MODEL:

CVAC45BW

OPERATING & MAINTENANCE

INSTRUCTIONS

Distributed by CLARKE International Ltd.

0706

SPARE PARTS LIST

No. Description Qty Part No. No. Description Qty Part No.

PARTS & SERVICE CONTACTS

For Spare Parts and Service, please contact your nearest dealer,

or CLARKE International, on one of the following numbers.

PARTS & SERVICE TEL: 020 8988 7400

PARTS & SERVICE FAX: 020 8558 3622

or e-mail as follows:

PARTS: Parts@clarkeinternational.com

SERVICE: Service@clarkeinternational.com

1 Basket, Hose Storage 1 HTCVAC01

2 End Cover, Motor 1 HTCVAC02

3 Cover, Motor 1 HTCVAC03

4 Switch 1 HTCVAC04

5 Power Cord 1 HTCVAC05

6 Inner Cover, Motor 1 HTCVAC06

7 PCB 1 HTCVAC07

8 Seal Ring, 1 HTCVAC08

9 Lid 1 HTCVAC09

10 Handle, Lid 2 HTCVAC10

11 Gasket 1 HTCVAC11

12 Seal, Motor 1 HTCVAC12

13 Motor 1 HTCVAC13

14 Lower Seal Ring 1 HTCVAC14

15 Base, Motor 1 HTCVAC15

16 Seal Ring, Float 1 HTCVAC16

17 Seal Ring, Filter 1 HTCVAC17

18 Float 1 HTCVAC18

19 Cage, Float 1 HTCVAC19

20 Base Plate, Cage 1 HTCVAC20

21 Cartridge Filter 1 HTCVAC21

22 Spring 2 HTCVAC22

23 Fixed Bracket 1 HTCVAC23

24 Dust Bag 1 HTCVAC24

25 Filter 1 HTCVAC25

26 Seal Ring, Tank 1 HTCVAC26

27 Handle, Tank 2 HTCVAC27

28 Clamp, Push Rod 3 HTCVAC28

29 Latch 3 HTCVAC29

30 Hose Connector 1 HTCVAC30

31 Tank 1 HTCVAC31

32 Handle 1 HTCVAC32

33 Clamp, Tank 2 HTCVAC33

34 Thumb Screw 2 HTCVAC34

35 Upright 2 HTCVAC35

36 Axle 1 HTCVAC36

37 Frame, Rear 1 HTCVAC37

38 Frame, Front 1 HTCVAC38

39 Bracket, Caster 1 HTCVAC39

40 Plastic Cover 1 HTCVAC40

41 Wheel 2 HTCVAC41

42 Castor, 3" 1 HTCVAC42

43 Circlip, 4 HTCVAC43

44 Brush, Water 1 HTCVAC44

45 Brush, Dust 1 HTCVAC45

46 Hose 1 HTCVAC46

47 Crevace Tool 1 HTCVAC47

48 Tube Extension 2 HTCVAC48

49 Bolt, Motor Base 4 HTCVAC49

- 11 -- 2 -

SPARE PARTS DIAGRAM

Thank you for selecting this VAC KING Vacuum Cleaner, which will provide you

with a cleaner and safer working environment.

This machine is capable of collecting both wet and dry materials as well as water.

DO NOT, however, collect any other type of liquid as this could be dangerous.

Before attempting to use this machine, please read this leaflet thoroughly and

follow the instructions carefully. In doing so you will ensure the safety of yourself

and that of others around you, and you can look forward to this Vacuum Cleaner

giving you long and satisfactory service.

GUARANTEE

This product is guaranteed against faulty manufacture for a period of 12 months from

the date of purchase. Please keep your receipt therefore, as proof of purchase.

This guarantee is invalid if the product is found to have been abused or tampered

with in any way, or not used for the purpose for which it was intended.

Faulty goods should be returned to their place of purchase, no product can be

returned to us without prior permission.

This guarantee does not effect your statutory rights.

SAFETY PRECAUTIONS

1. Do not allow the machine to run unattended.

2. Do not use with accessories other than those provided.

3. Do not use if the electric cable, plug, motor filter or the cleaner itself, is in poor

condition.

4. Do not attempt any electrical repair yourself. Consult a qualified electrician,

or our Service Departrment on 020 8988 7400

5. Do not pick up flammable or readily combustible material, hot ashes, coals,

or use in the presence of explosive liquids or vapour.

6. Do not use in enclosed areas where flammable, explosive or toxic vapours

are given off, by oil based paints, paint thinner, petrol etc.

7. Do not pick up burning cigarettes or other smoking substances.

8. When you have finished with the machine, ensure the electric cable is stowed

away and not left as a hazard, i.e. for others to trip over.

9. Do not change filters, or carry out any cleaning or servicing, without first

disconnecting the machine from the mains supply.

10. Do not pull the machine along by the electric cable, or pull the cable to

disconnect the plug from the mains socket. Keep the electric cable away

from heat , oil and sharp edges. Do not close doors on the cable, or allow it to

become snagged under furniture or objects with sharp edges.

11. If this machine is used outdoors, on no account must it be exposed to rain.

Ensure it is stored indoors.

- 10 -

- 3 -

ELECTRICAL CONNECTIONS

This product is provided with a standard 13 amp, 230 volt (50Hz), BS 1363 plug, for

connection to a standard, domestic electrical supply. Should the plug need changing at

any time, ensure that a plug of identical specification is used.

WARNING ! THIS APPLIANCE MUST BE EARTHED

This machine must be wired up in accordance with the following colour code:

BLUE - NEUTRAL

BROWN - LIVE

GREEN/YELLOW - EARTH

• Connect the BLUE coloured cord to the plug terminal marked “N”

• Connect the BROWN coloured cord to the plug terminal marked “L”

• Connect the GREEN/YELLOW coloured cord to the plug terminal marked “E”

If this appliance is fitted with a plug which is moulded on to

the electric cable (i.e. non-rewireable) please note:

1. The plug must be thrown away if it is cut from the

electric cable. There is a danger of electric shock if it

is subsequently inserted into a socket outlet.

2. Never use the plug without the fuse cover fitted.

PARTS LIST

3. Should you wish to replace a detachable fuse carrier, ensure that the correct

replacement is used (as indicated by marking or colour code).

4. Replacement fuse covers can be obtained from your local dealer or most electrical

stockists.

Fuse Rating

The fuse in the plug must be replaced with one of the same rating (13 amps) and this

replacement must be approved to BS1362.

If in doubt, consult a qualified electrician. Do not attempt any electrical repairs yourself.

Cable Extension

Always use an approved cable extension suitable for the power rating of this tool (see

specifications), the conductor size should also be at least the same size as that on the

machine, or larger. When using a cable reel, always unwind the cable completely.

IMPORTANT:

If a cable extension is needed, it is essential to comply with the following data.

Voltage Extension length Cable section

230v Up to 20m 2.5mm

230v From 20 to 50m 4mm

- 4 -

2

2

&

DIAGRAMS

- 9 -

4. Ensure the appropriate filter is properly in place and secured with the spring

clamp, before selecting the appropriate tool for attaching to the end of the

tube extension, plugging into the power supply and switching ON.

Be aware that when picking up water, the tank will gradually fill up. Check

and empty at frequent intervals, otherwise the float located within the filter

unit will rise and eventually shut off suction. This is a safety feature to prevent

water from coming into contact with electrical components.

Should suction cease, switch OFF immediately and empty the tank, otherwise

the motor could overheat.

UNPACKING

Carefully unpack and check components against the list below. Should there be

any transit damage, please contact your Clarke dealer immediately

MAINTENANCE

Maintenance is limited to inspecting the filters regularly, and replacing when

necessary. The linen bag may be washed as required and dried before use.

Also ensure that the hose is kept in good condition. A damaged hose will seriously

effect the efficiency of the machine, and should be replaced immediately.

Inspect all other components periodically, and replace damaged castors or

accessories when necessary. Contact your CLARKE dealer for replacements.

Regular inspection and the correct maintenance of the filters, will ensure the

efficient running and prolong the life of your machine.

SPECIFICATIONS

Motor - Power Rating ............................................. 1.2kW

Voltage ....................................................... 230V 50Hz 1Ph

Insulation Rating ........................................ E

Duty Cycle ............................................................... S1 (Continuous)

Tank Capacity - water ............................................ 23 Litres

Dust Capacity .......................................................... 39 Litres

Sound Pressure Level (at 2M) ................................. 90dB(A)

Dimensions ............................................................... 600x1005x490mm

Weight .................................................................... 16.5kg

Part No. .................................................................... 6470562

- 8 -

A. Frame - Front

B. Frame Rear

C. Caster with Bracket

D. Upright (2)

E. Handle

F. Axle

G. Wheel (2)

H. Cover

I. Tube Extension (2)

J. Crevace Tool

K. Wet Pickup

L. Master Brush

M. Flexible Hose

N. Vac. Cleaner

P. Loose Parts (see below)

Loose Parts

A. Hex. Slot Head Screw (1)

B. M5x20 Hex. Screw, w/ Nut,

flat & spring washer (4)

C. M4x20 Hex. Screw, w/ Nut,

flat & spring washer (4)

D. Flat Washer (4)

E. ‘E’ Ring(4)

F. Clamp assemblies (2)

- 5 -

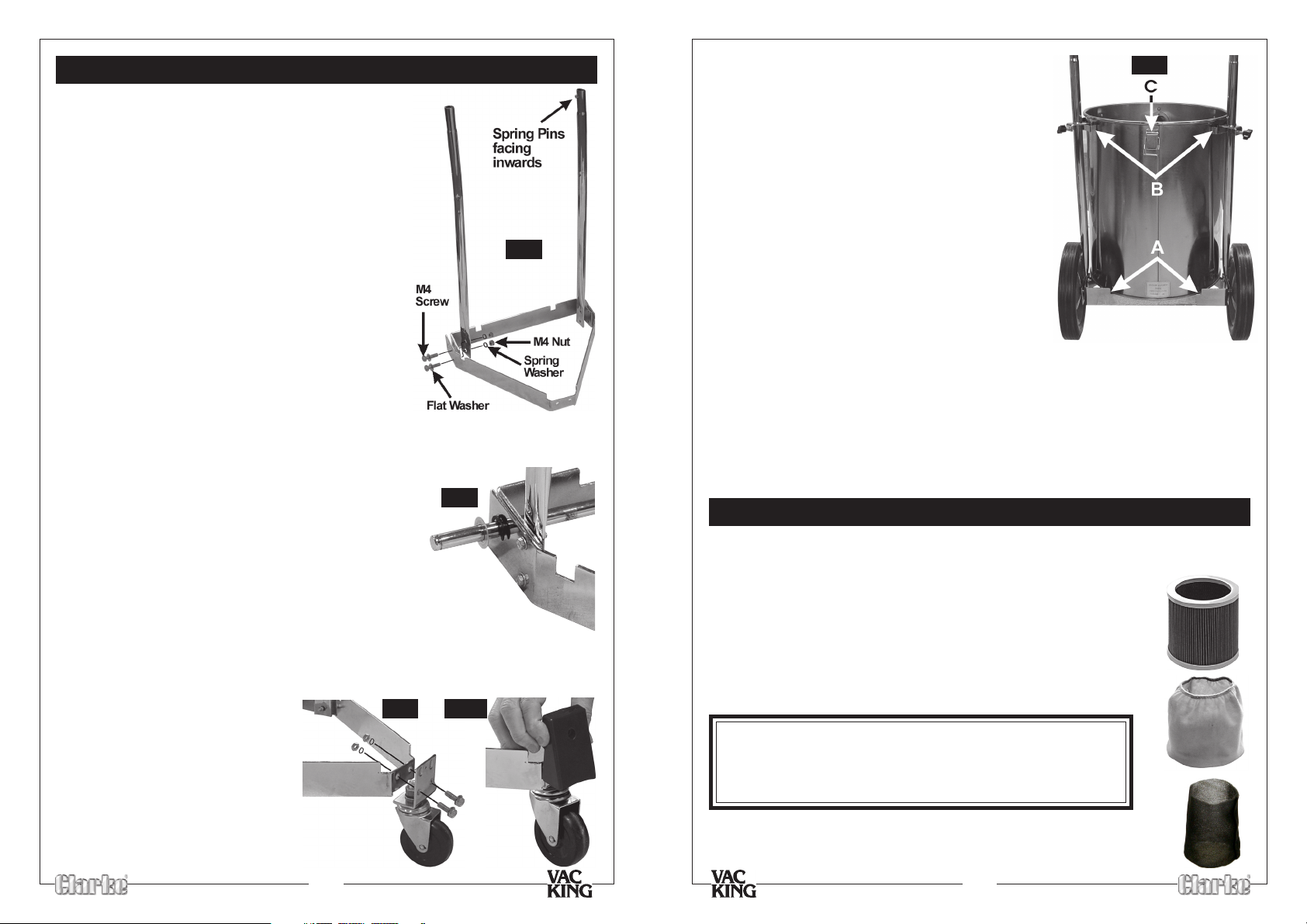

ASSEMBLY

1. Assemble the front and rear frames as indicated

in Fig.1, and attach an upright to each side in

turn, ensuring the spring loaded pins are facing

inwards.

Secure using M4x20 screws with flat, spring

washers and nut. Ensure all are tight.

Fig.1

4. With the hose connector on the tank facing

forwards, carefully lower the tank on to the frame

and locate in the slots provided - the rear two

shown at ‘A’ Fig 4. The tank should sit snugly in

each slot in both the front and rear frames.

5. Slide a clamp assembly on to each upright,

ensuring the clamping claws face downwards.

Push the spring pins, in the uprights - in, to allow

the clamps to drop.

At this point attach the handle to the uprights,

securing with the spring pins.

Engage the clamping claws firmly in the brackets

provided on the tank as shown at ‘B’ Fig.4, and,

ensuring the rear buckle ‘C’ is midway between

the uprights, tighten the clamping screws.

6. Finally slide the handle over the uprights ensuring

each side is locked using the spring pins.

7. Undo the three buckles. securing the tank lid with cage and motor assembly,

and lift off the lid complete.

8. Turn the lid assembly and rest it on its cage, with the filter uppermost.

Lift off the filter clamp pull off the cartridge filter complete with linen bag. A

foam filter cover, is housed within the cartridge filter. This should be removed

and retained.

Fig.4

2. Slide the axle through the holes in the rear frame

and locate an ‘E’ ring in the groove adjacent to

the frame, then thread on a flat washer, as shown

in Fig.2

Slide a wheel on to each side, followed by a flat

washer, then locate an ‘E’ ring in the outer

groove.

3. Bolt the caster to the bracket

using the nut and washers

provided, then attach to the

front frame in the manner

shown in Fig.3, using 2 M5x20

screws with flat, spring washers

and nut. Ensure all are tight.

Slide the cover on to the caster

bracket and secure using the

single screw provided.

- 6 -

Fig.3 Fig.3a

Fig.2

OPERATION

NOTE: Filters are essential to ensure that dust or foreign matter does not enter the

motor compartment which would reduce motor effeciency, and eventually cause

serious damage.

Three filters are supplied with the machine.

1. The Cartridge filter is the primary filter, and must be fitted

over the filter cage. This is used only for dry vacuuming.

2. The Linen Bag filter is the secondary filter and must be placed

securely over the cartridge filter for all normal operations,

i.e. dry vacuuming.

IMPORTANT: This double filtering action not only ensures

that the motor is kept dirt free, but is essential in ensuring

that the cleanest air possible is exhausted, therefore

preventing dust from being spread into the environment.

3. The Foam filter. This is only used for picking up water, and

replaces both the Cartridge filter and Linen Bag during this

operation.

- 7 -

Loading...

Loading...