Page 1

Engineering

Standards

Mounting

Name

Identifier Instructions

Digital Pressure Gauge

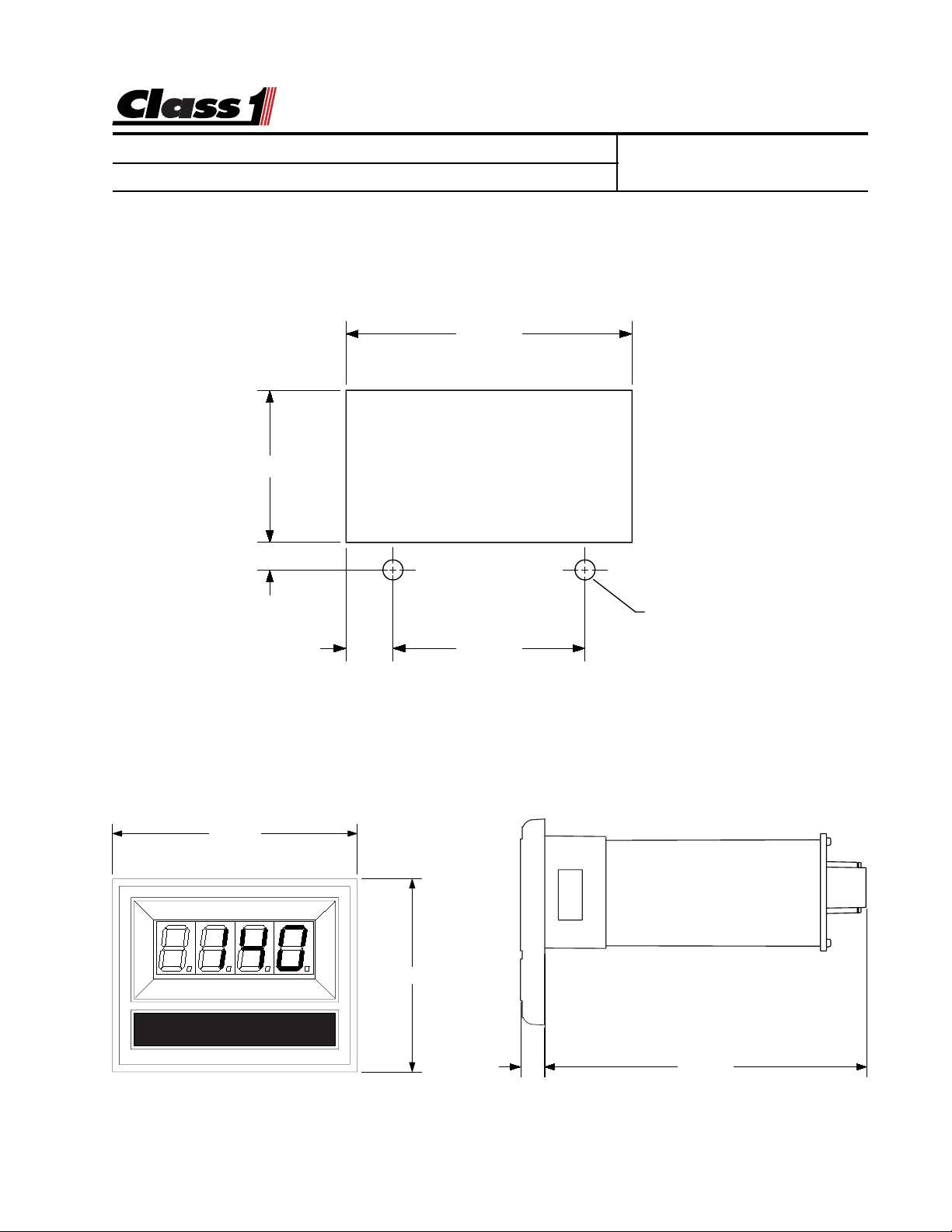

The Class1 digital display mounts in a 2.85” by 1.55” cutout.

Overall area necessary for installation is 2.5” by 3.2”.

T wo 0.20 diameter holes are provided for mounting screws.

1.510

.277

Engineering Standard Number

C1-102190-A

2.840"

3.125"

DIGITAL DISPLAY

Ø 0.201"

(2) HOLES

.470 1.900

2.462"

0.285" 3.832"

page 1 of 6 pages

Page 2

Engineering

Standards

Harness

Name

Identifier Instructions

Digital Pressure Gauge

Engineering Standard Number

C1-102190-A

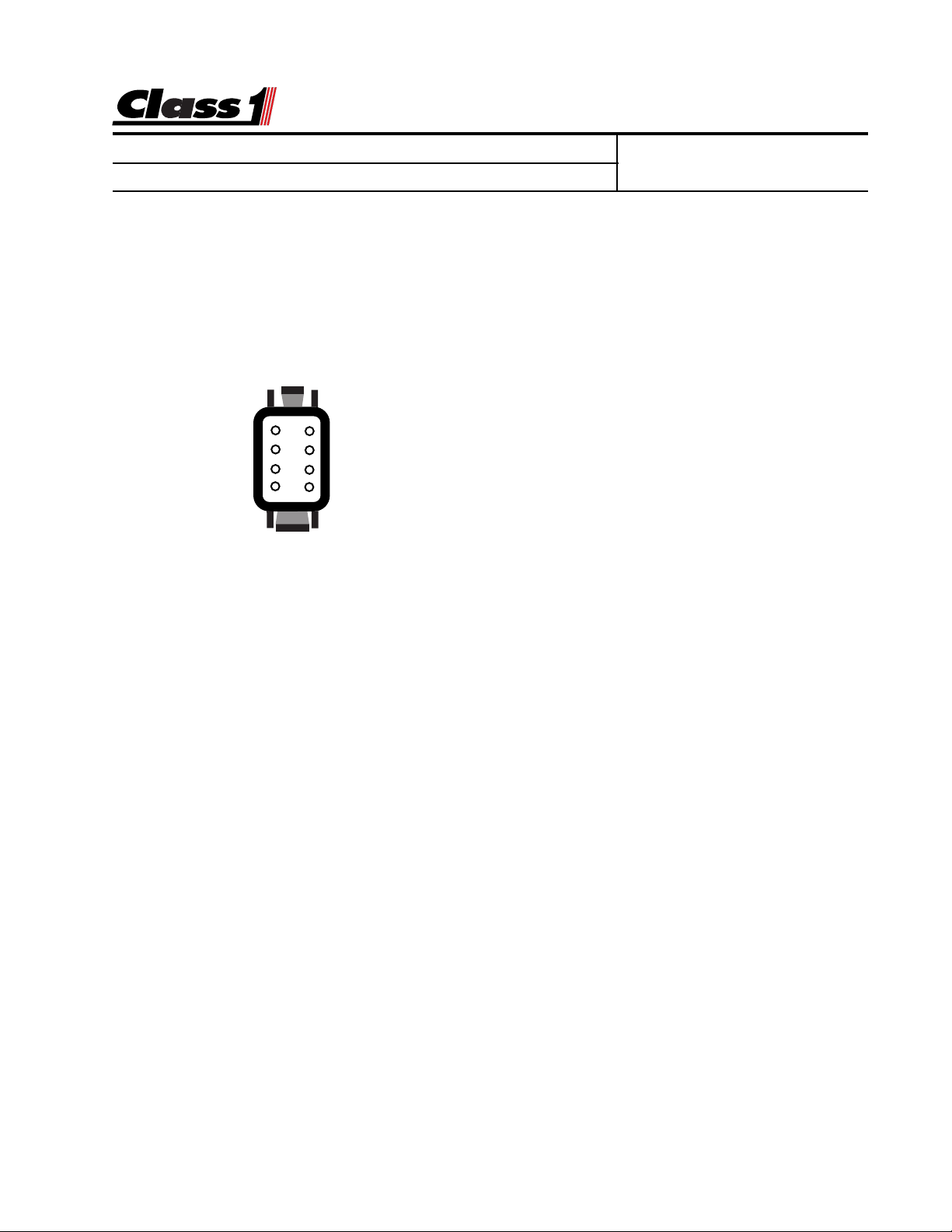

The digital displays are connected to the OEM harness with a Deutsch 8 pin miniconnector .

Mating Connector: DTM06-08S

Locking Wedge WM-8S

Mating T erminal: 0462-201-20141 20 gauge socket

General T erminal Assignments:

1) Alarm Output (Ground)

8

7

6

5

1

2

3

4

2) Primary Pressure Signal

3) Sensor Supply (+ 5 or +10 VDC)

4) Power (+ 12 VDC)

5) Ground

6) Sensor Ground

Wire Insertion View

7) Signal (frequency or secondary PSI in)

8) Test or Total or Alarm

Not all of the digital displays use all of the terminals.

See individual display pages for application information.

Harnesses are available for the digital displays in various lengths.

These include transmitter and power connections.

Harness Part Numbers by length and application.

5’ 10’ 20’ 30’

Flowmeter Display 102064 102033 102065 103165

Pressure Display 102060 102035 102061 102271

Breathing Air Display 102670 102671 102672

Oxygen System Display “ “ “

T ank Level Display 102193 102194 102195 102729

Dual Transducer 102439Y 102455

Speedometer 102242 102243 102244

DC Voltmeter “ “ “

Dual Display “Y” 102294 102295

Dual Current Amplifier 103318

Display Pigtail 102272 Extension 15’ 103367

page 2 of 6 pages

Page 3

Engineering

Standards

Cal. Overview

Name

Identifier Instructions

Digital Pressure Gauge

Engineering Standard Number

C1-102190-A

Location of Magnetic Switches

Digital Display Calibration should be performed to assure accuracy.

Display Calibration sequence for Gauges with 7 segment LED’s

A password will look like the following example.

L L L R R R

Enter the switch sequence with a magnet to enter the basic calibration mode.

Left Switch Left Switch Left Switch Right Switch Right Switch Right Switch

If the password is correctly entered, CAL will be displayed for 1/2 second followed by a number that is dependent on the display being calibrated (usually 0 ). If necessary , the calibration

number can be changed using the switch on the right side.

Establish accurate and stable conditions for calibration.

When the calibration conditions are stable, activate the left switch.

The display will read donE and then return to normal operation.

page 3 of 6 pages

Page 4

Engineering

Standards

Pressure Gauge

Name

Identifier Instructions

Digital Pressure Gauge

Engineering Standard Number

C1-102190-A

Installation and Operation of the Class1 Digital Pressure Gauge.

The pressure transducer (PN 102161) mounts to the pump with a 1/4” NPT fitting. Mount

the pressure transducer on the pump discharge manifold and tighten using the 1-1/4 hex.

Mount the digital display on the pump panel using the dimensions provided.

Connect the wiring harness PN 102035, 102060, or 102061 to the transducer , the display

and to the vehicle power and ground circuits.

8

7

6

5

Wire Insertion View

1

2

3

4

PUMP DISCHARGE

Operation is straightforward.

When the unit is turned on, the display indicates pump pressure at the transducer location. Normally no calibration is required, however if the gauge

does not read zero when the pump is not running, a ZERO calibration can be

performed. Password L R R L L.

This feature is available only on rP1.7 and above.

Harness PN 102060 5’

102035 10’

102061 20’

PIN COLOR FUNCTION

A BLACK SENSOR GROUND

B RED SENSOR SUPPLY

C WHITE SENSOR SIGNAL

Red +12 VDC

Black Ground

PIN COLOR FUNCTION

1 PLUG

2 WHITE SIGNAL

3 RED SENSOR SUPPLY

4 RED POWER IN

5 BLACK GROUND IN

6 BLACK SENSOR GROUND

7 PLUG

8 PLUG

page 4 of 6 pages

Page 5

Engineering

Standards

T-shoot

Name

Identifier Instructions

Digital Pressure Gauge

0462-201-20141 20 Ga.

Switch 8

Pulses IN 7

Sensor Ground 6

System Ground 5

DTM06-08SA

1 N/C

8

7

6

5

Wire Insertion View

1

2

2 PSI IN

3

3 Sensor +5/10 VDC

4

4 System Power

Engineering Standard Number

C1-102190-A

The display does not illuminate.

The display must have power at terminal 4 and ground at terminal 5.

With the connector removed, check across pins 4 and 5 for 12 VDC, if 12 volts is

present with the correct polarity , replace the display . If voltage and/or ground is

not present, check the vehicle wiring.

The pressure reading on a discharge or intake gauge does not change.

There is a problem with the pressure transducer or wiring. At the transducer

connector , check for 5 VDC between pins A (ground) and pin B (+5 VDC). These

are sent from the display and must be of the correct polarity for the transducer to

function. Plug the connector into the transducer and check for voltage at the

display between pin 6 (sensor ground) and pin 2 (signal). With zero pressure/

suction at the pump, this voltage should be between 500 mV and 900 mV . As the

pressure in the pump increases, the voltage should increase. If it does not, then

replace the transducer . If the voltage increases, and the display does not change,

perform a default calibration, call Class1 (1-800-533-3569) for instructions. If the

default calibration does not correct the problem, replace the display .

The pressure display reads SEnS .

There is a problem with the pressure transducer or wiring. At the transducer

connector , check for 5 VDC between pins A (ground) and pin B (+5 VDC). These

are sent from the display and must be of the correct polarity for the transducer to

function. Plug the connector into the transducer and check for voltage between

Pin A (sensor ground) and pin C (sensor signal) at the transducer . With zero

pressure/suction at the pump, this voltage should be between 500 mV and 900

mV , if it is not, replace the transducer . Check for voltage at the display between

pin 6 (sensor ground) and pin 2 (signal). With zero pressure/suction at the pump,

this voltage should be between 500 mV and 900 mV . If it is not, check the wiring

from the transducer to the display . If the correct voltage is present at pin 2,

replace the display .

page 5 of 6 pages

Page 6

Engineering

Standards

T-shoot

Name

Identifier Instructions

Digital Pressure Gauge

Engineering Standard Number

C1-102190-A

The tank level gauge has a bar traveling back and forth across the display .

There is a problem with the pressure transducer (PN 102162) or wiring. At

the transducer connector , check for 5 VDC between pins A (+5 VDC) and pin B

(ground). These are sent from the display and must be of the correct polarity for

the transducer to function. Plug the connector into the transducer and check for

voltage between Pin B (sensor ground) and pin C (sensor signal) at the transducer . With water in the tank, this voltage should be between 500 mV and 900

mV , if it is not, replace the transducer . Check for voltage at the display between

pin 6 (sensor ground) and pin 2 (signal). With an empty tank, this voltage should

be between 500 mV and 900 mV . If it is not, check the wiring from the transducer

to the display . If the correct voltage is present at pin 2, replace the display.

The T ank Level Gauge does not change or calibrate.

There is a problem with the pressure transducer or wiring. At the transducer

connector , check for 5 VDC between pins A (+5 VDC) and pin B (ground). These

are sent from the display and must be of the correct polarity for the transducer to

function. Plug the connector into the transducer and check for voltage at the

display between pin 6 (sensor ground) and pin 2 (signal). With an empty tank, this

voltage should be between 500 mV and 900 mV . As the water level in the tank

increases, the voltage should increase. If it does not, then replace the transducer .

If the voltage increases, and the display does not change, attempt to calibrate

the unit. If the calibration does not correct the problem, replace the display .

The Flow Meter does not read flow or calibrate.

Place the meter in to raw mode L R L R L L. Does the meter read pulses, and do

they change with a flow increase or decrease? If they do, re-calibrate. If you do

not read pulses, then it is a wiring or paddlewheel problem. At the paddlewheel,

check for 12 VDC between pins A (ground) and pin B (+12 VDC). These are sent

from the display and must be of the correct polarity for the paddlewheel to function. Plug the connector into the paddlewheel and check for pulses at the display

between pin 6 (sensor ground) and pin 7 (signal). If pulses are not present, then

check the paddlewheel orientation and the signal wire from the paddlewheel to pin

7 at the display . If everything checks out OK, then replace the paddlewheel. If the

signal is present and the display does not read raw pulses, replace the display .

A-Ground

Pressure Transducer Pinout

B-Supply

C-Signal

page 6 of 6 pages

Loading...

Loading...