10” TABLE SAW

MODEL NO: CTS16

PART NO: 6500748

OPERATION & MAINTENANCE

INSTRUCTIONS

ORIGINAL INSTRUCTIONS GC 0820 - ISS 3

INTRODUCTION

Thank you for purchasing this CLARKE product.

The table saw has been designed to use a 250 mm blade to perform the

sawing operations of ripping, cross-cutting, bevelling and mitering wood and

wood products.

Before attempting to use this product, please read this manual thoroughly and

follow the instructions carefully.

GUARANTEE

This product is guaranteed against faulty manufacture for a period of 12

months from the date of purchase. Please keep your receipt which will be

required as proof of purchase.

This guarantee is invalid if the product is found to have been abused or

tampered with in any way, or not used for the purpose for which it was

intended.

Faulty goods should be returned to their place of purchase, no product can

be returned to us without prior permission.

This guarantee does not effect your statutory rights.

ENVIRONMENTAL RECYCLING POLICY

Through purchase of this product, the customer is taking on the

obligation to deal with the WEEE in acance with the WEEE regulations

in relation to the treatment, recycling & recovery and

environmentally sound disposal of the WEEE.

In effect, this means that this product must not be disposed of with general

household waste. It must be disposed of acing to the laws governing Waste

Electrical and Electronic Equipment (WEEE) at a recognised disposal facility.

2

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CONTENTS

The following items should be supplied in the carton. If any parts are missing,

do not operate your table saw until the missing parts are obtained.

1 x Table Saw (main unit) 2 x Long Centre Brace

2 x Table Extension 2 x Short Centre Brace

4 x Support Strut 1 x Wrench

1 x Rip Fence (Parallel Fence) 1 x Saw Blade Spindle Key

1 x Mitre Fence 2 x Leg Support

1 x Mitre Guide Assembly 1 x Riving Knife,

1 x Guide Rail (with scale) 4 x Fixings Bags (A,B,C,D)

1 x Top Guard 4 x Leg, 4 x Rubber Foot

1 x Extraction Hose 1 x Crank Handle

1 x Saw Blade, (fitted) 1 x Operating Manual

SAFETY SYMBOLS

Read this

instruction booklet

carefully before

positioning,

operating or

adjusting the

table saw.

Wear eye

protection.

Keep bystanders

away.

3

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

Wear ear

protection.

Wear a dust mask

that is specially

designed to filter

microscopic

particles.

GENERAL SAFETY INSTRUCTIONS

WARNING: WHEN USING ELECTRIC TOOLS BASIC SAFETY PRECAUTIONS

SHOULD ALWAYS BE FOLLOWED TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK AND PERSONAL INJURY INCLUDING THE FOLLOWING. READ ALL

THESE INSTRUCTIONS BEFORE ATTEMPTING TO OPERATE THIS PRODUCT

AND SAVE THESE INSTRUCTIONS".

SAFE OPERATION

1. Keep work area clear

• Cluttered areas and benches

invite injuries.

2. Consider work area environment

• - Do not expose tools to rain.

• - Do not use tools in damp or

wet locations.

• - Keep work area well lit.

• - Do not use tools in the

presence of flammable liquids

or gases.

3. Guard against electric shock

• Avoid body contact with

earthed or grounded surfaces

(e.g. pipes, radiators, ranges,

refrigerators).

4. Keep other persons away

• Do not let persons, especially

children, not involved in the

work touch the tool or the

extension and keep them away

from the work area.

5. Store idle tools

• When not in use, tools should be

stored in a dry locked-up place,

out of reach of children.

6. Do not force the tool

• It will do the job better and safer

at the rate for which it was

intended.

7. Use the right tool

• Do not force small tools to do

the job of a heavy duty tool.

• Do not use tools for purposes not

intended; for example do not

use circular saws to cut tree

limbs or logs.

8. Dress properly

• Do not wear loose clothing or

jewellery, they can be caught in

moving parts.

• Non-skid footwear is

recommended when working

outdoors.

• Wear protective hair covering to

contain long hair.

9. Use protective equipment

• Use safety glasses.

• Use face or dust mask if working

operations create dust.

10. Connect dust extraction

equipment

• If the tool is provided for the

connection of dust extraction

and collecting equipment,

ensure these are connected

and properly used.

4

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

11. Do not abuse the cable

• Never yank the cable to

disconnect it from the socket.

Keep the cable away from

heat, oil and sharp edges.

12. Secure work

• Where possible use clamps or a

vice to hold the work. It is safer

than using your hand.

13. Do not overreach

• Keep proper footing and

balance at all times.

14. Maintain tools with care

• Keep cutting tools sharp and

clean for better and safer

performance.

• Follow instruction for lubricating

and changing accessories.

• Inspect tool cables periodically

and if damaged have them

repaired by an authorized

service facility.

• Inspect extension cables

periodically and replace if

damaged.

• Keep handles dry, clean and

free from oil and grease.

15. Disconnect tools

• When not in use, before

servicing and when changing

accessories such as blades, bits

and cutters, disconnect tools

from the power supply.

16. Remove adjusting keys and

wrenches

• Form the habit of checking to

see that keys and adjusting

wrenches are removed from the

tool before turning it on.

17. Avoid unintentional starting

• Ensure switch is in "off' position

when plugging in.

18. Use outdoor extension leads

• When the tool is used outdoors,

use only extension cables

intended for outdoor use and so

marked.

19. Stay alert

• Watch what you are doing, use

common sense and do not

operate the tool when you are

tired.

20. Check damaged parts

• Before further use of tool, it

should be carefully checked to

determine that it will operate

properly and perform its

intended function.

• Check for alignment of moving

parts, binding of moving parts,

breakage of parts, mounting

and any other conditions that

may affect its operation.

• A guard or other part that is

damaged should be properly

repaired or replaced by an

authorized service centre unless

otherwise indicated in this

instruction manual.

• Have defective switches

replaced by an authorized

service centre.

• Do not use the tool if the switch

does not tum it on and off.

21. Warning

• The use of any accessory or

attachment other than one

recommended in this instruction

manual may present a risk of

personal injury.

5

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

22. Have your tool repaired by a

qualified person

• This electric tool complies with

the relevant safety rules. Repairs

should only be carried out by

qualified persons using original

spare parts, otherwise this may

result in considerable danger to

the user.

SAW BLADES

1. The maximum speed of the saw

blade must always be equal to or

greater than the no-load speed of

the table saw as specified on the

rating plate.

2. Do not use saw blades which are

damaged or deformed.

3. Only use saw blades

recommended by the

manufacturer and which are the

exact bore and diameter required

for this machine. Do not use any

spacers to make a blade fit onto

the spindle. Use only the blades

specified in this manual, which

comply with EN 847-1.

4. Clean the spindle, flanges

(especially the installing surface)

and hex nut before installing the

blade. Poor installation may cause

vibration/wobbling or slippage of

the blade.

5. Take care that the selection of the

saw blade is suitable for the

material to be cut.

6. Make sure the blade is not

contacting the riving knife or

workpiece before the switch is

turned on.

7. Wear gloves when handling saw

blades and rough material. Saw

blades shall be carried in a holder

whenever practicable.

KICKBACK

Kickback is a sudden reaction to a

pinched, bound or misaligned saw

blade, it causes the workpiece to be

ejected from the tool back towards

the operator. Kickbacks can lead to

serious personal injury.

You can avoid kickbacks by:

a. keeping the blade sharp,

b. keeping the rip fence parallel to

the blade,

c. keeping the riving knife and

blade guard in place and

operating properly,

d. by not releasing the workpiece

until you have pushed it all the

way past the blade,

e. not ripping a workpiece that is

twisted or warped or does not

have a straight edge to guide

along the fence.

If you do not have a clear

understanding of kickback and how it

occurs, DO NOT operate this table

saw!

REMAINING HAZARDS

The machine has been built in

accordance with recognized safety

rules. Some remaining hazards may still

exist.

• The rotating saw blade can

cause injuries to fingers and

hands if the work piece is

incorrectly fed.

• Thrown work pieces can lead to

injury if the work piece is not

properly secured or fed, such as

working without a limit stop.

6

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

• Noise can be a health hazard.

The permitted noise level is

exceeded when working. Be

sure to wear personal protective

equipment such as ear

protection.

• Defective saw blades can

cause injuries. Regularly inspect

the structural integrity of saw

blades.

• The use of incorrect or

damaged mains cables can

lead to injuries caused by

electricity.

• Remaining hazards can be

minimized by following the

instructions in the operating

manual.

7

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

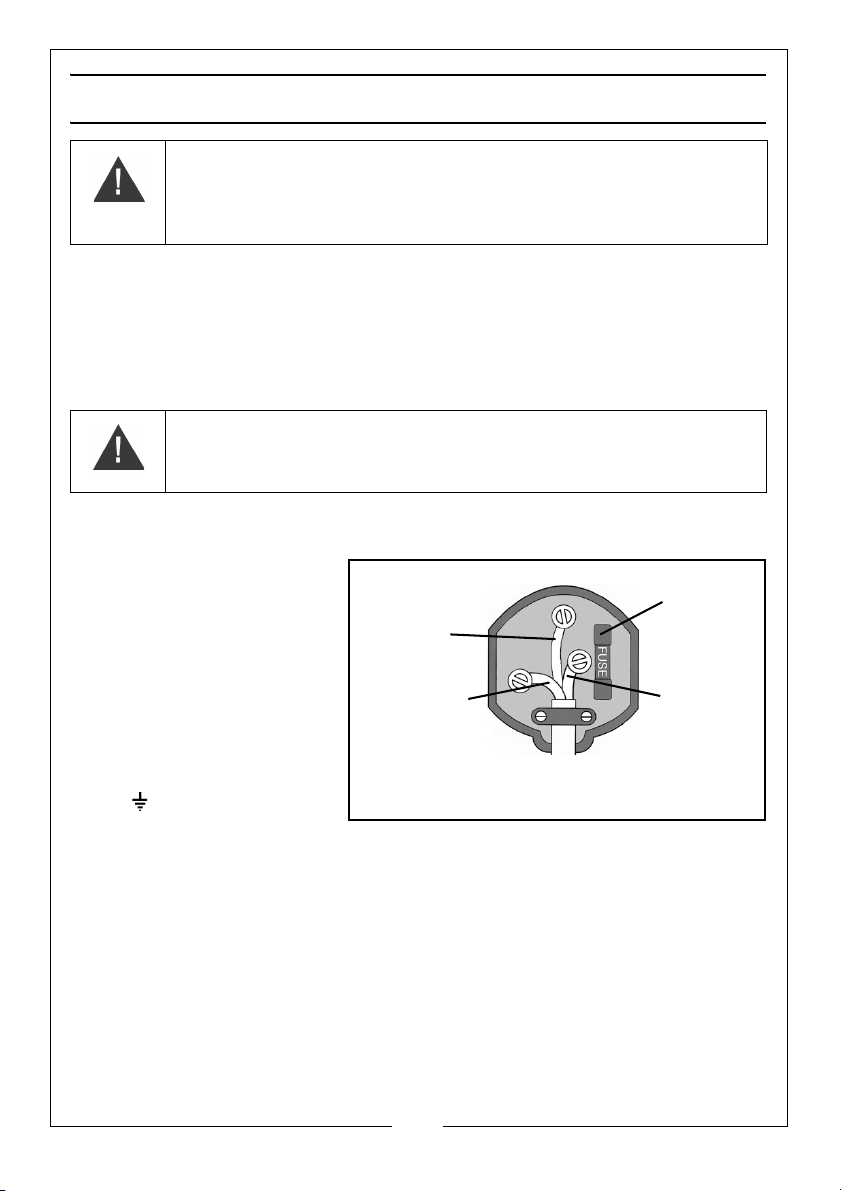

ELECTRICAL CONNECTIONS

Plug must be BS1363/A approved.

Always fit

Ensure that the outer sheath of

Neutral

(Blue)

Live

(Brown)

Earth

(Green and

a 13 Amp

the cable is firmly held by the clamp

fuse.

Yel low)

WARNING: READ THESE ELECTRICAL SAFETY INSTRUCTIONS

THOROUGHLY BEFORE CONNECTING THE PRODUCT TO THE MAINS

SUPPLY.

Connect the mains lead to a standard, 230 Volt (50Hz) electrical supply through

an approved 13 amp BS 1363 plug, or a suitably fused isolator switch.

If the plug has to be changed because it is not suitable for your socket, or

because of damage, it must be removed and a replacement fitted, following

the wiring instructions shown below. The old plug must be discarded safely, as

insertion into a power socket could cause an electrical hazard.

WARNING: THE WIRES IN THE POWER CABLE OF THIS PRODUCT ARE

COLOURED IN ACANCE WITH THE FOLLOWING CODE:

BLUE = NEUTRAL BROWN = LIVE YELLOW AND GREEN = EARTH

If the colours of the wires in the power cable do not agree with the markings on

the plug.

• The BLUE wire must be

connected to the terminal

marked N or coloured

black.

• The BROWN wire must be

connected to the terminal

marked L or coloured red.

• The YELLOW AND GREEN

wire must be connected

to the terminal marked E

or or coloured green.

We strongly recommend

that this machine is connected to the mains supply through a Residual Current

Device (RCD)

If you are not sure, consult a qualified electrician. DO NOT try to do any

repairs.

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

8

ASSEMBLY

ATTACH THE EXTENSION TABLES

1. Turn the table saw upside down.

2. Fix the extension table to the table

saw using two of the M6 x 12 bolts,

washers and nuts supplied.

3. Fit two of the braces to the

extension table using two of the

the M6 x 12 bolts, washers and

nuts supplied.

• The end of the brace nearest to

the table saw body will be

connected later.

4. Put the remaining extension table

on the other side of the table saw

and repeat steps 2-3.

ATTACH THE GUIDE RAIL

Attach the guide rail using 3 M6 x 12

bolts, washers and nuts.

9

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

ATTACH THE LEG KIT TO THE TABLE SAW

1. Attach each leg to a corner of

the table saw using two of the M6

x 16 bolts, washers and spring

washers supplied.

• Note that one of the bolts also

passes through the brace.

2. Fit the rubber feet to the legs.

3. Attach the cross members to the

legs using 16 of the M6 x 12 bolts,

washers and nuts supplied.

• The long cross members are

placed front and rear.

• The short cross members are

placed on the sides.

4. Attach the stabilisers to the rear

legs using two of the M6 x 12 bolts,

washers and nuts supplied.

5. Check that all bolts are tightened

and then turn the table saw over

onto the feet.

10

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

INSTALL THE HEIGHT ADJUSTING HANDLE

1. Remove the nut and washers from

the handle.

2. Place one washer back on the

handle.

3. Pass the handle through the arm

as shown and secure in place

using the remaining washer and

nut.

• Do not overtighten, the handle

must turn freely.

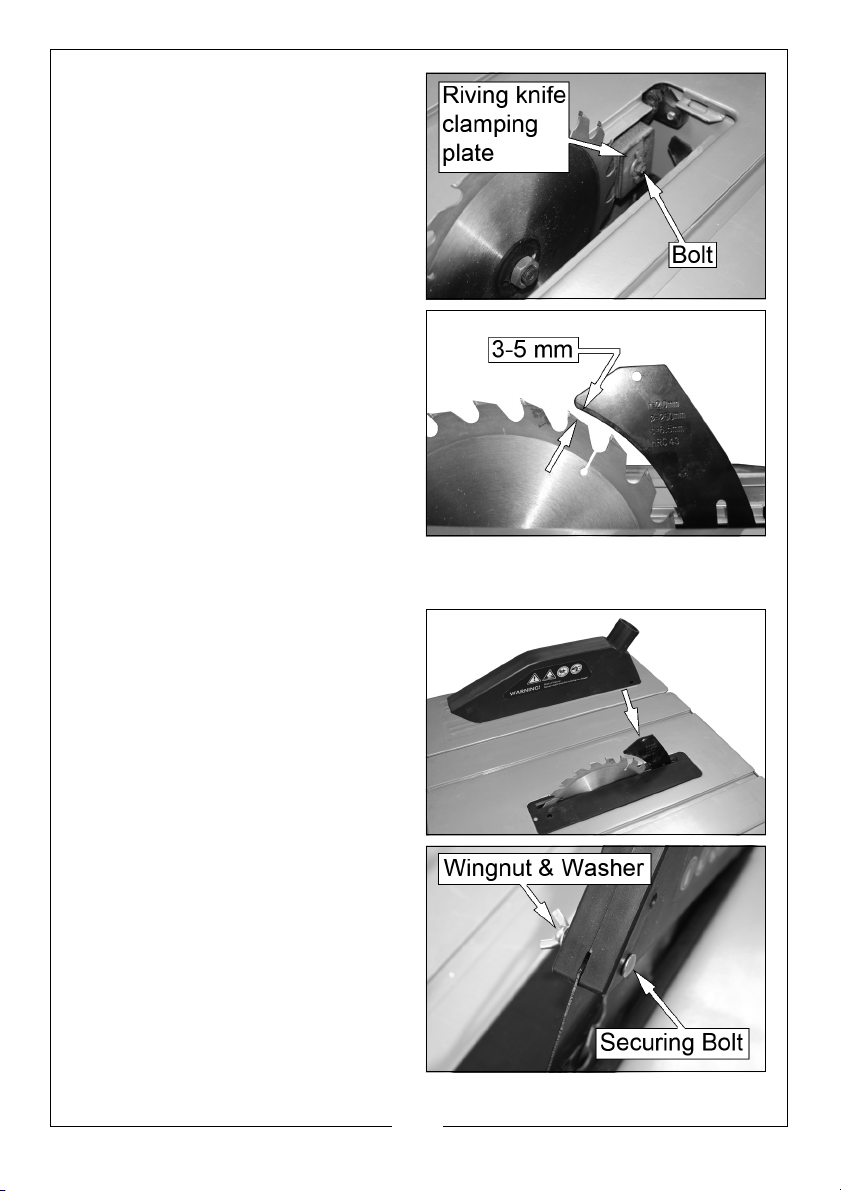

INSTALL THE RIVING KNIFE

1. Remove the table insert screw

and lift out the table insert.

2. Turn the blade height adjusting

handle clockwise to raise the

blade fully.

11

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

3. Loosen the bolt on the riving knife

clamping plate by a few turns.

4. Place riving knife behind the

clamp and push it all the way

down.

5. Adjust the riving knife until there is

a 3-5 mm gap between the riving

knife and the saw blade.

6. Tighten the riving knife clamp.

7. Replace the table insert.

ATTACH THE BLADE GUARD

1. Mount the blade guard on the

riving knife as shown.

2. Use the securing bolt to secure

the blade guard.

3. Do not overtighten - the blade

guard must rise and fall freely.

12

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

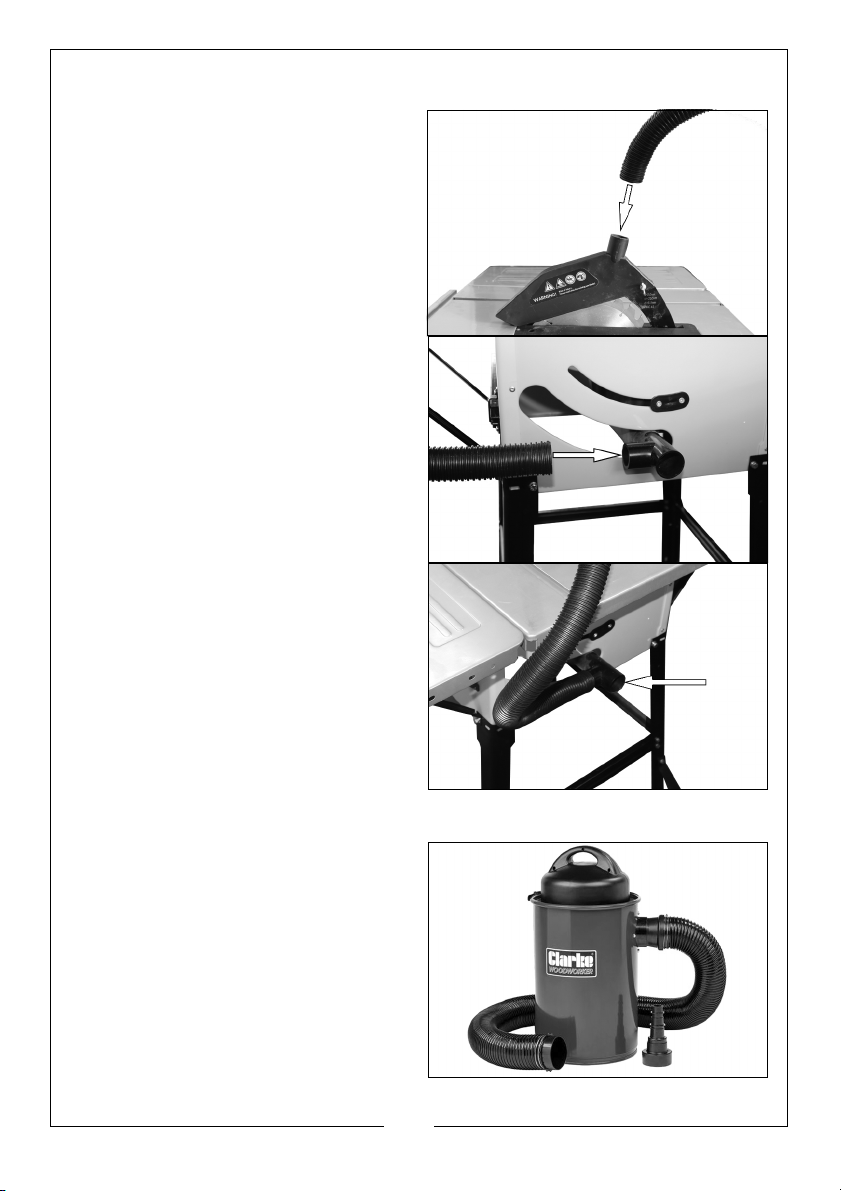

ATTACH THE DUST HOSE

1. Attach the hose to the top of the

blade guard.

2. Attach the other end of the hose

to the dust outlet on the rear of

the table saw.

3. Always use a dust extracting

device.

• The workplace should also be

well ventilated.

• The dust extraction port has an

inner diameter of 36 mm and

an outer diameter of 40 mm.

RECOMMENDED DUST EXTRACTING DEVICE

• The Clarke CWVE1 Vacuum

Extractor is an ideal companion

product for your CTS16 Table

saw and is available at your

local Clarke dealer (part

number 6471168).

13

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

ADJUSTMENTS

After every new adjustment we recommend you to make a trial cut in order to

check the new settings.

PARALLEL FENCE

CUTTING WIDTH

The parallel fence can be mounted on either side of the saw table. If you

change the side, you will need to attach the parallel fence to the other side of

the holder.

1. Slide the parallel fence into the

guide rail of the saw table.

2. Use the scale on the guide rail to

set the parallel fence the required

distance from the blade.

3. Lock the parallel fence in the

required position by pressing

down on the locking lever.

FENCE HEIGHT

The parallel fence has two different guide faces.

• For thick material you should use the high side of the parallel fence.

• For thin material you should use the low side of the parallel fence.

To change the parallel fence from

one to the other you have to:

1. Loosen the two thumb screws.

2. Remove the parallel fence from

the holder.

3. Remount the parallel fence onto

the holder by sliding the securing

bolt heads on the holder into the

relevant mounting slot in the

parallel fence.

4. Retighten the two thumb screws.

14

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

MITRE GAUGE

1. Insert the guide bar into one end

of the groove on the table.

2. Loosen the locking knob by

twisting it counterclockwise.

3. Rotate the gauge to the angle

you want.

4. Retighten the locking knob.

SETTING BLADE HEIGHT

Turn the blade height adjusting

handle to set the blade to the

required height.

• Clockwise to raise the blade.

• Anti-clockwise to lower the

blade.

SETTING THE BLADE ANGLE

1. Loosen the bevel lock.

2. Grasp the blade height

adjustment wheel and move it so

that the pointer is aligned with the

required angle shown on the

scale.

3. Lock the blade at the desired

angle by retightening the bevel

lock.

15

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

OPERATION

CAUTION: BEFORE STARTING THE SAW ALWAYS CHECK THE FOLLOWING

POINTS:

1. Is the saw blade firmly tightened?

2. Are all the locking levers firmly locked?

3. Is the riving knife aligned with the saw blade?

4. Is the blade guard fitted?

5. Make sure that the fences are not touching the saw blade.

6. Can the blade rotate freely?

7. Are there any wood pieces jammed between the blade and the

table insert?

8. Have all loose workpieces been removed from the table saw?

9. Have all the setting tools been removed?

10. Wear protective goggles, ear protection and dust mask.

ON/OFF SWITCH

1. To turn the saw on, press the

green start button “I”.

• Wait for the blade to reach its

maximum speed before

commencing with the cut.

2. To turn the saw off, press the red

stop button “0”.

NOTE: The blade will spin for several

seconds after the machine is

switched off.

MOTOR BRAKE

The motor is fitted with a brake which should stop the saw blade in under 10

seconds.

If this time is exceeded, the brake must be repaired by an authorised service

centre.

A saw with a defective brake must not be used.

16

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

OVERLOAD RESET BUTTON

This table saw has a thermal overload

protection device.

If the saw gets too hot, the thermal

overload device cuts the power

which prevents damage to the

motor.

If the thermal overload device

operates, let the motor cool down for

5 minutes and push the reset button

located just above the Start (I) button

If you start the saw and the overload cutout operates again, disconnect from

the power supply and have your table saw examined by a qualified service

agent.

CUTTING TIPS

RIPPING CUTS

Ripping is when you use the saw to cut along the grain of the wood.

The parallel fence must always be used when making ripping cuts.

1. Press one edge of the workpiece

against the parallel fence while

the flat side lies on the saw table.

• The blade guard must always

be lowered over the workpiece

and blade.

• When you make a ripping cut,

never stand in line with the

blade.

2. Set the parallel fence in

accordance with the workpiece height and the desired width.

3. Switch on the saw.

4. Place your hands (with fingers closed) flat on the workpiece and push the

workpiece along the parallel fence towards the blade.

5. Guide at the side with your left or right hand (depending on the position of

the parallel fence) only as far as the front edge of the blade guard.

17

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

6. Always push the workpiece through to the end of the riving knife using a

push stick.

7. Do not remove the offcut piece until the blade has stopped spinning.

8. Secure long workpieces against falling off at the end of the cut (e.g. with a

roller stand etc.).

CUTTING NARROW WORKPIECES

Always use a push stick when the

workpiece is smaller than 120 mm in

width.

When not in use, place the push stick

in its storage clip on the side of the

saw.

Replace a worn or damaged push

stick immediately.

BEVEL CUTS

Bevel cuts must always be made using the parallel fence.

1. Loosen the bevel lock.

2. Select the desired angle on the

scale.

3. Retighten the bevel lock to lock

the blade at the selected angle.

4. Set the parallel fence.

5. Perform the cut as you would for

a ripping cut.

18

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CROSS CUTS

1. Slide the mitre gauge into one of

the grooves in the table.

2. Adjust the mitre gauge to the

required angle.

3. Press the workpiece firmly against

the mitre gauge.

4. Switch on the saw.

5. Push the mitre gauge and the

workpiece toward the blade to

make the cut.

IMPORTANT: Always hold the guided part of the workpiece. Never hold the

part which is to be cut off.

6. Push the mitre gauge forward until the workpiece is cut all the way

through.

7. Switch off the saw. Do not remove the offcut until the blade has stopped

rotating.

TRANSPORTING

1. Turn the table saw off and disconnect it from the power supply before it is

moved

2. At least two people should carry the saw. Do not lift using the table

extensions. only use the hand holds for moving this table saw. These are

found in the housing on both sides of the main body.

3. Protect the saw against knocks, jolts and strong vibrations. e.g. when it is

transported in motor vehicles.

4. Secure the saw against tilting and sliding.

5. Never hold the blade guard when lifting the table saw.

STORAGE

Store the table saw in a dry place well out of reach of children.

19

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

MAINTENANCE

WARNING: REMOVE THE PLUG FROM THE MAINS POWER SUPPLY BEFORE

CARRYING OUT ANY ADJUSTMENT, SERVICING OR MAINTENANCE.

CLEANING

WARNING: THE TABLE SAW MUST NOT BE SPRAYED WITH WATER OR

PLACED IN WATER OTHERWISE THERE IS A RISK OF ELECTRIC SHOCK.

• Keep the safety devices, air vents and motor housing as free of dust

and dirt as possible. Wipe all dust off with a clean cloth or blow it out

with compressed air at a low pressure.

• We recommend that you clean the saw immediately after every

use.

• Clean the saw regularly with a damp cloth and some soft soap. Do

not use any detergents or solvents; these might attack the plastic

parts. Make sure that no water can get into the interior of the saw.

• Motor bearings are sealed for life and do not require oiling.

CHANGING THE BLADE

WARNING: REMOVE THE PLUG FROM THE MAINS SUPPLY BEFORE

CARRYING OUT ANY ADJUSTMENT, SERVICING OR MAINTENANCE

1. Turn the blade height adjusting

handle clockwise to raise the

blade fully.

2. Remove the table insert screw

and lift out the table insert.

20

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

3. Undo the blade retaining nut

using the wrench and spindle key

supplied as shown.

4. Take off the nut and outer flange

and remove the old saw blade.

• Replacement blades are

available from our parts

department (part number

ZLGCTS16114).

5. Clean the blade flange faces

thoroughly before fitting the new blade.

6. Mount and fasten the new blade in reverse order.

IMPORTANT: Note the running direction. The cutting angle of the teeth must

point in the running direction, i.e. forwards (see the arrow on the blade

guard).

7. Loosen the bolt on the riving knife

clamping plate by a few turns.

8. Adjust the riving knife until there is

a 3-5 mm gap between the riving

knife and the saw blade.

9. Tighten the riving knife clamp.

10. Replace the table insert.

11. Replace the saw blade guard.

12. Check to make sure that all

components are properly

mounted and in good working

condition, before you begin working with the saw again.

WARNING: RESET THE RIVING KNIFE EACH TIME THE SAW BLADE IS

REPLACED (STEP 7 ABOVE).

21

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

SPECIFICATIONS

Voltage 230V AC / 50Hz

Power input 1600 W

No-load speed 4100 rpm

Overload protection Yes

Table size with extension: 960 mm x 640 mm

Dust Extractor socket 36 mm (internal) - 40 mm (external)

Blade size: Outside Diameter 250 mm

Bore Diameter 30 mm

Thickness 2.4 mm

Maximum cut depth @ 90 degrees 73 mm

Maximum cut depth @ 45 degrees 53 mm

Machine weight: 22.5 kg

Sound pressure level LpA 96.2 dB (A)

Sound power level LWA: 109.2 dB (A)

Duty Cycle S6 40% 5mins

Please note that the details and specifications contained herein, are correct

at the time of going to print. We reserve the right to change specifications at

any time without prior notice.

22

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

PARTS DIAGRAM AND LIST

23

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

1 Rubber Foot ZLGCTS16001

2 Side Table Sup-

port

3 Washer 6 ZLGCTS16003

4 Spring Washer 6 ZLGCTS16004

5 Bolt 8.8 M6x16 ZLGCTS16005

6 Bolt 8.8 M6x12 ZLGCTS16006

7 Flange Nut M6 ZLGCTS16007

8 Screw M4x16 ZLGCTS16008

9 Screw M5x12 ZLGCTS16009

10 Rack ZLGCTS16010

11 Washer 4 ZLGCTS16011

12 Screw ST4.2x9.5 ZLGCTS16012

13 Big Washer 6 ZLGCTS16013

14 Limiting Washer ZLGCTS16014

15 Scale ZLGCTS16015

16 Capacitor ZLGCTS16016

17 Magnetic ring ZLGCTS16017

18 Switch ZLGCTS16018

19 Swich Fixing

Cover

20 Overcurrent Pro-

tector “

21 Screw M4x10 ZLGCTS16021

22 Lockwasher 4 ZLGCTS16022

23 Gasket ZLGCTS16023

24 Switch Box ZLGCTS16024

25 EU Plug& Cable ZLGCTS16025

26 Cable Clamp ZLGCTS16026

27 Cable Gland ZLGCTS16027

28 Screw M5x8 ZLGCTS16028

29 Cable Fixing

Plate

30 Handle ZLGCTS16030

31 Rocker ZLGCTS16031

32 Lock Nut M6 ZLGCTS16032

33 Spring Washer 4 ZLGCTS16033

34 Big Washer 4 ZLGCTS16034

ZLGCTS16002

ZLGCTS16019

ZLGCTS16020

ZLGCTS16029

35 Screw M4x20 ZLGCTS16035

36 Washer 8 ZLGCTS16036

37 Strut Spacer Bush ZLGCTS16037

38 Bevel Gear ZLGCTS16038

39 Motor Adjusting

Shaft

40 Motor Stop Block ZLGCTS16040

41 Roll Pin 3*16 ZLGCTS16041

42 Hand Wheel ZLGCTS16042

43 Roll Pin 4*22 ZLGCTS16043

44 Adjusting Wheel

Axle

45 Support Bush ZLGCTS16045

46 Support Bracket II ZLGCTS16046

47 Star Knob M6X15 ZLGCTS16047

48 Screw M4x12 ZLGCTS16048

49 Pointer ZLGCTS16049

50 Screw (Zn) M5*10 ZLGCTS16050

51 Screw M8*16 ZLGCTS16051

52 Spring Washer 8 ZLGCTS16052

53 Shaft Holder ZLGCTS16053

54 Shaft Fixing 1 ZLGCTS16054

55 Support Bracket I ZLGCTS16055

56 Screw (Zn) M5*14 ZLGCTS16056

57 Lock Nut M5 ZLGCTS16057

58 Screw M5*25 ZLGCTS16058

59 Needle Roller

Bearing

60 Flat Key A 5*10 ZLGCTS16060

61 Motor Holder ZLGCTS16061

62 Motor ZLGCTS16062

63 Guiding Rod ZLGCTS16063

64 Miter Gauge ZLGCTS16064

65 Circlip 15 ZLGCTS16065

66 Driven Gear ZLGCTS16066

67 Pan Head Screw

M4*10

68 Bearing 6003-2RS ZLGCTS16068

ZLGCTS16039

ZLGCTS16044

ZLGCTS16059

ZLGCTS16067

24

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

69 Bearing Seat

Shaft

70 Bearing Seat ZLGCTS16070

71 Spring Washer 5 ZLGCTS16071

72 Screw M5*12 ZLGCTS16072

73 Shaft Fixing 2 ZLGCTS16073

74 Lock Knob ZLGCTS16074

75 Locknut ZLGCTS16075

76 Screw ST3.5*13 ZLGCTS16076

77 End Cap ZLGCTS16077

78 Cross Stop ZLGCTS16078

79 Bolt M6*25 ZLGCTS16079

80 Main Scale ZLGCTS16080

81 Front Rail ZLGCTS16081

82 Table Extension ZLGCTS16082

85 Screw ST2.9*19 ZLGCTS16085

86 Bolt M6*40 ZLGCTS16086

87/88 Guard ZLGCTS16087/

89 Wing Bolt ZLGCTS16089

90 Extraction Hose ZLGCTS16090

91 Rip Fence ZLGCTS16091

92 Bolt M6*45 ZLGCTS16092

93 End Cap For

Square Tube

94 Square Tube ZLGCTS16094

95 Screw M5*12 ZLGCTS16095

96 Screw ST4*6 ZLGCTS16096

97 Magnifier ZLGCTS16097

98 Axle ZLGCTS16098

99 Lock Pad ZLGCTS16099

100 Sliding Seat ZLGCTS16100

101 Nut M5 ZLGCTS16101

102 Lock Handle ZLGCTS16102

103 Screw M5*16 ZLGCTS16103

104 Fixing Block ZLGCTS16104

105 Fixing Clamp ZLGCTS16105

ZLGCTS16069

88

ZLGCTS16093

106 Mounting Plate ZLGCTS16106

107 Dustproof Cover ZLGCTS16107

108 Connecting Plate ZLGCTS16108

109 Bolt 8.8 M6*16 ZLGCTS16109

110 Riving Knife ZLGCTS16110

111 Pressing Plate ZLGCTS16111

112 Washer 5 ZLGCTS16112

113 Pressure Kit ZLGCTS16113

114 Saw Blade Z24 ZLGCTS16114

115 Blade Pressing

Plate

116 Thin Nut M16 ZLGCTS16116

117 Torsion Spring ZLGCTS16117

118 Splash Guard ZLGCTS16118

119 Washer 4 ZLGCTS16119

120 Blade Guard ZLGCTS16120

121 Housing ZLGCTS16121

123 Screw ST4.2*9.5 ZLGCTS16123

125 Push Stick ZLGCTS16125

126 Saw Blade Spin-

dle Key

127 Open-ended

Wrench

128 Longitudinal Strut ZLGCTS16128

129 Leg ZLGCTS16129

130 Cross Strut ZLGCTS16130

131 Stability Bar ZLGCTS16131

ZLGCTS16115

ZLGCTS16126

ZLGCTS16127

25

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

DECLARATION OF CONFORMITY

26

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

27

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

Loading...

Loading...