Page 1

Circular Saw

Cirkelsåg

Sirkelsag

Pyörösaha

Important!

Read the entire instruction manual carefully

and make sure that you fully understand

it before you use the equipment. Keep the

manual for future reference.

Viktig information:

Läs hela bruksanvisningen noggrant och

försäkra dig om att du har förstått den innan

du använder utrustningen och spara den för

framtida bruk.

Viktig informasjon:

Les disse anvisningene nøye og forsikre deg

om at du forstår dem før du bruker enheten

og oppbevar dem for senere bruk.

Tärkeätä tietoa:

Lue nämä ohjeet huolellisesti ja varmista

että olet ymmärtänyt ne, ennen kuin alat

käyttää laitetta. Säilytä ohjeet myöhempää

tarvetta varten.

ENGLISHSVENSK ANOR SKSUOMI

Art.no Model

18-3034 M1Y-140-900A-UK

30-9166 M1Y-140-900A

Original instructions

Ver. 201110

Bruksanvisning i original

Original bruksanvisning

Alkuperäinen käyttöohje

Page 2

2

Page 3

Circular Saw

Art.no 18-3034 Model M1Y-140-900A-UK

30-9166 M1Y-140-900A

Please read the entire instruction manual before using and save it for future use.

We apologise for any text or photo errors and any changes of technical data.

If you have any questions concerning technical problems please contact our

Customer Service Department (see address on reverse.)

1. Safety

Warning! Read all the instructions. Failure to adhere to the following instructions may

lead to electric shocks, fires and/or serious injury. The term “electrical hand tools” in

the warning text below is referring to your mains operated or battery operated hand

tool. SAVE THE INSTRUCTIONS.

1.2 General safety instructions

1) The work space

a) Keep the work space clean and well illuminated. Cluttered and poorly lit areas

invite accidents.

b) Do not use electrical hand tools in explosive environments, i.e. nearby flammable

liquids, gas or dust. Electrical hand tools generate sparks that could easily ignite

dust or fumes.

c) Keep away from children and other spectators while using the electrical hand tool.

Distractions can make you lose your concentration and control.

ENGLISH

2) Electrical safety

a) The electrical hand tool’s plug must fit correctly in the wall socket. Never modify

the plug in any way. Never use an adaptor together with earthed electrical hand

tools. Unmodified plugs and suitable wall sockets decrease the risk of electric shock.

b) Avoid body contact with earthed objects, such as pipes, radiators, ovens or

refrigerators. There is an increased risk of electrical shock if your body is earthed.

c) Do not expose the electrical hand tool to rain or other wet conditions. If water gets

inside an electrical hand tool it increases the risk of electrical shock.

d) Do not misuse the lead. Never use the lead to carry, drag or pull the plug out of

the wall socket. Keep the lead away from heat, oil, sharp edges and movable

parts. Damaged or tangled leads increase the risk of electrical shock.

e) When you use an electrical hand tool outdoors; use an extension cord suitable

for this purpose. Use of an extension cord for outdoor use decreases the risk of

electrical shock.

3

Page 4

3) Personal safety

a) Pay attention to what you do and use common sense when using electrical hand

ENGLISH

tools. Never use an electrical hand tool if you are tired or under the influence of

drugs, alcohol or medication. One moment of not paying attention while using an

electrical hand tool may result in serious injury.

b) Use protective equipment. Always use safety glasses. Using protective equipment

such as a face mask, slip resistant protection shoes, a helmet and ear plugs when

needed decreases the risk of injury.

c) Avoid unexpected start. Make sure that the switch is set to OFF before you

connect the device to the wall socket. Never carry an electrical hand tool with one

finger on the trigger or never connect the hand tool to a wall socket when

the switch is set to ON, since it may result in injury.

d) Remove all service tools/keys before switching on the hand tool. A forgotten

service tool on a rotating part of the electrical hand tool may result in injury.

e) Do not overreach. Make sure you stand steady and well balanced at all times.

This gives better control in unexpected situations.

f) Wear suitable clothing. Do not wear loose fitting clothes or jewellery. Keep hair,

clothes and gloves away from movable parts. Loose fitting clothes, jewellery or

long hair could get caught in movable parts.

g) If the equipment for suctioning or collecting dust is available make sure it is

connected and used properly. Using technical aids may reduce dust related hazards.

4) Use and maintenance of the electrical hand tools

a) Do not overdrive the hand tool. Use a hand tool suitable for the work you are to

perform. At the correct rate of feed, the correct tool will carry out the work better

and more safely.

b) Never use the electrical hand tool if the switch does not work properly to turn

on and shut off the tool. All electrical hand tools that can not be operated by the

switch are dangerous and must be repaired.

c) Unplug the lead from the wall socket before making any adjustments, changes of

accessories or storing the electrical hand tool away. These precautions reduce the

risk of unexpected start of the electrical hand tool.

d) Store electrical hand tools that are not being used out of reach from children.

Do not let people unfamiliar with the electrical hand tool or its instructions use it.

Electrical hand tools can be dangerous if they get into the hands of inexperienced

users.

e) Maintenance of electrical hand tools. Check if something is incorrectly set, if

movable parts are getting jammed, or parts are broken or something else that

might cause the electrical hand tool to malfunction. If something is damaged it

must be repaired before use. Many accidents are caused by poorly maintained

electrical hand tools.

4

Page 5

f) Keep the tools sharp and clean. Properly maintained cutting tools with sharp

blades are less likely to jam and are easier to control.

g) Use the electrical hand tool, accessories and such according to the instructions

and in a way suitable for the type of electrical hand tool used. Using the electrical

hand tool for work other than that for which it is intended could result in

a dangerous situation.

5) Service

a) Repairs and service should only be performed by qualified persons, and only with

original spare parts. This guarantees the safety of the electrical hand tool.

Specific Safety Requirements for Circular Saws

DANGER:

a) Keep hands at a safe distance from the saw blade. Keep your other hand on

the front handle or on the housing. If you are holding the saw with both hands

you cannot cut your hand.

b) Do not reach under the workpiece. The blade guard will not protect you from

the blade underneath the workpiece.

c) Adjust the cutting depth to suit the thickness of the workpiece. Less than the

length of one of the saw blade’s teeth should be visible under the workpiece.

d) Do not hold the workpiece in your hands or across you leg. Fasten the workpiece

to a stable surface. It is important that the workpiece is correctly supported to

minimise the risk of personal injury, to prevent the saw blade from binding and to

prevent you from losing control of the saw.

e) Hold the electrical hand tool by its insulated handles whenever performing tasks

where there is a risk of the saw cutting through hidden power cables or its own

power cable. Contact with a live wire can lead to the metallic parts of the electrical

hand tool becoming live and giving the user an electric shock.

f) When rip sawing, a parallel fence or straight edge guide should be used. This

will improve the precision of the sawing and reduce the chances of the saw blade

binding.

g) Always use saw blades of the correct size and shape (diamond shaped or round).

Saw blades that do not fit the saw properly will rotate eccentrically leading to loss

of control over the saw.

h) Never use damaged or faulty washers or bolts. The washers and bolts for the saw

blade are specially designed to achieve maximum performance and safety.

ENGLISH

5

Page 6

Additional Safety Instructions for all Saws

Reasons for kickback and preventing kickback:

- Kickback is a sudden reaction to a pinched, jammed or incorrectly aligned saw

ENGLISH

blade which causes the saw to jump back violently out of the workpiece towards

the user.

- When the saw blade binds because the kerf behind the blade is closed, the blade

stops and the unit is ejected back towards the user.

- If the saw blade is twisted or distorted in the saw cut the teeth at the back of the

saw blade can fasten in the workpiece and eject it towards the user.

Kickback is caused by the saw being used incorrectly, for the wrong purpose

or under the wrong conditions and can be avoided by taking the following

precautions:

a) Hold the saw firmly in both hands and in such a way that you can parry any

kickbacks. Stand to the side of saw blade, not in line with it. A kickback can

cause the saw to jump backwards but it can be controlled if certain precautions

are taken.

b) When the saw blade jams, or if the sawing process is interrupted for some reason,

switch the power off and hold the saw still until the blade has completely stopped.

Never attempt to withdraw the saw from the workpiece when the blade is rotating,

as this could cause a kickback. Examine and take the necessary measures to

minimise the risk of blade jamming.

c) When restarting a saw in a workpiece, centre the saw blade in the saw cut and

make sure that the teeth of the blade are not touching the material. If the saw

blade has jammed it could wander upwards or be ejected from the workpiece

when the saw is restarted.

d) Support large boards to reduce the risk of the saw blade binding or of the saw

kicking back. Large boards tend to bow under their own weight. The boards need

to be supported on both sides, near the saw cut and near the edge of the board.

e) Do not use blunt or damaged saw blades. Blunt or incorrectly set saw blades can

produce saw cuts that are too narrow, producing too much friction and causing

the saw blade to bind or the saw to kickback.

f) The cutting depth and angle adjusters must be locked in place before sawing

begins. If any of the saw blade setting adjusters moves during cutting the blade

could jam or the saw could kickback.

g) Be especially careful when plunge sawing in walls or objects where it is not

possible to see what one is sawing. The saw blade could cut into objects that

could cause kickbacks.

6

Page 7

Safety Instructions for Saws Fitted with Inner Blade Guard

a) Make sure that the lower blade guard is properly closed before each use. Do not

use the saw if the lower blade guard does not move freely and close immediately.

Never clamp or bind the lower blade guard in the open position. If the saw is

accidentally dropped the lower blade guard can be bent. Lift the lower blade guard

using the handle and make sure that it can move freely without touching the saw

blade or any other part of the saw in any of the saw’s cutting angles and depths.

b) Make sure that the spring on the lower blade guard works. If the guard or spring

does not work properly it must be repaired before the saw is used. The lower

guard can stick due to damaged parts, sticky deposits or a build-up of sawdust.

c) The lower blade guard may only be moved to the side for special operations such

as plunge sawing and compound sawing. Move the lower guard to the side using

the handle and as soon as the saw blade makes contact with the material the

lower guard must be released. For all other sawing the lower guard must work

automatically.

d) Always make sure that the lower blade guard is covering the blade before laying

the saw on a bench or the floor. An uncovered rotating saw blade can cause the

saw to move backwards and saw through everything in its path. Bear in mind that

it takes time for the saw blade to come to a stop after the power switch has been

released.

Additional Safety Instructions for all Saws Fitted with

Riving Knives

a) Use a riving knife compatible with the saw blade being used. In order for

the riving knife to work it must be thicker than the saw blade but thinner

than the kerf of the saw blade.

b) Adjust the riving knife according to the directions in this instruction manual.

Incorrect distance, incorrect position and alignment can lead to the riving knife

not preventing kickbacks.

c) Always use the riving knife except when plunge sawing. The riving knife must be

reattached if it is detached for plunge sawing. The riving knife could get in

the way when plunge sawing and cause kickback.

d) In order for the riving knife to work it must pass through the workpiece.

The riving knife cannot prevent kickback on short saw cuts.

e) Do not use the saw if the riving knife is bent. Even a small defect can slow

the closing time of a safety guard.

ENGLISH

7

Page 8

- Tie the workpiece down if it is not held in place by its own weight.

- Use a dust extractor when using the circular saw.

- Always wear a dust mask when using the circular saw.

ENGLISH

- Use only those saw blades designed to be used with this circular saw.

- Always wear ear defenders when using the circular saw.

- Grinding/Cutting discs must not be used with this circular saw.

- New plugs or mains leads must only be fitted by qualified personnel.

Guide to Safety Symbols

Read the instructions thoroughly

Always use protective eyeglasses

Always use hearing protection

8

Page 9

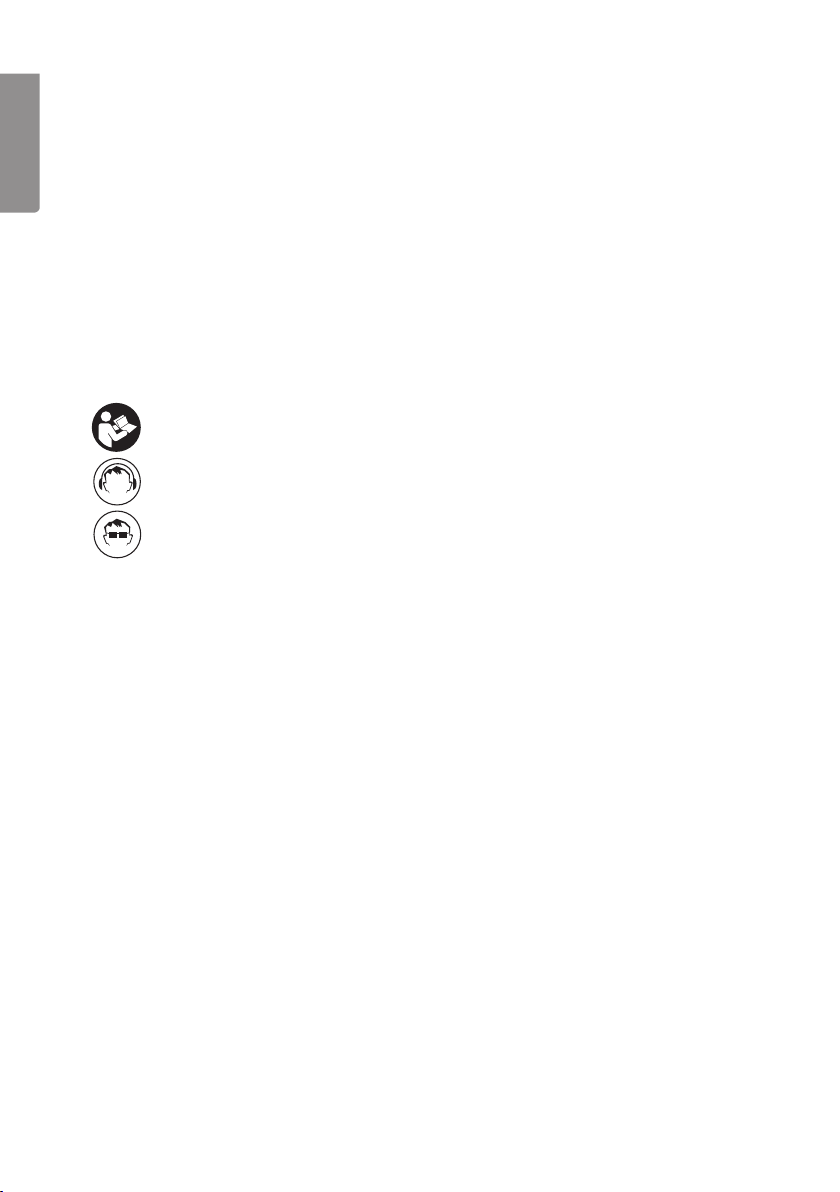

Description

1. Handle

2. Rating plate

3. Power switch

4. Lock button for power switch

5. Lock screw for depth

adjustment

6. Cord

7. Blade guard

8. Screw for saw blade

9. Foot plate

10. Blade flange

11. Saw blade

12. Parallel guide

13. Lock screw for parallel guide

14. Screw for angle adjustment

15. Connection for vacuuming

saw dust

16. Front handle

17. Manoeuvring lever for

blade guard

18. Riving knife

4 3

ENGLISH

2

5

6

15 17 7 1 16

14

Accessories

- Parallel guide

- Allen key

- Saw blade 140/16

9

18

8 10 11 12 13

9

Page 10

Adjustments and maintenance

Important! Pull plug from wall socket before making adjustments or doing

maintenance work.

ENGLISH

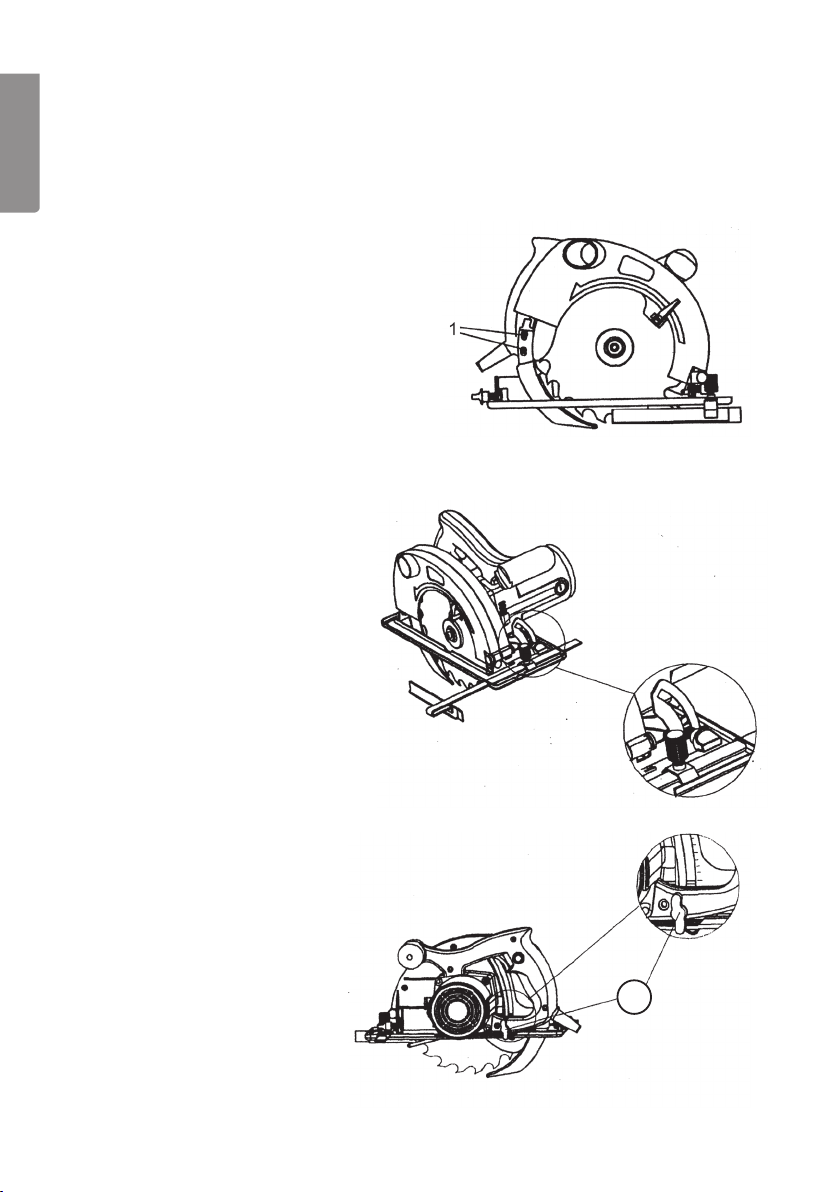

Adjustment of riving knife

1. Loosen both screws (1) holding

riving knife.

2. Push blade guard back and hold it

firmly with manoeuvring lever

3. Adjust riving knife to max. 5 mm

distance from the saw blade.

4. Saw blade must not protrude more

than 5 mm lower than the edge of

the riving knife.

5. Tighten both screws.

6. Check that the riving knife is lined

up with the saw blade.

Adjustment of saw angle

1. Loosen the lock screw.

2. Set the desired angle between

0 – 45°.

3. Tighten lock screw.

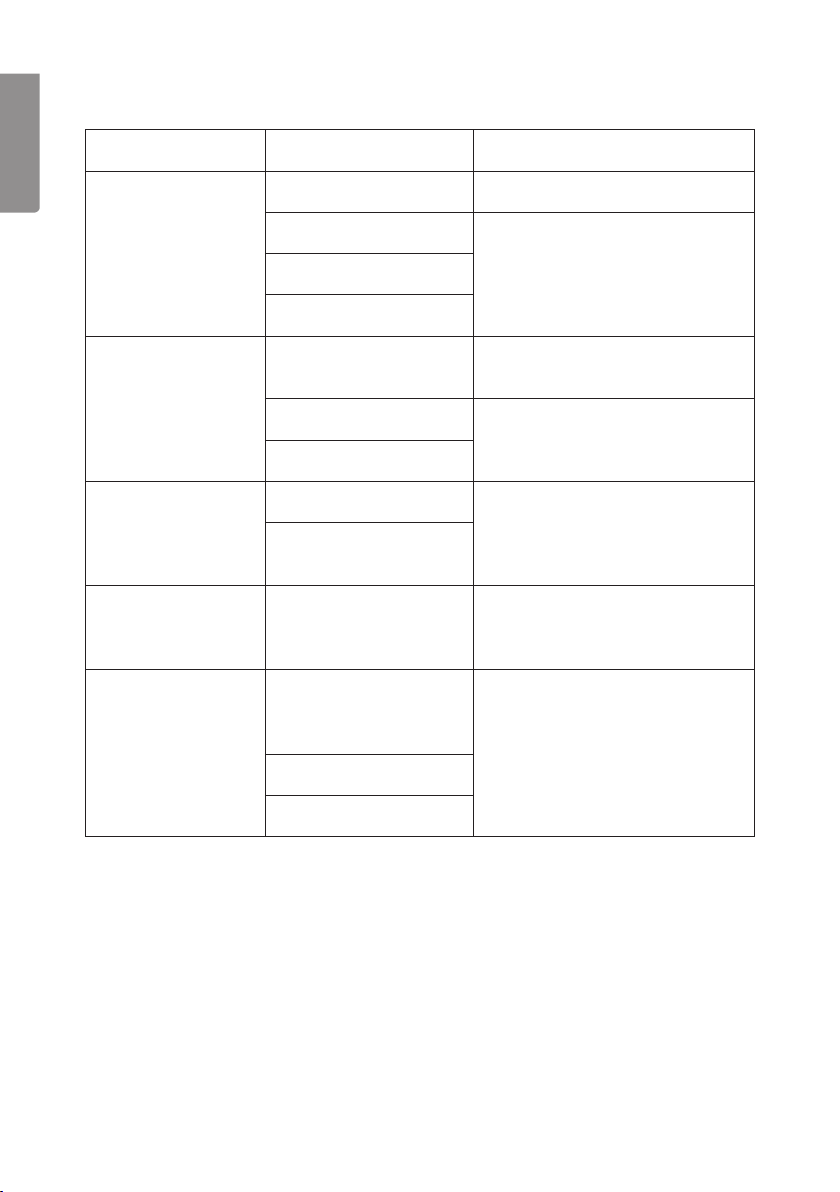

Adjustment of saw depth

1. Loosen the lock screw. (1)

2. Lower the foot to the desired depth.

3. Tighten lock screw.

1

10

Page 11

Adjustment of parallel guide

1. Loosen the lock screw (1).

2. For a 90° cut, read the scale up to the notch

A. For a 45° cut, read scale up to notch B.

Think about the width of the

saw cut. Tighten screw.

ENGLISH

1

B

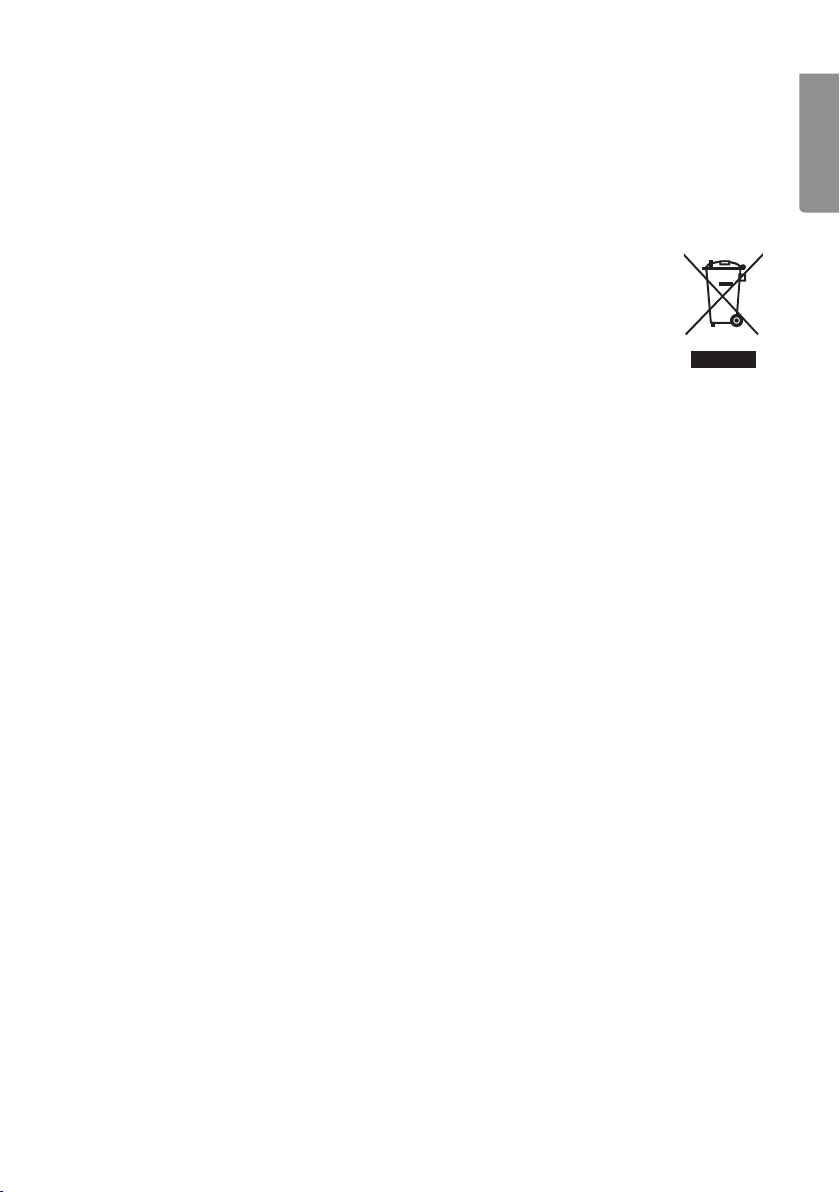

Replacing the saw blade

1. Lock the saw blade.

2. Unscrew the lock screw (1) using the allen

key (2) in the direction of the blade’s rotation

3. Push the saw guard back and hold firmly

with the manoeuvring lever (3).

4. Remove flange nut (4) and loosen

saw blade.

5. Insert new saw blade by performing

the above operations in reverse order.

6. Adjust the position of the riving knife

if necessary.

NOTE! Before restarting the saw after

changing the saw blade, check carefully

that it is correctly installed and that the lock

screw is tight.

Switching on and off

Start: Press in lock button (1) to enable

the power switch (2) to be pressed.

Stop: Release buttons.

A

3

1

4

2

2

1

11

Page 12

Troubleshooting chart

Problem Possible cause Action

ENGLISH

Appliance does not

start.

No power. Check that mains outlet is live.

Worn carbon brushes. Contact customer service if motor

or power switch defective.

Short circuit.

Defective power switch.

Appliance runs slow. Dull or damaged saw

blade.

Rpm too low. Feed with less force.

Motor is overheated.

Odd noise is heard. Mechanical obstruction. Contact customer service.

Winding partly short

circuited.

Strong vibrations. Saw blade is loose. See to it that saw blade is cor-

Sparks in motor. Carbon brushes are

stuck.

Winding short-circuited.

Commutator dirty.

Sharpen or replace saw blade.

rectly installed and tighten lock

screw on saw blade

Contact customer service.

12

Page 13

Care

- Keep the ventilation openings free of shavings and debris.

- Clean appliance regularly with washing-up detergent and soft cloth.

- Do not use solvents.

Disposal

Follow local ordinances when disposing of this product. If you are unsure

about how to dispose of this product contact your municipality.

Specifications

Power supply 230 V, 50 Hz

Capacity 900 W

Speed/dry run 4500 rpm

Saw depth at 90° 45 mm

Min. saw angle 45°

Saw blade 140/16 mm

Lpa (noise pressure level) 91.4 dB (A)

Lwa (noise power level) 102.4 dB (A)

Vibration value 0.4 m/s²

ENGLISH

13

Page 14

Cirkelsåg

Art.nr 18-3034 Modell M1Y-140-900A-UK

30-9166 M1Y-140-900A

Läs igenom hela bruksanvisningen före användning och spara den sedan för

framtida bruk. Vi reserverar oss för ev. text- och bildfel samt ändringar av tekniska

data. Vid tekniska problem eller andra frågor, kontakta vår kundtjänst (se adressuppgifter på baksidan).

M1Y-140-900A

SVENSK A

Generella säkerhetsinstruktioner

Varning! Läs alla instruktioner. Om nedanstående instruktioner inte följs kan detta

leda till elektrisk stöt, brand och/eller allvarlig skada. Termen ”elektriskt handverktyg”

i varningstexten nedan refererar till ditt nätanslutna eller batteridrivna handverktyg.

Spara dessa instruktioner!

1) Arbetsutrymmet

a) Håll arbetsutrymmet rent och väl upplyst. Belamrade och mörka utrymmen

inbjuder till olyckor.

b) Använd inte elektriska handverktyg i explosiva miljöer, som i närheten av

lättantändliga vätskor, gaser eller damm. Elektriska handverktyg genererar gnistor

som kan antända damm eller ångor.

c) Håll undan barn och åskådare medan du använder det elektriska handverktyget.

Störningsmoment kan göra att du tappar kontrollen.

2) Elektrisk säkerhet

a) Det elektriska handverktygets stickpropp måste passa i vägguttaget. Modifiera

aldrig stickproppen på något vis. Använd aldrig adapter tillsammans med jordade

elektriska handverktyg. Omodifierade stickproppar och passande vägguttag

minskar risken för elektrisk stöt.

b) Undvik kroppskontakt med jordade föremål, som rör, element, köksspis eller

kylskåp. Det finns ökad risk för elektrisk stöt om din kropp är jordad.

c) Utsätt inte det elektriska handverktyget för regn eller våta förhållanden.

Om vatten tränger in i ett elektriskt handverktyg ökar det risken för elektrisk stöt.

d) Misshandla inte nätsladden. Använd aldrig nätsladden för att bära, dra eller

rycka stickproppen ur vägguttaget. Håll nätsladden undan från värme, olja,

vassa kanter och rörliga delar. Skadade eller trassliga nätsladdar ökar risken

för elektrisk stöt.

e) När du använder ett elektriskt handverktyg utomhus, använd en skarvsladd

anpassad för detta ändamål. Användning av en skarvsladd för utomhusbruk

minskar risken för elektrisk stöt.

14

Page 15

3) Personlig säkerhet

a) Var uppmärksam på vad du gör och använd sunt förnuft när du använder ett

elektriskt handverktyg. Använd inte ett elektriskt handverktyg om du är trött eller

påverkad av droger, alkohol eller medicinering. Ett ögonblicks ouppmärksamhet

när du använder ett elektriskt handverktyg kan resultera i allvarlig personskada.

b) Använd skyddsutrustning. Bär alltid skyddsglasögon. Användning av

skyddsutrustning som andningsskydd, halksäkra skyddsskor, hjälm och

hörselskydd vid behov minskar risken för personskada.

c) Undvik oavsiktlig start. Se till att strömbrytaren är i läge ”OFF” innan du ansluter

stickproppen till vägguttaget. Att bära ett elektriskt handverktyg med ett finger på

strömbrytaren/avtryckaren eller att ansluta ett elektriskt handverktyg till elnätet när

strömbrytaren är i läge ”ON” inbjuder till olyckor.

d) Tag bort alla serviceverktyg/nycklar innan du slår på det elektriska handverktyget.

Ett kvarglömt serviceverktyg på en roterande del av det elektriska handverktyget

kan reslutera i personskada.

e) Sträck dig inte för långt. Se till att du står stadigt med god balans hela tiden.

Detta möjliggör bättre kontroll i oväntade situationer.

f) Bär lämplig klädsel. Bär inte löst sittande kläder eller smycken. Håll hår, kläder

och handskar undan från rörliga delar. Lösa kläder, smycken eller långt hår kan

fastna i rörliga delar.

g) Om utrustning för utsugning och uppsamling av damm finns tillgängligt, se till att

denna är ansluten och används ordentligt. Användning av dessa hjälpmedel kan

minska dammrelaterade faror.

SVENSK A

4) Användning och underhåll av det elektriska handverktyget

a) Pressa inte det elektriska handverktyget. Använd ett elektriskt handverktyg som

är avsett för det arbetsmoment du utför. Korrekt elektriskt handverktyg gör jobbet

bättre och säkrare med avsedd matningshastighet.

b) Använd inte det elektriska handverktyget om strömbrytaren inte slår på och

stänger av verktyget. Alla elektriska handverktyg som inte kan kontrolleras med

strömbrytaren är farliga och måste repareras.

c) Tag stickproppen ur vägguttaget innan du utför några justeringar, byter tillbehör

eller lägger undan det elektriska handverktyget för förvaring. Dessa åtgärder

i förebyggande syfte minskar risken för att starta det elektriska handverktyget

oavsiktligt.

d) Förvara elektriska handverktyg som inte används utom räckhåll för barn och låt

inte personer som inte är förtrogna med det elektriska handverktyget eller dessa

instruktioner använda det. Elektriska handverktyg är farliga om de kommer

i händerna på ovana användare.

15

Page 16

e) Underhåll elektriska handverktyg. Kontrollera om något är felinställt, om rörliga

delar kärvar, om delar har gått sönder eller något annat som kan påverka

funktionen av det elektriska handverktyget. Om något är skadat måste det

repareras före användning. Många olyckor beror på dåligt underhållna elektriska

handverktyg.

f) Håll verktygen vassa och rena. Ordentligt underhållna skärverktyg med vassa

eggar är mindre benägna att kärva och lättare att kontrollera.

g) Använd det elektriska handverktyget, tillbehör och liknande enligt instruktionerna

och på det sätt som är ämnat för just den typen av elektriskt handverktyg, och

ta även hänsyn till arbetsförhållandena och den typ av arbete som ska utföras.

SVENSK A

Användning av det elektriska handverktyget för arbeten andra än vad det är

ämnat för kan resultera i en farlig situation.

5) Service

a) Låt behörig personal utföra service och reparationer, endast med originalreserv-

delar. Detta garanterar att säkerheten på det elektriska handverktyget behålls.

Särskilda säkerhetsföreskrifter för cirkelsågar

FARA:

a) Håll händerna på avstånd från sågningsområdet och sågklingan. Håll andra

handen på det främre handtaget eller på höljet. Om du håller båda händer

i sågen kan du inte skära dig i handen.

b) Sträck dig inte under arbetsstycket. Skyddet skyddar dig inte från sågbladet

under arbetsstycket.

c) Justera skärdjupet så att det passar arbetsstyckets tjocklek. Mindre än hela

längden på sågklingans tänder ska synas under arbetsstycket.

d) Håll inte stycket som skall sågas i händerna eller över benen. Sätt fast

arbetsstycket på en stabil yta. Det är viktigt att arbetsstycket stöds på rätt sätt

för att minimera risk för personskada, att sågbladet kör fast eller att du förlorar

kontrollen över sågen.

e) Håll det elektriska handverktyget i de isolerade handtagen när du utför arbete

som medför risk att sågen kommer i kontakt med dolda kablar eller den egna

kabeln. Kontakt med en strömförande kabel gör att även utsatta metalldelar på

det elektriska handverktyget blir strömförande och användaren får en stöt.

f) Vid klyvsågning, använd sidoanslag eller raksågningsstycke. Detta förbättrar

precisionen på sågningen och minskar risken för att sågklingan fastnar.

g) Använd alltid sågklingor med rätt storlek och form (diamantformade eller runda).

Sågklingor som inte passar sågens fästdon rör sig excentriskt, vilket gör att du

kan förlora kontrollen över sågen.

16

Page 17

h) Använd aldrig skadade eller felaktiga brickor eller bultar. Brickorna och bultarna

för sågklingan är speciellt utformade för din såg för bästa prestanda och högsta

säkerhet vid användning.

Ytterligare säkerhetsinstruktioner för alla sågar

Anledningar till kast och förhindrande av kast:

• Kast är en plötslig reaktion på en klämd, fastkörd eller felinställd sågklinga

som gör att sågen på ett okontrollerat sätt lyfts upp och ur arbetsstycket mot

användaren.

• När sågklingan kläms eller körs fast genom att sågspåret stänger sig stannar

klingan och motorn gör att enheten kastas snabbt bakåt mot användaren.

• Om sågklingan blir vriden eller felriktad i spåret kan tänderna i den bakre delen

av klingan tränga in i ovansidan på träet, lämna sågspåret och kastas bakåt

mot användaren.

Kast är resultatet av att sågen används på fel sätt, för fel saker eller

under felaktiga förhållanden och kan undvikas genom att nedanstående

försiktighetsåtgärder vidtas.

a) Håll stadigt i sågen med båda händerna på sågen och håll armarna så att du

kan parera kast. Placera dig på endera sida om sågklingan, inte i linje med

sågklingan. Kast kan göra så att sågen hoppar bakåt, men kast kan kontrolleras

av användaren om nödvändiga försiktighetsåtgärder vidtas.

b) När sågklingan kör fast, eller om du av någon anledning avbryter sågningen,

släpp upp strömbrytaren och håll still sågen tills sågklingan stannar helt. Försök

aldrig att ta sågen från arbetsstycket eller dra sågen bakåt när sågklingan är

i rörelse, eftersom kast då kan inträffa. Undersök och vidta nödvändiga åtgärder

för att minska riskerna för fastkörning.

c) När du återstartar en såg i ett arbetsstycke, centrera sågklingan i sågspåret och

kontrollera att sågtänderna inte ligger an mot materialet. Om sågklingan har kört

fast kan den vandra upp eller sågen kan kastas från arbetsstycket när sågen

återstartas.

d) Stöd stora skivor för att minska risken för att sågklingan kläms eller att sågen

kastar. Stora skivor tenderar att bågna av sin egen vikt. Stöd måste placeras

under skivan på båda sidor, nära sågspåret och nära kanten på skivan.

e) Använd inte slöa eller skadade sågklingor. Oskärpta eller felinställda sågklingor

gör att sågspåret blir smalt, vilket ger för mycket friktion, sågklingan kan fastna

eller sågen kan kasta.

f) Reglagen för justering av sågdjup och sågvinkel måste vara åtdragna och

säkrade före sågning. Om justeringen för sågklingan ändras under sågning kan

den köra fast eller sågen kan kasta.

g) Var extra försiktig vid instickssågning i väggar eller andra föremål där du inte ser var

du sågar. Den utskjutande sågklingan kan såga i föremål som kan orsaka kast.

SVENSK A

17

Page 18

Säkerhetsinstruktioner för sågar med inre rörligt skydd

a) Kontrollera före varje användning att det nedre skyddet stängs ordentligt.

Använd inte sågen om det nedre skyddet inte rör sig fritt och stängs omedelbart.

Kläm eller bind aldrig fast det nedre skyddet i öppet läge. Om sågen av

misstag tappas kan det nedre skyddet bli böjt. Fäll upp det nedre skyddet med

handtaget och se till att det rör sig fritt utan att vidröra sågklingan eller någon

annan del vid sågning i samtliga sågvinklar och sågdjup.

b) Kontrollera att fjädern på det nedre skyddet fungerar. Om skyddet och fjädern

inte fungerar ordentligt måste service på dessa delar utföras före användning.

SVENSK A

Nedre skyddet kan röra sig trögt p.g.a. skadade delar, klibbiga avlagringar eller

ansamlat skräp.

c) Det nedre skyddet får föras undan manuellt endast vid speciell sågning som

instickssågning och sammansatt sågning. För undan det nedre skyddet med

handtaget, och så fort sågklingan har kontakt med materialet måste det nedre

skyddet släppas. För all annan sågning ska nedre skyddet fungera automatiskt.

d) Se alltid till att det nedre skyddet täcker sågklingan innan du lägger ifrån dig

sågen på en bänk eller ett golv. En oskyddad roterande sågklinga kan få sågen

att röra sig bakåt och såga i allt den kommer i kontakt med på vägen. Var

medveten om den tid det tar för sågklingan att stanna efter det att strömbrytaren

släppts upp.

Extra säkerhetsinstruktioner för alla sågar med klyvkniv

a) Använd klyvkniv anpassad för den sågklinga du använder. För att klyvkniven

ska fungera måste den vara tjockare än sågklingans kropp men tunnare än

tändernas skärbredd.

b) Justera klyvkniven enligt instruktionerna i denna bruksanvisning. Felaktigt

avstånd, felaktig position och riktning kan göra att klyvkniven inte kan förhindra

kast.

c) Använd alltid klyvkniven utom vid instickssågning. Klyvkniven måste monteras

tillbaka efter instickssågning. Klyvkniven stör vid instickssågning och kan

orsaka kast.

d) För att klyvkniven ska fungera måste den löpa i arbetsstycket. Klyvkniven kan

inte förhindra kast vid korta sågsnitt.

e) Använd inte sågen om klyvkniven är böjd. Även en liten defekt kan sakta ner

stängningshastigheten på ett skydd.

18

Page 19

• Spänn fast arbetsstycket om det inte ligger kvar av sin egen tyngd.

• Använd spånutsug vid användning av cirkelsågen.

• Bär alltid andningsskydd vid användning av cirkelsågen.

• Använd endast sågklingor som är avsedda för denna cirkelsåg.

• Bär alltid hörselskydd vid användning av cirkelsågen.

• Slip-/kapskivor får ej användas till denna cirkelsåg.

• Byte av stickpropp eller sladd skall alltid utföres av en serviceverkstad.

Produktmärkning med säkerhetssymboler

Läs hela bruksanvisningen!

Använd alltid hörselskydd.

Använd alltid skyddsglasögon.

SVENSK A

19

Page 20

Beskrivning

1. Handtag

2. Märkskylt

3. Strömbrytare

4. Låsknapp för strömbrytare

5. Låsskruv för djupinställning

SVENSK A

6. Kabel

7. Klingskydd

8. Skruv för sågklinga

9. Basplatta

10. Klingfläns

11. Sågklinga

12. Parallellanslag

13. Låsskruv för parallellanslag

14. Skruv för vinkelinställning

15. Anslutning för spånsugning

16. Främre handtag

17. Manöverspak för klingskydd

18. Klyvkniv

2

15 17 7 1 16

4 3

5

6

14

Tillbehör

- Parallellanslag

- Insexnyckel

- Sågklinga 140/16

9

18

8 10 11 12 13

20

Page 21

Inställningar och underhåll

Viktigt!

Drag stickkontakten ur vägguttaget innan du gör inställningar och underhåll.

Inställning av klyvkniv

1. Lossa båda skruvarna (1) som håller

klyvkniven.

2. Skjut sågskyddet bakåt och håll fast

det med manöverspaken.

3. Ställ in klyvkniven med max. 5 mm

avstånd till sågklingan.

4. Sågklingan får ej sticka ut mer än

5 mm i djupled från klyvknivens kant.

5. Drag åt båda skruvarna.

6. Kontrollera att klyvkniven står

i linje med sågklingan.

Inställning av sågvinkel

1. Lossa låsskruven.

2. Ställ in önskad vinkel

mellan 0-45°.

3. Drag åt låsskruven.

SVENSK A

Inställning av sågdjup

1. Lossa låsskruven. (1)

2. Sänk basplattan till önskat

sågdjup.

3. Drag åt låsskruven.

1

21

Page 22

Inställning av parallellanslag

1. Lossa låsskruven (1).

2. För 90° sågsnitt, läs skalan mot uttag A. Vid

45° sågning, läs skalan mot uttag B. Tänk på

sågklingans skärbredd. Dra åt skruven.

1

SVENSK A

Byte av sågklinga

1. Lås fast sågklingan.

2. Skruva ur låsskruven (1) i klingans

rotationsriktning med insexnyckeln (2).

3. Skjut sågskyddet bakåt och håll fast

det med manöverspaken (3).

4. Tag bort flänsbrickan (4) och lossa

sågklingan.

5. Sätt dit en ny sågklinga genom att utföra

ovanstående moment omvänt.

6. Justera vid behov klyvknivens läge.

OBS! Innan sågen startas efter byte av sågklingan, kontrollera noggrant att den är rätt

monterad och att låsskruven är åtdragen.

3

1

2

B

A

4

Till- och frånkoppling

Start: Tryck in låsknappen (1) för att

kunna trycka in strömbrytaren (2).

Stopp: Släpp knapparna.

2

1

22

Page 23

Felsökningsschema

Problem Möjlig orsak Åtgärd

Maskinen går inte. Ingen ström. Kontrollera att uttaget är

strömförande.

Slitna kolborstar. Kontakta kundtjänst.

Kortslutning

Fel på strömbrytaren.

Maskinen går

sakta.

Ovanliga ljud hörs. Mekaniska hinder. Kontakta kundtjänst.

Starka vibrationer. Sågklingan sitter löst. Se till att sågklingan är rätt

Gnistbildning

i motorn.

Slö eller skadad sågklinga. Slipa om sågklingan eller

byt ut den.

För lågt varvtal. Mata inte så hårt.

Motorn är överhettad.

Lindning delvis kortsluten.

installerad och drag åt sågklingans låsskruv.

Fastnade kolborstar. Kontakta kundtjänst.

Lindning kortsluten.

Kollektorn smutsig.

SVENSK A

23

Page 24

Skötsel

• Håll alltid ventilationsöppningarna fria från spån och skräp.

• Rengör maskinerna regelbundet med diskmedel och mjuk trasa.

• Använd inga lösningsmedel.

Avfallshantering

SVENSK A

När du ska göra dig av med produkten ska detta ske enligt lokala

föreskrifter. Är du osäker på hur du ska gå tillväga, kontakta din kommun.

Specifikationer

Strömförsörjning 230 V, 50 Hz

Effekt 900 W

Varvtal obelastad 4500 varv/minut

Sågdjup vid 90° 45 mm

Min. sågvinkel 45°

Sågklinga 140/16 mm

Lpa (bullernivå) 91,4 dB (A)

Lwa (bullereffekt) 102,4 dB (A)

Vibrationsvärde 0,4 m/s²

24

Page 25

Sirkelsag

Artikkelnummer 18-3034 Modell M1Y-140-900A-UK

30-9166 M1Y-140-900A

Les nøye igjennom hele bruksanvisningen og ta vare på den til senere bruk.

Vi reserverer oss mot ev. tekst- og bildefeil, samt forandringer av tekniske data.

Ved tekniske problemer eller andre spørsmål, ta kontakt med vårt kundesenter

(se opplysninger på baksiden).

Generelle sikkerhetsinstruksjoner

Advarsel! Les alle instruksjonene grundig. Dersom instruksjonene ikke følges,

kan dette lede til brann, elektrisk støt og/eller alvorlig skade. Med begrepet

”elektriske håndverktøy” i teksten under, menes strømtilkoblede håndverktøy.

TA VARE PÅ DENNE INSTRUKSJONEN!

1) Arbeidsplassen

a) Hold arbeidsplassen ren, ryddig og godt opplyst. Rotete arbeidsplass eller dårlig

opplyste områder kan føre til ulykker.

b) Bruk ikke elektriske håndverktøy i omgivelser med eksplosjonsfare, som for

eksempel i nærheten av lettantennelige væsker, gasser eller støv. Elektrisk

håndverktøy kan danne gnister som igjen kan antenne støv eller trespon.

c) Hold barn og andre tilskuere unna mens du bruker elektriske håndverktøy.

Du kan lett miste kontrollen dersom du blir forstyrret mens du arbeider.

NOR SK

2) Sikkerhet ved bruk av elektrisk strøm

a) Strømkabelens støpsel, til det elektriske verktøyet, må passe i vegguttaket.

Støpselet må ikke forandres på. Bruk aldri adapter sammen med elektrisk

håndverktøy som krever jording. Ved bruk av originale kontakter og støpsler

minskes faren for elektrisk støt.

b) Unngå kroppskontakt med jordede gjenstander som rør, ovner, komfyrer og

kjøleskap. Kroppskontakt med disse øker faren for elektrisk støt.

c) Elektrisk håndverktøy bør ikke utsettes for regn eller fuktighet. Hvis det kommer

vann inn i et elektrisk håndverktøy, øker faren for elektrisk støt.

d) Håndter strømkabelen med forsiktighet. Den må ikke bli brukt til å bære

verktøyet med. Dra ikke i kabelen når du skal ha stikket ut av kontakten. Hold

kabelen unna varme, olje, skarpe kanter og bevegelige deler. Skadde eller

deformerte støpsler kan øke faren for elektrisk støt.

e) Ved bruk av elektrisk håndverktøy utendørs, skal det benyttes skjøtekabel som

er beregnet til dette formålet. Når skjøtekabel som er beregnet for utendørs bruk

benyttes, minsker faren for elektrisk støt.

25

Page 26

3) Personlig sikkerhet

a) Vær våken og bruk sunn fornuft når du bruker et elektrisk verktøy. Ikke bruk

elektriske håndverktøy når du er trett eller påvirket av rusmidler, alkohol eller

sterke medisiner. Når du bruker elektrisk håndverktøy, kan et lite øyeblikk med

uoppmerksomhet resultere i store personskader.

b) Bruk verneutstyr. Benytt alltid vernebriller. Bruk av verneutstyr som støvmaske,

sklisikre såler på skoene, hjelm og hørselsvern, ved behov, minsker faren for

personskade.

c) Unngå uønsket oppstart. Påse at strømbryteren står i posisjon ”OFF” før du

kobler til strømmen. Det å bære et elektrisk håndverktøy med en finger på

avtrekkeren/strømbryteren, eller å koble til strømmen når strømbryteren står

i posisjon ”ON”, kan forårsake ulykker.

d) Fjern alle nøkler/serviceverktøy før du starter det elektriske håndverktøyet.

Et gjenglemt serviceverktøy på en roterende del, kan forårsake personskader.

e) Strekk deg ikke for langt. Påse at du står støtt og har god balanse hele tiden.

NOR SK

Da er du bedre forberedt når uventede situasjoner oppstår.

f) Benytt fornuftige arbeidsklær. Ikke bruk løstsittende klær og smykker. Hold klær,

hansker og smykker unna bevegelige deler. Løstsittende klær, smykker eller langt

hår, kan sette seg fast i bevegelige deler.

g) Hvis det er mulig å koble til en støvsamler/støvsuger, bør dette gjøres. Ved bruk

av sådanne hjelpemidler, kan en minske faren for støvrelaterte skader og ulykker.

4) Bruk og vedlikehold av elektrisk håndverktøy

a) Ikke press et elektrisk håndverktøy. Bruk elektriske håndverktøy som er beregnet

til den arbeidsoperasjonen du skal utføre. Riktig innmatings-hastighet er viktig for

å utføre bedre og sikrere arbeide.

b) Ikke bruk det elektriske håndverktøyet dersom ikke strømbryteren virker og

verktøyet kan skrues av. Alle elektriske håndverktøy, som ikke kan kontrolleres

med en strømbryter, er farlige og må repareres.

c) Dra ut støpselet før du utfører justeringer, bytter tilbehør eller legger det elektriske

håndverktøyet fra deg. Dette for å unngå at elektrisk håndverktøy får en

ukontrollert start.

d) Oppbevar elektrisk håndverktøy utilgjengelig for barn. Påse også at elektrisk

håndverktøy er utilgjengelig for personer som ikke har fått tilstrekkelig opplæring

på eller er fortrolig med verktøyet. Elektrisk håndverktøy kan være farlige dersom

de kommer i hendene på ukyndige.

e) Vedlikehold av elektrisk håndverktøy. Påse at verktøyet ikke er feilinnstilt, at

bevegelige deler ikke beveger seg usymmetrisk, at ingen deler er skadet eller at

det elektriske håndverktøyet har andre feil, som kan påvirke verktøyets funksjon.

Dersom noe er skadet må dette repareres før verktøyet tas i bruk. Mange ulykker

skyldes dårlig eller manglende vedlikehold.

26

Page 27

f) Hold verktøyet rent. Påse også at det elektriske verktøyet holdes skarpt. Godt

vedlikeholdt skjæreverktøy, med skarpe egger, er lettere å kontrollere.

g) Følg instruksjonen, ta hensyn til arbeidsforholdene og den type arbeide som skal

utføres. Bruk av elektrisk håndverktøy til andre arbeidsoperasjoner enn det det er

beregnet til, kan skape farlige situasjoner.

5) Service

a) La profesjonelle fagfolk utføre service og reparasjoner. Benytt kun originale

reservedeler. Dette for å opprettholde sikkerheten ved bruk av det elektriske

håndverktøyet.

Spesielle sikkerhetsforskrifter for sirkelsager

FARE:

a) Hold hendene på avstand fra sagingsområdet og sagklingen. Hold andre hånden

på det fremre håndtaket eller på dekslet. Dersom du holder sagen med begge

hendene, reduseres faren for skade på hendene.

b) Strekk deg ikke under arbeidsstykket. Beskyttelsen beskytter deg ikke fra

sagbladet under arbeidsstykket.

c) Juster skjæredybden så det passer arbeidsstykkets tykkelse. Mindre enn hele

lengden på sagklingens tenner skal sees under arbeidsstykket.

d) Hold ikke stykket som skal sages i hendene eller over beina. Sett fast

arbeidsstykket på en stabil flate. Det er viktig at arbeidsstykket støttes på riktig

måte for å minimere risikoen for personskade, at sagbladet kjører seg fast eller

at du mister kontrollen over sagen.

e) Hold det elektriske håndverktøyet i de isolerte håndtakene når du utfører arbeide

som medfører risiko for at sagen kommer i kontakt med skjulte kabler eller sin

egen kabel. Kontakt med en strømførende kabel gjør at selv utsatte metalldeler

på det elektriske håndverktøyet blir strømførende og brukeren får støt.

f) Ved kløyvesaging, bruk sideanslag eller rettsagingsstykke. Dette forbedrer

presisjonen på sagingen og minsker risikoen for at sagklingen setter seg fast.

g) Bruk alltid sagklinger med rett størrelse og form (diamantformete eller runde).

Sagklinger som ikke passer sagens feste vil bevege seg merkelig, dette gjør

at du kan miste kontrollen over sagen.

h) Bruk aldri skadde eller feil skiver eller bolter. Skivene og boltene tilsagklingen

er spesielt utformet for din sag for best mulig presisjon og høyest sikkerhet

ved bruk.

NOR SK

27

Page 28

Ytterligere sikkerhetsinnstruksjoner for alle sager

Grunner til kast og hvordan man skal forhindre kast

• Kast er en plutselig reaksjon på en klemt, fastkjørt eller feil innstilt sagklinge som

gjør at sagen ukontrollert løftes opp og ut av arbeidsstykket mot brukeren.

• Når sagklingen klemmes eller kjøres fast ved at sagsporet stenger seg, stopper

klingen og motoren gjør at enheten kastes raskt bakover mot brukeren.

• Dersom sagklingen blir vridd eller feilrettet i sporet kan tennene i den bakre delen

av klingen trenge inn på oversiden av treet, forlate sagsporet og kastes bakover

mot brukeren.

Kast er resultatet av at sagen brukes på feil måte, for feil arbeide eller under feil

forhold og kan unngås ved å følge nedenforstående forsiktighetstiltak brukes.

a) Hold godt tak i sagen med begge hendene på sagen og hold armene så du

kan parere kast. Plasser deg på den ene siden av sagklingen, ikke i linje med

NOR SK

sagklingen. Kast kan gjøre så sagen hopper bakover, men kast kan kontrolleres

hvis nødvendige tiltak tas i bruk.

b) Når sagklingen kjører seg fast, eller hvis du av noen anledning avbryter sagingen,

slipp opp strømbryteren og hold sagen i ro til sagklingen stopper helt. Prøv aldri

å ta sagen fra arbeidsstykket eller dra sagen bakover når sagklingen er i bevegelse, fordi da kan kast inntreffe. Undersøk og foreta nødvendige tiltak for å minske

risikoen for å kjøre seg fast

c) Når du starter opp igjen en sag i et arbeidsstykke, sentrèr sagklingen i sagsporet

og kontroller at sagtennene ikke ligger an mot materialet. Dersom sagklingen har

kjørt seg fast kan den vandre opp eller sagen kan kastes fra arbeidsstykket når

sagen startes på nytt.

d) Støtt store plater for å minske risikoen for at sagklingen klemmes eller at sagen

kaster. Store plater har en tendens til å bue seg på grunn av sin egen vekt. Støtte

må plasseres under platen på begge sider, nær sagsporet og nær kanten på

skiven.

e) Bruk ikke sløve eller skadde sagklinger. Uskarpe eller feilinstilte sagklinger gjør at

sagsporet blir smalt, hvilket gir for mye friksjon, sagklingen kan sette seg fast eller

sagen kan kaste.

f) Spaken for justering av sagdybde og sagvinkel må være dratt til og sikret før

saging. Dersom justeringen av sagklingen endres under saging kan den kjøre seg

fast eller sagen kan kaste.

g) Vær ekstra forsiktig ved innstikksaging i vegger eller andre gjenstander der du

ikke ser hvor du sager. Den utsstikkende sagklingen kan sage i gjenstander som

kan forårsake kast.

28

Page 29

Sikkerhetsinstruksjoner for sager med indre bevegelig

beskyttelse

a) Kontroller før hver gangs bruk at den nedre beskyttelsen stenges ordentlig. Bruk

ikke sagen hvis den ikke beveger seg fritt eller stenges umiddelbart. Klem eller

bind aldri fast den nedre beskyttelsen i åpen posisjon. Hvis sagen ved en feiltakelse mistes kan den nedre beskyttelsen bli bøyd. Trekk opp den nedre beskyttelsen med håndtaket og pass på at det beveger seg fritt uten å berøre sagklingen

eller noen annen del ved saging i samtlige sagvinkler og sagdybder.

b) Kontroller at fjæren på den nedre beskyttelsen fungerer. Dersom beskyttelsen og

fjæren ikke fungerer ordentlig må service på disse delene utføres før bruk. Den

nederste beskyttelsen kan bevege seg tregt p.g.a. skadede deler, klebrige avlagringer eller oppsamlet støv.

c) Den nedre beskyttelsen skal føres bort manuelt kun ved spesiell saging som

innstikkssaging og sammensatt saging. Før bort den nedre beskyttelsen med

håndtaket, og så fort sagklingen har kontakt med materialet må den nedre beskyttelsen slippes. For all annen saging skal den nedre beskyttelsen fungere automatisk.

d) Pass alltid på at den nedre beskyttelsen dekker sagklingen før du legger fra deg

sagen på en benk eller et gulv. En ubeskyttet roterende sagklinge kan få sagen til

å røre seg bakover og sage i alt den kommer i kontakt med på veien. Vær bevisst

på den tiden det tar for sagklingen å stoppe etter at strømbryteren slippes opp.

Ekstra sikkerhetsinstruksjoner for alle sager med kløyvekniv

a) Bruk kløyvekniv tilpasset den sagklingen du bruker. For at kløyvekniven skal

fungere må den være tykkere enn sagklingens kropp men tynnere enn tennenes

skjærebredde.

b) Juster kløyvekniven i henhold til innstruksjonene i denne bruksanvisning. Feil

avstand, feil posisjon og retning kan gjøre at kløyvekniven ikke kan forhindre kast.

c) Bruk alltid kløyvekniven bortsett fra ved innstikkssaging. Kløyvekniven må

monteres tilbaka etter instikkssaging. Kløyvekniven forstyrrer ved instikkssaging

og kan forårsake kast.

d) For at kløyvekniven skal fungere må den løpe i arbeidsstykket. Kløyvekniven kan

ikke forhindre kast ved korte sagsnitt.

e) Bruk ikke sagen dersom kløyvekniven er bøyd. Selv en liten defekt kan senke

stengningshastigheten på en beskyttelse.

NOR SK

29

Page 30

• Spenn fast arbeidsstykket hvis det ikke ligger stødig av sin egen tyngde.

• Bruk sponavsug ved bruk av sirkelsagen.

• Bær alltid støvmaske ved bruk av sirkelsagen.

• Bruk kun sagklinger som er beregnet for denne sirkelsagen.

• Bær alltid hørselsvern ved bruk av sirkelsagen.

• Slipe-/kappeskiver skal ikke brukes til denne sirkelsagen.

• Bytte av støpsel eller ledning skal alltid utføres av et serviceverksted.

Produktmerking med sikkerhetssymboler

Les bruksanvisningen.

Bruk hørselsvern.

NOR SK

Bruk vernebriller/visir.

30

Page 31

Beskrivelse

1. Håndtak

2. Merkeskilt

3. Strømbryter

4. Låseknapp for strømbryter

5. Låseskrue for dybdeinnstilling

6. Kabel

7. Klingevern

8. Skrue for sagklinge

9. Grunnplate

10. Flensbrikke

11. Sagblad

12. Parallellanhold

13. Låseskrue for parallellanhold

14. Skrue for vinkelinnstilling

15. Tilkobling for sponsuging

16. Fremre håndtak

17. Manøverspak for klingevern

18. Kløyvekniv

4 3

2

5

6

NOR SK

15 17 7 1 16

14

Tilbehør

• Parallellanhold

• Insexnøkkel

• Sagklinge 140/16

9

18

8 10 11 12 13

31

Page 32

Innstillinger og vedlikehold

Viktig!

Trekk støpselet ut fra vegguttaket før du foretar innstillinger og vedlikehold.

Innstiling av kløyvekniv

1. Løsne begge skruene (1) som holder

kløyvekniven.

2. Skyv sagbeskyttelsen bakover og hold

den med manøverspaken.

3. Still inn kløyvekniven med maks. 5 mm

avstand til sagklingen.

4. Sagklinken må ikke stikke mer en 5 mm

ut i dybden, fra klyveknivens kant.

NOR SK

5. Dra begge skruene ut.

6. Kontroller at kløyvekniven

står på linje med sagklingen.

Innstilling av sagevinkel

1. Løsne låseskruen.

2. Still inn ønsket vinkel mellom

0-45˚.

3. Dra til låseskruen.

Innstilling av sagedybde

1. Løsne låseskruen (1).

2. Senk grunnplaten til ønsket

sagedybde.

3. Skru til låseskruen.

1

32

Page 33

Innstilling av parallellanhold

1. Løsne låseskruen (1).

2. For 90˚ sagesnitt, les skalaen mot uttak A.

Ved 45˚ saging, les skalaen mot uttak B.

Vær oppmerksom på sagklingens skjærebredde. Dra til skruen.

1

Bytte av sagklinge

1. Lås sagklingen.

2. Skru ut låseskruen (1) i klingens rotasjonsretning med insexnøkkelen (2).

3. Skyv sagvernet bakover og hold det fast

med manøverspaken.

4. Fjern flensbrikken (4) og løsne sagklingen.

5. Sett på en ny sagklinge ved å utføre momentene over i motsatt rekkefølge.

6. Juster kløyveknivens posisjon etter behov.

OBS! Før sagen startes etter bytte av sagklingen, må det kontrolleres at klingen er

riktig montert og at låseskruen er dratt til!

Til- og frakobling

Start: Trykk inn låseknappen (1) for å kunne

trykke inn strømbryteren (2).

Stopp: Slipp knappene.

B

A

3

NOR SK

1

4

2

2

1

33

Page 34

Feilsøkingsskjema

Problem Mulig årsak Tiltak

Maskinen går ikke. Ingen strøm. Kontroller at uttaket er

strømførende.

Slitne kullbørster.

Kortslutning.

Feil på strømbryteren.

Maskinen går sakte. Sløv eller skadet sag-

klinge.

NOR SK

Uvanlige lyd fra motor. Mekaniske hinder. Kontakt kundetjenesten.

Sterke vibrasjoner. Sagklingen sitter løst. Påse at sagklingen er riktig

Gnistdannelse i

motoren.

For lavt turtal. Mat ikke så hardt.

Motoren er overopphetet.

Spole delvis kortsluttet.

Kullbørstene sitter fast. Kontakt kundetjenesten.

Spole kortsluttet.

Kollektoren er skitten.

Kontakt kundetjenesten.

Slip opp sagklingen eller

bytt den ut.

montert og at sagklingens

låseskrue er dratt til.

34

Page 35

Vedlikehold

• Hold alltid ventilasjonsåpningene åpne og fri for rusk og spon.

• Rengjør maskinen regelmessig med lett fuktet klut/fille (bruk kun mildt

rengjøringsmiddel).

• Bruk aldri løsningsmiddel på maskinen.

Avfallshåndtering

Når du skal kvitte deg med produktet skal dette skje i henhold til

lokale forskrifter. Er du usikker på hvordan du skal gå fram ta kontakt

med din kommune.

Spesifikasjoner

Strømforsyning 230 V, 50 Hz

Effekt 900 W

Turtall ubelastet 4500 o/min

Sagedybde vid 90° 45 mm

Min. sagevinkel 45°

Sagklinge 140/16 mm

Lpa (Støynivå) 91,4 dB (A)

Lwa (Støyeffekt) 102,4 dB (A)

Vibrasjonsverdi 0,4 m/s²

NOR SK

35

Page 36

Pyörösaha

Tuotenro. 18-3034 Modell M1Y-140-900A-UK

30-9166 M1Y-140-900A

Pidätämme oikeuden teknisten tietojen muutoksiin. Emme vastaa mahdollisista

teksti- tai kuvavirheistä. Jos laitteeseen tulee teknisiä ongelmia, ota yhteys myymälään tai asiakaspalveluun (yhteystiedot käyttöohjeen lopussa).

Yleisiä turvallisuusohjeita

Varoitus! Lue kaikki ohjeet. Seuraavien ohjeiden noudattamatta jättäminen

saattaa johtaa sähköiskuun, tulipaloon ja/tai vakavaan onnettomuuteen. Varoitustekstien termi ”sähkökäyttöinen käsityökalu” tarkoittaa sinun verkkovirralla

tai paristoilla/akulla toimivaa käsityökaluasi. Säästä nämä ohjeet!

1) Työtila

a) Pidä työtilat puhtaina ja hyvin valaistuina. Täynnä tavaraa olevat ja pimeät tilat

ovat avoin kutsu onnettomuudelle.

b) Älä käytä sähkökäyttöisiä käsityökaluja räjähdysherkässä ympäristössä,

kuten helposti syttyvien nesteiden, kaasujen tai pölyn lähellä. Sähkökäyttöiset

käsityökalut muodostavat kipinöitä, jotka saattavat sytyttää pölyn tai höyryt.

SUOMI

c) Pidä lapset ja vierailijat loitolla, kun käytät sähkökäyttöisiä käsityökaluja.

Häiriötekijät saattavat johtaa laitteen hallinnan menettämiseen.

2) Sähköturvallisuus!

a) Sähkökäyttöisen käsityökalun pistokkeen tulee sopia pistorasiaan. Älä muuta

tuotetta millään tavalla. Älä käytä adapteria maadoitettujen sähkökäyttöisten

sähkötyökalujen kanssa. Pistokkeet, joita ei ole muutettu sekä sopivat pistorasiat

pienentävät sähköiskun vaaraa.

b) Vältä koskettamasta maadoitettuja esineitä, kuten putkia, lämpöpattereita, hellaa

tai jääkaappia. Sähköiskun riski kasvaa, mikäli kehosi on maadoitettu.

c) Älä altista sähkökäyttöistä käsityökalua sateelle, äläkä käytä sitä kosteissa

olosuhteissa. Veden joutuminen sähkökäyttöiseen käsityökaluun lisää

sähköiskun vaaraa.

d) Käsittele sähköjohtoa varoen. Älä käytä sähköjohtoa laitteen kantamiseen,

äläkä irrota pistoketta pistorasiasta johdosta vetämällä. Älä altista virtajohtoa

kuumuudelle, öljyille, teräville reunoille tai liikkuville osille. Vioittuneet tai

sotkeutuneet virtajohdot lisäävät sähköiskun vaaraa.

36

Page 37

e) Kun käytät sähkökäyttöistä käsityökalua ulkona, käytä ainoastaan ulko-käyttöön

sopivia jatkojohtoja. Ulkokäyttöön sopivan jatkojohdon käyttäminen pienentää

sähköiskun vaaraa.

3) Oma turvallisuutesi

a) Ole huolellinen ja käytä tervettä järkeä kun työskentelet sähkökäyttöisellä käsityö-

kalulla. Älä käytä sähkökäyttöistä käsityökalua, mikäli olet väsynyt tai huumeiden,

lääkkeiden tai alkoholin vaikutuksen alaisena. Lyhyenkin hetken kestävä tarkkaavaisuuden herpaantuminen saattaa johtaa vakavaan loukkaantumiseen.

b) Käytä suojavarusteita. Käytä aina suojalaseja. Suojavarusteiden, kuten hengitys-

suojaimen, liukuestekenkien, kypärän ja kuulosuojaimien käyttäminen vähentää

loukkaantumisvaaraa.

c) Vältä tahatonta käynnistystä. Varmista, että virtakytkin on asennossa ”OFF” en-

nen kuin liität pistokkeen seinäpistorasiaan. On äärimmäisen vaarallista kantaa

sähkökäyttöistä käsityökalua sormi liipaisimella tai liittää sähkökäyttöinen käsityökalu pistorasiaan virtakytkimen ollessa ”ON”-asennossa.

d) Poista kaikki huoltotyökalut/avaimet ennen kuin käynnistät sähkökäyttöisen käsi-

työkalun. Sähkökäyttöisen käsityökalun liikkuvan osan päälle unohdettu työkalu

saattaa johtaa onnettomuuteen.

e) Älä kurota liian kauas. Varmista, että työasentosi on tasapainoinen työn jokai-

sessa vaiheessa. Näin olet paremmin varustautunut mahdollisen onnettomuuden

sattuessa.

f) Käytä sopivia vaatteita. Älä käytä löysiä vaatteita tai koruja. Pidä hiukset, vaatteet

ja käsineet loitolla liikkuvista osista. Löysät vaatteet, korut tai pitkät hiukset saattavat juuttua liikkuviin osiin.

g) Jos käytössäsi on pölynpoistojärjestelmä, käytä sitä. Näiden apuvälineiden käyttö

saattaa vähentää pölyyn liittyviä vaaroja.

SUOMI

4) Sähkökäyttöisten käsityökalujen käyttäminen ja

huoltaminen

a) Älä pakota sähkökäyttöistä käsityökalua. Käytä sähkökäyttöistä käsityökalua, joka

soveltuu suunnittelemaasi työtehtävään. Sopiva sähkökäyttöinen käsityökalu tekee työn paremmin ja turvallisemmin oikealla nopeudella.

b) Älä käytä sähkökäyttöistä käsityökalua, mikäli virtakytkin ei käynnistä ja sammuta

laitetta. Kaikki sähkökäyttöiset käsityökalut, joita ei voida hallita virtakytkimellä,

ovat vaarallisia ja ne tulee korjata.

c) Irrota pistoke pistorasiasta ennen kuin teet sähkökäyttöiseen käsityökaluun sää-

töjä tai ennen kuin vaihdat sen varusteita tai ennen kuin asetat sen säilytykseen.

Nämä ennaltaehkäisevät toimenpiteet vähentävät sähkökäyttöisen käsityökalun

tahatonta käynnistymistä.

37

Page 38

d) Säilytä sähkökäyttöisiä käsityökaluja lasten ulottumattomissa. Älä luovuta säh-

kökäyttöistä käsityökalua henkilöille, jotka eivät tunne sitä tai sen käyttöohjetta.

Sähkökäyttöiset käsityökalut ovat vaarallisia tottumattomien käyttäjien käsissä.

e) Huolla sähkökäyttöisiä käsityökaluja. Tarkasta, että säädöt ovat kunnossa, että

liikkuvat osat liikkuvat esteettä, että osat ovat ehjiä, ja että sähkökäyttöisessä käsityökalussa ei ole muita seikkoja, jotka vaikuttavat laitteen toimintaan. Jos jokin

osa on vioittunut, se tulee korjata ennen käyttöä. Monet onnettomuudet johtuvat

väärin hoidetuista sähkökäyttöisistä käsityökaluista.

f) Pidä työkalut puhtaina ja terävinä. Terätyökalun hallinta on helpompaa, kun se on

oikein hoidettu ja sen terät ovat teräviä.

g) Käytä sähkökäyttöistä käsityökalua, sen varusteita tms. ohjeiden mukaisesti ja

sellaisella tavalla, joka sopii kyseiselle sähkökäyttöiselle käsityökalulle ja ota myös

huomioon työskentelyolosuhteet ja suoritettava työ. Sähkökäyttöisen käsityökalun

käyttäminen muihin kuin sille tarkoitettuihin työtehtäviin saattaa johtaa vaaratilanteeseen.

5) Huolto

a) Laitteen saa huoltaa ja korjata ainoastaan ammattihenkilö ja huollossa tulee

käyttää ainoastaan alkuperäisosia. Näin taataan sähkökäyttöisen käsityökalun

turvallisuus.

SUOMI

Pyörösahaa koskevia turvallisuusohjeita

VAARA:

a) Pidä kädet poissa sahausalueelta ja sahanterästä. Pidä toista kättä etukahvalla tai

rungon päällä. Kun pidät sahasta kiinni molemmin käsin, et voi sahata kättäsi.

b) Älä kurkota sahattavan kappaleen alle. Suoja ei suojaa sinua sahanterältä sahat-

tavan kappaleen alapuolelta.

c) Säädä leikkuusyvyys sahattavan kappaleen mukaan. Sahanterä ei saa pistää ulos

sahattavan kappaleen alta kokonaista hampaan pituutta.

d) Älä pidä kiinni sahattavasta kappaleesta käsin, äläkä pidä sahattavaa kappaletta

jalkojesi päällä. Kiinnitä työkappale tasaiselle ja vakaalle pinnalle. Työkappaleen

oikea kiinnittäminen on hyvin tärkeää henkilövahinkoriskien pienentämisen kannalta. Huonosti kiinnitetty työkappale lisää myös sahanterän juuttumisen tai sahan

hallinnan menettämisen riskiä.

e) Pidä kiinni sahan eristetyistä kahvoista, kun työskentelet paikoissa, joissa on

mahdollisuus osua piilossa oleviin sähköjohtoihin tai sahan omaan virtajohtoon.

Osuminen virtaa johtavaan kaapeliin johtaa siihen, että myös sahan metalliosista

tulee jännitteisiä, mikä aiheuttaa käyttäjälle sähköiskun.

38

Page 39

f) Halkaisussa tulee käyttää sivuohjainta tai sahausohjainta. Tämä parantaa

sahauksen tarkkuutta ja pienentää sahanterän juuttumisriskiä.

g) Käytä aina oikean kokoista ja muotoista sahanterää (timantinmuotoinen tai

pyöreä). Sahan käyttöakseliin sopimaton terä pyörii epäkeskeisesti, mikä saattaa

aiheuttaa sahanhallinnan menettämisen.

h) Älä käytä vioittuneita tai vääränlaisia aluslaattoja tai pultteja. Sahanterän aluslaatat

ja pultit on suunniteltu erityisesti juuri tähän sahaan, ja ne takaavat sahan

turvallisen käytön.

Yleisiä sahan turvallisuusohjeita

Mistä takapotku aiheutuu ja miten takapotkun syntyminen voidaan estää:

• Takapotku on äkillinen liike, joka tapahtuu, kun jumittunut tai väärin asennettu

sahanterä nostaa sahan sahattavasta kappaleesta hallitsemattomasti kohti

käyttäjää.

• Kun sahanterä jumittuu esim. sahausuran kiristyessä, terä pysähtyy ja saha lentää

moottorin voimasta vauhdilla kohti käyttäjää.

• Mikäli terä kiertyy tai ohjautuu väärin sahausurassa, terän takaosan hampaat

saattavat pureutua puun yläosaan ja irrota sahausurasta, jolloin saha lennähtää

taaksepäin käyttäjää kohti.

Takapotkun riski kasvaa, jos sahaa käytetään väärällä tavalla, väärään tarkoitukseen tai väärissä olosuhteissa, mutta se voidaan välttää noudattamalla alla

olevia turvallisuusohjeita.

a) Pidä sahasta kiinni kunnolla molemmin käsin, ja pidä kädet sellaisessa asennossa,

että voit suojautua mahdollisen takapotkun sattuessa. Sijoitu sahanterän linjasta

sivuun – älä sijoitu sahanterän suuntaisesti. Takapotku aiheuttaa sahan lentämisen

taaksepäin, mutta takapotkua voidaan hallita, mikäli käyttäjä noudattaa kaikkia

turvallisuusohjeita.

b) Jos sahanterä jumittuu, tai jos lopetat sahauksen, päästä virtakytkin ja pidä kiinni

sahasta, kunnes terä on täysin pysähtynyt. Älä yritä irrottaa sahaa työkappaleesta,

äläkä vedä sahaa taaksepäin terän pyöriessä, sillä se lisää takapotkun vaaraa.

Suunnittele työ huolella ja noudata riittäviä tuvallisuusohjeita pienentääksesi terän

jumittumisen riskiä.

c) Kun jatkat tauon jälkeen sahausta samasta sahausurasta, keskitä terä uraan ja

varmista, että sahanterä ei kosketa uran reunoihin. Kiinni juuttunut terä saattaa

aiheuttaa uudelleen käynnistettäessä terän liikkumisen ylös tai sahan lentämisen

työkappaleesta.

d) Tue suuret levyt, sillä muuten on olemassa vaara, että terä jumittuu tai saha

lennähtää. Suurilla levyillä on taipumus taipua omasta painostaan. Levy tulee tukea

alta päin kummaltakin puolelta ja levyn reunojen läheltä.

39

SUOMI

Page 40

e) Älä käytä tylsiä tai viallisia teriä. Tylsät tai väärin asennetut terät tekevät kapean

sahausuran, mikä aiheuttaa suurta kitkaa, mikä taas saattaa johtaa terän

jumittumiseen tai sahan lentämiseen.

f) Kiristä sahauskulman ja –syvyyden säätimet ennen sahausta. Sahanterän

säätäminen sahauksen aikana saattaa aiheuttaa terän jumittumisen tai sahan

lentämisen.

g) Ole erityisen tarkkana, kun pistosahaat seiniä tai muita kohteita, joita et näe. Ulos

pistävä sahanterä saattaa osua kohteisiin, jotka aiheuttavat takapotkun.

Turvallisuusohjeita sahoille, joissa on sisempi liikkuva suoja

a) Varmista ennen jokaista käyttöä, että alempi suoja sulkeutuu kunnolla. Älä

käytä sahaa, mikäli alempi suoja ei liiku esteettä ja sulkeudu välittömästi. Älä

kiinnitä alempaa suojaa aukiasentoon. Sahan putoaminen saattaa aiheuttaa

alemman suojan taipumisen. Taita alempi suoja auki kahvan avulla ja varmista,

että se liikkuu kaikissa sahauskulmissa ja –syvyyksissä esteettä koskettamatta

sahanterään tai muihin osiin sahauksen aikana.

b) Varmista, että alemman suojan jousi toimii. Mikäli suoja ja jousi eivät toimi, ne

tulee huoltaa ennen käyttöä. Alempi suoja saattaa liikkua hitaasti, mikäli jokin osa

on vioittunut tai mikäli suojaan on kerääntynyt likaa tai sahanpurua.

c) Alempaa suojaa saa siirtää manuaalisesti ainoastaan erityisissä toimenpiteissä,

kuten pistosahauksesssa. Kevitä alempaa teräsuojaa kahvasta ja päästä se heti,

SUOMI

kun sahanterä koskettaa materiaalia. Muussa sahauksessa alemman suojan tulee

antaa toimia automaattisesti.

d) Varmista aina, että alempi teräsuoja peittää koko terän ennen kuin lasket sahan

käsistäsi. Suojaamaton pyörivä terä saattaa aiheuttaa sen, että saha liikkuu ja

sahaa kaikkea, mikä osuu sen tielle. Ota huomioon, että terä pyörii pitkään sen

jälkeen, kun virtakytkin on päästetty.

Erityisiä turvallisuusohjeita sahoille, joissa on rakoveitsi

a) Käytä sahanterään sopivaa rakoveistä. Jotta rakoveitsi toimii, sen tulee olla

paksumpi kuin terän runko, mutta ohuempi kuin hampaiden leikkuuleveys.

b) Säädä rakoveitsi tämän käyttöohjeen ohjeiden mukaisesti. Väärä etäisyys, väärä

asento tai suunta saattavat aiheuttaa sen, että rakoveitsi ei estä takapotkua.

c) Käytä rakoveistä aina (paitsi pistosahauksessa). Rakoveitsi tulee asentaa takaisin

paikoilleen pistosahauksen jälkeen. Rakoveitsi häiritsee pistosahausta ja saattaa

aiheuttaa takapotkun.

d) Rakoveitsen tulee liikkua työkappaleessa jotta se toimii. Rakoveitsi ei estä

takapotkua sahattaessa lyhyitä sahauksia.

e) Älä käytä sahaa, mikäli rakoveitsi on taipunut. Myös hyvin pieni taipuma voi

hidastaa suojan sulkeutumisnopeutta.

40

Page 41

• Kiinnitä työkappale, mikäli se ei pysy paikoillaan oman painonsa ansiosta.

• Käytä pölynpoistoa työskennellessäsi pyörösahalla.

• Käytä aina hengityssuojainta työskennellessäsi pyörösahalla.

• Käytä ainoastaan tähän sahaan sopivia teriä.

• Käytä aina kuulosuojaimia työskennellessäsi pyörösahalla.

• Tässä pyörösahassa ei saa käyttää hioma- tai katkaisulaikkoja.

• Pistorasian tai johdon saa vaihtaa vain valtuutettu sähköasentaja.

Tuotteen merkinnät ja turvallisuussymbolit

Lue käyttöohje huolellisesti ja säilytä se tulevaa tarvetta varten.

Käytä aina kuulosuojaimia.

Käytä aina suojalaseja.

SUOMI

41

Page 42

Kuvaus

1. Kahva

2. Merkkikilpi

3. Virtakytkin

4. Virtakytkimen lukituspainike.

5. Syvyydensäädön lukitusruuvi

6. Johto

7. Teräsuoja

8. Sahanterän ruuvi

9. Pohjalevy

10. Terälaippa

11. Sahanterä

12. Halkaisuohjain

13. Rinnakkaissuojan lukitusruuvi

14. Kulman säädön ruuvi

SUOMI

15. Pölynpoistoliitäntä

16. Etukahva

17. Teräsuojan kahva

18. Rakoveitsi

2

15 17 7 1 16

4 3

5

6

14

Tarvikkeet

- Rinnakkaissuoja

- Kuusiokoloavain

- Sahanterä 140/16

9

18

8 10 11 12 13

42

Page 43

Säädöt ja huolto

Tärkeää! Irrota pistoke pistorasiasta ennen laitteen huolto- ja säätötöitä.

Rakoveitsen säätäminen

1. Avaa rakoveitsen molemmat ruuvit (1).

2. Työnnä sahasuojaa taaksepäin ja pidä

kiinni siitä ohjausvivulla.

3. Säädä rakoveitsi maks. 5 mm:n päähän

sahanterästä.

4. Sahanterä saa syvyyssuunnassa pistää

ulos korkeintaan 5 mm rakoveitsen

reunasta.

5. Kiristä molemmat ruuvit.

6. Tarkasta, että rakoveitsi on

linjassa sahanterän kanssa.

Sahauskulman säätäminen

1. Avaa lukitusruuvi.

2. Säädä haluttu kulma 0–45°.

3. Kiristä lukitusruuvit.

Sahaussyvyyden säätäminen

1. Avaa lukitusruuvi (1).

2. Laske pohjalevy halutulle

korkeudelle.

3. Kiristä lukitusruuvit.

SUOMI

43

Page 44

Halkaisuohjaimen säätö

1. Avaa lukitusruuvit (1).

2. 90°:n sahaus: lue asteikko kohdasta A.

45°:n sahaus: lue asteikko kohdasta B.

Ota huomioon sahanterän leikkuuleveys.

Kiristä ruuvit.

Sahanterän vaihto

1. Lukitse sahanterä.

2. Ruuvaa auki lukitusruuvia (1) terän pyörimissuuntaan kuusiokoloavaimella (2).

3. Työnnä sahasuojaa taaksepäin ja pidä

kiinni siitä ohjausvivulla (3).

4. Irrota laippa-aluslevy (4) ja irrota sahanterä.

5. Laita uusi sahanterä päinvastaisessa

järjestyksessä.

6. Säädä tarvittaessa rakoveistä.

SUOMI

HUOM.! Tarkasta ennen sahan käynnistämistä terän vaihdon jälkeen, että terä on

asennettu oikein ja lukitusruuvit ovat

kireällä.

1

B

A

3

1

4

2

Käynnistäminen ja sammuttaminen

Käynnistys: Paina lukituspainiketta (1)

voidaksesi painaa virtakytkintä (2).

Pysäytys: Päästä painikkeet.

44

2

1

Page 45

Vianhakutaulukko

Ongelma Mahdollinen syy Toimenpiteet

Laite ei käy. Ei virtaa. Varmista, että pistorasiassa

on virtaa.

Kuluneet hiiliharjat. Ota yhteys myymälään.

Oikosulku

Virtakytkimessä vikaa.

Laite käy hitaasti. Tylsä tai vioittunut terä. Hio tai vaihda terä.

Liian alhainen kierrosluku. Älä syötä liian kovaa

Moottori on ylikuumentunut Älä syötä liian kovaa

Epätavallisia

ääniä.

Laite tärisee voimakkaasti.

Moottori kipinöi. Juuttuneet hiiliharjat. Ota yhteys myymälään.

Mekaaninen este Ota yhteys myymälään.

Käämi osittain oikosulussa.

Sahanterä ei ole kunnolla

kiinni.

Käämi oikosulussa

Kollektori on likainen

Varmista, että sahanterä on

keskellä ja kiristä lukitusruuvi.

SUOMI

45

Page 46

Hoito

• Pidä ilmanvaihtokanavat puhtaana lastuista ja roskista.

• Puhdista koneet säännöllisesti miedolla astianpesuliuksella ja pehmeällä

puhdistusliinalla.

• Älä käytä liotinaineita.

Kierrätys

Kierrätä tuote asianmukaisesti, kun poistat sen käytöstä. Ota yhteys

kuntasi jäteneuvojaan, mikäli olet epävarma.

Tekniset tiedot

Virtalähde 230 V, 50 Hz

Teho 900 W

Kuormittamaton kierrosluku 4500 k./min

Sahaussyvyys 90°:ssa 45 mm

SUOMI

Minimisahauskulma 45°

Sahanterä 140/16 mm

LpA (melutaso) 91,4 dB (A)

LwA (meluteho) 102,4 dB (A)

Tärinäarvo 0,4 m/s²

46

Page 47

Declaration of Conformity

Försäkran om överrenstämmelse

Samsvarerklæring

Vakuutus yhdenmukaisuudesta

CLAS OHLSON AB

SE-793 85 INSJÖN, SWEDEN

Declares that this product complies with the requirements of the following directives and standards

Intygar att denna produkt överensstämmer med kraven i följande direktiv och standarder

Bekrefter at dette produktet er i samsvar med følgende direktiver og standarder

Vakuuttaa, että tämä tuote täyttää seuraavien direktiivien ja standardien vaatimukset

CIRCULAR SAW

COTECH 30-9166 / 18-3034

M1Y-140-900A / M1Y-140-900A-UK

Machinery directive

2006/42/EC

EN 60745-1:2009

EN 60745-2-5:2007

+A11

EC type certificate, no. S1 50015618

Issued by the following notified body:

Utfärdats av följande anmälda organ:

Utstedt av følgende teknisk kontrollorgan:

Myöntänyt seuraava ilmoitettu laitos:

TüV Rheinland Product Safety GmbH, Am Grauen Stein, D-51105 Köln

EMC directive

2004/108/EC

EN 55014-1:2006

EN 55014-2:1997+A1

EN 61000-3-2:2006

EN 61000-3-3:1995

+A1+A2

Klas Balkow

President

Insjön, Sweden, 2011-10-06

Page 48

SVERIGE

KUNDTJÄNST Tel: 0247/445 00

Fax: 0247/445 09

E-post: kundtjanst@clasohlson.se

INTERNET www.clasohlson.se

BREV Clas Ohlson AB, 793 85 INSJÖN

NORGE

KUNDESENTER Tlf.: 23 21 40 00

Faks: 23 21 40 80

E-post: kundesenter@clasohlson.no

INTERNETT www.clasohlson.no

POST Clas Ohlson AS, Postboks 485 Sentrum, 0105 OSLO

SUOMI

ASIAKASPALVELU Puh: 020 111 2222

Faksi: 020 111 2221

Sähköposti: info@clasohlson.fi

INTERNET www.clasohlson.fi

OSOITE Clas Ohlson Oy, Yrjönkatu 23 A, 00100 HELSINKI

UNITED KINGDOM

For consumer contact, please visit

www.clasohlson.co.uk and click on

customer service.

INTERNET www.clasohlson.co.uk

Loading...

Loading...