10”(250MM) TABLE SAW

MODEL NO: CTS17

PART NO: 6500752

OPERATION & MAINTENANCE

INSTRUCTIONS

ORIGINAL INSTRUCTIONS GC0322

INTRODUCTION

Thank you for purchasing this CLARKE product. This table saw has been

designed to perform the sawing operation of ripping, cross-cutting, bevelling

and mitering wood and wood products. This unit is designed for use with an

10” (250mm) carbide tipped blade.

Before attempting to use this product, please read this manual thoroughly and

follow the instructions carefully. In doing so you will ensure the safety of yourself

and that of others around you, and you can look forward to your purchase

giving you long and satisfactory service.

SPECIFICATIONS

Model CTS17

Voltage 230V - 50 Hz

Power input 2000 W

No-load speed 4800 rpm

Ingress protection (IP) rating IPX0

Table size 643 mm x 546 mm (ex extension)

Dust Extractor connector 34.9 (internal) / 39.5 mm (external)

Blade size: Outside Diameter 250 mm

Bore Diameter 30 mm

Thickness 2.8 mm

Number of teeth 24 TCT

Maximum cut depth @ 90 Degrees 72 mm

Maximum cut depth @ 45 Degrees 50 mm

Machine weight: 22 kg

Machine size (L x W x H) 695 x 917 x 1030mm (max)

Sound pressure level LpA 93.7 dB (A)

Guaranteed sound power level LWA: 106.7 dB (A)

This saw is NOT suitable for cutting:

• Timber greater than 70mm

• Metal, stone, rubber, plastic etc

•Logs or round timber

2

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

GUARANTEE

This product is guaranteed against faulty manufacture for a period of 12

months from the date of purchase. Please keep your receipt which will be

required as proof of purchase.

This guarantee is invalid if the product is found to have been abused or

tampered with in any way, or not used for the purpose for which it was

intended. Faulty goods should be returned to their place of purchase, no

product can be returned to us without prior permission.

This guarantee does not effect your statutory rights.

ENVIRONMENTAL RECYCLING POLICY

By purchasing this product, the customer is taking on the obligation to

deal with its safe disposal in accordance with the Waste Electrical and

Electronic Equipment (WEEE).

In effect, this means that this product must not be disposed of with general

household waste. It must be disposed of according to the laws governing

Waste Electrical and Electronic Equipment (WEEE) at a recognised disposal

facility.

If disposing of this product or any damaged components, do not dispose of

with general waste. This product contains valuable raw materials. Metal

products should be taken to your local civic amenity site for recycling of metal

products.

3

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

SAFETY SYMBOLS

Read instruction

manual before use

Wear safety glasses Wear ear defenders

Indoor Use Only Danger of cut hand

The above safety symbols appear on the product.

Wear dust mas k

injury. Ensure guards are

in place.

SAFETY WARNINGS

CAUTION: DO NOT LET FAMILIARITY WITH YOUR TABLE SAW MAKE YOU

CARELESS. REMEMBER THAT A CARELESS FRACTION OF A SECOND IS

SUFFICIENT TO CAUSE SEVERE INJURY.

PERMITTED USAGE

The table saw is constructed exclusively for the sawing of wood. The

appropriate saw blade should be fitted according to the wood type (solid

wood, chipboard or plywood).

• Read and understand the entire owner's manual before attempting

assembly or operation.

• Read and understand the warnings posted on the machine and in

this manual. Failure to comply with all of these warnings may cause

serious injury.

HEALTH

When sawing, dust particles will be produced which in some instances can be

harmful (e.g. lead from old gloss paint, arsenic and chromium from chemically

treated lumber).

To reduce the risk you should:

4

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

• Work in a well-ventilated area.

• Work with approved safety equipment such as dust masks that are

specially designed to filter microscopic particles.

• If possible use/connect to a suitable dust extractor.

GENERAL

1. DO NOT expose the saw to rain.

2. DO NOT use the saw in damp or wet conditions.

3. Keep the work area well lit.

4. DO NOT use the saw in the presence of flammable liquids and gases.

5. Remove loose items and unnecessary work pieces from the area before

starting the saw.

6. Clean out sawdust from the interior of the saw to prevent a potential fire

hazard. Attach a vacuum cleaner to the dust port for additional sawdust

removal.

7. Wear ear protectors (plugs or muffs) during extended periods of operation.

8. Wear safety glasses. Everyday eyeglasses are not suitable as safety glasses.

9. Wear a dust mask when sawing wood.

10. NEVER wear gloves during operation.

11. Before operating this table saw, remove any neck tie, rings, watches and

other jewellery and roll sleeves up past the elbows. Remove all loose

clothing and confine long hair. Non-slip footwear or anti-skid floor strips are

recommended.

12. Make sure that the machine stands stable on a firm, flat surface.

13. Before use, carefully check the saw and mains cable for damage or any

other condition that may affect its operation. DO NOT use the saw if any

part is damaged or defective.

14. DO NOT use the saw if the switch does not turn it on and off.

15. Remove keys and wrenches. Ensure that keys and wrenches are removed

from the saw before turning it on following blade replacement.

16. Use the right tool for the task - DO NOT force small tools to do the job of a

heavy duty tool. It will do the job better and safer at the rate for which it

was intended. DO NOT use tools for purposes not intended; for example DO

NOT use table saws to cut tree limbs or logs.

17. The use of any accessory or attachment other than one recommended in

this instruction manual may present a risk of personal injury.

18. Connect table saws to a dust-collecting device when sawing wood.

5

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

19. Guard against electric shock - Avoid body contact with earthed or

grounded surfaces.

20. Extension cables - Before use, inspect the extension cable and replace if

damaged.

21. Avoid unintentional starting. Make sure the switch is in the OFF position

before connecting the machine to the power supply.

22. DO NOT abuse the cable. Never yank the cable to disconnect it from the

mains supply. Keep the cable away from heat, oil, water and sharp edges.

23. This table saw is designed and intended for use by properly trained and

experienced personnel only. If you are not familiar with the proper and

safe operation of a table saw, DO NOT use until proper training and

knowledge have been obtained.

24. Stay alert, watch what you are doing. Use common sense. DO NOT

operate the saw when you are tired or under the influence of drugs,

alcohol or any medication.

25. Keep hands clear of the saw blade.

26. Maintain a balanced stance at all times so that you do not fall on to the

blade. DO NOT overreach or use excessive force to perform any operation.

27. Use push-sticks or push blocks to feed the workpiece past the saw blade.

Keep your hands and fingers well away from the blade.

28. The push-stick should always be stored with the machine when not in use.

29. Pay particular attention to instructions on reducing risk of kickback on

page 9.

30. NEVER perform any operation freehand, which means using only your

hands to support or guide the workpiece. Always use either the fence or

the mitre fence to position and guide the work.

WARNING: FREEHAND CUTTING IS THE MAJOR CAUSE OF KICKBACK AND

FINGER AMPUTATIONS.

31. Give your work undivided attention. Looking around, carrying on a

conversation and “horse-play” are careless acts that can result in serious

injury.

32. When not in use, store the saw in a dry place out of reach of children and

animals.

33. Replace the warning labels if they become obscured or removed.

6

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

34. Turn off and unplug the saw before cleaning. Use a brush or compressed

air to remove chips or debris — DO NOT use your hands. Eye protection

should be used when using compressed air.

35. Disconnect the saw from the mains supply before changing blades or

carrying out maintenance.

36. Keep blades sharp and clean for better and safer performance. Inspect

power cables periodically and if damaged have them repaired.

37. Repairs should only be carried out by qualified persons using original spare

parts, otherwise this may result in considerable danger to the user.

38. Keep handles dry, clean and free from oil and grease.

39. Unplug the saw - switch off and wait for the blade to come to a complete

standstill before leaving it unattended.

ADDITIONAL SAFETY RULES FOR TABLE SAWS

1. The thickness of the saw blade must be greater than the thickness of the

riving knife.

2. DO NOT stand on the table saw.

3. During transportation make sure that the upper part of the saw blade is

covered by the guard.

4. DO NOT use the guard for handling or transportation.

5. Check that the workpiece is properly supported. Always provide additional

support for long workpieces.

6. DO NOT exert side pressure on the saw blade.

7. Make sure that the blade rotates in the correct direction and that the teeth

are pointing to the front of the saw.

8. DO NOT apply lubricants to the blade when it is running.

9. NEVER reach around or over the saw blade. NEVER reach for a workpiece

until the saw blade has completely stopped.

10. Make sure that the blade and retaining discs are clean. Tighten the

retaining screw securely.

11. Keep the saw blade sharp.

12. Make sure that the riving knife is adjusted to the correct distance from the

blade.

13. NEVER operate the saw without the guard in place.

14. DO NOT use abrasive discs or diamond cutting wheels.

15. Rebating, slotting or grooving is not allowed.

7

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

16. DO NOT use a moulding head cutter with this saw.

17. Remove the rip fence when crosscutting. NEVER use the rip fence as a cutoff gauge when crosscutting.

18. Knock out any loose knots from the workpiece before you begin to cut.

19. Provide adequate support to the rear and the sides of the saw table for

long or wide workpieces.

20. NEVER leave the saw running unattended. Turn the power off and DO NOT

leave the saw until it comes to a complete stop.

21. Before using the saw on an actual workpiece, let it run for a few moments.

Watch for vibration or wobbling that could indicate poor installation or a

poorly balanced blade.

22. ALWAYS hold work firmly against the mitre gauge or rip fence.

23. NEVER stand or have any part of your body in line with the path of the saw

blade. keep your hands out of the saw blade path.

24. Feed work into the blade against the direction of rotation only.

25. NEVER attempt to free a stalled saw blade without first turning the saw off.

Turn the power switch off immediately to prevent motor damage.

26. Avoid awkward operations and hand positions where a sudden slip could

cause your hand to move into the saw blade.

27. Avoid abrupt, fast feeding. Feed as slowly as possible when cutting hard

workpieces. DO NOT bend or twist the workpiece while feeding. If you stall

or jam the blade in the workpiece, turn the table saw off immediately.

Unplug the saw, then clear the jam.

28. NEVER remove cut-off pieces near the blade or touch the blade guard

while the blade is running.

SAW BLADES

1. The maximum speed of the saw blade must always be equal to or greater

than the no-load speed of the table saw as specified on the rating plate.

2. Only use saw blades recommended by the manufacturer and which are

the exact bore and diameter required for this machine. DO NOT use any

spacers to make a blade fit onto the spindle. Use only the blades specified

in this manual.

3. Clean the spindle, retaining discs (especially the installing surface) and

retaining bolt before installing the blade. Poor installation may cause

vibration/wobbling or slippage of the blade.

4. DO NOT use saw blades which are damaged or deformed.

8

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

5. Take care that the selection of the saw blade is suitable for the material to

be cut.

6. Make sure the blade is not contacting the riving knife or workpiece before

the switch is turned on.

7. Wear gloves when handling saw blades and rough material. Saw blades

shall be carried in a holder whenever practicable. Take care that gloves

can catch on rotating blades.

KICKBACK

Kickback is a sudden reaction to a pinched, bound or misaligned saw blade,

it causes the workpiece to be ejected from the tool back towards the

operator. Kickbacks can lead to serious personal injury.

You can avoid kickbacks by:

a. Keeping the blade sharp,

b. Keeping the rip fence parallel to the blade,

c. Keeping the riving knife and blade guard in place and operating properly,

d. Not releasing the workpiece until you have pushed it all the way past the

blade,

e. Not ripping a workpiece that is twisted or warped or does not have a

straight edge to guide along the fence.

If you do not have a clear understanding of kickback and how it occurs, DO

NOT use the table saw.

REMAINING HAZARDS

The machine has been built in accordance with recognized safety standards

but some remaining hazards may still exist.

These can be minimized by following the instructions in the operating manual.

9

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

ELECTRICAL CONNECTIONS

Plug must be BS1363/A approved.

Always fit a 13 Amp fuse.

Ensure that the outer sheath of the cable is firmly held by the clamp

Neutral

(Blue)

Live

(Brown)

WARNING! READ THESE ELECTRICAL SAFETY INSTRUCTIONS

THOROUGHLY BEFORE CONNECTING THE PRODUCT TO THE

MAINS SUPPLY.

Before switching the product on, make sure that the voltage of your electricity

supply is the same as that indicated on the rating plate. This product is

designed to operate on 230VAC 50Hz. Connecting it to any other power

source may cause damage.

This product may be fitted with a non-rewireable plug. If it is necessary to

change the fuse in the plug, the fuse cover must be refitted. If the fuse cover

becomes lost or damaged, the plug must not be used until a suitable

replacement is obtained.

If the plug has to be changed because it is not suitable for your socket, or due to

damage, it should be cut off and a replacement fitted, following the wiring instructions

shown below. The old plug must be disposed of safely, as insertion into a mains socket

could cause an electrical hazard.

WARNING: THE WIRES IN THE POWER CABLE OF THIS PRODUCT ARE

COLOURED IN ACCORDANCE WITH THE FOLLOWING CODE:

BLUE = NEUTRAL BROWN = LIVE

If the colours of the wires in the power cable of this product do not correspond

with the markings on the terminals of your plug, proceed as follows.

•The Blue wire must be connected to the terminal marked N or coloured Black.

•The Brown wire must be connected to the terminal marked L or coloured Red

We strongly recommend that this machine is connected to the mains supply

via a Residual Current Device (RCD)

If in any doubt, consult a qualified electrician. DO NOT attempt any repairs

yourself.

This symbol indicates that this is a Class II product and does not

require an earth connection.

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

10

COMPONENT OVERVIEW

1 Table extension 9 Tilt adjusting knob

2 Mitre square assembly 10 On/Off switch

3 Blade Guard 11 Dust extract duct

4 Blade 12 Tilt angle scale

5 Parallel Guide Fence assembly 13 Height adjusting handle

6 Work table 14 Stand stabilisers

7 Fence securing handle/clamp 15 Blade removal wrench & key

8 Push stick

11

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

ASSEMBLY

The following items should be supplied in the carton. If any parts are missing,

do not use your table saw until the missing parts are obtained.

Table Saw Fixings Pack

Parallel Guide Fence assembly Push Stick

Mitre Guide/fence 10” TCT Blade (fitted)

Blade Guard Assembly Hex key

Sliding table extension x 2 Ring spanners (large & small)

Stand components:

4 x legs

4 x Upper crossbars

4 x Lower crossbars

4 x Rubber feet

2 x Stand stabilisers

ASSEMBLING THE STAND

NOTE: The table saw can be operated without the stand if required.

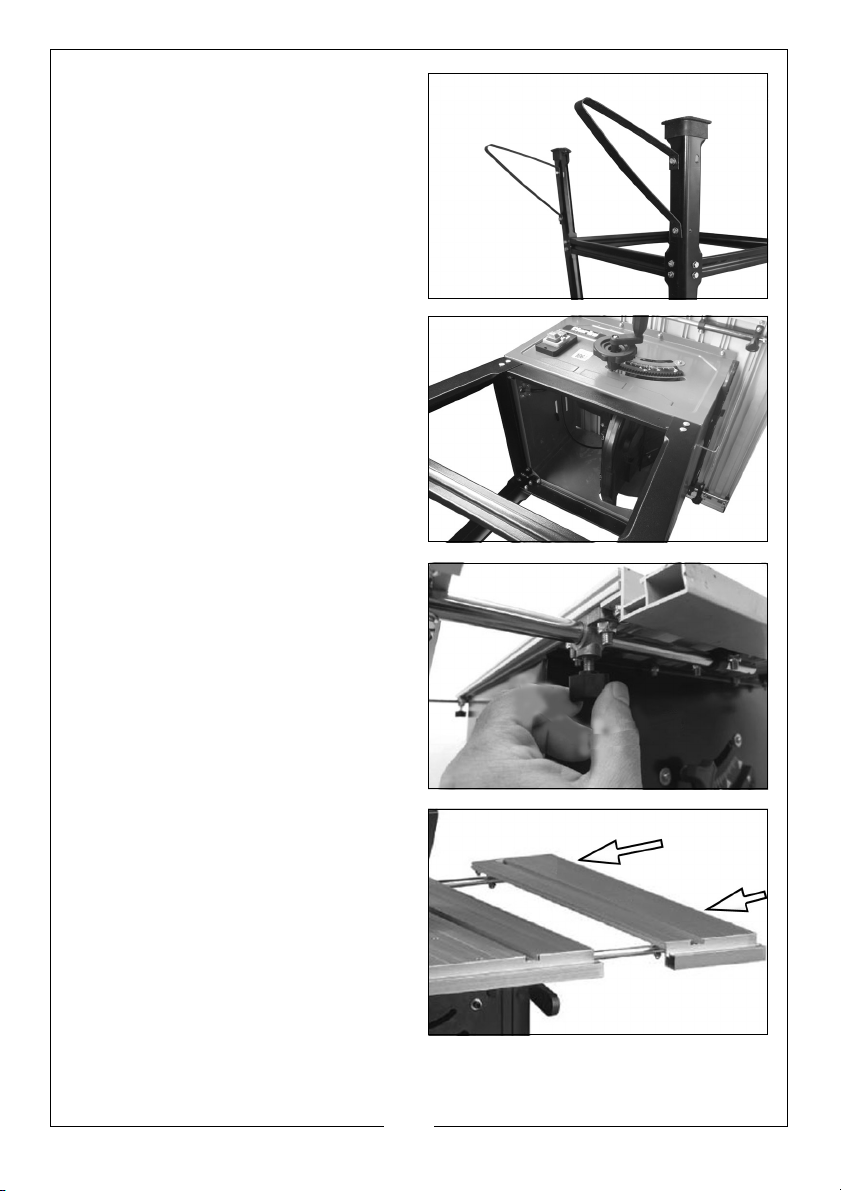

1. Assemble the stand as shown by

joining the cross members to the

legs using the bolts, flat washers,

spring washers and nuts supplied.

• The long cross members are

fitted nearer to the feet.

2. Fit the rubber feet to the legs.

12

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

3. Attach the stabilisers to the rear

legs using the bolts, washers and

nuts supplied.

4. Check that all bolts are tightened

and then turn the table saw and

stand over onto the feet.

5. Fit the table saw to the stand.

Secure the assemblies together by

bolting the stand to the base of

the machine.

FITTING THE TABLE EXTENSION

Fit the table extensions by slackening

the wingnuts on each support arm

and sliding both the rods into the

brackets under the table top.

Slide the table extension to the

required position and tighten the

knobs to secure.

13

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

FITTING THE BLADE GUARD

1. With the blade and riving knife

fitted, fit the blade guard to the

riving knife. Engage the socket in

the guard with the slot in the riving

knife and tighten the screw/

locknut to pinch it to the knife

ensuring it can still move up and

down in use.

FITTING THE MITRE ASSEMBLY

1. Fit the fence to the mitre angle

attachment and secure with the

two thumbscrews. Slide the heads

of the bolts into the channel in the

fence and attach the thumb nuts.

2. Slide the mitre attachment into

the groove in the table top.

FITTING THE PARALLEL FENCE

The parallel fence is essential to

ensure straight line cutting and

should always be used when rip

sawing.

The parallel fence can be mounted

on either side of the table. If you

change the side you will need to fit

the fence the other way round.

1. Engage the parallel fence over

the ends of the table.

2. Use the scale on the table to set the parallel fence to the required distance

from the blade.

3. Lock the parallel fence in the required position by tightening the locking

handle at the end.

The fence may be set at any suitable position on the table to either left or right

of the saw blade.

• Measurement scales (in mm) are provided at the front and back of

the table. These may be used to position the rip fence for rough

cutting. If precision is required, use a ruler between the rip fence and

the front and back of the blade.

14

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CONNECTING THE DUST EXTRACT

This table saw is equipped with a dust

extraction port. For safe operation,

we recommend that a suitable dust

extraction device or vacuum cleaner

is connected during operation.

WARNING: EXCESSIVE SAWDUST BUILD UP AROUND THE MOTOR COULD

POSSIBLY IGNITE AND CAUSE DAMAGE TO THE MOTOR, TABLE SAW OR

YOUR WORKSHOP.

15

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

OPERATION

CAUTION: BEFORE STARTING UP THE SAW ALWAYS CHECK THE

FOLLOWING POINTS:

1. Is the saw blade firmly tightened and can the blade rotate freely?

2. Are all the locking levers firmly locked?

3. Is the riving knife aligned with the saw blade?

4. Is the blade guard fitted?

5. Make sure that the fences are not touching the blade.

6. Are there any wood pieces jammed between the saw blade and

the table?

7. Have all loose workpieces been removed from the table?

8. Have all the setting tools been removed?

9. Wear protective goggles, ear protection and dust mask.

BEFORE STARTING WORK

All covers including the blade cover guard and side cover must be properly

fitted before switching on.

When working with wood that has been used before, take care to remove all

foreign bodies such as nails or screws etc before cutting.

Always stand the table saw on a flat and firm surface.

USE OF THE ON/OFF SWITCH

1. To turn the saw on, press the

green button “I”.

• Wait for the blade to reach its

maximum speed before

making the cut.

2. To turn the saw off again, press

the red button “0”.

NOTE: The blade will spin for several

seconds after the machine is

switched off.

NOTE: The guard must always be lowered over the workpiece before you

begin to cut.

16

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

ADJUSTMENTS

After every new adjustment, we recommend you to make a trial cut in order

to check the new settings.

PARALLEL FENCE

The parallel fence can be mounted on either side of the table. If you change

the side you will need to fit the fence the other way round.

1. Engage the parallel fence over

the ends of the table.

2. Use the scale on the table to set

the parallel fence to the required

distance from the blade.

3. Lock the parallel fence in the

required position by tightening the

locking handle at the end.

MITRE GAUGE

1. Insert the guide bar into the

groove in the table top.

2. Loosen the knob to set the angle

required.

3. Rotate until the pointer points to

the angle on the scale you want.

4. Retighten the knob.

• If required you can remove the

fence from the mitre assembly

using the 2 locking knobs, or slide it in either direction to suit the task

before re-tightening.

SETTING THE BLADE ANGLE

1. Release the bevel locking handle.

2. Tilt the saw blade and motor

assembly until the saw blade is at

the desired angle.

3. Tighten the bevel lock to lock the

blade at the required angle

shown on the scale.

17

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CUTTING TIPS

RIPPING CUTS & CROSS CUTS

Ripping is when you use the saw to cut along the grain of the wood.

The parallel fence must always be used when making ripping cuts.

1. Press one edge of the workpiece

against the parallel fence while

the flat side lies on the saw table.

• The blade guard must always

be lowered over the workpiece

and blade.

• When you make a ripping cut,

never stand in line with the

blade.

2. Set the parallel fence in

accordance with the desired width.

3. Switch on the saw.

4. Place your hands (with fingers

closed) flat on the workpiece and

push the workpiece along the

parallel fence towards the blade.

5. Guide at the side with your left or

right hand (depending on the

position of the parallel fence) only

as far as the front edge of the

guard hood.

6. Always push the workpiece

through to the end of the riving knife using a push stick.

7. Do not remove the offcut piece until the blade has stopped spinning.

8. Secure long workpieces against falling off at the end of the cut (e.g. with a

roller stand etc).

CUTTING NARROW WORKPIECES

Always use a push stick when the workpiece is narrow and for holding the

workpiece flat on the table.

• Take extra care to keep you thumbs away from the saw blade when

feeding the workpiece past the blade.

18

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

When not in use, store the push stick

in its holder on the side of the

machine.

Replace a damaged push stick

immediately.

MITRE CUTS

1. Slide the mitre gauge into the

groove in the table.

2. Adjust the mitre gauge to the

required angle.

3. Press the workpiece firmly against

the mitre gauge.

4. Switch on the saw.

5. Push the mitre gauge and the

workpiece toward the blade to

make the cut.

IMPORTANT: Always hold the guided part of the workpiece. Never hold the

part which is to be cut off.

6. Push the mitre gauge forward until the workpiece is cut all the way

through.

7. Switch off and do not remove the offcut until the blade has stopped.

BEVEL CUTS

Bevel cuts must always be made using the parallel fence.

1. Undo the bevel lock handle and

set the saw to the desired angle

on the scale.

2. Tighten the bevel handle to lock

the blade at the selected angle.

3. Set the parallel fence.

4. Perform the cut as you would for

a ripping cut.

NOTE: If precision is required, use a

protractor between the blade and table.

19

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

MAINTENANCE

WARNING: REMOVE THE PLUG FROM THE MAINS POWER SUPPLY BEFORE

CARRYING OUT ANY ADJUSTMENT OR MAINTENANCE.

Your saw has been designed to operate over a long period of time with a

minimum of maintenance. Continuous satisfactory operation depends upon

proper tool care and regular cleaning.

Never use caustic agents to clean plastic parts.

1. Remove dust regularly from the machine. Cleaning is best carried out with

a fine brush.

2. Regularly clean the table top.

3. Regularly clean the dust collection outlet.

4. Use a half-round file where necessary to keep the teeth sharp. A blade that

is badly dulled or with damaged teeth should be replaced immediately.

CHANGING THE BLADE

WARNING: WEAR SAFETY GLOVES WHEN CHANGING THE SAW BLADE.

WARNING: THE REPLACEMENT BLADE MUST BE RATED TO AT LEAST 7000

RPM.

1. Remove the transparent blade

guard.

2. Remove the table cover panel by

unscrewing the three securing

screws.

• The edge furthest from the

blade has a tongue and

groove joint with the table top.

20

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

3. Using the open spanner and hex

key provided, hold the spindle to

prevent the motor from turning

and undo the saw blade securing

nut (normal thread).

4. Remove the outer retaining disc

followed by the saw blade by

lifting it clear of the motor shaft

and carefully withdrawing it from

above.

5. Replace in reverse order ensuring the saw blade teeth face downwards at

the front of the table.

• The arrow on the face of the blade will show the rotation to be

anticlockwise.

6. Hold the blade firmly when tightening the centre nut, taking care to avoid

injuring your hand on the sharp teeth.

IMPORTANT: Note the running direction. The cutting angle of the teeth must

point in the running direction, i.e. forwards (see arrow on the blade guard).

7. Check that the riving knife lines up with the saw blade.

8. Refit the table insert and the transparent blade guard.

9. Check that all components are properly mounted and in good working

condition before you begin working with the saw again.

21

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

TROUBLE SHOOTING

Problem Probable cause Solution

Saw will not start 1. Saw not plugged in

2. Fuse blown

3. Power cable damaged

Does not make accurate

O

45

and 90O cuts

Material pinches blade 1. Fence not aligned with

Material binds on the

riving knife

Saw makes unsatisfactory

cuts

Material kicked back

from blade slot

Blade does not tilt freely 1. Sawdust in tilting

Blade does not come up

to speed

Machine vibrates 1. Saw not standing securely

1. Table adjuster not set

correctly

blade.

• Warped wood.

• Edge not set square to

fence.

1. Riving knife not aligned

correctly

1. Dull blade

2. Blade mounted backwards

3. Gum or pitch on blade

4. Incorrect blade for work

5. Gum or pitch on table

causing erratic feed

1. Rip fence out of alignment

2. Riving knife not aligned with

blade

3. Feeding stock without rip

fence

4. Riving knife not in place

5. Letting go of wood before

it is all the way past the saw

blade

6. Dull blade

mechanism

1. Extension cable too long 1. Replace or use shorter

on bench

2. Damaged saw blade

1. Plug in the machine

2. Replace fuse

3. Have cable replaced by

your dealer.

1. Check blade with a set

square and adjust pointer

to zero.

1. Check and adjust fence.

Select another piece of

wood.

2. Select another piece of

wood.

1. Check that riving knife is

correctly aligned with blade

1. Replace blade

2. Turn blade around

3. Remove blade and clean

with turpentine and

coarse steel wool

4. Change the blade

5. Clean table with

turpentine and steel wool

and apply wax

1. Align rip fence with blade

2. Align riving knife with

blade

3. Install and use rip fence

4. Install and use riving knife

with guard

5. Push work fully past blade

before releasing work

6. Replace blade

1. Brush or blow out loose

dust

cable

1. Reposition on flat level

surface

2. Replace blade.

22

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

DECLARATIONS OF CONFORMITY

23

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

PARTS DIAGRAM

24

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

PARTS LIST

No Item No Item No Item

1 Work table assembly 31 Stop nut 61 Stand upright

2 Drive motor 32 Threaded rod 62 Flat washer

3 Blade guard 33 Bevel gear 63 Spring washer

4 Locknut 34 S/t screws 64 Nut

5 Washer 35 Screw rod sleeve 65 Short crossbar

6 Tilting frame 36 Screw,washer & nut 66 Rubber foot

7 Retaining ring 37 Drive Base plate 67 Long lower crossbar

8 Connection plate 38 Handwheel mount 68 Long upper crossbar

9 Socket headed bolt 39 Bracket 69 Switchbox

10 Brake column 40 Blade lifting shaft 70 Grommet

11 Brake spring 41 Blade lifting handle 71 Stop sleeve

12 Riving knife 42 Handle end cap 72 Screw

13 Retaining plate 43 Screw, washer & nut 73 Connecting sheet

14 Hex flange bolt 44 Angle locking knob 74 Nut

15 Saw blade 45 Washer 75 Right angle bracket

16 Outer retaining disc 46 Screw 76 Rack

17 Large washer 47 Pointer needle 77 Screw

18 Socket head screw 48 Machine casing 78 Screw

19 Lower guard 49 Nut 79 On/Off switch

20 Rotating stop plate 50 Open bracket 80 Screw

21 Torsion spring 51 Closed bracket 81 Angle degree label

22 Stop plate stand 52 Screw 82 Screw

23 S/t screw 53 Carriage bolt 83 Washer

24 Washer 54 Pushstick 84 Screw

25 Screw 55 Storage hook 85 Cable gland

26 Inner retaining disc 56 Nut 86 Power cable

27 Blade guard 57 Small spanner 87 Hook

28 Riving knife mount 58 Ring spanner 88 Hex key

29 Spring pad 59 Carriage bolt 89 Winding clip

30 Socket head screw 60 Support arm 90 Screw

25

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

91 Handle grip 95 Slide bar 99 End block-left

92 Thumbscrew 96 End block 100 Hex screw

93 Screw 97 Endcap-right 101 Mitre base

94 Pointer needle 98 Mitre fence

FENCE COMPONENTS SET A

No Item No Item No Item

1a Phillips s/t screw 9a Flat washer 17a Locknut

2a Washer 10a Side fence 18a Clamp block

3a Pointer 11a Fence end cap LH 19a Tie rod

4a Roll pin 12a Fence end cap RH 20a Washer 4

5a Washer 13a Carriage bolt 21a Flat washer

6a Cam handle 14a Guide fence 22a Spring washer

7a End casting 15a Clamp arm 23a Bolt

8a Knob 16a Spring

TABLE COMPONENTS SET B

No Item No Item No Item

1b Hex screw M6x30 12b Locknut M6 23b Left side plate

2b Connect rod pad 13b Phillips screw M6x20 24b Right side plate

3b Slide rod 14b Hex screw M6x20 25b Hex screw M5x14

4b Washer 6 15b Fixed sheet 26b Hex screw M6x12

5b Spring washer 6 16b Hex screw M6x12 27b Connecting sheet

6b Wingnut M6 17b Long fixing plate 28b LH scale plate cover

7b Fixing plate cover 18b Hex screw M6x14 29b Left scale plate

8b Locknut M6 19b Slide extend table 30b Scale plate

9b Short fixing plate 20b Hex screw M6x12 31b Right scale plate

10b Triangular knob 21b Table - right part 32b RH scale plate cover

11b Slide rod stand 22b Table -left part 33b Cover nut

26

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

TABLE COMPONENTS SET B

USEFUL ITEMS FROM THE CLARKE CATALOGUE

Refer to the Clarke website www.clarkeinternational.com for a full range of

items for use with this saw. See also the following accessories;

CARS1 Roller Stand Part No: 6500980

CARS 3 in 1 Roller Stand Part No: 6500983

CEWVE1 Vacuum Dust Extractor Part No: 6471168

CVAC20P Vacuum Cleaner Part No: 6471100

27

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

Loading...

Loading...