Page 1

Engineering

Standards

Name Tank Level Display

Identifier Installation Information

Installation

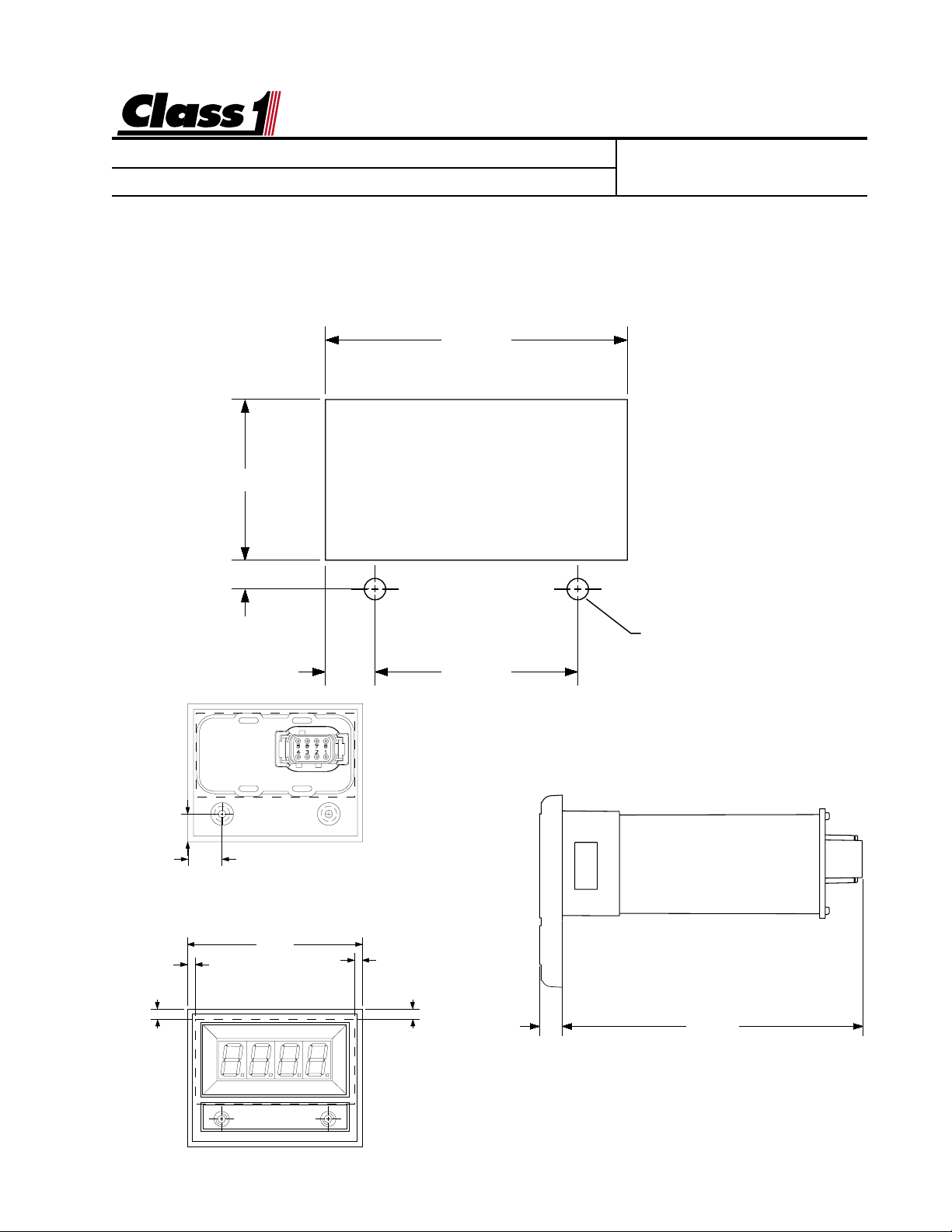

The display mounts in a 2.84” by 1.51” cutout.

Overall area necessary for installation is 3.2” by 2.5”.

Two 0.201d holes are provided for mounting scre ws.

1.510

.277

Engineering Standard Number

C1-102245-A

2.840"

0.496"

0.142"

Ø 0.201"

(2) HOLES

.470 1.900

0.612"

3.125"

0.142"

0.182"0.182"

0.285" 3.832"

page 1 of 5 pages

Page 2

Engineering

Standards

Name Tank Level Display

Identifier Installation Information

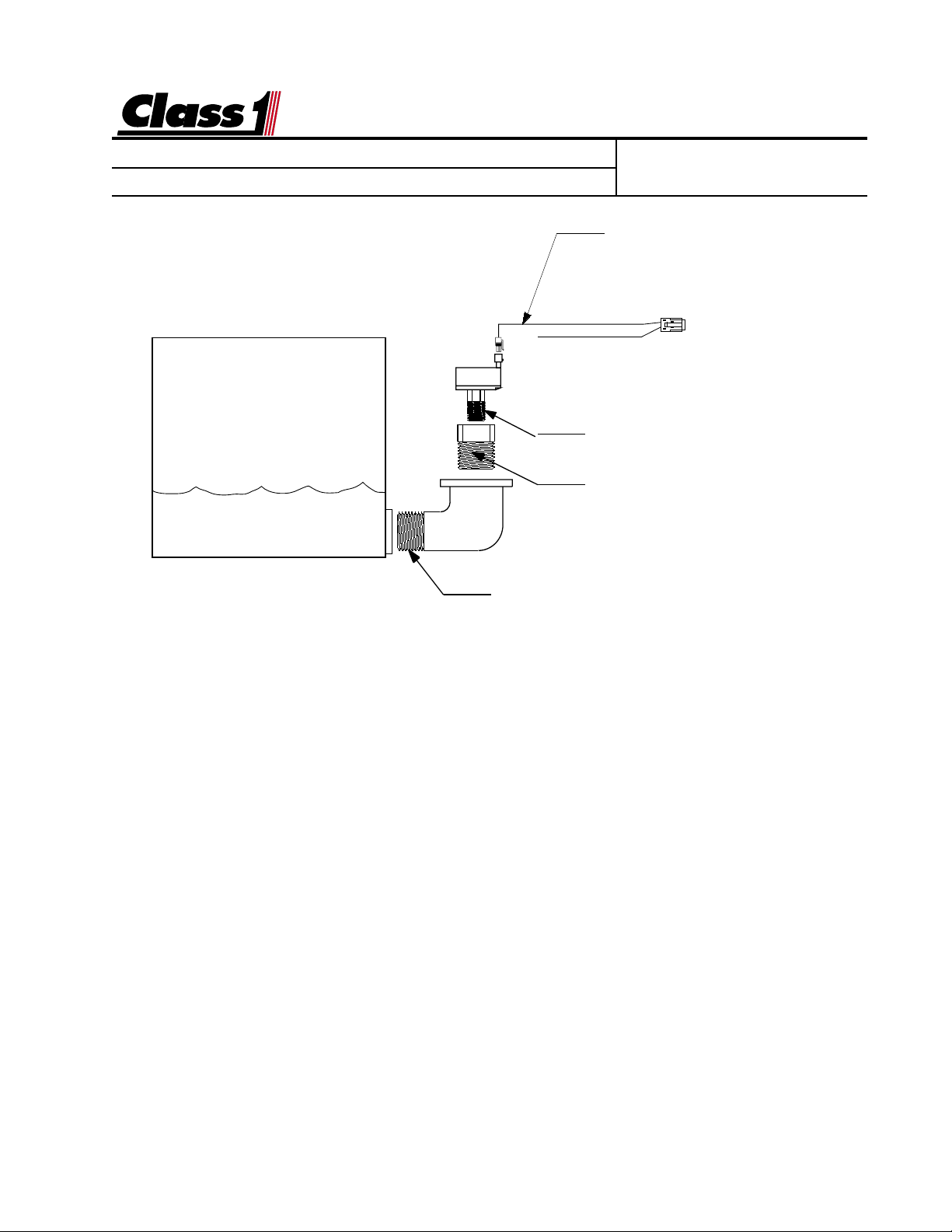

Tank Level Gauge

Transducer Installation

FLUID TANK

Engineering Standard Number

C1-102245-A

Harness

102193 5'

102194 10'

102195 20'

Pressure Transducer

1/4 NPT

Adapter 3/4-1/4 NPT Bushing (OEM)

Foam adapter is supplied when a

foam level system is ordered.

3/4 NPT Elbow (OEM)

The transducer must be mounted vertically as depicted to insure an accurate and reliable reading.

This will also prevent damage to the transducer from freezing.

The transducer measures the column of water in the tank above the opening of the elbow.

When calibrating for a full tank it is important that the tank not be overfilled. If the fill opening or

tank vent is above the transducer, care should be taken not to have water in this area when

calibrating the tank level gauge. The transducer should never be mounted in the sump area

because of sludge and potential inaccuracies in calibration.

Mount a 3/4 NPT elbow just off the bottom of the tank, enough to keep sediment out of the

elbow and transducer (PN 102162). Attach a 3/4 to 1/4 NPT adapter (supplied for foam) to the

elbow and mount the transducer to that. The elbow and adapter need to be installed so that

the transducer is mounted vertically.

Pressurized Tanks

If you have a pressurized tank, two pressure transducers (PN 102471) can be used to compensate for pressure or vacuum in the tank. One transducer should be mounted near the

bottom of the tank and one near the top.

Use “Y” harness (PN 102439) and two (2) (PN 102455) transducer harnesses for wiring this

application.

When calibrating the dual transducer installation, the tank should be vented to the atmosphere.

page 2 of 5 pages

Page 3

Engineering

Standards

Name Tank Level Display

Identifier Installation Information

Electrical

The Aerial Warning Display is connected to the OEM harness with a Deutsch 8 pin

mini-connector.

Mating Connector: DTM06-08S

Locking Wedge WM-8S

Mating Terminal: 0462-201-20141 20 gauge socket

Engineering Standard Number

C1-102245-A

Location of magnetic switches

0 25 50 75 100

BAR GRAPH DISPLAY

Mating connector viewed from the wire end

page 3 of 5 pages

Page 4

Engineering

Standards

Name Tank Level Display

Identifier Installation Information

Calibration

Basic Calibration:

With the fluid tank empty, enter the

calibration password.

L L L R R R

The left (0%) bar will flash to indicate

that you are ready to calibrate for an

empty tank.

Activate the right switch followed by

the left switch.

The right (100%) bar will flash to indicate that the display is ready to calculate for a full tank.

When the tank is full, actuate the right

and then the left switch.

Calibration is complete.

If after checking the accuracy of your

calibration, you are not satisfied, then

you can perform the advanced calibration procedure. This is rarely necessary except in the case of oddly

shaped tanks.

NOTE: Calibration is based on

the weight of the column of water

immediately above the transducer.

If the unit is calibrated with a water

level that is temporarily higher

than normal, this will result in an

inaccurate display.

Engineering Standard Number

C1-102245-A

Advanced Calibration:

With the fluid tank empty,

enter the calibration password.

L L R R L L

The left (0%) bar will flash to indicate

that you are ready to calibrate empty.

Activate the left switch followed by

the right switch.

The fifth bar from the left (25%) will

flash to indicate that the display is

ready to calculate for a quarter tank.

Fill the tank to 1/4 full, actuate the

right and then the left switch.

The tenth bar from the left (50%) will

flash to indicate that the display is

ready to calculate for a half tank.

Fill the tank to 1/2 full, actuate the

left and then the right switch.

The fifteenth bar from the left (75%)

will flash to indicate that the display

is ready to calculate for three four ths

tank.

Fill the tank to the 3/4 full, actuate

the right and then the left switch.

The right (100%) bar will flash to indicate that the display is ready to calculate for a full tank.

When the tank is full, actuate the right

and then the left switch.

Calibration is complete.

page 4 of 5 pages

Page 5

Engineering

Standards

Name Tank Level Display

Identifier Installation Information

Engineering Standard Number

C1-102245-A

The tank level gauge has a bar traveling back and f orth across the display .

There is a problem with the pressure transducer (PN 102162) or wiring. At the

transducer connector , check for 5 VDC between pins A (+5 VDC) and pin B

(ground). These are sent from the displa y and must be of the correct polarity for

the transducer to function. Plug the connector into the transducer and check f or

voltage between Pin B (sensor ground) and pin C (sensor signal) at the transducer. With an empty tank, this voltage should be between 500 mV and 900 mV, if

it is not, replace the transducer. Check for v oltage at the display betw een pin 6

(sensor ground) and pin 2 (signal). With an empty tank, this voltage should be

between 500 mV and 900 mV. If it is not, check the wiring from the transducer to

the display. If the correct v oltage is present at pin 2, replace the displa y.

The T ank Level Gauge does not change or calibrate.

There is a problem with the pressure transducer or wiring. At the transducer

connector, chec k for 5 VDC between pins A (+5 VDC) and pin B (ground). These

are sent from the display and must be of the correct polarity for the tr ansducer to

function. Plug the connector into the transducer and check f or voltage at the

display between pin 6 (sensor g round) and pin 2 (signal). With an empty tank, this

voltage should be between 500 mV and 900 mV. As the water le vel in the tank

increases, the voltage should increase. If it does not, then replace the transducer

If the voltage increases, and the displa y does not change, attempt to calibrate the

unit. If calibration does not correct the problem, replace the displa y.

8

7

6

5

Wire Insertion View

1

2

3

4

page 5 of 5 pages

Loading...

Loading...