Page 1

Contents

Table of Contents

Contents................................................................................1

Digital Display s ......................................................................2

Mounting................................................................................3

Harness.................................................................................4

Cal. Overview .................................................................... 5-6

Flowmeter.......................................................................... 7-9

Calibration ...........................................................................10

Example CAL.......................................................................11

V alue Flow...........................................................................1 2

Super Flow ..........................................................................1 3

V ehicle Speed.................................................................14-15

Pressure Gauge ..................................................................16

Aerial Loading.................................................................17-19

Water Le vel.....................................................................20-22

Breathing Air...................................................................23-25

Oxygen Supply ...............................................................26-28

Dual Amplifier ......................................................................29

GPM Flowchart ...................................................................30

IGPM Flowchart ..................................................................31

LPM Flowchart ....................................................................32

Notes...................................................................................33

Troubleshooting ..............................................................34-35

1

Page 2

Digital Displays

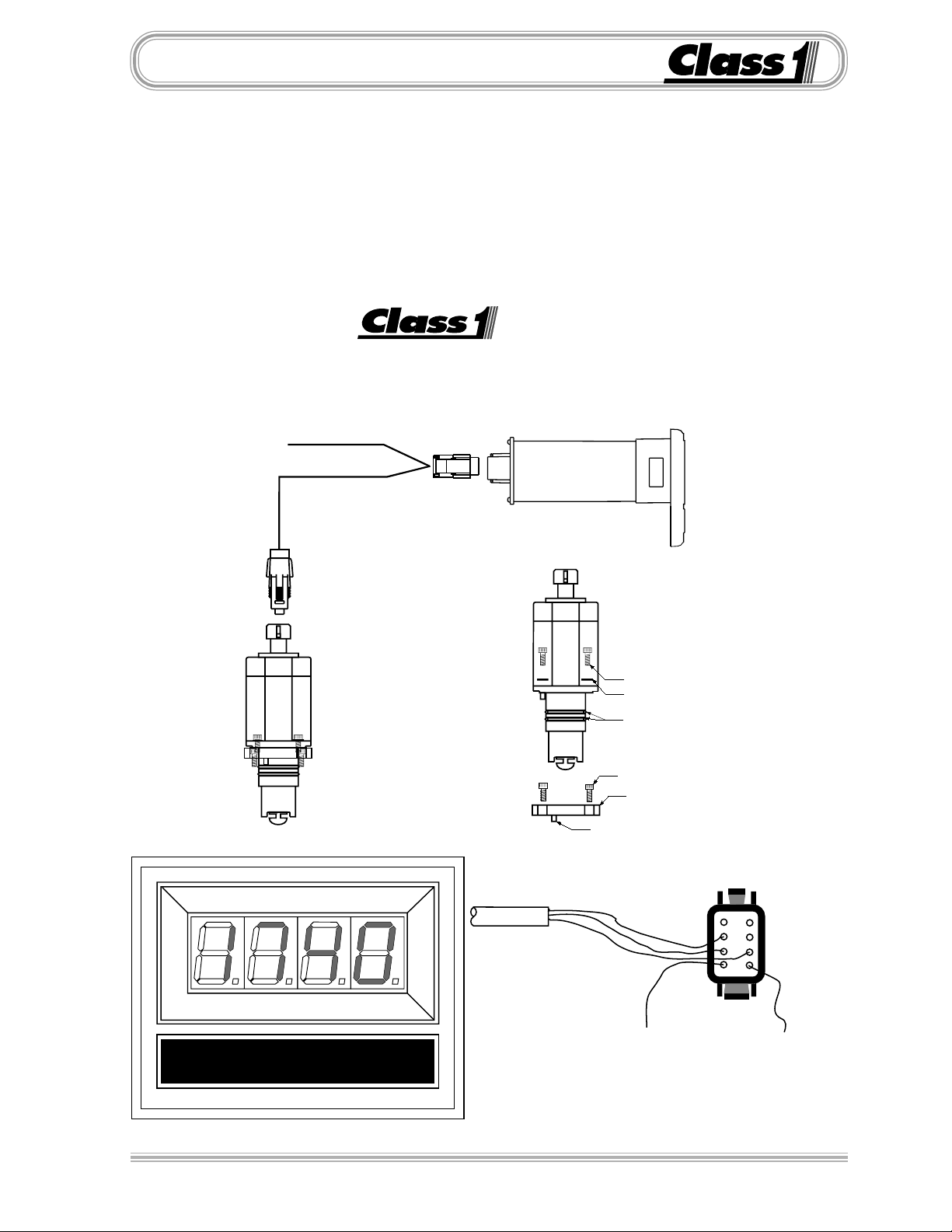

Class1

’s Digital Gauges.

Digital displays come in both seven (7) segment bright LED displays for alphanumeric

information and bargraph displays f or percentage information.

Currently available displa ys:

102046 Flowmeter

102190 Pump Pressure (Intake and Discharge)

102245 T ank Le vel Gauge (Water and F oam)

102245 Pressurized Tank Level (0 to 100 %)

102007 Speedometer

102342 Aerial Loading

102263 Breathing Air Lev el (0 to 100 %)

102264 Oxygen System Level (0 to 100 %)

103282 Dual Current Amplifier for dual displa ys

(air, O2 and Aerial Loading)

0 25 50 75 100

LOW LEVEL LOADING

0 25 50 75 100

% AIR REMAINING

TEST

ALARM SILENCE

0 25 50 75 100

WATER LEVEL

0 25 50 75 100

% OXYGEN REMAINING

TEST

ALARM SILENCE

SPEEDOMETER

PUMP INTAKE

FLOWMETER

TOTALIZER

PUMP DISCHARGE

2

Page 3

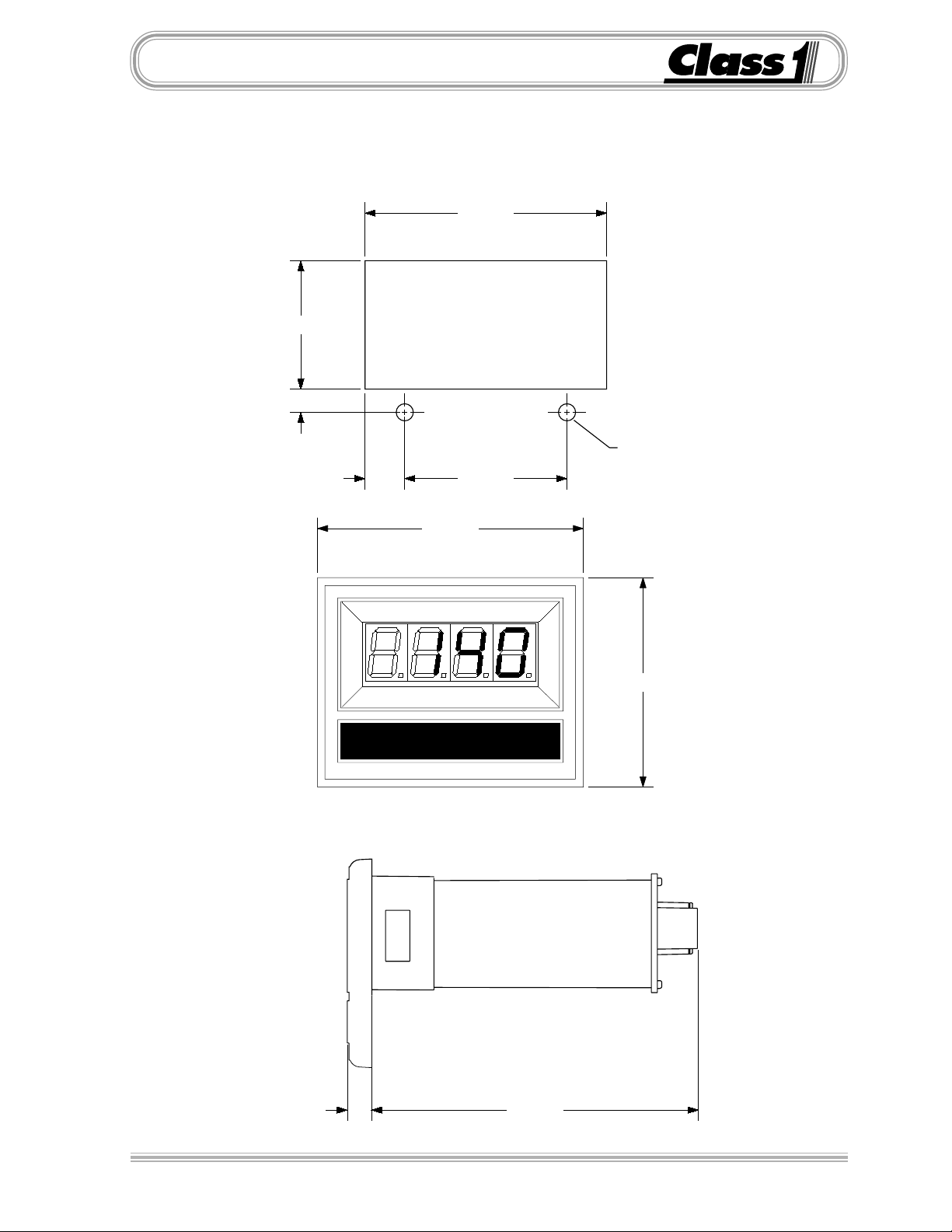

Mounting

The

Class1

Overall area necessary for installation is 2.5” by 3.2”.

Two 0.20 diameter holes are pro vided for mounting screws .

1.510

.277

digital display mounts in a 2.85” by 1.55” cutout.

2.840"

Ø 0.201"

(2) HOLES

.470 1.900

3.125"

DIGITAL DISPLAY

2.462"

0.285" 3.832"

3

Page 4

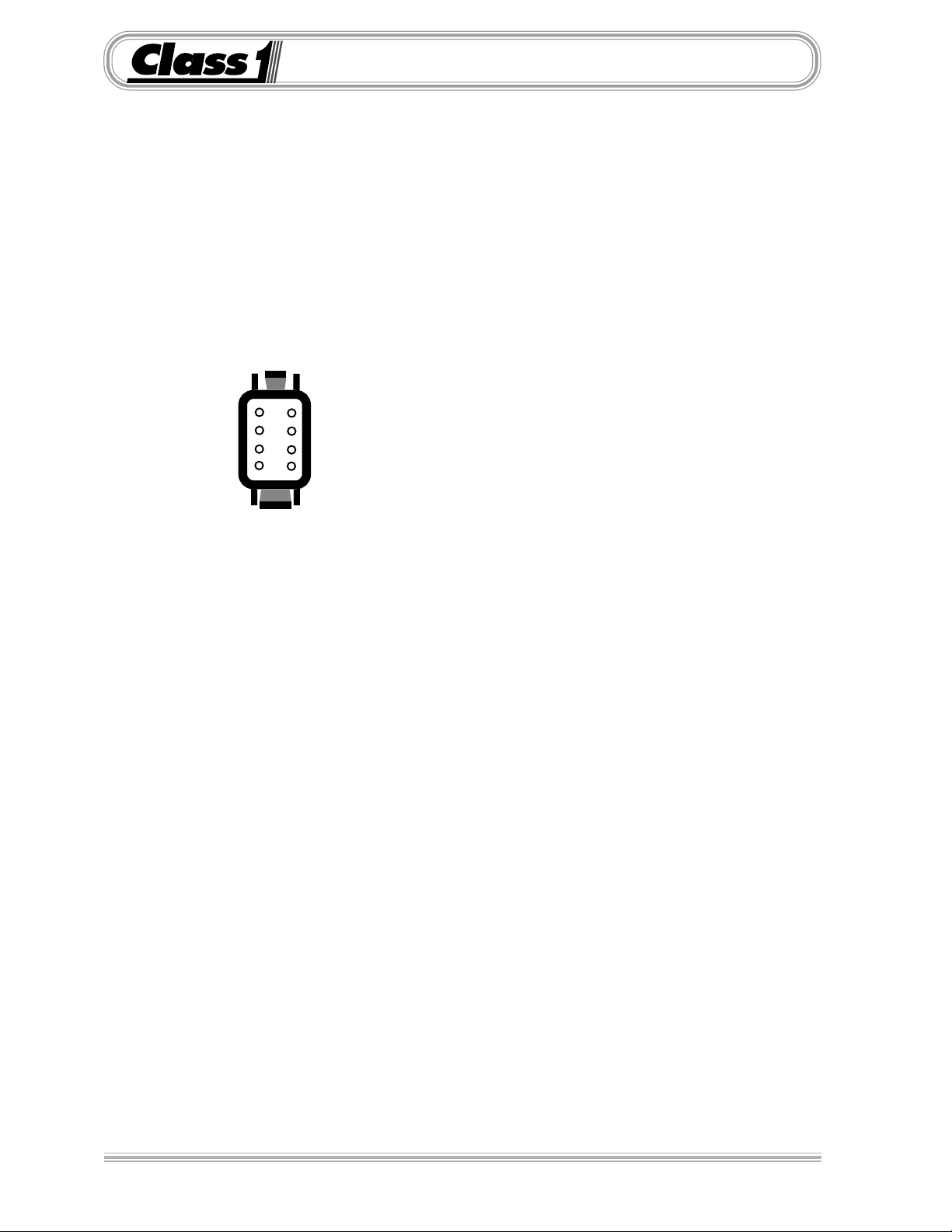

Harness

The digital displays are connected to the OEM harness with a Deutsch 8 pin miniconnector .

Mating Connector: DTM 06-08S

Locking Wedge WM-8S

Mating T erminal: 0462-201-20141 20 gauge socket

General T erminal Assignments:

1) Alarm Output (Ground)

8

7

6

5

Wire Insertion View

1

2

3

4

2) Primary Pressure Signal

3) Sensor Supply (+ 5 or +10 VDC)

4) System P ower (+ 12 VDC)

5) System Ground

6) Sensor Ground

7) Signal (frequency or secondary PSI in)

8) Test, Total or Alarm Switch (Ground)

Not all of the digital displays use all of the terminals.

See individual display pages for application specific inf ormation.

Harnesses are available for the digital displa ys in v arious lengths.

These include transmitter/transducer and power connections.

Harness Part Numbers by length and application.

5’ 10’ 20’ 30’

Flowmeter Display 102064 102033 102065 103165

Pressure Display 102060 102035 102061 102271

Breathing Air Display 102670 102671 102672

Oxygen System Display “ “ “

Tank Level Display 102193 102194 102195 102729

Dual T ransducer 102439Y 102455

Speedometer 102242 102243 102244

DC Voltmeter “ “ “

Dual Display “Y” 102294 102295

Dual Current Amplifier 103318

Display Pigtail 102272 Extension 15’ 103367

4

Page 5

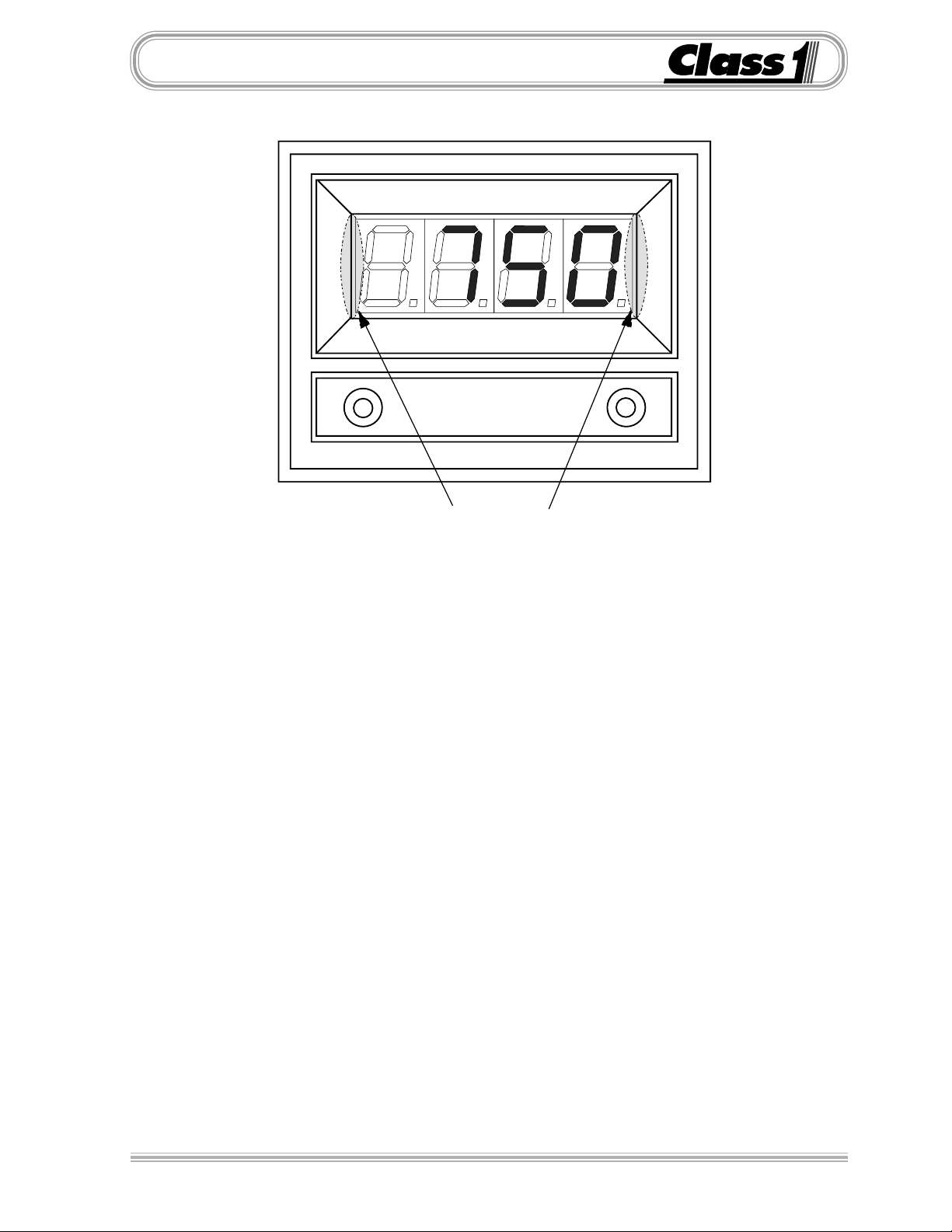

Cal. Overview

Location of Magnetic Switches

Digital Display Calibration should be performed to assure accuracy.

The calibration mode is entered by the use of a “password”.

There are two magnetic switches, one located at each side of the display.

These switches are activated with the use of a magnet.

Switch activation is visually confirmed by the lighting of the closest decimal point on

the display to the switch.

Display Calibration sequence for Gauges with 7 segment LED’s

A password will look like the following example.

L L L R R R

Enter the switch sequence with a magnet to enter the basic calibration mode.

Left Switch Left Switch Left Switch Right Switch Right Switch Right Switch

If the password is correctly entered,

ber that is dependent on the display being calibrated (usually 0 ). If necessary, the calibration

number can be changed using the switch on the right side.

CAL

will be displayed for 1/2 second followed by a num-

Establish accurate and stable conditions f or calibration.

When the calibration conditions are stable, activ ate the left switch.

The display will read

and then return to normal operation.

donE

5

Page 6

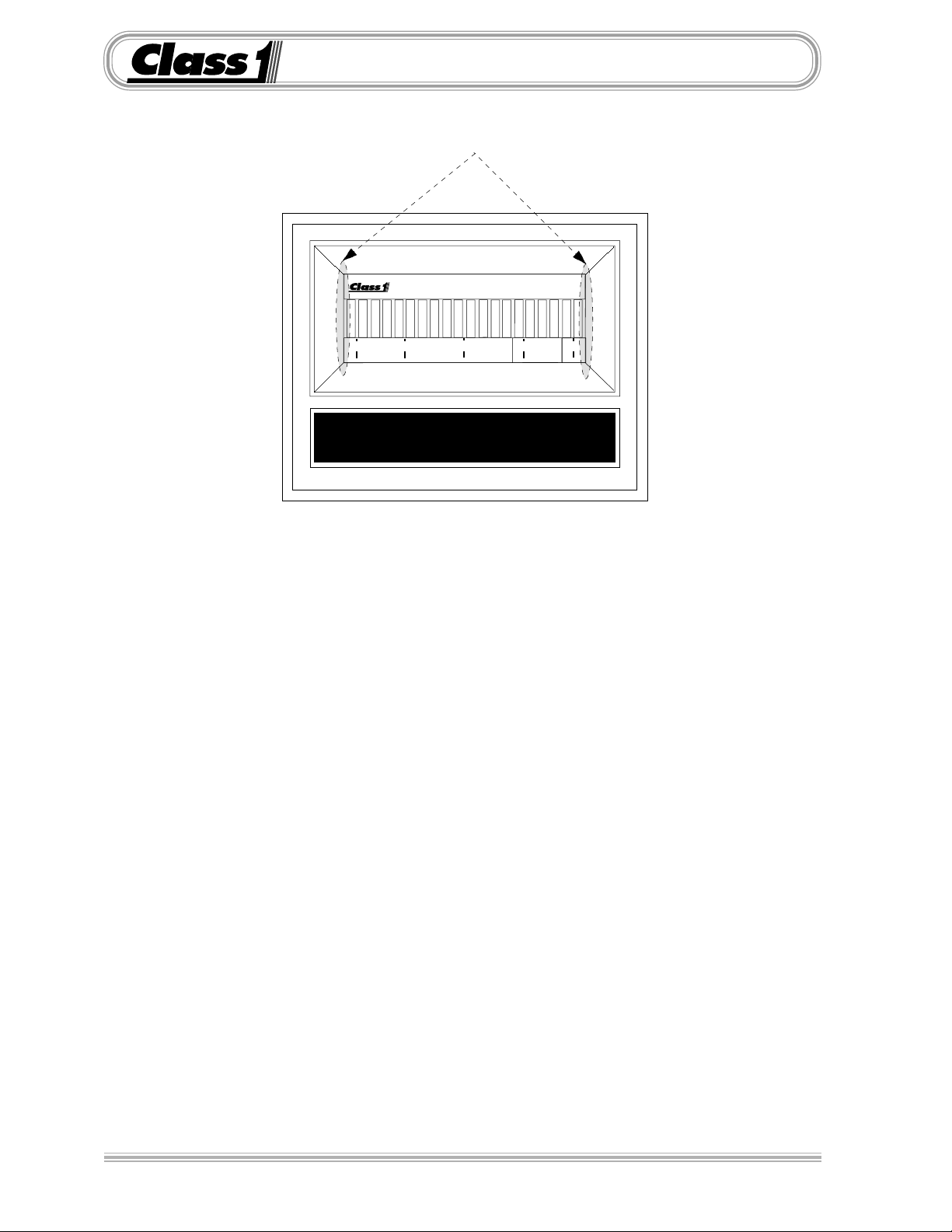

Cal. Overview

Location of magnetic switches

0 25 50 75 100

BAR GRAPH DISPLAY

Display Calibration for Gauges with bargraph displays

The calibration mode is entered by the use of a “password”.

There are two magnetic switches, one located at each side of the display.

These switches are activated with the use of a magnet.

Switch activation is visually confirmed by the toggling of the four closest bars on the

display to the switch. If they are on they will turn off, if they are off they will turn on.

A password will look like the following example.

L L L R R R

Enter the switch sequence with a magnet to enter the basic calibration mode.

Left Switch Left Switch Left Switch Right Switch Right Switch Right Switch

If the password is correctly entered, the left-most bar will turn on and flash. This indicates that

the display is ready to be calibrated for the low set point.

With the system adjusted to the minimum calibration point (the system should be empty or at

the lowest pressure condition) activate the left switch and then the right switch.

The right-most bar will begin to flash, indicating the display is ready for the high set point

calibration.

Adjust the system to it’s maximum operating condition. Activate the right switch followed by

the left switch.

The display will return to normal operation and indicate current system status as a percentage

of maximum calibrated capacity.

6

Page 7

Flowmeter

The

Class1

comes with the digital display, a paddlewheel transmitter and a connecting harness (specify length). Mounting the transmitter to the discharge can be done with a

saddle clamp, a welded boss or a valve

adapter. Call f or options and specify pipe

diameter.

digital flowmeter system

Paddlewheel Installation

The flow display includes a totaliz er function. A momentary switch (optional) is required to operate this feature . The display

will continuously monitor flow when the

unit has power and display the latest total

volume when the totalizer switch is

pressed. The total flow is cleared when

power is removed from the unit.

FLOW METER

6-32x7/16

Lockwasher

O-ring

6-32x7/16internal hex

Spacer

Indexing Pin

White (Signal)

Black (System Ground)

8

7

6

5

1

2

3

4

Red (System Power)

DTM06-08S

Wire Insertion View

7

Page 8

FlowmeterFlowmeter

Flowmeter

FlowmeterFlowmeter

Installation

The

Class1

the flow rate. The location of the paddlewheel transmitter is important for proper

operation and accurate readings. Mount the transmitter in a location that is accessible for future maintenance and in an area where laminar (non-turb ulent) flow is

most likely to be maintained. Most problems with flowmeter accuracy and perf ormance can be traced to the location of the transmitter .

The hole size for the paddlewheel transmitter (PN102714) mount is 1-1/2”.

The hole size for the paddle wheel transmitter (PN101199) mount is 1-7/8”.

T ransmitter Location

Elbows/Bends A straight run of pipe to the transmitter of at least six (6) times

the pipe diameter after an elbow or other turbulence producing item is desirable

for a successful installation. T ry to locate the transmitter using the longest straight

section of pipe available. Minimal turbulence at the transmitter provides the most

accurate reading.

Valves/Gates If the transmitter is downstream of a valve, the minimum distance is fifteen (15) times the pipe diameter. Whenev er possible, mount the

transmitter before a v alve .

Digital Flowmeter measures water velocity in the pipe to calculate

Horizontal Pipes The transmitter will work in any position, howe ver when mounted

on a horizontal run, it should be mounted in the top half of the pipe to allow debris

to be flushed out of the paddlewheel.

Increase/Decrease in pipe size The transmitter can be placed after an increase

in pipe diameter, ne ver after a decrease.

Class1

turbulence between the pump and discharge pipe.

Wiring

The Flowmeter system comes with a wiring harness that connects the transmitter to the display.

The OEM must supply power and ground to the digital displa y . Consideration

should be given to the conditions under which the displa y will have pow er.

The display is internally protected against short circuits, overvoltage and reverse

polarity , but standard installation procedures should provide f or circuit protection.

Maximum current used by the flowmeter is 1.5 Amps.

flexible hose can greatly assist in reducing the number of elbo ws and amount of

A momentary grounding switch can be added when the totalizer function is desired. This is connected to the display through the 8 pin mini-connector at pin 8.

8

Page 9

Operation

The flowmeter displays the current flo w rate whenever the displa y has power and

the discharge is open. Range is 0 to 9995 GPM, LPM or IGPM as calibrated.

Totalizer

The display includes a totalizer function that displa ys the total amount of water

that has been flowed since the unit was turned on. This feature is enabled b y

grounding terminal number eight (8) of the display connector .

When in the totalizer mode, all decimal points will flash to indicate this mode.

While terminal number 8 is grounded, activating the left switch resets the totalizer

to zero (0).

The totalizer resets to zero whene ver pow er is removed from the displa y.

Multiply the reading on the display b y 100 (add two zeroes) for total flow.

FlowmeterFlowmeter

Flowmeter

FlowmeterFlowmeter

9

Page 10

Calibration

Calibration matches the display to the paddlewheel tr ansmitter installation and

signal for a given flo w rate.

A method of accurately determining flow should be used to calibrate the unit.

A smoothbore nozzle and a Pitot gauge is suitable.

Flowmeter calibration must be perf ormed with the discharge flow stabilized at the

desired calibration flow rate.

Establish and maintain the calibration flow rate f or a minimum of 10 seconds to

assure an accurate and stable reading. When the flow is stab le, enter the

flowmeter calibration mode.

The calibration mode passw ord for the flowmeter isL L L R R R.

Switches are located at each side of the display.

These switches are activ ated with the use of a magnet.

Switch activation is visually confirmed by the lighting of the closest decimal point

on the display.

Enter the switch sequence below to enter calibr ation mode.

Calibration

L

eft Left Left Right Right Right

LEFT SWITCH LEFT SWITCH LEFT SWITCH RIGHT SWITCH RIGHT SWITCH RIGHT SWITCH

If the password is correctly entered,

follow ed b y

Using the right switch on the display, enter the flow rate you intend to calibrate. If

the department will use a standard flow for the discharge, use that figure for

calibration.

The speed that the display increments/decrements increases the longer that the

switch is held. If y ou pass the flow calibration n umber , “release” the s witch and

reactivate it. The display will “reverse direction” each time the switch is activ ated

and the speed will start out at the slowest rate.

When the number on the display matches the discharge flo w rate, check the Pitot

for the desired pressure and then activate the left s witch to complete calibration.

The display will read

0

.

donE

and then return to normal operation.

CAL

will be displayed for 1/2 second

10

Calibration is now complete.

Page 11

Example CAL

Example Calibration (4”)

Install a Pitot gauge and a two inch (2”) smoothbore nozzle on the deck gun.

Determine the flow rate that you want to use. (70 PSI=994 GPM).

Start pumping water through the deck gun until the Pitot gauge reads 70 PSI.

Enter the calibration mode by bringing a magnet close to the left side of the display and

removing it three (3) times, the left decimal point should light with each s witch closure.

Bring a magnet close to the right side of the display and remove it three (3) times, the

right decimal point should light with each switch closure.

The display should read

Bring the magnet close to the right side of the display and hold it, the display number

should increase. When the displa y reads

If you stop short of

bring it close again for the display to increase. If you pass

close to the right side and hold it until the number decreases to

994

CAL

for 1/2 second and then

994

, move the magnet aw ay from the displa y .

, you must bring the magnet close to the right side, remove it and

0

994

, just bring the magnet

994

When the flow has been stable at 70 PSI for at least 10 seconds , move the magnet close

to the left side of the display and remov e it.

The display should read

Adjust the flow so that the Pitot reads 50, the display should read

Adjust the flow so that the Pitot reads 110, the display should show

All readings should be within +- 3 % of the 120 PSI value. (+-40 GPM f or a 2” nozzle)

Use a Pitot nozzle flow chart to select a calibration setting. Ideally it should be a v alue

close to the average r ate expected from the discharge.

Check your calibration with flow values that are lower and higher than the calibration

flow but within normal flow rates f or the discharge.

donE

for se veral seconds and then displa y

994

840

1245

Note:

There is a default calibration setting f or 2”, 2.5”, 3”, 4” and 5” schedule 80 pipes.

Pass word to enter default calibration:

L R R R L L L

Scroll through the pipe sizes with the right switch and select with the left switch.

The defaults will only work with schedule 80 pipe.

11

Page 12

Value Flow

4.380

.683

2.750

.037

5.000"

3.750"

3.564"

R 1.325"

should be given to cutting out the panel and mounting this system if you plan to use the bezel.

The panel cutout is a little more difficult than just mounting a gauge and a display and some planning

The Value Series flowmeter uses the digital displa y and a 2-1/2” or 3-1/2” pressure gauge to giv

A stainless steel bezel is available that can have insets color coded to identify the associated discharge.

operator information on both flow and pressure f or the discharge.

e the pump

12

Page 13

Super Flow

The flowmeter Super System is designed using the digital flowmeter and the digital

pressure gauge. Each piece uses the standard digital display cutout. The only additional

consideration from the standard flowmeter is f or mounting the pressure transducer. This

should generally be mounted after the valve and is a 1/4 NPT fitting. Use only the 1-1/4”

hex to tighten the transducer, not the body of the sensor. Follo w the calibration procedure for pressure and flow as appropriate after installation.

FLOW METER

PUMP DISCHARGE

13

Page 14

Vehicle Speed

SPEEDOMETER

The Speedometer Display is connected to the OEM harness with a Deutsch 8 pin

mini-connector.

Mating Connector: DTM06-08S

Locking Wedge WM-8S

Mating T erminal: 0462-201-20141 20 gauge socket

Terminal Assignments: 1 N/C (no connection)

2 N/C

3 N/C

4 Display Power (Ignition 12 VDC)

5 System Ground

6 N/C

7 Pulses IN (speedometer input)

8 N/C

8

7

6

5

Wire Insertion View

1

2

3

4

14

A usable Pulses In signal is available on the World Transmission wire #157 at the

Vehicle Interface Module connection H-2.

Page 15

Vehicle Speed

Calibration

Digital Speedometer calibration is performed with the vehicle speed stabilized at 40 M.P.H.

or (40 K.P.H. )

The calibration mode is entered by the use of a “password”.

There are two magnetic switches, one located at each side of the display.

These switches are activated with the use of a magnet. Switch activation is visually

confirmed by the lighting of the closest decimal point on the display.

Enter the switch sequence below to enter calibration mode.

L L L R R R

Left Switch Left Switch Left Switch Right Switch Right Switch Right Switch

If the password is correctly entered, “

Maintain a constant speed of 40 for a minimum of 10 seconds to assure an accurate and

stable calibration before activating the left switch.

Activate the left switch.

The display will read “

donE

”

and return to normal operation showing the current speed.

CAL

” will be displayed for 1/2 second followed b y

“

40

”

Calibration is now complete.

NOTE:CALIBRATION SHOULD BE PERFORMED BY A PERSON OTHER THAN THE

APPARATUS

DRIVER.

IT IS UNSAFE FOR A DRIVER’S ATTENTION TO BE DIVERTED BY ANY TASK

OTHER

THAN THE SAFE OPERATION OF THE VEHICLE.

15

Page 16

Pressure Gauge

Installation and Operation of the

Class1

Digital Pressure Gauge.

The pressure transducer (PN 102161) mounts to the pump with a 1/4” NPT fitting. Mount

the pressure transducer on the pump discharge manifold and tighten using the 1-1/4 he x.

Mount the digital display on the pump panel using the dimensions provided.

Connect the wiring harness PN 102035, 102060, or 102061 to the transducer, the display

and to the vehicle power and ground circuits.

8

7

6

5

Wire Insertion View

1

2

3

4

PUMP DISCHARGE

Operation is straightforward.

When the unit is turned on, the display indicates pump pressure at the transducer location. Normally no calibration is required, however if the gauge

does not read zero when the pump is not running, a ZERO calibration can be

performed. Password L R R L L.

This feature works only on displays that read rP1.7 and above at power on.

Harness PN 102060 5’

102035 10’

102061 20’

PIN COLOR FUNCTION

A BLACK SENSOR GROUND

B RED SENSOR SUPPLY

C WHITE SENSOR SIGNAL

PIN COLOR FUNCTION

1 PLUG

2 WHITE SIGNAL

3 RED SENSOR SUPPLY

4 RED POWER IN

5 BLACK GROUND IN

6 BLACK SENSOR GROUND

7 PLUG

8 PLUG

Red +12 VDC

Black Ground

16

Page 17

Aerial Loading

0 25 50 75 100

LOW LEVEL LOADING

The

Class1

dangerous loading conditions when an aerial device is operated at low angles

of elevation. Live loads (factors that increase this load such as ice, occupants on the ladder, water load, extra equipment, etc.) are instantly taken into

account by the system and displayed to the operator.

The display presents load information in an easy to interpret LED bargraph

display as a percentage of maximum calibrated load and includes visual and

aural warnings.

When the aerial load approaches the maximum load (approx. 80%), 18-20

bars will be illuminated on the display. When the load is increased to 90%100%, the display will begin to flash, when the maximum load is exceeded by

50-100 pounds, an audible alarm output is activated in addition to the visual

warning to notify the operator of a potentially hazardous condition.

Aerial Loading Display is designed to warn aerial operators of

NOTE: THE DISPLAY PROVIDES A WARNING ONLY AND CANNO T

PREVENT

A TIP-OVER. THE AERIAL DEVICE MUST BE OPERA TED

STRICT ACCORDANCE WITH THE MANUFACTURER’S INSTRUC-

IN

TIONS AND OPERATORS MUST BE THOROUGHLY TRAINED.

17

Page 18

Single transducer installation:

The transducer (PN 102606) must be installed in the pressure feed line to the

actuating cylinder(s) or where it can sense the hydraulic pressure necessary to

lift the aerial device.

Supply 12 VDC and ground to the displa y .

Route the transducer wiring from the display to the transducer and plug in the

connector .

If an audible alarm is desired, connect the alarm output (ground) from terminal #1

of the 8 pin display connector to the ground side of the alarm. An alarm test

switch may be connected from ground to terminal #8 of the display connector .

Dual transducer installation:

Identical to a single transducer installation with the addition of a second transducer that should be installed on the rod side of the hydraulic actuator . This

transducer signal is read at terminal #7 of the display connector .

12 VDC

P.N.1800060

Display Power

Alarm Output (Ground)

Aerial Loading

PIN COLOR FUNCTION

1 OEM Alarm OUT (ground)

2 WHITE PRIMARY SIGNAL

3 RED SENSOR SUPPLY

4 RED POWER IN

5 BLACK GROUND IN

6 BLACK NC

7 WHITE SEC. SIGNAL (opt.)

8 OEM Alarm Test (ground)

Primary (barrel) Transducer Cable

Secondary (rod) Transducer Cable (OPTIONAL)

Display Ground

Alarm Test

WIRE COLOR FUNCTION

1 RED SENSOR SUPPLY

2 WHITE SENSOR SIGNAL

The Aerial Loading Display is connected to the OEM harness with a Deutsch 8 pin miniconnector.

Mating Connector: DTM06-08S

Locking Wedge WM-8S

Mating T erminal: 0462-201-20141 20 gauge socket

Terminal Assignments: 1 Alarm OUT (ground)

2 Pressure Signal IN (4-20 mA)

3 10 VDC OUT

4 Display Power (Ignition 12 VDC)

5 System Ground

6 Sensor Ground OUT

7 Rod pressure IN (Dual Transducer 4-20 mA)

8 Alarm Test IN (ground)

18

Page 19

Aerial Loading

WARNING:

CALIBRATION SHOULD ONLY BE PERFORMED BY THE

AERIAL

MANUFACTURER!

IF YOU FEEL THAT THE DISPLAY NEEDS CALIBRATION, CONTACT YOUR

AERIAL

Aerial manufacturers must ensure that the lift cylinder(s) do not bottom out

during operations. This would cause an erroneous hydraulic pressure reading and the warning system will not operate as designed.

The

Class1

ever two displays are operated from one current transducer (aerial loading, air pressure and oxygen gauges)

Dual Current Amplifier (PN 103282) should be used when-

MANUFA CTURER.

Dual Displays

.

A harness is available to simplify the installation (PN 103283)

19

Page 20

Tank Level

Tank Level Gauge

Transducer Installation

FLUID TANK

3/4 NPT Elbow (OEM)

The transducer must be mounted vertically as depicted to insure an accurate and reliable reading.

This will also prevent damage to the transducer from freezing.

Harness

102193 5'

102194 10'

102195 20'

Pressure Transducer

1/4 NPT

Adapter 3/4-1/4 NPT Bushing (OEM)

Foam adapter is supplied when a

foam level system is ordered.

The tank level gauge transducer should be mounted near the bottom of the

tank. (Approximately two (2) inches off the bottom)

The display, the transducer and the har ness are supplied to ease installation.

When ordered for foam, a special baffled adapter is included with the installation kit.

0 25 50 75 100

TANK LEVEL

20

Page 21

Tank Level

The Tank Level Display is connected to the OEM harness with a Deutsch 8

pin connector.

Mating Connector: DTM06-08S

Locking Wedge WM-8S

Mating Terminal: 0462-201-20141 (20 gauge socket)

Terminal Assignments: 1 Alarm OUT

2 Pressure Signal IN

3 5 VDC OUT

4 Display Power (Ignition 12 VDC)

5 System Ground

6 Sensor Ground OUT

7 Secondary pressure IN ( option )

8 Alarm Silence IN

Mount a 3/4 NPT elbow just off the bottom of the tank, enough to keep sediment out of the elbow and transducer (PN 102162). Attach a 3/4 to 1/4 NPT

adapter (supplied for foam) to the elbow and mount the transducer to that.

The elbow and adapter need to be installed so that the transducer is mounted

vertically.

Pressurized Tanks

If you have a pressurized tank, two pressure transducers (PN 102162) can

be used to compensate for pressure or vacuum in the tank. One transducer

should be mounted near the bottom of the tank and one near the top.

When calibrating the dual transducer installation, the tank should

be vented to the atmosphere .

21

Page 22

Tank Level

Basic Calibration: (2 point)

With the fluid tank empty, enter the

calibration password.

L L L R R R

The left (0%) bar will flash to indicate that you are ready to calibrate

for an empty tank.

Activate the left switch followed by

the right switch.

The right (100%) bar will flash to

indicate that the display is ready to

calculate for a full tank.

When the tank is full, actuate the

right and then the left switch.

Advanced Calibration: (5 point)

With the fluid tank empty, enter the

calibration password.

L L R R L L

The left (0%) bar will flash to indicate that you are ready to calibrate

empty.

Activate the left switch followed by

the right switch.

The fifth bar from the left (25%) will

flash to indicate that the display is

ready to calculate for a quarter tank.

Fill the tank to 1/4 full, actuate the

right and then the left switch.

Calibration is complete.

If after checking the accuracy of

your calibration, you are not satisfied, you can perf orm the adv anced

calibration procedure. This is rarely

necessary except in the case of

oddly shaped tanks.

The tenth bar from the left (50%)

will flash to indicate that the display

is ready to calculate for a half tank.

Fill the tank to 1/2 full, actuate the

left and then the right switch.

The fifteenth bar from the left (75%)

will flash to indicate that the display

is ready to calculate for three f ourths

tank.

Fill the tank 3/4 full, actuate the right

and then the left switch.

The right (100%) bar will flash to

indicate that the display is ready to

calculate for a full tank.

When the tank is full, actuate the

right and then the left switch.

22

Calibration is complete.

Page 23

Breathing Air

0 25 50 75 100

BREATHING AIR

The

Class1

visible indication of breathing air remaining and an audible warning when

there is less than 20% air remaining. The alarm will not activate when there is

less than 50 PSI air in the system, this silences the alarm when the air supply

is turned off.

The display represents air volume information in an easy to interpret LED

bargraph display as a percentage of maximum calibrated pressure. The

Breathing Air Display includes a visual warning and an auxiliary warning alar m

output.

When the relative volume of air remaining reaches 25%, the bars will begin to

flash and the alarm output will becomes active when system pressure drops

to 20%. The alarm can be silenced with an alarm silence switch. Once the

alarm is silenced, it will remain silent for five (5) minutes or until the unit is

turned off and then back on, and is reset whenever the volume of air exceeds

20%.

Breathing Air Display is designed to provide firefighters with a

23

Page 24

DTM06-08SA

0462-201-20141 20 Ga.

1 Alarm OUT (ground)

2 PSI IN (Pressure)

3 Sensor + 10 VDC

4 Power + 12 VDC

5 Ground

6NC

7NC

8 Alarm Silence (ground)

Wire Insertion View

8

7

6

5

1

2

3

4

Alarm OUT

PSI Supply

PSI Signal

BLACK

Breathing Air

0.410"

RED

Red

Black

Black

Red

1.125"

1.425"

OEM Power Feed

12 VDC

Ground

CONNECTOR

Pressure Transducer

PIN COLOR

1 PLUG

2BLACK

3 RED

4 RED

5BLACK

6 PLUG

7 PLUG

8 PLUG

MANUALS\DIGITAL\AIR_LEFT\AM_HARN.AI

The

PIN COLOR

1 RED

2 BLACK

Class1

PROVIDED HARNESS

manuals\digital\air_level\AM-wire.eps..100998

breathing air gauge is easily wired into the apparatus using the supplied

installation kit that includes the necessary wiring harness and connectors.

24

Page 25

Breathing Air

Calibration for Breathing Air Gauge installations:

Empty Cylinder (Closed Valve)

With the air bottle closed and the system purged, enter

the calibration password.

L L L R R R

The left (0%) bar will flash to indicate that you are ready to calibrate for an

empty system.

Activate the left switch followed by the right switch.

The right (100%) bar will flash to indicate that the display is ready to calibrate

for a full system.

Maximum Air

With a full air bottle and the valve open actuate the right switch

and then the left switch.

Calibration is complete.

Calibration should be accomplished using an air cylinder filled to the locally

established maximum pressure.

Dual Displays

The

Class1

are operated from one current transducer (aerial loading, air pressure and oxygen gauges).

A harness is available to simplify the installation (PN 103283)

Dual Current Amplifier (PN 103282) should be used whenever tw o displays

25

Page 26

Oxygen Supply

0 25 50 75 100

O2 REMAINING

The

Class1

a visible indication of Oxygen remaining and an audible warning when there

is less than 20% oxygen remaining. The audible warning is inactive whenever the pressure is below 50 PSI so that it will not sound when the supply is

turned off.

The display represents oxygen volume information in an easy to interpret

LED bargraph display as a percentage of maximum calibrated pressure. The

display includes a visual warning and an auxiliary warning alarm output.

When the relative volume of oxygen remaining reaches 25%, the bars will

begin to flash, and when the system pressure drops to 20%, the auxiliary

output will turn on. The alarm can be silenced with an alarm silence switch.

Once the alarm is silenced, it will remain silent until the unit is turned off and

then back on, and will reset whenever the volume of air exceeds 20%. When

the alarm is silenced, there will be an aler t chirp every fifteen (15) minutes to

remind the operator that the oxygen supply is low.

Oxygen Remaining Display is designed to provide operators with

26

Page 27

Oxygen Supply

DTM06-08SA

0462-201-20141 20 Ga.

1 Alarm OUT (ground)

2 PSI IN (Pressure)

3 Sensor + 10 VDC

4 Power + 12 VDC

5 Ground

6NC

7NC

8 Alarm Silence (ground)

Wire Insertion View

8

7

6

5

1

2

3

4

Alarm OUT

PSI Signal

PSI Supply

BLACK

RED

Red

0.410"

1.125"

1.425"

OEM Power Feed

12 VDC

GroundBlack

Black

Red

CONNECTOR

PIN COLOR

1 RED

2 BLACK

PROVIDED HARNESS

Pressure Transducer

PIN COLOR

1 PLUG

2 BLACK

3 RED

4 RED

5 BLACK

6 PLUG

7 PLUG

8 PLUG

MANUALS\DIGITAL\AIR_LEFT\AM_HARN.AI

manuals\digital\air_level\O2-wire.eps..100998

27

Page 28

Oxygen Supply

Calibration for Breathing Oxygen Gauge installations:

Empty Cylinder (Closed Valve)

With the oxygen bottle closed and the system purged, enter

the calibration password.

L L L R R R

The left (0%) bar will flash to indicate that you are ready to calibrate for an

empty system.

Activate the left switch followed by the right switch.

The right (100%) bar will flash to indicate that the display is ready to calibrate

for a full system.

Maximum Volume

With a full oxygen bottle and the system pressurized, actuate the

right switch and then the left switch.

NOTE:

Calibration is complete.

Calibration should be accomplished using an oxygen

cylinder filled to the locally established maximum pressure.

28

Page 29

PRIMARY DISPLAY

PIN COLOR CIRCUIT

1 OEM Alarm

2 BLACK Signal

3 RED 10 VDC

4 RED V IGN

5 BLACK GND

6 Black Sensor 7 PLUG --8 OEM Silence

DUAL OUTPUT CONVERTER

PIN COLOR CIRCUIT

1 BLACK SIGNAL 1

2 WHITE SIGNAL 2

3 BLACK XDucer IN

4 RED V IGN

5 BLACK GND

6 PLUG --

Ignition

2.5'

2.5'

Ground

5'

2.5'

7 RED T V+

8 PLUG --

Dual Amplifier

PIN COLOR CIRCUIT

1 RED 10 VDC

2 BLACK SIGNAL

PIN COLOR CIRCUIT

1 OEM Alarm

2 White Signal

3 PLUG --4 RED V IGN

5 BLACK GND

6 PLUG --7 PLUG --8 OEM Silence

SENSOR

Secondary DISPLAY

10'

DISPLAY 2 Signal Wire

Turntable

or

Reel

12"

12"

A Dual Current Amplifier should be used whenever two displays share a single 4-20 mA transducer.

29

Page 30

30

PIPE 3/4 2 2-1/2 3 3-1/2 4 5 6 12

Pitot PSI U.S. Gallons per Minute at various nozzle sizes approx

Pressure 1/2" 5/8" 3/4" 7/8" 1" 1-1/8" 1-1/4" 1-3/8" 1-1/2" 1-5/8" 1-3/4" 1-7/8" 2" 2-1/4" 2-1/2" 3" 6"

30 41 64 92 125 163 206 254 308 366 430 498 57 2 651 824 1017 1464 5856

35 44 69 99 135 176 222 275 332 395 464 538 61 8 703 890 1098 1581 6324

40 47 73 106 144 188 238 294 355 423 4 96 575 660 75 1 951 1174 1691 6764

45 50 78 112 153 199 252 311 377 448 5 25 610 700 79 7 1009 1245 1793 7172

50 53 82 118 161 210 266 328 397 473 5 55 643 738 84 0 1063 1313 1890 7560

55 55 86 124 169 220 279 344 417 496 5 82 675 774 88 1 1115 1377 1982 7928

60 58 90 130 176 230 291 360 435 518 6 08 705 809 92 0 1165 1438 2071 8284

62 58 91 132 179 234 296 366 442 526 6 18 716 822 93 5 1184 1462 2105 8420

64 59 93 134 182 238 301 371 449 535 6 28 728 835 95 0 1203 1485 2138 8552

66 60 94 136 185 241 305 377 456 543 6 37 739 848 96 5 1222 1508 2172 8688

68 61 96 138 188 245 310 383 463 551 6 47 750 861 98 0 1240 1531 2204 8816

70 62 97 140 190 248 315 388 470 559 6 56 761 874 99 4 1258 1553 2236 8944

72 63 99 142 193 252 319 394 477 567 6 66 772 886 1008 1276 1575 2268 9072

74 64 100 144 196 255 323 399 483 575 675 78 3 898 1022 1293 1597 2299 9196

76 65 101 146 198 259 328 405 490 583 684 79 3 910 1036 1311 1618 2330 9320

78 66 103 148 201 262 332 410 496 590 693 80 3 922 1049 1328 1639 2361 9444

80 66 104 150 203 266 336 415 502 598 702 81 4 934 1063 1345 1660 2391 9564

85 68 107 154 210 274 347 428 518 616 723 83 9 963 1095 1386 1711 2465 9860

90 70 110 159 216 282 357 440 533 634 744 863 991 1127 1427 1761 2536 10144

95 72 113 163 222 289 366 452 547 651 765 887 1018 1158 1466 1809 2605 10420

100 74 116 167 228 297 376 464 562 668 784 910 1044 1188 1504 1856 2673 10692

105 76 119 171 233 304 385 476 575 685 804 932 1070 1217 1541 1902 2739 10956

110 78 122 175 239 311 394 487 589 701 823 954 1095 1246 1577 1947 2803 11212

115 80 125 179 244 319 403 498 602 717 841 976 1120 1274 1613 1991 2867 11468

120 81 127 183 249 325 412 509 615 732 859 997 1144 1301 1647 2034 2928 11712

GPM Flowchart

Page 31

Flow Calibration Chart

PIPE 3/4 2 2-1/2 3 3-1/2 45612

Pitot PSI Imperial Gallons per Minute at various nozzle sizes approx

Pressure

30 3 4 53 77 104 136 172 211 256 305 358 415 476 542 686 847 1219 4876

35 3 7 57 82 112 147 185 229 276 329 386 448 515 585 741 914 1316 5266

40 3 9 61 88 120 157 198 245 296 352 413 479 550 625 792 978 1408 5632

45 4 2 65 93 127 166 210 259 314 373 437 508 583 664 840 1037 1493 5972

50 4 4 68 98 134 175 221 273 331 394 462 535 615 699 885 1093 1574 6295

55 4 6 72 103 141 183 232 286 347 413 485 562 644 734 928 1147 1650 6601

60 4 8 75 108 147 192 242 300 362 431 506 587 674 766 970 1197 1724 6898

62 4 8 76 110 149 195 246 305 368 438 515 596 684 779 986 1217 1753 7011

64 4 9 77 112 152 198 251 309 374 445 523 606 695 791 1002 1237 1780 7121

66 5 0 78 113 154 201 254 314 380 452 530 615 706 804 1018 1256 1809 7234

68 5 1 80 115 157 204 258 319 386 459 539 625 717 816 1033 1275 1835 7341

70 5 2 81 117 158 207 262 323 391 465 546 634 728 828 1047 1293 1862 7447

72 5 2 82 118 161 210 266 328 397 472 555 643 738 839 1062 1311 1888 7554

80 5 5 87 125 169 221 280 346 418 498 585 678 778 885 1120 1382 1991 7964

85 5 7 89 128 175 228 289 356 431 513 602 699 802 912 1154 1425 2053 8210

90 5 8 92 132 180 235 297 366 444 528 620 719 825 938 1188 1466 2112 8447

95 6 0 94 136 185 241 305 376 455 542 637 739 848 964 1221 1506 2169 8676

100 62 97 1 39 190 247 313 386 468 556 653 758 869 989 1252 1545 2226 8903

105 63 99 1 42 194 253 321 396 479 570 669 776 891 1013 1283 1584 2281 9123

110 65 102 146 199 259 328 406 490 584 685 794 912 1038 1313 1621 2334 9336

115 67 104 149 203 266 336 415 501 597 700 813 933 1061 1343 1658 2387 9549

120 67 106 152 207 271 343 424 512 610 715 830 953 1083 1371 1694 2438 9752

1/2" 5/8" 3/4" 7/8" 1" 1-1/8" 1-1/4" 1-3/8" 1-1/2" 1-5/8" 1-3/4" 1-7/8" 2" 2-1/4" 2-1/2" 3" 6"

IGPM Flowchart

IGPM FlowchartIGPM Flowchart

IGPM FlowchartIGPM Flowchart

31

Page 32

LPM Flowchart

Flow Calibration Chart

PIPE

Pitot Kpa Liters per Minute at various nozzle sizes

Pressure

140 2014 2551

150 2108 2676

170 2203 2797

180 2294 291 1

190 2381 3025

210 2464 3127

220 2548 3233

230 2623 3331

250 2699 3426

260 2775 3520

280 401 628 708 897 1113 1597 2177 2502 2847 3611

290 413 643 727 920 1 139 1635 2230 2562 2915 3702

300 420 659 742 939 1 166 1673 2283 2623 2983 3785

320 432 674 757 961 1 192 171 1 2336 2684 3051 3865

330 439 685 776 980 1219 1749 2385 2740 3119 3948

350 447 708 791 1003 1 1257 1787 2434 2824 3184 4031

360 458 716 806 1022 1268 1821 2483 2850 3244 4115

370 466 727 821 1041 1294 1855 2529 2907 3305 4194

390 473 742 837 1060 1317 1889 2574 2960 3365 4274

400 485 753 852 1079 1340 1923 2620 3013 3426 4349

420 492 774 867 1098 1374 1957 2665 3089 3483 4418

430 500 780 882 1117 1385 1987 2710 31 15 3543 4493

440 507 791 897 1 132 1408 2018 2752 3164 3600 4565

450 515 799 908 1 151 1419 2052 2794 3189 3653 4633

470 522 818 924 1 166 1450 2082 2839 3263 3710 4701

480 530 829 935 1 185 1472 21 12 2881 3308 3763 4770

500 538 840 950 1204 1491 2143 2919 3354 3816 4838

510 545 852 961 1219 1514 2173 2960 3403 3872 4900

530 553 869 977 1234 1542 2203 2996 3471 3922 4970

540 560 874 988 1249 1552 2230 3040 3494 3975 5035

550 568 886 999 1268 1575 2256 3078 3535 4024 5099

570 575 897 1014 1283 1593 2286 31 15 3581 4073 5163

580 583 908 1026 1298 1612 2313 3153 3622 4122 5224

590 587 920 1037 1314 1631 2339 3191 3668 4172 5284

610 594 927 1049 1329 1650 2370 3229 3709 4221 5345

620 602 939 1060 1344 1669 2396 3263 3751 4270 5409

640 609 956 1071 1359 1696 2423 3301 3813 4315 5470

650 613 961 1083 1374 1703 2449 3335 3834 4361 5527

660 621 969 1094 1389 1722 2476 3369 3876 4406 5587

680 628 980 1105 1401 1741 2496 3407 3914 4452 5644

690 636 992 11 17 1416 1760 2525 3441 3955 4501 5701

730 651 1020 1147 1450 1812 2585 3528 4075 4611 5837

760 666 1037 1173 1484 1843 2646 3611 4148 4720 5977

790 681 1060 1200 1518 1885 2707 3770 4239 4826 6113

830 693 1083 1226 1552 1927 2763 3891 4330 4932 6242

19mm23.8mm 25.4mm 28.5mm 31.8mm 38.1mm 44.5mm 47.6mm 50.8mm 57.2mm

32

Page 33

Notes

All of the digital displays have a built in lamp test feature. The password to

activate this function is:

L L R L L.

When activated, all segments on the display LED’s will illuminate for a few

seconds and then return to normal operation.

The digital displays that utilize a pressure sensor have a sensor check feature. The password to activate this function is:

L R R L R R.

Special Function Passwords:

Transducer Status Check:

L R R L R R

Pressure Gauge:

Zero Calibration to match transducer to display:

Used if the gauge indicates pressure or vacuum erroneously.

Flowmeter:

Display Raw Pulses:

Checks paddlewheel operation.

Noise cancellation:

Cancels out flow indication from eddy currents on a transmitter when

the discharge valve is closed. Toggles

Reset Totalizer :

rP1.7 or above

L R L R R R R L

L R R L L

L R L R L L

C on

L

or

C off.

This password will only work when the flowmeter is in totalizer mode.

33

Page 34

0462-201-20141 20 Ga.

(ground) Switch 8

Pulses IN 7

Sensor Ground 6

System Ground 5

The display does not illuminate.

The display must hav e power at terminal 4 and ground at terminal 5.

With the connector removed, chec k across pins 4 and 5 for 12 VDC , if 12 volts is

present with the correct polarity , replace the displa y. If v oltage and/or ground is

not present, check the vehicle wiring and display harness terminations.

DTM06-08SA

1 Alarm OUT (grund)

8

7

6

5

Wire Insertion View

1

2

2 PSI IN

3

3 Sensor +5/10 VDC

4

4 System Power

T-shoot

The pressure reading on a discharge or intake gauge does not change.

There is a problem with the pressure transducer or wiring. At the transducer

connector, chec k for 5 VDC between pins A (ground) and pin B (+5 VDC). These

are sent from the display and m ust be of the correct polarity for the transducer to

function. Plug the connector into the transducer and check f or v oltage at the

display between pin 6 (sensor g round) and pin 2 (signal). With zero pressure/

suction at the pump, this v oltage should be between 500 mV and 900 mV. As the

pressure in the pump increases, the voltage should increase. If it does not, then

replace the transducer . If the v oltage increases, and the display does not change,

perform a default calibration, call Class1 (1-800-533-3569) f or instructions. If the

default calibration does not correct the problem, replace the displa y .

The pressure display reads

SEnS

.

There is a problem with the pressure transducer or wiring. At the transducer

connector, chec k for 5 VDC between pins A (ground) and pin B (+5 VDC). These

are sent from the display and m ust be of the correct polarity for the transducer to

function. Plug the connector into the transducer and check f or voltage between

Pin A (sensor ground) and pin C (sensor signal) at the transducer . With zero

pressure/suction at the pump, this v oltage should be between 500 mV and 900

mV, if it is not, replace the transducer. Check f or v oltage at the display betw een

pin 6 (sensor ground) and pin 2 (signal). With zero pressure/suction at the pump ,

this voltage should be between 500 mV and 900 mV. If it is not, check the wiring

from the transducer to the displa y. If the correct voltage is present at pin 2,

replace the display.

34

Page 35

T-shoot

The tank level gauge has a bar traveling back and f orth across the display .

There is a problem with the pressure transducer (PN 102162) or wiring. At the

transducer connector , check for 5 VDC betw een pins A (+5 VDC) and pin B

(ground). These are sent from the display and m ust be of the correct polarity for

the transducer to function. Plug the connector into the transducer and check f or

voltage between Pin B (sensor ground) and pin C (sensor signal) at the trans-

ducer. With an empty tank, this voltage should be between 500 mV and 900 mV, if

it is not, replace the transducer . Check f or v oltage at the display betw een pin 6

(sensor ground) and pin 2 (signal). With an empty tank, this v oltage should be

between 500 mV and 900 mV. If it is not, check the wiring from the transducer to

the display. If the correct voltage is present at pin 2, replace the displa y.

The T ank Level Gauge does not change or calibrate.

There is a problem with the pressure transducer or wiring. At the transducer

connector, chec k for 5 VDC between pins A (+5 VDC) and pin B (ground). These

are sent from the display and must be of the correct polarity for the tr ansducer to

function. Plug the connector into the transducer and check f or voltage at the

display between pin 6 (sensor g round) and pin 2 (signal). With an empty tank, this

voltage should be between 500 mV and 900 mV. As the water le vel in the tank

increases, the voltage should increase. If it does not, then replace the transducer

If the voltage increases, and the displa y does not change, attempt to calibrate the

unit. If the calibration does not correct the problem, replace the display.

The Flow Meter does not read flow or calibrate.

Place the meter in raw mode L R L R L L. Does the meter read pulses, and do

they change with a flow increase or decrease? If they do , re-calibrate . If you do

not read pulses, then it is a wiring or paddlewheel problem. At the paddlewheel,

check for 12 VDC between pins A (ground) and pin B (+12 VDC). These are sent

from the display and must be of the correct polarity for the paddle wheel to func-

tion. Plug the connector into the paddlewheel and check f or pulses at the display

between pin 6 (sensor ground) and pin 7 (signal). If pulses are not present, then

check the paddlewheel orientation and the signal wire from the paddlewheel to pin

7 at the display. If e v erything checks out OK, replace the paddlewheel. If the

signal is present and the display does not read ra w pulses, replace the display.

A-Ground

Pressure T ransducer Pinout

B-Supply

C-Signal

35

Loading...

Loading...