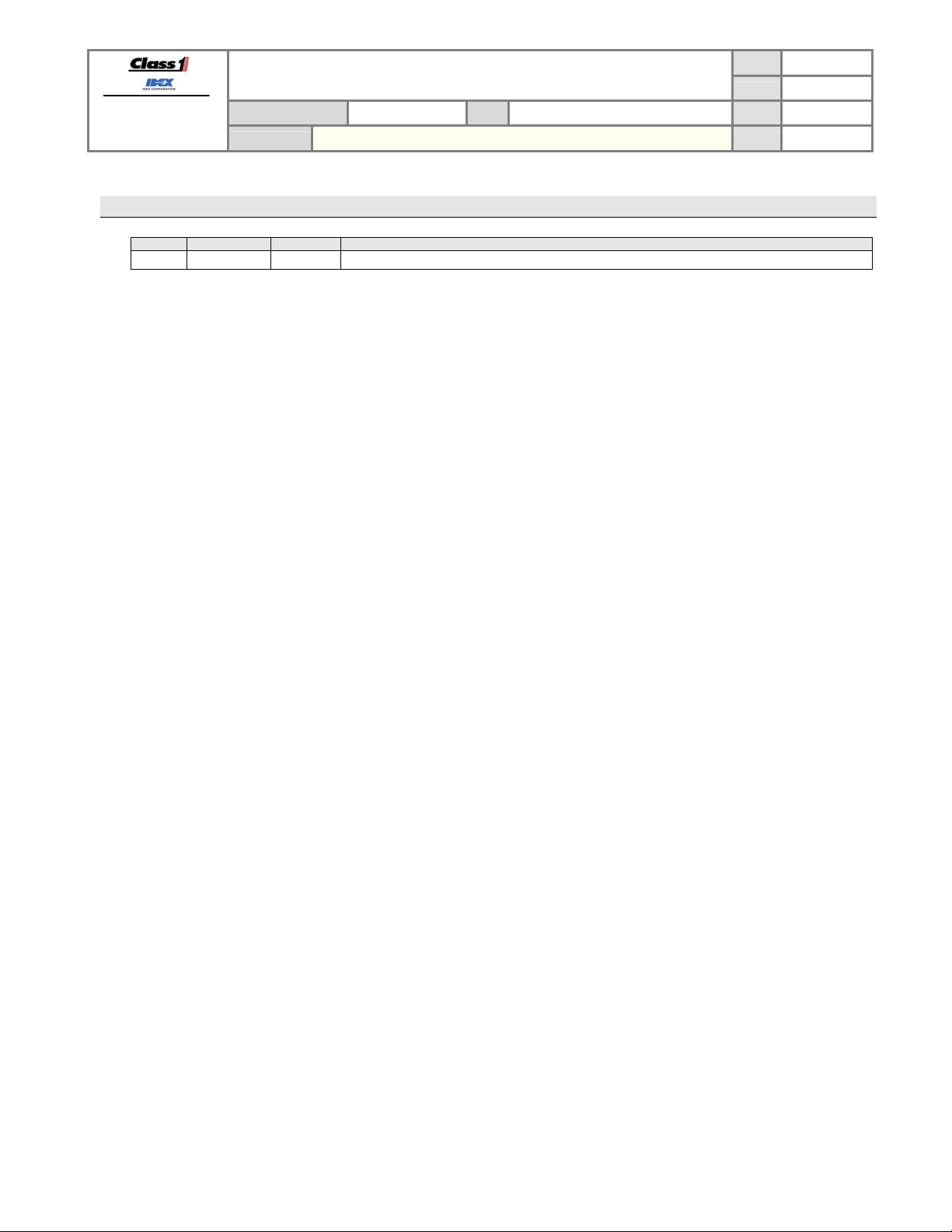

1. Revision Log

Rev Date Approved Changes

1.00 9-24-2008 AGK Initial requirements

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

Intelli-Tank Level 40

PAGE

DATE 9/24/2008

BY AMS

3 of 25

MANUAL P/N:118253 PRINTED: 1/8/09

Page 5

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

Intelli-Tank Level 40

PAGE

DATE 9/24/2008

BY AMS

4 of 25

2. System Overview

2.1. Scope

The Intelli-Tank Level 40 (ITL40) is designed to display a liquid’s volume to an eighth of a tank level accuracy through

180-degree viewable ultra-bright LEDs. An Intelli-Tank Level 40 set as a MASTER uses a 0-5 PSI (0-34.47 kPa,

0-0.3447 bar) pressure sensor to obtain tank level information and then relays that information along the

communication line(s) (1-Wire or CAN) to ITL40’s set as REMOTES. Multiple REMOTE units can be linked to the

MASTER tank level.

2.2. Part numbers

Tank Level Gauge C1 – p/n 118404-01 – Red LEDs

p/n 118404-02 – Amber LEDs

p/n 118404-03 – Yellow LEDs

p/n 118404-04 – Green LEDs

p/n 118404-05 – Blue LEDs

p/n 118404-06 – 2 Red, 2 Yellow, 2 Blue, 2 Green rows of LEDs

Labels C1 – p/n 117691 – water (blue)

p/n 117692 – foam (red)

p/n 117693 – foam (green)

Pressure Sensor C1 – p/n 102162 – 0 to 5 PSI (0 to 34.47 kPa, 0 to 0.3447 bar) gage

Adapter bushing C1 – p/n 102219 – ¾ to ¼ NPT

Installation Harness C1 – p/n 118485-10 – Master display, 10 feet

p/n 118485-20 – Master display, 20 feet

p/n 118485-30 – Master display, 30 feet

p/n 118485-40 – Master display, 40 feet

p/n 118695 – Remote display

Terminating resistor (CAN) C1 – p/n DT06-3S-P006

“Y” connector (CAN) C1 – p/n DT04-3P-P007

Operation Manual C1 – p/n 118253

One Page Manual C1 – p/n 118252

2.3. Modes of Operation

Master When the ITL40 display is calibrated with a proper pressure signal it automatically becomes a MASTER

display and will send tank level information along the communication line(s) (either 1-wire or CAN) to all

other REMOTE displays.

Remote ITL40 displays are initially shipped as REMOTE displays. A REMOTE display only requires power,

ground and communications line(s) (either 1-wire or CAN). The REMOTE display mimics the MASTER

display’s LEDs by reading the appropriate information on the communication line(s).

MANUAL P/N:118253 PRINTED: 1/8/09

Page 6

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

3. Operation

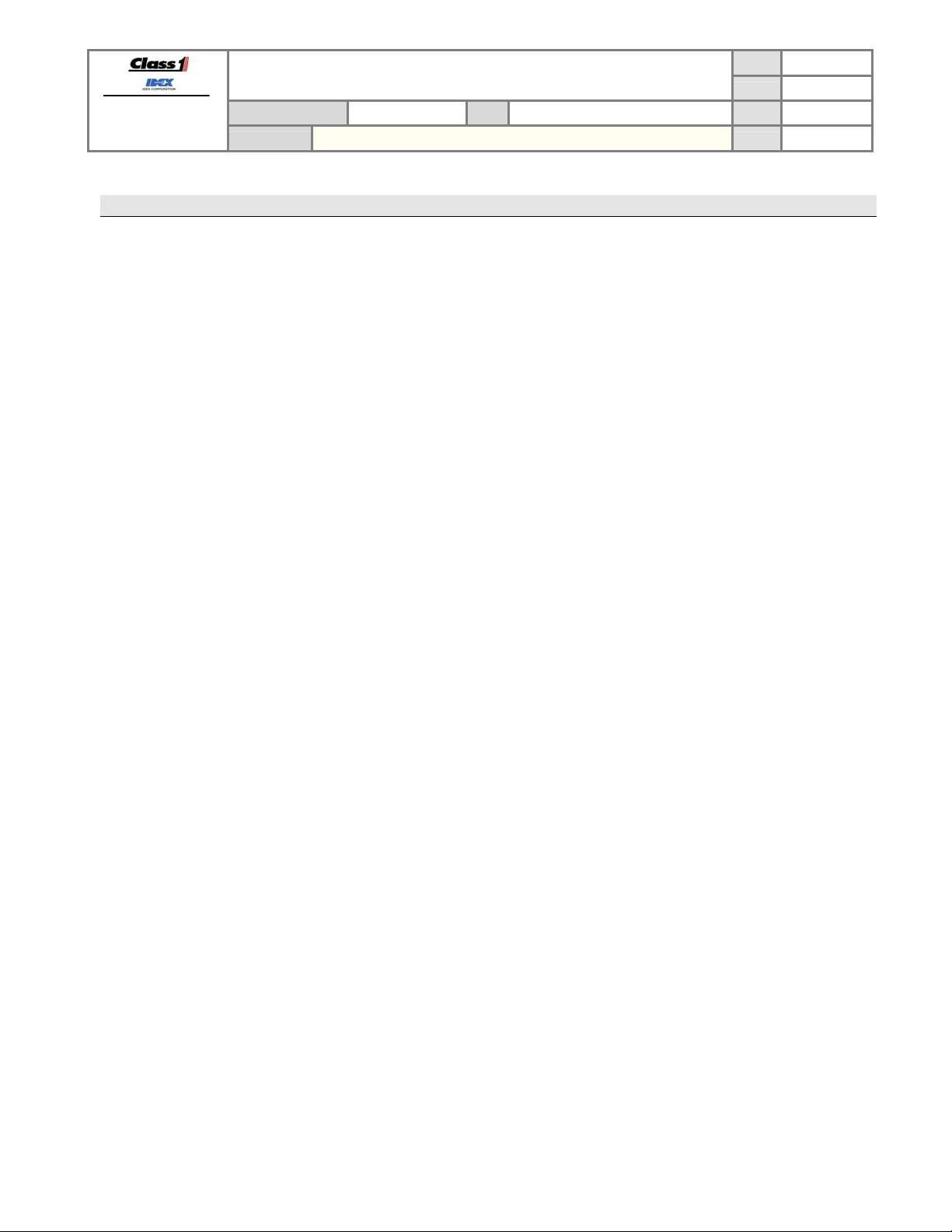

3.1. LED indications

The ITL40 display uses 8 rows of LEDs to show the unit status, tank level indication (section 3.1.2), and error

indications (section 3.1.3).

3.1.1. Initial power ON indications

When the ITL40 is first powered up the display will…

1. Turn ON all of the LEDs then immediately cycle OFF each LED starting at the top row.

2. Display the custom scroll greeting (default is “CLASS 1”, but can be custom configured – section 3.8).

3. The LEDs will show the tank level indication (section 3.1.2) or error indication (section 3.1.3).

3.1.2. Level indications

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

Intelli-Tank Level 40

PAGE

DATE 9/24/2008

BY AMS

5 of 25

MANUAL P/N:118253 PRINTED: 1/8/09

Page 7

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

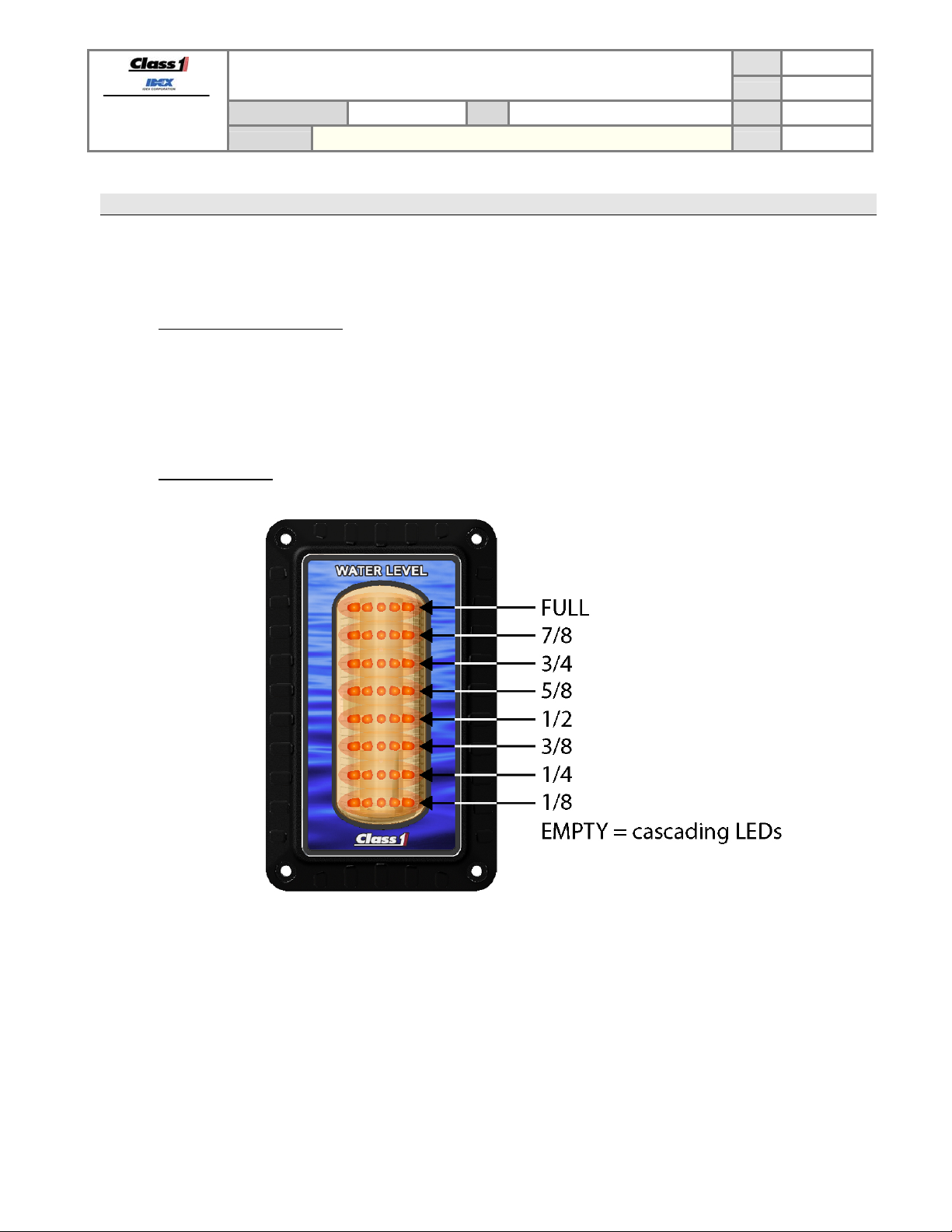

3.1.3. Error indications

Invalid calibration

Condition Visual

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

Intelli-Tank Level 40

Condition Visual

PAGE

DATE 9/24/2008

BY AMS

6 of 25

“NO DATA”

REMOTE is not

receiving data from

MASTER

Incomplete

calibration

EEPROM error

Sensor signal

voltage above 4.8V

Sensor signal

voltage below 0.4V

Password Error

(1)

Unit type error

The display is not

configured as a

MASTER or

REMOTE

(2)

(1)”

“X” flashed four times.

(2)

Indicates that the unit type has erroneously changed. The two valid unit types are REMOTE and MASTER.

MANUAL P/N:118253 PRINTED: 1/8/09

Page 8

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

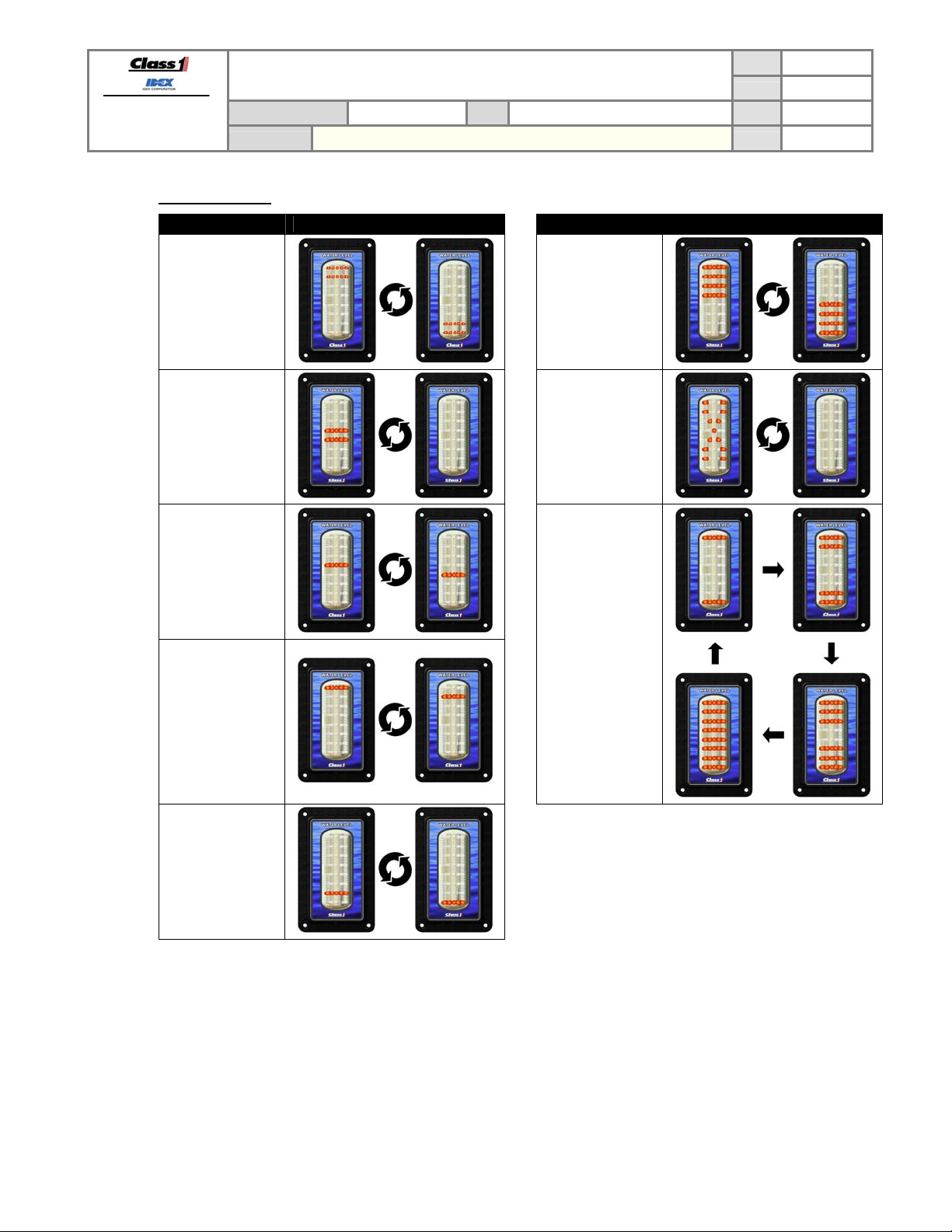

3.2. Magnetic switches

The ITL40 has two magnetic switches (left and right). The switches are activated by touching a magnet to either side

of the display in the areas shown in picture below. The label has a small “o” to indicate the location of the magnetic

switch.

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

Intelli-Tank Level 40

PAGE

DATE 9/24/2008

BY AMS

7 of 25

For best results the magnet should be positioned over the desired switch approximately 2 inches from the front of the

display, pushed directly to the front of the display, and then pulled back to the start position (do not using a swiping

motion).

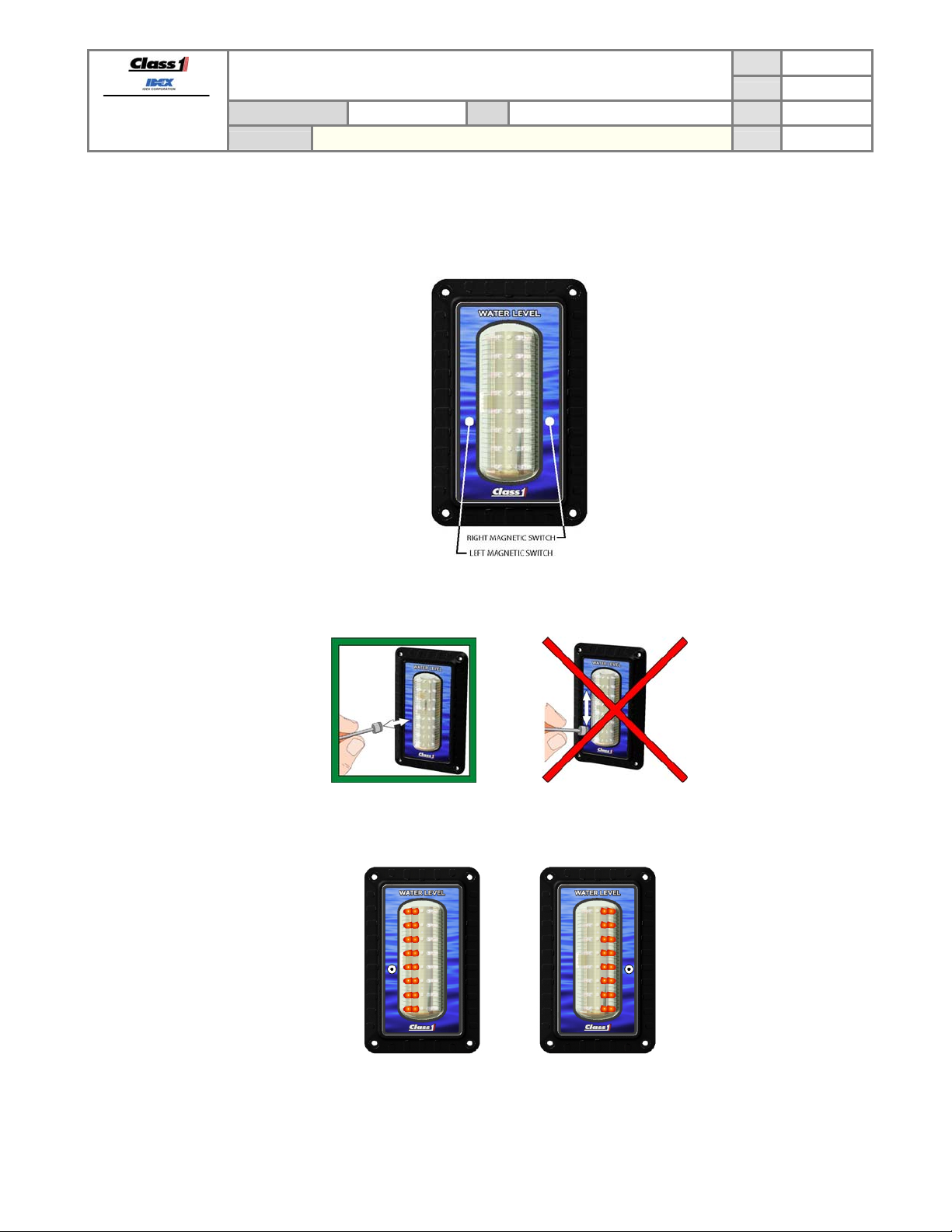

The LEDs on the display will indicate which switch was activated for approximately half a second and then the display

will go blank (LEFT = left two columns of LEDs, RIGHT = right two columns of LEDs).

LEFT (L) indication RIGHT (R) indication

The maximum time between magnetic switch activations is two seconds. If longer than two seconds have passed

between activations the unit will resume normal operation and the password attempted will be cleared.

MANUAL P/N:118253 PRINTED: 1/8/09

Page 9

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

Intelli-Tank Level 40

3.3. Calibration

The ITL40 display can be calibrated five different ways: 1-point (quick calibration), 2-point (level calibration) empty

then full, 2-point (level calibration) full then empty, 5-point and 9-point (volume calibration).

To enter calibration mode use a magnet and activate the magnetic switches in the order of the appropriate password.

Entering an invalid password will initiate a “password error” pattern on the display (“X”

flashed four times). The unit will then resume its normal operation and the user can

attempt to re-enter the password.

Calibrate the unit by entering the desired point calibration password –

1 point RLLR LRRL

(see section 3.3.1)

PAGE

DATE 9/24/2008

BY AMS

8 of 25

2 point (empty then full) RLLR LLRL

2 point (full then empty) RLLR LRRR

5 point (start at empty) RLLR LRLR

9 point (start at empty) RLLR RLLR

(see section 3.3.2)

(see section 3.3.3)

(see section 3.3.4)

(see section 3.3.5)

During calibration, the process can be cancelled at any time by activating the LEFT magnetic switch. This will allow the

display to exit without showing an “incomplete calibration error” (section 3.1.3) on the next power cycle.

3.3.1. 1 Point Calibration

1 point calibration only calibrates the full point. The empty calibration is always set to 0.55V (approximately 1.5

inches of liquid).

1. Make certain that the tank is FULL.

2. Enter the password RLLR LRRL. The display will respond by showing the number “1”. The display will then

start normal operation with the new calibration by displaying FULL (all LEDs on).

3.3.2. 2 Point Calibration (empty then full)

1. Enter the password RLLR LLRL. The display will respond by showing the number “2”. The display will then

begin scrolling the text “SET EMPTY” across the display.

2. Make certain that the tank is EMPTY and then activate the RIGHT switch to store that point. The display will

flash the top two LED rows and then begin scrolling the text “SET FULL”.

3. Fill the tank and then activate the RIGHT switch. The display will respond by flashing the top two LED rows

and then start normal operation with the new calibration by displaying FULL (all LEDs on).

3.3.3. 2 Point Calibration (full then empty)

1. Enter the password RLLR LRRR. The display will respond by showing the number “2”. The display will then

begin scrolling the text “SET FULL” across the display.

2. Make certain that the tank is FULL and then activate the RIGHT switch to store that point. The display will

flash the top two LED rows and then begin scrolling the text “SET EMPTY”.

3. Drain the tank and then activate the RIGHT switch. The display will respond by flashing the top two LED

rows and then start normal operation with the new calibration by displaying EMPTY (cascading LEDs).

MANUAL P/N:118253 PRINTED: 1/8/09

Page 10

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

3.3.4. 5 Point Calibration

1. Enter the password RLLR LRLR. The display will respond by showing the number “5”. The display will then

2. Make certain that the tank is EMPTY and then activate the RIGHT switch to store that point. The display will

3. Fill the tank to the one-quarter tank point and then activate the RIGHT switch. The display will flash the top

4. Fill the tank to the one-half tank point and then activate the RIGHT switch. The display will flash the top two

5. Fill the tank to the three-quarter tank point and then activate the RIGHT switch. The display will flash the top

6. Fill the tank to the full point and then activate the RIGHT switch. The display will respond by flashing the top

3.3.5. 9 Point Calibration

1. Enter the password RLLR RLLR. The display will respond by showing the number “9”. The display will then

2. Make certain that the tank is EMPTY and then activate the RIGHT switch to store that point. The display will

3. Fill the tank to the one-eighth point and then activate the RIGHT switch. The display will flash the top two

4. Fill the tank to the one-quarter point and then activate the RIGHT switch. The display will flash the top two

5. Fill the tank to the three-eighths point and then activate the RIGHT switch. The display will flash the top two

6. Fill the tank to the one-half point and then activate the RIGHT switch. The display will flash the top two LED

7. Fill the tank to the five-eighths point and then activate the RIGHT switch. The display will flash the top two

8. Fill the tank to the three-quarter point and then activate the RIGHT switch. The display will flash the top two

9. Fill the tank to the seven-eighths point and then activate the RIGHT switch. The display will flash the top two

10. Fill the tank to the full point and then activate the RIGHT switch. The display will respond by flashing the top

3.3.6. Calibration retention

Calibration data is saved in non-volatile memory (EEPROM) and the display does not need power to retain

calibration data.

3.3.7. Invalid calibration

Calibration automatically makes the ITL40 a MASTER display if the calibration is valid. An invalid calibration is

determined when any calibrated point is not at a higher level than the previous calibrated point, or if the sensor

voltage falls outside of the valid minimum (0.4V) or maximum (4.8V) range.

An invalid calibration is acknowledged by flashing “X” four times and then scrolling the text “CHECK SENSOR

VOLTS” followed by a continuous scroll of the voltage detected on the sensor’s signal (pin 6).

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

begin scrolling the text “SET EMPTY”.

flash the top two LED rows and then begin scrolling the text “SET 1/4".

two LED rows and then begin scrolling the text “SET 1/2".

LED rows and then begin scrolling the text “SET 3/4".

two LED rows and then begin scrolling the text “SET FULL".

two LED rows and then start normal operation with the new calibration by displaying FULL (all LEDs on).

begin scrolling the text “SET EMPTY”.

flash the top two LED rows and then begin scrolling the text “SET 1/8".

LED rows and then begin scrolling the text “SET 1/4".

LED rows and then begin scrolling the text “SET 3/8".

LED rows and then begin scrolling the text “SET 1/2".

rows and then begin scrolling the text “SET 5/8".

LED rows and then begin scrolling the text “SET 3/4".

LED rows and then begin scrolling the text “SET 7/8".

LED rows and then begin scrolling the text “SET FULL".

two LED rows and then start normal operation with the new calibration by displaying FULL (all LEDs on).

SUITABLE FOR EXTERNAL DISTRIBUTION

Intelli-Tank Level 40

OPERATION MANUAL

PAGE

DATE 9/24/2008

BY AMS

9 of 25

MANUAL P/N:118253 PRINTED: 1/8/09

Page 11

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

3.3.8. Calibration incomplete

If the calibration is not completed the display will continually flash the “incomplete calibration” error (section 3.1.3),

during all subsequent power cycles. This indicates that a calibration was attempted but never completed.

Recalibrate the display completely to remove this error condition.

3.4. Self test

The ITL40 can check its hardware for proper operation by entering the password RLLR LLRR.

The display will turn all the LEDs ON and then cycle each LED OFF individually starting with the top LED. All LEDs

will come on and begin flashing between full bright and the calibrated dim level for 5 seconds. The display will then

scroll text indicating the self test condition.

Memory test

“MEM-PASS” Memory (EEPROM) is good.

“MEM-FAIL” Memory (EEPROM) failure detected.

Sensor signal test (MASTER unit only)

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

Intelli-Tank Level 40

PAGE

DATE 9/24/2008

BY AMS

10 of 25

“SIG-PASS” Sensor signal voltage within tolerance (0.4 volts to 4.8 volts).

“SIG-FAIL” Sensor signal voltage out of tolerance (0.4 volts to 4.8 volts).

Communication wire test

‘WIRE-PASS” Data communication lines good.

“WIRE-FAIL” Data communication lines shorted or open.

If the self test password is used on a MASTER display all REMOTE displays will also perform their self test.

3.5. Setting the di m LED level

The display can be dimmed by applying system power to pin 4 (Dim Display input). The ITL40 has 9 levels of

brightness available (9 = brightest, 1 = dimmest, default value is 3).

To select the dim level of the display use the magnetic switches to enter the password RLLR LLLR.

All of the LEDs will be illuminated during the set-up. Touch a magnet against the RIGHT switch and the display will

dim to the next level and show the dim value number (9 through 1). Release the magnet and again touch it against

the RIGHT switch again to drop to the next dim level. Once the dim level is at the dimmest setting (1) the next touch

of the magnet will cycle to the highest dim level (9).

When the dim level is at the desired point activate the LEFT switch to save and exit.

3.6. Show software version, device settings, and errors

The ITL40 can display its setting by entering the password RRRR RRRR.

The display will scroll the software version, unit type, communication method, and then display any errors.

Software version

“Vx.x” Where x.x equals the numeric software version. For example, V1.0.

Unit type

“MASTER” The unit is set as a MASTER.

“REMOTE” The unit is set as a remote.

“CAL INCOMPLETE” A calibration was started but never completed.

“UNKNOWN” The unit type cannot be determined – ERROR.

MANUAL P/N:118253 PRINTED: 1/8/09

Page 12

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

Intelli-Tank Level 40

Communication method

“1-WIRE” Using 1-wire communication method.

“CAN” Using CAN communication method.

CAN device address (if communication method = CAN)

“ADDR=1” The unit ‘s CAN address is 1 (0xCB).

“ADDR=2” The unit ‘s CAN address is 2 (0xCC).

“ADDR=3” The unit ‘s CAN address is 3 (0xCD).

“ADDR=4” The unit ‘s CAN address is 4 (0xCE).

“ADDR=PCM” The unit ‘s CAN address is Pump Control Module (0xCA).

Error indications

“NO ERRORS” No errors detected.

“MEM-ERROR” Memory error detected.

“CAL-ERROR” Validation of calibration problem detected.

“NO-COMM” Not receiving communication from MASTER display.

“SIG-HIGH” Sensor signal voltage too high (greater than 4.8V).

“SIG-LOW” Sensor signal voltage too low (less than 0.4V).

“CAL NOT FINISHED” Calibration was started but not completed.

“TYPE-BAD” Unit type cannot be determined (not MASTER, REMOTE, or CAL INCOMPLETE).

3.7. Configure the communication method

A MASTER display can communicate to other displays that are configured as remotes via CAN or 1-wire.

The 1-wire communication method is the default method and will work with ITL40 and ITL displays.

The CAN communication method is new for the ITL40 displays and is a more robust communication method. This

method requires two wires (CAN high, CAN low) and approved J1939 CAN wiring and connectors. There should be

two (2) 120 ohm terminating resistors located at the ends of the CAN bus (see section 6.3.5).

3.7.1. Configuring a display as a Master with 1-wire communication s

Enter the password LRLL LLLR to set the communication method to 1-wire. If the display was not previously a

MASTER display, calibrate the display

3.7.2. Configuring a display as a Remote with 1-wire communicatio ns

Enter the password LRLL LLLR to set the communication method to 1-wire. If the display is a MASTER display,

enter the password LRLR LRLR to turn the display into a REMOTE.

3.7.3. Configuring a display as a Master with CAN communications

Enter the password LRLL LLRL to set the communication method to CAN. If the display was not previously a

MASTER display, calibrate the display

Choose the CAN identification address to use (either address 1, 2, 3, 4, or PCM) and enter the appropriate

password to set the address (LRRR LLLL address 1, LRRR LLLR address 2, LRRR LRRR address 3,

LRRR RLLR address 4, LRRR LRLR address PCM). All REMOTE displays that are to mimic this Master display

must have their addresses matching the MASTER’s.

3.7.4. Configuring a display as a Remote with CAN communications

Choose the CAN identification address to use (either address 1, 2, 3, 4, or PCM) and enter the appropriate

password to set the address (LRRR LLRL address 1, LRRR LLRR address 2, LRRR LRRL address 3,

(see section 3.3).

(see section 3.3).

PAGE

DATE 9/24/2008

BY AMS

11 of 25

MANUAL P/N:118253 PRINTED: 1/8/09

Page 13

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

Intelli-Tank Level 40

LRRR RLLL address 4). All REMOTE displays that are to mimic the MASTER display must have their addresses

matching the MASTER’s.

The display can also be configured to mimic a Class 1 Pump Sensor Module (p/n 111097) by entering the

password for the desired tank (LRRR LRLL PCM tank 1, LRRR RLRL PCM tank 2, LRRR RLRR PCM tank 3).

3.8. Configure a custom message scroll

The ITL40 scrolls a custom message during start-up. The default scroll text is “Class 1” but the text can be custom

configured to a desired message (maximum of 21 characters allowed).

List of available characters.

A B C D E F G H I J K L M N O P Q R S T U V

W X Y Z

Enter the password LLLL LRLR and the display will show the first available character - “A”.

Use the LEFT and RIGHT magnetic switches to enter the desired text.

SP

0 1 2 3 4 5 6 7 8 9 + - / = ? .

PAGE

DATE 9/24/2008

BY AMS

12 of 25

• The LEFT magnetic switch changes the character. Each LEFT switch activation moves forward or backward

through the available characters. Wait two seconds between switch activations and the direction reverses.

• The RIGHT magnetic switch saves the displayed character to memory.

There are three methods of exiting…

• Save two SPACE characters in a row.

Configure the maximum number of characters (21).

•

Turn OFF power to the ITL40.

•

The custom message scroll can also be configured through a CAN message. Contact Class 1 for details.

3.9. Use the display reference mark

The level the ITL40 shows may be difficult to distinguish at a distance for some

viewers. The ITL40 can be configured with a reference mark at the top of the

display (single LED ON) which will help quickly determine level.

• Enter the password LLRR RRRR to turn the reference mark ON.

• Enter the password LLRR LLLL to turn the reference mark OFF.

The default for the reference mark is OFF.

MANUAL P/N:118253 PRINTED: 1/8/09

Page 14

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

3.10. Slosh dampening feature

Some applications (off-road vehicles, etc) may submit the tank to conditions of extreme movement which causes the

fluid to slosh producing significant fluctuation in the displayed tank level.

The ITL40 can counteract these conditions by averaging the rhythmic changes (sloshing) detected by the pressure

sensor creating a more consistent displayed tank level.

Example with the slosh dampening feature DISABLED (default).

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

Intelli-Tank Level 40

PAGE

DATE 9/24/2008

BY AMS

13 of 25

Example with the slosh dampening feature ENABLED.

• Enable the slosh dampening feature by entering the password LRRL LRRL.

The display will scroll “SLOSH ON” to indicate that the feature has been enabled.

• Disable the slosh dampening feature by entering the password LRRL LRRR.

The display will scroll “SLOSH OFF” to indicate that the feature has been disabled.

MANUAL P/N:118253 PRINTED: 1/8/09

Page 15

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

4. Password list

RLLR LRRL

RLLR LLRL 2 point calibration, empty then full (section 3.3.2)

RLLR LRRR 2 point calibration, full then empty (section 3.3.4)

RLLR LRLR 5 point calibration (section 3.3.4)

RLLR RLLR 9 point calibration (section 3.3.5)

RLLR LLRR Self test (section 3.4)

LRLR LRLR Configure display as Remote display (section 2.3)

RLLR LLLR Configure dim level (section 3.5)

LLRR LLRR Display voltage (section 7.2)

LRLL LLLR Configure for 1-wire communi cations (section 3.7)

LRLL LLRL Configure for CAN communications (section 3.7)

LRRR LLLL Configure as Master display with CAN address 1 (section 3.7.3)

LRRR LLLR Configure as Master display with CAN address 2 (section 3.7.3)

LRRR LRRR Configure as Master display with CAN address 3 (section 3.7.3)

LRRR RLLR Configure as Master display with CAN address 4 (section 3.7.3)

LRRR LRLR Configure as Master display with CAN address PCM (section 3.7.3)

LRRR LLRL Configure as Remote display with CAN address 1 (section 3.7.4)

LRRR LLRR Configure as Remote display with CAN address 2 (section 3.7.4)

LRRR LRRL Configure as Remote display with CAN address 3 (section 3.7.4)

LRRR RLLL Configure as Remote display with CAN address 4 (section 3.7.4)

LRRR LRLL

LRRR RLRL

LRRR RLRR

LRRL LRRL Slosh dampening feature enabled (section 3.10 )

LRRL LRRR Slosh dampening feature disabled (section 3. 10)

LLRR LLLL Reference mark turned OFF (section 3.9)

LLRR RRRR Reference mark turned ON (section 3.9)

LLRR LRRL Load defaults (remote, 1-wire, dim level 3, “CLASS 1” scroll, slosh dampening OFF)

LLLL LRLR Configure custom start-up text scroll (section 3.8)

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

Intelli-Tank Level 40

PAGE

DATE 9/24/2008

BY AMS

14 of 25

1 point calibration (section 3.3.1)

Configure as Remote display for use with Pump Sensor Module, Tank 1

(section 3.7.4)

Configure as Remote display for use with Pump Sensor Module, Tank 2

(section 3.7.4)

Configure as Remote display for use with Pump Sensor Module, Tank 3

(section 3.7.4)

MANUAL P/N:118253 PRINTED: 1/8/09

Page 16

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

5. Installation

5.1. Cutout dimensions

The display requires a cutout as shown. The display is water tight and may be mounted in any location on the

operator’s panel.

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

Intelli-Tank Level 40

PAGE

DATE 9/24/2008

BY AMS

15 of 25

Unit of scale: inches [millimeters]

5.2. Outer bezel dimensions

Unit of scale: inches [millimeters]

MANUAL P/N:118253 PRINTED: 1/8/09

Page 17

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

5.3. Label orientation

Before mounting the display and adhering the label insure that the display is situated correctly (TOP is UP). Refer to

the drawing for orientation.

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

Intelli-Tank Level 40

PAGE

DATE 9/24/2008

BY AMS

16 of 25

p/n 117691

p/n 117692

p/n 117693

5.4. Pressure sensor

The pressure sensor (p/n 102162) is threaded for ¼” NPT and must be mounted vertically as depicted to insure an

accurate reading.

5.4.1. Approved fluids

The pressure sensor has been tested and approved for water and Class A and B foams.

MANUAL P/N:118253 PRINTED: 1/8/09

Page 18

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

6. Wiring

6.1. ITL40 connector

The ITL40 has one connector and the following definitions apply:

Mating connector: Deutsch DT06-12SB BLACK

Mating sockets: Deutsch 0462-201-16141

Wedge lock: W12S Recommended wire gage: 16-18 AWG

PIN CIRCUIT DESCRIPTION

1 SUPPLY (+) (INPUT) – battery voltage (+9VDC…+32VDC)

2 CAN HIGH (DATA) – SAE J1939 CAN 2.0B, 250Kbits/s

3 CAN SHIELD (DATA) – SAE J1939 CAN 2.0B, 250Kbits /s

4 DIM DISPLAY (INPUT) – Dim display input (positive polarity)

5 Sensor REF (OUTPUT) – pressure sensor supply (+5VDC)

6 Sensor SIGNAL (INPUT) – pressure sensor signal (+0.5VDC to +4.5VDC)

7 Sensor GND (OUTPUT) – pressure sensor ground

8 ---- ----

9 1-WIRE SIG (DATA) – Class 1proprietary communication

10 GROUND (OUTPUT) – common ground

11 CAN LOW (DATA) – SAE J1939 CAN 2.0B, 250Kbits /s

12 SUPPLY (-) (INPUT) – battery ground

6.2. Pressure sensor connector

The pressure sensor has one connector and the following definitions apply:

Mating connector: Packard Metri-Pack 150 series, 12047909

Mating sockets: Packard Metri-Pack 150 series, 12103881

Recommended wire gage: 18-20 AWG

PIN CIRCUIT DESCRIPTION

A SUPPLY (+) (INPUT) – pressure sensor supply (+5VDC)

B SUPPLY (-) (INPUT) – pressure sensor ground

C Signal (OUTPUT) – pressure sensor signal (+0.5VDC to +4.5VDC)

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

Intelli-Tank Level 40

PAGE

DATE 9/24/2008

BY AMS

17 of 25

MANUAL P/N:118253 PRINTED: 1/8/09

Page 19

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

Intelli-Tank Level 40

6.3. Communication wiring examples

The ITL40 display can be set up to use the 1-wire or CAN communication methods. The simplest system would be

comprised of a single ITL40 MASTER display.

6.3.1. 1-wire method, 1 MASTER and 2 REMOTES

PAGE

DATE 9/24/2008

BY AMS

18 of 25

System configured with 1-wire communication method. Make certain that the ground for each display is tied to a

common point or the REMOTE displays will not receive communication data from the MASTER display.

6.3.2. 1-wire method, 2 MASTERS and 2 REMOTES

System configured with 1-wire communication method. Make certain that the two MASTER 1-wire data lines are

not connected and that the ground for each display is tied to a common point or the REMOTE displays will not

receive communication data from their associated MASTER display.

MANUAL P/N:118253 PRINTED: 1/8/09

Page 20

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

Intelli-Tank Level 40

6.3.3. CAN method, 1 MASTER and 2 REMOTES

PAGE

DATE 9/24/2008

BY AMS

19 of 25

System configured with CAN communication method. This example shows one MASTER display (configured with

address 1) communicating with 2 REMOTE displays (configured with address 1).

Two CAN terminating resistors (p/n DT06-3S-P006) are required in the system (one at each end of the CAN bus).

6.3.4. CAN method, 2 MASTERS and 2 REMOTES

System configured with CAN communication method. This example shows two MASTER displays (configured

with address 1 and address 2) communicating with 2 REMOTE displays (configured with address 1 and address 2).

REMOTE display address 1 only follows the indications of MASTER display address 1, and REMOTE display

address 2 only follows the indications of MASTER display address 2.

Two CAN terminating resistors (p/n DT06-3S-P006) are required in the system (one at each end of the CAN bus).

MANUAL P/N:118253 PRINTED: 1/8/09

Page 21

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

Intelli-Tank Level 40

6.3.5. Terminating resistor requirement (CAN communication)

Two terminating resistors (120 Ohm) are required on the CAN bus for proper operation (one at each end of the

CAN bus). Only two terminating resistors are allowed on a CAN bus.

Terminating resistor p/n DT06-3S-P006

CAN 3-way “Y” connector p/n DT04-3P-P007

6.4. Communication compatibility with Class 1 products

The ITL40 display is compatible with other Class 1 CAN and 1-wire products.

6.4.1. 1-wire compatibility

An ITL40 display configured with 1-wire communication is compatible with…

• 4 light remote driver module (p/n 106877)

• Pump input sensor module (p/n 111097)

• Mini remote driver module (p/n 112648)

• Mini remote dash gauge (p/n 112649)

• 4 and 5 light ITL displays (p/n 106299, 106296, 108858, 108859, 113739, 114378, 114005, 114379)

6.4.2. CAN compatibility

An ITL40 display configured with CAN communications is compatible with…

• Command Master (p/n 111084, 111085, 111086)

• Pump input sensor module (p/n 111097)

• 4 and 5 light ITL displays (p/n 113739, 114378, 114005, 114379)

PAGE

DATE 9/24/2008

BY AMS

20 of 25

MANUAL P/N:118253 PRINTED: 1/8/09

Page 22

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

7. Troubleshooting

7.1. Evaluation table

Condition Visual Evaluate

Bottom two LEDs rows

alternate flashing.

Signal voltage too low

(less than 0.4 V).

Top two LED rows

alternate flashing.

Signal voltage too high

(greater than 4.8V).

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

Intelli-Tank Level 40

Check sensor wiring. Ensure +5V at pin A, ground at pin B and at least 0.4V at

pin C (Signal).

Use password LLRR LLRR to view sensor voltage on display.

Check sensor wiring. Ensure +5V at pin A, ground at pin B and no more than 4.8V

at pin C (Signal).

Use password LLRR LLRR to view sensor voltage on display.

PAGE

DATE 9/24/2008

BY AMS

21 of 25

Middle two LED rows

alternate flashing.

Memory error.

Outer two LED rows

alternate flashing.

Invalid calibration.

Bottom four and Upper

four LEDs rows alternate

flashing.

Not receiving data.

No LEDS on.

Master Tank level unit

does not change when

actual tank level is

changing.

No picture

Perform self test RLLR LLRR. If it shows “MEM-FAIL” replace display, otherwise

recalibrate or reset as REMOTE.

Try to recalibrate. If condition remains, check if the sensor signal voltage (pin C)

changes as tank level increases. If it doesn’t, replace sensor. If it does, verify

depth of tank. It may be impossible to calibrate a tank with a depth of less than 6

inches.

The display is configured as a REMOTE. Recalibrate if a MASTER is required. If

the display is supposed to be a REMOTE check communication data lines for

continuity.

Check power (Pin 1) and ground (Pin 12) connection.

Check sensor wiring. Ensure sensor signal voltage (Pin C) is varying. If it does,

check for same signal changes at Pin 6 of tank level connector (if it is not the

same - repair wiring). If signal is good at both locations try re-calibrating.

Remote Tank level unit

does not follow Master

No picture

display.

MANUAL P/N:118253 PRINTED: 1/8/09

Perform self test. If self test is good, verify communication data lines for

continuity. Insure 1-wire data line is not routed near noisy power or RF sources.

Page 23

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

Condition Visual Evaluate

No passwords are

accepted.

The bottom four LED

rows are on and

occasionally they go out

and the top four LED

rows flash and then

return to the bottom four

LED rows on (or vice-

versa). (REMOTE).

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

Intelli-Tank Level 40

PAGE

DATE 9/24/2008

BY AMS

22 of 25

If the display flashes “X” four times after entering a password, insure the display is

installed right side up. During power-up the display should turn on all LEDs and

then cycle them OFF starting with the top row, then the display should scroll the

custom greeting from right to left.

Check that the left and right magnetic switches are recognized by activating each

switch and verifying that the associated LEDs illuminate.

Check for large noise spikes on the 1-wire data line.

Insure that the display’s ground potential is the same as the MASTER’s.

Insure that the data line is not chaffed and making contact with other electrical

wires.

Check the pressure sensor for problems.

The points calibrated

seemed to have

changed.

Unit will not dim display.

The middle two LED

rows are flashing

together.

LEDs cycle ON toward

the center continuously.

No picture

No picture

Recalibrate the display and take a voltage reading from the sensor (pin 6 on the

display’s connector) at each calibration point. When the calibration points again

look wrong check the voltages at those points and determine if they are the same

as the voltage reading taken during calibration – if they are not then replace the

sensor.

Insure the Dim input voltage on Pin 4 is at least 9V. Recalibrate dim setting

(RLLR LLLR). If display does not dim LEDs while in the dim configure mode,

replace display.

A calibration was started on the display but not completed correctly. Set the

display to a REMOTE display (LRLR LRLR) or calibrate it as a MASTER (follow

calibration steps exactly).

The display has had a unit type memory error.

Attempt to set the display back to REMOTE or MASTER as required.

Replace the display if this error cannot be corrected.

7.2. Using the display to verify pressure sensor signal voltage

The display can show the voltage level that it detects on the pressure sensor signal line by entering the password

LLRR LLRR.

The display will then scroll the text “VOLTS” and then continue to scroll the voltage detected at pin 6.

The display will continue showing the voltage until either of the magnetic switches is activated.

MANUAL P/N:118253 PRINTED: 1/8/09

Page 24

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

Intelli-Tank Level 40

PAGE

DATE 9/24/2008

BY AMS

8. Glossary

1-wire Proprietary communication method that uses only one wire for data transfer.

C1 Class 1

CAN C

EEPROM Electrically Erasable Programmable Read-Only Memory. The memory of the tank level display,

ESD E

Foam A Class “A” type foam used when fighting fires where the cooling effect of water is of prime

Foam B Class “B” type foam used when fighting fires involving flammable liquids where blanketing or

IP I

ITL I

ITL40 Intelli-Tank Level 40. The tank level display.

LED L

MASTER Master display. The tank level display wired to the sensor. This display transmits data to other

NPT Normal Pipe Taper. Pipe thread specification.

OEM Original Equipment Manufacturer.

PCM P

P/N part number

PSI P

REMOTE Remote display. A tank level display that receives data from the master unit. The remote display

SAE S

Sensor The pressure sensor.

System voltage The normal power level used by the system or vehicle. This voltage level will normally come from

TBD T

ontroller Area Network. SAE J1939 communication method.

used to store the display information (tank level points, display type, dim value, etc).

lectroStatic Discharge.

importance in extinguishing (wood, paper, etc.)

smothering effect of water is of prime importance in extinguishing (gasoline, etc.)

ngress Protection (IP 67, etc).

ntelli-Tank Level. Class 1’s 4 and 5 light tank level display.

ight Emitting Diode. The lights on the display used to show tank level and information.

remote displays.

ump Control Module. Class 1 module p/n 111097.

ounds per Square Inch. Pressure measurement.

will only display what the master display commands.

ociety of Automotive Engineers.

the vehicle’s battery and charging system (vehicle ignition, vehicle power, etc.)

o Be Developed.

23 of 25

MANUAL P/N:118253 PRINTED: 1/8/09

Page 25

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

Intelli-Tank Level 40

9. Technical details

9.1. Technical details

Product category ITL40 (Intelli-Tank Level 40)

Voltage range +9VDC…+32VDC

Power consumption

@13.8VDC (25ºC)

@27.6VDC (25ºC)

Operational temperature range -40ºC…+85ºC

Environmental range IP 67

CAN specification SAE J1939 proprietary, 250 Kbits/second

1-Wire specification Class 1 proprietary, 425 bits/second

Protection

Dimensions (W x H x D) in inches [mm] 3.185 [80.90] x 5.125 [130.17] x 2.150 [54.61]

Weight in ounces [grams] 7.9 [223.96]

9.2. WEEE (Waste of Electrical and Electronic Equipment) directive

This symbol [crossed-out wheeled bin WEEE Annex IV] indicates separate collection of waste electrical and

electronic equipment in the European Union countries.

Please do not throw the equipment into the domestic refuse.

Each individual European Union member state has implemented the WEEE regulations into national law in

slightly different ways. Please follow your national law when you want to dispose of any electrical or electronic

products.

More details can be obtained from your national WEEE recycling agency.

9.3. CE statement

This device complies with the European Regulations for Electromagnetic Compatibility (EMC) of the European

Union and it is equipped with the CE mark. This unit must be used in accordance with the details specified within

this manual.

100 mA

52 mA

Internal thermal fuse

Reverse voltage protection (pins 1 and 12 of connector)

CAN buses protected to 24V

ESD voltage protected to SAE J1113 specification for heavy duty trucks

Transient voltage protected to SAE J1113 specification for heavy duty trucks

PAGE

DATE 9/24/2008

BY AMS

24 of 25

MANUAL P/N:118253 PRINTED: 1/8/09

Page 26

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

SUITABLE FOR EXTERNAL DISTRIBUTION

OPERATION MANUAL

PRODUCT GROUP ITL40 P/N 118404-XX REV 1.00

PRODUCT

Intelli-Tank Level 40

PAGE

DATE 9/24/2008

BY AMS

25 of 25

10. 板料信息声明 (RoHS 声明) – Declaration Information Sheet (RoHS Declaration)

10.1. 产品中有毒和有害的物质或成份的名称和含量 – (NAMES AND CONTENTS OF THE TOXIC AND

HAZARDOUS SUBSTANCES OR ELEMENTS IN THE PRODUCTS)

Class1 is committed to comply with the Management Methods on Control of Pollution from Electronic Information

Products of China (China RoHS). The RoHS Directive restricts substances including lead (Pb), mercury (Hg),

Cadmium (Cd), hexavalent chromium (CrVI) and certain halogenated flame retardants such as polybrominated

biphenyls (PBB) and polybrominated diphenyl ethers (PBDE) in electrical and electronic equipment.

零件名称

Parts

基准

Base

盒子

Box

镀层

Coating

面板

Faceplate

标签

Label

透镜

Lens

印制电路

PCB

元器件

Components

连接器

Connector

密封垫

Gasket

螺钉

Screw

○ :表示该有毒有害物质在该部件所有均质材料中的含量均在SJ/T 11363-2006标准规定的限量要求以下。

○ :Indicates that this hazardous substance contained in all homogeneous materials of this part is below the limit requirement in

SJ/T 11363-2006.

×:表示该有毒有害物质至少在该部件的某一均质材料中的含量超出SJ/T 11363-2006标准规定的限量要求。

×:Indicates that this hazardous substance contained in at least one of the homogeneous materials of this part is above the limit

requirement in SJ/T 11363-2006.

除非另外特别的标注,此标志为针对所涉及产品的环保使用期限标志.此环保使用期限只适用于产品在产品手

册中所规定的条件下工作.

The Environment-Friendly Use Period (EFUP) for all enclosed products and their parts are per the symbol

shown here, unless otherwise marked. The Environment-Friendly Use Period is valid only when the

product is operated under the conditions defined in the product manual.

TOXIC AND HAZARDOUS SUBSTANCES OR ELEMENTS

铅

(Pb)

O O O O O O

O O O O O O

O O O O O O

O O O O O O

O O O O O O

O O O O O O

X O O O O O

X O O O O O

O O O O O O

O O O O O O

O O O O O O

汞

(Hg)

MANUAL P/N:118253 PRINTED: 1/8/09

有毒和有害的物质或成份

六价铬

(CrVI)

多溴联苯

(PBBs)

多溴二苯醚

(PBDEs)

镉

(Cd)

Loading...

Loading...