TOOL STAND

Model No. CUTS1

ASSEMBLY INSTRUCTIONS 0513

Storage

To store the Tool Stand, the legs need to be collapsed, as follows:

Fitrstly remove the Rollers if fitted, and ensure the table extensions are fully IN.

Invert the unit and remove the leg brace by unscrewing the two large knobs,

securing it.

Collapse the legs. Be sure to retain all nuts bolts,knobs and accessories and store

in a safe place.

Specifications

MAXIMUM Load ............................................................................ 125kg

Weight (incl. Accessories) ........................................................... 17.5kg

Overall Dimensions

Min Length ................................................................ 1160mm

Max. Length .............................................................. 1899mm

Width ......................................................................... 608mm

Length (Rollers, centre to centre)

Min ............................................................................. 1058mm

Max. ........................................................................... 1795mm

Height (To surface of Tool Mounting Clamps)

Min. ............................................................................ 614mm

Max. ........................................................................... 760mm

Max Height of Rollers from surface of Tool Clamps .................. 420mm

2

Thank you for purchasing this CLARKE Universal Tool Stand

Although this product is of rugged construction, it should nevertheless be used

with care and consideration, and the precautions closely followed. You can

then look forward to it giving long and reliable service. Immediately on

unpacking the product, please refer to the parts list and satisfy yourself that

all parts are present. Should there be any deficiency, then you should

immediately contact your Clarke dealer, or CLARKE INTERNATIONAL Parts

Department, on 020 8988 7400

Guarantee

This CLARKE product is guaranteed against faulty manufacture for a period of 12

months from the date of purchase. Please keep your receipt which will be required

as proof of purchase.

This guarantee is invalid if the product is found to have been abused in any way,

or not used for the purpose for which it was intended.

Faulty goods should be returned to their place of purchase, no product can be

returned to us without prior permission.

This guarantee in no way affects your statutory rights under common law.

Safety Precautions

• The maximum capacity of this Tool Stand is 125kgs. On no account must this

be exceeded.

• Do not stand on the Cross Members or use as a step ladder, as this could

cause severe damage. Do not stand on top of the Stand.

• Take care when placing a load on to the Tool Stand, It should be placed

gently so that the strain is taken up gradually. Do not drop a load carelessly.

• Always check the Tool Stand for wear, damage or looseness of parts before

use.

• Always ensure you are working on a firm flat surface, and that the Tool Stand

is completely stable.

• DO NOT mount a machine in a manner where work would need to be passed

across the table, as this could cause table instability.

3

Assembly

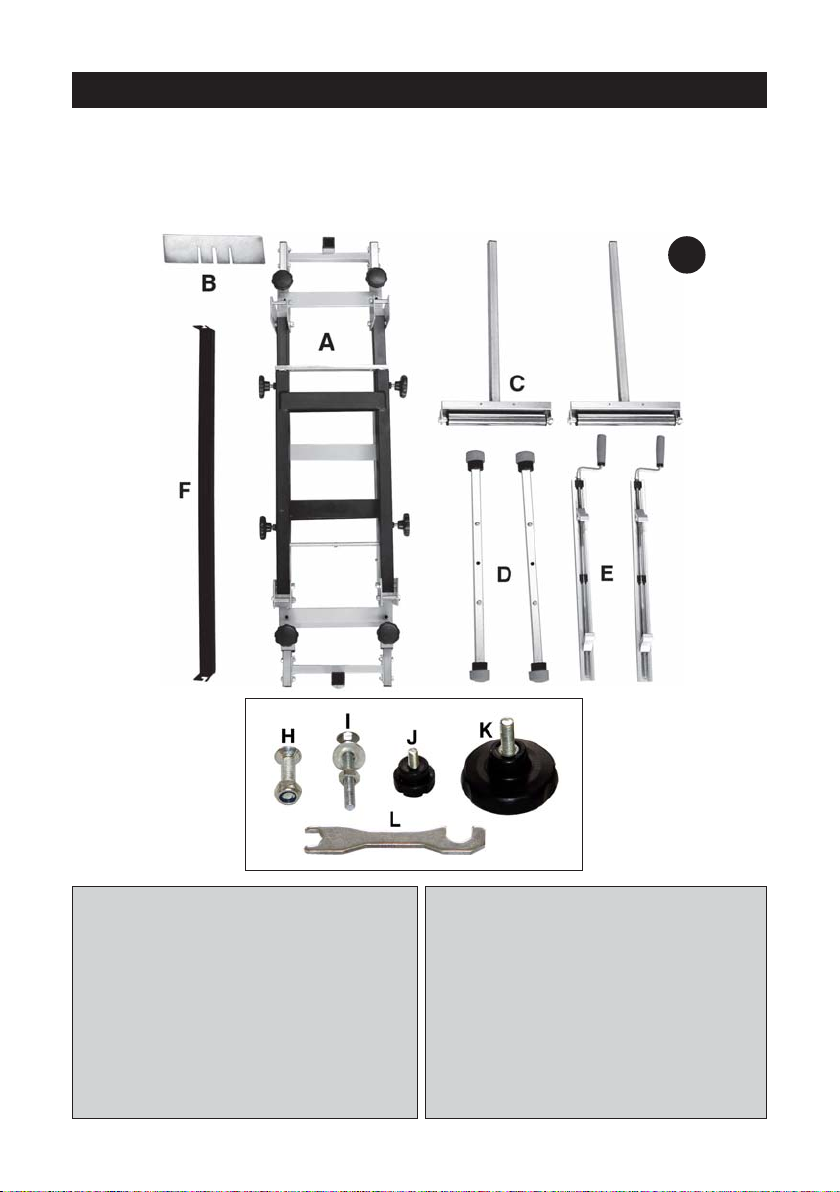

Remove the components from the packaging and carefully lay them out,

checking to ensure that no damage was suffered during transit.

Should any damage be apparent, please contact your Clarke dealer

immediately.

1

A. 1 x Frame c/w Legs

B. 1 x Stop Plate

C. 2 x Roller Supports

D. 2 x Stabilisers

E. 2 x Tool Mounting Clamps

F. 1 x Brace

H. 4 x M5x25 C’sk Hd Screw w/self

locking nut

I. 4 x M6 x45 Carriage bolt w/nut

and flat washer

J. 4 x Small Knob Hd Screw

K. 8 x Large Knob Hd Screw

L. 1 x Spanner

4

Assembly cont.

1. Place the frame on the floor in the

inverted position, i.e. legs

uppermost, and raise the legs, so

that the brace may be fitted, using

two large lock knobs - one at each

end, as shown in Fig. 2.

2

3

2. Attach the stabilisers, one to each leg, as shown in Figs 3 and 4.

The locating peg, in the leg cross member, should sit snugly in thre hole in the

stabiliser, and the stabiliser secured using two countersunk screws with self

locking nuts supplied.

3. Raise frame to its upright position. The height may be adjusted by undoing

the large knobs securing the telescopic legs and locating at the desired

position using the pins provided. Tighten the locking knobs securely.

4. Place the Tool Supports on the frame but

do not tighten the clamps. Two carriage

bolts should be slid into the groove of

each clamp as shown in Fig.5.

The tool (Mitre Saw etc.) is placed on the

tool supports so that the carriage bolts

enter the holes in the base of the tool.

The flat washer and lock nuts are then

screwed on andf tightened to secure the tool.

Finally, tighen the tool support clamps using the handles to do so.

5

4

5

NOTE: Should the tool not have suitable holes for mounting to the table, then the

tool should firstly be mounted on to a suitable board of at least 15mm thickness,

and the board, with tool, secured to the table, again using the carriage bolt

provided.

5. The Extension Rails may be adjusted to suit the length of the workpiece, with

the work Roller Supports located in their brackets and adjusted to height as

required.

Additionally a WorkStop may be attached to a roller support, and adjusted for

height using two small knob screws provided.

The table extension together with the work stop may be positioned as required so

that stock lengths may be cut.

6

Turn foot so

that it lays flat

IMPORTANT.

Always ensure that before mounting a machine - Mitre Saw, etc., you take into

consideration the type of cuts and the size of the workpiece you will be working

with. Stability of the table is of paramount importance. Take extra care if/when

working with large or very long pieces, extra support may be required.

6

Notes

Loading...

Loading...