Page 1

Intelli-Tank

Water/foam tank level display

utilizing a 0-5 PSI transducer

Contents ………………………………………………….. 1 Overview ………………………………………………….. 2 Operation ………………………………………………….. 3 Installation ………………………………………………….. 5 Wiring ………………………………………………….. 7 Calibration ………………………………………………….. 9 Dim function ………………………………………………….. 11 Self test ………………………………………………….. 11 Passwords ………………………………………………….. 12 Troubleshooting ………………………………………………….. 13

Intelli-Tank Manual (106759) 021502 – 1 – Class 1

Page 2

The Intelli-Tank 4 light tank level is designed to display a liquid’s volume to an

eighth of a tank level accuracy through 180-degree viewable ultra-bright LEDs.

The unit set as a Master uses a 0 – 5 PSI pressure transducer to obtain tank

level information and then relays that information along the data line to units set

as Remotes. Multiple Remote units can be linked to the Master tank level unit.

Tank Level Gauge C1 – PN 106299 – 12V

106296 – 24V

Pressure Transducer C1 – PN 102162

Installation Harness C1 – PN 106690 – Master

106691 – Remote

User Manual C1 – PN 106759

Modes of Operation:

Master When the unit is calibrated with a proper pressure signal it

automatically becomes a Master Unit and will send tank level

information along the 1-wire data transfer line to all other Remote

units on the line.

Remote Units are initially shipped as Remote units. A Remote unit only

requires power, ground and the 1-wire data transfer line. The

Remote unit mimics the Master unit’s display by reading the

appropriate information on the 1-wire data transfer line.

Self Test When the self test password is entered the unit will perform a self

test and display the results on the display. A Master unit will

command all Remote units to perform the self test also.

Note: All units are shipped as Remote units. A valid calibration will set the unit

as a Master. A Master can be reset as a Remote by entering a password.

Intelli-Tank Manual (106759) 021502 – 2 – Class 1

Page 3

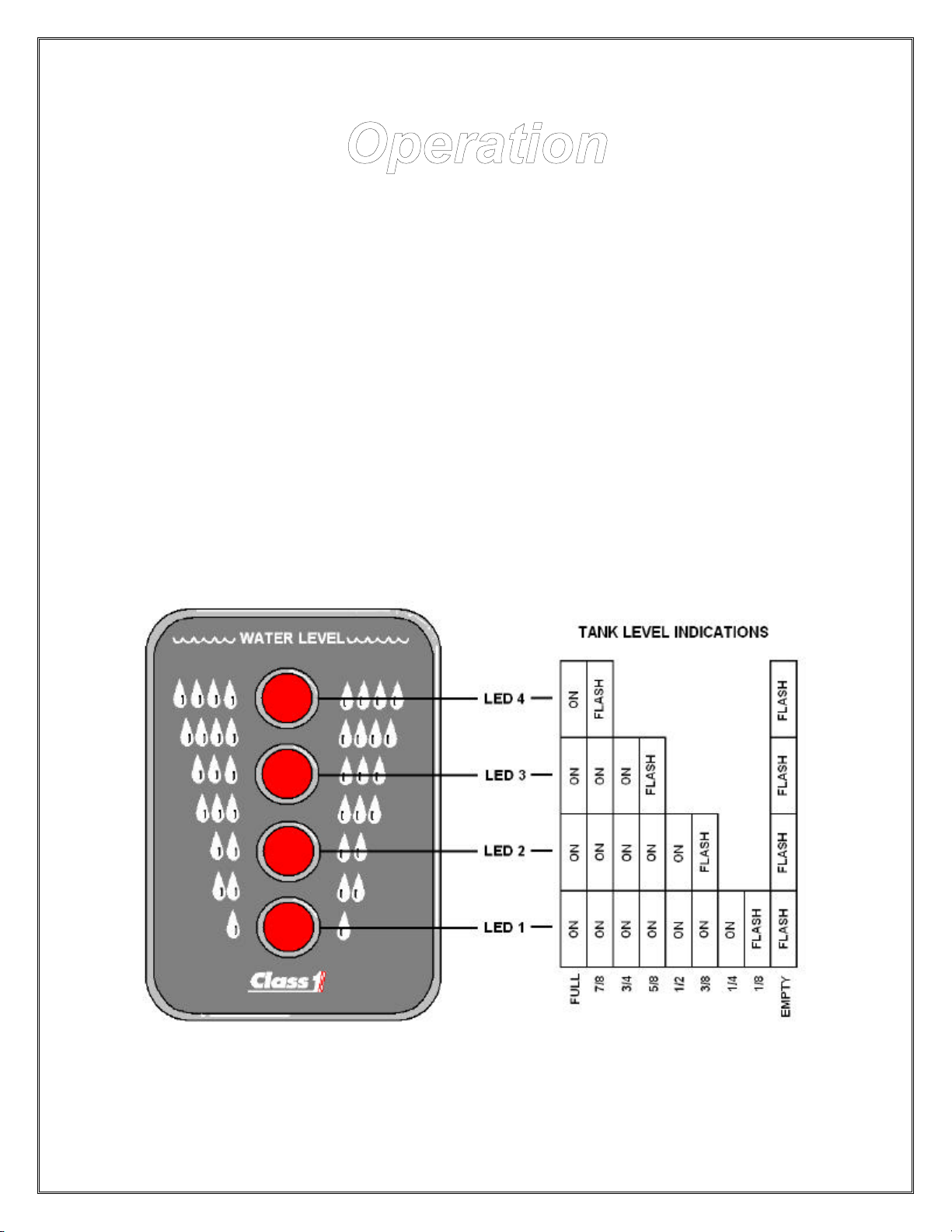

When the unit is first powered up the LEDs will cycle on individually starting with

the EMPTY (bottom) LED and then the LEDs will show current status.

• A Master unit properly connected to a functioning transducer will display

current tank level information.

• A Master unit not connected to a pressure transducer will alternately flash the

bottom two LEDs.

• A Remote unit connected to a Master unit (through the 1-wire data line) will

mimic the Master unit’s LED condition and flash rate.

• A Remote unit not connected to a Master unit will alternately flash the upper

two LEDs and the lower two LEDs. This indicates a “no data” condition.

Level indications:

Intelli-Tank Manual (106759) 021502 – 3 – Class 1

Page 4

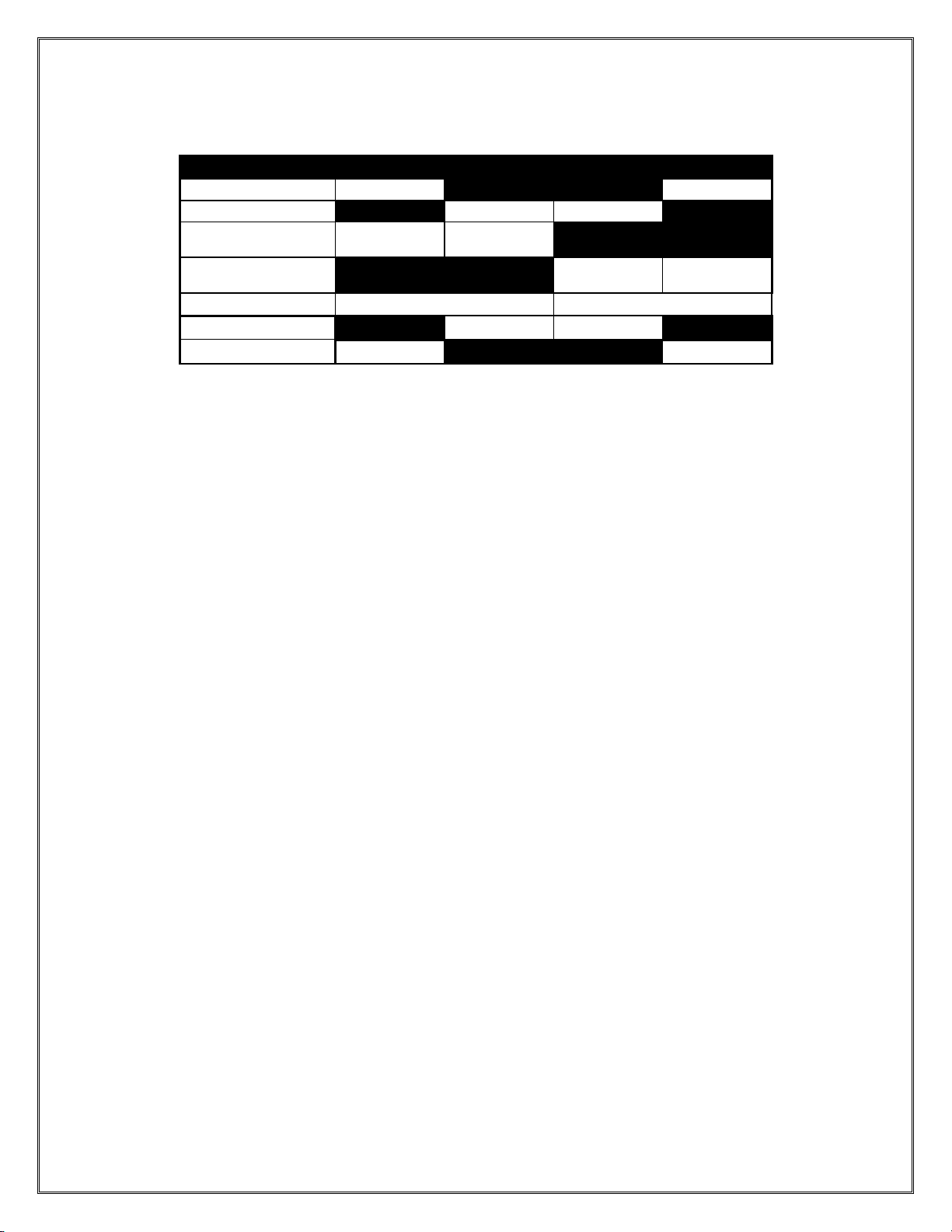

Miscellaneous indications:

Condition LED 4 LED 3 LED 2 LED 1

Invalid calibration AlternaFLASH AlternaFLASH

EEPROM error AlternaFLASH AlternaFLASH

Signal voltage above

4.8V

Signal voltage below

.4V

Remote “NO DATA” AlternaFLASH AlternaFLASH

User Error (wave off) ON ON

4 quick cycles ON ON

The tank level has two flash rates: FAST (1.6Hz) and SLOW (.8Hz). AlternaFLASH flashes two lights

alternately at the SLOW flash rate.

“Wave off” pattern : two center LEDs, two outer LEDs flashing quickly for 4 cycles.

AlternaFLASH AlternaFLASH

AlternaFLASH AlternaFLASH

Intelli-Tank Manual (106759) 021502 – 4 – Class 1

Page 5

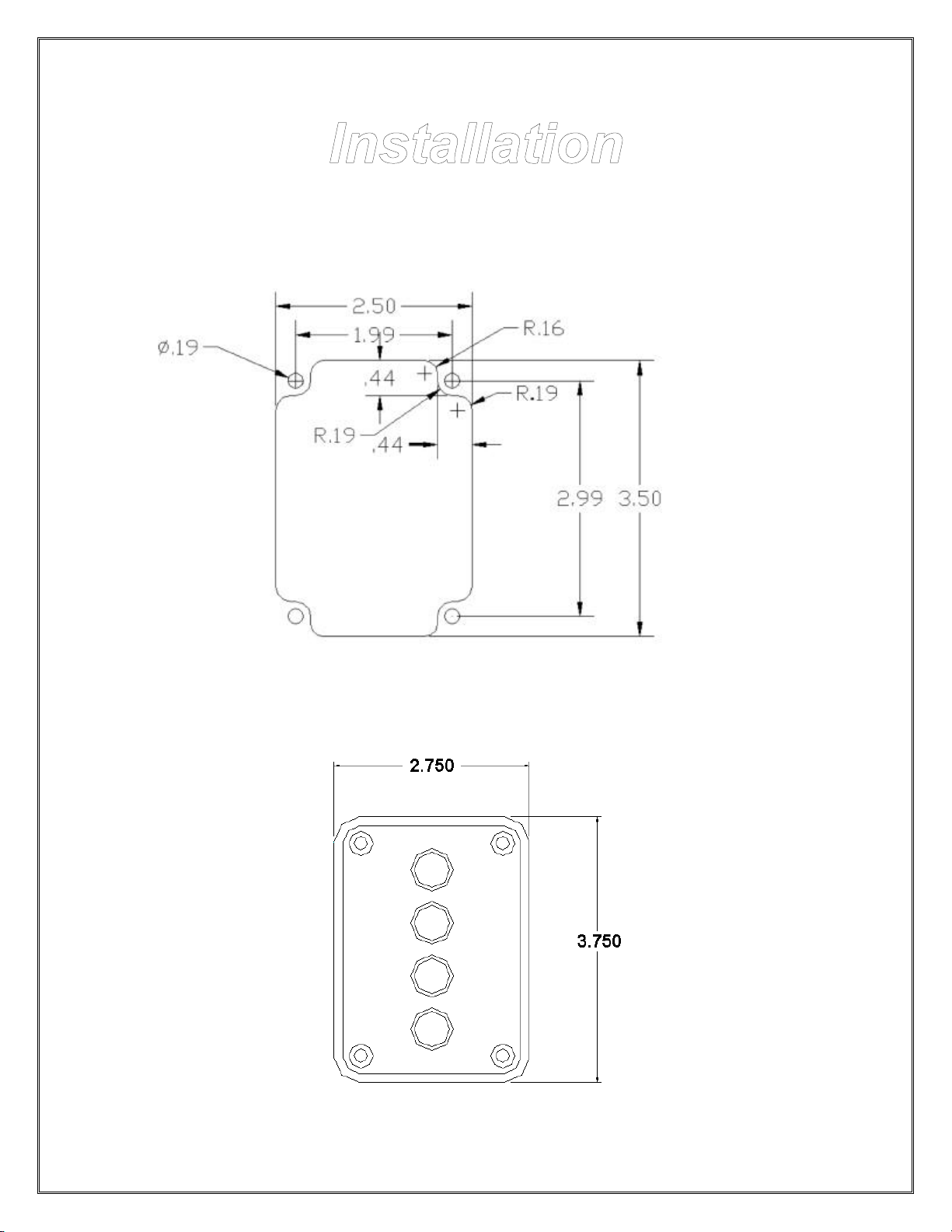

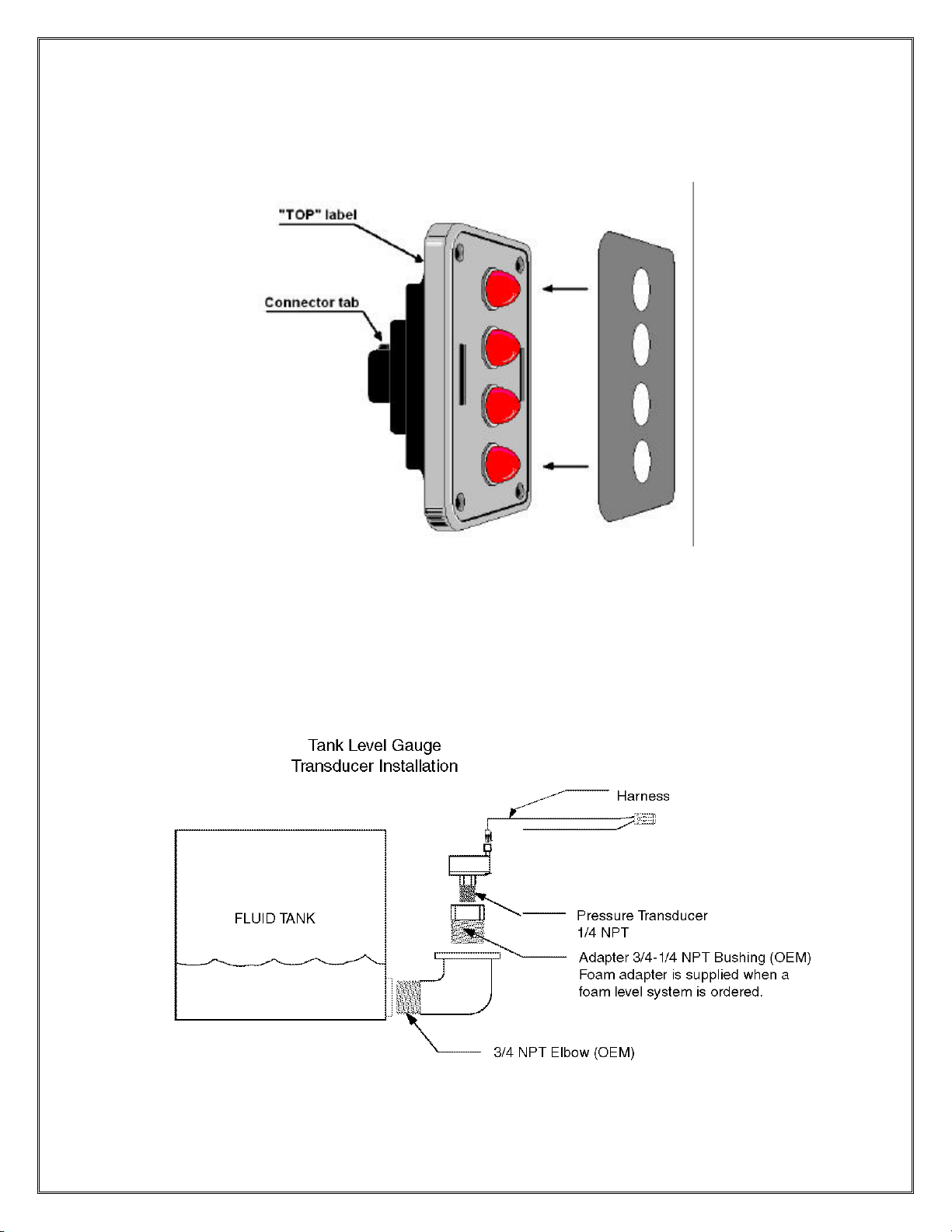

Intelli-Tank display The display requires a cutout as shown. The unit is water tight and may

be mounted in any location on the operator’s panel.

Outer bezel dimensions.

Intelli-Tank Manual (106759) 021502 – 5 – Class 1

Page 6

Before mounting the display and adhering the label insure that the unit is situated correctly (TOP

is UP). Refer to the drawing for orientation.

Pressure Transducer

The transducer has a ¼” NPT mount and must be mounted vertically as depicted to insure an

accurate reading.

Intelli-Tank Manual (106759) 021502 – 6 – Class 1

Page 7

Power and Ground

It is imperative that a system utilizing Master and Remote tank level units connected by the 1-wire

data line have a common ground.

Pin 1 Vehicle power

Pin 2 Ground

Dim Function

The LEDs on the tank level unit can be dimmed to a user selectable dim setting by applying

vehicle voltage to the Dim display Input.

Pin 3 Dim display input (VIGN)

Transducer Connection

Pin 6 Sensor power (+5)

Pin 7 Sensor signal

Pin 8 Sensor ground

1-Wire Data Line

Pin 4 Master to Remote data transfer line

Intelli-Tank Manual (106759) 021502 – 7 – Class 1

Page 8

Typical installation layout.

Intelli-Tank Manual (106759) 021502 – 8 – Class 1

Page 9

The Intelli-Tank display can be calibrated three different ways: 2-point (level

calibration), 5-point and 9-point (volume calibration).

To enter calibration mode use a magnet and activate the magnetic switches in

the order of the appropriate password.

When a magnetic switch is activated the display will indicate which switch was activated

(Left = upper two LEDs, Right = lower two LEDs) for approximately half a second and

then the display will go blank. There is a limit of 2 seconds between switch activation’s

before the the unit reverts to normal operation.

Entering an invalid password will initiate a “wave off” pattern on the display. (Two center

LEDs, two outer LEDs flashing quickly for 4 cycles.)

Calibrate the unit by entering the desired point calibration –

2 point RLLR LLRL

5 point RLLR LRLR

9 point RLLR RLLR

Intelli-Tank Manual (106759) 021502 – 9 – Class 1

Page 10

The unit will respond by flashing the two center LEDs the same number of times

as the desired calibration. The unit will then indicate the level to be calibrated by

lighting the proper LEDs for that level starting with empty (see page 3, tank level

indications). When the tank is filled to the proper level for calibration (dictated by

the LEDs) activate the RIGHT switch to store that point. The unit will flash the

top LED and then set the LEDs for the next calibration point. Continue filling the

tank to the proper level dictated by the LEDs and storing that point with the

RIGHT switch until finished (after the FULL point has been calibrated). The unit

will respond to a completed calibration procedure by lighting the two center LEDs

and then reverting to normal operation by displaying the proper tank level, which

at this point should indicate FULL (all LEDs on) because the tank level is full.

To get out of calibration mode at any time without saving, activate the LEFT

switch.

Calibration data is saved in non-volatile EEPROM so the unit does not need

power to retain calibration data.

Calibration automatically makes the unit a master if the calibration is valid. An

invalid calibration is determined if any point is not at a higher level than the

previous, or if the transducer voltage falls outside of the valid minimum (.4V) or

maximum (4.8V) range. An invalid calibration is acknowledged by giving the

“wave off” and if this was a master unit previously will alterna-flash the outer two

LEDs, while a Remote will revert to Remote operation.

Calibration in a nutshell.

1. Enter the password for the desired calibration (wait for center LEDs to

flash back the calibration number).

2. Ensure tank level is at proper level for calibration point as indicated by the

LEDs.

3. Activate the RIGHT switch to store point (Top LED flashes).

4. Continue steps 2 and 3 until finished (Full has been calibrated).

Intelli-Tank Manual (106759) 021502 – 10 – Class 1

Page 11

Dimming the Display

The display can be dimmed by applying VIGN to pin 3 (Dim Display input). To

select the dim level of the display use the magnetic switches to enter the

password

RLLR LLLR

all of the LEDs will come on. Hold the magnet against the RIGHT switch and the

display will either brighten or dim. Release the magnet and again hold it against

the RIGHT switch and the display’s brightness will move in the opposite

direction. When the dim level is at the desired point activate the LEFT switch.

Each unit has its own calibrated dim level and dim input.

Self Testing the Unit

The Tank Level can check its hardware for proper operation by entering the

password

RLLR LLRR

the unit will then cycle each LED on individually starting with the bottom LED and

then all LEDs will come on and begin flashing between full bright and the

calibrated dim level for 5 seconds. The display will then show the condition of

the self test for 5 seconds.

A PASS condition is indicated when only the top LED (LED 4) is on.

A FAIL condition exists if LED 4 is off and any other LED is on.

LED 3 ON Memory failure.

LED 2 ON Data line error.

LED 1 ON Transducer signal line out of tolerance or shorted to

+5V.

LED 1 Flashing Transducer signal shorted to ground (too low).

If the self test password is used on a Master unit all Remote units will also

perform their self test.

Intelli-Tank Manual (106759) 021502 – 11 – Class 1

Page 12

RLLR LLRL 2 point calibration

RLLR LRLR 5 point calibration

RLLR RLLR 9 point calibration

RLLR LLRR Self test

RLLR LLLL Configure unit as Remote unit

RLLR LLLR Configure dim level

Software revision check

Hold a magnet on the LEFT magnetic switch while powering the unit. The LEDs

will display the software revision. (Use the chart below to decipher).

Example. (LED 4 – OFF, LED 3 – ON, LED 2 – OFF, LED 1 – ON) = Ver 1.1

Intelli-Tank Manual (106759) 021502 – 12 – Class 1

Page 13

Condition Evaluate

Bottom two LEDs

alternate flashing.

Check transducer wiring. Ensure +5V at pin A, ground at pin B and

at least .4V at pin C (Signal).

Unit fails self test,

LED 1 flashing.

Top two LEDs

alternate flashing.

Check transducer wiring. Ensure +5V at pin A, ground at pin B and

no more than 4.8V at pin C (Signal).

Unit fails self test,

LED 1 on.

Middle two LEDs

Perform self test. If it fails with LED 3 on replace unit.

alternate flashing.

Outer two LEDs

alternate flashing.

Try to recalibrate. If condition remains, check if transducer signal

voltage (pin C) changes as tank level increases. If it doesn’t, replace

transducer. If it does, verify depth of tank. It may be impossible to

calibrate a tank with a depth of less than 6 inches.

Bottom two and

Upper two LEDs

alternate flashing.

The unit is configured as a Remote. If it required to be a Master

then recalibrate. If the unit is required to be a Remote check Data

line (Pin 4) continuity and insure line is not grounded.

No LEDS on. Check power (Pin 1) and ground (Pin 2) connection.

Master Tank level

display does not

change when actual

tank level is

changing.

Remote Tank level

display does not

follow Master

display.

Unit fails self test,

LED 2 on.

No passwords are

accepted.

Check transducer wiring. Ensure transducer signal voltage (Pin C)

is varying. If it does, check for same signal changes at Pin 6 of tank

level connector (if it is not the same repair wiring). If signal is good

at both locations try re-calibrating.

Perform self test. If self test is good, check pin 4 (data line) for

continuity and insure it is not shorted to ground or power. Insure

data line is not routed near noisy power or RF sources.

Check pin 4 (data line) for continuity and insure it is not shorted to

ground or power.

If the display issues the “wave off” after entering a password, insure

the unit is installed upright. During power-up the display should

cycle on each LED individually starting with the bottom LED.

Check that the left and right magnetic switches are recognized by

activating each switch and verifying that the associated LEDs

illuminate.

Intelli-Tank Manual (106759) 021502 – 13 – Class 1

Page 14

Condition Evaluate

The bottom two

LEDs are on and

occasionally they go

out and the top two

flash and then return

to the bottom two

LEDs on (or viceversa). (REMOTE).

The points

calibrated seemed

to have changed.

Unit will not dim

display.

Check for large noise spikes on the data line.

Insure that the unit’s ground potential is the same as the Master’s.

Insure that the data line is not chaffed and making contact with

other electrical wires.

Self test the unit to check for any malfunctions.

Check the pressure transducer for problems.

Recalibrate the unit and take a voltage reading from the transducer

(pin 7 on the unit’s connector) at each calibration point. When the

calibration points again look wrong check the voltages at those

points and determine if they are the same as the voltage reading

taken during calibration.

Insure the Dim input voltage on Pin 3 is at least 9V. Recalibrate dim

setting (RLLR LLLR). If unit does not dim LEDs while in dim

calibrate mode, replace unit.

Intelli-Tank Manual (106759) 021502 – 14 – Class 1

Page 15

Intelli-Tank Manual (106759) 021502 – 15 – Class 1

Loading...

Loading...