2.5 TONNE GARAGE JACK

Model No: CTJ2500QLG

P ART NO: 7621802

OPERATING & MAINTENANCE

INSTRUCTIONS

GC07/12

INTRODUCTION

Thank you for purchasing this CLARKE Garage Jack.

Before attempting to use this product, please read this manual throughout

and follow the instructions carefully. Thoroughly familiarise yourself with this

product & its operation in order to ensure the safety of yourself and others

around you. In doing so, you can look forward to the product giving you

long and satisfactory service.

GUARANTEE

This product is guaranteed against faulty manufacture for a period of 12

months from the date of purchase. Please keep your receipt which will be

required as proof of purchase. This guarantee is invalid if the product is found

to have been abused or tampered with in any way, or not used for it’s

intended purpose.

Faulty goods should be returned to their place of purchase, no product can

be returned to us without prior permission. This guarantee does not effect

your statutory rights.

SPECIFICATION

erutaeF noitacificepS

thgieWgk6.52

)HxWxL(snoisnemiDeldnahtuohtiwmm032x503x306

daoLdetaRgK0052

elddaSfothgieHniMmm001

eHmm564

xaMelddaSfothgi

yticapaCliOertil91.0

thgieHxaMotniMmorfsekortSfooN)daolonhtiw(5.5

Please note that details and specifications contained herein, are correct at

the time of going to print. However, CLARKE International reserve the right to

change specifications at any time without prior notice.

2

Parts & Service: 020 8988 7400/E-mail:Parts@clarkeinternational.com or Service@clarkeinternational.com

GENERAL SAFETY PRECAUTIONS

GENERAL

1. ALWAYS read and ensure you fully understand the following precautions

and the hazards associated with this product. Do not allow anyone who

has not read these instructions to use the jack.

2. Only use this jack for its intended purpose.

3. NEVER carry out any modifications to this product. If experiencing difficulty

of any kind consult your local dealer.

WORK AREA

1. NEVER use the jack on sloping surfaces, only on level ground. The jack

may move away slightly as soon as it lifts the tyre from the ground.

2. DO NOT start the vehicle engine with the jack in use.

3. This jack is for lifting only. DO NOT move a load using the jack as a dolly.

4. Ensure the load is taken by the full saddle and that the point of lift on the

load is of sufficient strength to support the full load adequately.

5. Never allow children or bystanders in the area while the jack is in use.

6. NEVER work underneath a vehicle supported only by this product. If

working under a vehicle, always use stands designed for the purpose.

7. Ensure the jack is on a firm solid base and that there is no likelihood of it

slipping when under load.

8. Ensure that all personnel are well clear of a load being raised or lowered.

SERVICING & REPAIRS

1. Check the jack for damage before use and do not use if damaged. If in

doubt, DO NOT use. Consult your local dealer.

2. ALWAYS use spare parts supplied by Clarke International. Using nonstandard parts could be extremely dangerous.

3. Ensure that the jack is properly maintained at all times and that no

corrosion or other damage is allowed to weaken any part of it.

4. When necessary, have your jack serviced or repaired by a qualified

technician using identical replacement parts. This will ensure that the

safety of the jack is maintained.

5. NEVER use the jack if it has been subjected to excess load (over 2.5

tonne). The jack should be removed from service immediately and fully

inspected by qualified personnel and passed as serviceable before further

use.

Please keep these instructions in a safe place for future reference.

3

Parts & Service: 020 8988 7400/E-mail:Parts@clarkeinternational.com or Service@clarkeinternational.com

UNPACKING AND ASSEMBLY

1. Remove the retaining clip, by

pressing the handle mounting

downwards and releasing the clip

from the base of the jack and

from the handle opening.

2. Undo the thumbscrew until the

lower handle can be inserted fully

into the handle socket.

• The handle has a groove which

should engage with the thumb

screw once it is re-tightened.

• The socket within the handle will

engage with the jack control

valve.

3. Re-tighten the thumb screw to

secure the lower handle.

4. Add the upper handle by sliding it

onto the lower handle and

securing with the bolt provided.

Groove

Securing bolt

Handle

Mounting

Thumb

Screw

Retaining

Clip

OPERATION

Before use, visually inspect the jack for oil leaks or any other sign of damage.

Should any be apparent, have the jack inspected and repaired by a

qualified technician.

WARNING! NEVER WORK ON THE VEHICLE WHEN SUPPORTED BY A

JACK. THIS IS A HIGHLY DANGEROUS PRACTICE. THE VEHICLE MUST BE

SUPPORTED ON AXLE STANDS, OR SUITABLE SUPPORTS, BENEATH THE

JACKING/SUPPORT POINTS RECOMMENDED BY THE VEHICLE

MANUFACTURER. THERE SHOULD BE NO LOAD ON THE JACK.

1. Ensure the vehicle to be raised is stable and on firm level ground with the

wheels chocked.

2. Position the jack so that the saddle is directly beneath the lifting point.

• Consult the vehicle handbook to determine suitable lifting points.

3. Engage the square socket in the end of the handle with the control valve

(positioned within the handle mounting). Turn clockwise to close the valve.

4. Pump the handle to raise the saddle until it reaches the vehicle lifting

point.

4

Parts & Service: 020 8988 7400/E-mail:Parts@clarkeinternational.com or Service@clarkeinternational.com

5. Take care that no obstruction prevents a clean lift. Keep all personnel at a

safe distance before pumping the handle to lift the vehicle.

NOTE: The jack may move slightly during operation. It is important

therefore, that the floor is clean and completely free from debris.

6. Position axle stands directly beneath suitable supporting points on the

vehicle, and very gently twist the handle anticlockwise.

• This will open the control valve to lower the load onto the stands.

7. To stop it lowering at any point, turn the handle clockwise again. Always

avoid a rapid descent by turning the handle slowly.

8. Carefully lower the vehicle onto the axle stand, checking constantly,

preferably with an assistant, that the vehicles supporting point rests snugly

and cleanly on the stand, and that the supporting stand is stable before

all the weight is taken.

NOTE: Ensure this operation is carried out under complete control. DO NOT

allow the load to drop suddenly as this could damage internal parts.

9. Completely remove the jack from the vehicle.

MAINTENANCE

PURGING AIR FROM THE SYSTEM

If air bubbles become trapped inside the hydraulic system, the efficiency of

the jack will be reduced. Air can be purged from the system as follows.

1. Use the handle to turn the control

valve counter-clockwise, relieving

the pressure within the jack, then

remove the cover plate & oil filler

plug. A broad-bladed screwdriver

is required for the plug.

2. Pump the handle several times to

purge air from the system.

3. Replace the oil filler plug, then

turn the control valve clockwise

and test the jack. If efficiency is still low, check the oil level as below.

Cover Plate

Filler

Plug

CHECKING THE OIL LEVEL

If the jack has been stored for long periods, check for oil leaks before use. If

necessary, check the oil level as follows:

1. Ensure the jack is fully lowered by using the handle to turn the control

valve fully anticlockwise.

2. Remove the cover plate and the oil filler plug.

5

Parts & Service: 020 8988 7400/E-mail:Parts@clarkeinternational.com or Service@clarkeinternational.com

• The oil should be almost level with the bottom of the oil filler hole.

• Oil can be topped up using Clarke Hydraulic Oil (p/no 3050830 for 1 litre).

OIL REPLACEMENT

1. With the jack lowered, remove the cover plate and the filler plug. Tilt the

jack onto its side and drain the old oil into a container.

2. Return the jack to upright and refill with hydraulic oil up to the bottom of

the oil filler hole.

3. Purge any air from the system and replace the oil filler plug.

4. Dispose of old oil appropriately and be sure to wipe up any spillage.

GENERAL CARE

1. Periodically lubricate the hinges, front wheels & rear castors with light oil.

2. Store in a dry location.

3. In the event of damage or broken components, replacements are

available from Clarke Parts & Service.

TROUBLESHOOTING

MELBORP ESUAC NOITULOS

otesiartonlliwkcaJ

.thgiehllufeht

ehtdlohtonlliwkcaJ

.daol

lyC

rewoltonseodkcaJ

.denepoevlavnehw

ygnopssleefkcaJ

.gnitfilnehw

Parts & Service: 020 8988 7400/E-mail:Parts@clarkeinternational.com or Service@clarkeinternational.com

.levelliowoLfipupotdnaegakaelrofkcehC

.metsysniriAsametsysmorfr

.nrowsgnir-OrofrelaedekralCruoyotnruteR

vesaeleR

.gnitaes

.liohtiw

cennocsiD

tonevla

.desolcylthgit

tonevlavesaeleR

.metsysniriAsametsysmorfriaegruP

dellif-revoredni

mratovipronotsiP

.gnidnibrotneb

rodet

.gnirpsnruternekorb

stnenopmocdegniH

.yleerfgnivomton

6

.metsysnideppartriAsametsysmorfriaegruP

.deriuqer

iaegruP

.5egapnodebircsed

.luahrevo

.yllufgnisolcsievlavkcehC

rofrelaedekralCruoyotnruteR

hrevo

.lua

.5egapnodebircsed

.lioevissecxeffoniarD

rofrelaedekralCruoyotnruteR

.riaper

rofrelaedekralCruoyotnruteR

.riaper

degnihetacirbuL

.stnioj

.5egapnodebircsed

DECLARATION OF CONFORMITY

7

Parts & Service: 020 8988 7400/E-mail:Parts@clarkeinternational.com or Service@clarkeinternational.com

GENERAL COMPONENT PARTS

oN tsiLstraP ytQ oN noitpircseD ytQ

121MtuN452eldnaHreppU1

2rehsaW262ylbmessApmuPciluardyH1

3hsuB272mm02pilcriC2

4leehWtnorF282egakniLnnoCpmuP1

5etalPemarF29204x4

6eldnaHgniyraC203tfahStoviPrelloR1

752x8MwercSdh/S413relloR1

8rehsaWtilpS423wercSteSeldnaH1

9mm61pilcriC233mm21pilcriC1

01e

11elxAtnorF15361x5MwercS4

21etalPrevoC163ekoYeldnaH1

31doReiT173niPgniniateRekoY2

L183doReiT1

41ylbmessAmrAgnitfi

51elddaS193reffuBrebbuR2

61wercSgnixiFellddaS10402x8wercSdh/S4

7102x01MwercS0114hsuBtoviP2

81rehsaWgnirpS0124mm21reh

91rehsaWegraL234mm52x21MwercS6

02rehsaWegraL244daPelddaS1

12tekcarBrotsaCraeR254pilCgniniateR2

gakniLsuidaR24321x3niP1

niP1

saW6

22yssArotsaCraeR264gnirpS

3253x6tloB174tnioJlasrevinU1

42eldnaHrewoL1

nruteR2

When requesting replacement parts, please quote the prefix;

HACTJ2500QLG, followed by the number listed above.

8

Parts & Service: 020 8988 7400/E-mail:Parts@clarkeinternational.com or Service@clarkeinternational.com

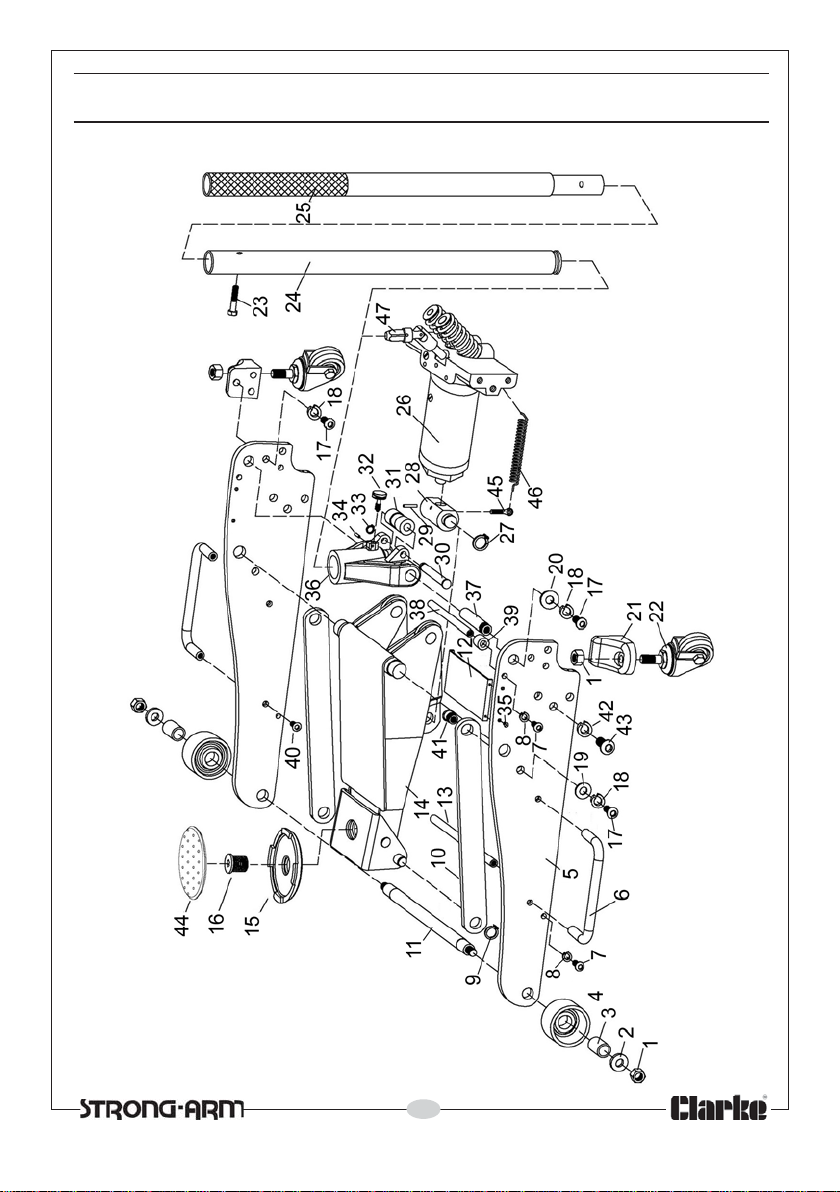

GENERAL COMPONENT PARTS

9

Parts & Service: 020 8988 7400/E-mail:Parts@clarkeinternational.com or Service@clarkeinternational.com

HYDRAULIC COMPONENT PARTS

ENVIRONMENTAL PROTECTION

One of the most damaging sources of environmental pollution is oil

products. Never throw away used hydraulic oil with domestic refuse or

flush it down a sink or drain. Collect any hydraulic oil in a leak proof

container and take it to your local waste disposal site.

If disposing of this product or any damaged components, do not dispose of

with general waste. This product contains valuable raw materials and should

be taken to your local civic amenity site for recycling of metal products.

10

Parts & Service: 020 8988 7400/E-mail:Parts@clarkeinternational.com or Service@clarkeinternational.com

HYDRAULIC COMPONENT PARTS

oN tsiLstraP ytQ oN noitpircseD ytQ

84gniRlaeSmottoB # 186gniRgnilaeSrednilyC2

94riovreseRliO196rednilyCllamS1

05gniRlaeSpoT # 107gniR-O # 2

15gniR-O # 117pilcr

25tuNpoT127notsiP1

35doRnotsiP137gnirpSnruteRnotsiP1

45mm03pilcriC147revoCtsuD1

55esaBdoRnotsiP157reniateRgnirpSnruteR1

5rehsaW # 167mm51gniRgniniateR1

6

75gniR-O # 177tnioJlasrevinU1

85redloHliO187mm6llaBleetS1

95gniRgnilaeSreppoC19721x6MgulPwerc

06gnitsaCydoB108rednilyCegraL1

16mm4llableetS118gniR-O # 2

26tekcoSllaB228mm51reniateR # 2

36gnirpSevlaVytefaS238notsiP1

46werc

56gniR-O # 358revoCtsuD1

66gulPni-wercS368reniateRgnirpSnruteR1

76mm5llaBleetS578mm02

StsujdAerusserP248gnirpSnruteRnotsiP1

iC # 2

S1

reniateR1

a/ntiKlaeSciluardyHa/n

tiKlaeSehtfostnenopmocera#dekramsmetI

When requesting replacement parts, please quote the prefix;

HACTJ2500QLG, followed by the number listed above.

11

Parts & Service: 020 8988 7400/E-mail:Parts@clarkeinternational.com or Service@clarkeinternational.com

Loading...

Loading...