Page 1

FORM-ENG-0018 REV A 06-02-03

ISO 9001 CERTIFIED

607 NW 27th Ave

Phone: (352) 629-5020 or 800-533-3569

Ocala, FL 34475

Fax: (352)-629-2902

TECHNICAL PRODUCT DATASHEET

Electronic Throttle

(Analog version)

P/N 119971

Page 2

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

TECHNICAL DATA SHEET

THROTTLE CONTROL

Twister Electronic Throttle (Analog version)

P/N 119971 REV 1.20

PAGE

DATE 10/1/2010

BY AMS

1 OF 16

1.

REVISION LOG ..................................................................................................................................................................................... 2

2. PART NUMBERS .................................................................................................................................................................................. 3

2.1. SYSTEM PART NUMBERS .................................................................................................................................................................. 3

3. OVERVIEW ............................................................................................................................................................................................ 4

3.1. PRODUCT DESCRIPTION ................................................................................................................................................................... 4

3.2. THROTTLE READY LED INDICATOR .................................................................................................................................................... 5

3.3. ACTIVE LED INDICATOR ................................................................................................................................................................... 5

3.4. CONTROL KNOB ............................................................................................................................................................................... 5

3.5. IDLE BUTTON.................................................................................................................................................................................... 5

4. CONFIGURATION ................................................................................................................................................................................. 6

4.1. ENTERING PASSWORDS .................................................................................................................................................................... 6

4.2. INTERLOCK POLARITY ....................................................................................................................................................................... 6

4.2.1. Positive polarity (default) .......................................................................................................................................................... 7

4.2.2. Ground polarity ......................................................................................................................................................................... 7

4.3. KNOB ROTATION .............................................................................................................................................................................. 7

4.3.1. Clockwise rotation increases RPM (default) ............................................................................................................................. 7

4.3.2. Counter-clockwise rotation increases RPM .............................................................................................................................. 7

4.4. INITIAL DEADBAND CLICKS ................................................................................................................................................................ 8

4.5.

LOAD DEFAULTS ............................................................................................................................................................................... 8

4.6. ENGINE RPM RANGE CONFIGURATION .............................................................................................................................................. 8

4.6.1. Idle RPM configuration ............................................................................................................................................................. 9

4.6.2. Maximum RPM configuration ................................................................................................................................................... 9

4.7.

OUTPUT RAMP RATE ......................................................................................................................................................................... 9

5. OPERATION ........................................................................................................................................................................................ 10

5.1. INITIALIZATION ............................................................................................................................................................................... 10

5.2. INTERLOCKING (ENABLING THE TWISTER) ........................................................................................................................................ 10

5.3. CONTROLLING ENGINE SPEED ......................................................................................................................................................... 11

5.3.1. Returning the engine speed to idle ......................................................................................................................................... 12

6. MOUNTING & INSTALLATION........................................................................................................................................................... 13

6.1. PANEL CUTOUT DIMENSIONS ........................................................................................................................................................... 13

6.2. TWISTER SIDE-VIEW DIMENSIONS .................................................................................................................................................... 13

6.3. MAINTENANCE ............................................................................................................................................................................... 14

7. WIRING ................................................................................................................................................................................................ 14

7.1. TWISTER CONNECTOR .................................................................................................................................................................... 14

7.2. TWISTER WIRING ............................................................................................................................................................................ 14

8. TECHNICAL DETAILS ........................................................................................................................................................................ 15

9. REFERENCES ..................................................................................................................................................................................... 16

9.1. LIST OF FIGURES ............................................................................................................................................................................ 16

9.2. LIST OF TABLES .............................................................................................................................................................................. 16

9.3. LIST OF PASSWORDS ...................................................................................................................................................................... 16

Manual P/N 120478

Page 3

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

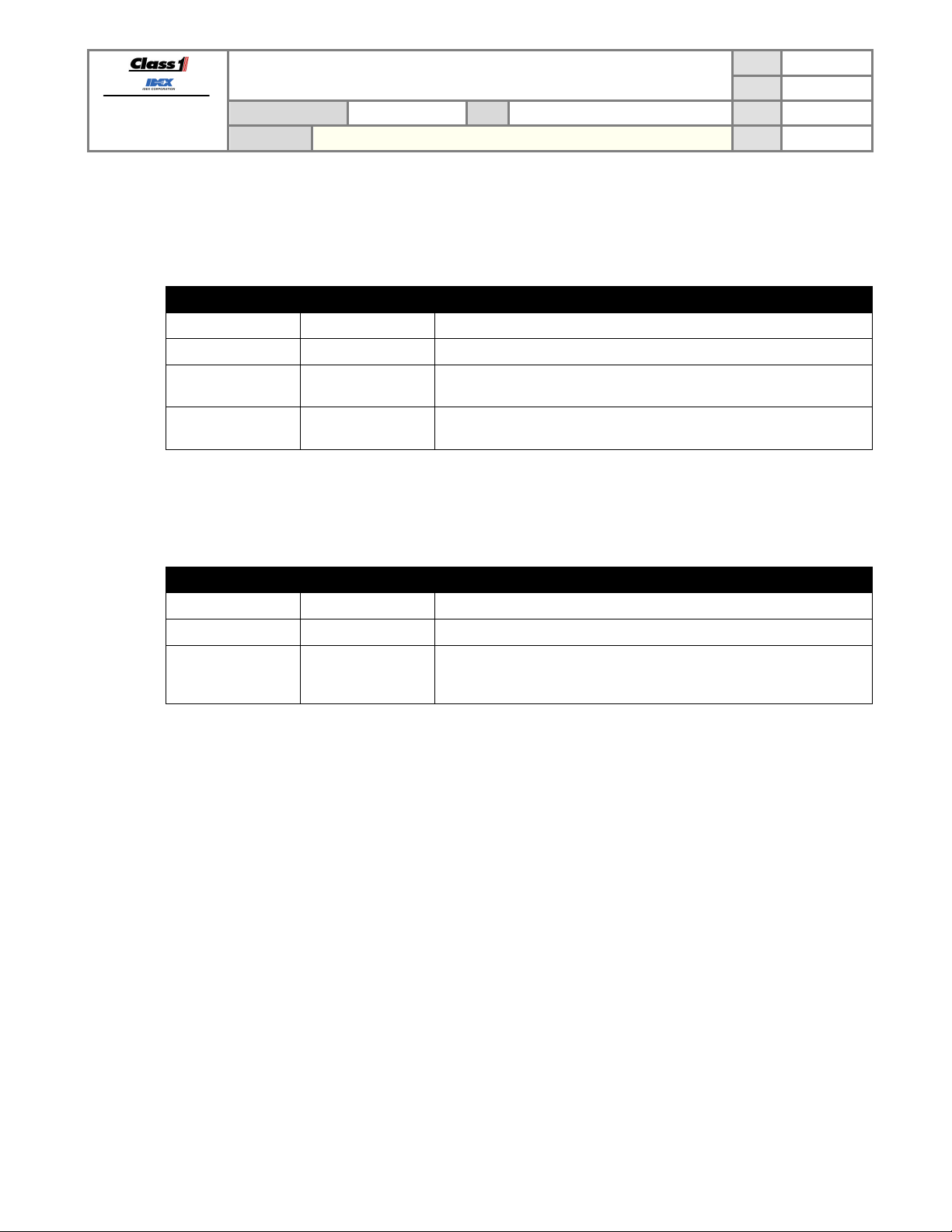

1. Revision Log

Rev Date Changes

1.00 11/16/2009 Initial revision

1.10 9/7/2010 Clarified password entry.

1.20 10/1/2010 Added passwords for “slow” output mode

PAGE

PRODUCT GROUP

PRODUCT

TECHNICAL DATA SHEET

THROTTLE CONTROL

Twister Electronic Throttle (Analog version)

P/N 119971 REV 1.20

DATE 10/1/2010

BY AMS

Product specifications in this manual are subject to change without notice.

2 OF 16

Manual P/N 120478

Page 4

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

2. Part numbers

2.1. System part numbers

Twister Electronic Throttle (analog) system kit TWIST-A

TECHNICAL DATA SHEET

THROTTLE CONTROL

Twister Electronic Throttle (Analog version)

P/N 119971 REV 1.20

PAGE

DATE 10/1/2010

BY AMS

3 OF 16

Kit includes

Twister Electronic Throttle (analog) QTY-1 119971

Twister main system harness QTY-1 120430

Knob rotation direction label set QTY-1 120462

Documentation (available from Class 1’s website - www.class1.com)

Twister Electronic Throttle Manual (this manual) 120478

Twister Quick Manual 120319

Manual P/N 120478

Page 5

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

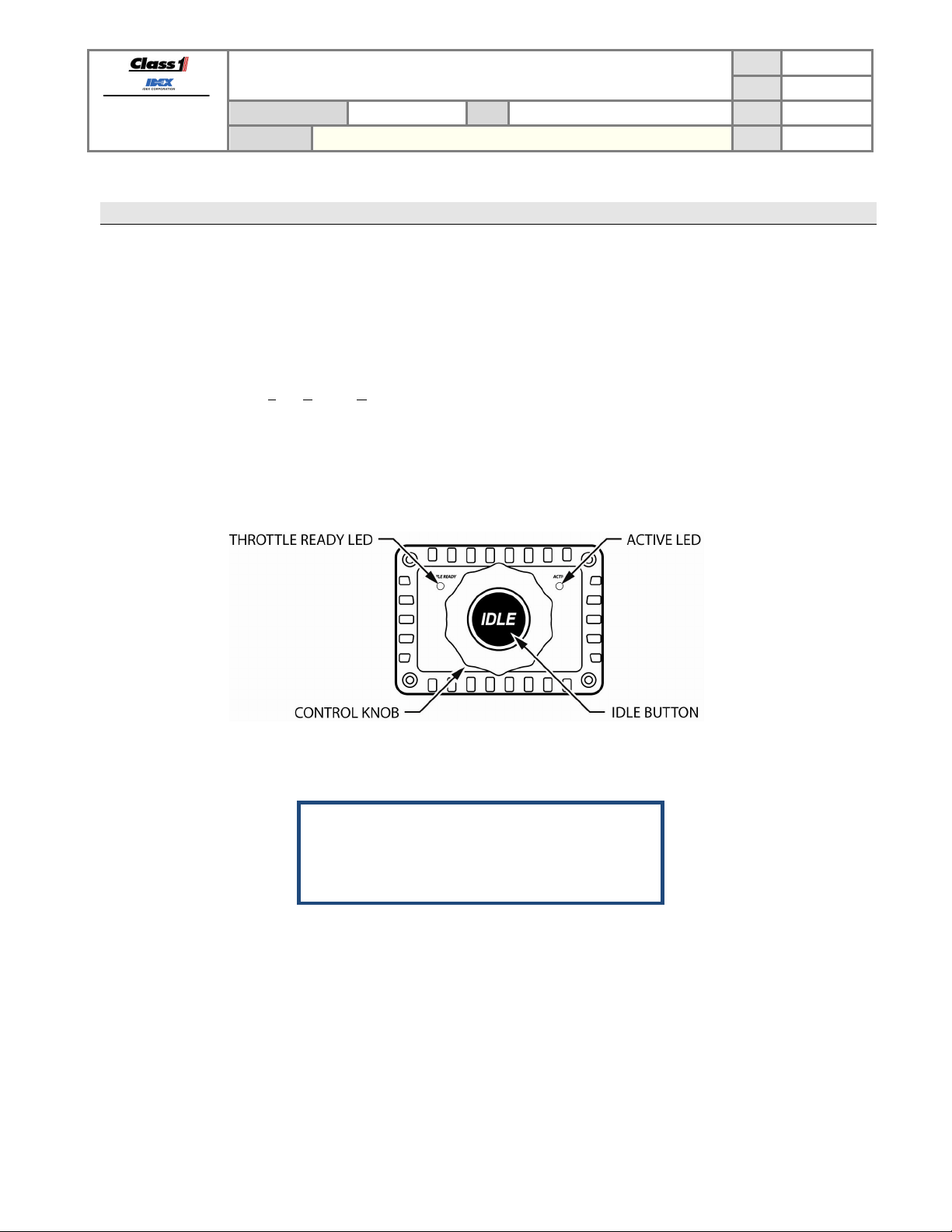

3. Overview

3.1. Product description

The Twister Electronic Throttle (p/n 119971) controls engine speed using a variable analog voltage connected to the

engine ECM for remote throttle applications. The Twister’s analog voltage range is 0.235 volts to 4.448 volts and the

minimum (idle) and maximum voltages can be configured between the standard range for specific engine

manufacturer requirements (refer to section 4.6).

The Twister utilizes L

READY LED is on the left-side of the control knob and the blue ACTIVE LED is on the right-side of the control knob.

The Twister has a control knob and an idle button for the operator to control engine speed. The control knob allows

manipulation of the engine speed within the configured (and engine allowable) RPM range. The idle button returns

the engine speed to the configured idle RPM.

TECHNICAL DATA SHEET

THROTTLE CONTROL

Twister Electronic Throttle (Analog version)

P/N 119971 REV 1.20

PAGE

DATE 10/1/2010

BY AMS

4 OF 16

ight Emitting Diodes (LED) to convey status information to the operator. The green THROTTLE

Figure 1. Twister controls and indicators.

THROTTLE READY LED………………… section 3.2

ACTIVE LED………………………………. section 3.3

Control knob……………………………….. section 3.4

Idle button………………………………….. section 3.5

Manual P/N 120478

Page 6

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

3.2. Throttle ready LED indicator

The green THROTTLE READY LED indicator shows the status of the Twister interlock input (pin 3) and analog signal

diagnostic information.

FAST FLASH

DOUBLE BLINK NOT PERMITTED

3.3. Active LED indicator

The blue ACTIVE LED indicator shows the status of the Twister control.

PRODUCT GROUP

PRODUCT

Twister Electronic Throttle (Analog version)

LED state Throttle control Description

ON PERMITTED Twister interlock input (pin 3) is active.

OFF NOT PERMITTED Twister interlock input (pin 3) is NOT active.

(10 Hz)

NOT PERMITTED

LED state Throttle control Description

ON ACTIVE The twister is in control of engine RPM.

OFF NOT ACTIVE The Twister is not controlling the engine RPM (engine at idle).

FLASHING AT RPM LIMIT

TECHNICAL DATA SHEET

THROTTLE CONTROL

Table 1. Throttle ready LED states.

P/N 119971 REV 1.20

Analog signal error (voltage too low).

Verify analog +5 VDC reference and signal line voltage.

Analog signal error (voltage too high).

Verify analog ground reference and signal line voltage.

The Twister’s control knob is being rotated while the analog output

signal voltage is already at the configured limit (minimum or

maximum).

PAGE

DATE 10/1/2010

BY AMS

5 OF 16

Table 2. Active LED states.

3.4. Control knob

The control knob is the operator’s interface for RPM control. The control knob is rotated to change the engine speed

(RPM). The control knob can be configured to increase engine speed with clockwise or counter-clockwise rotation

(section 4.3).

3.5. Idle button

The idle button is the operator’s interface to return the engine’s speed to its idle RPM. Press and hold the idle button

for a half-second to ramp the engine speed to idle and release active engine control from the Twister. The Twister

ramps the output signal down at a rate of 0.9 volts per second.

Manual P/N 120478

Page 7

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

4. Configuration

4.1. Entering passwords

The Twister utilizes passwords to modify its operational parameters. All operational parameters are stored in memory

and will not be lost when power is disconnected.

TECHNICAL DATA SHEET

THROTTLE CONTROL

Twister Electronic Throttle (Analog version)

P/N 119971 REV 1.20

PAGE

DATE 10/1/2010

BY AMS

6 OF 16

Figure 2. Password entry mode.

To enter a password:

Press and hold the IDLE button until the ACTIVE LED blinks twice (two seconds). Continue holding the

IDLE button while entering the password.

A clockwise

rotation will turn the ACTIVE LED ON for a half- second and a counter-clockwise rotation

will turn the THROTTLE READY LED ON for a half-second. Wait for the LED indication to turn OFF before

rotating the knob again.

A rotation consists of at least one tactile click and a single rotation event is complete when the knob remains

stationary for at least half a second.

If an error is made while entering a password, release the IDLE button to clear and then re-attempt the

password from the beginning.

Invalid password entry

The THROTTLE READY and ACTIVE LEDs will quickly flash numerous times to indicate an attempted password is

invalid.

Manual P/N 120478

Page 8

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

4.2. Interlock polarity

The Twister interlock input (pin 3) must be active before control of the engine speed is possible. The Twister interlock

input can be configured for positive (default) or ground input polarity.

PRODUCT GROUP

PRODUCT

TECHNICAL DATA SHEET

THROTTLE CONTROL

Twister Electronic Throttle (Analog version)

P/N 119971 REV 1.20

PAGE

DATE 10/1/2010

BY AMS

7 OF 16

4.2.1. Positive polarity (default)

Positive polarity interlock configuration password:

4.2.2. Ground polarity

Ground polarity interlock configuration password:

4.3. Control knob rotation

The control knob can be configured to increase engine RPM with clockwise or counter-clockwise rotation. Included

with the Twister is a label set (p/n 120462) which contains a clockwise increase and a counter-clockwise increase

label. Affix the label to the Twister which indicates the configured knob rotation direction.

Figure 3. Rotation direction labels (p/n 120462).

4.3.1. Clockwise rotation increases RPM (default)

Clockwise knob rotation configuration password:

4.3.2. Counter-clockwise rotation increases RPM

Clockwise knob rotation configuration password:

Manual P/N 120478

Page 9

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

4.4. Initial deadband clicks

The Twister requires a number tactile clicks of the control knob in the increase direction before it will allow engine

control. The default number of tactile clicks is five (5) but can be changed to one (1) or ten (10).

Initial deadband clicks required = 1:

Initial deadband clicks required = 5 (default):

Initial deadband clicks required = 10:

4.5. Load defaults

PRODUCT GROUP

PRODUCT

TECHNICAL DATA SHEET

THROTTLE CONTROL

Twister Electronic Throttle (Analog version)

P/N 119971 REV 1.20

PAGE

DATE 10/1/2010

BY AMS

8 OF 16

The Twister’s default configurations are:

Knob increase direction: Clockwise

Interlock polarity: Positive voltage

Maximum output signal voltage: 3.990 VDC

Idle output signal voltage: 0.235 VDC

Control knob initial dead band: 5 initial tactile clicks

4.6. Engine RPM range configuration

The Twister allows configuration of its idle output signal voltage and maximum output signal voltage which directly

affects the engine’s RPM range. The defaults are 0.235 volts at idle and 3.990 volts at maximum.

The idle offset voltage level affects the Twister’s maximum voltage level. When the idle offset voltage is configured to

its lowest level (0.235 volts) the maximum attainable voltage is 3.990 volts. When the idle offset voltage is configured

to its maximum level (2.392 volts) the maximum attainable voltage is 4.448 volts. The graph below (Figure 4) shows

the relationship between the configured idle offset voltage and its associated maximum voltage level.

Manual P/N 120478

Figure 4. Idle offset voltage versus maximum voltage.

Page 10

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

4.6.1. Idle RPM configuration

Enter the password:

PRODUCT GROUP

PRODUCT

TECHNICAL DATA SHEET

THROTTLE CONTROL

Twister Electronic Throttle (Analog version)

P/N 119971 REV 1.20

PAGE

DATE 10/1/2010

BY AMS

9 OF 16

Release the IDLE button.

The Twister sets its output signal voltage to the lowest point. Use the control knob to increase the output signal

voltage until the engine begins to increase its RPM. Use the control knob to find the base limit of control and then

press the IDLE button to save the output signal voltage as the idle voltage.

Engine manufacturers will program their ECMs for a curb idle. The Twister cannot force the engine ECM to attain a

lower RPM than the manufacturers curb idle.

4.6.2. Maximum RPM configuration

Enter the password:

Release the IDLE button.

The Twister sets its output signal voltage the configured idle voltage. Use the control knob to increase the output

signal voltage until the desired maximum RPM is attained. Press the IDLE button to save the output signal voltage

as the maximum voltage.

Engine manufacturers will program their ECMs for a maximum safe RPM limit. The Twister cannot force the engine

ECM to attain more RPM than the manufacturers limit.

4.7. Output Ramp Rate

The Twister (software version 1.2 and above) can be set for two different output ramp rates. The normal mode, which

is the default, increases/decreases the output signal voltage for every click of the control knob. The slow mode

increases/decreases the output signal voltage for every two clicks of the control knob, effectively creating a slower

response to the user input. In slow mode, the ramp time when returning to IDLE using the IDLE button is also twice as

long. The slow mode can be useful in matching the Twister to certain engines if the default ramp speeds are too fast.

Normal Mode (default):

Slow Mode:

Manual P/N 120478

Page 11

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

5. Operation

5.1. Initialization

The Twister uses a two (2) second initialization cycle. The green throttle ready LED and blue active LED will be ON

during the initialization. The Twister will then begin normal operation.

PRODUCT GROUP

PRODUCT

TECHNICAL DATA SHEET

THROTTLE CONTROL

Twister Electronic Throttle (Analog version)

P/N 119971 REV 1.20

PAGE

DATE 10/1/2010

BY AMS

10 OF 16

Figure 5. Twister initialization.

5.2. Interlocking (enabling the Twister)

The Twister will not allow control of the engine speed until the interlock input (pin 3) has been activated. The interlock

input is activated when the proper voltage level is applied. The interlock voltage can be configured for system voltage

(default) or system ground (see section 0).

Figure 4 illustrates a typical interlocking scheme with the Twister’s interlock configured for system voltage. In this

example the OEM makes certain that the park brake and transmission are in the proper modes before allowing

system voltage to pass through to the Twister’s interlock input (pin 3).

Figure 6. Twister interlocking example.

The Twister’s green throttle ready LED will be ON when the proper voltage is applied to the interlock input. This

indicates that the Twister is ready for operator initiated control via the control knob. Refer to table Table 1 in section

3.2 for a description of the throttle ready LED status indication.

Manual P/N 120478

The OEM is responsible for creating a safe interlocking scheme to enable the Twister.

Page 12

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

5.3. Controlling engine speed

The Twister allows the operator to control of the engine’s speed by rotating the control knob as long as the interlock is

active.

The blue ACTIVE LED will be ON once the control knob has been rotated in the increase RPM direction enough

clicks to overcome the configured initial deadband (default is 5 clicks).

Each tactile click of the control knob equals a 0.014 volt increase of the analog output signal voltage. With most

manufacturers this equals from 5 to 10 RPM per tactile click.

PRODUCT GROUP

PRODUCT

TECHNICAL DATA SHEET

THROTTLE CONTROL

Twister Electronic Throttle (Analog version)

P/N 119971 REV 1.20

PAGE

DATE 10/1/2010

BY AMS

11 OF 16

Figure 7. Active LED.

The blue ACTIVE LED indicator shows the status of the twister control (see Table 2 in section 3.3). The ACTIVE

LED will blink when the control knob is being rotated while the output signal voltage is already at the configured limit

(minimum or maximum voltage).

5.3.1. Control knob initial deadband

The Twister requires a number tactile clicks of the control knob in the increase direction before it will allow engine

control. This initial deadband keeps the Twister from inadvertently controlling engine speed caused by accidental

bumps, vibration, etc. The default number of tactile clicks is five (5) with each click occurring within a half-second

of the last. The blue ACTIVE LED activates and throttle control is allowed once the number of tactile clicks has

been established.

Manual P/N 120478

Figure 8. Initial deadband explanation.

Page 13

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

In the previous graphic (Figure 8) the first three tactile clicks are more than a half-second apart and are not counted

for the required number of deadband clicks. The next series of tactile clicks are a half-second (or less) apart and

the deadband counter counts each one up to the required number of clicks (5). The Twister then activates the blue

ACTIVE LED and allows active throttle control. Subsequent tactile clicks change the RPM of the engine and the

timing between clicks is not important. The initial deadband requirement will not be required again until the IDLE

button has been pressed and the engine RPM has been reduced to curb idle.

5.3.2. Returning the engine speed to idle

Press the idle button for a half-second to return the engine speed to idle. The twister will ramp the engine speed

from the current RPM down to the configured idle RPM at which time the blue ACTIVE LED will turn OFF to

indicate that idle has been reached.

TECHNICAL DATA SHEET

Twister Electronic Throttle (Analog version)

THROTTLE CONTROL

PAGE

DATE 10/1/2010

P/N 119971 REV 1.20

BY AMS

12 OF 16

Figure 9. Pressing the idle button.

Manual P/N 120478

Page 14

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

6. Mounting & installation

6.1. Panel cutout dimensions

Mount the Twister on the operator’s panel with four #6 screws and nuts.

TECHNICAL DATA SHEET

THROTTLE CONTROL

Twister Electronic Throttle (Analog version)

P/N 119971 REV 1.20

PAGE

DATE 10/1/2010

BY AMS

13 OF 16

Figure 10. Installation dimensions in inches [millimeters].

6.2. Twister side-view dimensions

Figure 11. Side view dimensions in inches [millimeters].

Manual P/N 120478

Page 15

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

6.3. Maintenance

The Twister does not require regular maintenance. The control knob does not require lubrication.

7. Wiring

7.1. Twister connector

The module has one connector and the following definitions apply:

Mating connector: Deutsch DT06-6S GRAY

Mating sockets: Deutsch 0462-201-16141

Gold mating sockets: Deutsch 0462-201-1631

Recommended wire gage: 16-20 AWG

Wedge lock: W6S

PIN CIRCUIT DESCRIPTION

1 SYS POWER (INPUT) – battery voltage (+9VDC…+32VDC)

2 SYS GROUND (INPUT) – battery ground

3 INTERLOCK (INPUT) – Positive/Ground polarity (configurable)

4 SIGNAL REF + (INPUT) – ECM reference voltage, +5 VDC

5 SIGNAL REF - (INPUT) – ECM reference voltage, ground

6 OUTPUT SIG (OUTPUT) – ECM remote throttle control voltage

TECHNICAL DATA SHEET

THROTTLE CONTROL

Twister Electronic Throttle (Analog version)

P/N 119971 REV 1.20

PAGE

DATE 10/1/2010

BY AMS

14 OF 16

7.2. Twister wiring

Figure 12. Twister harness connections.

Manual P/N 120478

Page 16

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

PRODUCT

8. Technical Details

Product category Throttle control (analog)

Voltage range +9VDC…+32VDC

Maximum current draw

@13.8VDC

@27.6VDC

Temperature range -40ºF…+185ºF (-40ºC…+85ºC)

Environmental range IP 67

LED 2 LEDs (green and blue) to indicate status

Electrical protection

Electrical performance

Environmental performance

Mechanical performance

Dimensions (W x H x D)

in inches [millimeters]

Weight in ounces [grams] 22.8 [646.4]

TECHNICAL DATA SHEET

THROTTLE CONTROL

Twister Electronic Throttle (Analog version)

Logic supply+ input (pin 1 of 6-pin connector)

240 mA

163 mA

Internal thermal fuse (750mA on pin 1 of black 6-pin connector)

Transient voltage protected to SAE J1113 specification for heavy duty trucks (24V)

Load dump voltage protected to SAE J1113 specification for heavy duty trucks (24V)

Immunity to Radiated Electromagnetic Fields– Bulk Current

Injection (BCI) method, Class C device

Reverse voltage protection on power leads (pins 1 and 2 of 6-pin

connector), Class C device

Overvoltage due to failing generator, Class A device ISO 16750-2

Immunity to conducted transients on power leads, Class C device

(24V)

Immunity to Electrostatic Discharge – powered and unpowered

modes

Immunity to radiated electromagnetic fields, Class C device SAE J1113-21

Conducted emission on power leads (level 3 limits) SAE J1113-41

Radiated emissions, absorber-lined shielded enclosure (level 2

limits)

Reset behavior on voltage drop 24V, Class C device ISO 16750-2

Thermal shock

Exposure to humidity

Thermal shock due to splash

Pressure cleaning

Exposure to salt spray atmosphere/fog

Exposure to outdoor UV

Resonance dwell

Random vibration

Mechanical shock

4.438 [112.73] x 3.188 [80.98] x 2.312 [58.74]

P/N 119971 REV 1.20

PAGE

DATE 10/1/2010

BY AMS

15 OF 16

SAE J1113-4

ISO 16750-2

SAE J1113-11

SAE J1113-13

SAE J1113-41

SAE J1455

(sec 4.1.3.2)

MIL-STD-810F

(method 507.4)

Class 1

(STD-0001)

SAE J1455

(sec 4.4)

SAE J1455

(sec 4.3)

ISO 4892-2

(method A)

SAE J1455

(sec 4.9.4.1)

SAE J1455

(sec 4.9.4.2)

SAE J1455

(sec 4.10.3.4)

Manual P/N 120478

Page 17

FORM-ENG-0018 REV A 05-27-03

607 NW 27th Ave

Ocala, FL 34475

Ph: 352-629-5020 or 1-800-533-3569

Fax : 352-629-2902 or 1-800-520-3473

PRODUCT GROUP

9. References

9.1. List of figures

FIGURE 1. TWISTER CONTROLS AND INDICATORS. ................................................................................................................ 4

FIGURE 2. PASSWORD ENTRY MODE. ................................................................................................................................. 6

FIGURE 3. ROTATION DIRECTION LABELS (P/N 120462). ...................................................................................................... 7

FIGURE 4. IDLE OFFSET VOLTAGE VERSUS MAXIMUM VOLTAGE. ............................................................................................. 8

FIGURE 5. TWISTER INITIALIZATION. ................................................................................................................................. 10

FIGURE 6. TWISTER INTERLOCKING EXAMPLE. ................................................................................................................... 10

FIGURE 7. ACTIVE LED. ................................................................................................................................................. 11

FIGURE 8. INITIAL DEADBAND EXPLANATION. ..................................................................................................................... 11

FIGURE 9. PRESSING THE IDLE BUTTON. ........................................................................................................................... 12

FIGURE 10. INSTALLATION DIMENSIONS IN INCHES [MILLIMETERS]. ....................................................................................... 13

FIGURE 11. SIDE VIEW DIMENSIONS IN INCHES [MILLIMETERS]. ............................................................................................ 13

FIGURE 12. TWISTER HARNESS CONNECTIONS. ................................................................................................................. 14

9.2. List of tables

TABLE 1. THROTTLE READY LED STATES. .......................................................................................................................... 5

TABLE 2. ACTIVE LED STATES. ......................................................................................................................................... 5

9.3. List of passwords

Passwords are entered by pressing and holding the IDLE button while rotating the control knob (see section 4.1).

The “rotate” column in the tables below show the control knob rotation directions with 1’s indicating a clockwise

rotation and 0’s indicating a counter-clockwise rotation.

User passwords

Function Rotate Hex

Controlknobdirection–counter‐clockwiseincreasesenginespeed 10010000 90

Controlknobdirection–clockwiseincreasesenginespeed 10010001 91

ConfigureidleRPM 01100101 65

ConfiguremaximumRPM 10010111 97

OEM passwords

Function Rotate Hex

Interlockpolarity–groundinputACTIVE 111010000000 E80

Interlockpolarity–positiveinputACTIVE 111010000001 E81

Controlknobinitialdeadband–1tactileclick 111000000001 E01

Controlknobinitialdeadband–5tactileclicks 111000000101 E05

Controlknobinitialdeadband–10tactileclicks 111000001010 E0A

Loaddefaultconfigurations 111011110000 EF0

SetoutputrampratetoSLOW 111010100001 EA1

SetoutputrampratetoNORMAL 111010100000 EA0

Boldtextindicatesthedefaultconfigurations.

PRODUCT

TECHNICAL DATA SHEET

THROTTLE CONTROL

Twister Electronic Throttle (Analog version)

P/N 119971 REV 1.20

PAGE

DATE 10/1/2010

BY AMS

16 OF 16

Manual P/N 120478

Loading...

Loading...