©

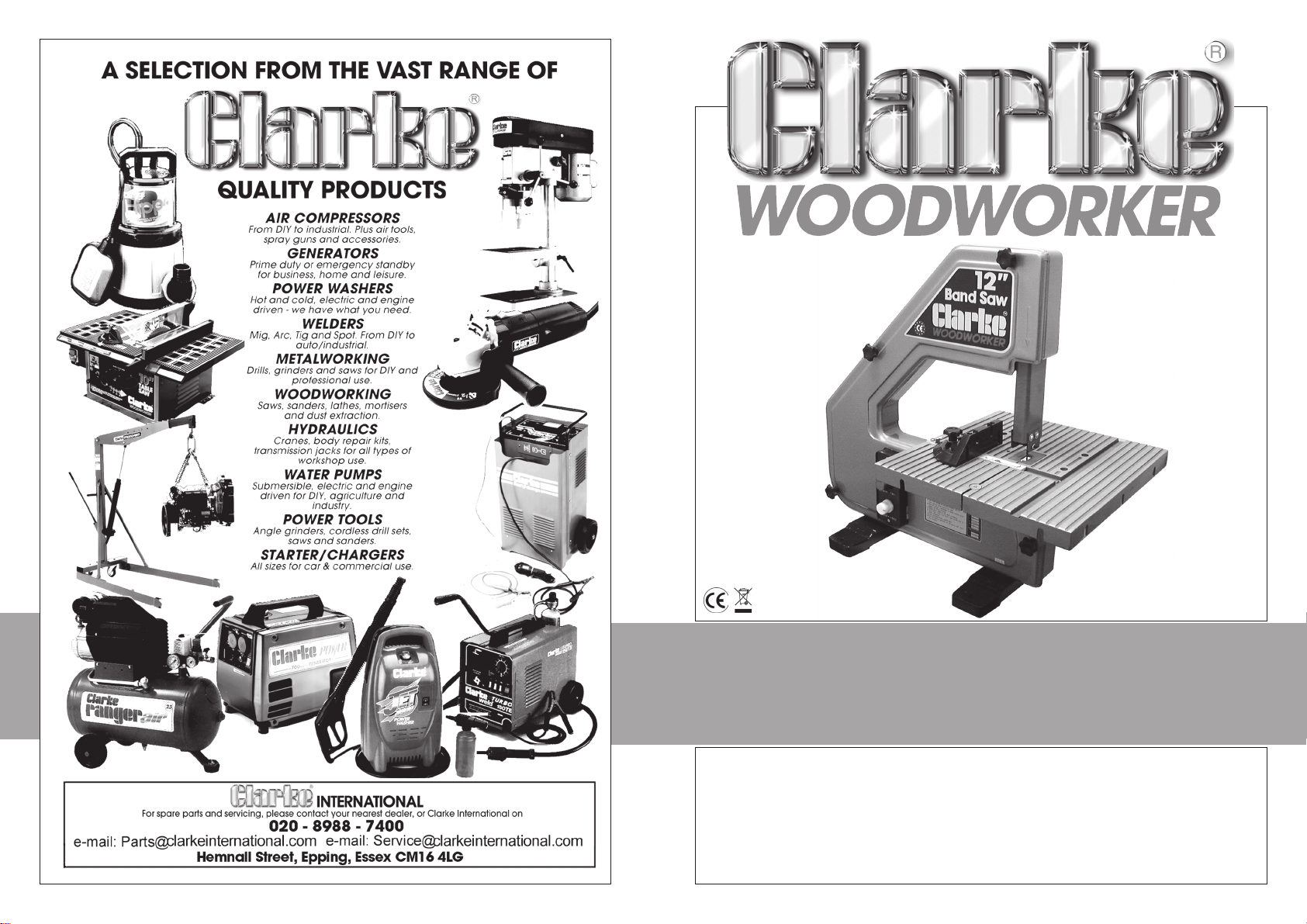

305mm (12”) Portable Bandsaw

305mm (12”) Portable Bandsaw

Model CBS12WV

Model CBS12WV

Part Number 6460030

OPERATING & MAINTENANCE

INSTRUCTIONS

0107

Spare Parts Diagram

©

Copyright Clarke International. October, 2000. All rights reserved

2

15

Spare Parts List

Specifications

No. Description Part No. No. Description Part No.

2 Wheel HT14600203

3 Hex Nut HT270100312

7 Mitre Shaft HT2601008112

11 Knob Screw HT14601101

12 Switch Box HT14601201

13 Machine Screw HT2651011112

15 Switch Cover HT14601501

16 Mitre Shaft HT2601057112

17 Knob Screw HT14601701

18 Hex. Screw HT2611105112

21 Screw HT775515

22 Guide Holder HT14602201

23 Blade Guard HT14602301

24 Ball Bearing HT280120635

25 Mitre Shaft HT2621013112

26 Hex. Nut HT270100312

28 Motor HT12056

29 Motor Cover HT14602901

30 Self-Tap Screw HT845519

31 Spring Seat HT14603101

33 Drive Gear HT14603301

34 Shaft HT14603401

35 Screw HT14603501

36 Washer HT2920073

37 C. S. Washer HT14603702

38 Set Screw HT2621031112

39 Washer HT254201322

40 Machine Screw HT2651104112

41 Spiral Spring HT14604101

42 Set Screw HT2621017112

43 Table Tilt Truss HT14604301

44 Square Nut HT397606

45 Machine Screw HT2641017112

46 Self-Tap Screw HT8453512

47 Speed Switch HT14604701

48 Machine Screw HT2651108112

50 Timing Belt HT301204

51 Hex. Nut HT270100412

53 Hex. Head Bolt HT2601023112

54 Drive Wheel HT14605402

55 Screw HT1460550

56 Front Cover HT14605601

57 Wheel Body HT14605601

58 Machine Screw HT2651047112

60 Angle Pointer HT14302401

61 Machine Screw HT2651010113

62 Insert Plate HT14606201

63 Table HT14606301

67 Base HT14606701

68 Electronic Switch HT286007

69 Wheel Support HT14606902

70 Saw Blade 6470031

71 Micro-Switch HT3013020

77 Machine Screw HT2641005112

78 Mitre Gauge HT14607801

79 Angle Pointer HT14302401

81 Machine Screw HT2651010113

83 Knob Screw HT14608301

85 Guide Bar HT14608502

86 Clamp HT10308202

89 Machine screw HT818850320

90 Hex Nut HT617003

92 Wire HT278035

95 Nameplate HT14609502

97 Nameplate HT14609701

98 Nameplate HT14609802

99 Knob HT301305

103 Machine Screw HT81885412

104 Earthplate HT30013

105 Washer HT958504

106 Spring Washer HT937604

107 I.G.Washer HT861760

108 Guide Holder HT300902

109 Washer HT300303

110 Hex. Nut HT617006

111 Washer HT958508

112 C. S. Washer HT89418606

113 Ball Bearing HT80029

114 H. S. Washer HT89318626

115 C. S. Washer HT89418609

116 Rubber Tyres HT300505

117 Motor Brush Set see dealer

Model No. ..................................................................................... CBS12WV

Part No. .......................................................................................... 6460030

Motor ............................................................................................. 230V 50Hz 1Ph

Power Rating ................................................................................. 550 Watts

Motor Speed ................................................................................. 1430rpm max.

Blade Speed .................................................................................

Max. Depth of Cut ........................................................................ 85mm (3 5/16”)

Max. Throat Width ......................................................................... 305mm (12”)

Table Tilt ......................................................................................... 0-45 Degrees

Table Size ...................................................................................... 345 x 345mm

Dust Port ......................................................................................... 41.5mm

Weight............................................................................................ 15.5kg

Noise Level .................................................................................... 90dB LWA*

*(Sound Power Level) Cutting 25mm soft wood at maximum speed

Do not dispose of this product with general waste. It must be disposed of according to law at an

approved disposal facility.

200-600 M/Min under Load

Restrictions of Use

This saw is NOT suitable for cutting:

•

Timber greater than 110mm in depth.

•

Metal, stone, rubber, plastic, bones, etc.

•

Logs or round timber.

Spare Parts & Service Contacts

For Spare Parts and Service, please contact your nearest dealer,

or CLARKE International, on one of the following numbers.

PARTS & SERVICE TEL: 020 8988 7400

PARTS & SERVICE FAX: 020 8558 3622

or e-mail as follows:

PARTS: Parts@clarkeinternational.com

SERVICE: Service@clarkeinternational.com

14

3

Thank you for purchasing this Clarke 12 inch Bandsaw. This machine is designed to rip and

cross cut wood exclusively and for DIY, and hobby use ONLY. Before attempting to operate

this machine, please read this instruction manual thoroughly and follow all directions carefully.

This is for your own safety and that of others around you, and to help you achieve long and

trouble free service from your bandsaw.

Guarantee

This product is guaranteed against faults in manufacture for 12 months from purchase date.

Please keep your receipt as proof of purchase.

This guarantee is invalid if the product has been abused or tampered with in any way, or

not used for the purpose for which it is intended. The reason for return must be clearly stated.

This guarantee does not affect your statutory rights.

For your own Safety

WARNING!

operating instructions, and before using the equipment.

✔ ALWAYS wear suitable safety goggles, manufactured to the latest European Safety

Standards, when using the bandsaw.

✔ ALWAYS keep your hands and fingers clear of the blade when sawing. Use a push stick

with small workpieces.

✔ ALWAYS set the blade guide/guard assembly as close as possible to the workpiece.

✔ ALWAYS switch off the saw, and make sure the blade has come to a complete stop

before clearing sawdust or off-cuts from the table.

✔ ALWAYS keep the saw properly adjusted, paying particular attention to the blade tension

and tracking, and the blade guides.

✔ ALWAYS disconnect the saw from the mains supply before removing the front cover.

✔ ALWAYS make sure ON/OFF switch is in ‘OFF’ position before plugging in. Avoid

accidental starting.

✔ ALWAYS keep children away. All visitors should be kept a safe distance from the work

area, especially while operating unit.

✔ ALWAYS use in a well ventilated area. Remove sawdust frequently. Clean out sawdust

from the interior of the saw to prevent a potential fire hazard.

✔ ALWAYS Wear proper apparel. Loose clothing or jewellery may get caught in moving

parts. Wear protective hair covering to contain long hair.

✘ NEVER leave this saw running unattended. Turn power OFF. Don’t leave tool until it

comes to a complete stop.

✘ NEVER operate this saw while under the influence of drugs, alcohol or any medication.

✘ NEVER attempt to free a stalled saw blade without first turning the saw OFF. Turn off `

power switch immediately to prevent motor damage.

Read these safety instructions in conjunction with the

Replacing the Saw Blade: (Ref: Fig.4)

The saw blade is not easy to sharpen, and we recommend fitting a replacement when the

blade becomes blunt, loses its set, or becomes bent or cracked. Replacement blades are

available from your local dealer or Clarke International Spare Parts Department.

1. Remove the table by first removing the table set screw then fully unscrewing the securing

knobs.

2. Back off all blade guides and blade supports as detailed under ‘Blade Guide

Adjustments’ on page 10.

3. Remove the front cover to gain access to the blade.

4. Turn the blade tension locking knob (25) one complete turn anticlockwise.

5. Turn the blade tension Hex. socket head adjuster screw (24) fully anticlockwise to relieve

all tension from the blade.

5. Carefully pull the blade from the wheels taking great care not to damage your hands

on the teeth. It is recommended that a pair of industrial gloves be worn for this task.

6. Position the new blade over the wheels, feeding it through the blade guides, ensuring

that the teeth point downwards toward the table. Position it as close to the centre of

each wheel as possible.

7. Turn the blade tension locking knob clockwise and correctly tension the blade.

8. Carry out tracking checks and adjust if necessary.

9. Readjust all blade guides and blade supports as detailed under ‘Blade Guide

Adjustment’ on page 10.

10. Replace the table and the front cover.

11. Plug the machine into the mains supply and with a slow speed selection, push the ON

(I) button. Gradually build up the speed and allow to run for 10 - 15 minutes at a moderate

speed in order to settle the blade. (Essential when running the blade for the first time).

Before use, check blade tension and adjust if required.

NOTE: It is strongly advised that for the first few cuts, the cutting pressure exerted on the

workpiece should be minimised in order to allow time for the blade to ‘run in’.

Fault Finding

The bandsaw is fitted with a microswitch to prevent the saw from operating if the cover is

opened whilst the saw is running. If the saw does not start, check the microswitch to ensure

it operates correctly when the cover is closed. An audible click should be heard, when the

cover is fitted, denoting the switch has closed. It may be necessary to adjust the mounting

in order to achieve this.

Most operational problems with the saw can be corrected by adjusting blade tension, the

blade guides or tracking. Poor adjustment will lead to the blade wandering, or not cutting

in a straight line, or slipping from the wheels. It can even result in the blade breaking. Make

sure the machine is always correctly set up and adjusted, and that the blade teeth are

pointing downward toward the table. Similarly, if the blade is blunt or has lost its set, or is

bent or cracked, it will not cut easily or in a straight line. A damaged or blunt blade must be

replaced.

4

13

IMPORTANT: Before plugging in to the mains supply, the blade guard MUST be adjusted so

that a minimum amount of blade is visible when cutting takes place. This is achieved as

follows:

Offer the workpiece up to the blade, then lower the Upper Blade Guard by slackening the

locking knob, (23, Fig.4) and tightening it again when the guard is as close to the workpiece

as possible without interference.

When satisfied, plug the machine into the mains supply and observing all safety precautions

previously stated, switch ON the machine by pushing the Green Knob on the control panel,

marked ‘I’. Turn the white speed control knob to select the appropriate speed.

Feed the workpiece slowly into the blade, with a light pressure. Pushing too hard will cause

the blade to twist, resulting in a poor cut, or even cause the blade to stall or break. Thicker

or hardwood workpieces will need to be fed more slowly than thin, softer stock.

Keep your hands and fingers well clear of the blade when cutting.

Always use a push stick or piece of scrap to push the work when the cut line is close to the

edge of the workpiece, or when cutting small workpieces.

When cutting curves with the bandsaw, make relief cuts to allow the blade to follow the

cutting line. Do not try to cut to too small a radius as you can twist and break the blade.

If you want to back the blade out of a cut, stop the saw and wait for the blade to come to

a halt before backing the workpiece gently off the blade.

Always switch the bandsaw off after use. NEVER leave the bandsaw running unattended.

Maintenance

WARNING!

removing the front cover.

The bandsaw requires very little maintenance other than routine adjustment and cleaning,

and occasional inspection of the blade guides, blade and motor brushes.

Keep the saw clean, by clearing away sawdust and scrap frequently whilst working. When

you have finished using the saw, remove the front cover and clear sawdust from inside the

machine and around the motor vents using a vacuum cleaner or brush. Inspect the blade

guides occasionally and replace them if they become worn.

Motor Brush Replacement (Ref: Fig.2)

WARNING!

checking or replacing motor brushes.

Disconnect the bandsaw from the mains supply before

Disconnect the bandsaw from the mains supply before

Electrical Connections

WARNING!

IMPORTANT:

As the colours of the flexible cord of this appliance may not correspond with the coloured

markings identifying terminals in your plug proceed as follows:

• Connect GREEN & YELLOW coloured cord to plug terminal marked with a letter E or

Earth symbol “ ” or coloured GREEN or GREEN & YELLOW.

• Connect BROWN coloured cord to plug terminal marked with a letter L or coloured RED

• Connect BLUE coloured cord to plug terminal marked with a letter N or coloured BLACK

IMPORTANT!

(i.e. non- re-wireable) please note:

1. The plug must be thrown away if it is cut from the electric cable. There is a danger

2. Never use the plug without the fuse cover fitted.

3. Should you wish to replace a detachable fuse carrier, ensure that the correct

4. Replacement fuse covers can be obtained from your local dealer or most electrical

The wires in the mains lead are coloured in accordance with the following code:

Green & Yellow - Earth

If this appliance is fitted with a plug which is moulded onto the electric cable

of electric shock if it is subsequently inserted into a socket outlet.

replacement is used (as indicated by marking or colour code).

stockists.

Fuse Rating

The fuse in the plug must be replaced with one of the same rating (13 amps) and this

replacement must be ASTA approved to BS1362.

THIS APPLIANCE MUST BE EARTHED

Blue - Neutral

Brown - Live

Assembly and Installation

Upon unpacking the contents of the carton you will note that some assembly work is

necessary before the Bandsaw can be Installed. The Feet (12, Fig.1) and the Table Assembly

must be fitted before the Bandsaw may be attached to a suitable workbench.

The motor brushes must be checked after every 100 hours of use.

1. Remove the front cover to gain access to the two screws securing the motor cover

(18, Fig.2).

2. Remove the motor cover (22 Fig. 3). The brush housings are each secured by two

screws. Remove the screws and withdraw the brushes from the holders. The brushes

must be replaced when they are worn down to 6mm in length.

3. Take care to avoid damaging the springs and wires when replacing the brushes.

12

WARNING!

Disconnect the bandsaw from the mains supply before

removing the front cover.

Note: The bandsaw is provided with a microswitch to prevent the saw from operating if the

cover is left open or is opened whilst the saw is running. If the saw does not operate when

the cover is replaced it may be because the microswitch is not closed. Check that the

microswitch will operate when replacing the cover.

5

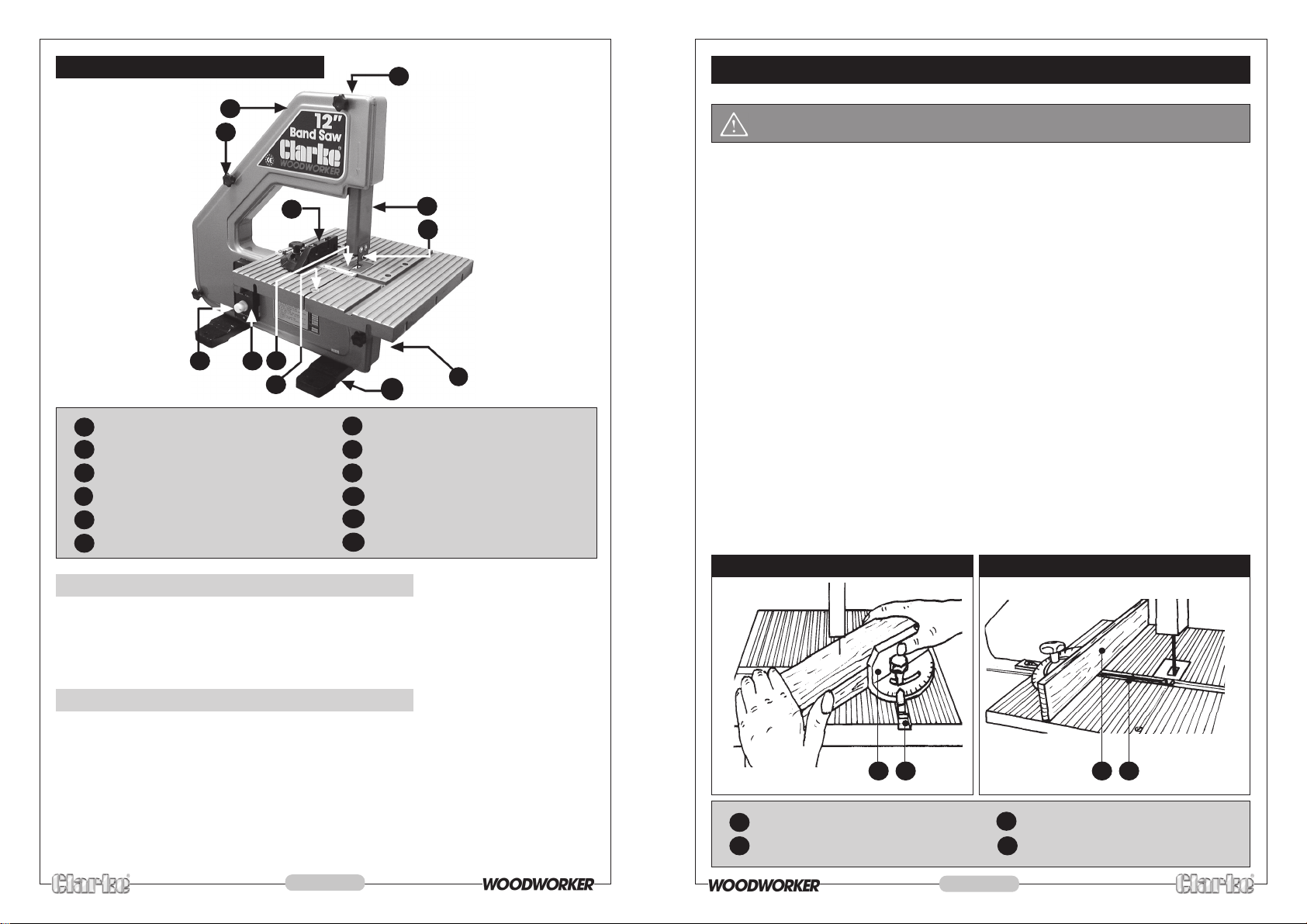

Fig. (1) Main Components

8

OPERATION

1

2

3

5 6

7

4

1 Front Cover

2 Front Cover Securing Knob (x4)

3 Rip Fence/ Mitre Gauge

4 Table Set Screw

5 Control Panel (ON/OFF)

6 Speed Control Knob

7 Table Insert

8 Blade Tensioning Screw

9 Blade Guard

10

11

12

9

10

12

Upper Blade Guide

Dust Extraction Port

Feet

11

(1) Attach the Feet (Ref: fig 1)

1. Unscrew the fours securing knobs (2) and remove the front cover. (see WARNING above)

2. Attach the feet (12) to the underside of the machine using the nuts and screws

supplied, two for each foot (13, Fig.2).

3. Replace the front cover.

WARNING!

Make sure the bandsaw is correctly assembled and adjusted

before use. Read and follow all safety instructions (see page 3)

• The blade supplied with the saw is suitable for general purpose cutting of hard and soft

woods . It is not suitable for cutting metals (See restrictions of use, page 3). The speed of

the bandsaw can be adjusted to suit the material by using the control knob below the

on/off switch. Use slower speeds for harder materials.

• A dust extractor may be used during use. Simply connect a suitable hose (not supplied),

from the dust extractor, to the dust extractor port (23, Fig.3). Dust Extractors are available

from your Clarke dealer.

• The saw is supplied with a mitre gauge to allow mitre cuts to be made.

Set the gauge to the desired angle, and use the guide slot in the table to

gauge with the workpiece across the table, into the blade as shown in Fig. 6 .

run the mitre

• The mitre gauge can also be used as a rip fence by placing it in the slot at right angles

to the blade. Fix it into place at the desired distance from the blade by using the

countersunk screw in the slot. When using the mitre gauge as a rip fence you may wish

to screw a suitable piece of hardwood or plywood (approximately 300 x 75 x 12 mm) to

the face of the gauge to extend its length (fig 7).

• The saw table can be tilted up to 45 degrees to allow you to cut bevels and compound

mitres. Slacken the table securing knobs, position the table to the desired angle, as

shown on the scale beneath the table, and tighten the knobs (see fig 3).

NOTE: If accurate mitres are required, check the table angle using a suitable gauge between

the table and blade. When adjusted, check to ensure the pointer is indicating the correct

angle and adjust if necessary.

Fig. (6) Using the Mitre Gauge

Figure (7) Using as a Rip Fence

(2) Attach the Table (Ref: fig 3)

1. Attach the table tilt bracket (19) to the underside of the table, using the four

screws and nuts supplied, as shown in fig. 3.

2. Remove the table insert (7, Fig. 1) and the counter sunk screw (4, Fig. 1) from the

table slot. (This set screw locks the two sides of the slot together, preventing the

table from flexing during use.)

3. Place the table into position from the motor side of the saw, taking care when

passing the blade through the slot, then secure the table using the washers and

adjusting knobs (18) supplied.

4. Replace the set screw (4, Fig. 1) , and fit the table insert (7, Fig. 1).

6

31 Mitre Gauge

32 Mitre Gauge Slot

31 32 33 34

33 Option Rip Fence Extension

34 Rip Fence Fixing Screw

11

(d) Blade Guide Adjustments (Ref: fig 5)

NOTE: These adjustment are carried out at the factory. It is not therefore necessary to check

or make readjustments before using for the first time.

These adjustments MUST be carried out periodically or whenever replacing a saw blade or

whenever blade tracking adjustment is carried out.

The lower guide is located beneath the table as shown at 17, Fig.2; The upper guide is

within the blade guard assembly shown at 18, Fig.2.

NOTE: It simplifies the procedure if the table is removed in order to gain easy access to the

lower blade guides.

1. Slacken the guide lock nuts (28) and back off the guides, so that there is clearance

between the guide and blade, and the support bearing locknut and back off the

support bearing. (Support bearings are shown at 29, Fig.5)

NOTE: This procedure would have been carried out previously if a new blade is being installed,

or if tracking has been reset.

2. Slacken the Guide Bracket securing screws (27) sufficiently to move the bracket laterally

so that the guides are positioned approximately in the centre of the blade. They must

not touch the teeth of the blade. When satisfied tighten the securing screws.

3. Screw in each guide until it makes light contact with the blade, then back off so that a

clearance of not more than 0.5mm is achieved, then tighten the locknut. An ideal

method of obtaining the correct clearance is to place a piece of paper between the

guide and blade then screw in the guide until the paper is just nipped.

4. Screw in the Blade Support Bearings (shown at 29) until they make light contact with the

back edge of the blade, then back off until a clearance of 0.5mm is obtained and

tighten the locknut.

Fig. (2) Cover Removed

18

15 18 16

14

13 Foot Securing screw (x4)

14 Control Panel (On/Off/Speed)

15 Microswitch

Fig. (3) Rear View

17

13

16 Drive Wheel

17 Lower Blade Guide

18 Motor Cover Securing Screws

Fig. (5) Blade Guides

29

28

27 Guide Bracket Securing Screws

28 Guide Lock Nuts (x4)

29 Blade Support Bearings

10

27

27

28

21

19

18

23

18 Table Securing Knobs (x2)

19 Table Tilt Bracket

20 Table Tilt Indicator (Degrees)

20

21 Table Adjusting Screw

22 Motor Cover

23 Dust Extraction Outlet

7

22

(3) Attach the Bandsaw to a Workbench

Fix the bandsaw to a suitable Workbench using screws or bolts (not supplied), through the

holes in the feet with washers under the screw heads. Do not overtighten the securing screws.

1. Remove the table by fully unscrewing the two securing knobs, then slacken off all upper

and lower blade guides as described under ‘Blade Guide Adjustments’ on page 10.

2. Correctly tension the blade as described under ‘Blade Tension’ on page 8.

3. Remove the front cover in order to gain access to the blade and wheels.

Adjustments

IMPORTANT: To achieve the best performance and maintain the maximum level of safety,

certain adjustments must be made, BEFORE use.

WARNING! The machine MUST be disconnected from the mains supply

before any adjustments are made.

(a) Table Adjustment (Ref: Fig. 3)

The screw (21) allows the table to be adjusted so that it is square to the blade.

With the table securing knobs (18) slackened, slide a small square across the table so that

it contacts the side of the blade, then check to ensure the angle made is a right angle. If

necessary turn the adjuster screw (21) clockwise or anticlockwise, whilst maintaining a slight

pressure on the adjusting screw side of the table top, until the table is at 90 degrees to the

blade. Tighten the table securing knobs, then check the table angle Indictor (20). If

necessary, reposition the pointer so that it points to zero on the scale.

(b) Blade Tension (Ref: fig 4)

1. Slacken the blade tension locking knob (25) one full turn.

2. Adjust the blade tension Hex. socket head adjuster screw (24) a little at a time:

clockwise to tighten increase tension, anticlockwise to decrease.

3. When correct tension has been achieved tighten the blade tension locking knob (25).

The blade needs to be tight enough to give a straight cut without allowing it to wander

or slip or lose its tracking, but must not be so tight that it is rigid, there must be a certain

degree of flexibility.

A few minutes using the machine will allow you to get a feel for correct blade tension.

If the saw is not to be used for some time we recommend that you release the tension on

the blade. REMEMBER therefore to ALWAYS check blade tension before use.

WARNING!

Disconnect the bandsaw from the mains supply before

removing the front cover.

4. Carefully turn the driving wheel (16, Fig. 2) by hand to check blade tracking, taking

care to keep fingers well clear of the blade, and not trapping them between the blade

and the wheel. The blade must run true, as close to the centre of the rim of each wheel

as possible.

5. Adjust the tracking by turning the Hex. socket head adjuster screw (26) a little at a

time....clockwise to move the blade inwards towards the motor side of the machine,

and anticlockwise to move it outwards. Turn the driving wheel by hand as you turn the

adjuster screw.

6. Check blade tension once again after completing the tracking adjustment and adjust

if necessary.

7. Replace the front cover (1), then adjust the Blade Guides as described in the following

paragraphs.

Fig, (4)

24

25

23

26

(c) Blade Tracking (Ref: fig 4)

NOTE: This adjustment is carried out at the factory. It is not therefore necessary to check or

readjust before use for the first time.

The adjustment MUST be made whenever replacing a saw blade or if the saw blade runs off

the wheels.

The blade must ‘track’ correctly otherwise it will continually run off the drive and idler wheels.

The blade should run in the middle of the wheels rims, and the procedure for checking and

adjusting is as follows:

8

23 Blade Guard Locking Knob

24 Blade Tension Adjuster Screw

25 Blade Tension Locking Knob

26 Blade Tracking Adjust Screw

9

Loading...

Loading...